- Call a specialist

- How to defrost a plastic pipe?

- Heating of metal-plastic pipes

- Method two: we create circulation of hot water in a frozen pipe

- How to warm up a pipe ways that work

- How to restore the health of the water supply or sewerage

- How to prevent system freeze?

- How to defrost a pipe indoors

- Tip 2 Use an artificial temperature rise against the ice

- Boiling water

- Blowtorch or industrial hair dryer

- Electricity

Call a specialist

In case of severe freezing of the water supply, you need to use the services of professionals.

Specialists will help restore water supply in the system in a few hours using a hydrodynamic installation. This device is a special equipment for cleaning water pipes in order to eliminate severe blockage. In addition, the use of a hydrodynamic unit is a very effective method of thawing frozen collectors. The principle of operation of the device is to supply very hot water (at least 150 degrees) under high pressure through the sleeve. At the same time, the resulting pressure allows you to "warm up" the pipeline as quickly as possible.

So, the above methods for heating the pipeline are the most effective and proven in practice.Regardless of the method chosen to solve the problem, the main thing to remember is that appropriate measures should be taken in a timely manner.

Remember, the best way to prevent the formation of such troubles is to exclude the possibility of freezing of the pipeline. To do this, in severe frosts, leave a small stream of water overnight, which will ensure the circulation of fluid in the system and reduce the risk of blockage from ice.

How to defrost a plastic pipe?

Recently, steel pipes for plumbing are used less and less, they have been replaced by plastic pipes. Such pipes are not subject to corrosion and do not collapse if water freezes in them.

However, if an ice plug appears in them, practically all methods of external influence cannot be applied to them. Naturally, the use of open fire to heat the plastic will lead to the destruction of the pipe, and the use of a building hair dryer often turns out to be ineffective, since plastic does not conduct heat well.

Connecting a welding machine to such pipes is also completely useless, since the pipes do not conduct electricity.

The mechanical method of action, that is, the removal of the ice plug by inserting a steel bar inside, can be effective with a small freezing area, however, its use creates a serious risk of damaging the pipe.

Thus, if it is necessary to defrost plastic pipes, the only way remains - the use of hot water poured inside.

The first way to defrost is to organize the supply of hot water to the place of freezing.

It is done like this:

To defrost a plastic pipe, a pipe or hose of high rigidity with a smaller diameter should be prepared.

For defrosting use gas or oxygen hoses.

- Metal-plastic pipes are sold, as a rule, rolled into coils. Therefore, the pipe should first be unbent, and then begin to move along the pipeline, pushing the ice plug all the way.

- Now you can pour hot water into the pipe, trying to maintain the highest possible temperature.

- Defrosted water will flow out at the pipe connection, so a collection container should be placed there.

- As the ice melts, the plastic pipe will need to be pushed further and further until the problem is completely fixed.

This defrosting method is good if an ice plug has formed in an area located near the entrance to the pipe. If the pipe is frozen far from home and there are turns and bends in the pipeline section, then the pipe cannot be pushed into the pipeline.

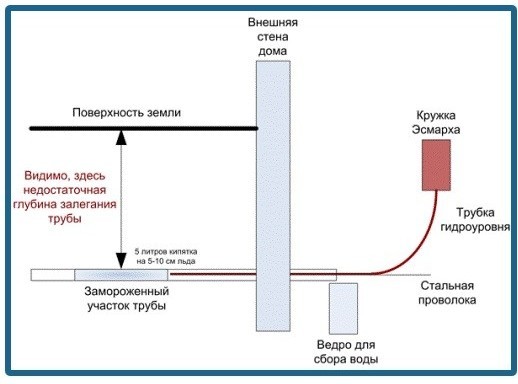

- To carry out the work, you will need a hydraulic level, a coil of steel wire with a diameter of 2-4 mm, and an Esmarch mug, that is, a device that is used in medicine for cleansing enemas.

- We take the tube of the hydraulic level and wrap it with wire or attach the wire to the tube with adhesive tape or electrical tape. This must be done so that the wire does not stick out in different directions, while the tip of the tube should protrude by one centimeter.

- Now we connect the second end of the hydraulic level tube to the outlet pipe of the Esmarch mug and begin to push our structure into the pipe.

