- Does not keep the float in the toilet and other breakdowns

- Internal organization

- Modern models with lever drain

- With button

- How to adjust the toilet video

- How to buy a float for a toilet bowl

- Blitz Tips

- The main types of drain equipment designs

- Automatic

- Recommendations

- Level control

- Features of adjusting various types of float valves

- Float on the lever

- Float on vertical rails

- How to adjust the toilet float: troubleshooting

- Types of drain tank

- The internal device of the drain tank

- How to adjust the float

- Recommendations

Does not keep the float in the toilet and other breakdowns

The most common causes of toilet cistern failure and their solutions.

In order not to have to replace the cistern, due to possible damage to the toilet lid during repairs, before starting work, pay attention to how its lid is fixed. The drain tank can be filled above the required level for several reasons: the float is skewed and cracked, the float membrane is damaged

And also the case may be in the shut-off valve, which ceases to protect the float from the penetration of water into it.

The drain tank can be filled above the required level for several reasons: the float is skewed and cracked in it, the float membrane is damaged. And also the case may be in the shut-off valve, which ceases to protect the float from the penetration of water into it.

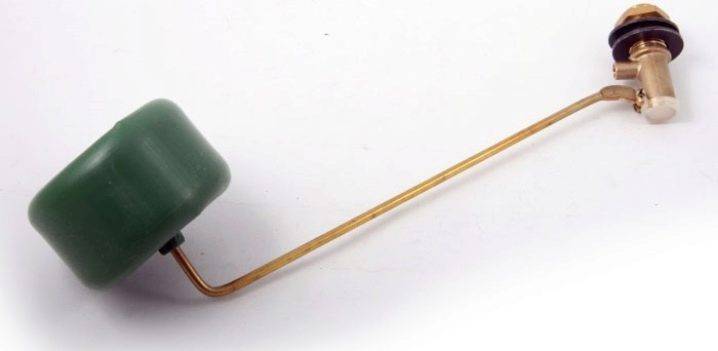

Let's talk first about how to put the float itself in order. Materials such as brass and plastic can be used to create a toilet float. In the first option, it only needs to be bent a little. With a plastic float, the situation is somewhat different. To adjust it, you will have to use a mounting screw or a plastic ratchet.

Before starting work on replacing the shut-off valve, make sure that there is no water left in the tank. After that, you can disconnect the valve from the downpipe, and remove the lever. To remove the valve, you will need to unscrew the nuts, which can also be used when installing a new valve. At the end of the work, fill the tank with water and put the float.

If a crack appears in the float, then it becomes unusable. This can be understood when it begins to sink into the water in the tank. It should be replaced or you can try to repair it.

If you prefer to install a new float, then before removing the old one, you need to turn off the water supply to the tank and, using an adjustable wrench, unscrew the pipe through which the water flows. Once the new float has been installed, the valve can be opened to allow the tank to fill with water. As soon as the tank is filled with water to the desired level, it will be necessary to fix the float in the desired position.

How to repair the float in the toilet, you need to get it out of the tank and wait until it dries.Then you should seal the crack with heated plastic or you can use a plastic bag that will have to be put on the float.

If you need to replace the damaged membrane, first you need to get rid of the presence of water in the tank by tying the float lever to the crossbar. To remove the pipe through which water from the toilet enters the sewer pipes, you will have to unscrew the nut. After that, having slightly unscrewed the fastening nut, remove the siphon and put a new membrane in the place where the old part was previously located.

