- Video

- Is it possible to drink water from a well

- Removal of bacterial iron

- How to get rid of iron in water

- settling

- Industrial cleaning systems

- Folk cleaning methods

- Effect of water on iron

- In what cases is it required?

- 2.3 Iron removal by ion exchange (iron up to 20 mg/l and in combination with manganese, hardness and organic matter)

- Permissible concentration

- How to understand that the concentration of iron in the water is increased?

- Folk recipes for water purification

- Important Points

- Fluid collection for bacteriological examination

- How is water analyzed?

- Purification of water from a well from iron: various methods and technologies

- Purification of water from a well in a country house to a drinking state by settling

- aeration method

- Ozonation process

- Ion exchange method

- reverse osmosis method

- Application of reagents

- Do-it-yourself water purification from iron from a well

- settling

- Aeration

- Introduction of catalysts and reagents

- Folk ways

- Ozonation

Video

From the videos presented, you can learn how to make a system for aerating water from a well with your own hands and effectively get rid of excess iron, as well as get acquainted with the advice of summer residents that will help eliminate the unpleasant hydrogen sulfide smell, metallic taste of water and achieve its transparency:

About the author:

Found an error? Select the text with the mouse and click:

ctrl

+

Enter

Do you know that:

The birthplace of pepper is America, but the main breeding work for the development of sweet varieties was carried out, in particular, by Ferenc Horvath (Hungary) in the 20s. XX century in Europe, mainly in the Balkans. Pepper came to Russia from Bulgaria, which is why it got its usual name - “Bulgarian”.

Is it possible to drink water from a well

Residents of holiday villages often face the problem of water supply. The usual solution is to drill a well that can be used by several houses. Such wells are not drilled very deep, so aquifers are poorly protected from bacteria getting there. It is often impossible to drink from such wells, and to make sure of this, you can take the liquid for analysis.

If this is not possible, then you can do some analysis yourself:

- Watch the liquid as it boils. This process can reveal stiffness. If deposits remain on the walls or bottom of the container after boiling, then this water cannot be drunk.

- Pour the well fluid into any container and leave for a day. If a ferruginous sediment has formed in it, it is undrinkable.

- The smell of hydrogen sulfide cannot be ignored. Most of the time this water is not drinkable.

Let's figure out how to get rid of excess iron in water, why there is a smell of hydrogen sulfide and how to deal with it.

Removal of bacterial iron

If there is a large amount of iron in the source water, the user may face another problem - the appearance of bacterial contamination - the active development of iron bacteria. If the problem of iron bacteria is detected at an early stage, regular chlorination or treatment with chelating agents (organic substances that form soluble complexes with iron deposits), as well as constant monitoring of the condition of the equipment will help to minimize its consequences.

At an early stage of the appearance of iron bacteria, shock chlorination can help - it is necessary to create an excess concentration of chlorine of 50 mg / l. Before using chlorination, you need to find out how resistant to chlorine the installed water treatment equipment is.

The problem with bacterial iron can be solved by the redox medium, however, in the supply pipelines, iron bacteria will continue to develop and form slimy deposits.

How to get rid of iron in water

To remove dissolved iron from water, it must be oxidized to an insoluble compound, and then the precipitate formed must be removed. This principle underlies all known methods of iron removal, which differ only in the methods of oxidation and filtration, as well as in the reaction rate.

settling

This is the simplest and most inexpensive, but at the same time the slowest way to iron out water from a well. This, of course, is not about pouring water into saucepans and waiting for it to settle.

