- Causes of pump jamming in the body of the well

- 1. Sagging electrical cable

- 2. Silting of the well as a result of long downtime

- 3. Solid-state obstacle - a complex barrier

- 4. Reverse silting effect

- Probe use

- Folk ways to lift a jammed pump

- Possible reasons

- slack cable

- Well silting

- Reverse siltation

- Pipe wall damage

- What not to do and what to do

- First 1: slack cable

- Dismantling problems

- The pump is silted up

- The unit is stuck in the well while lifting

- The pump fell into the well

- How to avoid the problem of submersible pump jamming

- When can a pump get stuck?

- Submersible pump stuck due to sand silting

- Causes of a stuck pump

- Silting at maximum depth

- Jamming when lifting

- Possible technological reasons

- Well Owner Warnings and Recommendations

- Recommendations:

- Causes of a difficult situation

- Lifting the unit from an idle well

Causes of pump jamming in the body of the well

Basically, all the reasons leading to the occurrence of this unpleasant problem are due to the human factor.When during the installation of the pump the technological requirements for fastening the elements of pumping equipment are violated, and due attention is not paid to their workmanship, it is difficult to expect a favorable outcome during the dismantling of the pump.

1. Sagging electrical cable

For this reason, the largest number of cases of equipment jamming occurs. This happens by biting a sagging electrical cable in a loop that is tightened around the pump housing.

In this situation, you should not pull the device with all your might, as this will not lead to success. But what you pull on can break. Then it will be difficult to do something on your own.

Experts who have repeatedly lifted pumps from wells advise in this case to try to push the device back. Repeating attempts, try to feel the slack and at this moment continue to slowly rise. In general, “prevention is better than cure”. In order not to encounter sagging of the electric cable in your practice, it is necessary to fasten it with special clamps to the pipe or hose at the stage of system installation. Moreover, it is not recommended to attach an electric cable to the cable, since when it is tensioned, the clamps can fly off. When lifting the pump, it is also necessary to ensure that the cable and hose come out at the same time to the surface. Weakness must not be allowed either on the cable, or on the cable, or on the hose.

2. Silting of the well as a result of long downtime

There are also often cases in practice when a long downtime of a well leads to its strongest siltation. The resulting layer of silt becomes an insurmountable obstacle in the way of the pump.When the pump is stuck in the well for this reason, experts recommend starting its swing, during which the device is either raised or lowered. What does this lead to? Water can gradually begin to wash away the silt deposits. In the end, perhaps, the road to the top will be free, which will allow you to remove the pump outside. The main thing is not to rush things and do not be excessively active in order to prevent the pump from deafly jamming.

There is also a non-standard way to deal with a silted well. It is necessary to involve firefighters in solving the problem, who, with the help of a hose lowered into the well, will be able to wash away silt deposits. The released pump will go up smoothly. To prevent the process of well silting, it is necessary to carry out its preventive cleaning, the frequency of which should be once every three years.

3. Solid-state obstacle - a complex barrier

On the path of the pump, a solid obstacle may be encountered, which will play the role of a wedge. Such a barrier can be:

- a dent in the pipe caused by ground movement;

- flattened edge of the pipe;

- burrs from a sloppy weld;

- defect in the assembly of the sedimentary column, in which instead of threaded connection of pipes, they are welded, allowing axial displacement.

Meeting with such an obstacle is accompanied by a characteristic hard knock, while the downward movement of the pump is free. Is it possible and how to pull the pump out of the well in this situation? There are cases when the rotation of the pump with the help of a pipe around its axis helps to go around the obstacle that has stood in the way. However, a 100% probability of the release of the movement of the device is not guaranteed. It may be a one-time success.But it's worth a try, suddenly in a particular situation the problem will be solved in this way.

A tool, fastener or other foreign object that accidentally fell into the well can also become a solid obstacle. In this case, the pump stop occurs during the rise abruptly and unexpectedly. This happens when a solid object enters the gap between the well wall and the pump, which leads to jamming. In this case, the downward movement is free, and the jamming intervals upward vary depending on the cable selection. The object will not be able to slip through, the gap is too narrow. Therefore, experts advise to stop, call specialists. The special equipment available to them is able to extract interference from the well.