Internal organization

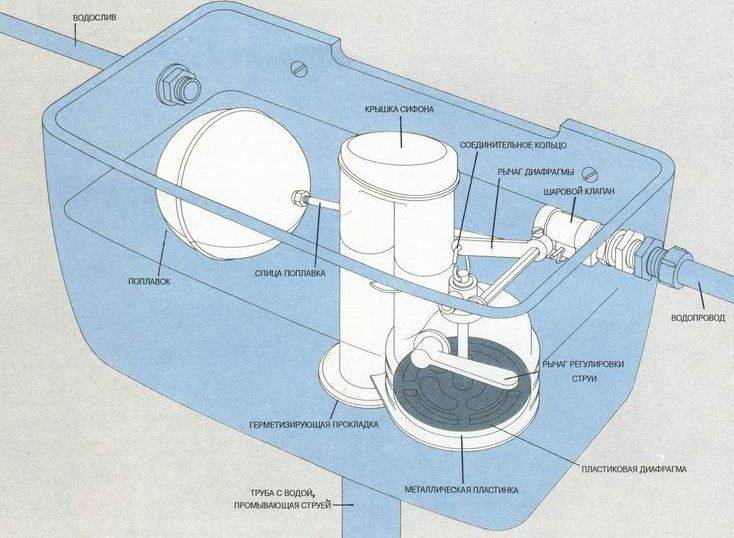

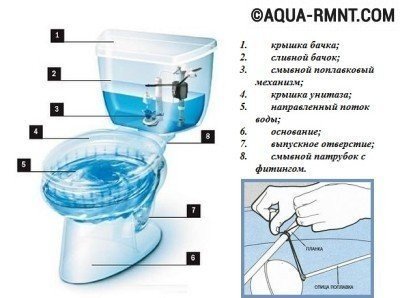

The toilet cistern consists of two simple systems: a set of water and its discharge. To troubleshoot possible problems, you need to understand how everything works and works. First, consider what parts the old-style toilet bowl consists of. Their system is more understandable and visual, and the operation of more modern devices will be clear by analogy.

The internal fittings of a tank of this type are very simple. The water supply system is an inlet valve with a float mechanism. The drain system is a lever and a pear with a drain valve inside. There is also an overflow pipe - through it excess water leaves the tank, bypassing the drain hole.

The device of the drain tank of the old design

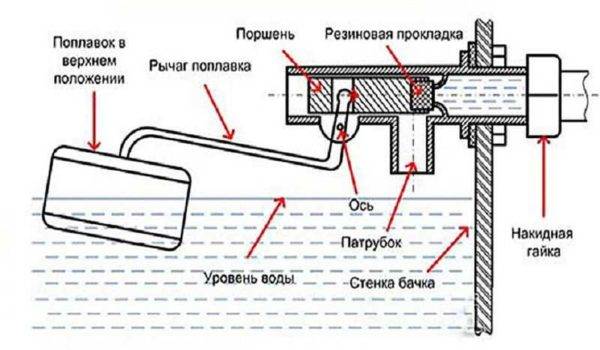

The main thing in this design is the correct operation of the water supply system. A more detailed diagram of its device is in the figure below. The inlet valve is connected to the float using a curved lever. This lever presses on the piston, which opens / closes the water supply.

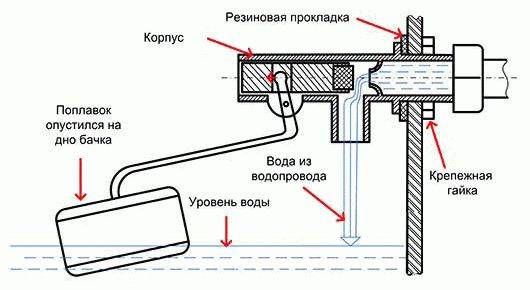

When filling the tank, the float is in the lower position. Its lever does not put pressure on the piston and it is squeezed out by water pressure, opening the outlet to the pipe. Water is gradually drawn in.As the water level rises, the float rises. Gradually, he presses the piston, blocking the water supply.

The device of the float mechanism in the toilet bowl

The system is simple and effective, the filling level of the tank can be changed by slightly bending the lever. The disadvantage of this system is a noticeable noise when filling.

Now consider how water drain works in a jar. In the variant shown in the figure above, the drain hole is blocked by a bleed valve pear. A chain is attached to the pear, which is connected to the drain lever. We press the lever, lift the pear, the water drains into the hole. When the level drops, the float goes down, opening the water supply. This is how this type of cistern works.

