- Work technique. Step-by-step instruction

- Benefits and disadvantages

- Mineral wool and polyethylene foam

- Rules to follow

- Foamed polyethylene

- Where to insulate

- A simple solution

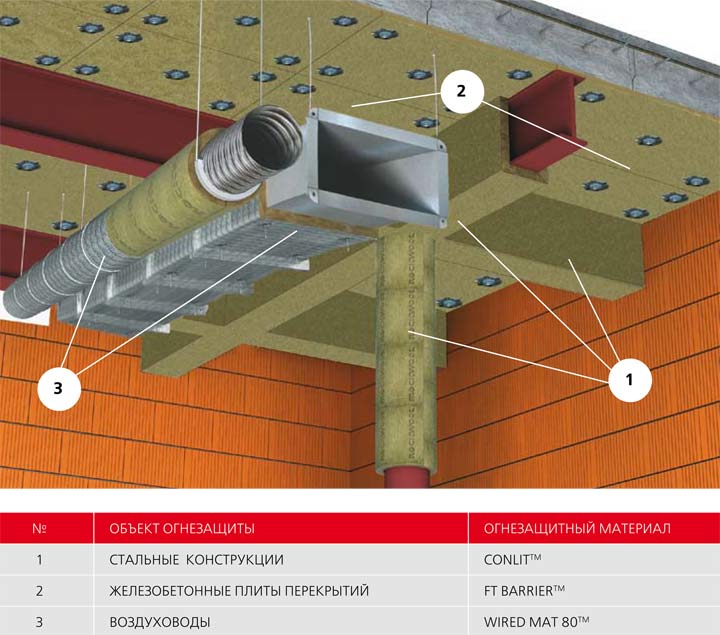

- Thermal insulation for industrial systems

- polyurethane foam

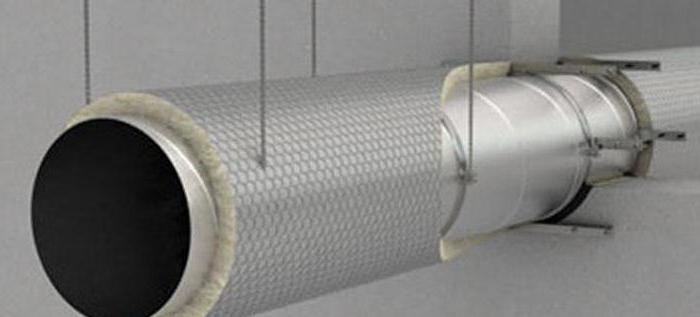

- Insulated air ducts

- Why is it needed

- A special case

- The right approach to insulation

- Finding the best location

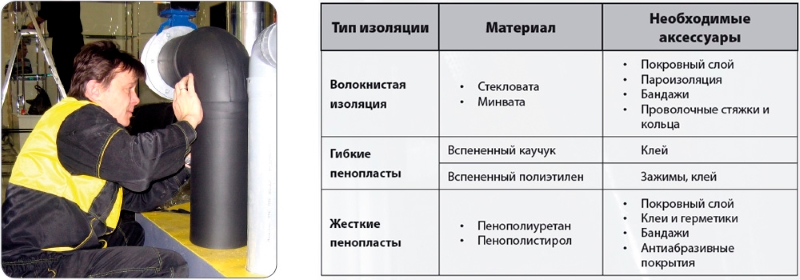

- Choosing the best material

- material performance requirements

- Ventilation without insulation

- Thermal insulation of the exhaust system at home

- How to insulate

- Insulation for domestic ventilation system

- Insulation for industrial insulation

- Expert advice

- Do-it-yourself thermal insulation installation technology

- Necessary calculations

- Preparatory work

- Warming with mineral wool

- Insulation with polyurethane foam

- Foam insulation

- The nuances of installing self-adhesive thermal insulation

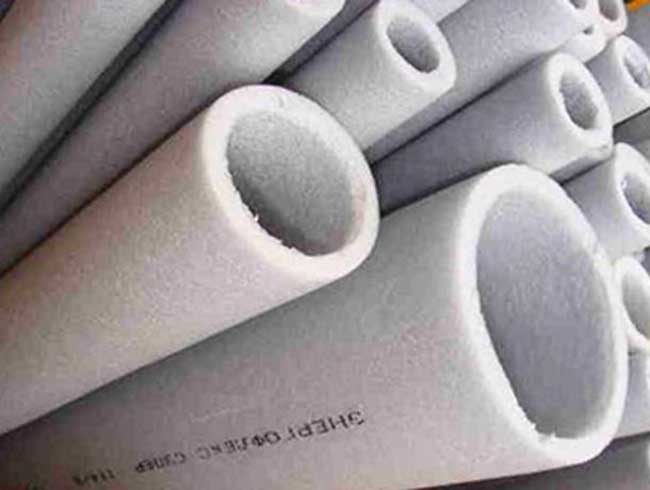

- Thermal insulation with special cylinders

Work technique. Step-by-step instruction

When insulating air ducts that are located outside the heated premises, insulation is carried out from the outlet to the deflector. If the pipe goes through the attic and passes through the roof, it must be insulated throughout the length of the segment in the attic. The same requirements apply to the zone that goes through an unheated room.

The heated supply system is equipped with the appropriate material throughout. The use of boxes is often resorted to in attics. Thermal insulation in this case has the form of casings and consists of foamed polyethylene. Among the advantages of this approach, one should highlight the affordable cost and the ability to purchase goods in any hardware store. The casing is recommended to be selected taking into account the size of the pipe.

Foamed polyethylene can deteriorate under the influence of ultraviolet radiation. To eliminate this effect, it is necessary to cover the outside of the structure with aluminum kitchen foil. When performing thermal insulation of supply air ducts, it is necessary to measure the diameter and height of the system from the outside. Next, a casing of the desired size is prepared. If an umbrella is installed, it must be removed. The casing is stretched to the base of the pipeline. The umbrella can then be returned to its place.

Foil is applied from bottom to top on the system. This will increase the life of the structure. With the help of copper or stainless steel clamps, the winding can be fixed. If the work is carried out in central Russia, this solution is best suited. If we are talking about a more severe climate, you will need reinforced insulation like mineral wool. It works well on domestic and industrial ventilated ducts. If desired, the material can be used inside and out. A typical example is Isover coatings.

Benefits and disadvantages

Ventilation insulation prevents the formation of condensation and mold