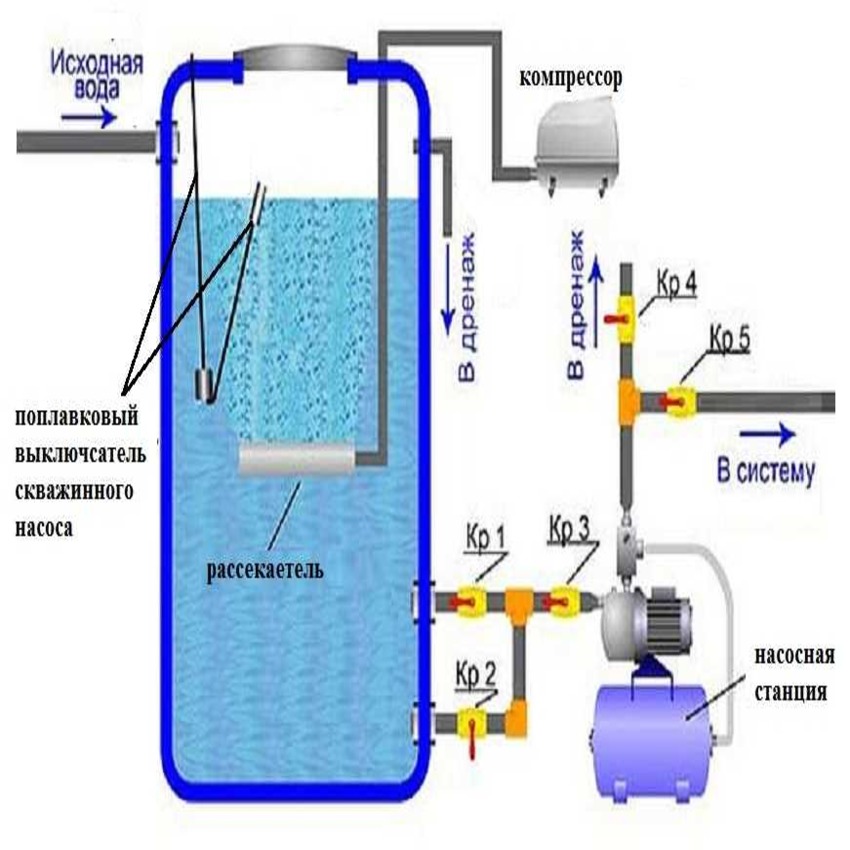

In order not to limit yourself in the ability to use the system water supply, you need to organize the settling of a large volume of water in a capacious tank installed in the attic of the house.From it, it will be supplied to the house water supply in the country. You can do this yourself by assembling the structure shown in the following diagram:

Scheme of the aerator device for removing iron

Install a large polyethylene or stainless steel tank in the attic or in the attic room. The size of the tank should be such that 70-75% of its volume covers your daily water requirement;

- Bring water from the well to the top of the tank. To prevent overflow, it must be supplied through a float valve, which you can buy or use the one provided with the toilet cistern system;

- To ensure intensive contact of water with atmospheric oxygen, the tank should not be hermetically sealed, and the water supply to it should be organized through sprayers. This can be done by installing special nozzles in the pipe or simply by drilling many small holes in it;

Aquarium compressor

The outlet for purified water should be located 10-20 cm above the bottom. And at the very bottom it is necessary to install a pipe with a tap to remove sediment and flush the tank.

The instruction for using such a cleaning system is simple: water should be drawn into the tank in the evening so that it has time to settle overnight, and clean water can be used all the next day.

This method has many disadvantages, ranging from the impossibility of completely removing iron to the need to control water consumption and regularly clean the tank and filter. But there are also advantages.

This is the presence of a storage tank in case of a pump breakdown or a power outage, as well as the associated purification of water from hydrogen sulfide, which is very often present in the water of artesian wells and spoils its taste and smell.

