- Well silting

- Rope break

- 5 ways to get the pump out of the well

- How to get a stuck pump

- What needs to be done so that the pump does not get stuck

- How to get a pump that has fallen into a well

- What needs to be done so that the pump does not fall

- Do's and Don'ts when Removing a Stuck Pump in a Well

- How to remove a stuck pump

- interferes with the cable

- Silting

- Deformations or deviations of the casing pipe vertically

- foreign objects

- Possible reasons

- slack cable

- Well silting

- Reverse siltation

- Pipe wall damage

- Probe use

- Folk ways to lift a jammed pump

- Lifting the unit from an idle well

- Causes of a stuck pump

- Silting at maximum depth

- Jamming when lifting

Well silting

If the "Kid" pump is stuck in the well, silting may be the reason for this. This happens quite often when the water source is not used for a long time. As a result, a layer of silt is formed, which becomes an obstacle in the way of the equipment.

If you encounter a similar problem, then you should swing the unit. During this, the device can be lowered or raised.This will lead to the fact that the water will begin to wash away the deposits, and the road to the top will be freed up, which will allow the device to be removed outside. You should not rush at the same time, showing excessive activity. Indeed, otherwise, a deaf jamming of the unit may occur.

If the pump is stuck in the well, you can understand how to pull it out only after you determine the cause. If it is accumulated sludge, then you can use a non-standard way to deal with it. Firefighters should be involved in solving the problem, who can wash away the deposits with a sleeve. The sleeve is lowered into the well. When the pump is released, you will be able to understand this, because it will smoothly go up. In order to exclude silting of the well, it is necessary to subject it to preventive cleaning with a certain frequency, which is once every three years.

Rope break

The situation when the cable breaks and the whole structure slides down happens quite often. Usually, a metal cable does not break, just the fixing elements, over time, they are unclenched due to metal corrosion, the thread is not able to fix the mount and the cable is released. For the metal of a steel rope or cable, alloys that are not subject to corrosion or structures that have an additional protective sheath of plastic are usually selected. But an ordinary steel cable, being constantly in a state of tension, scuffs and a center of active corrosion can form at the place of fixation, because the pump experiences vibration during operation, which is transmitted to the cable.

In this case, it is recommended to continue lifting if the well is shallow and the pump is light, using a hose or pipe as the main lifting device.The upward feed should be smooth, without sharp interceptions and twitches. The use of a cable as a lifting element is not permitted! With this method, it is necessary to prevent the pump from rotating around the axis, since if the pump jams, a pipe or hose can come off, which will further aggravate the situation.

Broken pump at the bottom of the well also not the best option for the job, but if the power cable is intact and still attached to the pump housing, then the chances of lifting the equipment are greatly increased. For centrifugal pumps, screw pumps and vibratory models, the cable usually has an entry into the housing slightly below the outlet and practically at the level of the holes for attaching the cable.

