- Variety of gas meters

- Vortex

- Turbine

- Rotary

- Membrane

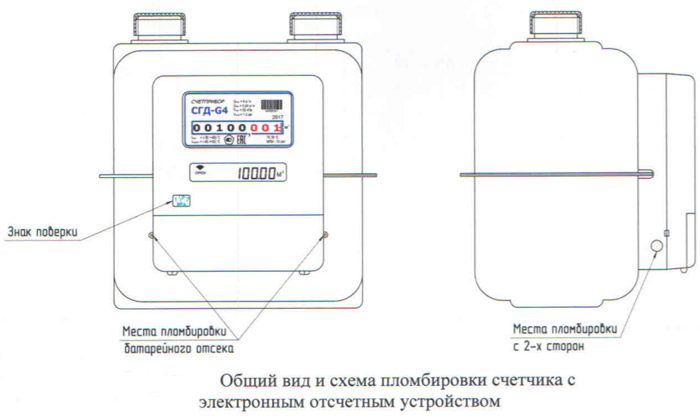

- Types of gas meter seals

- Lead

- Paper stickers

- Plastic clamps

- Plastic number seals

- Antimagnetic seals

- If verification is overdue

- Varieties and procedure for verification

- Features of verification in the company

- Features of verification at home

- Features of verification of a gas meter

- How is the meter checked at home?

- Method for checking the gas meter outside the home

- Unscheduled gas meter verification

- Popular models of gas meters for an apartment

- VC (G4, G6)

- Grandee

- CBSS (Betar)

- SGM

- SGK

- Arzamas SGBE

- Gasdevice NPM

- Check and replacement

- How to choose a gas meter

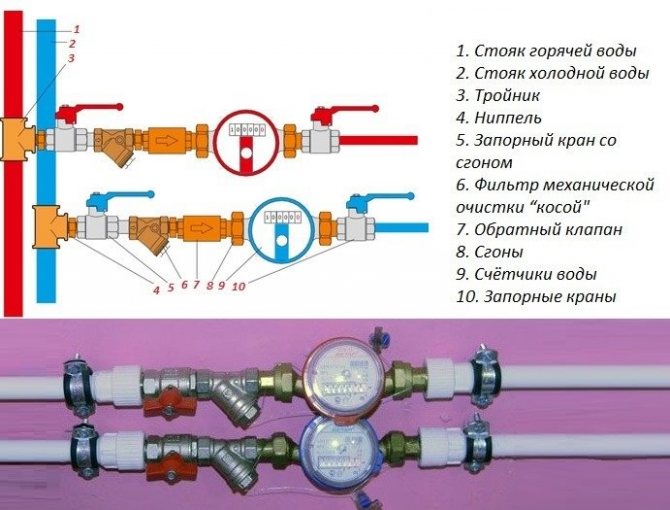

- The main types of household gas meters

- More about the document

- What information does the paper contain?

- Filling Requirements

- Citizens

- For HOA

Variety of gas meters

The flow meter is built into the gas pipeline that supplies the resource to the room. Devices vary in design. The method of operation can be based on taking into account the characteristics of the movement of the mechanism initiated by the properties of the fuel, or on the analysis of pulses generated by sensors during the passage of gas. Indications are displayed for the consumer by means of the counting block or the electronic display.

Vortex

The operation of devices of this type is based on the analysis of the frequency of pressure changes that occur when the path of the gas passing through the meter is in the form of a vortex. As a rule, such devices are mounted in industrial or municipal premises. Other types of counters are produced for home use. Vortex models have complex electronic components inside and are expensive devices.

Turbine

Here, the gas flow initiates the torsion of the turbine element provided with bearings. The main accounting parameter is its speed. Since the bearings soon dry out when gas flows through the mechanism, they must be regularly lubricated to ensure the smooth functioning of the device. This function is performed by a pump built into the device. Like the previous type of apparatus, turbine models are industrial devices. This is due to their large size and excellent throughput. New models are usually equipped with sensors that record pressure and temperature.

Most often, such gas meters have a body in the form of a cylinder. At the entrance they have a rectifier unit. Behind it is the main component - a rotating impeller. The number of its revolutions depends on how much gas fuel has passed through the structure. The counting unit of the device can be both mechanical and electronic.

Rotary

Devices with rotary blades are intended for mounting on a vertical pipe through which the gas moves downward. The movable block consists of two 8-shaped blades adjacent to each other, rotating in opposite directions. They are tightly fixed in a special box.This prevents excessive gas losses (provided that the pressure does not go beyond the specified limits).

