- Classification of electric corded screwdrivers by operational area

- How to work with a screwdriver instruction

- Comparison

- According to specifications

- By type of work and purpose

- Varieties of screwdrivers

- Cordless screwdriver

- Screwdriver with impact and non-impact drill function

- Screwdrivers, wrenches

- No. 2. Household and professional drills

- How to choose?

- Threading

- Battery Select + (Video)

- Can a drill be used as a screwdriver?

- How to tighten screws and self-tapping screws with a drill

- Definition

- Drill

- screwdriver

- Number 3. Types of drills by purpose

- conventional drill

- Impact drill

- Drill driver

- Drill mixer

- Angle drill

- Corded screwdriver Shturm ID2145P: the best value for money

- Unconventional use cases

Classification of electric corded screwdrivers by operational area

- household;

- professional.

Household appliances are bought for private use at home. Such models, as a rule, differ in democratic cost and are quite simple. There are practically no additional functions in this case, since the products must perform simple work with large time intervals between them.

Hand-held electric drills-screwdrivers of a household type are characterized by a small engine power.Experts categorically do not recommend subjecting such a device to prolonged use. Despite all the disadvantages of the device, its cost is fully consistent with the functionality. If you follow the operating rules, then such a device will last quite a long time.

Drill drivers are classified into professional and household

Professional models are used by craftsmen in various areas of the construction industry. With the help of them, work is performed that requires high power. Such devices are resistant to overheating. Another advantage of such models is their long service life, however, professional screwdrivers need special care.

In order to select the model suitable for use in a particular application, it is recommended to study the characteristics of individual drill/drivers. Reviews left on specialized forums also contribute to the acquisition of a reliable device.

There are also special compact devices that have minimal power. It is enough to perform simple operations. They can be used in both domestic and professional construction industry.

How to work with a screwdriver instruction

Before you work with a screwdriver, you need to study the instructions and its purpose. Devices differ in power, which indicates their abilities. The instructions indicate the operational capabilities of the unit. Cordless screwdrivers are more powerful, so they can be used for a variety of jobs, and even for drilling concrete.

If you bought a screwdriver, then you must first learn how to use it.This will allow not only to perform high-quality work with a screwdriver, but also to eliminate the likelihood of its quick failure. So, consider the features of using a screwdriver, which will allow you to learn how to work with it correctly.

- For drilling bricks and concrete - it is impossible to drill concrete or bricks with a conventional screwdriver. To do this, the design of the tool must have a built-in option for drilling with impact, and if there is none, then the device is simply useless. It is not difficult to fix a drill with a win in the cartridge, but when exposed to concrete or brick, it will simply fidget, since there is no shock option. For such purposes, impact drills or rotary hammers are used.

- For drilling wood - to drill a hole in a tree with a screwdriver, you must use special drills with a spike at the end. The maximum drilling diameter with a wood screwdriver is 20 mm. It all depends on the power of the device. When drilling, it is necessary to hold the drill strictly at an angle of 90 degrees with respect to the surface to be drilled.

- For drilling metal - special drills are also used for this. The quality of drilling depends on the sharpening of the edge. You can drill metal with a screwdriver up to 10 mm. When performing work, you must consider how to use a screwdriver. First, you need to make a recess with the help of a core, along which the drill will be guided. To prevent overheating of the cutting edge of the drill, it is necessary to lubricate the nozzle with a special compound or water during operation. In this case, it must be borne in mind that water must be supplied during the drilling process, and not after. If you lower a hot drill into water, then its strength properties will be lost, and it will quickly become dull.It is also necessary to hold the drill strictly at an angle of 90 degrees with respect to the surface to be treated in order to avoid jamming of the nozzle or its breakage.

- Screwing self-tapping screws - for this, a bit or an adapter for bits is attached to the cartridge. Fasteners should be twisted and unscrewed at the first speed, which will prevent breakage of not only the tool, but also the bit. It is imperative to select the correct bits, depending on the type of fastener head design. The edges of the bits must fit tightly into the grooves of the fasteners, otherwise they will slide in the process and erase the edges of the fasteners.