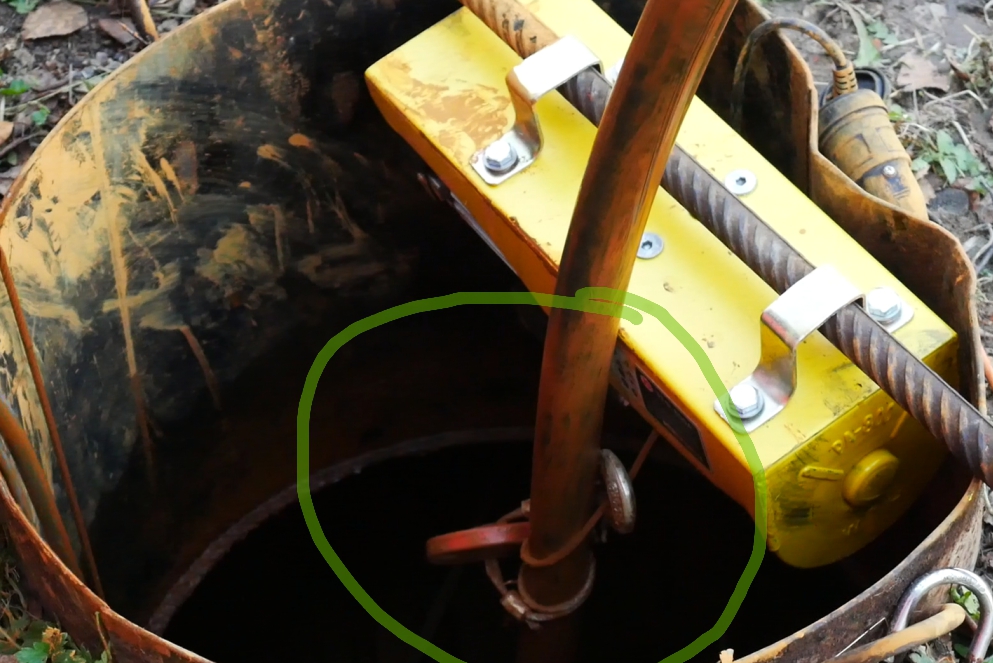

For lifting here, a device made of a piece of metal pipe and welded wire, on the one hand, and a lifting cable on the other, can be used. The cable is threaded into the pipe to the bottom, which is welded and bent in the form of a hook wire. The hook descends along the cable and, having reached the lowest point on the pump housing, enters the eye for the cable. Such an operation is somewhat similar to winter fishing, when the bait is slightly supported to attract fish, and the lifting hook, with small up and down movements, should fall into the eye and hook the pump.

5 ways to get the pump out of the well

How to get a stuck pump

To quickly get rid of the problem, you need to know how to get the pump out of the well if it is stuck and does not move. For every reason there is a solution.

This is how the vibration pump can get stuck in the casing

Available methods:

Cable slack. If this situation occurs, you need to slowly and carefully lower the device.As soon as it is at the bottom, loosen the cable and try to lift again. At the same time, they move slowly, trying to avoid sagging of the electric wire and other structural elements (cable, hose).

Silting. With such a problem, it will be difficult to lift a stuck device. To correct the situation, silt deposits must first be washed out.

To do this, carefully swing the cable, in parallel trying to lift the stuck device. Gradually, the “grip” of the silt will weaken and after a few minutes of such work it will be possible to raise the equipment to the surface.

Burrow in limestone

If such a problem occurs, you should perform all the same actions as with silting. Slow rocking will gradually break up deposits near the hull and allow you to lift the device from the bottom.

Pipe damage. To get stuck equipment will help rotational movements that need to be given to its body. Lift the device slowly, as one careless movement will be enough to damage its outer part.

Foreign object stuck in the shaft. In such a situation, you need to take the help of professionals, since it will be difficult to get this item with your own hands. This is due to the risk of it falling to the bottom of the well or damaging the hull.

What needs to be done so that the pump does not get stuck

These include the following:

- Attaching the electrical cable to the hose. This simple action will help to avoid sagging of the wire and its wrapping around the body of the pumping equipment. Fixation is carried out with the help of special clamps, which must be regularly replaced with new ones.

- Placement of the pump above the filter.This installation option will avoid sticking to the body of silt, which often causes the device to get stuck.

- Annual cleaning. Regular carrying out of this event will not allow silt and sand to accumulate at the bottom of the well.

- preventive treatment. In this case, professionals recommend using citric acid to remove limescale. She will quickly deal with the problem and eliminate the possibility of the device getting stuck.

- During the arrangement of an autonomous water supply system, only high quality pipes should be used. Due to this, there will be less risk of breakage as a result of mechanical stress.

How to get a pump that has fallen into a well

If the cable breaks and the pump falls into the well, it will be difficult to get it from the bottom. Even if you manage to do this work, you will have to change the device to a new one.

Procedure:

- Find a rod made of any durable metal. Its size should be enough to reach the bottom.