4. Reverse silting effect

This effect is observed in wells drilled in limestone soils. As a result of long-term operation, a sedimentary layer forms over the location of the pump, turning into a "plug". To stop this process, clean the well every three years.

Probe use

Depending on the design, HDPE pipes are produced with or without a probe (broaching).

Broach - a thin cable, wire - which is used to pull the cable into the pipe. To facilitate the work, it is better to use a double corrugation, the inner wall of which is smooth, made of PVD, which facilitates the passage of wiring.

- Start by measuring the desired length. The excess pipe is cut off with a knife or a special pipe cutter, the probe is bitten with side cutters. When cutting the probe, be sure to hold the inner end, otherwise it can fall and be almost impossible to get.

- After cutting, bend the broach and hook it on the outer wall of the pipe.We wrap the wire with a cable or pierce the internal insulation.

- Having tied the opposite end of the cable to a fixed object, you need to gradually drag the cable through the HDPE pipe. You can carry out this operation on your own, or with a partner: one holds, the second stretches.

- For better sliding, it is worth wrapping the clutch of the broach and PVC cable with electrical tape.

Folk ways to lift a jammed pump

In some cases, homeowners want to resort to more economical ways of lifting stuck equipment. The use of improvised means to eliminate such a problem is not always justified and correct from the technical side.

Equipment with a broken cable can be removed with a metal cat tool equipped with special pins. A homemade device allows you to hook and lift the pump to the surface. If the cat breaks off and falls into the shaft, it will need to be removed along with the pump.

To push the stuck equipment, scrap metal is used, tied to a flexible cable. Broken scrap is impossible to get, moreover, it can lead to disruption of the hydraulic structure. This method can be used in the case when an old pump is removed, which requires a quick replacement, because the probability of damage to the housing is quite high.

If the pump fell into the well, it can be removed with a pipe with an “ear” that is welded to the base

A cable or cable is passed through the cavity of the pipe, after which it is carefully lowered into the well. Under the influence of the pipe, the pump can hang freely on a flexible cable

All that remains to be done is to pull the equipment and fixture out of the mine.Such a design is able to withstand extreme loads, so it will not be able to break even if the pump is seriously stuck.

You can remove the equipment by tapping on the cable. In this case, the metal cable is held at maximum tension to make rhythmic taps. In this position, the pump will not be able to fall to the bottom of the well, and in the absence of any obstacles in the hydraulic structure, it will not be difficult to get it.

Possible reasons

The most common cause of equipment getting stuck in the well is human error. This can be both a violation of technological requirements during the installation process, and the quality of installation materials.

It is very important that during the installation process you choose proven equipment, and the installation itself is carried out by qualified specialists.

But improper installation and poor-quality equipment are only a factor influencing the causes themselves. But why the pump can get stuck in the well, let's look below.

slack cable

A slack cable is one of the most common reasons that pumping equipment can get stuck in a well. If the electrical cable is sagging, it can simply be bitten by a cable loop that holds the equipment. When this happens, in no case should you pull the cable with all your might, as you can break it, and it will be much more difficult to get the pump out of the well on your own.

It is worth noting that this is the most common and quickly solved problem. If the pump is stalled and won't go up, try lowering it a bit and choosing the moment when the cable loosens, repeat the lift.In the process, make sure that the cable, cable and hose do not sag.

In order to avoid such troubles in the future, simply connect the cable to the hose with clamps, fixing it. During the lifting process, make sure that the cable and hose come out at the same time, and do not allow any slack, as the situation may repeat itself.

Well silting

Quite often, the reason that it is not possible to pull the pump out of the well is its silting, due to rare use. It is the layer of silt that serves as an anchor that prevents you from pulling out the pumping equipment.

If silting is the cause, you can try to get it by rocking it, slightly raising and lowering the pump down. Under the influence of mechanical up and down movements, the water will erode the space around the pump, thus facilitating its release.

