- How to cut an external thread. Cutting threads on pipes and fittings. Die. Klupp

- Threading with round dies (lerks).

- Klupp for threading.

- Thread cutting technology.

- Cooling and lubrication for threading.

- Screw boards.

- Cutting threads on pipes and fittings.

- Klupp for cutting threads on pipes.

- We make a carving with our own hands

- Training

- Cutting the outer thread with a screw

- Thread cutting die

- Cutting the internal thread

- Method 2. Manual threading

- Thread assignment and tools used

- Preparatory stage

- Thread cutting with a die

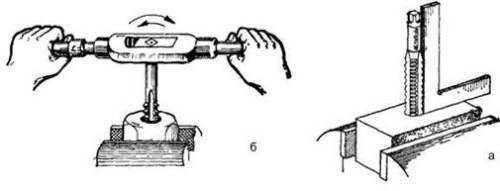

- Working with a klupp

- Circumstances for the appearance of defective threads

- I cut the threads on the pipe with a lerka, or a screw clamp.

- What is klupp?

- We make a carving with our own hands

- Training

- Cutting the outer thread with a screw

- Thread cutting die

- Cutting the internal thread

- Thread tool overview

- Industrial equipment and threading machines

- Manual Methods

- Tools used for threading

- Thread cutting by hand

How to cut an external thread. Cutting threads on pipes and fittings. Die. Klupp

How to cut an external thread. Cutting threads on pipes and fittings. Die. Klupp. 4.46/5 (89.23%) lost 13

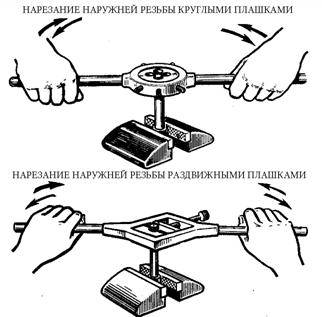

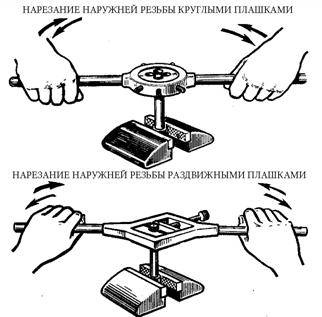

An external thread is cut using round or sliding dies, as well as screw boards.Thread cutting can be done both on machines and manually.

Threading with round dies (lerks).

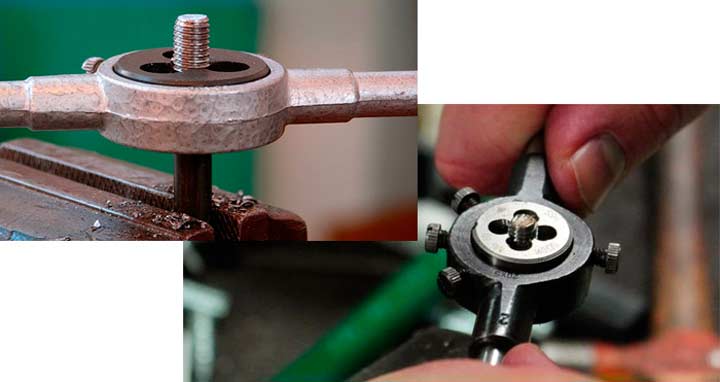

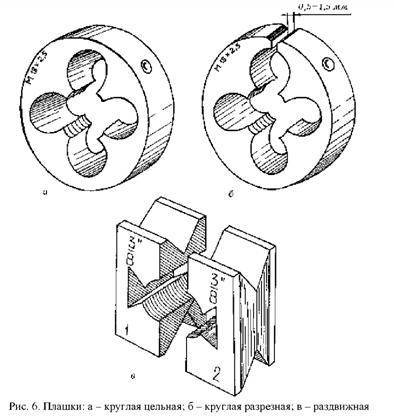

Round dies (lehrs) are a disk with a cut hole. To remove chips and form feathers with cutting edges (Fig. 1), several chip holes are made in the die. The dies (lehrs) are inserted into the lerko holder and clamped with screws (Fig. 2).

Rice. 1. Die round cut (lerka).

Rice. 2. Lerko holder:

1 - frame; 2 - handle; 3 - clamping screw.