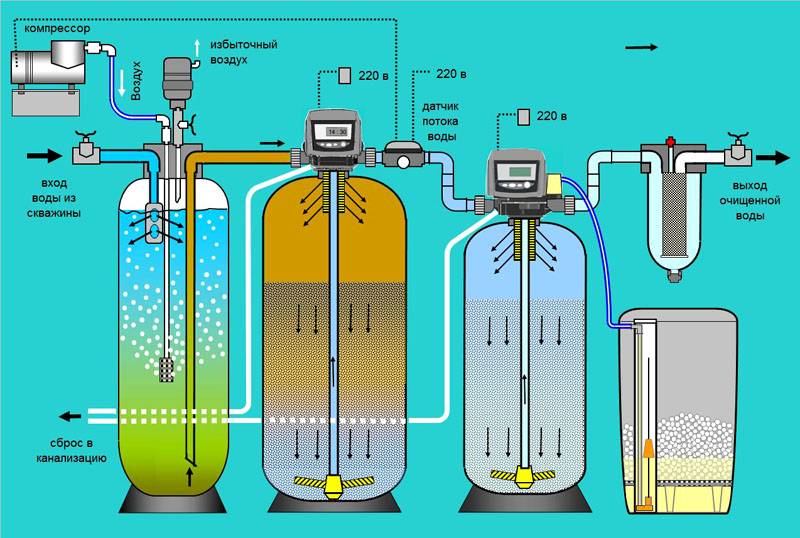

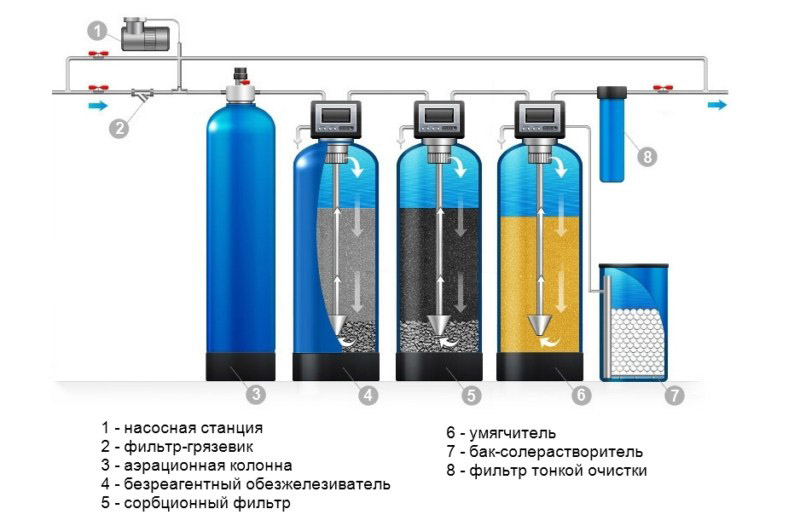

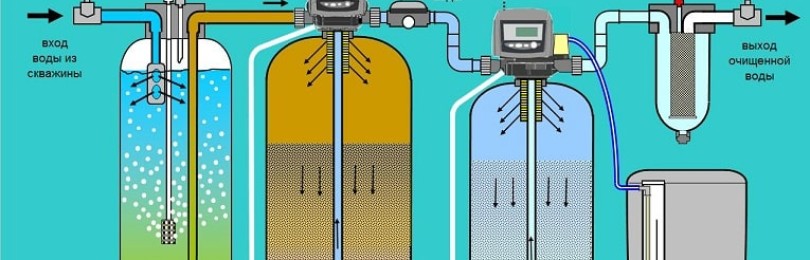

Industrial cleaning systems

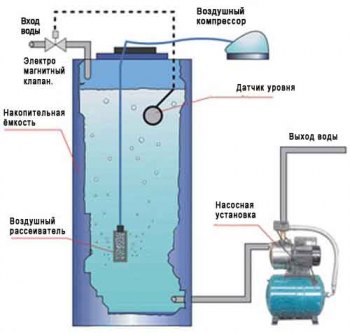

All industrial iron removers work on the same principle as described above, but they are not designed for long-term settling, so they are provided with filters for iron removal from well water, through which water passes after contact with oxygen and oxidizing agents that speed up the process.

The water treatment system may consist of several units connected in series

These devices can be pressure and non-pressure. Water also enters the latter through spray nozzles, and air is forced into it by a compressor.

The difference is that the water treatment system is not installed in the attic, but in the utility room or basement of the house, so it needs to install an additional pump that provides pressure to the network.

Non-pressure aerator device

The cleaning process takes place somewhat differently in pressure units, which are thick-walled sealed cylinders, which can be divided into three types - reagent, reagentless and combined. So:

- Air is supplied to the combined plants using a powerful compressor, after which oxidizing agents are added to oxygenated water, accelerating the process of converting iron into insoluble compounds. Then the treated liquid passes through a filter that retains iron suspensions.

- In reagent systems, water immediately mixes with chemical reagents and enters the filter. But the lack of aeration requires an increase in the dose of the oxidizer and, as a result, its more frequent refueling.

Photo of an industrial plant for iron removal of water

The advantage of all pressure systems is that there is no need for an additional pump - the pressure created by the pump for the well is used in the network.

Folk cleaning methods

What if the water smells a little like iron, but does not change its taste characteristics? Use the available cleaning methods:

- Freezing. Fill the container with water and send to the freezer. After preliminary freezing and ice formation, the remaining liquid is drained. This is necessary in order to get rid of harmful substances that, when frozen, settle to the bottom. When defrosting, water undergoes restructuring and purification.

- Activated carbon. Wrap a few charcoal tablets in thick cotton wool or cotton pads to get a homemade filter. To clean, pass some of the liquid through the filter and drain into a separate container. Such a simple method will allow you to get rid of harmful impurities and eliminate the sedimentary mass.

- Mineralization with silicon and shungite. Natural materials provide safe purification and disinfection of water. Cleaning is carried out as follows: clean stones are laid out on the bottom of the water tank to activate the filtration process, which lasts no more than 2 days. Purified water is safe for domestic and drinking needs. It is also recommended to drain the lower part of the liquid containing sedimentary masses.

Even professional well drilling is not a guarantee of clean drinking water. A source with a high concentration of iron requires high-quality purification.

In order to choose an effective iron removal method, it is recommended to conduct a detailed chemical analysis and determine the reasons why the water is contaminated. At the same time, any owner of a hydraulic structure can solve a similar problem.

Effect of water on iron

The principle of operation of the deironing cleaning plant is based on the fact that ferrous iron oxidizes upon contact with atmospheric oxygen and, turning into trivalent, precipitates. It remains only to speed up this process, for which the water is additionally saturated with oxygen.

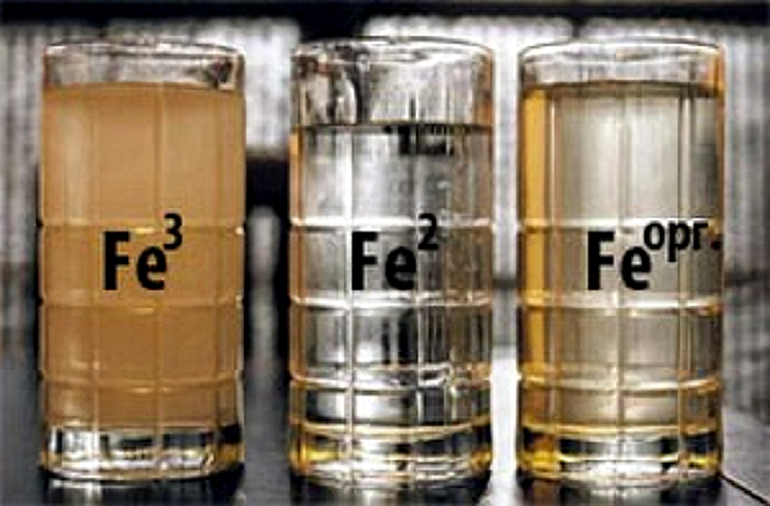

iron water

Valex:

My water treatment system works like this. A submersible pump is installed in the well. It pumps water into a barrel with a volume of 250 liters. The top of the barrel is closed with a lid with holes. On the lid, upside down, I installed a regular plastic bucket of 10 liters. In the center of the bucket, above the lid of a high barrel, there is a watering nozzle, like a shower head, directed to the bottom of the bucket.

