- Introduction

- LNG is the fuel of the 21st century

- Prospects for liquefied hydrogen

- Fire/explosion risk and mitigation

- Why liquefy natural gas?

- Economics and safety of transportation

- Use in various fields

- Properties and abilities of liquefied propane, butane and methane

- Liquefied petroleum gas - why is it better than other fuels

- Gas cooling

- US gas

- Advantages of liquefied gas

- Octane number

- Diffusion

- Tank pressure

- Exhaust

- impurities

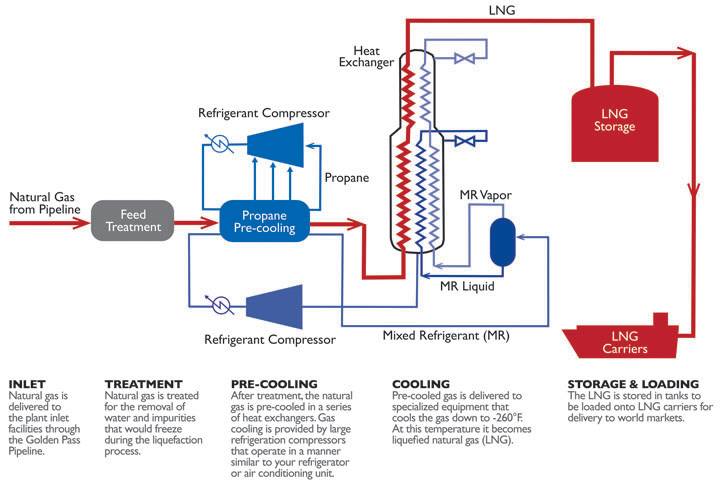

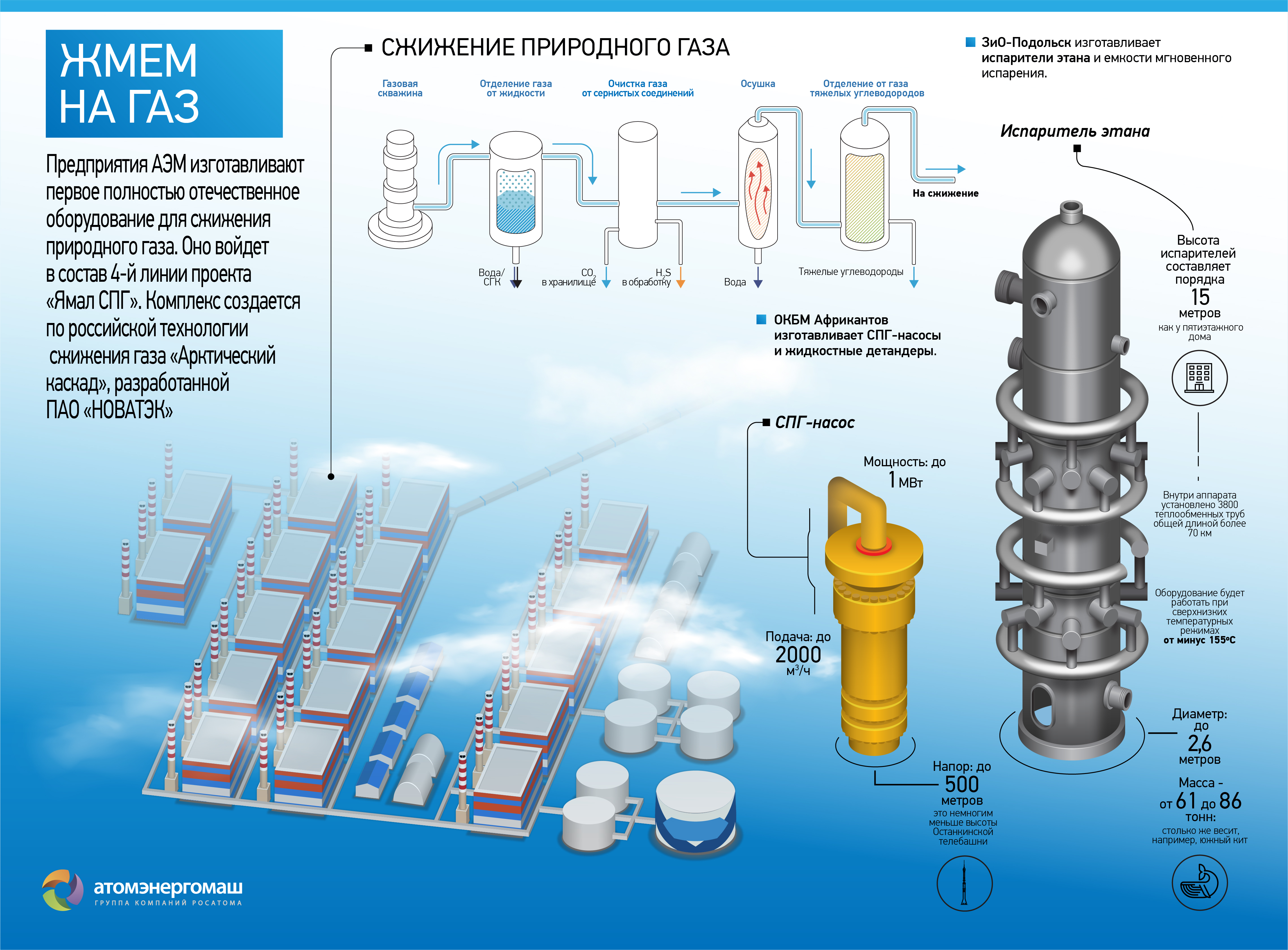

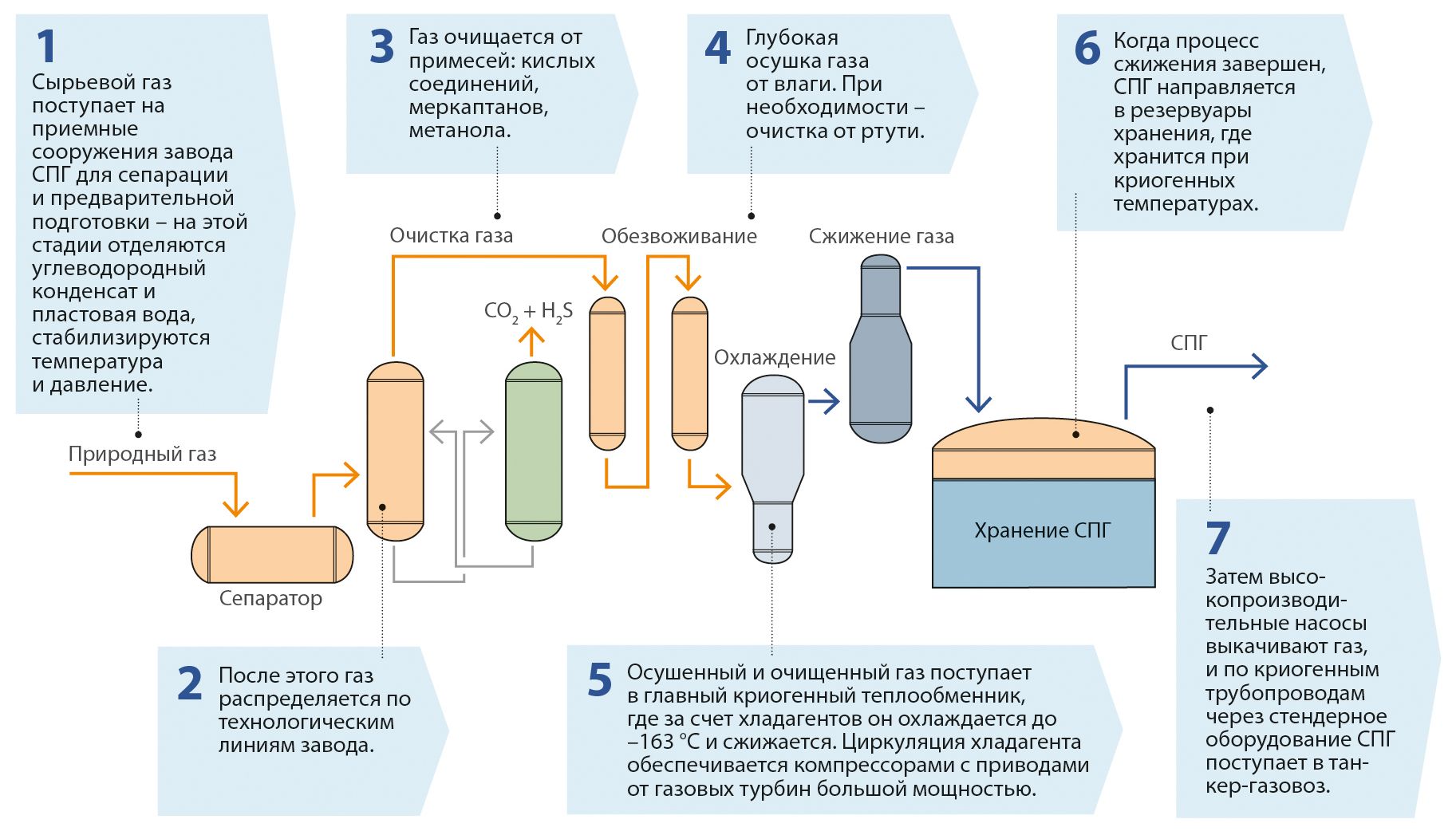

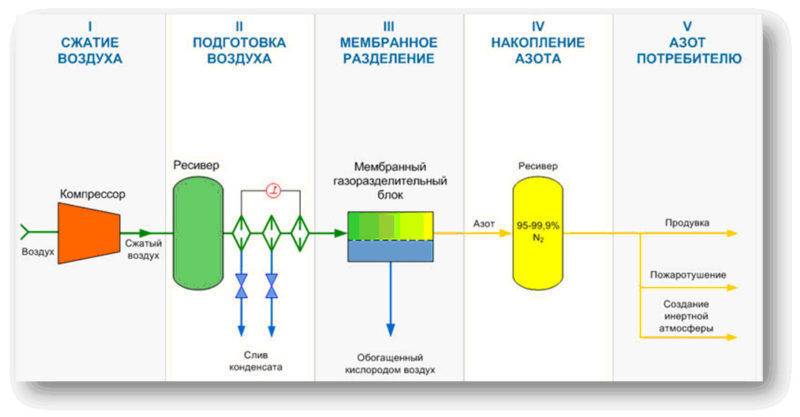

- Production process

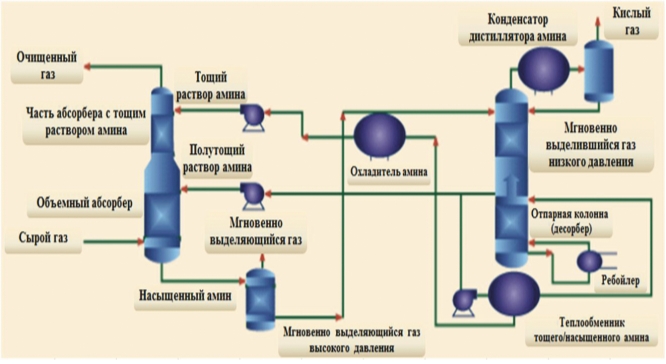

- Gas purification and liquefaction

- How to obtain

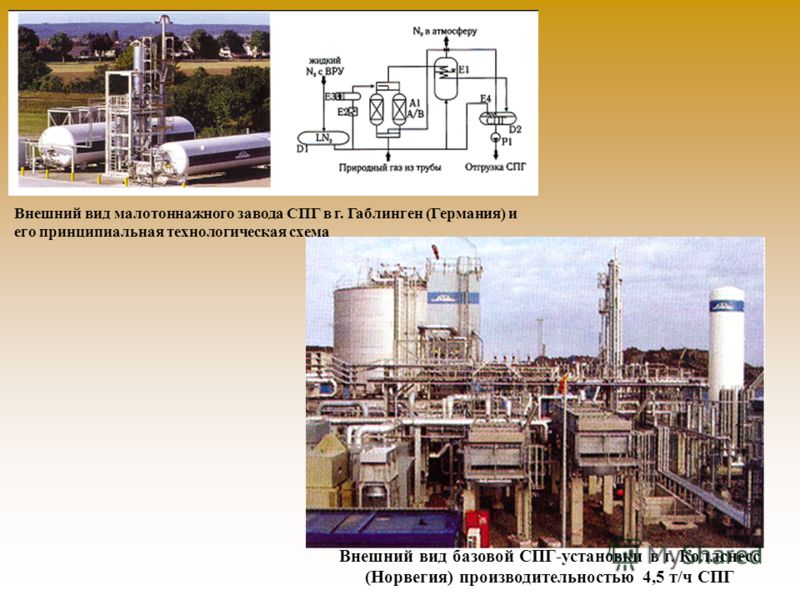

- Construction of an LNG plant

- LNG and investments

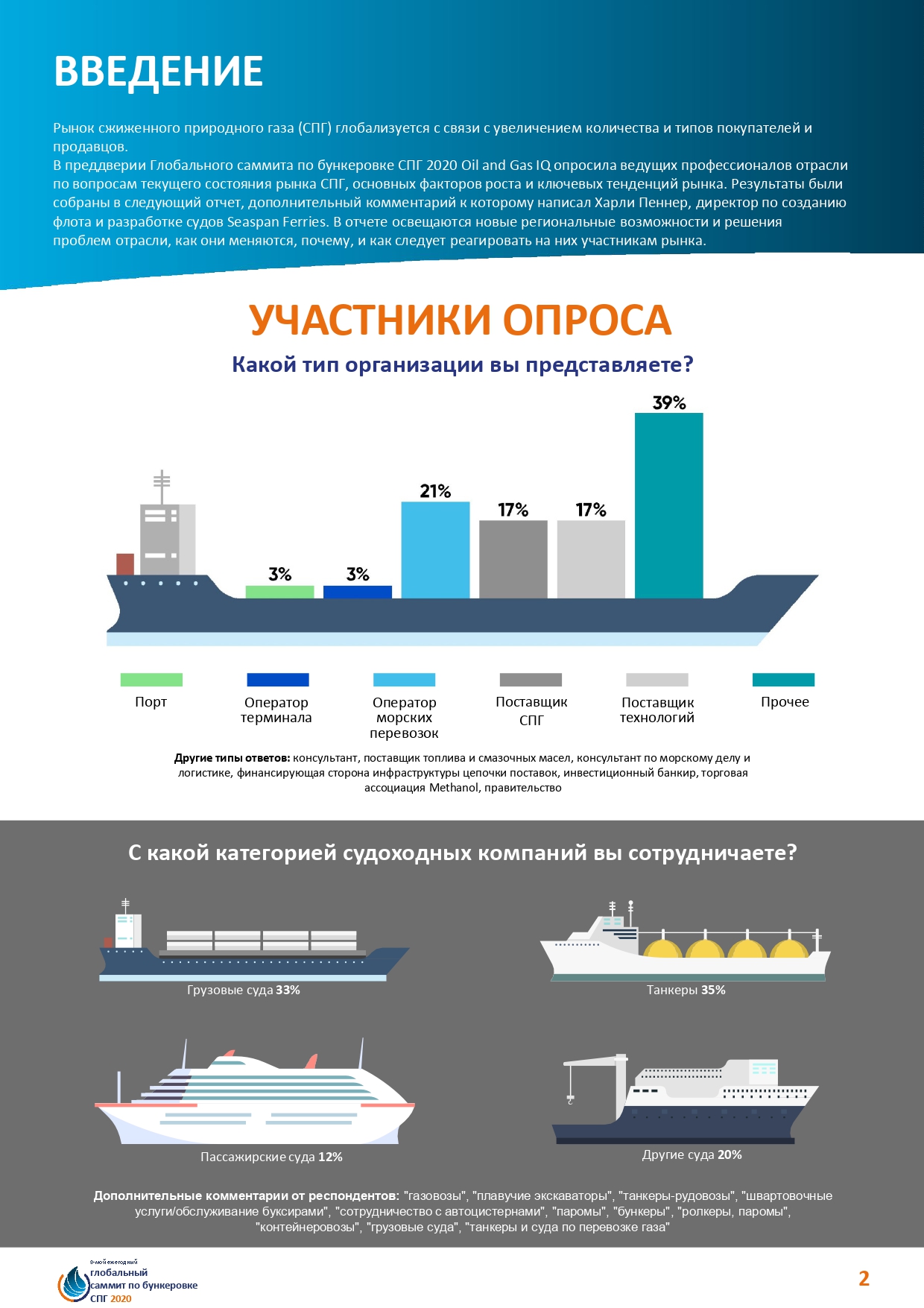

Introduction

Currently, in boiler houses that are part of the infrastructure of railway transport enterprises, in most cases, coal and fuel oil serve as an energy source, and diesel fuel is a reserve. So, for example, an analysis of the heat supply facilities of the Oktyabrskaya Railway, a branch of Russian Railways, showed that the boiler houses mainly operate on fuel oil, and only some of them run on natural gas.