If a puncher and a drill are purely male tools, then even a woman can work with a screwdriver, for example, when you need to tighten a screw or screw on a shelf. Before using the tool, check that the battery is charged. Then you need to fix the working nozzle in the cartridge, and get to work. A detailed description of how to operate a screwdriver correctly is described in the video material.

Comparison

To find the differences between the instruments, a comparative analysis should be carried out. You can evaluate the characteristics of devices and the types of work that can be performed using them. Only after that the master will be able to determine which tool will be best for him.

According to specifications

Each device has individual features. More expensive models have high power, and budget options are often not able to drill holes of sufficient depth. But the tools also have common characteristics that are inherent in most popular models.

- Screwdriver.Models for private use most often have a torque of 16 Nm and a rotation speed of 600 rpm. Professional tools boast 130 Nm and 1300 rpm. Batteries come in several types. Nickel-cadmium can be charged and discharged completely up to a thousand times. Li-Ion does not have a memory factor, so it can be easily recharged at any time. There is also a nickel-metal hybrid battery. Its capacity is enough for 500 full charges, but it will not work to use the tool at low temperatures. Also, a screwdriver can have two types of chuck: key (or cam) and quick-clamping, with one or two clutches.

- Drill. Classic tools have a power of 0.6 kW, as well as the ability to control the speed. The device has a clamping chuck, as well as a wheel for setting the number of revolutions and a mode switch. Also often there is an electronic control and a holder for nozzles. To protect the mechanism from breakage and unscrewing the screws, there is a reverse. Its location allows you to use the function with the finger of the working hand.

This information indicates that the speed of the drill is much higher than that of a screwdriver. Therefore, it can be used to quickly complete large volumes of work.

By type of work and purpose

With the help of a drill and a screwdriver, tasks of a different plan are performed. Their differences are as follows:

- Screwdriver is designed for installation or dismantling of bolts, self-tapping screws, nuts and other hardware with thread. The main distinguishing feature of the tool is the ability to adjust the torque. This helps to deepen the screws to the correct position in the work surface.The head of the screw will not go inside the wall, but will remain flush with it. In addition, some modern models provide the function of grinding and drilling holes using additional equipment. Of course, performing side tasks with a screwdriver will be less effective than with specialized equipment.

- The drill was invented for making holes in various surfaces (wood, metal, plastic, concrete). It differs from a screwdriver in that the main indicator of performance is the speed of rotation. This tool is also capable of performing additional functions: grinding, cutting metal or wood parts. It can be used as a drill, but this should be done carefully. There is no twisting depth limiter in the design of the device, so it is easy to rip off the slots or push the hardware too deep into the surface.

A drill and a screwdriver have external similarities, but their design and functionality are different. If the main task that a person plans to perform after acquiring a tool is to tighten self-tapping screws, then you just need to choose a screwdriver. If he needs a tool as a device for drilling holes, then it would be better to opt for a drill.

Varieties of screwdrivers

Cordless screwdriver

Usually equipped with a built-in non-replaceable 3.6 V battery and a socket for bits with a hex shank. The main advantage of the tool is its compactness and light weight (200-300 g), and the disadvantage is the lack of rotation speed adjustment.

Screwdriver with impact and non-impact drill function

The drill has a higher spindle speed. Therefore, such screwdrivers are equipped with a rotation speed switching mechanism (two speeds). Impact drills-screwdrivers come with an axial impact (for drilling stone) and with a tangential impact (for the development of large efforts).

Bosch

Compact impact drill driver EasyImpact 12 (Bosch).

Bosch

Cordless drill driver of the UniversalDrill 18 series (Bosch).

Bosch

Cordless drill driver of the UniversalDrill 18 series (Bosch).

AEG

Angled replaceable nozzle for the BBS12C2 (AEG) drill/driver.

AEG

Cam replaceable nozzle for BBS12C2 (AEG) drill/driver.

Screwdrivers, wrenches

This is usually a professional technique. They are used with interchangeable bolt and nut sockets and feature the highest maximum torque.

GeenWorks

Powerful impact screwdriver, model 24V GD24ID (GreenWorks), 24 V, 327 Nm.