The diameter of the cut rod is taken slightly less than the outer diameter of the thread and sawed down cone-shaped for the lehr to enter. The choice of rods for cutting metric or inch threads is given in Table. one:

Table 1. Shaft diameters for threaded bolts.

| Metric thread | Inch thread | ||

| Outer diameter in mm | Stem diameter in mm | Outside diameter in inches | Stem diameter in mm |

| 5 | 4,89 | 1/4 | 6,19 |

| 6 | 5,86 | 5/6 | 7,7 |

| 8 | 7,83 | 3/8 | 9,3 |

| 10 | 9,8 | 7/16 | 10,8 |

| 12 | 11,7 | 1/2 | 12,4 |

| 14 | 13,7 | 5/8 | 15,6 |

| 16 | 15,7 | 3/4 | 18,7 |

| 20 | 19,6 | 7/8 | 21,8 |

| 22 | 21,6 | 1 | 25 |

| 24 | 23,6 | 1 1/4 | 31,3 |

| 27 | 26,6 | 1 1/2 | 37,6 |

| 30 | 29,5 | 1 3/4 | 43,8 |

| 36 | 35,4 | 2 | 50 |

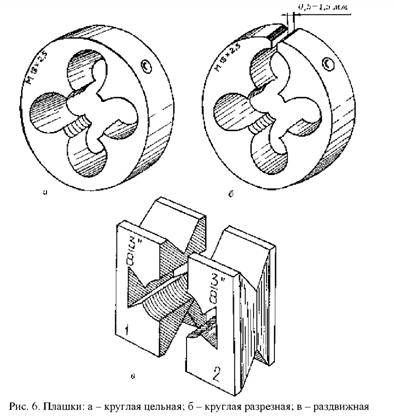

Sliding dies (Fig. 3, a) consist of two prismatic halves with a cut hole. A groove is made in the middle part of the die hole, which forms the cutting edges.

Rice. 3. Sliding dies and crackers:

a - plate; b - cracker.

Klupp for threading.

For fastening the dies, a screw clamp with a rectangular or oblique frame is used (Fig. 4). The prismatic protrusions of the klupp enter the grooves of the dies, and from the side the dies are pressed with bolts.

Rice. 4. Klupp (oblique)

1 - frame; 2 - handle; 3 - clamping screw.

To avoid direct pressure of the bolt on the dies, a so-called cracker is installed between the dies and the bolt (see Fig. 3, b), which has the shape of a dies.

Thread cutting technology.

Cutting with prismatic dies is somewhat different from cutting with lerks.When cutting with dies, the rods are not sawn into a cone, but the dies are moved apart.

Then they are clamped on the rod, the end of which must coincide with the upper plane of the dies. By turning the die to the right and slightly to the left, threading is performed.

The position of the lerkoderzhatel and klupp is set strictly perpendicular to the cut rod, otherwise the thread will be oblique and one-sided.

Cooling and lubrication for threading.

At tapping and dies must be lubricated. As a lubricant, you can use a regular emulsion, dissolving one part of the emulsion in one hundred and sixty parts of water. In addition, you can apply: for cast iron - lard and kerosene; for steel and brass - boiled and rapeseed oil and lard; for red copper - lard and turpentine; for aluminum - kerosene.

It is not recommended to use machine and mineral oils when cutting threads, since they, by increasing cutting resistance, do not give clean holes and lead to rapid wear of taps and dies.

Screw boards.

In order to cut threads on screws with diameters up to 6 mm, screw boards are used. On the screw boards there are several cut holes of different diameters with chip grooves, two for each hole.

Threading with dies is performed in the same way as tapping. The rod is firmly clamped in a vise, lubricated with oil, and then a die with dies is put on the rod, clamped with a screw and rotated a full turn in one direction and half a turn in the other. If the rod is thicker than required, it must be filed.

The thread of the bolts is measured with annular thread gauges or a thread gauge.