Modern models with lever drain

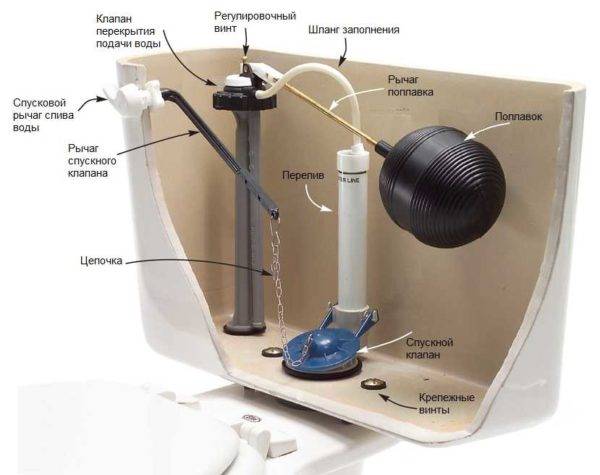

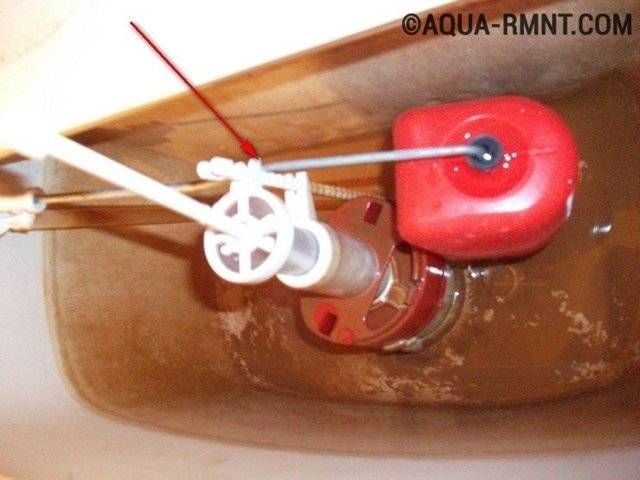

They make less noise when filling the cistern for toilet bowls with a lower water supply. This is a more modern version of the device described above. Here the tap / inlet valve is hidden inside the tank - in a tube (in the photo - a gray tube to which the float is connected).

Drain tank with water supply from below

The mechanism of operation is the same - the float is lowered - the valve is open, water flows. The tank was filled, the float rose, the valve turned off the water. The drain system remained almost unchanged in this version. The same valve that rises when you press the lever. The water overflow system has not changed much either. This is also a tube, but it is brought out into the same drain.

You can clearly see the operation of the drain tank of such a system in the video.

With button

Models of toilet bowls with a button have similar water inlet fittings (there are with a side water supply, there are with a bottom one). Drain fittings they have another type.

Tank device with push-button drain

The system shown in the photo is most often found in toilet bowls of domestic production. It is inexpensive and reliable. The device of imported units is different. They basically have a bottom water supply and another drain-overflow device (pictured below).

Imported cistern fittings

There are different types of systems:

- with one button

- water drains as long as the button is pressed;

- draining starts when pressed, stops when pressed again;

- with two buttons that release different amounts of water.

The mechanism of work here is slightly different, although the principle remains the same. In this fitting, when you press the button, a glass rises, blocking the drain. The stand remains stationary. In short, this is the difference. The drain is adjusted using a swivel nut or a special lever.

How to adjust the toilet video

That's all, only useful tips on our construction blog.

- Vyacheslav 27 July 2015 17:23

Question: What if the adjusting bolt is “tightly” connected to the guide bar? It just doesn't spin. And your instructions are very good. Tell. Thank you.

Sergey February 29, 2016 16:31

Good evening! When you press the drain button of the fitting, the water is drained only at the moment of pressing and holding the button. How and how is the full drain mode regulated / set / when the button is pressed and without its forced holding? Those. water drains only when the button is pressed and held. The button does not sink and is not fixed at the bottom.

Leave a comment or two

How to buy a float for a toilet bowl

What should I be guided by when choosing a float toilet valve?

In order not to have to change the float valve again and again, you must immediately select the appropriate part, based on the pressure in the water supply.