GeenWorks

Powerful impact screwdriver, model R18IDBL (Ryobi) with brushless motor, 18 V, 270 Nm.

No. 2. Household and professional drills

Like many other power tools, drills are divided into two fundamental types:

- household, for home use;

- professional.

Sometimes there is also a transitional type - semi-professional drills. The principle of operation for household, professional and semi-professional devices is the same - the difference is in power, weight, price, feature set and some other features.

A household drill for the vast majority of simple home repairs will be preferred. Its advantages, in addition to a lower price compared to a professional tool, include:

lightweight design, so it is easier to work with the tool;

versatility. Household drills are often equipped with additional functions, such as a screwdriver and a mixer, and there are a lot of accessories in the case with them.

Professional drills are focused on performing a specific task, therefore they are inferior in terms of versatility;

good protection and thoughtful design makes working with a household drill more convenient and safe, which is very important for an inexperienced user;

The warranty for household drills is usually higher than for professional tools.

On the other hand, it is impossible to use a household tool for more than 4 hours a day, otherwise the drill will quickly break. The optimal time for continuous work is 15-20 minutes, after which the tool is allowed to rest and cool down for about the same time, then you can return to work again. The thing is that less powerful engines and not so strong materials are used to assemble household models. This does not mean that the drill will break quickly - it means that it is designed for small or irregular loads.

If you have to regularly work with a drill for 5 or more hours a day, then it is better to take a professional tool. It is distinguished by the presence of a powerful engine that easily withstands solid loads without overheating and without failing. A professional drill can work continuously for more than an hour and about 7-8 hours a day, you can take small breaks. Such a tool is more expensive than a household one, less versatile, heavier, but better protected from dust and moisture, and a professional cannot do without it.

Semi-professional drills are a rather limited class of devices.Transitional models can be represented by household drills with some properties from professional ones, or professional ones, but without any elements.

Which drill to choose depends on what kind of work and how often you are going to carry out. If it is needed in order to hang a shelf or a picture if necessary, then you can safely dwell on the household version. If repairs are your main or additional income, then it makes sense to consider professional drills.

How to choose?

When choosing a particular model of impact screwdriver, pay attention to the smallest details. The first thing they usually pay attention to is the type of food.

Pneumatic models are definitely not needed at home, but electric models are networked and battery-powered, as mentioned above.

The network option is good for working in an equipped room, it is most valued for its almost unlimited power. Having given preference to just such a device, evaluate its cable - it must have a considerable length and thickness, have good insulation and not raise doubts about the strength of the place where it enters the unit.

In the case of the battery model, there are more selection criteria. First of all, you need to find a balance between a large battery capacity, which extends battery life, and the weight of the device, because a capacious battery always weighs quite a lot.

Another point is the choice of battery type: lithium-ion models are the most common today, but nickel-cadmium models are also found.The first are good with a small mass with a significant capacity, they allow charging at any time, but they are more expensive than their main competitor and can wear out quickly at low temperatures. The advantages of the nickel-cadmium solution completely offset the disadvantages of the lithium-ion version - such a battery is cheaper and is not afraid of frost, but it is both heavy and environmentally hazardous, and most importantly, it must be completely discharged and then fully charged, otherwise the "memory effect" will provoke rapid wear of the carrier .

When the voltage is high, the power of the motor also increases, but for home use sky-high indicators are not needed: 500-700 W will be enough, otherwise the tool will be heavy and unreasonably expensive.

Screwdriver chucks, in which interchangeable nozzles are attached, are quick-clamping and key. The first can be organized in different ways, but its advantage is that maintenance can be done with bare hands. The key cartridge has a characteristic rim; a special key is needed for its maintenance, which is not always convenient.

Since we are talking about the cartridge, an important criterion is the maximum diameter of its opening - the larger it is, the more different nozzles you can use.

The maximum torque is an indicator of how much force the nozzle will rotate. This indicator does not always directly depend on the power of the motor, sometimes it can be increased due to the gearbox, but it is always desirable that the maximum torque be quite high. Models with smooth torque control are preferred, as they are more gentle on fasteners and surfaces that are drilled.