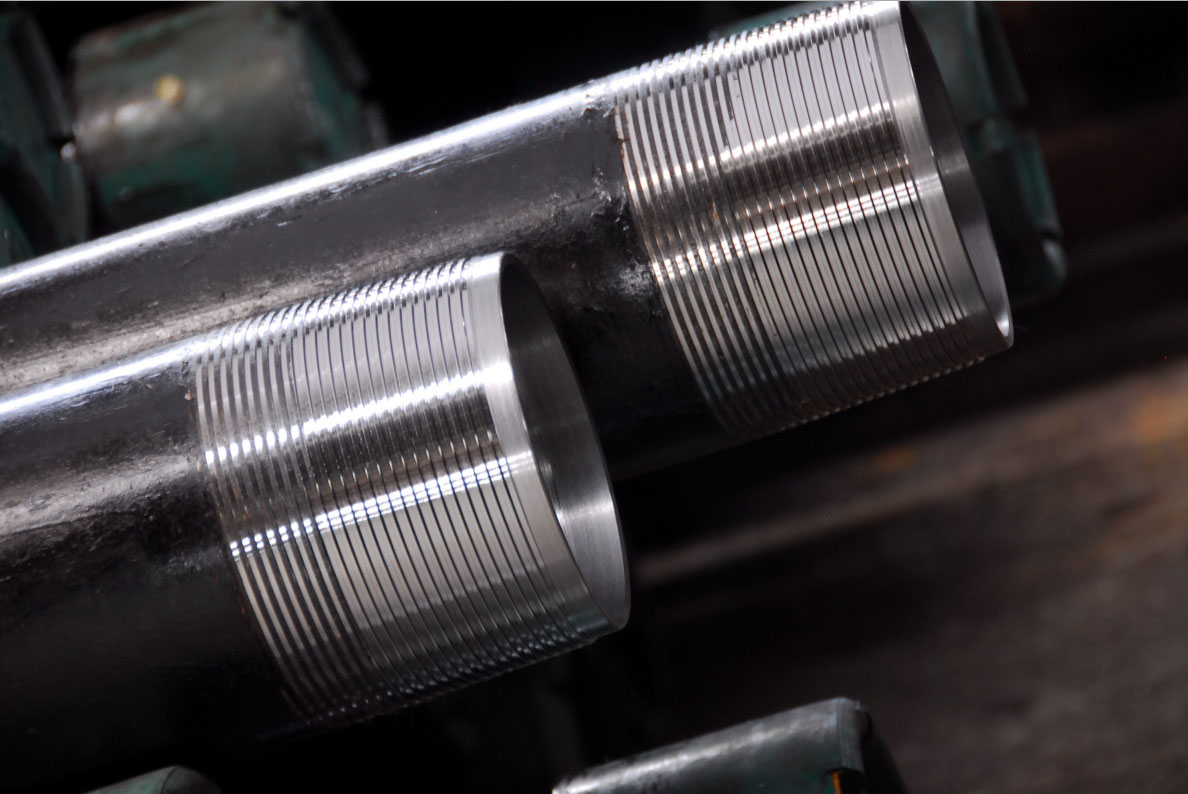

Cutting threads on pipes and fittings.

Pipes and fittings (connecting parts for pipes) are cut with a special tool using fixtures.

Klupp for cutting threads on pipes.

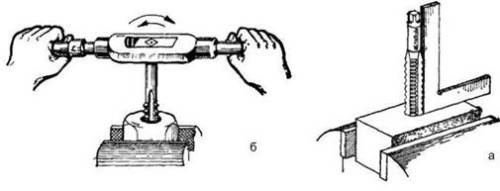

On pipes, the thread is cut with a special screw thread (Fig. 5). The die cutter for cutting pipes according to the device differs from ordinary die cutters. Four steel combs enter the slots of its holder.

By turning the top handle, they can be brought together or moved apart. Therefore, pipes of various diameters can be cut with one die. In addition, the klupp has guides that are regulated by the lower handle.

The guides ensure the correct position of the die on the pipe when cutting.

Rice. 5. Klupp for cutting pipes.

Pipes during cutting are fixed with a special pipe clamp. The clamp consists of a frame in which crackers with cutouts for pipes of various diameters are placed.