Thermal insulation of air ducts has the following advantages:

- prevention of condensation on surfaces (external, internal) and all the negative consequences that it entails;

- reduction of heat loss;

- protection against noise arising from the operation of ventilation;

- providing fire resistance in order to avoid the spread of fire if a fire occurs.

The disadvantages include:

- considerable costs;

- if the work on the thermal insulation of the air duct is not performed correctly or poor-quality materials are used, mold and fungi may occur, which is dangerous to health;

- the insulation used can release substances harmful to people.

Mineral wool and polyethylene foam

If you use mineral wool with an outer foil layer, you will not only be able to make the structure more efficient, but also protect it mechanically

It is important to take into account that cotton wool gradually becomes caked, and over time it will begin to crumble, so care must be taken when working with it.

Thermal insulation of air ducts is quite often carried out with polyethylene foam. Such work is cheaper, since the cost of materials is less. The insulation has a small thickness, so the pipe must be wrapped with polyethylene several times. According to its characteristics, this material is similar to foamed rubber. Among the roll options, mineral wool insulation is considered as a priority.

Rules to follow

- Installation of flexible and semi-flexible air ducts is carried out in full tension.

- The air hose should not sag in any area - pressure is lost at each deflection.

- Air duct grounding is mandatory: during operation, static electricity accumulates in the line.

- During the operation of the ventilation system, the air in the channels moves in a spiral (aerodynamics), this must be taken into account when designing and installing.

- Flexible ducts must not be used on vertical sections of the main line with a length of more than 2 floors.

- In rooms below ground level (basements, ground floors), in contact with the ground, in concrete structures passing through floor / ceiling ceilings - only rigid air ducts.

- If the air duct was damaged during installation, it should be replaced. The same applies to the outer thermal insulation coating.

- When passing through walls, adapters and metal sleeves must be used.

- With a sharp turn, the aerodynamic properties of the pipe are reduced, the turning radius should be no less than two duct diameters.

Foamed polyethylene

Today it is one of the most popular insulating materials. It's easy to work with:

- It is enough to cut the roll into the necessary blanks.

- Wrap them around the air duct.

- Secure the joints using mounting tape.

Self-adhesive thermal insulation for air ducts is now in great demand in the domestic market. It has a low thermal conductivity coefficient of 0.038 W/m C° and low vapor permeability, and the different thickness of this insulation will optimally solve all issues related to the thermal insulation of air outlets.

We hope that all the materials presented in this publication were useful and will allow you to achieve a good result with self-insulation of air ducts.

The ventilation system is a complex of equipment, the main task of which is the supply and removal of air in order to maintain the desired microclimate in the room.Among other things, ventilation consists of air ducts. They carry out the transport of air masses. They are located both inside and outside the building. According to regulatory documentation, air ducts must have a certain margin of safety, sufficient throughput, be equipped with sound and heat insulation. Why is it necessary to insulate ventilation ducts?

Where to insulate

Where exactly do you need insulation for ventilation pipes?

A simple solution

The simple answer to this question is obvious: where a sharp and significant cooling of the air flow is possible.

- If the exhaust ventilation is brought out through the main wall, the pipe is passed through a heat-insulated sleeve and insulated up to the deflector.

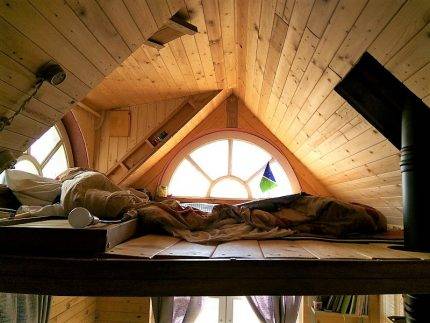

- In a private house, insulated ventilation pipes go through a cold attic and exit through the gables or roof. Insulation again starts from the point where the ventilation duct cools noticeably (see also the article Attic insulation - we consider the possible options in detail).

Ventilation is of particular note. Here, the possibility of moisture condensation on the outer walls of the supply ventilation duct depends on its length and location.

If necessary, these pipes can be insulated in the same way as exhaust pipes, however, the influx of cold air itself can create some discomfort; adjustable dampers for fresh air ventilation can even freeze.

One solution to this problem is an insulated valve for ventilation. Probably, in the imagination of the reader, a ventilation grill with a layer of thermal insulation arose? It wasn't there.

The design in the photo bears little resemblance to blinds for ventilation.

The insulated ventilation damper is a solution for large premises, primarily for office, warehouse and production purposes. It really is an adjustable louvre that allows you to limit the air flow and ... if necessary, heat it up with tubular heaters.

Adjustment can be carried out manually - a system of traction and lever, or using a simple electric drive. The open area of the valve in a fully open state can be up to 3.5 m2, the power of heating elements is up to 8 kW.

The function of heating elements, however, is not to supply warm air into the room. With a valve area of 3.5 m2, 8 kilowatts of thermal energy is a drop in the ocean. Heating elements only warm up the valve flaps before changing their position in order to avoid icing and breakage.

Thermal insulation for industrial systems

For the insulation of pipes in industrial ventilation systems, in addition to the heaters listed above, more expensive methods can be used:

- applying a sprayed variety of polyurethane foam;

- installation of heat-insulated air ducts ready for installation.

polyurethane foam

Sprayed polyurethane foam insulation is considered one of the most effective ways to protect industrial ventilation pipes from freezing. A layer of foam is applied over the air ducts using specialized equipment.

Varieties of polyurethane foam:

- Hard. It has cells of a closed type and, in addition to excellent insulating qualities, serves as a waterproofing at the same time, absorbing no more than 4% of moisture.

- Light.It is distinguished by the presence of open-type cells, has a low weight, perfectly absorbs sound, and is relatively inexpensive. But for outdoor work it cannot be used, and for internal work, waterproofing is required, since the insulation absorbs up to 15 percent of moisture.

Characteristics:

- thermal conductivity indicators vary from 0.019 to 0.04 W / m ° C;

- operating temperature range is -160°С — +150°С;

- low combustible material;

- compressive strength indicators - over 150 kPa;

- standard service life - more than 20 years.

Advantages:

- the insulation layer is as close as possible to the surface of the pipes;

- seams are completely absent;

- it is possible to apply the material on pipes of complex configuration;

- installation does not take much time.

Flaws:

- high price category;

- installation is quite complicated and requires some experience;

- the composition of the material contains toxic substances, which require the employee to have special protective clothing, masks and goggles. In this case, the frozen foam does not pose any danger.

Insulated air ducts

One of the convenient options for solving the problem of condensation in the ventilation system is the use of already heat-insulated air ducts during installation.

Varieties:

- Flexible. A metallized film, an insulating layer and a film foil cover are fixed on a spiral wire frame.

- Rigid. Consists of PIR boards (PirroVentiDuct) or Climaver fiberglass boards, etc. The strength of pipes made from such materials is similar to that of traditional steel ducts. Flanges can be used to connect to conventional steel ventilation pipes.

Advantages of insulated air ducts:

- reducing the cost of purchasing materials;

- reduction in the total weight of the entire ventilation system;

- installation speed.

There are no critical shortcomings in air ducts with thermal insulation.

Why is it needed

The key word is condensation. Without insulation, it will inevitably form on the inner surface of the ventilation duct and flow down the inner walls, flowing through leaky joints into the main walls and ceilings. The consequences are obvious: dampness of walls and ceilings, the appearance of mold and their gradual destruction.

The effect of condensate on the ventilation duct itself depends on what material it is made of:

- Galvanization can suffer if the protective anti-corrosion layer is violated. Which, however, is inevitable when cutting a sheet.

- PVC and corrugated aluminum pipes tolerate contact with moisture without any consequences.

Another trouble associated with moisture condensation is the gradual freezing of frost on the inner walls of the ventilation duct outside a warm room. For several weeks of operation in severe frosts, the pipe clearance can decrease from 100 - 150 millimeters to zero.

Where does the condensate come from?

There are two reasons for its appearance.

- Human life is associated with excessive moisture in the air. When washing dishes, cooking, washing, even just breathing, the atmosphere is saturated with water vapor.

- Meteorologists have long used the concept of relative humidity. The higher the air temperature, the more water vapor it can hold. 100% relative humidity is the maximum amount of water that can be contained in the air in vapor form. However, it is worth changing the temperature - and with the same amount of vapor in the air, the relative humidity will change.With significant cooling, it can exceed 100%, after which excess water will inevitably begin to condense on surfaces with a low temperature. In our case, on the inner surface of the ventilation duct.

Consequences of moisture condensation in the ventilation duct.

A special case

In production, there is often a need for forced ventilation with a high air flow rate. In particular, to remove harmful volatile products of production, sawdust, shavings, etc.

The noise of the air and what it carries becomes a serious problem in some cases. In factory premises, ventilation insulation often aims not so much to combat condensate as to simply soundproof. The methods, however, apply the same.

The right approach to insulation

To answer the question: how to insulate a ventilation pipe in a private house correctly and at the same time economically, you should understand the reasons for the appearance of condensate. The temperature difference always leads to the appearance of condensate, but the most abundant release of "dew" is observed in the segment of active contact between warm and cold air. The closer you can move it to the outlet of the pipeline, the less potential danger and damage from condensate will be.

The ideal case is considered to be a situation in which the mixing of cold and hot air occurs in a section of the ventilation pipe located outside the building. But this is not always possible in practice.

Therefore, for chimneys and air ducts in an unheated attic, channel insulation is considered mandatory. Thanks to this, it will be possible to bring the “wet” zone - the place of the most active dew formation - beyond the walls of the building.Such a solution will help, even with the active appearance of a large amount of condensate, to prevent moisture from penetrating into the walls, provoking the appearance of dampness, fungus and other related troubles.

Finding the best location

A vertical chimney from a stove heating, fireplace or gas boiler, due to the exit of hot air, will be completely cleaned of moisture during the heating of the room. Horizontal air ducts, the outlet of which is located in the wall, must initially be mounted with a downward slope of at least a few degrees. This allows accumulated moisture to drain outward rather than into the room. Therefore, the most important point before insulating such air ducts is to check for a slope for its withdrawal. Otherwise, even insulated ventilation pipes will become a source of problems in the future, albeit much later than without thermal insulation at all.

A mandatory place for insulating duct pipes is an unheated attic. It is in it that the temperature difference in the cold season becomes a source of problems due to the formation of moisture. Condensation on them, regardless of whether plastic or metal pipes are used, is formed both inside and outside.

Choosing the best material

In order for the thermal insulation of any: plastic, metal and various other ventilation pipes to be quite effective, but not to hit the budget, you should choose the right insulation. Today there is a fairly rich selection of materials for this, both affordable and quite expensive. The most recommended options are the following types of insulation:

- Mineral wool.An inexpensive fireproof option available at almost any hardware store. The downside of the availability of mineral wool is the complexity of installation and the need for its subsequent protection with foil or galvanization. Afraid of moisture.

- Stone wool. It has the advantages of mineral wool, as well as its disadvantages. Over time, it becomes caked and loses its thermal insulation properties.

- Polyurethane foam and polystyrene. Detachable structures for pipes of a certain diameter. Inexpensive, but providing excellent heat and moisture insulation. The disadvantage of materials is a high fire hazard and a rather low resistance to mechanical damage.

- Foamed polyethylene. Insulation, offered in the form of finished tubes of different diameters. Inexpensive, differ in good indicators of thermal insulation, is not afraid of moisture. The disadvantage is the need to put a heat insulator on the duct pipe, which is inconvenient or even sometimes impossible.

The choice - how to insulate the ventilation pipe - everyone makes for himself. The main rule that is recommended to rely on when choosing is to purchase the material that will most fully solve the problem of condensate in a private ventilation network.

material performance requirements

In order for the insulation to serve for a long time, not to become damp ahead of time, not to become moldy and to fulfill all the tasks assigned to it, it must have the following qualities.

One of the most important characteristics is the coefficient of thermal conductivity, expressed in W / m • ° С. The degree of cooling of the air in the pipes depends on it.Manufacturers, given the different installation conditions, produce heat-insulating materials of various thicknesses and densities.

The table shows the popular building materials used for thermal insulation of air ducts. Using the given data, it is possible to determine the dependence of the thermal conductivity coefficient on the density and thickness of the material

The second important parameter is vapor permeability. If the air ducts are prone to the formation of condensate, it first of all penetrates into the insulation and increases its moisture content, which increases thermal conductivity.

If you chose porous, fibrous materials that easily absorb moisture for insulation, take care of additional vapor barrier. The simplest option is to wrap the insulated area with plastic wrap

If you chose porous, fibrous materials that easily absorb moisture for insulation, take care of additional vapor barrier. The simplest option is to wrap the insulated area with plastic wrap

The next characteristic is acoustic efficiency. Air moves inside the channels, causing vibrations and noise. A running fan also creates sound waves. They are transmitted through the air and through the rigid structure of the air duct into the surrounding space and create discomfort for the residents of the house.

To minimize the noise level, you need to think over the design features of the air ducts, make them straight, with a minimum number of turns. Noise can be significantly reduced with the help of noise-absorbing insulation.

Do not lose sight of such quality as resistance to biological attack. The less the material is suitable for the formation of colonies of mold fungi, the reproduction of various microorganisms, the longer it will last, and with it the structure of other building materials, such as wood or concrete, will be preserved.

Mold causes not only the destruction of natural materials, but also negatively affects well-being. If you plan to place a living room in the attic, ensure the normal temperature and humidity level

Mold causes not only the destruction of natural materials, but also negatively affects well-being. If you plan to place a living room in the attic, ensure the normal temperature and humidity level

For a heat-insulating material, such a parameter as the operating temperature is also important. It differs for different heaters, but the average can be called a range from -35 ° C to + 60 ° C.

And one more characteristic - sanitary and hygienic properties. Thermal insulation must not spread toxic gases harmful to health. From this point of view, materials that contain components of natural origin are valued - for example, felt or mineral wool.

Ventilation without insulation

In this case, we will analyze the case when the ventilation goes up through the attic. Warm air passes through the ventilation ducts, which tends upward due to its physical properties. When heated air enters the part of the pipe located in the attic area, condensation forms on it, on the inside and outside. As a result, we are faced with the following problems:

- Water flows down the pipe, soaks through the ceiling and causes its destruction.

- The ceiling suffers from water stains, and the plaster begins to flake off and collapse.

- Excessive humidity causes the appearance of fungus and mold.

- In the case when the temperature drops below zero Celsius (and this phenomenon is not uncommon for attic spaces), frost forms and causes the destruction of ventilation ducts.

If we do not want this to happen to us, or if it has already happened, move on.

Thermal insulation of the exhaust system at home

Thorn-groove lock.

The hood is an essential attribute of modern kitchens and bathrooms.Through it, excess steam and moisture, which were formed as a result of cooking and using hot water, go out into the street. Due to the large temperature difference between the exhaust air and the environment, condensation forms on the surface of the duct. The metal is corroded. In addition, the accumulated moisture penetrates the material of the walls and ceiling of the room. To prevent the formation of condensate, the duct must be thermally insulated. How to insulate the hood in a private house?

If a factory-made exhaust system was purchased and installed, it must be equipped with an internal, insulating layer. But this part of the duct remains indoors. Insulation of the hood in a private house, which is located outside the living quarters, can be done with mineral wool.

At the initial stage, the pipe is cleaned of dust, dirt, debris. Further, the pipe is wrapped with a purchased slab or roll insulation. The thickness of the material is calculated based on building codes. But in most cases, one layer of mineral wool, 5 cm thick, is enough. Fasteners are carried out using adhesive tape. In this case, the seams are glued with aluminum adhesive tape. On top of the wool, it is wrapped with reflective thermal insulation with a thickness of thermal insulation material of 2 cm. All connecting seams are additionally glued with adhesive, foil tape.

Insulation of external ventilation. Do I need to insulate the ventilation pipe that runs through the attic? In the case of an unheated attic, insulation work is mandatory.

When choosing a material, not only the danger of moisture penetration is taken into account, but also the likelihood of damage to the insulation by rodents. Foam pads are suitable here

They are produced in the form of a kind of shell, which greatly simplifies installation work.

Insulation of exhaust ventilation is carried out according to the following scheme:

- selection of suitable thermal insulation;

- its installation;

- protective cover installation.

The choice of thermal insulation is carried out according to the dimensions of the air pipe itself. Otherwise, the insulation may not completely cover the surface of the duct or will overlap, which will also adversely affect its protective functions. Further, with the help of a knife or a saw, the shell is cut with subsequent installation.

Insulation of fresh air ventilation ends with gluing the joints with a special tape and installing a protective cover. It is attached with bandages.

Mineral wool with foil is ideal.

Work with rectangular ducts. How to insulate rectangular exhaust ventilation? Here you can use both rolled and slab material. The ideal option is basalt fiber. It does not contribute to the spread of fire, does not rot. Disadvantages - vapor permeability and hygroscopicity - are eliminated by installing a hydro- and vapor barrier.

How to insulate ventilation in a private rectangular house? Prepare insulation of the desired thickness. Cut it into easy-to-assemble pieces. As fasteners, calcined, steel wire is taken. To seal the seams, foil, adhesive tape is useful.

Work is performed in the following order:

- installation of a heater;

- gluing joints;

- fasteners with wire;

- winding with protective, foil insulation;

- fixation of the protective shell.

When working with basalt fiber, be sure to use personal protective equipment.

How to insulate

To answer this question, it is necessary, as mentioned above, to divide ventilation systems into two categories. The first includes engineering networks in private homes, shops, restaurants and other consumer service points. That is, where the ventilation system itself is a small and not too branched piping. It works either by the natural method of removing air, or by forced air with the help of fans. The second category is industrial ventilation networks. They apply only to the forced system.

Insulation for domestic ventilation system

Here are some traditional materials that have proven to be useful for many years:

- mineral wool glass wool;

- foamed polyethylene (penofol), covered with foil;

- polystyrene, which today has been replaced with polystyrene foam boards;

- asbestos slabs or mortar.

All of the above-mentioned heaters belong to the group of budget options. The first two positions refer to a fibrous species with a high hygroscopicity, that is, they quickly and easily absorb moisture, which simply destroys them.

Therefore, an important condition for use is waterproofing over insulation. This is especially important if the insulation for air ducts is used outdoors.

Previously, roofing felt was used for protection, today special membranes with a foil surface are used.

As for the plates, they are installed if the duct has a rectangular cross section.

Asbestos mortar, like cotton wool, can be applied to both rectangular pipes and round ones.If it is used on the street, then a prerequisite is the installation of a box that will close the insulation from mechanical stress. Roofing material or tin is used as a box.

Insulation for industrial insulation

Here you can also use all those materials indicated in the previous section. But there are also unique technologies. Therefore, when the question is raised, how to insulate ventilation pipes, for example, at a factory, several additional options are offered.

- The use of polyurethane foam. This is a two-component mixture, which is a foam. It is applied under pressure to the air ducts, to which it easily adheres and envelops.

- Ready heat-insulated air ducts. They appeared on the market relatively recently, but quickly became popular by reducing labor costs and increasing the speed of installation work. Manufacturers today offer air ducts with different thermal insulation materials: mineral wool, polyurethane foam, polystyrene foam, penofol.

Expert advice

If pipes run indoors, the top protective layer can be omitted

Basic recommendations for isolating ventilation ducts:

When insulating outdoors with mineral wool, high-quality waterproofing is required. Roofing material can be used for this.

In the case of using PPS or PPU shells in a dark room (basement, attic), the top cover layer can be omitted.

Plastic insulators must not be bonded to bitumen or bitumen primer

It breaks the structure, due to which the shell can crack.

Particular attention is paid to the waterproofing of the passage of pipes on the roof.

It is here that all the condensate accumulates, so it is important to protect the place.

A master flash is suitable for waterproofing the node.

It is important to pay attention to the thermal insulation of cold air blowers before entering the house. Also, sections of pipes for supplying air to the boiler or fireplace are insulated.

An exception is coaxial chimneys.

You can make high-quality insulation with your own hands

It is only important to choose the right material and tools, and then make thermal insulation according to the instructions.

Do-it-yourself thermal insulation installation technology

When planning the thermal protection of the duct, you should prepare the right amount of insulation and fasteners based on preliminary measurements.

Necessary calculations

If you plan to use ready-made shells, you need to determine the length of the treated areas and prepare the material with some margin. In the case of roll insulation, you should additionally calculate the desired width of the product. To do this, determine the diameter of the pipe, add the double parameter of the thickness of the insulator, multiply the result by 3.14 (Pi number).

Preparatory work

Before starting work on insulating the outer section of the ventilation duct, the deflector should be removed if you have to work with a finished casing that is pulled over the pipe. In other cases, there is no need to dismantle the protective umbrella

It is also important to prepare clamps and other fasteners in the required quantity.

Warming with mineral wool

For the installation of roll insulation, the following set of tools and materials is required:

- construction knife;

- stapler;

- aluminum tape;

- roulette;

- rubber spatula.

Aluminum tape will be needed to insulate air ducts with mineral wool

Foiled mineral wool is used, which leads to reliable waterproofing of the fibrous base of the insulation. Insulation in the form of stone wool with Isover brand foil is especially in demand.

Stages of work:

- perform marking on the canvas with an aluminum coating, taking into account overlapping, cut the required number of blanks. Moreover, an incision should be made along the length of the end, retreating from the edge by 7-8 cm. Next, the cotton wool is removed along the incision line, leaving a layer of foil;

- wrap the pipe with insulation so that the protrusion of the foil along the edge closes the joint seam;

- the connecting line is fixed with a stapler in 10 cm increments, glued on top with aluminum tape.

To isolate the corner elements of the ventilation duct, curvilinear fragments of insulation are used, cut according to the parameters of the base. The street section of the duct must be strengthened with clamps over the mineral wool. It is also required to build a protective box of tin.

Insulation with polyurethane foam

Polyurethane foam insulation is sprayed using special equipment. Due to the high cost of installation work with the participation of professionals, PPU is mainly used in the arrangement of industrial exhaust air systems. Manufacturers also offer compact units for mixing foam insulator components for insulating air ducts in private housing construction. The complete set weighs within 30 kg and allows you to foam a small piping in the attic and on the roof.

Foam insulation

Plate material is used in the arrangement of rectangular ventilation systems. The expanded polystyrene layer is completed with special waterproofing products in the form of a membrane or foil.Billets are cut from the plates to the required dimensions, fragments are mounted using clamps, adhesive tape, a stapler or metal wire. To eliminate gaps at the outer corners, the joints are additionally sealed with mounting foam.

Waterproofing is required depending on the density parameters of the boards. For example, for PPS-60 there is no need to protect against moisture, and PPS-40 should be used complete with a waterproofing membrane.

The nuances of installing self-adhesive thermal insulation

Self-adhesive insulation - penofol brand "C" - is valued for ease of installation. The outer surface of the material based on polyethylene foam is finished with an aluminum coating. Glue is applied to the back of the insulator, which is covered with a film. The canvas is cut to the required size in accordance with the parameters of the air duct, the film is removed and glued to the selected pipe surface. The edges of the self-adhesive thermal insulation are folded with an overlap of at least 5 cm and secured with aluminum tape.

Thermal insulation with special cylinders

The shell is used only for round pipes, selecting a model of the appropriate size. One-piece cylinders with a longitudinal section are relevant for the arrangement of ventilation ducts of small diameter. The shell is opened along the gap line, put on the pipe and fastened with tape or a clamp. Collapsible models of finished cylinders are also in demand for thermal insulation of air duct outlets outside the heated room and outdoor segments of the ventilation duct with the obligatory construction of a protective box.