In any case, the ability to adjust the speed is a good bonus for working with materials of different densities, and the present option of reverse rotation allows you to save the nozzle once again and remove screws if necessary, not limited only to screwing.

Threading

If the farm has a drill, lubricant, taps and a device for fixing them, you can safely cut the thread yourself. To do this, do the following:

Prepare a tap corresponding to the diameter of the bolt (the parameter is specified in mm).

Choose the right size drill. To do this, subtract the thread pitch from the thread diameter.

Make a hole in the workpiece - through or deaf.

Rough tap (differs in a line at the base) clamp in the drill lock.

Apply lubricant to the cutting surface.

Attach the tap to the hole

It is important that the cutter is perpendicular to it.

If the thread in the hole suits, replace the rough tap with a medium one (with two stripes). Repeat the process.

Battery Select + (Video)

How to choose the right battery for a screwdriver? In order to objectively answer this question, consider the possible options.

There are three types of batteries used in cordless drills:

- Li-ion type. A popular type of battery that supports a large number of charges (up to 3000), charging is fast. They are light in weight and are considered an environmentally friendly product. Suitable for long term work. The disadvantages include poor resistance to low temperatures: in the cold, the battery is discharged almost instantly.

- Nickel-cadmium type.It can only be charged up to 2000 times, while a complete discharge is likely to lead to battery failure. A tool with such a battery is inexpensive, but works less efficiently.

- Nickel metal hydride type. The number of charges is only 1500 cycles. Its large weight also causes inconvenience in work.

So, after analyzing the types of batteries, let's say that it is better to choose the first option.

Can a drill be used as a screwdriver?

Structurally, a screwdriver is a miniature drill, so many are interested in whether it is possible to use a drill as a screwdriver. However, another node has been added to the design of the latter. This is a force adjustment mechanism that prevents over-tightening of the screw, breaking off the head or slot, and also licking off the bit. When the screw is screwed in, the tool stops turning the chuck. The drill simply does not have such a function, which, however, does not prevent using it instead of a screwdriver.

Screwdriver: a ring with numbers regulates the torque of the self-tapping screw

Sometimes a drill becomes indispensable instead of a screwdriver, especially if you need to screw long self-tapping screws into hardwood. Battery models have a low-power motor that does not always cope. But a 400-600 W drill easily screws screws of almost any length.

How to choose a screwdriver?

How to tighten screws and self-tapping screws with a drill

Before you tighten the screws with a drill, you need to take into account several features of this mode of operation of the tool and follow the recommendations mentioned below.

- Don't use cheap bits. Due to not the most optimal mode of use, cheap nozzles become unusable too prematurely.Bits for 5 UAH may not be enough even for a dozen self-tapping screws if the wood is hard.

- Adjust the rotation speed. If the start button is equipped with a wheel to adjust the speed, you need to reduce them to the minimum value. The fact is that the rotation speed of the chuck of a screwdriver is several times lower than that of a drill. If there is no wheel and the speed depends only on the pressing force, you should not immediately “push on the gases”: you need to press the start smoothly.

- Hold the tool firmly in the direction of the screw. If you tighten the screws with a drill, you need to constantly press on their hat with a bat so that it does not slip off the slot. If you loosen the pressure during the tightening process, the bit may jump off. This is not scary, but in such a situation the bit wears out, and if it jumps off the cap to the side, you can scratch or deform the part.

- Stop right. The main advantage of a screwdriver is the lack of inertia. As soon as the screw is screwed in (or the tool becomes too heavy), or the worker releases the button, the chuck will stop. The drill continues to spin by inertia even after the power supply is cut off. Therefore, to prevent the screw head from breaking off and reduce the wear of the bit, you need to monitor the immersion of the self-tapping screw. As soon as it is screwed in, you need to remove the bit from the slot of the head with a quick short movement.

Subject to the advice, the process of tightening the screws will pass without complications. With some practice, you can drive screws faster with a drill than with a specially designed tool. But the answer to the question of whether it is possible to use an impact drill as a screwdriver is somewhat more complicated. The fact is that impact drills are larger and heavier than conventional ones.When you turn off the shock mode, you can safely use the tool instead of a screwdriver, but fatigue will come much faster.

