- Why is it profitable to buy a diesel gun: design advantages

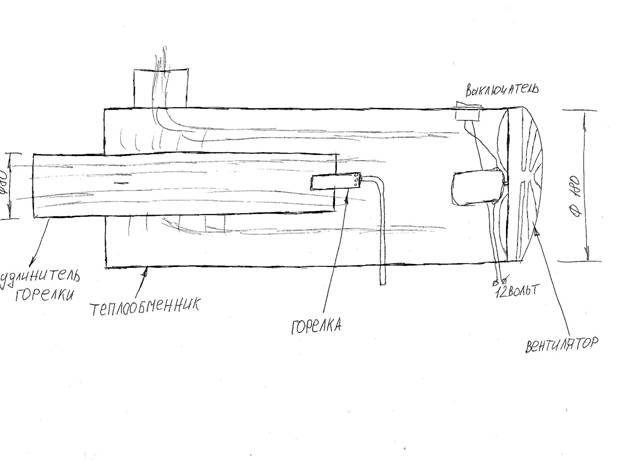

- Do-it-yourself gun

- Homemade heater device

- Necessary parts and materials

- Installation of the device for testing

- Tips for Using Heat Guns

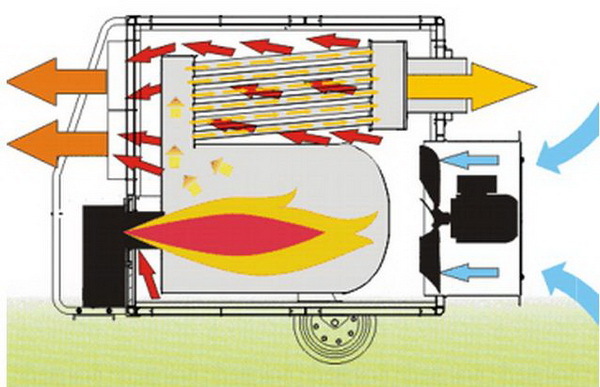

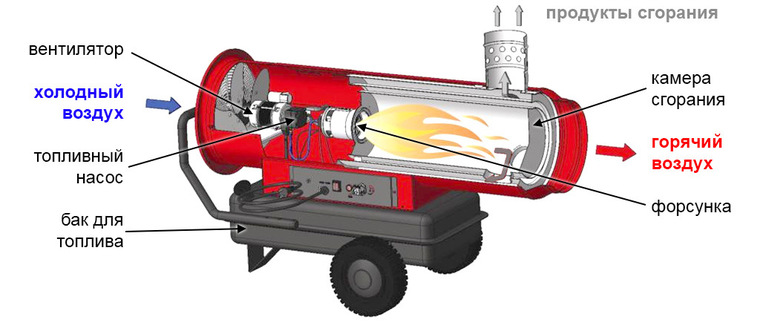

- Principle of operation

- Other characteristics

- Air flow

- Dimensions

- Shape and material

- Functions

- A few important rules that must be observed during installation work

- What guns do we repair?

- Scope and principle of operation

- Maintenance of heat guns

- What you need to know about the electric gun?

- The device and principle of operation of the heat generator

- Advantages and disadvantages of homemade guns

- Do-it-yourself wood-burning heat gun

- Installation and connection of the heat gun

- Step-by-step instruction

- Varieties of gas guns

- Diesel options

- Appearance

- Making a heat gun with your own hands

- Video: do-it-yourself electric gun for heating a garage

- Heat gun on diesel fuel and diesel fuel

- Video: multi-fuel heat gun

- gas heat gun

- Video: homemade gas heat gun

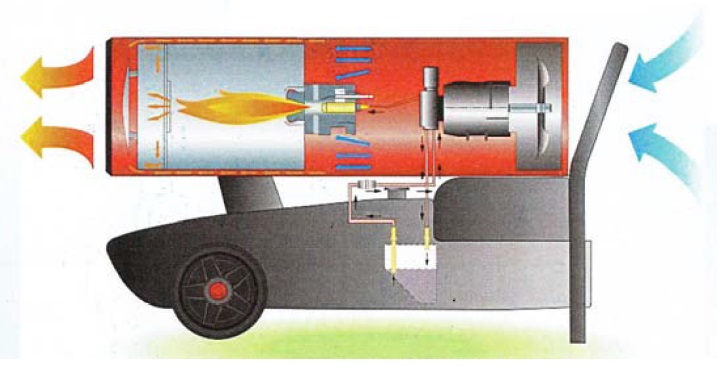

Why is it profitable to buy a diesel gun: design advantages

Guns that heat rooms by burning diesel fuel have many undeniable advantages.They are compact in size and light in weight, while they have excellent technical characteristics. These designs are easy to use. The mechanism is launched with just one push of a button. The user has the ability to control the temperature in the room.

Many diesel designs have a built-in system for connecting a rheostat. The principle of operation of this mechanism is very simple. Before launching the gun, it is enough just to set the required parameter. When the room temperature reaches this value, the equipment will automatically turn off. When the temperature drops below the level of the specified mark, the structure will start on its own.