The flow of the resource initiates the rotation of the blades. This is achieved due to the pressure difference between the supply and output. A single revolution redirects a clearly defined amount of gas downwards. The fixation of the number of twists and their conversion into units of volume is carried out by a counting mechanical unit. Resource losses are also taken into account. This ensures high accuracy of the counter.

The device has many advantages - energy independence, small size, almost silent operation, good bandwidth. It is capable of measuring over a wide range. The downside is the short period of time between inspections - 5 years. This is due to the design with a movable blade unit.

Membrane

Instruments of this type are popular due to their high accuracy combined with ease of operation. They are used for apartments and houses located in the private sector. Boxes with membrane elements are installed in the body of the device, communicating with each other through tubules. The latter are equipped with valves, the opening and closing of which occurs due to the transfer of force through a special block with levers.

When gas is supplied inside, the first box is filled first. After that, the valve opens, redirecting the fuel to the second chamber. And so it passes sequentially through all the boxes with membranes placed inside the case. The more there are, the more accurate the data will be.

Such metering devices have a significant duration of the interval between verifications (10 years or more) and operation in general (up to 20 years).They function normally on a low-purity resource. As disadvantages, we can designate the generation of whistling noise (the severity depends on the activity of gas consumption), as well as large size. The latter is not a problem for private households, but can be annoying when installing a meter in a small apartment.

Types of gas meter seals

The effectiveness of gas consumption control largely depends on what seals are placed on gas meters.

Lead

The lead seal is universal, as various options for its execution are possible. It is quite reliable due to the metal composition. The installation is carried out using sealers, so it is disposable.

It is easy to apply special unique prints on lead, which are difficult to fake. A lead seal-nail for gas meters is used by manufacturers of instrumentation.

Paper stickers

The paper seal on the gas meter pipe is attached temporarily, as the material wears out quickly and is quite easy to damage.

The seal-sticker is used in hard-to-reach places and where other types of sealing are not acceptable.

Plastic clamps

Plastic clamps are easy to install and affordable, so their scope is quite wide. To seal a gas meter with such a seal, no special equipment is required; it is enough to pass a narrow pointed edge into the hole at the opposite end and pull it off well.

To remove this seal from the gas meter, you will have to cut the clamp.

Plastic number seals

The numbered plastic seal on the gas meter is a rotary type device.Its fasteners are carried out with a locking wire by winding a rotor rod located in the middle onto the thread. It must be rotated only in a clockwise direction. A special flag placed on the seal is broken off after fixing.

On its case there is a special insert on which a unique number is applied. As a rule, seals with numbers on the gas meter are fixed at the site of its connection to the pipe during commissioning or after scheduled verification.

It is possible to remove the seal from the metering device only after cutting the wire.

Antimagnetic seals

An anti-magnetic seal on a gas meter is used to prevent illegal interference using a magnet that slows down the operation of the control and measuring device.

The principle of operation of an antimagnetic seal is that even with a short exposure to a magnet, the structure in the capsule is destroyed. Such a reaction indicates third-party interference.

For sealing control and measuring devices, magnetic seals with one and two elements are used:

- Under the influence of a magnetic field on single-element seals, the anti-magnetic element disintegrates and the readings of the control and measuring device are fixed.

- The two-element anti-magnetic seal for gas works in such a way that the element turns black after the influence of the magnet.

If verification is overdue

According to the current RF PP No. 354, if the calibration interval has expired, the device is recognized as out of order. Readings will no longer be the basis upon which payment is calculated.

Possible consequences:

- For the first three months, the calculation is based on the average monthly values for the previous six months.

- Further accrual occurs according to the standard with an additional coefficient. Penalties are not collected.

- If the owner does not carry out actions to verify or replace the expired IPU, the gas supply organization may decide to install a new meter. Starting in 2016, companies are allowed to force the installation of flow meters. The failed device will no longer be part of the resource consumption accounting system.

Verification of a gas flow meter is a complex procedure if it includes dismantling, because the work cannot be done by hand.

Varieties and procedure for verification

Verification of gas meters can be:

- planned;

- unscheduled.

The terms for checking gas meters according to the plan are set by the manufacturer of gas equipment and are indicated:

in the passport of the flow meter. The manufacturer sets the calibration interval, and you can determine the period for a scheduled inspection by adding the date of manufacture with the established interval. For example, the Betar flow meter has a calibration interval of 6 years;

Calibration interval set by the manufacturer

in the receipt for payment for the consumption of "blue fuel".