Water with an excess of iron, pumped under pressure, flies out of the hole in the watering can and hits the bottom of the bucket. Upon impact, it breaks into water dust and, under the influence of this, is saturated with oxygen to the limit. After that, the drops, already enriched with oxygen, flow down the walls of the bucket and through the drilled holes fall back into the storage barrel.

Valex:

- So, I have implemented aeration. The barrel itself is filled automatically. The water level is regulated by electrodes of different lengths. As soon as it goes down, the submersible well pump turns on.

After the water tank, the forum member mounted another pump that maintains the necessary pressure in the water pressure system of the house.After the pump, a self-made column is installed - a container for a cationite filler, which additionally purifies and softens the water, making it suitable for drinking.

The column is made of a polyethylene pipe with a diameter of 20 cm. The forum member closed the ends of the pipe plastic plugs for stilettos, used rubber from the camera as a gasket.

The container with cation exchanger must be regularly flushed with a reverse flow of water.

Valex:

- Flushing takes about 45 minutes, during the process the borehole pump is turned off, and all wastewater from the storage barrel and column is sequentially (for this, taps are switched) is discharged into the sewer.

The higher the concentration of iron in the water, the faster the cation exchanger “caking”. Therefore, to calculate the frequency of flushing, the following value is taken: on average, 1 liter of cation exchanger absorbs about 1 gram of iron.

Based on the analysis of water and water consumption, the frequency of flushing is calculated. The standard flushing frequency is once every 7 days, but it can be more.

lmv16:

– Even with low water consumption, rinsing should not be done less than 1 time at 2 weeks, the number of baths can even be increased. If you do not regularly backwash, then there is a high probability that the filler will become heavily clogged with iron, and it will have to be picked out of the column with a spatula.

- I would recommend using not a bucket, but an inverted barrel with a neck of a smaller diameter than the storage barrel. And the longer the barrel where aeration takes place, the better.

Such systems for cleaning from excess harmful impurities have become so popular among members of the forum that we can talk about a whole series of home-made non-pressure aeration installations.

OAK-OAK:

- I have an excess of iron levels - 48 mg / l, this is above the norm .. I thought a lot about how to stop harming myself and my family and came to the conclusion that forced aeration is the best way to clean water from excess iron.

Because the amount of impurity went off scale, OAK-OAK modernized the aeration unit by mounting a system of three barrels of 500 liters each.

To speed up the oxidation process, aeration is carried out around the clock.

The hourly air flow supplied by the compressor is 3000 liters/hour. As a result, the concentration dropped to 0.15 mg/l!

Drinking water safe for the body.

At FORUMHOUSE you will learn about the features of choosing a water supply and heating system, read about all the nuances of installing a home-made water treatment system. Get to know the story about how our forum member independently assembled non-pressure aeration unit.

We have collected all the experience of FORUMHOUSE users on home-made water treatment systems.

In our video you will learn about the latest innovations in water treatment systems. And from another one about the water supply system of the house from a well based on a condensing boiler.

In what cases is it required?

In order to verify the presence of iron impurities, first the water must be carefully examined immediately after pumping out, then after some time after settling.

- The presence of iron oxides and hydroxides is detected by the presence of red-brown impurities in the solution. If such water is allowed to stand, after a short time a brown precipitate will appear at the bottom.

- Ions of ferrous iron have no color, they are not visible in the solution. After a short exposure to air, they oxidize, due to which the liquid acquires a red color.Gradually, a brown precipitate forms at the bottom.

- Iron in the trivalent state immediately gives the color of the liquid. If such ions are present in the solution, it has a reddish color.

- Sometimes in water from wells there are iron-organic compounds, the presence of which is indicated by a red film with iridescent highlights on the surface.

For food purposes, technical needs, it is impossible and impossible to use water with iron impurities.

For food purposes, technical needs, it is impossible and impossible to use water with iron impurities.

In heating appliances, it quickly forms a precipitate and flakes.

When washing, red stains remain on the linen, when washing dishes - brown stains.

Problems begin to be felt when the concentration of iron compounds exceeds 0.5 mg/l.

Reference. The change in taste and color becomes very noticeable at the content of 1 mg of iron in a liter of water.

If the mass of iron impurities reaches 3 mg per liter, then mixers and taps soon fail. In any of these situations, special cleaning is necessary - iron removal.

2.3 Iron removal by ion exchange (iron up to 20 mg/l and in combination with manganese, hardness and organic matter)

Ion exchange technology for iron removal has a number of significant advantages compared to other methods:

— Simple design makes it easy to operate, no need for labor-intensive maintenance, it is only necessary to regularly change the ion exchange resin cartridges in the unit.

- Versatility - it is used for iron removal not only from well water, but also successfully treats wastewater on an industrial scale.Installations for iron removal in domestic conditions, as well as for production facilities, are identical in principle of operation and structural design and differ only in the size of working tanks and the composition of active reagents.