The float in the toilet is for weak, medium and strong water pressure. And there is also a stabilizing valve that allows you to make the pressure in the water supply stable.

According to the type of design, diaphragm and piston float valves, as well as croydon valves, are distinguished. Piston float valves are more reliable than croydon valves and are therefore the most commonly used. As part of the diaphragm valves, instead of a gasket, there is a disc-shaped rubber membrane.

This mechanism is very reliable and has a long service life. But the presence of coarse particles and impurities in the water can lead to rapid damage to the membrane, which will lead to water leakage. To protect the membrane, you will need to install a filter that will clean the water.

It is necessary at least two or three times a year to constantly monitor the condition of the mechanisms. If you do not find damage in the mechanisms in a timely manner, then you will have to repair them in the future. Regular inspection can save not only you, but also your neighbors from loss of funds and from repair work.

Dimensions corrugations for the toilet

sewer chopper pump for toilet bowl

Do-it-yourself installation of a toilet bowl with an oblique outlet

Blitz Tips

- If you plan to install a new toilet, then you should choose models with a lower location of the glass-type float. Such models operate almost silently, and technical malfunctions associated with the float mechanism are extremely rare.

- When installing a new float, you must choose a model that is designed to work with the pressure in your plumbing system. Floats differ in carrying capacity and the stronger the pressure, the higher this figure should be. If you neglect this rule, then even a serviceable float system will pass some of the water from the tank into the toilet bowl.

- Adjustment in the vertical plane, allows you to change the amount of water that is used when draining the liquid from the drain tank. If the element moves to the upper part and is fixed in this position, then the amount of water that flows out of the drain tank will be maximum, if it is in the lower part, then, pouring in, will be minimal in volume. In most cases, it is enough to adjust the position of the float in the middle of the scale so that during the drain there is no overflow of liquid, and the device copes with its task.

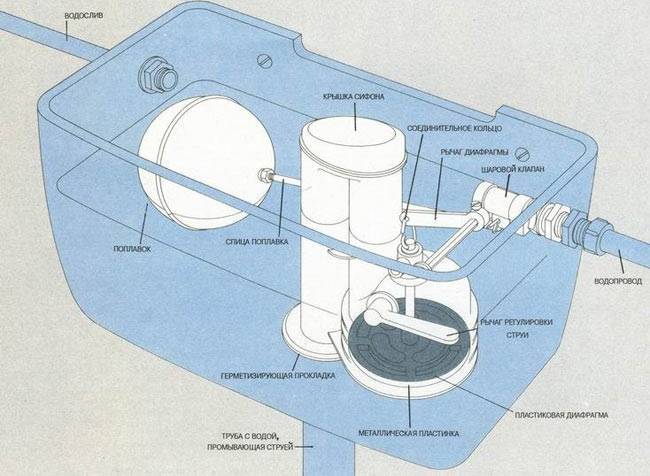

The main types of drain equipment designs

First of all, they depend on the type of filling and drainage mechanisms. The functions of draining water are performed by products of lever, push-button and automatic execution.

The float (1) controls the inlet valve (3) through the lever (2). The water level depends on the adjustment of the float lever on the valve lever (4). The water pressure during filling is regulated on the valve using a set screw.

Lever models - were the main models installed on the toilets of the last century. In some places they are still in use today. Lever devices are distinguished by their simplicity. The first products worked out the drain only at the moment of pressing, while the shut-off valve was held manually (by the “puller” - a chain or fishing line).Then there were systems using the siphon effect, which themselves control the flow after activation. But both the first models and subsequent ones differ increased unregulated water flow. In addition, such plumbing does not meet the current requirements of aesthetics.

drain toilet mechanism, made in a push-button version, is installed on most modern plumbing products. The predominant location of the button is top, on the covers of compact systems, and can also be wall-mounted for products installed in building structures. Their advantages, in addition to good aesthetics, are the ability to adjust the parameters of the drain and overflow. Push-button mechanisms also, after activation, keep the shut-off valve in the open state without human intervention. And models with paired buttons allow full or partial discharge of liquid into the toilet.