- Since the hydraulic tube has a small diameter and weight, there are no difficulties when pushing through, even if there are turns along the way.

- Push the tube until the tube hits the ice plug.

- Now pour hot water into Esmarch's mug and open the supply valve.

- As the ice plug decreases, push the tube further.

- A suitable container should be installed at the junction of pipes to collect the escaping water.

This method of defrosting is quite effective, but it takes time. For one hour of work, you can have time to free from ice about 0.8-1.0 m of the pipe.

So, there are several fairly effective ways to help solve the problem of how to defrost water pipes. However, all of them are time-consuming, so it is more correct to take the necessary measures, for example, to prevent freezing of water in the pipeline.

The lack of water in the water supply in a private house can be due to various reasons. One of them is the formation of an ice plug in the pipe. Such a nuisance occurs if the temperature is very low outside, and the rules were violated when laying the water supply. You can try to fix the problem yourself, but it requires considerable effort. Consider the answer to the question: water froze in a pipe underground - what to do in this situation?

Before figuring out what to do if the water in the water pipes froze, let's figure out why this can happen. Main reasons:

- laying pipes at insufficient depth;

- a small layer of insulation, its poor quality or complete absence;

- insignificant or zero water consumption during severe frosts;

- abnormal weather conditions.

As a rule, pipes passing on the street - outside or underground - freeze.But in the absence of heating and significant sub-zero temperatures for a long time, the problem may occur indoors or at the point where the pipe enters the wall.

Heating of metal-plastic pipes

Before you warm up a plastic pipe, you need to study well the algorithm for performing this work, which includes several stages:

- The first step is to localize the frozen part of the pipeline. To do this, you need to carefully examine the pipes located right next to the house. As a rule, the problem area is located tactilely - it is usually much colder to the touch than the functioning part of the pipe.

- After the localization of the ice plug, the pipe is wrapped with a rag. Next, you need to open all the taps of the water supply, having a supply of hot water with you. If not, you can melt the snow.

- The pipe is poured with water in two stages: first it is cold, and after it - hot. A gradual increase in water temperature is necessary so that the pipe is not damaged due to sudden temperature changes.

- Water that has changed from solid to liquid will exit through open taps.

So that the thawed pipe does not freeze in the future, it is better to immediately take measures to insulate it - then in the future you will not have to think about how to warm the pipe with water.

If the water is frozen in plastic pipes located under a layer of soil or foundation, then to warm them up you will need a barrel, a pump and an oxygen hose, with which you need to carry out the following steps:

- The barrel is filled with hot water, the temperature of which is constantly rising.

- The hose is inserted into the pipeline exactly until it hits the ice crust.

- The tap opens and connects to the hose, which must be brought into the barrel. If the barrel itself or the possibility of installing it near the tap is not available, then an ordinary bucket will do.

- The pump starts, after which the water heated in the barrel is pumped into the plastic pipeline. The hose must be constantly pushed inside the pipe so that it defrosts all the ice in the system. The pump periodically turns off to drain excess water.

- When the blockage has resolved, the hose is removed and the water is drained from the pipeline.

Heating a plastic pipe can be done in other ways. For example, you can always use a hydrodynamic machine for these purposes. Her hose is launched into the pipe, after which the device starts. The ice in this case will break with the help of pressure.

A safer option for plastic pipes is a steam generator, which eliminates ice by turning it into a gaseous state. A pressure gauge and a valve designed for a pressure of 3 atm are attached to the thick-walled pipe of the device. When working with a steam generator, you must strictly follow the instructions in order to avoid possible troubles.

Conclusion

Questions like “a pipe froze underground - what to do?” quite common among owners of private houses. Solving the problem with a frozen pipeline is not so difficult, but the task itself is quite troublesome and time-consuming. It would be much better to design the pipeline in advance so that the water in it does not freeze even in the coldest times.

Are you familiar with the situation when, at a negative temperature outside, the water supply from the tap stops? Such a problem occurs in your home with the onset of a cold season, and you do not know how to quickly fix it? To fight, it is required to choose an effective method for resuming the working capacity of the water supply network. Do you agree?

We will tell you how to thaw a frozen pipeline and how to prevent a problem situation in the future. Let's talk about effective ways to quickly restore water supply on a cold winter day for sanitary purposes and cooking.