Determining the date for checking the receipt

The reasons for unscheduled verification may be:

damage to the verification mark/seal and/or illegibility of the information indicated on the mark (seal). The causes of damage may be mechanical impact or normal wear and tear;

Seal breach

- damage to the housing of an individual meter;

- depreservation - putting the flowmeter into operation after the expiration of at least one calibration interval;

- the presence of suspicions of the user to receive incorrect readings.

The result of the verification is a protocol confirming:

- the possibility of using the metering device further;

- unsuitability of the flowmeter for further operation.

The standard document states:

- the name and address of the organization that conducted the research;

- counter type;

- the date of the inspection;

- counter number;

- research results;

- expert opinion;

- date of the next check;

- cause of unsuitability if the meter has not been tested and needs to be repaired or replaced.

Document with verification results

Verification of meters can be done:

- in a specialized organization;

- at home.

Features of verification in the company

If it is planned to check the meter in a specialized company, then the following procedure is performed:

- the consumer personally or through a legal representative visits the office of the selected organization and applies for the removal of the meter for the purpose of verification. The application is written in free form or on a special letterhead of the company. The application must be accompanied by:

- a copy of the applicant's civil passport and a power of attorney, if the document is submitted by the legal representative of the owner;

- a copy of the certificate (extract) confirming the ownership of the premises in which the metering device is installed;

- a copy of the technical passport of the flow meter;

- at the appointed time, a representative of the company arrives and removes the meter for research. Instead of a metering device, a special arc is installed - a plug. An act is drawn up on the removal of the flow meter, which must be submitted to the resource supply organization;

Arc instead of a gas meter

While the meter is not available, the gas fee is charged according to the standards established in the region.

- the owner personally takes the device for examination, which can last from 5 to 30 days;

- obtaining a metering device and a research protocol. If the meter can be used further, then specialists are called who install and seal the flow meter. If the flowmeter is unsuitable for further use, then it is replaced;

- sending a verification document to a resource supply company.

Features of verification at home

If the gas system maintenance company has special equipment designed to calibrate the meter without removing it at home, and the type of installed meter supports this possibility (for example, Grand meters), then the verification procedure is simpler and requires less time (1 - 3 working days).

Verification is carried out according to the following scheme:

- filing an application for a flow meter check;

- arrival of a specialist who performs the following actions:

- external inspection of the metering device, during which defects, deformations and violation of the seal are detected;

- checking the operation of the shut-off valves;

- if no external defects are found, then special equipment is connected to the meter;

- joints are washed to eliminate possible leakage, and when it is detected, they are sealed;

- research is being done;

- a protocol is drawn up containing the result of verification;

Conducting meter studies without removing the device

- payment for services rendered;

- transfer of documents to a resource supply company or replacement of a gas meter.

How to check at home, look at the video.

Features of verification of a gas meter

Verification of a gas meter can be either field (the meter is removed and taken to the laboratory) or local (a specialist comes with the equipment to the applicant and performs verification on the spot).

How is the meter checked at home?

Gas consumers can buy gas meters, which can be verified at home. That is, the device for reading the amount of gas consumed will not need to be dismantled.

It is enough to call a specialist who, using special diagnostic tools, will check the device. You can also check the meter at home by contacting a specialized company that has mobile equipment for checking meters at home with this question.

The procedure for checking gas meters at home without removal is as follows:

- The verifier comes to the apartment, asks to take him to the place where the gas meter is installed.

- Having gone to the installation site of the counter, the specialist asks to remove all things from the stove.

- Then he inspects the counter, checks the safety of the seal.

- If there are no complaints about the appearance of the device, then it starts verification - it lathers the connections, connects a special installation.

- At the end of the verification procedure, the equipment is turned off, the specialist installs the connections. Connections are re-washed and inspected for leaks.

- The trustee completes the certificate for the client. He also fills out his register of gas appliances and writes out a receipt for payment.

- The consumer makes a settlement with a gas service employee.

Method for checking the gas meter outside the home

If a gas consumer, when installing a gas meter, concluded an agreement with a specialized company for further maintenance, then the agreement usually states that this citizen must initiate the meter verification procedure, call a company specialist to come, dismantle the meter and take it for diagnostics.

Also, an interested person can contact the gas service of the region where he lives and write an application for the dismantling of the meter and its further verification. Together with the application, a citizen must provide his civil passport, as well as a passport for a gas meter.