Automatic

Today, rare and expensive products for draining water that justify themselves when installed in elite products or used in public places. Their work is controlled by touch infrared sensors.

The shut-off valves for the toilet bowl, represented by filling mechanisms, work, as they did many years ago, using the principle of a feeding tap opened and closed by a float. In the classic version, the float transmits force to the faucet valve with side supply through a horizontal rocker.

Floats blocking the water supply through a system of levers.

However, now more often floats are installed that move along a vertical guide, blocking the water supply through a system of levers for both the side connection and the bottom one.

Important! Modern filling valves, due to the peculiarities of their design, allow water to be collected much faster than systems with a rocker arm

Recommendations

So, in case of problems with the water supply of the drain tank, you need to remember the following:

- Most often, the cause of this is a malfunction of the float, the membrane of the permeable valve or its holes.

- Having understood the reason, you can try to repair the failed part. In some cases, repair is not possible, replacement is necessary.

- When purchasing a new float design, you need to have an idea about the type of drain system in your toilet. It depends on what kind of detail is needed.

- Installing a new float is quite within the power of everyone. The main thing is not to forget to temporarily block the water supply system, correctly dismantle the broken part and set the new one to the required level.

- If there is no confidence that it will be possible to successfully carry out the required plumbing manipulations, the best solution would be to contact a specialized specialist.

Level control

The required water level in the cistern is adjusted by adjusting the float valve.

First you need to figure out what a float valve is. This is a device that automatically maintains the water in the tank at a given level. Consists of 3 main parts:

- the actual valve that supplies water to the flush tank;

- a float that controls the state of the valve;

- a system of levers / rods / pushers / guides, with the help of which the float is connected to the valve and controls its state.

Valve adjustment scheme (if necessary). Table for adjusting the height of the valve for discharging water.

The valve is rigidly fixed to the tank. The float relative to the valve can move freely up and down. They are interconnected in such a way that the valve is closed in the highest position of the float. In all other float positions, the valve is open. To shut off the water supply to the flush tank, you need to raise the float to the upper limit of its free play. For this, the buoyancy force of the water is used.

Tank cycle:

- The tank is empty, the float is down, the valve is open, water flows freely into the tank.

- Filling. The water rises, the float rises, but the valve is still open.

- The float is raised by water to the upper limit of its stroke, the valve is closed. The water supply to the tank is stopped. The float, supported by the force of Archimedes, cannot go down and keeps the valve closed. The flush tank will remain full until someone uses the flush button.

- Drain. Water flows out, the float goes down, the valve opens. After that, the cycle starts over.

In order for the water supply to stop when it reaches the required level, it is necessary to fix the upper limit of the float free play at the same level. This can be done by changing the geometric parameters (dimensions and angles) of the float-valve connection system.

All of the above was of a general nature and applied to all types of float valves. Specific adjustment methods will depend on the design features of the reinforcement.

Features of adjusting various types of float valves

With all the variety of existing PCs, two main types of connection between a float and a valve can be distinguished:

- float on the lever;

- float on vertical guides.

Float on the lever

Relative to the valve, the float moves on the lever in an arc. At the top of the stroke, the lever should be nearly horizontal for proper valve actuation. The designs of such levers can also differ from each other.

Float on the lever (photo 1)

In the simplest version, such a PC looks like this (photo 1):

Adjusting the water level consists in roughly bending the wire lever. To increase the water level in the tank, the lever must be bent up, to lower it - down.

Advantages: simplicity, reliability, low price.

Disadvantages: inconvenience and inaccuracy of adjustment, large dimensions.

Adjustable lever (photo 2)

Adjustment of the water level: the necessary break of the lever is fixed with a screw.

Advantages: simplified adjustment, low price.

Disadvantage: the fragility of plastic (compared to wire) during aging, all the same large dimensions.

Adjusting device with the ability to move the float along the length of the lever. This allows you to more conveniently position the float among other fittings. The water level is adjusted by changing the tilt of the entire lever.