- High efficiency - the maximum level of water purification from iron, as well as other harmful impurities that have the ability to exchange ions.

As a rule, the ion exchange method is resorted to in case of a simultaneous need to reduce the hardness and the iron content in the water. This technology is especially effective at high mineral salt content (100-200 mg/l).

Ion exchange filters use the ability of ion exchangers (ion exchange materials) to replace negatively or positively charged ions in water with the same amount of ion exchanger ions. Ion exchangers are almost water-insoluble compounds of organic or inorganic origin, containing an active anion or cation. Cations replace positively charged salt particles, and anions replace negatively charged ones. Synthetic ion-exchange resins are used as ion exchangers to remove iron and soften water.

Cation exchangers remove almost all divalent metals from water, replacing them with sodium anions.

The design of the ion-exchange filter for deferrization of water from a well consists of:

- a cylinder with a filter load (ion-exchange resin),

- electronically controlled water supply valve,

- containers for regenerating solution.

Scheme of operation of the ion-exchange filter: water comes from the source and flows through the ion-exchange resin that fills the filter, during which the ions of heavy metals and hardness salts are replaced by ions of the filter material.The degasser then removes oxygen and carbon dioxide from the water. Purified water goes to the consumer channel.

One of the advantages of the method is that it is a reversible process and a mechanism for regeneration of the filter media is provided. This is usually done with alkaline or acidic solutions, thus prolonging the lifetime of the plant.

Despite the high efficiency of ion exchange technology for removing iron, there are several points that limit its use:

- Cannot be used to purify water containing trivalent iron, as the filter resin quickly becomes contaminated and becomes unusable.

- The presence of oxygen and other oxidizing substances in water is also unacceptable, as it leads to the formation of iron in solid form.

- The pH value should be no more than 6.5 in view of the above points.

- It is recommended to use an ion-exchange filter where an increased concentration of iron is observed in combination with excessive hardness, otherwise it will be irrational.

Rice. 4 Ion exchange filter

Ion exchange plants can be used in any field. For domestic use, there are compact filters that also work on the basis of ionic resin. For industrial production, equipment is on a larger scale. To increase productivity, you can install several ionic columns. Most often this is provided in industrial production. The bottom line is that two or three columns with ion loading are installed. They can work both simultaneously and in turn. With variable device filtering, regeneration also starts in turn.That is, first, a supply of ionic resin is produced in the first column, it goes to regeneration, and the second one is turned on. When the second flush time comes up, the first one is activated again. When installing three or more ion plants, they can also work several at a time. They are connected by a control unit. It is installed on each column separately or combines everything at once. It is this element that monitors the sequence of equipment operation and the beginning of the regeneration mode.

The ionic method allows not only to remove iron impurities, but also to soften the water at the same time. The ionic resin allows iron impurities to be removed without prior oxidation. At the same time, the cost of operating the system will remain the same. Ionic resin requires only regeneration with saline. And it is desirable to automate the system.

Permissible concentration

In water from wells, even deep water, the metal concentration can range from 0.6 to 21 mg/l.

How to understand that the concentration of iron in the water is increased?

Signs by which you can determine the excess without analysis:

- The taste of unboiled and unfiltered water has a metallic taste and smell. If the concentration exceeds 1.2 mg / l, the taste will be felt even in drinks (tea, coffee) and in boiled water.

- On the plumbing (sink, toilet, in the bathroom, shower) there are reddish streaks, sometimes with sediment.

To more accurately identify the problem, you can:

- Make a paid analysis. The approximate cost of a comprehensive analysis for the content of various impurities is 3000-3500 rubles.

- Pour unboiled water into a glass and leave to stand overnight. If a reddish precipitate appears after 1-2 days, the iron concentration is exceeded.

- Use an aquarist kit (costs about 1000-1200 rubles).It is used specifically for the determination of iron, according to the instructions.

- Use potassium permanganate. If half a glass of potassium permanganate pour 2-3 tbsp. l. water, and the solution will turn dirty yellow - there is a lot of iron in the liquid, and you can’t drink it.

- Use sulfosalicylic acid, ammonia and ammonia. The recipe is as follows: 1 ml of ammonia, 1 ml of sulfosalicylic acid and 1 ml of ammonia are taken. The reagents are poured into 25 ml (1 tablespoon) of water and stirred. If after 15 minutes the solution becomes yellowish, the concentration of the metal is increased.

Folk recipes for water purification

- Stand in the air. The easiest and cheapest, but long way. It is necessary to fill the container with water and leave for several hours (for example, from morning to evening). At the end of the time, most of the water, about ⅔, can be poured into another clean container through 5 layers of gauze. The remaining water will contain particles of oxidized iron, as well as mechanical impurities: sand, lime, clay. Also, in the case of the presence of chlorine, it will also “evaporate” from the water during this time.

- To freeze. In winter, this method is easy to implement: water is poured into a container and taken out. At other times of the year - in the freezer. Make sure the water is about three-quarters frozen. Pour out the rest of the water. What you need is ice. In the case of a large amount of large contamination, 1 more stage will be added to the beginning of the method. After installing the water container in the freezer, you need to track the moment when the water is covered with the first crust. It usually contains basic debris and large impurities. This ice should be carefully removed. This option also applies to the budget.