If the application is accepted and submitted for execution, then a team of specialists comes to the applicant on the appointed day, who remove the gas meter, put a bracket (a pipe of the required diameter, bent in an arc), write out an act, after which the applicant independently carries the meter for verification to the Standardization Center of his district .

If, after the results of the check, it is established that the meter is suitable for further operation, then a special stamp and the signature of the verifier are affixed to the device passport, confirming that the meter has been verified.

While the meter is being verified, gas consumption will be calculated based on the average monthly rate, provided that the consumer has used the gas meter for a period of at least 1 year.

After checking the meter, the person must send an application to the department for the installation of a seal. And within 5 working days from the date of registration of this application, the gas supplier is obliged to seal the meter.

Unscheduled gas meter verification

The consumed gas meter sometimes requires an unscheduled check:

- if any damage was found on the meter, for example, the seal was broken;

- if the consumer has doubts about the correct operation of the device;

- if the consumer has lost the results of the last verification.

Popular models of gas meters for an apartment

We tried to compile for you a certain rating of gas meters available and popular in Russia. The models of gas meters presented in it have been on the market for a long time and have already proven themselves.

VC (G4, G6)

Membrane gas meters of this brand have proven themselves well in the gasification of private houses. But they are also suitable for installation in apartments, if gas boilers are used for their heating. There are many modifications, we are only interested in two:

- G4

- G6

There are left and right modifications. They work at temperatures from -30 to +50. Withstand pressure up to 50 kPa. Thanks to their sealed housing, they are perfect for outdoor installations, even without protective cabinets. Calibration interval - 10 years. Service life - 24 years. Warranty - 3 years.

Grandee

Grand is an electronic small-sized gas meter widely used in Russia.

It is found in the following modifications (the numbers indicate the throughput):

- 1,6

- 2,3

- 3,2

- 4

Models are available with thermal correctors and special outputs for remote data acquisition. Mounted on horizontal and vertical pipes. Thanks to the robust housing, it can be installed outdoors. The verification period is 12 years. Service life - 24 years.

CBSS (Betar)

Betar meters are silent, do not vibrate, do not interfere with radio devices.These meters are mainly installed inside heated rooms, since their operating range is between -10 and +50 °C. They are easy to install due to their dimensions of 70x88x76 mm, weight of 0.7 kg and the possibility of installation on both horizontal and vertical gas pipes. Due to the presence of union nuts with 1/2 thread, installation is carried out without welding and other connecting elements.

The device is electronic, a lithium-ion battery is used as a power source, the service life of which is 5-6 years. The service life of the device itself is 12 years. Working pressure - 5kPa

The SGBM counter can be purchased in the following modifications (the numbers indicate the throughput):

- 1,6

- 2,3

- 3,2

- 4

There is a built-in "Calendar" function - it allows you to record the moments of power failure during the operation of the meter. Additionally, you can order a meter with temperature correction. It will take into account the ambient temperature and bring it to a temperature of 20 ° C. That will allow you to take into account the volume of gas, regardless of external conditions. It is possible to equip the BETAR meter with a pulse output for automatic remote collection and transmission of readings.

SGM

SGM is an electronic device for measuring the flow of natural or liquefied gas. Differs in small dimensions (110х84х82) and weight 0.6 kg. The case is sealed and resistant to mechanical damage. Installation on a vertical and horizontal pipe is possible. The scoreboard is turning. There is a modification with a pulse output for connection to an external accounting system.

SGM brand models:

- 1,6

- 2,5

- 3,2

- 4

For autonomous power supply, the device has a lithium battery of “AA” class. The maximum pressure is not more than 5 kPa.Mounted with union nuts with 1/2 thread. The counter works at temperatures from -10 to +50. Calibration interval - 12 years. Manufacturer's warranty - 12 years.

It is possible to order a version with an impulse transmitter for remote transmission of gas flow readings.

SGK

Membrane meter made of sheet steel. Works at temperatures from -20 to +60. Thread fitting M30×2mm. There is left and right handed. The maximum working pressure is 50 kPa. Dimensions - 220x170x193, weight - 2.5 kg.

The following models are available, differing by numerals that indicate the nominal gas flow rate.

- SGK G4

- SGK G2.5

- SGK G4

The service life is 20 years, the interval between verifications is 10 years.

Arzamas SGBE

Household electronic meters of the Arzamas brand are available in two versions:

- 1,6

- 2,4

The device is compact, without moving parts, reliable, lightweight and durable. Easy to install. It is powered by a lithium battery, which lasts for 8 - 12 years. Service life - 24 years.