Diesel guns are economical, fuel consumption depends on the technical parameters of the device. Equipment with a power of 20 kW and a capacity of 550 m³ / h will need about 1.5 liters of diesel fuel to warm up this volume. Using such a gun, you can achieve quick results. According to the information declared by the manufacturers, diesel devices instantly warm up the room. The air temperature of +10°С in a room with a volume of 120 m³ can be raised by a gun to a level of +180°С in 15 minutes. And this speed is not the limit.

Small diesel-fueled heat guns are convenient for use in closed, unheated rooms.

Small diesel-fueled heat guns are convenient for use in closed, unheated rooms.

Diesel devices are safe to operate. If the room is well ventilated, the inhalation of burnt air does not cause such unpleasant consequences as headaches and dizziness. High-quality designs are able to work for a long time without additional refueling.The guns are equipped with tanks of large volumes, thanks to which they are able to work continuously throughout the day.

On a note! The body of the structure is heated to a temperature of + 30-35 ° C maximum. Therefore, accidentally touching the gun will not cause burns.

Do-it-yourself gun

The design of the heat gun is quite simple, therefore, having certain work skills, you can try to assemble such a unit yourself.

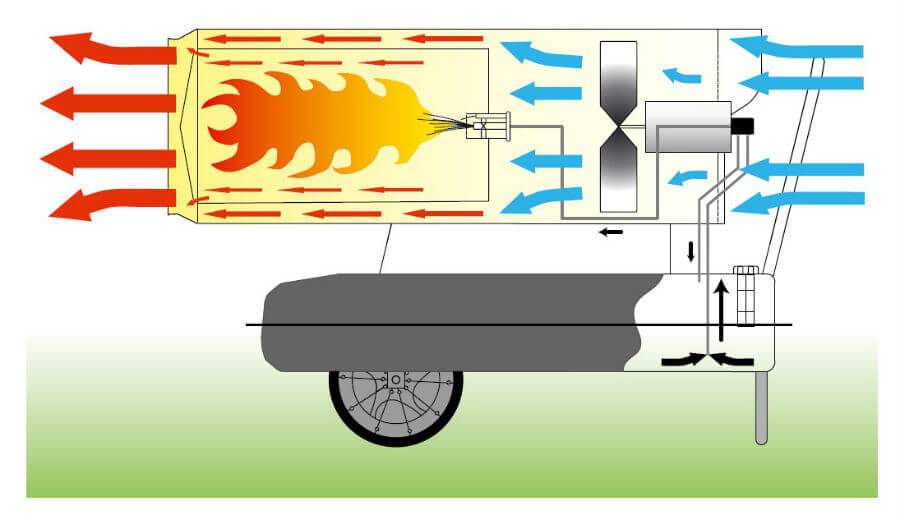

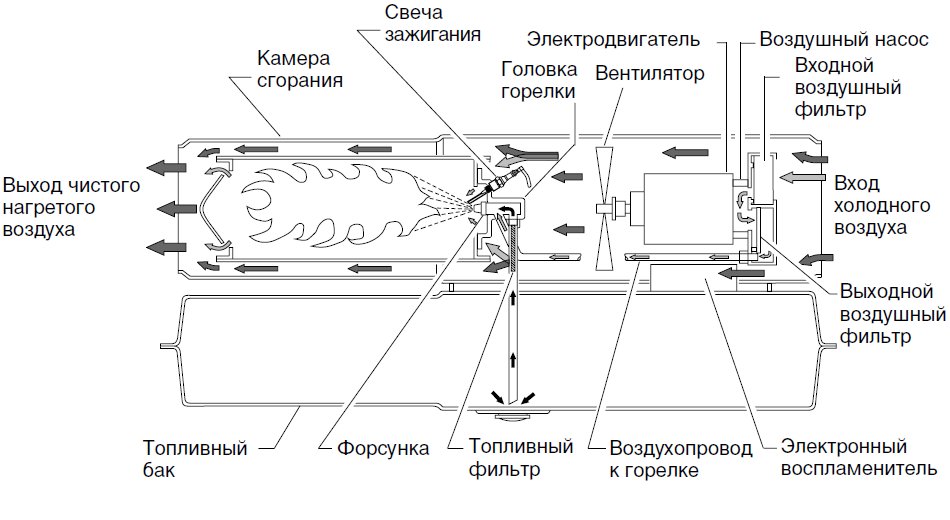

Homemade heater device

To perform the device yourself, you can use a simplified scheme of the heat gun. At the bottom of the structure is a fuel tank, above which there is a fan and a working chamber. Fuel is supplied to the latter, while the fan blows hot air into the room.

A self-made thermal device for testing will cost much less than purchased in a store, but its technical characteristics are slightly lower

In addition, the device provides for a pump, a filter and a connecting tube through which fuel passes, a nozzle for the exit of combustion products, a pipe for heated air and a number of other elements.

Necessary parts and materials

Before starting work, stock up on materials or finished components of the device.

In the manufacture of a waste oil thermal heater, a sawn off part of an old gas cylinder can be used as a body

The body of the heat gun, for which it is necessary to use thick-walled metal. As this part, for example, a pipe section of a suitable size or another suitable product is suitable. You can also make a case from a sheet of thick stainless steel (3-4 mm) by welding a seam.

The combustion chamber. A metal cylinder is suitable for this part, the diameter of which is half that of the same indicator of the body.

Fuel tank. This element is a bowl made of a material with low thermal conductivity. An ordinary metal tank, carefully closed with a heat insulator, is also suitable.

The fan, which is necessary for the device of a thermal device for working out, can be purchased at a store or use an existing device, provided that it is in good condition

Fan. To ensure simplicity and reliability of the design, it is preferable to use a reliable and economical 220 volt vane fan, which is easy to use and durable.

There are several articles on our website in which we examined in detail how to build a heat gun with our own hands. We recommend reading them:

- Heat gun on different types of fuel.

- Heat gun on waste oil.

- Diesel heat gun.

- Thermal gas gun.

Installation of the device for testing

First of all, you should take a pipe, cylinder or other outer shell of the device.

Below is a heater and a fuel tank, which must be separated from the top of the device at a distance of 15 cm. To make this part of the device look neater, it can be hidden in a metal box.

A combustion chamber is installed in the center of the free space, for which a galvanized pipe can be used. On both sides, the compartment is sealed, after which holes are made in it for the nozzle and chimney. The combustion chamber is firmly fixed to the walls of the housing. It is desirable to equip the working compartment with a piezo ignition, and also connect a fan to it.

Next, you need to install a fuel pump with a nozzle, adding a filter between these parts

It is also important to organize an outlet pipe from the tank through which the waste will enter the fuel filter and nozzle.

It is also necessary to resolve the issue of the fan power supply. If there is an electrical outlet within reach, this item can be plugged into an outlet

In its absence, you will have to use the battery.

At the end, it is necessary to cover the holes located at the top with nets.

Tips for Using Heat Guns

Experts recommend paying attention to the following points in the production of heating devices:

- When operating the device, you should follow the safety rules: remember that at a distance of 1 meter from the device, the temperature of the heated air jet can reach 300 °C.

- To warm up a room of 600 square meters, only 10 liters of fuel are enough.

- It is necessary to clean the evaporation bowl, removing slag from mining, once after 20-50 hours of operation of the device.

- Water must not be allowed to enter the fuel cell along with used oil or other fuel. If a large amount of this liquid enters the tank, the burner may go out.

You should also not forget about fire safety rules: it is better not to leave home-made thermal devices unattended, and also to have a fire extinguisher or other fire extinguishing device within reach.

Principle of operation

Electric heat guns work on the principle of convective heat transfer.By means of a fan, cold air moves towards the heating element, and then it is supplied to the premises, while its temperature is already noticeably higher. Many modern models have a built-in thermostat that automatically turns off the heating if the required temperature has already been reached, and then turns it on when the air in the room cools down. Typically, such a thermostat is located at a certain distance from the device itself, so it shows the actual temperature inside the room.

Other characteristics

We have analyzed the main parameters: the rest do not seem so important. But if you want to approach the choice with all responsibility, then study them.

Air flow

Shows how much air mass the device creates per hour. This characterizes the heating rate and depends on the fan.

You should look at throughput in conjunction with power. If the flow rate is high and the heating capacity is low, the outlet stream will be barely warm. There is no point in such equipment.

There is no such parameter for infrared models.

Dimensions

Compact samples have little performance. Be prepared to put up with bulkiness if you need a high-powered unit. In general, the weight ranges from 1 to 1500 kg.

Electric guns weigh 3-70 kg, and gas ones from 3 to 700 kg. The spread in the mass of liquid-fuel specimens is huge: from a modest 1 kg to 1.5 tons.

Shape and material

The body may be in the form of a tube or a rectangle. The first resembles a real military weapon with its elongated cylindrical shape.It is capable of delivering higher temperatures than its competitor. At the same time, rectangular units provide more even heat distribution due to the increased dissipation area.

All structures are made of metal. This is due to the danger of plastic melting. In household models, there are plastic inserts, for example, knobs, switches. As a rule, they are hidden in such a way as to prevent their excessive heating.

Functions

Heat guns do not differ in a variety of functions. These are already quite expensive products and it makes no sense to complicate them with additional gadgets.

Increased attention is paid to security. The devices are equipped with a rollover shutdown option.

Liquid fuel and gas facilities are equipped with flame control: if it goes out, the fuel supply stops.

The thermostat helps to control the heating level. As soon as the room temperature reaches the set value, the element stops working. Also, a shutdown occurs if the internal parts reach critical values. If you plan to leave the device unattended, then definitely buy a device with a thermostat.

Ventilation without heating allows you to mix the air in the room. And in hot weather, the device will replace your fan.

A few important rules that must be observed during installation work

During the installation of equipment that involves the use of liquid fuels, several general rules must be observed, as well as the requirements specified by the manufacturer of the equipment being installed.

Important guidelines include the following:

- diesel boilers cannot be installed in garages with a small area and city apartments, since the boiler itself takes up a lot of space, requires a fuel tank and has a high noise level;

- diesel equipment must be installed in separate rooms, the ceilings of which are at a height at least two and a half meters;

- from the surface of the boiler to the wall opposite, there must be a distance exceeding one meter;

- the walls of the boiler room must be concrete or brick, covered with plaster or tiles;

- in the boiler room it is necessary to install doors of the third class of fire protection;

- no more than nine hundred liters of fuel should be stored in the fuel tank, which leads to the need to equip a room separate from the boiler room for the tanks.

What guns do we repair?

They are used in cold weather, kerosene, gasoline, diesel fuel, waste oil are used for refueling. The equipment is used in fuel depots, oil depots, in car workshops. The machine's burner supports the combustion of engine oil, helping to dispose of residual oil and reduce fuel costs.

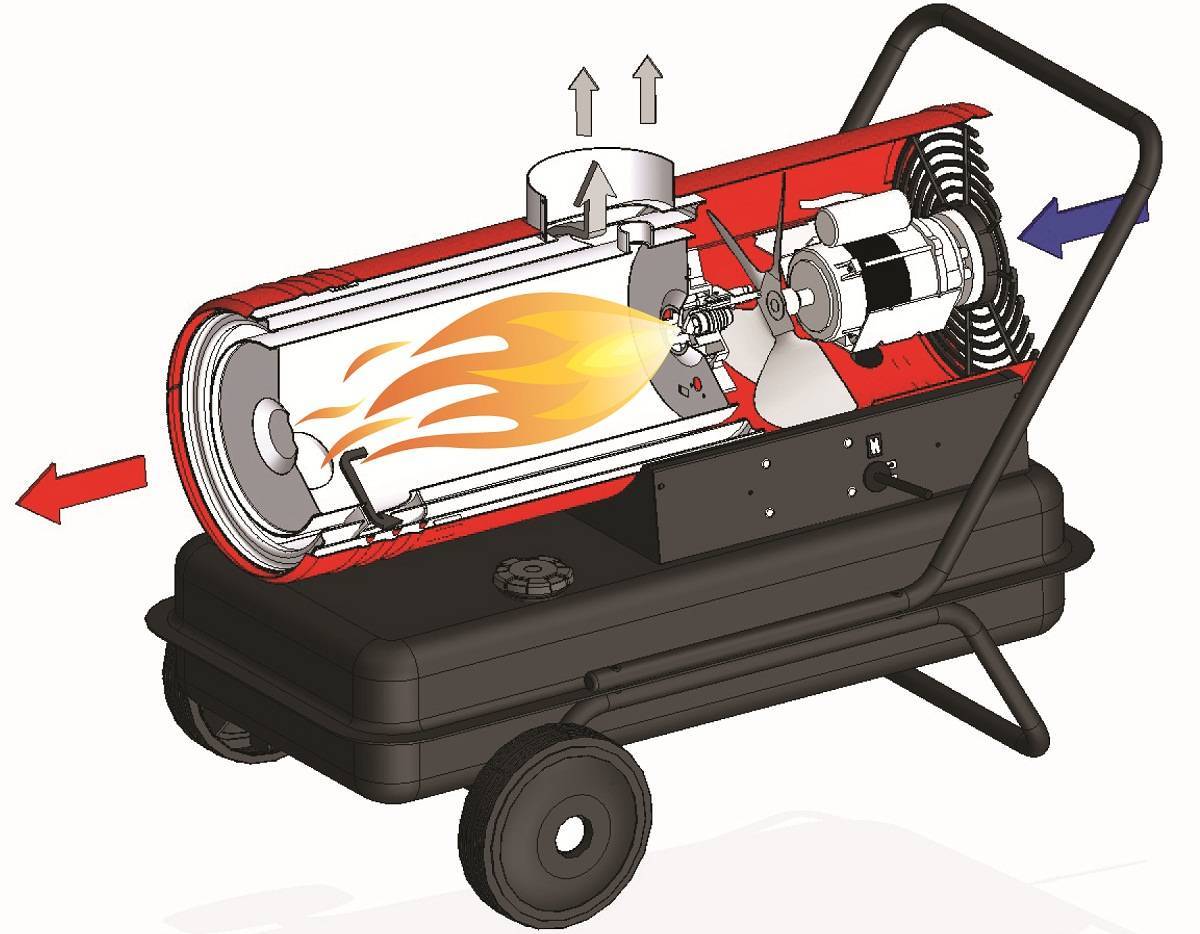

Direct heating devices

The efficiency of the equipment is 100%, since the fuel burns completely in them. The power of the guns is 220 kW, while they can work up to 15 hours. If there is a thermostat responsible for periodically disconnecting and turning on the unit, depending on the ambient temperature in the room, the gun on one fuel tank can be constantly in operation for 24 hours.

It should be noted that the direct heating device consumes oxygen and emits exhaust gases together with the heated air.Therefore, there are restrictions on the use of such devices. They are used in rooms with a constant supply of oxygen. The machine must not be operated in places where there are people, as this will cause carbon monoxide poisoning.

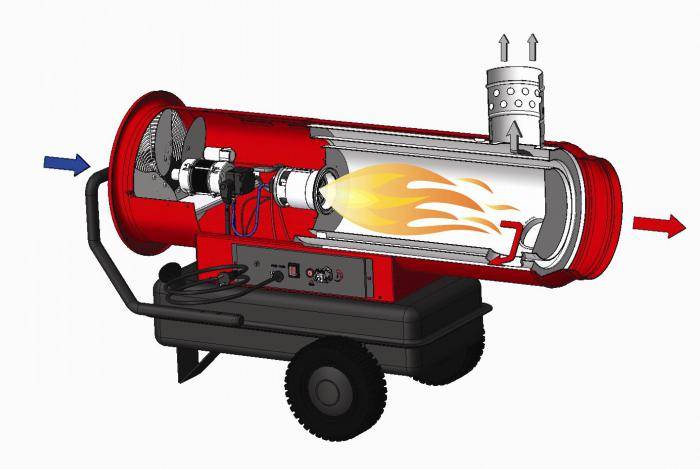

Indirect heating appliances

The design of the machines includes a gas outlet, through which warm air enters the room. At the same time, there are no exhaust gases and other combustion products in the air. The duration of the equipment is up to 16 hours.

The design has protection against overheating, which turns off the unit when its surface reaches significant temperatures, and the option of controlling the burner flame. This function automatically turns off the device when there is no flame in the burner, thus making it safe to use.

The equipment is suitable for use in rooms where people stay. To maintain the combustion process, an influx of oxygen is necessary, that is, the heated space must be constantly ventilated.

Diesel devices

These devices operate only on diesel fuel and are operated during winter construction. Diesel devices by design are direct, indirect heating. They are less fuel efficient than multi-fuel models. But they are compact, mobile, powerful, thanks to which the space heats up faster and the temperature is maintained for a long time.

If you need repair of diesel heat guns in St. Petersburg, call our managers. They will advise on issues of interest.

Gas Models

Machines ensure complete combustion of the gas they operate on. Their connection to the gas network makes the unit stationary.Gas appliances are used in agriculture and industrial buildings. It is better to entrust the repair of a gas heat gun to our masters.

Gas guns can run on bottled propane or butane. This makes them mobile, allows you to move from place to place.

Scope and principle of operation

The principle of operation of such a unit can be compared with the functioning of a fan, however, a heat gun releases not cold, but warm air into the room.

The air functioning inside the housing is heated by a heating element or burners operating on various types of fuel.

The name "cannon" is caused both by the external resemblance of the device to an artillery gun, and by the powerful jet of heated air that the unit "shoots"

Heat guns of various modifications find a wide range of applications.

They are successfully used:

- in industry for heating extensive production and storage facilities;

- in agriculture to maintain a comfortable air temperature in greenhouses, greenhouses, greenhouses;

- in construction for quick drying of plastered, painted or otherwise finished rooms;

- in everyday life for heating and drying utility rooms and garages;

- for heating residential buildings in emergency situations (for example, accidents on heating lines).

There are other ways to use such devices, for example, gas units are widely used in the installation of stretch ceilings.

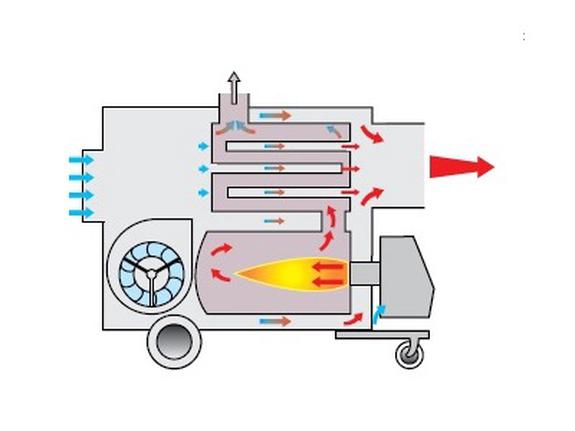

Maintenance of heat guns

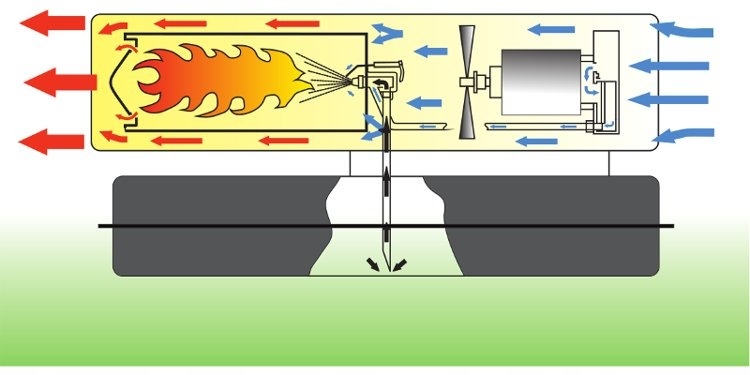

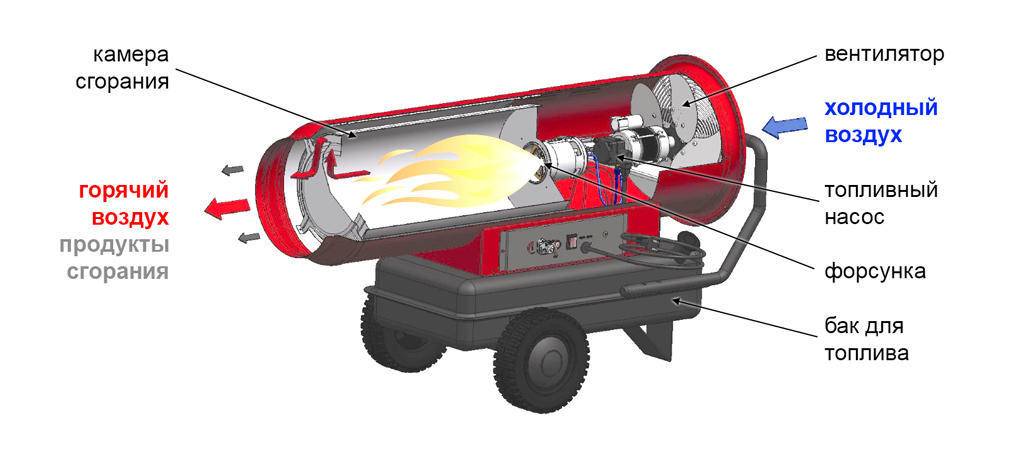

Indirect diesel gun

All preventive work on equipment are reduced to setting and treatment of the air intake system, compressor and fuel pump. The procedure for each individual heat gun is approximately the same.Let's look at the maintenance details using the example of a classic model with indirect heating and automatic flame control.

The design of a thermal diesel gun cannot be called complex. Fuel is supplied to the nozzle by the pump, after which it is produced in the combustion chamber. The burner is ignited using a pair of electrodes. The fan during operation expels the flow through the chamber. Indirect heating assumes the presence of an independent circuit, as a result of which the combustion products practically do not come into contact with the heated air.

Equipment Prevention:

- Remove the cover and clean the fan from dirt.

- We disconnect high-voltage wires from the combustion chamber and remove the fuel hose. We blow the last one.

- We loosen the fasteners on the camera and remove the block. We clean from soot.

- We unscrew the nuts at the end of the chamber and get access to the nozzle. We blow it out.

- We collect everything in the reverse order.

What you need to know about the electric gun?

Unlike other types of heat guns, almost any home craftsman who is familiar with the basics of electronics can make an electrical appliance.

Although the efficiency of an electric gun is much lower than diesel or gas devices, it does not emit combustion products harmful to health and can be installed in any room - a residential building, a greenhouse, outbuildings.

The power of guns for industrial use varies from 2 to 45 kW, and the number of heating elements in them can reach up to 15 pcs.

Consider how an electrical unit works.

The device and principle of operation of the heat generator

Any electric gun consists of three main components: a body, an electric motor with a fan and a heating element.Varieties of this type of devices are described in detail in an article on the classification and principles of operation of heat guns.

Additionally, the device can be equipped with any "bonuses" from factory units - a speed switch, a heat controller, a room thermostat, a case heating sensor, engine protection and other elements, but they increase not only comfort and safety during operation, but also the cost of homemade.

The rate of air heating in the entire volume of the room depends on the number and power of the heating elements - the larger their area, the more actively the heat transfer will occur

The electric gun works like this:

- when connected to the network, the heating element converts electric current into thermal energy, due to which it heats up itself;

- the electric motor drives the impeller blades;

- the fan drives air from the room inside the case;

- cold air flow comes into contact with the surface of the heating element, heats up and, forced by the fan, is removed from the "muzzle" of the gun.

If the appliance is equipped with a thermostatic element, it will stop the heater when the programmed temperature is reached. In primitive devices, you will have to control the heating yourself.

Advantages and disadvantages of homemade guns

The main plus of a thermal power generator is the possibility of its use in any room where there is a network of at least 220 watts.

Such devices, even in a home-made version, are mobile, weigh a little and are quite capable of heating an area up to 50 m2 (theoretically, more is possible, but it is better not to experiment with high-power devices and buy a ready-made unit, and a gun from 5 kW will already require connection to a three-phase network) .

The performance characteristics of the device must correspond to the heated area. On average, 1 kW will be needed for every 10 m2, but a lot depends on the room itself - building materials, glazing quality and the presence of insulation

Pros of a homemade electric gun:

- Cost savings - factory units are not cheap, and you can assemble a heating device with a minimum of purchased parts or even completely from improvised means by removing the missing elements from old appliances.

- Safety - of all home-made heat generators, an electrical appliance is the easiest to operate, since it does not require connection to gas or refueling with combustible fuel. With the correct assembly of the electrical circuit, the risk of spontaneous combustion in such guns is minimal.

- Fast heating of the room - the work of the heat gun is much more efficient than other options for homemade electric heaters, such as fireplaces or oil radiators.

Of the minuses, a large power consumption can be noted (the amount depends on the engine power and heating element). In addition, the operation of the fan is quite noisy, and the larger the wingspan and rotational speed, the louder the noise will be.

Well, any drawback of a home-made electrical device is the likelihood of an error during assembly or connection, which can cause a short circuit in the network, electric shock and spontaneous combustion of the device.

Do-it-yourself wood-burning heat gun

- Fuel is loaded into the combustion chamber.

- As soon as the air heats up, the fan will turn on, which will be connected to the pipe of the heating chamber with a corrugator.