Our article provides a selection of the best ways to help deal with this trouble on your own. Methods for pipelines made of various materials are considered. So that you can better understand the nuances of warming, we have selected visual photos and thematic videos detailing recommendations for saving water pipes from ice captivity.

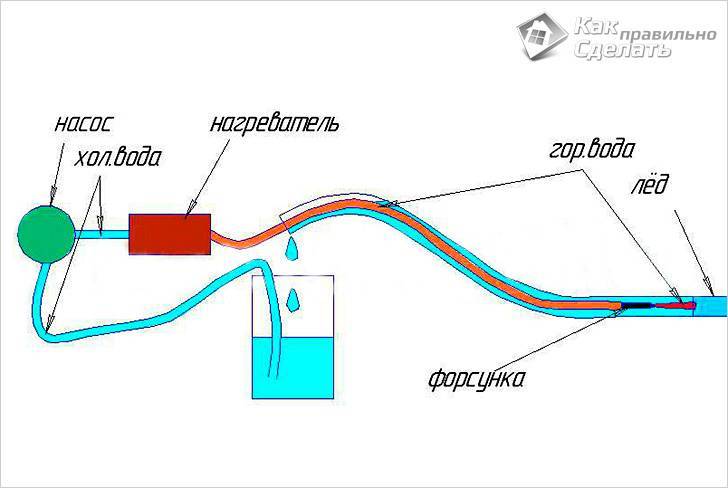

Method two: we create circulation of hot water in a frozen pipe

This option will be appreciated by motorists - auto parts will be needed here. The method is safe, relatively fast and reliable. It is applicable to both plastic and metal pipes.

The principle is based on a constant supply of hot water to the ice dam. So, we make a water circulator!

To make the device you will need:

- washer reservoir or vehicle fuel pump;

- car battery or household step-down transformer (power supply);

- wire, clamps;

- a tube from a hydraulic level or any plastic tube of a suitable diameter;

- container (basin, bucket);

- kettle or kettle;

- water, salt.

Helpful Hints

It is not necessary to remove the washer from your car, especially if it is a foreign car. It can be easily purchased in the store new or used by ads. The price of a VAZ washer is from 200 to 700 rubles.

The tube or hose must be selected according to the length of the water pipe.

When using a hydrocirculator, clean water should be used.

For large diameter pipes, you can use a rubber hose, for example, oxygen.

Here you need to understand the difference - if the conduit runs horizontally and the ice jam is not far, then a washer will do. If the pipe has a vertical direction, a considerable length, a large diameter, it has corner joints, it is worth using a fuel pump. It creates pressure and more efficiently delivers the coolant to a hard-to-reach area.

What to do when using a washer

- Connect the tube to the tank.

- Place the tube in the water conduit until it freezes.

- Heat salt water to a temperature of 60-70 degrees.

- Pour water into the tank.

- Connect washer to power supply.

Hot water will begin to flow into the conduit and melt the cork. As it thaws, the tube must be advanced to the site of the blockage. Hot water must be constantly topped up so that the tank does not run idle.

Salt will speed up the defrosting process, and will also prevent water from freezing if work is carried out in severe frost.

What to do when using the pump

- Attach the tube to the pump, securing it with a clamp.

- Connect the pump and prepare for operation.

- Pour salt water into the container and place the boiler.

- Place a container under the pipe so that the water drains back.

- Place the tube in the water supply.

- Place the pump in a container.

- Turn on the boiler and wait for the water to heat up.

- The water is hot, turn on the pump.

Helpful Hints

Water should not be heated above 70 degrees. The heated tube will soften, making it difficult to move.

As it thaws, the tube must be advanced close to the congestion.

If there is an angle connector on the water supply and the tube does not move forward, then it is worth increasing the water temperature to 90 degrees and maintaining circulation. Hot water in any case will give a positive effect, but it will take some time.

How to warm up a pipe ways that work

The consequences of low temperatures for open water supply

Hello dear readers. This time I will tell you about how to warm the pipe in the ground, using improvised means for this.

There are many passive and active anti-freeze measures that are carried out during the laying of the supply pipeline. For example, a pipeline is laid well below the freezing level of the ground, lined with thermal insulation materials, wrapped in a special thermal cable, etc.

These methods allow you to maintain the health of the water supply and sewerage system during the cold season. But what to do if the frost protection was not implemented in a timely manner and an ice plug formed in the water supply?