Gasdevice NPM

The NPM membrane meter differs by models:

- G1.6

- G2.5

- G4

Available in left and right hand execution. Works at temperatures from -40 to +60. It has standard dimensions for membrane devices 188x162x218 and a weight of about 1.8 kg.

The period between verifications is 6 years. Service life - 20 years, warranty - 3 years.

Check and replacement

The frequency of checks also depends on the specific meter model. In most cases, this procedure should be carried out once every eight years. It looks like this:

- Calling a specialist (usually the receipts contain a notification that the time has come to check).

- Replacing the old meter with a service company device (the new device is installed at the time of the old one being checked).

- Checking the dismantled product.

- Issuance of a conclusion based on the results of the test, which will indicate whether it is possible to continue to use this device.

If the conclusion indicates that the device can be used, it will be installed in place. Otherwise, an act is drawn up in which information is written about the impossibility of further use of the meter. It is provided to the owner, who will have to replace the meter.

If replacement of the meter in the MKD (located in the basement of the building) is required, the municipal services are fully responsible for the process.

Residents of the house do not need to spend money on the procedure. If we are talking about replacing an in-house device or an apparatus located in a private house, the responsibility for the replacement lies with the owner of the home.

In this case, the citizen must apply to the gas service, with which he has signed an agreement, with a corresponding request. In this case, you must specify the time and date of replacement.

You must first purchase the device itself. It is desirable that it be the same model as the previous product. If a similar product is not available on the market, you should contact the gas service staff to pick up a new device.

At the appointed time, an employee of the company with which the citizen has an agreement will perform the necessary work. After their completion, the device must be sealed. This can happen within no more than five days from the date of installation. Before installing the device, a preliminary check of the serviceability of the device is carried out.

How to choose a gas meter

Despite the fact that in order to agree on a project for installing a metering device, it is required to provide a technical passport for the flow meter, the choice of equipment should be carried out only after consultation with specialists. Be sure to ask for a list of approved devices, as unlicensed devices cannot be put into operation.

In order to choose a flow meter, its technical characteristics should also be taken into account, paying particular attention to two criteria: throughput and type of device

The first criterion depends on the number and power of gas appliances installed in the house. For one slab, for example, a throughput of 1.6 m3/h is sufficient. This parameter is indicated on the front panel and you can find it out by looking at the value indicated after the letter “G”, that is, in this case, you need a device marked G1.6.

The choice of meter depends on the throughput of gas appliances. For example, if for a gas stove it is from 0.015 to 1.2 m3 / h, then a meter with parameters of 1.6 m3 / h is optimal. In the event that several devices are installed and operated, the minimum values of the least powerful and the limiting data of the highest flow must be taken into account.

But it must be taken into account that it is often an impossible task to ideally select a flowmeter for such a requirement, therefore the maximum values are taken into account. For example, if the minimum plate consumption is 0.015 m3 / h, and the maximum throughput of the boiler is 3.6 m3 / h, then you should purchase a meter marked G4

However, it is imperative to take into account the fact that the meter will be allowed to be installed if the deviation in the minimum value does not exceed 0.005 m3 / h. Otherwise, it may be necessary to install separate metering devices and, as a result, maintain two separate personal accounts

The main types of household gas meters

When choosing a counter, it is necessary to take into account its type, which determines the principle of its operation, as well as the accuracy of the data obtained. According to this criterion, individual consumers can choose devices:

- membrane. These gas meters are characterized by low price, high reliability and quite reliable values. But they are very noisy devices;

- rotary devices. These devices are popular due to their compact size and rather low price, but they have a short service life and are not distinguished by high measurement accuracy;

- ultrasonic devices. These meters are electronic devices and have high measurement accuracy. They are quite compact, silent and can be integrated into a common system for remote data transmission.

Also, when choosing a gas meter, one should take into account its installation location, since these devices are right- and left-hand

It is also necessary to take into account on which section of the pipe the installation will be carried out: horizontal or vertical. You also need to decide on the location of the gas meter: in the house, in a warm, heated room, or on the street

In the latter case, you should buy a device with thermal correction, as evidenced by the letter "T" on the front panel of the device, indicated next to the throughput of the device.

Particular attention should be paid to the date of issue of the meter, since it is it that is the starting point for determining the calibration interval, which is individual and ranges from 3 to 15 years

More about the document

Consider what information should be contained in the document, how to arrange it and what nuances of registration exist for citizens and homeowners associations.

What information does the paper contain?