- Boil. Unlike those described, this method has an undeniable plus: water disinfection.After the water boils, it must be left on a small fire for about 1 hour. Harmful impurities will precipitate inside the container. The disadvantages include water loss and the need to remember about water.

- “Home Reagent”: clean with activated charcoal. In addition to iron, ordinary pharmaceutical tablets will remove unpleasant odors and lime particles. Cleaning is done at the rate of 1 tablet per liter of water. To clean 3 liters, you need to wrap 3 tablets of coal in a filter cloth (for example, gauze), and immerse them in a tank with 3 liters of water for 12 hours. After a while, the water will be much cleaner both externally and chemically.

- Silicon cleaning. The method is more complicated, since this chemical element is somewhat more difficult to find. But it is also more effective: in addition to iron, it removes a number of bacteria and metal salts. Principle of operation: put a piece of silicon in a container with water for 4-8 days. Just as in the previous methods, the lower layer of water is disposed of, the rest is usable. In addition to draining contaminated water, it is also necessary to clean the reagent itself from sediment.

Important Points

Water purified by one of the listed methods will not necessarily be potable, since other harmful impurities may remain in it. And we do not recommend drinking it.

Buying a filter in a store without a preliminary analysis is also not recommended, especially in case of serious water problems. In case of serious pollution, a complex of cleaning plants is often needed, often from different manufacturers.

If you decide to take the issue of water purification seriously and buy a ready-made filter, it is important to first study the nuances of care.There are many different options, and if someone is satisfied with cleaning the cartridges every six months, then it is easier for another to buy and install a new one.

Fluid collection for bacteriological examination

Analyzes for organoleptic and radiological impurities do not require such a thorough and thorough approach to material sampling

- For this analysis, you need to purchase exclusively sterile containers (as sanitary standards say).

- If your well is not new, it should be treated with sodium hypochlorite. The same applies to the new source.

- The tap from which water will be drawn must be burned or treated with medical alcohol.

- When taking liquid, do not touch the neck of the bottle with your hands (it is better to wear sterile gloves), and the neck of the tank - to the tap.

- After drinking water is taken, we tightly tighten the lid and send the water to the laboratory in a short time to identify its tank composition.

How is water analyzed?

Having drilled a well on the site, it is impossible to use water immediately

It is important to carry out an appropriate chemical analysis to ensure that the water quality is correct. This is a question of liquid safety for health, not a whim of marketers

How water is analyzed

Thus, the analysis is performed by certain organizations that have the appropriate authority, license and equipment. Do not be fooled by the low cost of services - it is better to choose a proven laboratory. In the case of working with intermediaries, you can get false test results.

The one who will perform the analysis must take water samples. When the well is drilled, you can invite a specialist.It is advisable to call laboratory assistants a couple of weeks after the construction of the well - then there will be less various contaminants and other third-party substances in the water that got into the reservoir during the construction of the well.

How to recognize the presence of iron in water

Water is taken into clean laboratory glassware to avoid errors

If samples are taken on their own, then it is important to follow simple rules: take water with clean hands into a container that does not smell of anything and is well washed. Moreover, before taking the liquid, rinse the container with this same liquid a couple of times.

It is better to drive water through the well for 5 minutes before sampling. Pour water into the container in a thin stream along the wall of the container to the very top so that there is no room for air to accumulate.

Water analysis result

This is interesting: How to plaster penoplex: we explain the nuances

Purification of water from a well from iron: various methods and technologies

There are a number of different cleaning methods, each of which is good and effective in its own way.

Purification of water from a well in a country house to a drinking state by settling

This method is the simplest in the conditions of a suburban area, where it is possible to place an additional reservoir, the volume of which must correspond to the volume of daily water consumption by the residents of the house. Optimal purification of water from a well in a country house to drinking water is possible only if all installation and operation requirements are met.

Such a solution has a number of advantages, for example, rather low costs and ease of implementation, as well as the possibility of using purified water even in the event of a power outage, and additional purification from hydrogen sulfide.

The disadvantages are the incomplete removal of iron, as well as the need for constant cleaning of sediment accumulated at the bottom of the tank, and control over the water level in it.

Settling is the simplest, but far from the most effective, cleaning method.