The advantages of fuel oil boilers include their complete autonomy (the possibility of using them for facilities remote from gas mains) and the low cost of the fuel component (in comparison with coal, diesel and electric boilers), the disadvantages are the need to organize a storage facility, ensure the supply of fuel oil, control fuel quality, problems environmental pollution. When delivering fuel in large volumes, it is necessary to organize an unloading system (heating and draining fuel oil) and access roads, the need to heat storage facilities and fuel oil pipelines for transporting fuel to boilers, and additional costs for cleaning heating heat exchangers and fuel oil filters.

In connection with the expected sharp increase in fees for harmful emissions into the atmosphere, the Central Directorate for Heat and Water Supply of Russian Railways decided to reduce the use of fuel oil in railway boilers. In the Murmansk region, where part of the Oktyabrskaya railway passes, a project is presented aimed at reducing the fuel oil dependence of city and district boiler houses, including the option of switching them to liquefied natural gas (LNG). It is planned to build an LNG plant in Karelia and a gas infrastructure in the Northwestern Federal District.

Moving away from fuel oil will increase the efficiency of boiler houses in the Murmansk region by 40%.

LNG is the fuel of the 21st century

In the near future, Russia may become one of the leading producers and suppliers to the world market of liquefied natural gas, a relatively new type of alternative fuel for our country.Of all natural gas produced in the world, more than 26% is liquefied and transported in liquid form in special tankers from the countries of production to the countries of gas consumers.

Liquefied natural gas has significant advantages over other energy carriers. They can provide non-gasified settlements in a short time. In addition, liquefied natural gas is the most environmentally friendly and safe of the mass-used fuels, and this opens up broad prospects for its use in industry and transport. Today, several options are being considered for the construction of natural gas liquefaction plants in Russia and terminals for its shipment for export, one of which is supposed to be implemented in the port of Primorsk, Leningrad Region.

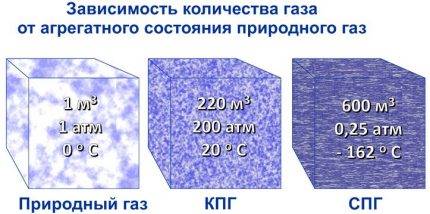

Liquefied natural gas as an alternative fuel has a number of advantages. First, the liquefaction of natural gas increases its density by 600 times, which increases the efficiency and convenience of storage and transportation. Secondly, LNG is non-toxic and non-corrosive to metals, it is a cryogenic liquid that is stored under a slight overpressure at a temperature of about 112 K (-161 °C) in a container with thermal insulation. Thirdly, it is lighter than air, and in the event of an accidental spill, it evaporates quickly, unlike heavy propane, which accumulates in natural and artificial depressions and creates an explosion hazard. Fourthly, it makes it possible to gasify objects located at considerable distances from main pipelines. LNG today is cheaper than any petroleum fuel, including diesel, but surpasses them in terms of calories.Boilers operating on liquefied natural gas have a higher efficiency - up to 94%, do not require fuel consumption for preheating it in winter (like fuel oil and propane-butane). The low boiling point guarantees complete vaporization of the LNG at the lowest ambient temperatures.

Prospects for liquefied hydrogen

In addition to direct liquefaction and use in this form, another energy carrier, hydrogen, can also be obtained from natural gas. Methane is CH4, propane is C3H8, and butane is C4H10.

The hydrogen component is present in all these fossil fuels, you just need to isolate it.

The main advantages of hydrogen are environmental friendliness and wide distribution in nature, however, the high price of its liquefaction and losses due to constant evaporation negate these advantages.

In order to transfer hydrogen from a gas state to a liquid, it must be cooled to -253 ° C. For this, multi-stage cooling systems and “compression/expansion” units are used. So far, such technologies are too expensive, but work is underway to reduce their cost.