Float on vertical rails

Adjustable lever (photo 2)

In such devices, the float moves vertically along guides and is usually located directly above/below the valve.

This design increases the compactness, but complicates the product, which, of course, affects its cost. The disadvantages include possible jamming when the float slides along the guides. The accuracy of the work is highly dependent on the quality of the product.

If the tank is equipped with a similar PC, then adjusting the water level is reduced to changing the length of the rod / pusher that connects the float to the valve locking mechanism. Adjustment can be threaded (the most convenient and accurate), on a latch, ratchet, etc.

Well, that's, perhaps, all that could be said about regulating the water level in the toilet cistern. without affecting rare types of fittings and unlikely cases of its failure. Don't let the amount of information presented scare you - if you understand the essence of the process and there are no breakdowns, there will be nothing complicated in adjusting the water level, and it will not take more than 5 minutes.

How to adjust the toilet float: troubleshooting

It may happen that the functionality of the toilet barrel has failed and its work has been disrupted. The float ball valve is responsible for filling the tank with water, to adjust the amount of water in the tank. The reason for the constant leakage from the tank into the toilet or the complete absence may lie in the breakdown of the float valve. To adjust the float of the toilet bowl, and make an independent repair of the cistern, you need to know about its structure and principle of operation.

Types of drain tank

Toilet bowls are divided into several types. Types differ in the type of escapement device, in the material of manufacture and in the method of installation.

According to the location of the trigger lever of the tank:

According to the material from which the tank is made:

- wall installation;

- installation on the toilet shelf;

- wall mounting.

For more information on how the tank is installed and fastened, read in a separate article.

The internal device of the drain tank

Each type of flush tank has an internal device that performs the work of filling water into the tank, adjusting the rate of water in it and flushing.

The device of a ceramic drain tank consists of:

The inlet valve is a part of the tank, which is responsible for the flow of water from the water pipes, for its strictly defined limit. A float acts as an indicator of the water level. The action of the float ball of the crane is aimed at supplying water to the tank, its dosage and rate. The principle of operation of the float valve is that when there is enough water in the tank, the float pops up, setting in motion a special plug with a lever, which blocks the access of water to the tank.

The overflow is responsible for directing excess water into the toilet. It is needed so that the tank does not overflow, and water does not pour over its edge. This mechanism is made in the form of a small plastic tube and is located in the center of the tank. To regulate the water level, the tube either goes down or goes up.

Drain fittings are designed to ensure that water is drained from the tank. The drain button on the tank is connected to a lever that starts this mechanism.

How to adjust the float

A broken float valve can cause water to constantly flow from the tank into the toilet. There can be several reasons for the breakdown of the float and its improper operation. The float may warp, a hole may form in it, or the membrane may become unusable. It may also happen that the shut-off valve begins to let water into it.

All work related to the repair of the float and its adjustment can be done independently, without involving plumbers. Depending on the cause of unstable operation or in the event of a breakdown, the following actions are carried out:

- adjusting the lever, bringing it to the desired position;

- shut-off valve replacement;

- float repair;

- complete replacement.

To adjust the float lever, bring it to the desired position, it is necessary to take into account the material from which it is made. The brass lever is bent. The desired position is determined by raising and lowering the lever.

The plastic lever is adjustable with a fixing screw or a plastic ratchet. The fastening type changes the bend of the lever, and the ratchet fixes the lever in the desired position.

In order to replace the shut-off valve, you must first drain all the water from the drain tank, disconnect the faulty valve from the water pipe. After removing the lever, you need to unscrew the fixing nuts and remove the valve. After that, a new valve is installed, the drain tank is filled with water, and the float is brought to the desired position.

When repairing a float, you can seal the damaged area with heated plastic. Wrapping the float in a plastic bag can also solve this problem.

If the float needs to be replaced, the water supply to the tank is first shut off and it is completely emptied. After unscrewing the water supply pipe, the old float is removed and a new one is installed in its place. The required position of the new float is fixed.

When replacing the membrane, it is necessary to tie the float to the crossbar, drain all the water from the tank, and unscrew the fixing nut of the flush pipe.