We make a carving with our own hands

Training

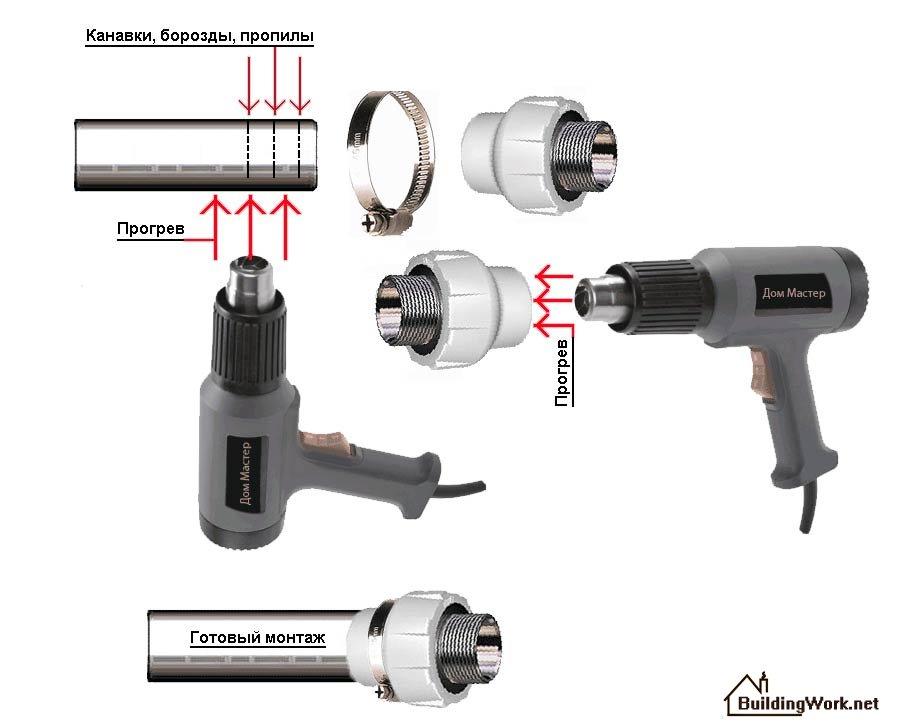

Before you cut the thread on the pipe with your own hands, you need to carry out a number of preparatory work:

- cut a piece of pipe to the desired size. If any section of the pipeline is being replaced, then it is required to carefully cut out the pipe that has become unusable;

The cut of the pipe must be perpendicular to its walls. Otherwise, the threaded connection will not be reliable.

- the section of the pipe where the thread will be cut is cleaned of paint, rust, and so on. All extraneous deposits interfere with the work;

- a chamfer is removed from the end of the pipe to facilitate the work of the die.

The initial stage of threading

Cutting the outer thread with a screw

Threading a pipe with a screw thread is carried out as follows:

- a screw plug of the appropriate diameter is selected. For the correct selection of equipment, a caliper is used;

- the inner surface of the die and the prepared section of the pipe are treated with machine oil;

- the screw plug is inserted into a metal tube, which facilitates the work of rotating it. The holder is included in the pipe threading kit;

- if the initial assembly of the pipeline takes place, then the pipe is fixed in a vice. If you need to cut a thread on a water pipe during the reconstruction of a water pipe or other engineering system, you can cut it directly on the installed pipe;

- Klupp is installed on the prepared pipe and its rotation begins, that is, the process of threading.

After making several turns around the pipe, it is necessary to take the screw plug in the opposite direction by approximately 90º. This will remove the chip being removed from the future thread.

Making a thread with a screw thread

After cutting is complete, the oil must be completely removed.

You can clearly see the process of threading with a screw thread in the video.

Thread cutting die

A die for threading pipes can be:

- round shape. For threading pipes of various diameters, different-sized dies are used;

- sliding. The use of such a die helps in threading pipes of various diameters. A special holder is used for the sliding plate.

Various threading dies

Dies for cutting threads on pipes are used more often, as they have a lower cost.

Before cutting a thread on a pipe with a die (lerka), you need to prepare the pipe in the manner described above. Then you can carry out the procedure itself according to the following scheme:

- using a caliper, select the die of the required diameter;

- lubricate the inside of the lerka and the surface of the pipe with any available material;

- fix the plate in a special holder. Pipe tapping pliers must be firmly fixed in the holder. Otherwise, the thread will turn out to be uneven, which will lead to the formation of a leak at the junction;

- the die holder rotates in the desired direction. After several turns, it is necessary, as in the previous case, to get rid of the accumulated chips. To do this, the tool is rotated slightly in the opposite direction;

- after threading, the pipe and the tool used are cleaned of grease.

At the initial stage, roughing dies are used, which clearly cut through the pipe, but do not give great thread accuracy. The final cut is made with a finishing die.