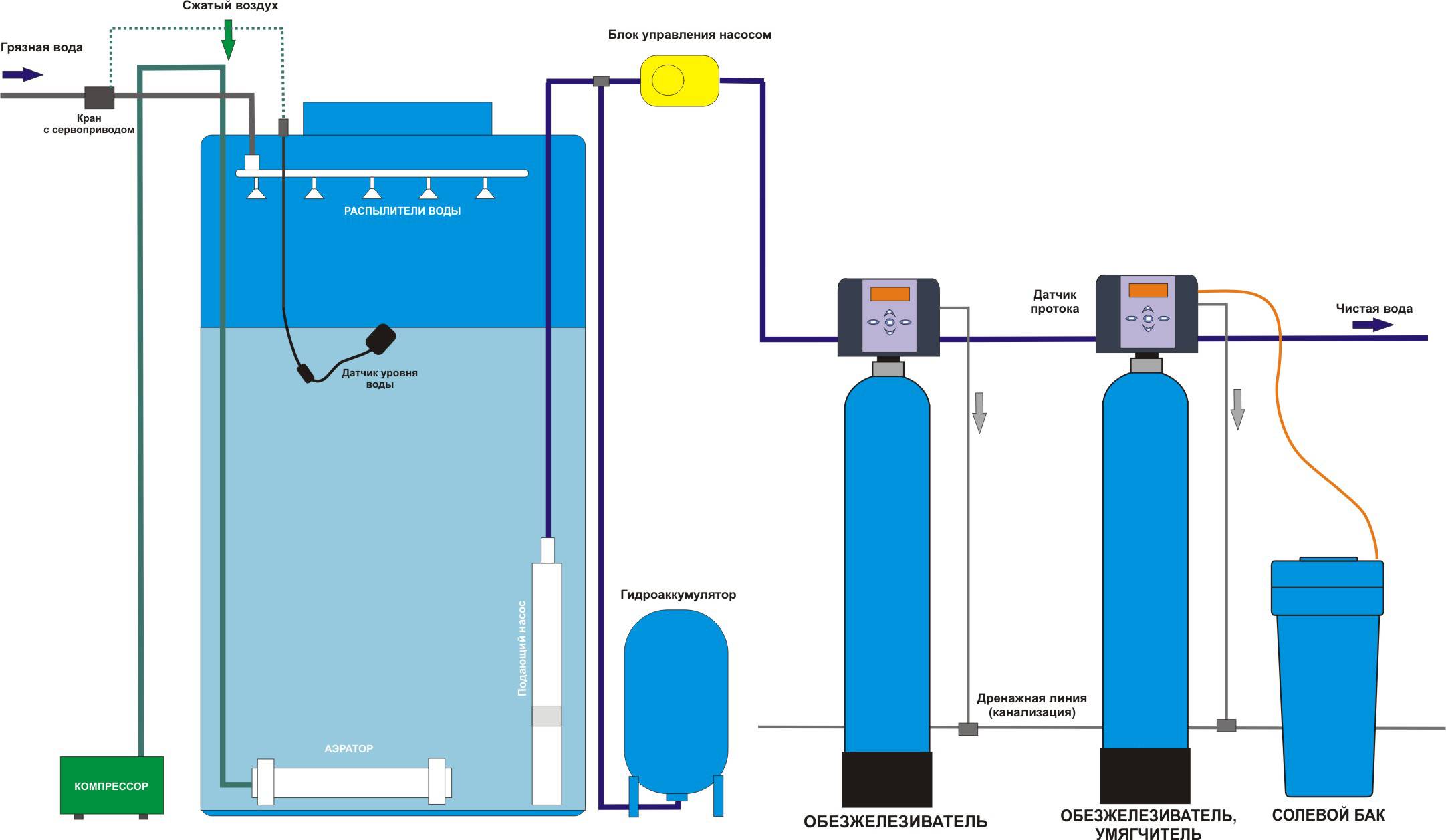

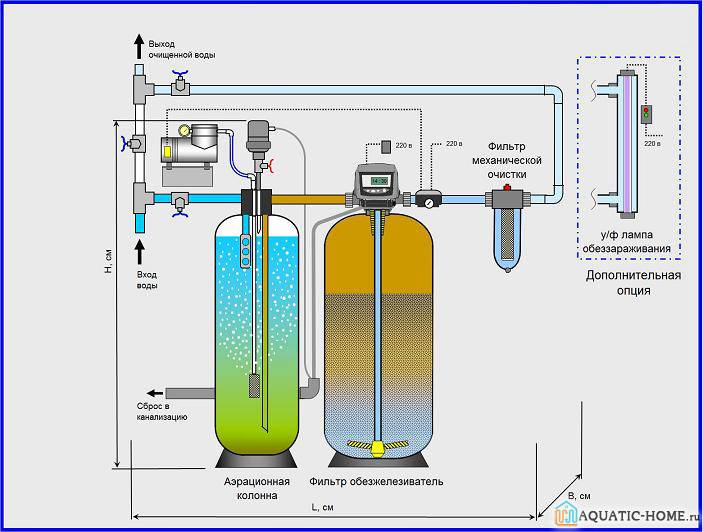

aeration method

This method provides a more complete purification of water from the well than the previous method. The principle of its operation is quite simple: contact of water with air is ensured, where iron impurities react with oxygen. Thus, the element is oxidized and passes into the trivalent state, while precipitating. It is for this that a special filter is installed at the outlet of the tank, which traps particles and prevents them from passing through the water supply system further. An aeration water purification system from iron is an excellent and inexpensive choice for giving.

There are two types of this solution:

- Non-pressure option, which involves the installation of sprayers, and, if desired, to increase the efficiency of the design, a compressor is mounted in the tank itself, which further enriches the water with oxygen.

- The pressure method involves the flow of water under high pressure into a special column, where the pressure of the jet and the action of the compressor provide the most effective cleaning.

Example of a pressurized aeration plant

The advantage of this method is, first of all, its environmental friendliness.