Knowing the device of the drain tank, the principle of operation of the mechanisms that ensure its proper functioning, you can independently eliminate minor malfunctions. Adjusting the float will help solve the problem with constant water leak from the drain tank into the toilet, normalizing its quantity in the tank, and also with the lack of a drain. Doing all the work on adjusting the float with your own hands, you can eliminate the cost of calling plumbers. You can contact specialists in cases where all the measures have been taken, but the malfunction of the drain tank has remained.

Recommendations

Summing up, it should be noted that the problems associated with the leakage of the tank or insufficient water supply to it are practically solved by referring only to the float and valve.

Main problems in water supply or sanitation drain tank occur due to a malfunction of the float, valve or membrane (gasket).

It is likely to repair the failed part

In cases where this is not possible, it is necessary to replace the spare part with a new one.

When buying a valve, you should pay attention to a number of nuances so as not to make a mistake with the choice. First of all, you need to find out how water is supplied to the tank: the system is installed with a side or bottom connection. The next issue is the flush system itself: push-button (piston), lever or lifting.

Be sure to remember that if there is even the slightest uncertainty in your actions, do not take risks.

Contact a specialist who can make your life easier by solving a plumbing problem quickly and easily.

The next issue is the flush system itself: push-button (piston), lever or lifting.

Be sure to remember that if there is even the slightest uncertainty in your actions, do not take risks. Contact a specialist who can make your life easier by solving a plumbing problem quickly and easily.

I would also like to return to the question of the types of floats: “ball” and “glass”. In the first group, this type of breakdown often occurs, such as the ingress of water into a sealed container. This happens when a crack forms in the ball. The way out of the situation is to drain the water from the tank and seal the hole. Most often, hot molten plastic is used for this, which is applied to the crack. Thus, the ball is “sewn up” and can still last for some time. But, unfortunately, it should be understood that such a measure is not lifelong. Subsequently, you will still have to replace either the ball or the drain system as a whole.

Very often, during operation, the volume of water entering the drain tank exceeds all conceivable limits. Sometimes the problem is associated with an increase in the pressure of the fluid supply to the system. In another case, the plastic tube located inside the tank is to blame, through which water does not flow like a waterfall, but calmly descends down an additional chute, making almost no sound

Thus, if there is a sudden increase in the sound of water intake, pay attention to this small tube

To reduce the risk of leakage through the mounting bolts connecting the tank to the toilet shelf, experts advise treating these places with silicone sealant immediately after assembling the structure. Thus, you will extend the life of these fasteners.

The internal filling and principle of operation of flush tanks of hidden structures is practically no different from the described stationary ones. In addition, their body is always made of high-strength plastic without a single seam.

For this reason, special precautions must be taken

In order for the flush valve in concealed structures to last longer, it is best to ensure that the tap fluid is completely filtered throughout the dwelling, and for flushing the toilet too. Check the water level in the tank several times a year. Despite their high strength, even these designs can leak. And the closed type of installation does not allow timely detection of a breakdown. Also check the tightness of the connection of the tank with the downpipe.

Be sure to have scheduled inspections of your drain a few times a year. Since the quality of our tap water leaves much to be desired, parts can get dirty very quickly. This factor is at the heart of most breakdowns. In order for the float, valve and all their components to serve you as long as possible, wash and clean them at least twice a year. Then you can not only prevent wiping membranes or gasketsbut also clogging or mechanical failure of the valve.

A detailed study of the cistern device, causes breakdowns and how to fix them allow you to get by with minimal sacrifices in the process of repairing a plumbing device. To do this, it is absolutely not necessary to call a specialized specialist or completely change the drain system - the toilet bowl. You can easily fix such a malfunction with your own hands, without waiting for the arrival of the master.

From the following video you will learn how to adjust the water pressure in the toilet bowl.

![[instruction] do-it-yourself toilet installation | video](https://fix.housecope.com/wp-content/uploads/e/0/5/e05c3aaa569c15a65a76abf551b1139c.jpg)