How to restore the health of the water supply or sewerage

Methods for removing ice plugs are based on thermal action and subsequent mechanical punching.

When starting to warm the supply water supply, it is necessary to take into account the fact that the liquid medium in the pipes does not freeze completely, but in certain areas.Therefore, before proceeding with the removal of the plug, you need to find out in which part of the pipe the plug is located.

How to determine the location of the cork?

The pipeline, depending on the location, is divided into two types:

- buried - located in the ground below the level of freezing,

- surface (non-buried) - located above the ground.

The greatest threat of freezing is exposed to the pipeline in the surface section. If there are problems with water during the cold season, you need to act as quickly as possible so that the ice plug does not spread underground.

You can find the location of the cork in two ways:

- bending the pipe - relevant if the pipeline components are plastic and do not exceed 50 mm in diameter,

- tapping the pipe and determining the presence of a solid body by the tone of the sound.

When bending plastic pipes in the freezing area, you can hear a characteristic crunch. If we hear a crunch, then the ice is cracking, and, therefore, a cork has been found.

We start tapping the pipe from the area where the water has not frozen. We do this with a metal object, for example, a medium-sized wrench will do. Gradually moving towards the cork, you will notice that the sound from the blows will become more deaf.

To bend a polypropylene pipe to detect an ice plug, you need to manually, carefully and not much. The maximum bending angle should not exceed 170 degrees on the basis that a straight pipe cut is 180 degrees. Plastic at low temperatures loses its original elasticity, so excessive deformation can lead to cracking.

So, a frozen section of the pipeline was found, what is the instruction to fix the problem?

Ways to eliminate the ice plug

Traditional methods of defrosting household plumbing

The problem of a frozen pipeline has been relevant since the beginning of the operation of closed communications for transporting a liquid medium. Since then, many effective methods have been invented that can be implemented with your own hands using available tools and devices.

The most popular ways to eliminate an ice block are listed in this diagram.

How to prevent system freeze?

The issue of the probability of freezing of the pipeline must be foreseen at the stage of its laying. According to the current norms of SNiP, pipes must be laid below the freezing depth.

For regions located in middle latitudes, the depth of freezing of the earth is on average 1.0 - 1.5 meters from the day surface

The depth of freezing of the soil layers is determined empirically in the coldest period for the region, taking into account the maximum soil moisture index and provided that there is no snow cover. If it is not possible to lay pipes at a sufficient depth, it is worth taking care of the thermal insulation of the structure.

The place where the pipe enters the house is the most vulnerable and therefore needs effective insulation with waterproofing materials.

Ideal as a heat insulator

- foam strips;

- mineral wool;

- glass wool.

It is not necessary to use rags, sawdust and paper as a winding even for temporary insulation. These materials, when the temperature changes, easily absorb moisture from the air, preventing the formed condensate from evaporating.

On sale you can also find chemicals that prevent the freezing of water. But their aggressive composition makes them unacceptable for the plumbing system.It is better to use a concentrated saline solution, which corrodes ice perfectly. It is fed through a hose, the diameter of which is slightly smaller than the cross section of the pipeline.

In addition, salt water does not freeze at temperatures below zero, so the formation of a cork behind a salt solution is definitely not expected.

Alternatively, lay a heating cable along the pipeline. It is equipped with thermal sensors that, when the system is heated to a certain temperature, turn it off. The main advantage of self-heating cables is that they are able to adapt to external conditions. And this in no way affects the work of its other parts.

The self-regulating heating cable will turn on as needed, and turn off when the set temperature mark is reached

The length of the heating cable can reach 20 meters, thanks to which it can be used to heat both individual sections of the pipeline and the entire system located in the zone of soil freezing.

Keep in mind that water freezes faster in pipes with a small diameter. Therefore, when arranging autonomous water supply, it is preferable to use pipes with a diameter of 50 mm or more.

Since concrete freezes much faster than soil, in places where the pipeline passes through the basement or basement, it is desirable to place pipe sections in sleeves - pipes with a slightly larger diameter. The resulting voids can be blown out with polyurethane foam.

In the future, with irregular use of engineering networks during downtime during the cold season, it is necessary to completely remove water from the pipes and keep them dry.