- Inside the cylinder there is a horizontal partition, due to the fact that it perceives the greatest heat load, the air heats up quite quickly.

- Hot air coming from the second branch pipe will be able to heat any point of the room.

The blower in this device is a fan, the choice of which depends on the area of \u200b\u200bthe room: for a small room, a cooler located in a computer system unit is suitable. For medium-sized housing, you can use household fans located in the hoods.

- Cut off the upper part from the cylinder, this must be done along the weld. For a more powerful construction, cut the top below the weld. Before that, you need to unscrew the valve, and so that the remaining propane does not explode, fill it with water. If this is not done, then working with an angle grinder will be dangerous.

- Make additional parts. Cut out a circle of about 300 mm in size from metal, it will act as a partition. For doors, you need to frame in the form of a strip 80 mm wide. If the material remains, then small strips can be cut from it, which will go for heat exchange fins.

- Run the grate, adjusting the length of its rods to the size of the cylinder, then place it in its lower part.

- Trim openings for installing the loading door. Door frames are inserted into them; they are a welded structure of strips. You should first prepare the doors by welding hinges and handles to them.

- Build an air chamber.Lay the prepared metal circle instead of the cut off upper part and weld it tightly. Attach a fan in it and weld the ribs.

- Install the flue pipe.

Installation and connection of the heat gun

The method of connecting the heater depends on the type of its drive. There are also general operating rules that must be followed when connecting any heat gun.

General rules for operating a heat gun:

Place the appliance only on a level surface.

From the ceiling to the gun, it is desirable to leave a gap of at least one and a half meters.

Do not lean the back of the heat gun against walls or other objects.

Do not cover the nozzle of the heat gun. This reduces its effectiveness, increases the risk of overheating and even fire. It is desirable that there is at least three meters of empty space in front of the outlet.

Do not attach any sleeves to the gun nozzle.

Do not place any objects on the heat gun.

Do not move the heat gun if it is turned on.

Do not aim the heat gun at flammable objects.

Do not use the heat gun in places where there are vapors of flammable or explosive substances: gasoline, acetone, alcohol, etc.

Do not turn on the heat gun in places where there is a lot of dust.

Do not use the heater in rooms with high humidity or outdoors during rain.

Do not leave the heat gun running unattended.

Do not modify the design of the heat gun.

During repairs, use only the parts specified in the instructions.

If you want to disassemble, refuel or repair the heater, then it must be turned off and unplugged from the outlet.

If you use the heater indoors, then do not forget to ventilate it at least occasionally.

If the heat gun is dirty and dusty, then it must be cleaned before turning it on.

Before using the device at full power, let it warm up for an hour or two.

This is especially important in winter when working outdoors or in cold rooms.

Step-by-step instruction

The first step is to make the body. You can use sheet steel with a thickness of 3-4 mm or a regular pipe. The sheet must be given the required parameters, and then it must be rolled into a pipe. The edges are fixed with bolts or a special connecting lock.

After that, a pipe is sawn, which is used to supply gas. This is necessary so that later it will be possible to weld the next element to it.

Homemade gas gun:

Now you need to increase the diameter of the hole, which is intended for the flow of gas into the system. You need to bring it up to 5 mm.

Then the heat exchanger is made. A metal pipe with a diameter of 80 mm is taken. The end must be welded to the wall of the burner and a hole drilled. The torch extension passes through this element.

To exit the heated air in the heat exchanger housing, you need to make a hole. Then, in that place, weld a tube with a diameter of 8 cm.

Finally, you need to drill holes for igniting the gas. It is also necessary to provide for the structure on which the heat gun will be located. You can use a ready-made stand or weld from reinforcement.

Heat gun. do it yourself:

Varieties of gas guns

Air can be heated in one of two ways:

- direct heating;

- indirect.

Gas guns (do it yourself or factory-made) with direct heating have a fairly simple design, which is why their cost is low. The burner is not isolated in them, so that, in addition to heated air, gas combustion products also enter the room. For this reason, the device is compact and shows good efficiency. But if it is used to heat a dwelling, then you must first make sure that it (the room) has a good ventilation system that would remove combustion products.

Video

Guns operating on an indirect principle are equipped with isolated combustion chambers. They have special nozzles with which these products are discharged and which are connected to a common chimney. They are ideal for any type of space where many people gather.

All this is a description of stationary guns, but besides them, there are also portable or mobile guns. They are used together with gas cylinders. In order to make it convenient to transport and operate the device, it has special wheels and handles.

Note! Mobile guns require strict adherence to safety rules. The operating time of such devices is dictated only by the volume of the gas cylinder, fuel consumption ranges from 0.6-7 liters. in hour

In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. The most economical option is a gun that is equipped with a thermostat. With it, the device turns off after the required room temperature is reached.In a word, heating the room with such guns - distinguishing the opportunity to save on heating

in hour. In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. The most economical option is a gun that is equipped with a thermostat. With it, the device turns off after the required room temperature is reached. In a word, heating the room with such guns - distinguishing the opportunity to save on heating

The operating time of such devices is dictated only by the volume of the gas cylinder, fuel consumption ranges from 0.6-7 liters. in hour. In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. The most economical option is a gun that is equipped with a thermostat. With it, the device turns off after the required room temperature is reached. In a word, heating the room with such guns is an opportunity to save on heating.

Diesel options

Malfunctions of a diesel heat gun are in the following important points:

- Fuel is supplied to the combustion chamber intermittently. The appearance of this defect is primarily associated with contamination of the fuel tank and its supply system. In this case, it is recommended to drain the fuel from the tank and rinse thoroughly. Then you need to purge the entire fuel system.

- The fuel mixture is not flammable. This failure is primarily due to defects in the spark plug. To eliminate the malfunction, it is necessary to remove the candle, clean it mechanically, and also adjust the gap between the electrodes of this ignition element.

- The heat gun began to work intermittently. A malfunction of this kind is associated with a clogged air filter. In this situation, you need to install a new filter.

- The heat exchanger does not heat up well due to the small flame in the combustion chamber. This defect is due to the fact that the nozzle is very dirty. Cleaning in this case occurs non-mechanically. In other words, the nozzle is thoroughly washed and then purged with a compressor.

- The heater gets very hot during operation. This problem arose because the thermostat failed. To eliminate the defect, you need to clean all the elements of the thermostat or, if necessary, replace them with new ones.

In conclusion, we would like to wish you that your heat gun never breaks down, and if such a nuisance has already happened, then following our recommendations, you can easily identify all defects and feel free to do the repair yourself.

Watch a video in which an experienced user clearly demonstrates the process of repairing a gas heat gun with his own hands:

Appearance

It takes into account such nuances as aesthetic appeal, achieved through the use of two basic shapes - rectangular and cylindrical, as well as high-quality paint and unit dimensions. If the device is planned to be used exclusively for domestic purposes in a small room, then a compact heater, the mass of which is 5-10 kilograms with dimensions in the range of 25-50 centimeters, is the best option. If there is a need to purchase a unit of greater power, then you should be prepared to transport equipment, the weight of which will be 50-150 kilograms with dimensions of 1-3 meters for each of the parameters.

Making a heat gun with your own hands

The process of creating a homemade heat gun always begins with the manufacture of a frame from the corners, to which the body and other components will be attached. The next steps depend on the type of installation.

First, a diagram of the electrical circuit of the installation is drawn up. If the master does not have the relevant knowledge, he can use ready-made developments.

It looks like a drawing of a circuit diagram of a heat gun

An electric heat gun is made as follows:

Video: do-it-yourself electric gun for heating a garage

Heat gun on diesel fuel and diesel fuel

The manufacturing process consists of the following steps:

We draw the reader's attention to the fact that this heat gun operates according to the direct heating scheme, therefore it cannot be used in residential and other premises with the stay of people or animals.

To control the correctness of the assembly, it is advisable to invite a master from some auto repair shop.

The self-made model does not have a flame control sensor and an overheating protection system, so it cannot be left unattended during operation.

Video: multi-fuel heat gun

gas heat gun

This setup is made like this:

- A meter-long piece of pipe with a diameter of 180 mm is used as a body. In the absence of a finished pipe, it is made from galvanized sheet, fastening its edges with rivets.

- At the ends of the body, on the side, you need to cut out a hole - with a diameter of 80 mm (a pipe for the removal of heated air will be connected here) and 10 mm (a burner will be installed here).

- A combustion chamber is made from a meter-long piece of pipe with a diameter of 80 mm. It must be welded into the body exactly in the center, for which several plates must be used.

- Next, a disk is cut out of the steel sheet, which will be used as a plug. Its diameter must correspond to the diameter of the heat gun body (180 mm). A hole with a diameter of 80 mm is cut in the center of the disk - for the combustion chamber. Thus, a plug welded to the body on one side will close the gap between it and the combustion chamber. The plug must be welded from the side of the heated air supply.

- A pipe for supplying heated air is welded to a hole made in the body with a diameter of 80 mm.

- A burner with a piezoelectric element is installed in a 10 mm hole. Next, a gas supply hose is connected to it using a clamp.

- The manufacture of the heat gun is completed by installing a fan and connecting it and the piezo igniter to the power supply through a switch.

Video: homemade gas heat gun

The easiest way to make such a heater is from an old gas cylinder. If it is not available, a thick-walled pipe with a diameter of 300–400 mm can also be used as the main blank - then the cover and bottom will need to be welded on their own (these elements are already available for the cylinder).

One of the options for a wood-fired heat gun is shown in the drawing:

Drawing of a general view of a heat gun with an indication of its main dimensions

As you can see, the body of the heat gun is divided into a furnace and an air chamber with inlet and outlet openings. The partition between them and the improvised lamellar radiator act as a heating element for the air passed through the chamber. The location of the radiator fins is shown in the sections.

Sections - frontal and horizontal, which show the internal structure of the gun

By attaching a corrugated hose to the outlet pipe of the air chamber, the user will be able to supply hot air to any point in the room.

The installation is made as follows:

An overly powerful fan is not required for this heat gun. It is enough to install a model for extracting a bathroom with a capacity of about 50 m 3 / h. You can use a fan from the stove of the car. If the room is very small, a cooler from a computer power supply is also suitable.