We also recommend reading our other article, where we described in detail how to do hydrogen generator for home with your own hands. More details - go.

Also, unlike LPG and LNG, liquefied hydrogen is much more explosive. Its slightest leakage in combination with oxygen gives a gas-air mixture, which ignites from the slightest spark. And storage of liquid hydrogen is possible only in special cryogenic containers. There are still too many disadvantages of hydrogen fuel.

Fire/explosion risk and mitigation

A spherical gas container commonly used in refineries.

In a refinery or gas plant, LPG must be stored in pressurized tanks. These containers are cylindrical, horizontal or spherical. Usually these vessels are designed and manufactured in accordance with some rules. In the United States, this code is governed by the American Society of Mechanical Engineers (ASME).

LPG containers have safety valves so that when exposed to external heat sources, they release LPG to the atmosphere or flare stack.

If a tank is exposed to a fire of sufficient duration and intensity, it may be subject to a boiling liquid expanding vapor explosion (BLEVE). This is usually a concern for large refineries and petrochemical plants that handle very large containers. As a rule, tanks are designed in such a way that the product will exit faster than the pressure can reach a dangerous level.

One of the means of protection that is used in industrial environments is to equip such containers with a measure that provides a degree of fire resistance. Large spherical LPG containers can have steel walls up to 15 cm thick. They are fitted with a certified pressure relief valve. A large fire near the vessel will increase its temperature and pressure. The top safety valve is designed to relieve excess pressure and prevent the destruction of the container itself.With sufficient duration and intensity of the fire, the pressure created by the boiling and expanding gas may exceed the ability of the valve to remove the excess. If this happens, the overexposed container can rupture violently, ejecting parts at high speed, while the released products can also ignite, potentially causing catastrophic damage to anything in the vicinity, including other containers.

People can be exposed to LPG in the workplace through inhalation, skin contact and eye contact. The Occupational Safety and Health Administration (OSHA) has set the legal limit (Permissible Exposure Limit) for LPG exposure in the workplace at 1,000 ppm (1,800 mg/m 3 ) over an 8-hour workday. The National Institute for Occupational Safety and Health (NIOSH) has set a recommended exposure limit (REL) of 1,000 parts per million (1,800 mg/m 3 ) over an 8-hour workday. At 2000 ppm levels, 10% lower explosive limit, liquefied petroleum gas is considered directly dangerous to life and health (only for safety reasons related to the risk of explosion).

Why liquefy natural gas?

Blue fuel is extracted from the bowels of the earth in the form of a mixture of methane, ethane, propane, butane, helium, nitrogen, hydrogen sulfide and other gases, as well as their various derivatives.

Some of them are used in the chemical industry, and some are burned in boilers or turbines to generate heat and electricity. Plus, a certain volume of the extracted is used as gas engine fuel.

Calculations by gas workers show that if blue fuel needs to be delivered over a distance of 2,500 km or more, then it is often more profitable to do it in liquefied form than by pipeline

Calculations by gas workers show that if blue fuel needs to be delivered over a distance of 2,500 km or more, then it is often more profitable to do it in liquefied form than by pipeline

The main reason for liquefying natural gas is to simplify its transportation over long distances. If the consumer and the gas fuel production well are located close to each other on land, then it is easier and more profitable to lay a pipe between them. But in some cases, building a highway turns out to be too expensive and problematic due to geographical nuances. Therefore, they resort to various technologies for producing LNG or LPG in liquid form.

Economics and safety of transportation

After the gas is liquefied, it is already in the form of a liquid pumped into special containers for transportation by sea, river, road and/or rail. At the same time, technologically, liquefaction is a rather costly process from an energy point of view.

At different plants, this takes up to 25% of the original fuel volume. That is, to generate the energy required by the technology, one has to burn up to 1 ton of LNG for every three tons of it in finished form. But natural gas is now in great demand, everything pays off.

In liquefied form, methane (propane-butane) occupies 500–600 times less volume than in a gaseous state

In liquefied form, methane (propane-butane) occupies 500–600 times less volume than in a gaseous state

As long as natural gas is in a liquid state, it is non-flammable and non-explosive. Only after evaporation during regasification, the resulting gas mixture is suitable for combustion in boilers and cooking stoves. Therefore, if LNG or LPG is used as a hydrocarbon fuel, then they must be regasified.

Use in various fields

Most often, the terms "liquefied gas" and "gas liquefaction" are mentioned in the context of the transportation of a hydrocarbon energy carrier. That is, first, blue fuel is extracted, and then it is converted into LPG or LNG. Further, the resulting liquid is transported and then again returned to the gaseous state for a particular application.

LPG (liquefied petroleum gas) is 95% or more of a propane-butane mixture, and LNG (liquefied natural gas) is 85–95% methane. These are similar and at the same time radically different types of fuel.

LPG (liquefied petroleum gas) is 95% or more of a propane-butane mixture, and LNG (liquefied natural gas) is 85–95% methane. These are similar and at the same time radically different types of fuel.

LPG from propane-butane is mainly used as:

- gas engine fuel;

- fuel for injection into gas tanks of autonomous heating systems;

- liquids for filling lighters and gas cylinders with a capacity of 200 ml to 50 liters.