LED lamps: history, types, how to choose, how to calculate power

It is interesting: Bathroom sealant - how to choose best + like apply and remove sealant

Definition

To find the differences between a drill and a screwdriver, you need to consider them in detail. These tools have external similarities, but they also have a huge number of structural and functional differences. The principle of operation is also different. In the article we will understand what is the difference between a screwdriver and a drill.

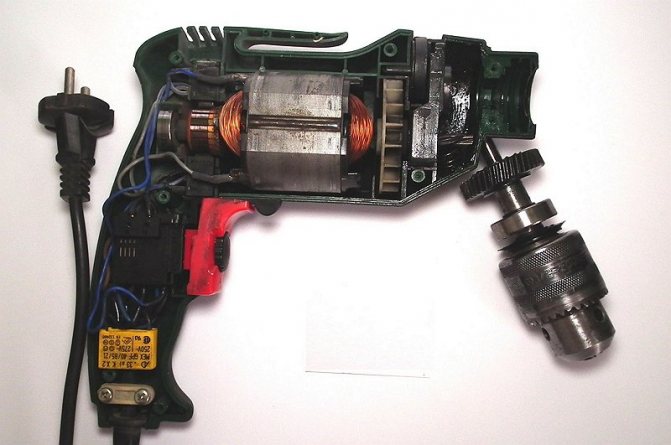

Drill

It is used for drilling holes in blanks made of wood, metal, brick, plastic or concrete (reinforced concrete structures).

Most often, a drill is used during construction work or repair of premises in industrial or domestic conditions.

Modern models of tools have additional functionality. For example, with their help, you can grind the surface, use it as a grinder or a construction mixer.

The design of the drill consists of the following elements:

- Housing made of plastic or aluminum with a rubberized handle and an additional handle;

- Collector motor with rotor, starter, armature and brushes;

- Keyless chuck (used to hold the nozzle);

- Start button, fixed in a certain position during long work;

- Speed control knob (it should be adjusted according to the material being processed);

- Power cord for connecting to an outlet;

- Metal limiter (made in the form of a rod, necessary to control the depth of the holes);

- LED backlight for precision.

Before starting tasks, you should set the depth gauge to the desired position, as well as adjust the speed. This is done depending on the structure of the material (the harder the workpiece, the less revolutions are required).

Then you need to take the tool by the handle and press the start button. Be sure to direct the nozzle along the same axis that should be at the hole in the material. Changing the angle is prohibited. From the spindle, the torsion is transmitted to the gearbox, which allows the drill to enter the prepared surface.

Most drills develop a fairly high speed, so you should do all work carefully.

screwdriver

It is designed for unscrewing or tightening screws, screws, self-tapping screws, as well as other hardware with a thread with hexagonal or slotted heads.

It is often used at home and at work. With the help of a screwdriver it is convenient to mount or dismantle furniture, roofing, fences.

If a special nozzle is included with the tool, then it is also used for grinding surfaces and drilling holes, thereby the manufacturer combined a drill and a screwdriver in one tool. The screwdriver can be powered by a wall outlet or a battery. Some models operate on compressed air (pneumatics). The design of the tool consists of a body, a mounting unit, an electrical and mechanical part, as well as a protection and adjustment system.

Components of the construction of a screwdriver:

- Housing made of metal or plastic with a rubberized handle;

- Electric (or gas) engine that turns the nozzles;

- Planetary gearbox (performs transmission from the motor to the spindle with a clamp);

- Clutch for adjustment, which is connected with the cartridge;

- Clamp chuck (holds nozzle in place);

- Electronic control unit (it has a reverse switch and a start button);

- Battery or power cord.

For the tool to function, it is necessary to insert and fix a bit with a hex shank into the chuck. Also, with the help of a coupling, the tightening torque is set (depending on the model, there may be 8-5 positions). When the start button is pressed, the engine is turned on, which, with the help of a planetary gearbox, begins to rotate the spindle and the chuck with a bit. The more force is applied, the higher the speed rises.