If the pump is stuck, it is important not to rush during the rocking process, and not to pull with all your might, as it may completely jam or completely break the cable. If you can’t get the pump on your own, you can resort to the help of firefighters so that they lower the fire hose and wash away the layer of silt with water pressure

Reverse siltation

One of the reasons for pump jamming in the well can be the effect of reverse siltation. It should be noted right away that it is observed only in wells drilled on limestone soils, therefore, if your well is not on limestone, this option can be excluded.

Jamming of pumping equipment occurs due to the deepening of the pump during operation. Over time, a precipitate forms, which settles on the pipes and pump

It is important to note that you will not get off by flushing the well, as in the previous version, since the sediment can be very dense. In this case, you can pull out the pumping equipment by swinging it up and down, after turning it on

Pipe wall damage

Damage to the walls of the casing is a fairly rare reason that the pump is stuck. But, nevertheless, it should be considered. If, while lifting the pump up, you encountered an obstacle and heard a knock, then most likely the problem is in the casing. This can be either its deformation (plastic), formed in the process of soil displacement, or marriage in welding and pipe connection. In this situation, you can get the pump out of the damaged pipe using rotational movements. By rotating the pump in a circle, you have a chance to go around the obstacle.

Lime deposits on casing pipes

An object that has accidentally fallen into the pipe can also serve as an obstacle to lifting the pump. If it gets into the space between the pump and the well, it can stall the lift. In such a situation, as a rule, the downward stroke is free, but when moving upward, the pump begins to wedge. Try to rotate the pump and lift it up again. If there is no positive trend, it is better to call specialists who have all the necessary equipment to fix the problem and raise the pump.

What not to do and what to do

When removing pumping equipment stuck in a well, its users often make erroneous actions that can only exacerbate the problem, and not resolve it. Let's consider these actions in more detail.

Excessive effort

The result of this is often a break in the cable or hose that holds the pump, and the device may fall into the well.

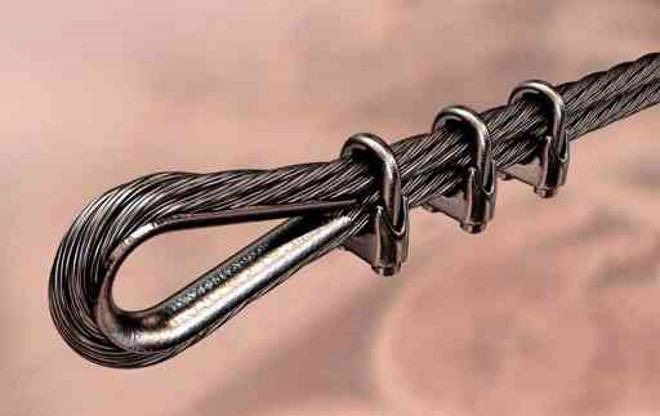

It should be borne in mind that it is necessary to remove a stuck submersible pump with the utmost care. When placing the pump in the well, you should initially use a cable that can withstand increased loads for this.

Robust cable made of 4 mm stainless steel with a tensile strength of 1000 kgf

The use of various devices (hooks, assault crampons, etc.)

In most cases, the use of such devices to extract a pump stuck in the well leads to the fact that both the pump and the device for its extraction remain in it. This situation will greatly complicate the task of removing the pump, which is stuck in the well shaft.

The use of such devices can both solve the problem and exacerbate it.

The use of scrap tied to a rope or cable

In the event that such scrap falls into the well, one can not hope for the prospects for its further use.

If we talk about the most effective and safe methods of extracting a pump stuck in a well, then among them are the following:

- sampling the cable holding the pump in the well, fixing it in a taut state and tapping (this procedure should be performed several times until the pump starts to rise along the well pipe);

- pushing a stuck pump into the lower part of the well, for which a load tied to the end of a cable or rope is used (in this case, a piece of steel pipe of the appropriate diameter can be used as a load).

Pull out the stuck pump a homemade hook trap, similar to those devices used by professionals, will help

In the event that a pump stuck in a well cannot be moved by any means, it is better to use the services of specialized companies that have special equipment and all the necessary tools to solve the problem.