Threading with lerok

Cutting the internal thread

To make an internal thread, you need:

- prepare the hole. It must be clean and free of any coatings or foreign deposits. The hole is lubricated;

- select a tap by diameter;

- install the tap in the hole, while maintaining the verticality of the cutting equipment. Start turning the tap clockwise.

Procedure for threading inside a pipe

To apply an internal thread, two taps are required: roughing and finishing. The rough tap removes about 70% of the chips, while the finishing tap removes the remaining 30%.

You can make a thread on a metal pipe with your own hands. This will require the purchase of a special tool and a small amount of time. Carrying out work is available not only for professionals, but also for ordinary users.

Method 2. Manual threading

Thread assignment and tools used

Before proceeding specifically to the process of work, you should decide what, by and large, you need a thread for.

The fact is that only by means of the connection type are joined:

- plastic parts with iron;

- shut-off valves and other similar details;

- plumbing fixtures.

Currently used for cutting:

- special die (lerka);

- klupp (or as it is also called the club for cutting pipe threads).

By means of these tools it is possible to carry out joining of products of any diameter and purpose.

Preparatory stage

Having acquired the tool of your choice for cutting threads on pipes, we proceed to the execution of the work.

First, go to properly prepare the workpiece:

- the pipe is cleaned of traces of corrosion, remnants of the existing coating, dust and dirt until a characteristic iron sheen appears;

- a chamfer is removed from the end of the workpiece with a file;

- the cutting point is perfectly lubricated to facilitate the work of the cutting tool.

If you are using a die, it is recommended that you practice on a piece of dilapidated pipeline before starting work. An incorrectly made threaded connection will not allow you to properly connect the necessary parts.

In addition, it is not recommended to save money when buying a tool. Poor quality dies or pipe clamps can damage the entire pipeline.

Thread cutting with a die

When you use dies to make the connection, the work order will be as follows:

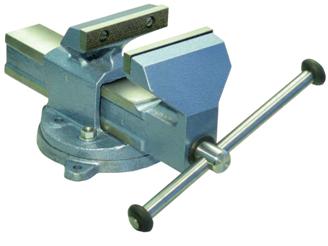

- The pipe is clamped in a vice or otherwise suitable. It is necessary that during the work the workpiece is completely motionless and securely fixed.

- A die of the required diameter is installed in a special holder and fixed there by means of the appropriate screws.

- Lubrication is applied to the die and tube to make work easier and protect the tools from damage.

- After that, carefully place the tool on the end of the workpiece and, turning it clockwise, cut the first turn.

- Do not forget that the die must be placed strictly perpendicular to the workpiece.

- Having made the connection of the desired length, unscrew the tool and walk it through the connection again.

Working with a klupp

This device allows you to easily cut threads, moreover, to inexperienced craftsmen. It is the same die, but additionally equipped with a guide ratchet and a device. Much more often sold in a set with lerks of different sizes.

The work is as follows:

- Klupp of the desired size is installed in the ratchet and fixed.

- A lubricant is applied to the tool and the end of the pipe.

- The guide is put on the end of the pipe. This ensures that the cutting tool will be placed strictly perpendicular.

- To cut, rotate the ratchet.

- In the course of work, it is necessary to additionally lubricate the required section of the workpiece.

Circumstances for the appearance of defective threads

If the above requirements are not met, the thread may turn out to be defective, which will not allow proper and hermetic connection of shut-off valves or fittings for sewer pipes.

Much more often the circumstances of marriage are:

- incorrectly selected tools - dies and pipe diameter, connection stroke or its appearance do not match;

- low-quality dies or dies - if the cutting edge is damaged or blunt, it will not be possible to make a quality connection;

- insufficient amount of lubricant;

- the use of dies without relevant work experience.

I cut the threads on the pipe with a lerka, or a screw clamp.

For cutting threads on a pipe with a diameter of 15 (it is also 1/2″, it is also half an inch), I usually use a lerk in the holder, which I put on the prepared cut of the pipe, on the side that has edges, due to its length it acts as a guide, which is important for a uniform hook with a lerkoy. I lightly press down on the end with my hand and rotate it beyond the edges with an adjustable wrench, clockwise. It is not always possible to use the guide side, this happens due to the fact that the cut of the pipe for some reason was made very close to the tie-in into the riser, then you make the entry from the side of the lerka

In this case, you need to be more careful, keep the handle perpendicular to the axis of the pipe, otherwise the thread may go crooked and the fourth turn will push the pipe through. Actually, if the chamfer was removed evenly over the entire diameter, then the entry will go smoothly, respectively, and the entire thread

It is not always possible to use the guide side, this is due to the fact that for some reason the cut of the pipe was made very close to the tie-in into the riser, then you make the entry from the side of the lerka. In this case, you need to be more careful, keep the handle perpendicular to the axis of the pipe, otherwise the thread may go crooked and the fourth turn will push the pipe through. Actually, if the chamfer was removed evenly over the entire diameter, then the entry will go smoothly, respectively, and the entire thread.