It is necessary to insulate not only the pipeline itself, but also the source of water itself, and other structural elements passing outside the house and in unheated premises.

Despite the wide range of effective equipment for removing ice blockages from pipes, it is best not to bring the situation to such problems. After all, heating frozen pipes is a rather problematic process, which is aggravated by the complexity of performing work in the cold.

By adhering to simple recommendations, you can prevent pipes from freezing and stopping the system, thereby extending its service life.

How to defrost a pipe indoors

The methods used to defrost utilities directly depend on where exactly the pipeline is located. So if it is mounted indoors, then you can get rid of ice jams using:

- hot water;

- building hair dryer;

- electricity.

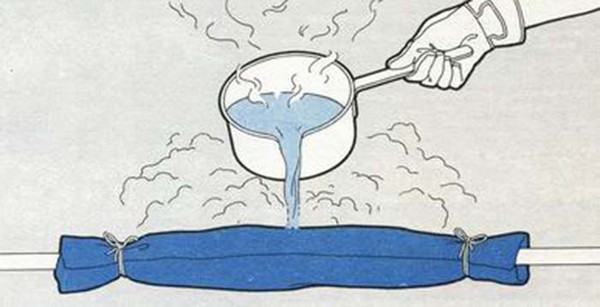

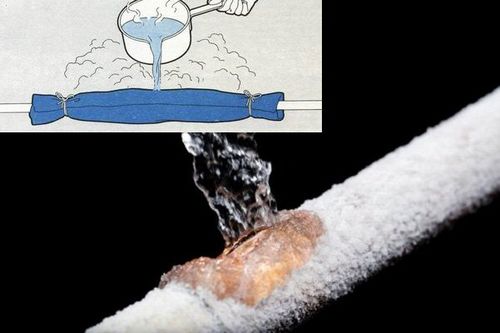

Hot water is used to warm pipes in open sections of highways, while this method can be used to clean products, both metal and plastic. In this case, it is best when it is boiling water, since it is it that allows you to melt the ice the fastest. In addition, rags and rags are also used to speed up the process.

- To begin with, rags and rags are placed on the pipe.

- The place of the alleged congestion begins to be poured with boiling water or hot water. The process is lengthy, since the surface of the line will have to be constantly irrigated with new portions of hot water.

- The heating process stops only after water does not start flowing from the open taps.

- Complete removal of ice from the system can be completed in a few hours and during this time the valves should not be closed.

Rags and rags are needed here to increase the area of contact of the pipe with boiling water, as well as to extend its impact on it.

Rags and rags increase the area of contact of the pipe with boiling water, and also prolong its effect on it.

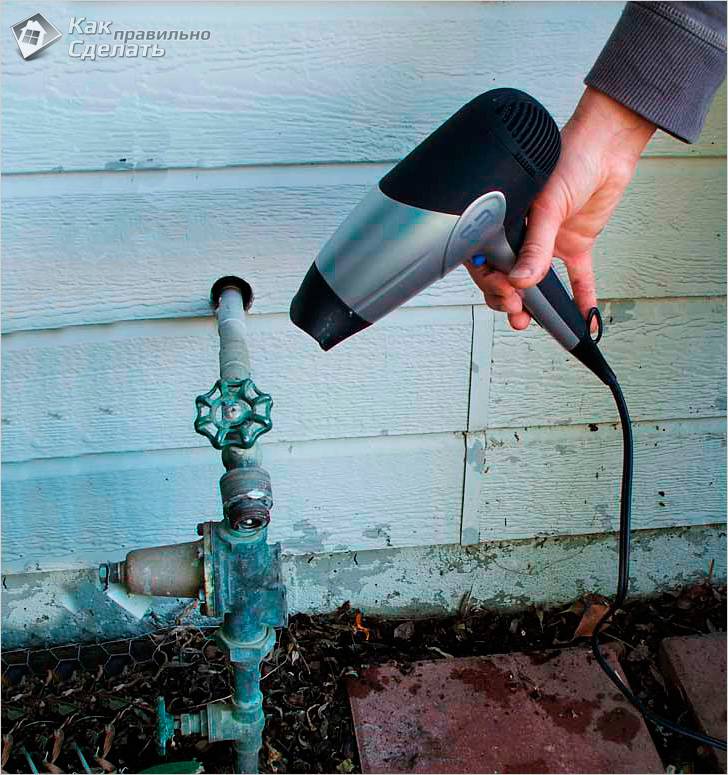

Frozen plumbing can also be warmed up with hot air by exposing it to open areas of the system. For this purpose, a heat gun or a powerful building hair dryer is usually used. At the same time, a temporary canopy from improvised materials is erected over the problem area. In the same case, when the homeowner does not have industrial equipment, he can use any device that generates warm air. So they can be a regular household hair dryer.

The third common way to defrost pipes is the use of electricity. It is considered one of the most effective and can be used to get rid of ice from both metal and plastic products.

At the same time, it should be noted separately that this method requires the adoption of certain precautionary measures.

Metal lines are heated in this way using a welding transformer.

- The output cables of the device must be connected to a suspicious area at a distance of at least half a meter from the blockage.

- Voltage is applied so that a current of 100 to 200 amperes passes through the metal.

- Usually, a few minutes of such exposure causes the ice to melt, thereby restoring the patency of the pipe.

As for plastic communications, they are heated using a two-core copper wire with a cross section of 2.5 - 3 mm:

- One of the cores is partially stripped and 5 turns are made around the cable.

- The second vein falls below the first and the same manipulations are performed on it. Trying to make a spiral winding at a distance of 3 millimeters from the first winding. The resulting device is the simplest homemade boiler.

- The finished product is inserted into the pipe and the current is turned on. Under the influence of the potential that has arisen between the coils, the water heats up, and the ice begins to melt.

This method is good because when using it, the system does not heat up and the plastic does not deteriorate.

Tip 2 Use an artificial temperature rise against the ice

Do-it-yourself heating of the pipeline from freezing by raising its temperature is possible only if it is made of metal. You will only damage the plastic construction. And taking into account the fact that the frozen liquid tends to expand, it is desirable to react quickly, until the pipes burst.

Whichever way you choose from the methods listed below, you should follow some general rules in order to avoid the unpleasant consequences of your activities:

- Open the faucet before starting workso that the melted water has somewhere to move;

- Do not heat the frozen area from the middle. After all, again, there will be no way out, and it is not known where this will lead;

- Heat the water supply system from the tap to the riser, and the sewer, on the contrary, from the riser to the tap. This will also provide a controlled outflow of melt water;

- First of all, examine the place of freezing, evaluate it and select the best method of heating.

Boiling water

This elementary and incredibly cheap method is suitable even for plastic products, since the least resistant to high temperatures polypropylene pipes can withstand heating up to 90-100 degrees Celsius. But it has two important drawbacks:

- Possibility of application only to open sections of the pipeline. If crystallization has occurred, for example, underground, then you simply will not get there with a kettle;

- Low efficiency. Frankly speaking, there is little benefit from pouring boiling water over pipes. Unless we are talking about a very small ice plug in a thin product.

Blowtorch or industrial hair dryer

The action plan here is simple:

Turn on the device;

We methodically drive an outgoing stream of hot air or flame over the frozen area, observing all the above precautions.

Efficiency in this case, of course, increases significantly in comparison with the method described above, but access is still limited to only visible gaps in the highway.

Electricity

If you once bothered to install a heating cable, then to remove ice from the pipeline using electricity, you just need to turn on the appropriate toggle switch. But if you have not done this, then you need to get a welding machine somewhere and make the pipe itself a heating element. After all, everyone remembers that the metal heats up when an electric current passes through it?

The instruction for defrosting an object in this case will be more complicated:

- We connect the terminals to the edges of the proposed ice plug. It is noteworthy that here it is enough to have only some points of the pipeline open, and not the entire freezing zone, which greatly expands the possibilities of the described method;

- We set the power on the regulator to the minimum;

- We click the power on toggle switch and let the device work for thirty seconds;

- Then turn it off for a minute so that the equipment “rests”. Burning it is a simple matter, but very costly;

- We repeat the procedure several times. If there is no overheating of the pipe in the process, then the power can be increased;

- After the thawed water begins to drip from the tap, we warm up several more times, after which we turn off the device completely. It is not necessary to completely melt the ice, it is enough to make a gap in it so that the rest is completed by the water flow;

- The tap should not be closed for some more time in order to clean the pipeline from the remnants of icing as best as possible.