First 1: slack cable

In the process of the last successful lifting and lowering of the pump, the workers were too lazy to fasten the power cable with clamps-screeds to the riser pipe or hose every 700-1000 mm, choosing an excessively large step or not putting screeds at all.

The result of this negligence is the electric cable entwining the body of the submersible water pump or wedging it between the pump and the casing wall, which occurred during the next raising of the pump unit from the well. In such a situation, attempts to pull the pump out by the efforts of several people, or with a jack or winch, will be followed by one result - a cable break.

When lifting a submersible pumping device together with a water-lifting pipe string from a well, one should carefully monitor the slack of the cable (when lifting with a cable) or the electric cable and cable (when lifting by the pipe). Do not count on the reliability of the ties, carefully tighten the cable or cable and cable as the pipes rise higher, gradually picking up the slack and watching for their simultaneous exit - at least two workers, and preferably three, will be required.

If slack is still formed and the pump does not go up, grab the pipe string with both hands and push it down half a meter. Then tighten the cable along with the cable and slowly continue lifting, constantly monitoring the slack in the cable and cable.Having found the pump jammed - pushing the pipe with your hands does not move it lower - apply more physical effort to push it down.

You can try to knock out a jammed pump by dumping scrap on a rope into the well, but negative consequences can no longer be avoided - the scrap will break and fall into the well, the water pump will be broken, or, much worse, the well casing may suffer.

Dismantling problems

But sometimes removing the equipment becomes impossible due to various problems.

The pump is silted up

Silting of the unit body in the casing is a fairly common problem when removing the apparatus. Silting occurs if the apparatus for supplying water from a source is rarely used. It is the layer of silt accumulated in the casing pipe that interferes with the removal of the device from the well.

In this case, to get the equipment out of the casing, the rocking method is used. The essence of the method is the forced movements of the pump up and down, due to which the space around the unit will be washed with water and freed from accumulated sludge.

If swinging fails to free the equipment, you will have to resort to the help of firefighters. They, having lowered the fire hose into the well closer to the pump, wash away the accumulated layer of silt with a strong pressure of water.

If the well in which the unit is stuck is drilled in limestone, then a possible cause of jamming of the equipment may be limescale on the casing.

Advice! In this case, the rocking method with the engine running is used to retrieve the unit so that the casing is cleaned more intensively.

The unit is stuck in the well while lifting

Often when lifting equipment from a well, due to slack in the electrical cable or slack in the cable, it is firmly stuck in the casing. In this case, the cable (cable) wraps around the body of the unit and does not allow it to move freely. The pump is “released” according to the following algorithm.

- Try lowering the device to the bottom. After that, you should unwind the loop formed around the device by slowly swinging the cable in different directions while pulling the cable (cable).

- When lifting the unit, do not forget to simultaneously tighten all the elements connected to the pump: hose, cable and rope.

- Fix all elements with clamps every meter.

- Lift the equipment slowly and with the utmost care.

The pump fell into the well

If, when removing the unit, it fell into the well, then it is not always possible to get it. But it's certainly worth trying.

- Make a cat hook out of steel wire.

- Weld the steel wire to the hook. Its length should be equal to the depth of the well plus another 50 cm.

- Lower the hook into the well, and when it reaches the fallen pump, start spinning the wire to try and hook the hose.

- If you succeeded in hooking the hose, then try to slowly and carefully pull the device out of the well. A winch or other lifting equipment can be used to retrieve it.

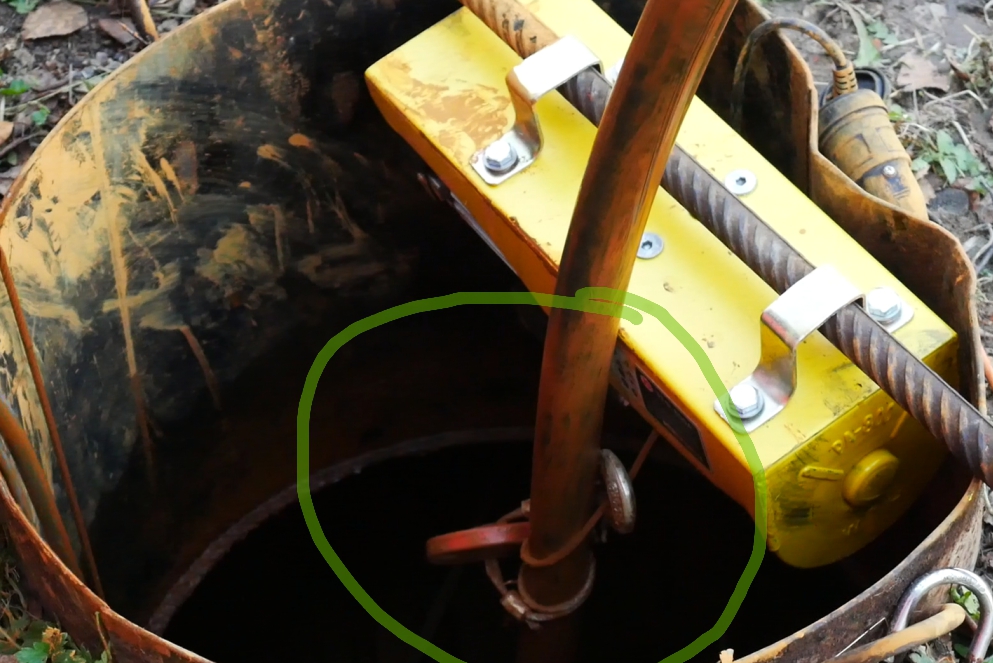

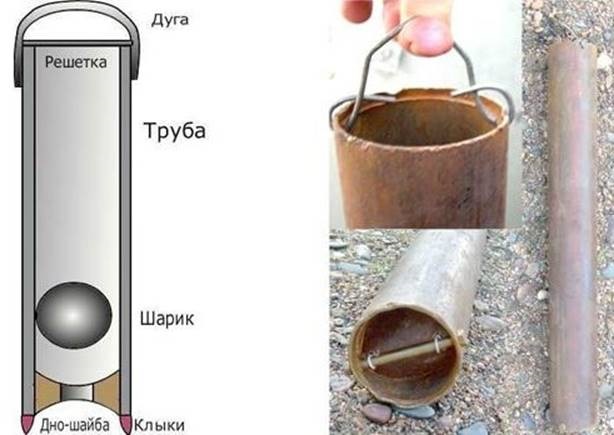

When it is not possible to remove the pump, it can be left in the well, provided that it does not interfere with its filling with water. Sometimes a non-recoverable aggregate is destroyed with a bailer (see figure below)

The unit is broken into small pieces and either removed in parts or left in the well.

How to avoid the problem of submersible pump jamming

The above reasons for blocking a water pump in a borehole can be foreseen at the stages of well construction and operation by following the following recommendations:

- do not fasten the cable with clamps to either the pipe (or hose) or the cable. When the pump is pulled out, the cable will stretch and break the ties (especially plastic ones), and the electric cable will sag;

- the maximum fastening step of the riser pipe with electric cable ties is 1 meter. If water is pumped out by a pump through a hose, then the clamps are set in half-meter increments, which will reduce the risk of their imperceptible sagging;

- the cable for hanging the submersible pump must be made of stainless steel. Rope ropes, cables made of ordinary steel with copper plating, galvanization or dressed in plastic are unsuitable for many years of operation;

- one-piece rope, riser pipe and electric cable are required. Their splicing from pieces sharply increases the likelihood of divergence of connections when lifting the pumping device with bending of the ends into the wellbore and jamming of the lifted equipment;

- a water pump model is required, whose diameter leaves the largest gap between the casing and the wall of the casing pipe. Then the risk of jamming will be the least;

- wellhead is required. The mouth of the casing should be kept closed during daily use of the well for water, otherwise contaminants of various sizes will enter the wellbore.

Keep in mind that the well needs periodic inspection. As a maximum every 5 years, it is necessary to remove and inspect the submersible pump, measure the dynamic level and the actual depth of the well. And then place the pumping device in it no deeper than a certain level - at least a meter from the bottom, but not more than 10 m from the dynamic level

The last condition is especially important for limestone wells.

When can a pump get stuck?

In most cases, well owners have problems with the extraction of pumping equipment, which has already worked for a certain time in development.

Lifting the deep pump is necessary in the following cases:

- carrying out repair work;

- Maintenance;

- replacement with a more powerful or new pump;

- replacing the flush pump with a permanent one.

Much less often, the pump jams in the wellbore when trying to lower it to the bottom of the well. The causes of sticking in this case are, as a rule, a mismatch between the size of the pump and the diameter of the casing pipe, or the ingress of a foreign object into the string, which prevents the descent of the unit.

These two reasons are easily eliminated: the size and model of the pump is selected before the start of the descent, and the foreign object that has entered the casing is removed or pushed down.

To prevent the pump from getting stuck during descent, it is necessary to observe safety measures: carefully inspect the unit and make sure that all its parts are in good order, avoid foreign objects (stones, tools, packaging) from entering the pipe, use a reliable cable and clamps.

The use of a surface pump instead of a deep one will avoid the problems that arise when lowering and raising equipment inside an aquifer

Submersible pump stuck due to sand silting

As a rule, silting occurs if the well is used either rarely or incorrectly. As a result, the well pump is inside the mud "trap". To release it, the cable is alternately pulled and loosened. And at the same time they rock the unit. In principle, this is enough to free him from the sludge.

If the well has not been used for a long time, the silt in it may become solid. To remove the aggregate was possible, the sludge is pre-washed out. This is done with a flexible hose or fire hose. Through them, water is fed into the cavity of the well.

However, the soaking of the sludge can be quite long. It can last two days. To find out if the unit has been released from silt captivity, you should periodically try to stir it up, pull it. At the same time, excessive efforts should not be applied.

Silting occurs especially often if the well has not been cleaned for several years. If preventive cleaning is done annually, then silting is simply excluded. Therefore, bogging down in silt never occurs.

Causes of a stuck pump

In order to figure out how to pull out the pump, it is necessary to consider the reasons leading to this situation. Most often they are explained by the human factor. For example, it was installed incorrectly, the well was not inspected for too long, the requirements for installing pump elements were violated, etc. The main causes of downhole equipment jamming are:

- well silting;

- damage to the walls of the well casing;

- ingress of foreign objects into the pipe;

- sagging power cable.

The main difficulty lies in the fact that sometimes it is impossible to determine exactly what happened to the pump. The gap between the pipe wall and the device itself can be literally 1-2 cm, and it is not possible to see the cause without special equipment. To determine the cause of the jam and decide how to get the pump out of the well, you need to analyze all the symptoms.

Silting at maximum depth

The device worked for several years without any problems, but it is not possible to get it. Most likely, the well silted up. This happens quite often, the reason is the downtime of the well for a long time. The water level can be at least a meter and block the device.

Location of the silted area in the well

The solution to the problem is to swing the pump with a cable

You need to act carefully so as not to aggravate the situation. You can gently pull up, and then lower

Gradually, the silt deposits will begin to erode the water, and the device can be lifted.

To get rid of such a problem, the well should be cleaned every 1-3 years. Unable to pull pump out of limestone well.

In limestone wells, normal siltation does not occur, perhaps the matter is “reverse siltation”. The reason for its appearance is that the device sank too deep, and water began to stagnate around it. As a result, sediment appears on the end and pipes, which causes blocking of movement. Moreover, the sediment is formed strong, and flushing the well will not give any result.

You can get the pump, as in the case of silting, by swinging. In this case, the device must be turned on, then the water will more successfully wash out the resulting plug. To prevent the problem from occurring in the future, it is worth paying more attention to maintaining the operation of the well, as well as correctly placing the pump in it.

Jamming when lifting

While lifting, the pump is stuck in the well and does not move despite all efforts. This is the most common cause of pumping equipment jamming in a pipe. Most likely, such "symptoms" mean that the cable wrapped around is sagging.

This problem is much easier to deal with than others. The stuck device must be lowered and the cable loosened. After that, pull out the pump again, trying to prevent the cable and cable from sagging again. In no case should you pull with all your might - the cable can break, and then it will be very problematic to get the equipment.

The scheme of fastening the pump to the casing to prevent sagging

To prevent the cable from sagging, it can be attached to a pipe or hose even at the stage of installation of the pumping system. For this, special clamps are used. It is not worth attaching a cable to the cable - when the cable is pulled, the clamps can fly off. Before lifting, they will have to be removed, and then replaced with new ones. But this simple measure will avoid problems with lifting a stuck pump.

The reason is a broken pipe. Perhaps a dent has formed, the edge has flattened, the joint has parted. Burrs formed due to poor-quality welding of the seam can interfere with movement. Before removing the stuck pump from the well, it is given a rotational motion.

In some cases, this can help - the device will pass by the damaged area, although there are no guarantees. Perhaps the result will be one-time, but there is a chance that this will help solve the problem. The pump stuck sharply when lifting approximately in the middle.

The reason may be that a tool or a small object (for example, a small pebble) has entered the well and blocked the movement. Stopping the movement of downhole equipment occurs precisely at the moment when a solid object gets between the wall and the pump.

Jamming intervals may vary - it depends on which cable selection is installed, while the device drops down without interference.

You cannot cope with such a problem on your own; you need to call a team of specialists for help. Using the right equipment, only specialists can pull out the part that causes jamming.

Possible technological reasons

An analysis of the causes of possible jamming of equipment pumping water from a well is important for the prevention of such phenomena. It is always easier to prevent an accident than to try to fix it. The following main factors can be distinguished:

Wrong choice of equipment. If a submersible pump is selected only for power and depth, without taking into account the actual size of the casing, then this is a direct path to jamming. Sometimes it happens that an incorrectly selected pump can be pulled into the well by force to the desired depth and even start pumping water, but attempts to lift it when such a need arises are no longer successful

When selecting equipment, it is important to provide a gap between the apparatus and the wall of the order of 3-5 cm, for example, when using casing pipe with a diameter of 110 mm, a pump with a diameter of 4 inches (100 mm) should be lowered.

Well construction violations. The most common reasons are: the presence of poor-quality welds at the joints of pipes during the installation of the casing, misalignment of the location of pipes in different areas and drilling a well with a significant deviation from the vertical

Such defects create obstacles for the passage of the pump, which can lead to its pinching.

Violations in the installation of equipment. A fairly common cause of pump jamming is improper fastening of the electrical cable.It must not be overstretched during installation, but excessive slack can do a disservice. The cable loop gets into the gap between the pump and the well wall and jams the equipment. In order to exclude such a reason, the cable is fixed with special bandages after 3-5 m.

Well Owner Warnings and Recommendations

For self-repair work, the following should be considered:

- excessive force will break the cables;

- you can pull out a stuck mechanism using “cats”, hooks, and other devices, but there is a risk of a breakdown and fall of the suspended structure during pulling out. If the pump falls into the well to the bottom, it can break all the cables or be fatally damaged due to a fall. After that, pulling it out will be much more difficult;

- an attempt to move the pump with a suspended crowbar is the most common way to disable the equipment, as well as the entire production as a whole. A fallen scrap is guaranteed to render it inoperable. After that, it is extremely difficult to restore work. Should not be doing that.

Recommendations:

- after purchasing the pump, you need to replace the cable from the factory with a stronger steel

- fasten all cords so that there are no distortions, use stainless steel clamps

- the recommended diameter of the pump should be less than 2/3 of the pipe section

- hose from several pieces is risky to use

- the head will protect the well from falling debris

An example of a submersible pump mounting method

Permissible force manipulations:

- in a situation where deposits interfere, the cable is selected, fixed in a taut position, and periodically tapped. Further, they wait for some time until it weakens and choose the slack. The procedure is repeated many times;