You can also cut threads with a screw clamp, but usually a pipe of this diameter is used for wiring, and it is not possible to use a wrench due to its massiveness.

Everything for pipe threading.

On a pipe with a diameter of 20 (it’s 3/4″, it’s also three quarters of an inch), I cut the thread with a screw clamp, although just in case I also have a three-quarter lehr in the lerko holder. For the same reasons as in the paragraph above.

And pipes with a diameter of 25 (it's 1 ″, it's an inch) and a diameter of 32 (it's 1 1/4 ″, it's an inch and a quarter), I cut it only with screw caps with a ratchet. This is due solely to the complexity of this work. Using klupps, the process is much simplified, facilitated and accelerated.

In the photo, in addition to the lerka and klupps with a crank, I imagined that I use for the tightness of the threaded connection, namely, universal, sanitary sealant and sanitary flax. After I cut the thread, I apply sealant on it, trying to distribute it evenly over all the turns, and after that I wind flax, I tell (and show) this in detail in another article, I will leave the link below.

Connections are not only threaded.

In my profession, I have to combine polypropylene with cast iron when installing sewers.

Basically, this connection is carried out by means of a transitional rubber cuff, which, when smeared with sealant, is inserted into the socket of a cast-iron pipe or fitting, and already into it you insert a fitting or polypropylene pipe smeared with sealant. Due to this, the connection is hermetically sealed.

The photo shows a cable, different in thickness, it is also used in the installation of sewers, by tamping into the gap between the materials described above. The use of a cable is convenient in that it can be dissolved and a strand of the required thickness can be selected. Its use is relevant in the case when the adapter cuff does not fit in size, such cases are not frequent, but still occur.

Video: klupp - a tool for threading a pipe:

Perhaps these articles will be useful to you: How to thread a pipe. 10 important nuances How to rewind the thread hermetically (video) How easy it is to cut with a grinder

If you have any questions or additions, write in the comments box. That's all for today, success in your work, regards Andrey.

Tired of looking for information from practitioners? Subscribe (scroll down the page) and the information will find you by itself. A click on the social network icon is the best reward for my work.

Share with friends online:

What is klupp?

A pipe die can be compared with dies. They are a one-piece tooling that allows you to cut precise grooves on the metal of the desired shape. However, the solidity of the structure creates serious stress when processing elements of large diameter pipelines. You can relieve stress by making the die body less durable. But this will reduce the hardness of the incisors, from which they will quickly become dull. To extend the life of the lerka before sharpening, the equipment is equipped with a spring mechanism.

Klupp is not much different from the dies familiar to plumbers. It consists of a cylindrical body made of metal with holes for chip removal. Along the perimeter of the metal ring there are separate clamps to securely hold the equipment on the pipe.On the inside, incisors are fixed, arranged in a certain order.

We make a carving with our own hands

Training

Before you cut the thread on the pipe with your own hands, you need to carry out a number of preparatory work:

- cut a piece of pipe to the desired size. If any section of the pipeline is being replaced, then it is required to carefully cut out the pipe that has become unusable;

The cut of the pipe must be perpendicular to its walls. Otherwise, the threaded connection will not be reliable.

- the section of the pipe where the thread will be cut is cleaned of paint, rust, and so on. All extraneous deposits interfere with the work;

- a chamfer is removed from the end of the pipe to facilitate the work of the die.

The initial stage of threading

Cutting the outer thread with a screw

Threading a pipe with a screw thread is carried out as follows:

- a screw plug of the appropriate diameter is selected. For the correct selection of equipment, a caliper is used;

- the inner surface of the die and the prepared section of the pipe are treated with machine oil;

- the screw plug is inserted into a metal tube, which facilitates the work of rotating it. The holder is included in the pipe threading kit;

- if the initial assembly of the pipeline takes place, then the pipe is fixed in a vice. If you need to cut a thread on a water pipe during the reconstruction of a water pipe or other engineering system, you can cut it directly on the installed pipe;

- Klupp is installed on the prepared pipe and its rotation begins, that is, the process of threading.