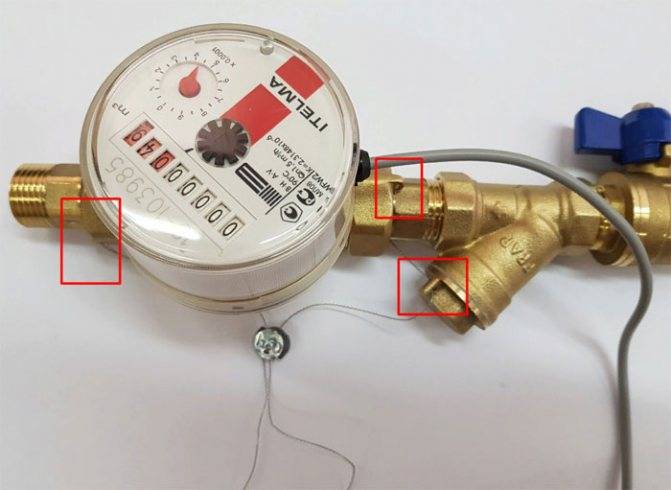

The act of sealing water meters contains the following information:

- the word "act";

- serial number of the document;

- date and place of preparation of the paper;

- surname, name, patronymic and address of the subscriber;

- the name of the organization that seals the device;

- information about the meter (purpose, model, serial number);

- indications of the equipment at the time of the procedure;

- seal number;

- place of equipment installation;

- date of the next verification;

- surname, initials and signature of the employee of the organization that performed the sealing;

- surname, initials and signature of the subscriber;

- seal of the organization that carried out the procedure.

There are no strict requirements for the name of the paper. Therefore, it may not be called the “Act of sealing”, but the “Act of acceptance into operation”. Sometimes these two titles are combined.

Filling Requirements

The document is drawn up on the form of the established sample. Necessary information can be entered into it:

- With a fountain pen.

- With the use of a computer.

The paper must necessarily contain a seal, the signature of an official of the organization that carries out the sealing, as well as the subscriber.

- Download the form of the act of sealing water meters

- Download a sample act of sealing water meters

Citizens

To seal a citizen who owns a dwelling, you first need to install the device.

For this you need:

For this you need:

- hold a meeting of residents;

- send documents to the management company;

- install the device;

- control the preparation of documentation and put your signature.

The homeowner does not need to fill out the paper on their own. This is done by employees of the Criminal Code or a specialized organization.

When it is compiled, you must perform the following steps:

- Make sure the paper contains the word "act".

- Check that the date and place of registration, which are indicated at the top of the form, correspond to the actual data.

- Carefully study the full name. and the address of the subscriber in the appropriate columns and make sure that they are entered correctly.

- Compare information about the device and its readings, entered in the tabular part of the document, with the actual ones.

- Check the spelling of the name of the Criminal Code at the end of the form.

- Make sure that the paper contains the signature of the person who compiled it, as well as the seal of the Criminal Code.

- Check whether it is written in the form that the device is sealed and put into operation.

- Check that the seal number matches the number indicated on the paper.

- Check the physical integrity of the seal itself.

The last two points are especially important. If the seal is damaged, the subscriber will be liable for this (even if the damage was not due to his fault).

Only when all of the above is done, you can put your signature on the document. There are no uniform all-Russian rules for sealing. They are installed by the management company. Therefore, the procedure for residents may differ from the above.

For HOA

If the house is managed by the HOA, then the responsibility for installing metering equipment, sealing it and compiling documentation lies with it.

To properly format paper, you must:

To properly format paper, you must:

- develop your own form or download a ready-made sample on the Internet;

- conduct a detailed briefing with the employees responsible for registration;

- make sure that all forms used in the work are certified by the seal of the organization.

The HOA employee fills out the document as follows:

- Indicates the number, as well as the date and place of its execution at the top of the form.

- Prescribes full name. and subscriber's address.

- In the tabular part of the form, it indicates information about the meter (factory number, installation location, indications at the time of installation, seal number).

- Indicates the name of the HOA, its position, surname and initials.

- Puts a signature on the act.

Also, in order to avoid conflict situations with residents and complaints from them, it is necessary that HOA employees:

- put on paper reliable information that is fully true;

- be sure to familiarize the subscriber with the result of registration, take into account his comments and, if necessary, make corrections;

- without fail handed over to the tenant a copy of the filled-in document.

So that the HOA employees do not forget the procedure for registration and the list of information necessary for entering, each employee responsible for compiling the documentation needs to be given a sample of the completed paper, with which he can compare his actions in the "field" conditions.