After the self-tapping screw is completely screwed into the surface, the resistance increases significantly. This causes the ratchet to slip and stop the transmission. If it is necessary to unscrew the self-tapping screw, then the reverse takes over. It launches nozzles in the opposite direction.

Number 3. Types of drills by purpose

Depending on what set of functions a drill has, the following main types of tool are distinguished:

- ordinary drill, it is sometimes called unstressed;

- hammer drill;

- drill driver;

- drill mixer;

- angle drill.

conventional drill

This is a no-frills drill. It does not have an impact function, so only wood, drywall, metal and other not very hard surfaces can be drilled with it. This tool is suitable for minor repairs in the country, in a barn, a wooden house. Conventional drills without impact function can be cordless or mains operated.

Impact drill

An impact drill will be needed for those who are going to drill holes in concrete, brick, stone and other hard materials. Such a tool is cheaper than the simplest puncher, but has some limitations. Such a drill will not withstand constant work with dense materials - it will quickly break. In addition, frequent drilling in concrete and stone can adversely affect the accuracy of conventional drilling. If you have to work regularly with dense materials, then it is better to take a puncher.

The impact drill acquires the ability to penetrate hard materials due to its special design. During operation, not only rotational action is transmitted to the drill, but also shock. If in a perforator the blow is provided due to a complex electromechanical or electropneumatic unit, then in a drill the blow is achieved due to the presence of two ratchets. One is located inside the drill, the second is attached to the chuck. When the two elements are connected, the chuck and drill begin to move in an axial and translational direction, thereby providing a chiseling or impact function. If necessary, the impact function can be turned off, the ratchets open, and the drill operates in normal mode. However, in some models, the ability to turn off is not provided - be careful when choosing.

A drill with an impact function is more expensive than a regular drill, but cheaper than a hammer drill. Plus, it is also lighter than a puncher, so it can be called a universal household tool.

When choosing an impact drill, pay attention to the power of the tool. For the impact function to be normal, this figure must be at least 800 W

Also pay attention to the reverse rotation function and the presence of a safety clutch.

Drill driver

It makes sense to choose a drill driver when you also need a tool for tightening / unscrewing screws, self-tapping screws and screws. In the screwdriver mode, such a drill has a low speed and high torque, in the drill mode, on the contrary. It is impossible to call the device completely universal, since such a drill is not suitable for drilling concrete and brick.

Drill mixer

A drill mixer differs from a conventional universal drill by the presence of special nozzles in the kit, which allow you to conveniently mix liquid and semi-liquid formulations. The design of the tool, as a rule, provides for special handles for a comfortable grip during mixing. The drill mixer is suitable for mixing putties, adhesives, paints and other mortars up to 10 liters in volume and allows you to achieve more thorough mixing than with a manual process.

Angle drill

As the name suggests, such a tool is designed for drilling holes in the most inaccessible and narrow places where you can’t get with a conventional drill. The design of the device is characterized by the presence of an angular gearbox and the location of the rotating shaft perpendicular to the body. Such drills, as a rule, have low power and there is no need to talk about any impact function.

An angle drill is a very specific tool, so it's better to take a regular model and use a special nozzle if necessary - it's cheaper and in most cases more reasonable.

Corded screwdriver Shturm ID2145P: the best value for money

This device is produced by a German company, whose products are of high quality components.The device of this series belongs to the budget range, so anyone can purchase it. It is perfect for home use.

This type of corded screwdriver includes a drill function. With it, you can drill holes in materials that have not only medium, but also high strength. The model with a hammerless drill is equipped with a motor with a power of 450 watts. For commercial use, this value is quite enough.

In the rating of electric drills, this device occupies a high position also because its torque is 35 N / m. A similar device is used for screwing long metal products. The device has a keyless chuck with a cross section of 10 mm.

Among other things, this screwdriver can operate in two speed modes. The possibility of reverse rotation is also present. In order to protect the master during work, such a device has a blocking of the "Start" key.