After making several turns around the pipe, it is necessary to take the screw plug in the opposite direction by approximately 90º. This will remove the chip being removed from the future thread.

Making a thread with a screw thread

After cutting is complete, the oil must be completely removed.

You can clearly see the process of threading with a screw thread in the video.

Thread cutting die

A die for threading pipes can be:

- round shape. For threading pipes of various diameters, different-sized dies are used;

- sliding. The use of such a die helps in threading pipes of various diameters. A special holder is used for the sliding plate.

Various threading dies

Dies for cutting threads on pipes are used more often, as they have a lower cost.

Before cutting a thread on a pipe with a die (lerka), you need to prepare the pipe in the manner described above. Then you can carry out the procedure itself according to the following scheme:

- using a caliper, select the die of the required diameter;

- lubricate the inside of the lerka and the surface of the pipe with any available material;

- fix the plate in a special holder. Pipe tapping pliers must be firmly fixed in the holder. Otherwise, the thread will turn out to be uneven, which will lead to the formation of a leak at the junction;

- the die holder rotates in the desired direction. After several turns, it is necessary, as in the previous case, to get rid of the accumulated chips. To do this, the tool is rotated slightly in the opposite direction;

- after threading, the pipe and the tool used are cleaned of grease.

At the initial stage, roughing dies are used, which clearly cut through the pipe, but do not give great thread accuracy. The final cut is made with a finishing die.

Threading with lerok

Cutting the internal thread

To make an internal thread, you need:

- prepare the hole. It must be clean and free of any coatings or foreign deposits. The hole is lubricated;

- select a tap by diameter;

- install the tap in the hole, while maintaining the verticality of the cutting equipment. Start turning the tap clockwise.

Procedure for threading inside a pipe

To apply an internal thread, two taps are required: roughing and finishing. The rough tap removes about 70% of the chips, while the finishing tap removes the remaining 30%.

You can make a thread on a metal pipe with your own hands. This will require the purchase of a special tool and a small amount of time. Carrying out work is available not only for professionals, but also for ordinary users.

Thread tool overview

Threading on pipes is possible both at home and in the factory. Required Techniques:

- threaded combs or a plate with a number of fixed cutters;

- dies, heads, taps and tools based on them;

- flat and round dies with holders;

- easel industrial milling;

- grinding with abrasive factory tools.

Combs for threading

Combs for threading

Industrial equipment and threading machines

The main method of industrial production of threaded pipes is knurling with a three-roller head. This tool for threading pipes gives an ideal groove surface, since the roughening chips are not removed during the processing of the end of the pipe. The end of the pipe, tightly clamped in a vice, is rolled between the corrugated heads in a cold or heated state, and they leave an imprint on the metal surface.This thread provides an ideal combination of interconnected nodes: the role of the seal in such connections is minimal. A manual threading tool for pipes of this quality cannot provide.

thread cutter

thread cutter

Less common, but used in private workshops and enterprises, are milling, in which thread grooves are created with a special comb clamped in the vise of the machine, and grinding. With the latter, the mutually rotating pipe and grinding wheel form smooth spiral grooves. As in the case of thread rolling, the accuracy and uniformity of the pitch, which is one of the most important criteria for the quality of work, can only be ensured by a professionally calibrated mechanism.

Manual Methods

The most popular way to create a thread is based on round dies made of high-strength steel with cutters along the inner edge. In order to reduce the effort of the master and more precisely control the process of work, the cutting block is inserted into the holder or die. This device both simplifies the process and reduces the cost of purchasing a tool: the master kit includes one, less often two, die holders into which the necessary cutters are inserted.

Threading pipes with a die cutter gives greater accuracy than the comb method: the angle of the helical grooves is easier to control. Even when applying a long thread, you do not have to take steps, that is, the risk of knocking down uniformity is minimal.

Set with screw plugs of different diameters

Chip outlets are provided on the die or lerk: this makes it possible to apply threads to a copper or steel pipe in one pass.Masters with experience are advised not to succumb to such a temptation and have a die of a similar diameter in stock for rough work. So the main tool will dull much more slowly.

Hand tools for cutting threads on pipes are not designed for industrial volumes of work.

Tools used for threading

Before starting work, it is necessary to prepare a tool for cutting threads on pipes, which includes the following devices:

- tape measure, pencil and caliper. The assembly of the pipeline takes place according to a previously prepared scheme. At the first stage, it is necessary to prepare pipes of a certain length indicated in the diagram. For marking, a tape measure and a pencil are used. The caliper is used to measure the diameter of pipes and select the right tool;

Tape measure and caliper for measuring pipes

It is necessary to mark the pipes very carefully and accurately. Any error in measurement may result in the assembly of an incorrect design, resulting in the need to remanufacture the pipeline.

- Bulgarian. The tool is used for cutting pipes according to previously applied markings. Instead of a grinder, you can use a hacksaw;

Tool for cutting metal pipes

- vise. Threading on pipes must be done clearly horizontally. To do this, the pipe section must be securely fixed;

Device for fixing the pipe in a certain position

- engine oil and any other lubricant. Threading pipes by hand will be much easier if the tool and the end of the pipe are lubricated with special means;

- goggles for eye protection. Any work must be carried out in compliance with all safety rules.When cutting threads, metal chips can get into the eyes and cause severe damage to them, so protection in the form of glasses is necessary;

- tool for cutting threads on pipes. It can be one of three options:

Set of die cutters for cutting threads of various sizes

Die set and die holder

Tools for cutting internal threads

The choice of tool should be based on the type of thread and the priority of the craftsman. For applying external threads, dies are used that are installed in a screw die or die holder. To apply an internal thread, taps are used.

Thread cutting by hand

All work is done with a die or lerka. These are identical concepts and are synonyms. Depending on the design, they can be:

- Adjustable or sliding. Usually they have several incisors, the distance between which can be changed. They are especially useful in cases where the pipe profile is uneven due to deformation or manufacturing defects, but you still need to cut the thread. Most often they are installed in klupps, which provide them with a good fixation. With the help of such products, threads can be cut in several passes, which increases its accuracy and quality.

- Monolithic. They are a small cylinder with a hole in the middle. Such a tool is clamped in a special die holder. Usually fixed with one or more bolts. With this tool, cutting is made in one pass.

- Cone. Designed for cutting the corresponding threads mentioned above.

The end is aligned

The lerka is selected depending on the diameter of the pipe being processed, as well as on what the direction of the thread should be - right or left. All designations are applied to the packaging or directly to the instrument itself. The whole process will boil down to the following steps:

The workpiece is fixed. If it is not fixed in any system, then it is clamped in a vise. In the case when cutting will be done on a water pipe or a heating pipe, it is necessary to make linings to immobilize it.

The end of the prepared pipe section is lubricated with machine oil or grease. If these components are not available, then you can use what is at hand - even lard.

The surface of the tool cutters is also subjected to lubrication.

A die holder with a handle is brought to the end of the pipe. This must be done exactly at a right angle. It is much easier to do this with a guide plate holder.

At the same time, it is necessary to rotate the threading tool and press it against the nozzle. Clutch must take place

Thus, it is important to cut the first 2 turns.

If you do not use a guide die holder, you will need to constantly ensure that the angle remains 90°. If you do not comply with this requirement, then there may be a distortion

This threatens that the thread will be broken, the tool will be damaged, or the required step will not be observed.

Do not cut continuously. In the process, metal chips will form. In order to remove it, it is necessary to make one turn in the direction of travel and half a turn back. It is through this that the accumulated waste will be removed.

Along the way, you also need to add lubrication.

After completion, it is necessary to unscrew the lehr and walk it again to make a finishing eyeliner.

Thread cutting dies

Klupp set

Threading with a die cutter follows the same mechanism. In addition to everything, in some products it is possible not only to shift the incisors, but also to deploy them. In this situation, it is possible to perform both a finishing and a roughing pass with the same tool. When using such a unit, you must be very careful during the initial stage. This is due to the fact that thanks to the ratchet handle, more force can be applied than in the case of a conventional lerk holder. If at the very beginning you do not set the angle correctly, then you can ruin the entire workpiece and not notice it. Klupp is inconvenient to use in cases where the pipe is already installed and is close to the wall. It will either need to be bent with a wedge or a part of the plaster should be hollowed out so that the nozzle fits well and does not move.