LNG is usually produced exclusively for long-distance transportation. If for storage of LPG there is enough capacity that can withstand a pressure of several atmospheres, then for liquefied methane, special cryogenic tanks are required.

LNG storage equipment is highly technological and takes up a lot of space. It is not profitable to use such fuel in passenger cars due to the high cost of cylinders. LNG trucks in the form of single experimental models are already driving on the roads, but this “liquid” fuel is unlikely to find wide application in the passenger car segment in the near future.

Liquefied methane as a fuel is now increasingly used in operation:

- railway diesel locomotives;

- sea vessels;

- river transport.

In addition to being used as an energy carrier, LPG and LNG are also used directly in liquid form in gas and petrochemical plants. They are used to make various plastics and other hydrocarbon-based materials.

Properties and abilities of liquefied propane, butane and methane

The main difference between LPG and other types of fuel is the ability to quickly change its state from liquid to gaseous and vice versa under certain external conditions. These conditions include the ambient temperature, the internal pressure in the tank, and the volume of the substance. For example, butane liquefies at a pressure of 1.6 MPa if the air temperature is 20 ºС. At the same time, its boiling point is only -1 ºС, so in severe frost it will remain liquid, even if the cylinder valve is opened.

Propane has a higher energy density than butane. Its boiling point is -42 ºС, therefore, even in harsh climatic conditions, it retains the ability to rapidly form gas.

The boiling point of methane is even lower. It passes into a liquid state at -160 ºС. LNG is practically not used for domestic conditions, however, for import or transportation over long distances, the ability of natural gas to liquefy at a certain temperature and pressure is of great importance.

transportation by tanker

Any liquefied hydrocarbon gas has a high coefficient of expansion. So, in a filled 50-liter cylinder contains 21 kg of liquid propane-butane. When all the “liquid” evaporates, 11 cubic meters of a gaseous substance is formed, which is equivalent to 240 Mcal. Therefore, this type of fuel is considered one of the most efficient and cost-effective for autonomous heating systems. You can read more about it here.

When operating hydrocarbon gases, it is necessary to take into account their slow diffusion into the atmosphere, as well as low flammability and explosive limits when in contact with air. Therefore, such substances must be handled correctly, taking into account their properties and special safety requirements.

Property table

Liquefied petroleum gas - why is it better than other fuels

The industry of LPG application is quite wide, which is due to its thermophysical characteristics and operational advantages compared to other types of fuel.

Transportation. The main problem of delivering conventional gas to settlements is the need to lay a gas pipeline, the length of which can reach several thousand kilometers. Transportation of liquefied propane-butane does not require the construction of complex communications. For this, ordinary cylinders or other tanks are used, which are transported by road, rail or sea transport over any distance. Considering the high energy efficiency of this product (one SPB bottle can cook meals for the family for a month), the benefits are obvious.

produced resources. The purposes of using liquefied hydrocarbons are similar to the purposes of using main gas. These include: gasification of private facilities and settlements, electricity generation through gas generators, operation of vehicle engines, production of chemical industry products.

High calorific value. Liquid propane, butane and methane are very quickly converted into a gaseous substance, the combustion of which releases a large amount of heat.For butane - 10.8 Mcal/kg, for propane - 10.9 Mcal/kg, for methane - 11.9 Mcal/kg. The efficiency of thermal equipment that runs on LPG is much higher than the efficiency of devices that use solid fuel materials as raw materials.

Ease of adjustment. The supply of raw materials to the consumer can be regulated both in manual and automatic modes. To do this, there is a whole range of devices responsible for the regulation and safety of the operation of liquefied gas.

High octane. SPB has an octane rating of 120, making it a more efficient feedstock for internal combustion engines than gasoline. When using propane-butane as a motor fuel, the overhaul period for the engine increases and the consumption of lubricants is reduced.

Reducing the cost of gasification of settlements. Very often, LPG is used to eliminate the peak load on the main gas distribution systems. Moreover, it is more profitable to install an autonomous gasification system for a remote settlement than to pull a network of pipelines. Compared to laying network gas, specific capital investments are reduced by 2-3 times. By the way, more information can be found here, in the section on autonomous gasification of private facilities.

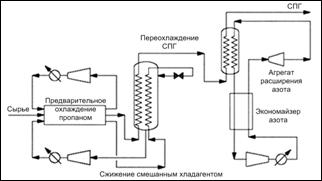

Gas cooling

In the operation of installations, gas cooling systems of different principles can be used. In industrial implementation, there are three main methods of liquefaction:

- cascade - gas sequentially passes through a series of heat exchangers connected to cooling systems with different boiling points of the refrigerant. As a result, the gas condenses and enters the storage tank.

- mixed refrigerants - the gas enters the heat exchanger, a mixture of liquid refrigerants with different boiling points enters there, which, boiling, sequentially reduce the temperature of the incoming gas.

- turbo expansion - differs from the above methods in that the method of adiabatic gas expansion is used. Those. if in classical installations we reduce the temperature due to the boiling of the refrigerant and heat exchangers, then here the thermal energy of the gas is spent on the operation of the turbine. For methane, installations based on turbo-expanders have been used.

US gas

The US is not only the home of reduced gas production technology, but also the largest producer of LNG from its own feedstock. Therefore, when the Donald Trump administration put forward the ambitious Energy Plan - America First program with the goal of making the country the main energy power in the world, all players on the global gas platform should listen to this.

This kind of political turnaround in the US was not much of a surprise. The US Republican position on hydrocarbons is clear and simple. This is cheap energy.

Forecasts for US LNG exports are varied. The biggest intrigue in trade "gas" decisions is developing in the EU countries. Before us is unfolding a picture of the strongest competition between Russian “classic” gas via Nord Stream 2 and American imported LNG. Many European countries, including France and Germany, see the current situation as an excellent opportunity to diversify gas sources in Europe.

As for the Asian market, the trade war between the US and China has led to a complete refusal of Chinese power engineers from imported American LNG.This move opens up huge opportunities for delivering Russian gas through pipelines to China for a long time and in huge volumes.

Advantages of liquefied gas

Octane number

The octane number of gas fuel is higher than gasoline, so the knock resistance of liquefied gas is greater than even the highest quality gasoline. This allows for greater fuel economy in an engine with a higher compression ratio. The average octane number of liquefied gas - 105 - is unattainable for any brand of gasoline. At the same time, the combustion rate of gas is slightly lower than that of gasoline. This reduces the load on the cylinder walls, the piston group and the crankshaft, and allows the engine to run smoothly and quietly.

Diffusion

The gas mixes easily with air and fills the cylinders with a homogeneous mixture more evenly, so the engine runs smoother and quieter. The gas mixture burns completely, so there is no carbon deposits on pistons, valves and spark plugs. Gas fuel does not wash off the oil film from the cylinder walls, and also does not mix with the oil in the crankcase, thus not impairing the lubricating properties of the oil. As a result, cylinders and pistons wear out less.

Tank pressure

LPG differs from other automotive fuels by the presence of a vapor phase above the surface of the liquid phase. In the process of filling the cylinder, the first portions of liquefied gas quickly evaporate and fill its entire volume. The pressure in the cylinder depends on the saturated vapor pressure, which in turn depends on the temperature of the liquid phase and the percentage of propane and butane in it. Saturated vapor pressure characterizes the volatility of the HOS.The volatility of propane is higher than that of butane, therefore, its pressure at low temperatures is much higher.

Exhaust

When burning, less carbon and nitrogen oxides and unburnt hydrocarbons are released than gasoline or diesel fuel, without the release of aromatic hydrocarbons or sulfur dioxide.

impurities

High-quality gas fuel does not contain such chemical impurities as sulfur, lead, alkalis, which enhance the corrosive properties of the fuel and destroy the parts of the combustion chamber, injection system, lambda probe (sensor that determines the amount of oxygen in the fuel mixture), exhaust gas catalytic converter.

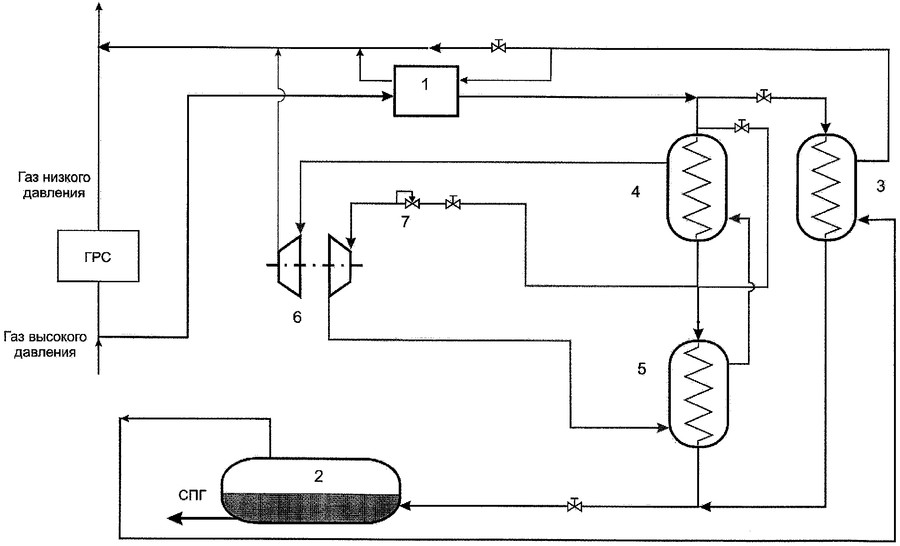

Production process

The feedstock for production is natural gas and refrigerant.

There are two technologies for the production of LNG:

- open cycle;

- nitrogen expansion cycle.

Open cycle technology uses gas pressure to generate the energy needed for cooling. Methane passing through the turbines is cooled and expanded, the output is a liquid. This is a simple method, but it has one significant drawback - only 15% of methane is liquefied, and the rest, not gaining enough pressure, leaves the system.

LNG production technologies

If there are direct gas consumers near the plant, then this technology can be safely used, since it is less expensive - the minimum amount of electricity is spent on the production process. The result is a lower cost of the final product. But if there are no consumers, then it is not economically feasible to use this method - large losses of feedstock.

Production technology using nitrogen:

- in a closed circuit containing turbines and compressors, nitrogen constantly circulates;

- after nitrogen is cooled, it is sent to a heat exchanger, where methane is delivered in parallel;

- the gas is cooled and liquefied;

- nitrogen is sent to the compressor and turbine for cooling and passing through the next cycle.