The disadvantages are the need for frequent cleaning of the tank and filter from accumulated contaminants, still not complete elimination of iron and the dependence of the technology on the availability of electricity, which is a rather significant disadvantage in conditions of poor power supply to suburban areas.

Ozonation process

This process is iron removal by introducing special oxidizing agents. Chlorine as such an element was gradually abandoned, since one or another part of it still remains at the outlet, and has a negative impact on human health.

Ozonation is more beneficial than adding bleach

This method is not very suitable for self-installation, since special equipment is quite expensive, and rather complex calculations are also required, which are very difficult to perform without proper knowledge.

Ion exchange method

Such a solution involves the installation of a special filter with free sodium ions, which, reacting with water, are replaced by ions of iron impurities. This method is quite simple, and besides, it is convenient, because such a filter can be installed even in the space under the sink.

Ion exchange method

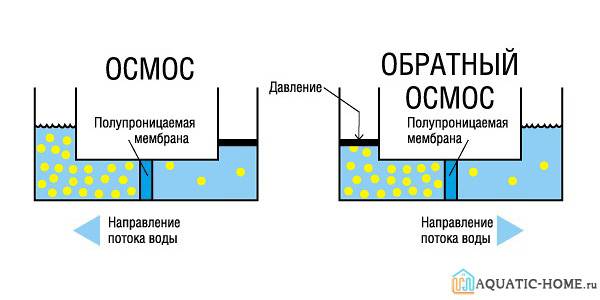

reverse osmosis method

This method is rightfully considered the most effective among all methods of purification from impurities. Such a filtration plant is capable of retaining iron at the molecular level, even in dissolved form.

How a reverse osmosis plant works

However, such a solution involves the installation of a whole structure, which includes pre-filters for water purification from iron to prevent rapid clogging of the main membrane, as well as mineralizers that restore water after its complete desalination.

Mineralizer Example

Application of reagents

Such a solution is most often used in industry, since it requires serious subsequent purification from chemical compounds. However, it can also be used for private homes, for example using sodium hypochlorite. The principle of operation of the reagents is quite simple: when they react with impurities, they form an insoluble precipitate that does not enter the outlet water with the help of a filtration system.

Sodium hypochlorite can be used at home, unlike many other elements

Do-it-yourself water purification from iron from a well

Water with a high iron content is unsuitable for drinking

Before proceeding with the purification of well water, they are convinced that it contains a large amount of ferrous iron.

- To verify the presence of a chemical, you need to keep a small amount of well water in an open container for a while. At first, it does not manifest itself in any way, but upon prolonged contact with air, it precipitates a brown color.

- A clear sign of a high concentration of a substance in water is an unpleasant specific odor from the well.

- It is possible to calculate the presence of bacterial iron in water “by eye” if there are iridescent films on the surface of the water mirror.

The yellow tint of water indicates an increased content of organic iron in it (not bacterial!), but when settling, it does not precipitate.

Purifying water from iron from a well in the old-fashioned way is quite simple and not financially expensive.

settling

This is the least expensive and easiest to implement method of deferrization of well water. A self-made system is additionally equipped with a tank, the volume of which corresponds to the total daily consumption of all households. The method has both advantages and disadvantages.

Advantages:

- Mounting the tank in the attic will ensure gravity flow, and this will save the liquid from hydrogen sulfide.

- An easy-to-implement method that does not require large waste.

- There is always a purified volume of liquid in stock.

Aeration

Water aeration

Using this method provides excellent cleaning results. The filtration process is quite simple - an oxygen-enriched environment reacts with iron, as a result, the latter decomposes and precipitates. At the outlet after cleaning, the solid particles of the sludge are retained by mechanical filters.

Advantages:

- Purification of well fluid from iron and hydrogen sulfide.

- Environmentally friendly cleaning, since it is a reagentless method.

Of the shortcomings, only one is distinguished - a small percentage of iron still remains in the composition.

Introduction of catalysts and reagents

In industry, in order to purify fluid from a well, I use chlorine or ozone. The peculiarity of these substances lies in their high oxidizing ability, however, for their production, special installations are required. At home, chemicals are not recommended for use due to their high toxic ability.

As an analogue, it is preferable to use grains or granules of activated glauconite clay, the surfaces of which are equipped with particles of oxidized manganese.

Folk ways

Calcite for water treatment

The most common, safe and budgetary way to clean well fluid is to clean the streams with lime and then pass through a thick layer of natural calcite. This process leads to the fact that iron is transformed into an insoluble salt. This makes the water softer and more drinkable. This purification method can also be used in cases where the composition of the well fluid fully meets the requirements for use.

Excellent results can be achieved using the dry method. In this case, heated potassium permanganate is used

Approximately 4-5 g of the active substance is placed in a tank made of ceramic or fire-resistant glass. Potassium permanganate is slowly and carefully heated in a sand bath. The container must be covered with a lid

This volume of the active substance will be enough to purify 5 liters of water.

Ozonation

This process is effective, but it is not easy to implement. It is almost impossible to clean the liquid in this way on your own at home. The use of chlorine is no longer in such high demand, since this substance partially remains in the liquid and poisons the human body when consumed.

Ozonation is the most reliable and high-quality method of purification. The method is implemented by the action of ozone on the particles contained in the liquid.