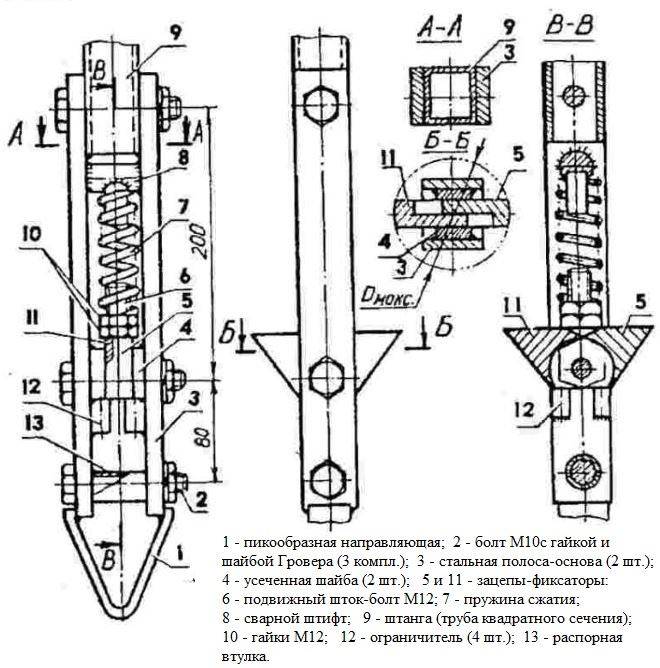

- an “ear” is welded to a piece of steel pipe, to which a reliable rope is attached. Then, all pump cables are passed through the pipe. The structure, the weight of which can reach 50 kg, is lowered down in order to push the unit down under its weight. After that, everything is pulled out. The bottom line is to pull all the cables evenly, tightening if any is sagging or lowering it too tight.

Excessive force will damage the pump or deform the pipe. First of all, craftsmen recommend pulling the cable a little, lowering and pulling it out. They do this several times. This method helps, even if it seems that the mechanism is stuck tightly. When the cable sags the structure is lowered to the bottom, then, shaking it, the loop is removed.

Causes of a difficult situation

First of all, you need to understand why this situation happened, what are its causes. And starting from them, you can choose ways to fix the problem. But you must immediately understand the fact that the installed pump in the well is a cylindrical equipment inserted into the casing. So, there is a very small distance between the walls of the pump and the pipe, measured by several centimeters. It is this small gap that often causes the pump to jam.

- A foreign object, for example, a pebble, may fall into the gap.

- An electrical cable supplying the pump with electricity can get into it.

But there are other common reasons as well. For example, the well itself silted up if it was not operated for a long time. The sludge became large, and part of the pump was in it. The cause may also be the casing pipe, which, under the action of formation movements, bent, or mechanical damage to its walls appeared.

Lifting the unit from an idle well

In some cases, it becomes necessary to remove the device with your own hands from a well that has not worked for 2-3 years. It should be taken into account that in such a well the level of sludge can rise above the unit. If you try to lift such a pump, it can immediately jam. To fix the problem, you can act on your own, but it is better to call a specialist. The owner can try to remove the pump by rolling.

To do this, it is necessary to evenly tighten and then loosen the cable on which the pump unit is installed. Sometimes it is possible in this way to free the pump from the sludge. If this succeeds, then water will penetrate into the resulting gap, wash away the silt. This will make it easier to lift the machine. During operation, do not act by force, as this can lead to a break in the cable with the pump. If, after dismantling the equipment, the water in the well remains transparent, then such a well can be used.

Sometimes, when trying to lift the unit from a silted well, the pump falls to the bottom. Then you need to use the cat to lift the apparatus from the well.

When the pump falls to the bottom of the limestone, it is best to call in specialists with the appropriate equipment. They will determine the presence of damage on the pipes, the condition of the pumping unit, the presence of foreign objects in the well.

Specialists have many different devices that will help you quickly get rid of the problem. If during the test it becomes clear that a coil of cable has formed in the well, then it can be removed with various traps. Most often, specialists use a cat or a special brush. The hook helps to capture and wrap the pieces of the cable that appeared after the break. If the pipes are damaged, they are removed with a special trap. Then lift the pumping unit itself.