- A special screw nozzle is attached to one edge, which is shaped like a corkscrew with a pointed end.

- At the second end of the rod, a rod is fixed, which allows you to rotate a home-made structure.

- Lower the finished product and find the fallen equipment.

- Applying force, screw the screw nozzle into the body of the device.

- As soon as it deepens to half its length, the pump slowly begins to rise.

What needs to be done so that the pump does not fall

Lifting a pump from a well is considered a difficult undertaking, so you need to try to prevent it from falling to the bottom. To do this, you need to take several steps.Among them are:

- use the most rigid and durable cable;

- use a one-piece long hose, and not assembled from several small pieces;

- the pipe diameter should be selected in a ratio of 3:2 with the dimensions of the pump;

- install a head on the well to prevent falling objects.

This is interesting: How to seal the seams in a well of concrete rings: the whole point

Do's and Don'ts when Removing a Stuck Pump in a Well

When removing the pumping device from the well, abrupt actions should not be allowed. Excessive force applied to the pump can simply break the cable holding it.

It is recommended to check the strength of the cable and the reliability of its attachment to the pump even at the stage of installing the equipment in the well. If the cable that comes with the pumping equipment does not inspire confidence in you, get another one. It is advisable to use a steel cable with a special anti-corrosion coating, or a fairly reliable synthetic analogue.

Galvanized steel cable

Do not try to pull out the pump stuck in the well with the help of a "cat". Such a device can get stuck in the well, exacerbating the problem. And of course, you should not try to break through a plug of silt or push a pumping device deep into the well. With a heavy crowbar, you can render the pump unusable.

There are several methods that are used when removing a stuck pump.

Tighten the cable and from time to time tap it in a taut state with a hammer. Vibrations from the cable will be transferred to the pump and the plug, or deposits, may collapse. Do not expect that such a technique will lead to instant results.It may take you a few days to pull the pumping device of the well centimeter by centimeter.

If you use any additional devices to retrieve equipment from the well, then do not forget to carefully fix them to the head or other strong object near the well with a cable.

To push a stuck pump deep into the well, it is better to use a pipe with a cross section slightly smaller than the diameter of the well. A metal bracket is welded to the upper end of such a pipe, which is fixed with a strong cable. Pass the cable, hose and cable from the pump through this pipe.

Carefully lower the structure down until it touches the jamming point and, gradually increasing the amplitude, try to push the pump deeper.

If, when trying to remove a stuck pump, you still break the fastening cable, then the well will have to be re-drilled with a drill. But even when using a drill, there is no guarantee that it will destroy the pump along with the obstacle or push it down. In this case, the well will have to be drilled again.

In the worst case, the well will have to be re-drilled.

How to remove a stuck pump

There are many ways to release pumping equipment from wells. They depend on the degree of pump suction or stuck in the casing, as well as the suspected cause of the problem. Unfortunately, it is not always possible to solve it due to insurmountable difficulties. But trying to remove the equipment is still worth it.

interferes with the cable

The most common cause of device jamming is a sagging electrical wire. It can be quite difficult to get a pump wrapped with a cable out of the well.When lifting the equipment, even with force, only additional sealing of the gap between the casing and the pipe will occur. In this case, do not use jacks or winches, otherwise the cable may break under significant loads.

It is necessary to try to push the pump down with rotational movements either clockwise or counterclockwise. Scrolling is carried out by means of a water intake pipe. The cable sag that has appeared is tightened and the rise begins again. The main thing here is to be patient and not overdo it.

Silting

The pump, overgrown with silt, releases the "swing" by raising and lowering it many times. Start with the smallest step and increase as needed. In this case, only a cable or a cable with a hose should be used. As a result of reciprocating movements, the hardened sludge will gradually begin to liquefy and, in the end, weaken the position of the pump.

No one can predict in advance how long it will take to “build up” the pump. It depends on the duration of the non-production period of the well, the thickness of the silted layer above the pump and the density of the deposits.

Deformations or deviations of the casing pipe vertically

A slight lifting of the pump to a certain point, a knock and a sharp stopper indicate that there are deformations inside the well that make it difficult for the equipment to move up. But there may not be a knock - it all depends on the nature of the defect.

In this situation, you can try to get around the obstacle by simultaneously lifting and rotating the pump by the hose. This should be done smoothly and slowly. With a successful combination of circumstances, the body will eventually “slip”, and with an unsuccessful one, you will have to part with the equipment or the well.

foreign objects

Jamming of the pump can be caused by a small object or a pebble, since the gap between the wall of the casing pipe and the casing of the device is usually minimal. In most cases, independent attempts to extract only lead to a break in the cable. But the situation may be subject to professionals with experience and diagnostic equipment.

In the arsenal of specialists there are underwater cameras, with the help of which the cause of jamming is determined. The masters will analyze the situation and offer an option to save the well. But you should immediately make a reservation - the services of such companies will be expensive. It is recommended to contact them if expensive equipment is located in the well.

Possible reasons

The most common cause of equipment getting stuck in the well is human error. This can be both a violation of technological requirements during the installation process, and the quality of installation materials.

It is very important that during the installation process you choose proven equipment, and the installation itself is carried out by qualified specialists.

But improper installation and poor-quality equipment are only a factor influencing the causes themselves. But why the pump can get stuck in the well, let's look below.

slack cable

A slack cable is one of the most common reasons that pumping equipment can get stuck in a well. If the electrical cable is sagging, it can simply be bitten by a cable loop that holds the equipment.When this happens, in no case should you pull the cable with all your might, as you can break it, and it will be much more difficult to get the pump out of the well on your own.

It is worth noting that this is the most common and quickly solved problem. If the pump is stalled and won't go up, try lowering it a bit and choosing the moment when the cable loosens, repeat the lift. In the process, make sure that the cable, cable and hose do not sag.

In order to avoid such troubles in the future, simply connect the cable to the hose with clamps, fixing it. During the lifting process, make sure that the cable and hose come out at the same time, and do not allow any slack, as the situation may repeat itself.

Well silting

Quite often, the reason that it is not possible to pull the pump out of the well is its silting, due to rare use. It is the layer of silt that serves as an anchor that prevents you from pulling out the pumping equipment.

If silting is the cause, you can try to get it by rocking it, slightly raising and lowering the pump down. Under the influence of mechanical up and down movements, the water will erode the space around the pump, thus facilitating its release.

If the pump is stuck, it is important not to rush during the rocking process, and not to pull with all your might, as it may completely jam or completely break the cable. If you can’t get the pump on your own, you can resort to the help of firefighters so that they lower the fire hose and wash away the layer of silt with water pressure

Reverse siltation

One of the reasons for pump jamming in the well can be the effect of reverse siltation.It should be noted right away that it is observed only in wells drilled on limestone soils, therefore, if your well is not on limestone, this option can be excluded.

Jamming of pumping equipment occurs due to the deepening of the pump during operation. Over time, a precipitate forms, which settles on the pipes and pump

It is important to note that you will not get off by flushing the well, as in the previous version, since the sediment can be very dense. In this case, you can pull out the pumping equipment by swinging it up and down, after turning it on

Pipe wall damage

Damage to the walls of the casing is a fairly rare reason that the pump is stuck. But, nevertheless, it should be considered. If, while lifting the pump up, you encountered an obstacle and heard a knock, then most likely the problem is in the casing. This can be either its deformation (plastic), formed in the process of soil displacement, or marriage in welding and pipe connection. In this situation, remove the pump from the damaged pipe possible with rotational movements. By rotating the pump in a circle, you have a chance to go around the obstacle.

Lime deposits on casing pipes

Lime deposits on casing pipes

An object that has accidentally fallen into the pipe can also serve as an obstacle to lifting the pump. If it gets into the space between the pump and the well, it can stall the lift. In such a situation, as a rule, the downward stroke is free, but when moving upward, the pump begins to wedge. Try to rotate the pump and lift it up again. If there is no positive trend, it is better to call specialists who have all the necessary equipment to fix the problem and raise the pump.

Probe use

Depending on the design, HDPE pipes are produced with or without a probe (broaching).

Broach - a thin cable, wire - which is used to pull the cable into the pipe. To facilitate the work, it is better to use a double corrugation, the inner wall of which is smooth, made of PVD, which facilitates the passage of wiring.

- Start by measuring the desired length. The excess pipe is cut off with a knife or a special pipe cutter, the probe is bitten with side cutters. When cutting the probe, be sure to hold the inner end, otherwise it can fall and be almost impossible to get.

- After cutting, bend the broach and hook it on the outer wall of the pipe. We wrap the wire with a cable or pierce the internal insulation.

- Having tied the opposite end of the cable to a fixed object, you need to gradually drag the cable through the HDPE pipe. You can carry out this operation on your own, or with a partner: one holds, the second stretches.

- For better sliding, it is worth wrapping the clutch of the broach and PVC cable with electrical tape.

Folk ways to lift a jammed pump

In some cases, homeowners want to resort to more economical ways of lifting stuck equipment. The use of improvised means to eliminate such a problem is not always justified and correct from the technical side.

Equipment with a broken cable can be removed with a metal cat tool equipped with special pins. A homemade device allows you to hook and lift the pump to the surface. If the cat breaks off and falls into the shaft, it will need to be removed along with the pump.

To push the stuck equipment, scrap metal is used, tied to a flexible cable.Broken scrap is impossible to get, moreover, it can lead to disruption of the hydraulic structure. This method can be used in the case when an old pump is removed, which requires a quick replacement, because the probability of damage to the housing is quite high.

If the pump fell into the well, it can be removed with a pipe with an “ear” that is welded to the base

passed through the cavity of the pipe rope or cable, after which it carefully lowers into the well. Under the influence of the pipe, the pump can hang freely on a flexible cable

All that remains to be done is to pull the equipment and fixture out of the mine. Such a design is able to withstand extreme loads, so it will not be able to break even if the pump is seriously stuck.

You can remove the equipment by tapping on the cable. In this case, the metal cable is held at maximum tension to make rhythmic taps. In this position, the pump will not be able to fall to the bottom of the well, and in the absence of any obstacles in the hydraulic structure, it will not be difficult to get it.

Lifting the unit from an idle well

In some cases, it becomes necessary to remove the device with your own hands from a well that has not worked for 2-3 years. It should be taken into account that in such a well the level of sludge can rise above the unit. If you try to lift such a pump, it can immediately jam. To fix the problem, you can act on your own, but it is better to call a specialist. The owner can try to remove the pump by rolling.

In some cases, it becomes necessary to remove the device with your own hands from a well that has not worked for 2-3 years. It should be taken into account that in such a well the level of sludge can rise above the unit. If you try to lift such a pump, it can immediately jam. To fix the problem, you can act on your own, but it is better to call a specialist. The owner can try to remove the pump by rolling.

To do this, it is necessary to evenly tighten and then loosen the cable on which the pump unit is installed.Sometimes it is possible in this way to free the pump from the sludge. If this succeeds, then water will penetrate into the resulting gap, wash away the silt. This will make it easier to lift the machine. During operation, do not act by force, as this can lead to a break in the cable with the pump. If, after dismantling the equipment, the water in the well remains transparent, then such a well can be used.

Sometimes, when trying to lift the unit from a silted well, the pump falls to the bottom. Then you need to use the cat to lift the apparatus from the well.

When the pump falls to the bottom of the limestone, it is best to call in specialists with the appropriate equipment. They will determine the presence of damage on the pipes, the condition of the pumping unit, the presence of foreign objects in the well.

When the pump falls to the bottom of the limestone, it is best to call in specialists with the appropriate equipment. They will determine the presence of damage on the pipes, the condition of the pumping unit, the presence of foreign objects in the well.

Specialists have many different devices that will help you quickly get rid of the problem. If during the test it becomes clear that a coil of cable has formed in the well, then it can be removed with various traps. Most often, specialists use a cat or a special brush. The hook helps to capture and wrap the pieces of the cable that appeared after the break. If the pipes are damaged, they are removed with a special trap. Then lift the pumping unit itself.

Causes of a stuck pump

In order to figure out how to pull out the pump, it is necessary to consider the reasons leading to this situation. Most often they are explained by the human factor. For example, it was installed incorrectly, the well was not inspected for too long, the requirements for installing pump elements were violated, etc. The main causes of downhole equipment jamming are:

- well silting;

- damage to the walls of the well casing;

- ingress of foreign objects into the pipe;

- sagging power cable.

The main difficulty lies in the fact that sometimes it is impossible to determine exactly what happened to the pump. The gap between the pipe wall and the device itself can be literally 1-2 cm, and it is not possible to see the cause without special equipment. To determine the cause of the jam and decide how to get the pump out of the well, you need to analyze all the symptoms.

Silting at maximum depth

The device worked for several years without any problems, but it is not possible to get it. Most likely, the well silted up. This happens quite often, the reason is the downtime of the well for a long time. The water level can be at least a meter and block the device.

Location of the silted area in the well

The solution to the problem is to swing the pump with a cable

You need to act carefully so as not to aggravate the situation. You can gently pull up, and then lower

Gradually, the silt deposits will begin to erode the water, and the device can be lifted.

To get rid of such a problem, the well should be cleaned every 1-3 years. Unable to pull pump out of limestone well.

In limestone wells, normal siltation does not occur, perhaps the matter is “reverse siltation”. The reason for its appearance is that the device sank too deep, and water began to stagnate around it. As a result, sediment appears on the end and pipes, which causes blocking of movement. Moreover, the sediment is formed strong, and flushing the well will not give any result.

You can get the pump, as in the case of silting, by swinging. In this case, the device must be turned on, then the water will more successfully wash out the resulting plug.To prevent the problem from occurring in the future, it is worth paying more attention to maintaining the operation of the well, as well as correctly placing the pump in it.

Jamming when lifting

While lifting, the pump is stuck in the well and does not move despite all efforts. This is the most common cause of pumping equipment jamming in a pipe. Most likely, such "symptoms" mean that the cable wrapped around is sagging.

This problem is much easier to deal with than others. The stuck device must be lowered and the cable loosened. After that, pull out the pump again, trying to prevent the cable and cable from sagging again. In no case should you pull with all your might - the cable can break, and then it will be very problematic to get the equipment.

The scheme of fastening the pump to the casing to prevent sagging

To prevent the cable from sagging, it can be attached to a pipe or hose even at the stage of installation of the pumping system. For this, special clamps are used. It is not worth attaching a cable to the cable - when the cable is pulled, the clamps can fly off. Before lifting, they will have to be removed, and then replaced with new ones. But this simple measure will avoid problems with lifting a stuck pump.

The reason is a broken pipe. Perhaps a dent has formed, the edge has flattened, the joint has parted. Burrs formed due to poor-quality welding of the seam can interfere with movement. Before removing the stuck pump from the well, it is given a rotational motion.

In some cases, this can help - the device will pass by the damaged area, although there are no guarantees. Perhaps the result will be one-time, but there is a chance that this will help solve the problem. The pump stuck sharply when lifting approximately in the middle.

The reason may be that a tool or a small object (for example, a small pebble) has entered the well and blocked the movement. Stopping the movement of downhole equipment occurs precisely at the moment when a solid object gets between the wall and the pump.

Jamming intervals may vary - it depends on which cable selection is installed, while the device drops down without interference.

You cannot cope with such a problem on your own; you need to call a team of specialists for help. Using the right equipment, only specialists can pull out the part that causes jamming.