Membrane gas separation technology

Membrane gas separation technology

The advantages of this technology:

- 100% use of raw materials;

- compactness of the equipment and simplicity of its operation;

- high reliability and safety.

There is only one drawback - high electricity consumption (up to 0.5 kW/h is consumed for every 1 nm3 / h of finished products), which significantly increases the cost.

Nitrogen plant layout diagram

Nitrogen plant layout diagram

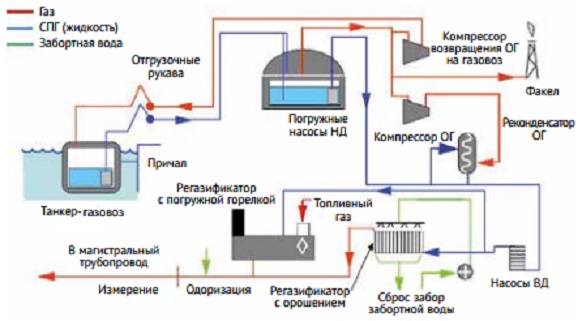

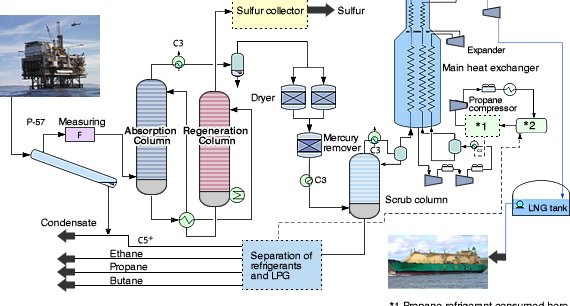

Gas purification and liquefaction

In essence, liquefaction of natural gas is the process of its purification and cooling. Only the temperature required is minus 161 degrees Celsius.

To achieve this order of temperatures, the Joule Thompson effect is used (change in gas temperature during adiabatic throttling - slow gas flow under the action of a constant pressure drop through the throttle). With its help, the temperature of the purified gas drops to the value at which methane condenses. (note requires clarification)

The liquefaction plant must have separate refrigerant treatment and recovery lines. Moreover, individual fractions of gas coming from the field (propane, ethane, methane) can act as a refrigerant at different stages of cooling.

Debutanization is part of the process of distillation of raw materials into fractions, during which fractions, the condensation temperature of which is higher, are separated, which makes it possible to purify the final product from unwanted impurities.Each condensation product is saved as a valuable by-product for export.

Condensate is also added to the final product. Stabilizers, which reduce the vapor pressure of condensate fuel, making it more convenient for storage and transportation. They also make it possible to make the process of transition of methane from a liquid state back to gas (regasification) manageable and less costly for the end user.

How to obtain

LNG is produced from natural gas by compression followed by cooling. When liquefied, natural gas is reduced in volume by about 600 times. The liquefaction process proceeds in stages, at each of which the gas is compressed by 5–12 times, then it is cooled and transferred to the next stage. The actual liquefaction occurs during cooling after the last stage of compression. The liquefaction process thus requires a significant expenditure of energy[source not specified 715 days] from 8 to 10% of its amount contained in liquefied gas.

In the process of liquefaction, various types of installations are used - throttle, turbo-expander, turbine-vortex, etc.

Construction of an LNG plant

Typically, an LNG plant consists of:

- gas pretreatment and liquefaction plants;

- LNG production lines;

- storage tanks;

- tanker loading equipment;

- additional services to provide the plant with electricity and water for cooling.

- Liquefaction Technology

Liquefaction processes of large LNG plants:

- AP-C3MRTM - Air Products & Chemicals, Inc. (APCI)

- AP-X - Air Products & Chemicals, Inc. (APCI)

- #AP-SMR (Single Mixed Refrigerant) - Air Products & Chemicals, Inc. (APCI)

- Cascade-ConocoPhillips

- MFC (mixed fluid cascade) - Linde

- PRICO (SMR) - Black & Veatch

- DMR (Dual Mixed Refrigerant)

- Liquefin-Air Liquide

LNG and investments

High metal intensity, complexity of the technological process, the need for serious capital investments, as well as the duration of all processes associated with the creation of infrastructure facilities of this kind: justification of investments, tender procedures, attraction of borrowed funds and investors, design and construction, which is usually associated with serious logistical difficulties, — create obstacles to the growth of production in this area.

In some cases, mobile liquefaction plants may be a good option. However, their peak performance is very modest, and the energy consumption per unit of gas is higher than that of stationary solutions. In addition, the chemical composition of the gas itself can become an insurmountable obstacle.

To reduce risks and ensure return on investment, plans are being developed for the operation of plants for 20 years in advance. And the decision to develop a field often depends on whether a given area is able to supply gas for a long period of time.

Plants are developed for a specific site and technical conditions, which are largely determined by the composition of the incoming gas feedstock. The plant itself is organized according to the principle of a black box. At the input of raw materials, at the output of products, which requires minimal participation of personnel in the process.

The composition of the site equipment, its quantity, capacity, sequence of procedures that are required to prepare the gas mixture for liquefaction are developed for each specific plant in accordance with the requirements of the Customer and consumers of products.