German drill driver Sturm ID2145P is characterized by high quality

The length of the power cable of the Shturm screwdriver of this series is 4 m. This allows you to work without the use of extension elements. The gearbox in this device is made of metal, which is also a serious advantage, extending the service life of the product.

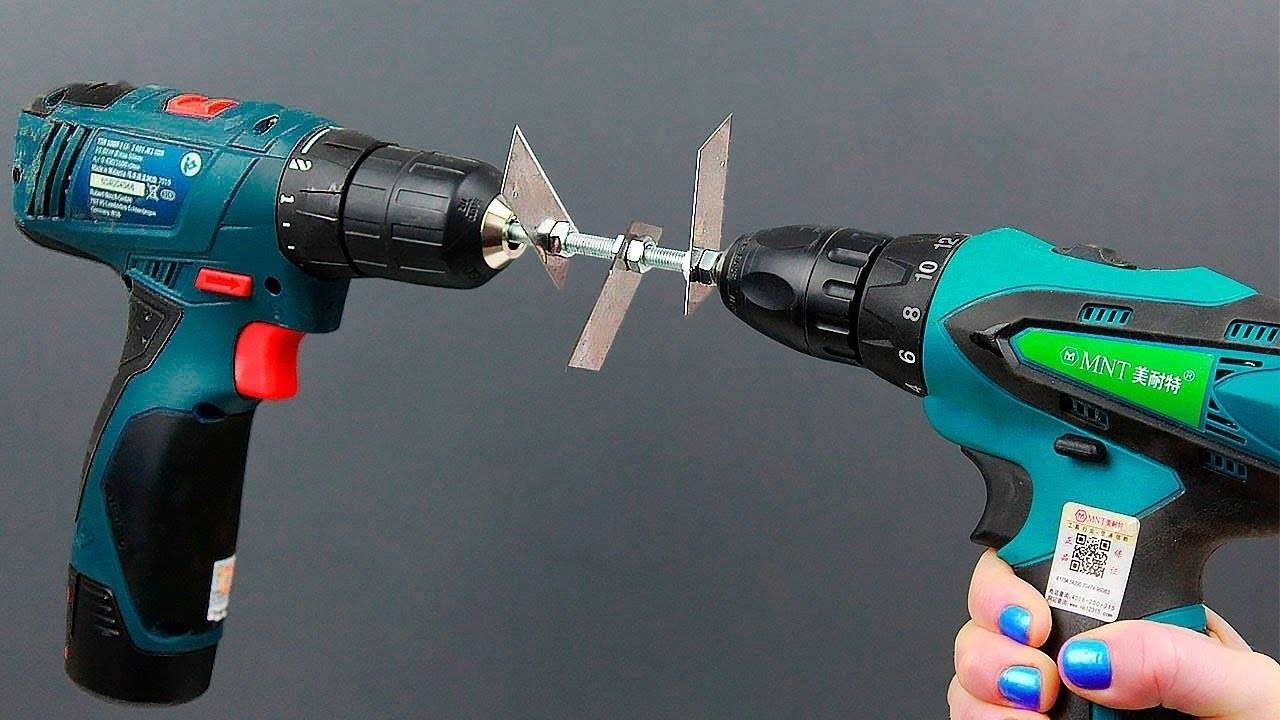

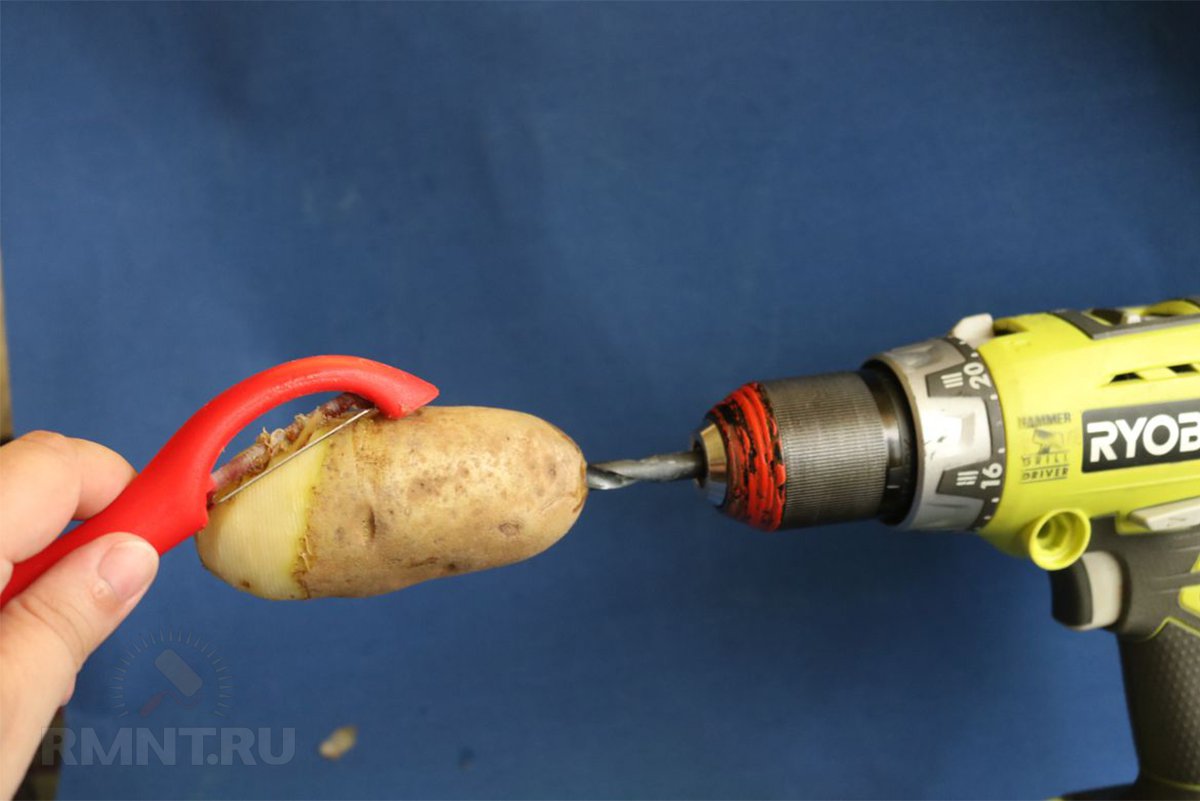

Unconventional use cases

In addition to its direct purpose, an electric screwdriver is used to perform various non-traditional operations. These include the following types of work:

- polishing the car and its headlights;

- mixing small volumes of various building mixtures and paints;

- drilling holes in ice (for this, the tool is equipped with a special nozzle - a drill);

- reinforcement knitting;

- thread cutting;

- mowing the grass cover (for this purpose, they remake the device into a trimmer or lawn mower, or simply insert a nozzle with blades into the cartridge);

- grinding soft grass or thin branches (for this, a garden chopper is created on the basis of a drill-driver);

- surface grinding;

- cutting materials;

- twisting wires.

This is a far from complete list of non-traditional work performed using cordless or corded models of electric screwdrivers. Inventive thought does not stand still. Almost every specialist has options for atypical work for this power tool.

Using a screwdriver, you can restore the car to its original color and shine. To polish the car, use the following types of nozzles:

- leather or fabric circles, with their help, perform the initial cleaning of surfaces;

- felt - they are used for initial processing and finishing polishing (nozzles made of sheepskin are suitable);

- foam.

Together with the equipment, polishing pastes and polishes are also used. They are of the following types:

- silicone;

- abrasive;

- non-abrasive.

With the help of similar tools, headlight polishing is also carried out.

Knitting reinforcing bars with steel wire is very common in the construction industry during the construction of reinforced concrete (monolithic) structures, for example, foundations, houses. Even if you have to do a small amount of work, then working with a hand crochet or pliers is not quite productive. A cordless or corded electric screwdriver equipped with a hook-shaped nozzle will help to knit reinforcement much faster.In this case, the power indicator of the tool is not particularly important.

Twisting cut ends of wires, for example, in junction boxes, is also quite a chore. You can speed up the process with a screwdriver with a special nozzle. How twisting is done is shown in the video below: