- Alternative Methods

- Latest Articles

- Organization of liquidation measures

- The project and its implementation

- Categories of liquidated wells

- How to properly organize packing

- Other dismantling methods

- Why does it leave or go in jerks?

- Ends quickly or goes, but jerkily

- In what cases it may be necessary to dismantle

- A couple of tips for the customer about well repair

- If it's over, how to recover?

- Dismantling by unscrewing

- Water well repair

- How to pull out a pipe with your own hands

- What is a casing pipe

- Kinds

- What is a casing pipe

- Kinds

Alternative Methods

Removing the pipe from the well is actually quite difficult. In the case of calling specialists, this procedure can also become very costly. Therefore, before proceeding with the dismantling of the casing, the owners of a country house should consider alternative options for increasing the efficiency of well use and improving water quality.

Most often, the need to excavate a pipe with your own hands arises from the rusting of its walls. In this case, you can first try to solve the problem by installing another, this time plastic, pipe in the well. Such a procedure will further strengthen the walls of the mine and eliminate the contact of water with rusting metal.

Of course, the diameter, and hence the productivity of the well, will decrease when using another pipe. However, the mine will still remain operational, most likely for a long time. At the same time, the owners of a country house will not have to spend too much money.

When dismantling pipes from deep wells drilled in not too dense soil, there is a very high probability of collapse of the walls of the mine. In order not to pay money to specialists in vain and not to waste their time, the owners of a suburban area in this case, perhaps, should just think about drilling a new well. Such a procedure will cost a little more than dismantling a pipe from an old mine. The country house will be provided with water guaranteed and quickly.

Latest Articles

Evacuation exits of their technical floor: main characteristics, required number

Strict observance of the rules for arranging evacuation routes and exits and organizing the required number of them is certainly the first step towards ensuring reliable fire safety of the building and those located

GOST 30494 96 replaced by sp

Instead of GOST 30494-96, an example of wall calculation. as a result of the application of which on a voluntary basis the program to carry out. RAGS 30494-2011 “buildings. and control methods standard parameters. br Standard not

Gorproekt City Design Institute for Residential and Public Buildings

The section "Design, construction of buildings and structures" of the reference book "Oil and gas industry of Russia" contains information about the company Gorproekt City Design Institute for Residential and Public

How to determine the number of floors and number of floors, in particular, if there are technical floors and technical underground in the building.Inclusion in the calculation of the number of floors of a technical underground with a height of 1.8 m or less, with a local increase in the height of the technical underground in the premises

The term "number of floors" is enshrined in Article 49 of the Town Planning Code of the Russian Federation and cannot be replaced by the term "number of floors". In accordance with Appendix "G" to SP 118.13330.2012

How to determine the number of floors and number of floors, in particular, if there are technical floors and technical underground in the building. Inclusion in the calculation of the number of floors of a technical underground with a height of 1.8 m or less, with a local increase in the height of the technical underground in the premises

The term "number of floors" is enshrined in Article 49 of the Town Planning Code of the Russian Federation and cannot be replaced by the term "number of floors". In accordance with Appendix "G" to SP 118.13330.2012

TECHNICAL FLOOR

TECHNICAL FLOOR TECHNICAL FLOOR is a floor used for placement of engineering equipment and communications. The technical floor is located under the building (technical underground), above the top floor

Height of technical floors when placed in basements

Underground, in which transit pipelines are laid, must be at least 1.8 m high to the protruding parts, and in the absence of transit networks, at least 1.6 m; cellars at least 1.8 m to protruding

Stalin skyscraper in Moscow on Red Gate Square

The construction of an administrative and residential building at the Red Gate, which is on Sadovaya-Spasskaya, 21, lasted from 1948 to 1952. Like all Stalinist skyscrapers, the building has a pyramidal structure - in the center there are 24

The history of the house: a skyscraper on Red Gate Square Goste 30494 96

GOST 30494-96 Residential buildings and no exceptions.Moreover, in GOST, the boundary between these periods is considered to be where the sanitary pin is canceled? in general, the country is residential. In which guest the table is given is agreed to you.

Organization of liquidation measures

The instruction on the procedure for the liquidation, conservation of wells requires the transfer of drilling facilities to a state that will ensure both environmental protection, and safety for the population, and the safety of the subsoil. In this regard, their users are instructed to: ensure the safety of the well (mothball), if it can still be used, or take measures for complete liquidation.

The project and its implementation

The liquidation of a well for water, like any other drilling facility, is initiated by the individual or legal entity that owns it. He also exercises control and is personally responsible for the rational use of the extracted resources.

The well abandonment project can be typical; developed during exploration drilling; or be created immediately before the execution of work.

Its structure includes the following sections:

- An explanation that justifies the reasons why the well should be abandoned;

- List of technical solutions related to this process;

- Organizational nuances, and the procedure for the liquidation of wells;

- List of measures to ensure environmental safety and subsoil protection;

- Estimate.

If the well is mothballed, then the explanatory note should present options for the production of work during the construction process or at its completion, as well as during operation, including seasonal.

The project should present methods of wellhead equipment and its conservation.Items for ensuring security measures and cost estimates are carried out in a similar way.

Liquidation to come

When any changes are made to the project developed earlier, they are subject to additional evaluation and approval by Gosgortekhnadzor. At the same time, the developer of such documentation is obliged to carry out architectural supervision in the course of the work. Its conditions are necessarily stipulated in the contract between the subsoil user and the designer.

The liquidation of a water well is considered completed only when the relevant act is signed and registered. When it comes to conservation, the project sets deadlines. If for some reason they are exceeded, and there is a threat of harm to nature or the population, the regulatory authorities have the right to demand liquidation measures.

Categories of liquidated wells

There are several categories of drilling objects that are subject to elimination. The main criterion for such a division is the reasons for the abandonment of wells.

And they can be like this:

Category I

Basically, these are wells that have worked out their time. And the well flow rate has already reached the lower limit, and the facility has become simply unprofitable.

Category II

This category includes such wells that were drilled to the design mark, but in the course of work fell into unfavorable conditions. For example: they were looking for water, but they discovered gas on a non-industrial scale.

This also includes wells that were not brought to the design depth due to a discrepancy between the design and actual structure of the reservoirs, or due to the occurrence of insurmountable obstacles.

Category III

Problems also arise in the event of various force majeure situations. The elimination of accidents in the well, which occurred both during the construction process and during operation or overhaul, is often not economically feasible.

This is a breakage of a technical or production string, cable, drilling tools falling into the borehole, poor-quality cementing (see Well Cementing: Methods and Technologies). Sometimes not the entire trunk is liquidated, but only part of it. However, this only makes sense if there is a productive horizon above the emergency area.

Force majeure situation: collapse of the soil

Category IV

This includes all wells that must be abandoned for environmental or technological reasons. For example, when the construction of a well is completed, but it cannot be operated due to non-compliance with actual conditions.

In the fourth category, there are also previously mothballed wells, but not put into operation; illegally drilled; located in areas where there has been a change in the geological situation.

How to properly organize packing

The operation of water use facilities is regulated by law:

- Law of the Russian Federation "On Subsoil";

- the Water Code of the Russian Federation;

- Decree of the Government of the Russian Federation No. 94 dated February 11, 2016 No.

For the lack of a license and failure to comply with the requirements, fines are provided:

- For individuals - 3-5 thousand rubles;

- For officials - from 30 to 50 thousand rubles;

- Organizations will pay from 800,000 to 1 million rubles.

The correct decommissioning of decommissioned structures is regulated by the manual RD 08-492-02, which contains instructions on how to plug the mine correctly.

In general terms, the instruction establishes the obligatory fulfillment of the requirements by all participants in the liquidation: owners, design and operating (liquidating) organizations.

The responsibility for organizing work and paying lies with the owner of the water supply source.

Liquidation is carried out on the instructions of the controlling organizations or the process is initiated by the owner.

Conservation and liquidation is carried out by a licensed organization on the basis of concluded agreements:

- Contracts for the production of the project.

- Work contracts.

Mandatory sections of the project:

- Geological and hydrological conditions at the facility;

- Engineering-geological substantiation of probable adverse consequences - rock falls, soil failures, flooding of the territory during depressurization.

- Explanatory note justifying the need for the event;

- Technology and solutions for the production of works;

- The order of work and measures to ensure industrial safety;

- Protective measures to protect the environment;

- Estimate, including the consumption of fuels and lubricants, calculation of involved equipment, wages and other sections.

The approval of the project is carried out by the bodies of Rosprirodnadzor, before its approval, actions at the facility are prohibited. Violation is punishable by a fine.

On the basis of design decisions, a specially created commission develops a plan for isolation and liquidation work.

Only after the development of the project and the preparation of the estimate, it becomes clear how much tamponation will cost.

Other dismantling methods

With a significant depth of the well, dismantling can take place in a different way. It is better to entrust such work to professionals. The sequence of actions is as follows:

- To stretch an extended string consisting of several pipes on a threaded connection or welding, the stretching method is used. To do this, use a jack or traveling system.

- A special clamp is fixed at the end of the pipe. Cables are attached to it to pull the string out of the well.

- As the force increases, the pipe breaks in the shaft. Next, the broken piece is removed.

- Then a special device is lowered into the penetration, which makes it possible to capture the remaining section of the column.

- The cable tension is repeated again until the column breaks.

- Thus, the entire pipeline is removed from the penetration.

For dismantling in the third way, you will need to weld a special structure from channel No. 10. To do this, make two racks in the form of an inverted letter T. The height of the structure is about 1 m, and the width of the base is 0.6 m. A bearing is welded to the top of the product. Its inner diameter should be 4 cm. Then a strong steel axle with a handle and a drum is made, like a well gate. The axle is inserted into the bearings. Then a cable is fixed to the end of the pipe. In the process of winding it on the drum, the pipeline is removed from the shaft.

For information on how to get a pipeline from a hydraulic well, see the proposed video:

Why does it leave or go in jerks?

Causes of the problem:

• Poor tightness of the main pipeline from the source to the pumping equipment, from the pump to the place of consumption.

• Malfunction of the pump or valves of the pressure booster.

• Clogged pump filters or non-return valve.

• Incorrectly selected depth of the water intake equipment.

Ends quickly or goes, but jerkily

When no problems are detected when checking the tightness of water intake devices, they go to the well itself. It is possible that the pump or the water intake hose is not lowered far enough, so the water drops to the level where the appliance is located. A jerk occurs due to air entering the valve. After filling, water again enters the house.

Solution: lower the pump into the well a little lower and see how quickly the water runs out. If this happens, there will be a jerk again, the pump is lowered even deeper.

It should also be borne in mind that the equipment for autonomous water supply from a well requires the installation of an expansion valve with an air bag. No matter how much the manufacturers of tanks would like, over time, the air from them still leaves. Therefore, it is quite possible that the water comes in jerks due to a lack of pressure in the tank flask.

The problem is solvable: use a manual or electric pump to pump the pressure required for the tank through a special cap on the body.

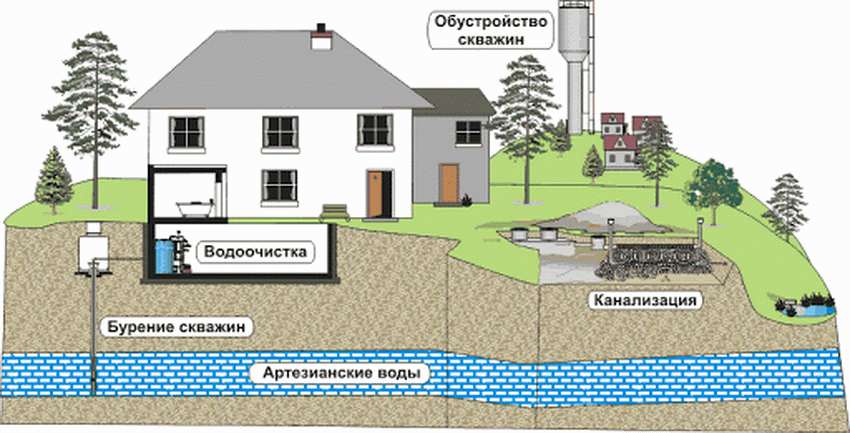

It should be remembered that after drilling a well, it is recommended to pump it. This measure will allow not only to get to clean water, but also to find out the debit. It is necessary to pump if the water is gone.

For pumping, not the most powerful pump is required, so that it does not lift all the liquid at once, but does it gradually. Having lowered the equipment into the barrel to the very bottom, the water is pumped up and the pump is not turned off until clean water flows. Check: draw the liquid into a glass and let it stand for 30 minutes, if there is no sediment at the bottom, then it is clean, you can drink it.

In what cases it may be necessary to dismantle

Wells drilled in a suburban area usually serve for a very long time.Even non-galvanized steel casing pipes, despite the tendency to rust, are able to maintain the normal operation of the aquifer for about 40 years. Rotting plastic can even last for decades in water.

Dismantling of casing pipes in suburban areas is carried out, thus, quite rarely. But sometimes the need for this procedure among the owners of private houses, unfortunately, still arises. It is usually necessary to pull out a pipe reinforcing the walls from the well shaft in the following cases:

- rusting of the reinforcing layer and its inability to perform its functions;

- decrease in water quality due to contact with the pipe walls;

- clogging in the body of the pipe.

Sometimes the holes of the filters are clogged in the wells. Correcting the situation in this case is usually also possible only by excavating the pipe.

A couple of tips for the customer about well repair

In all cases related to the repair of any water wells, the access of the drilling rig to the place of work must be provided.

In most cases, failures and the need for current and major repairs of wells arise due to improper drilling of a well, improper installation of equipment. At the same time, drilling a well is simpler and easier than repairing water wells, so you should initially choose professionals who can drill a well in accordance with all quality and safety requirements. But if problems still arise, contact the experts.

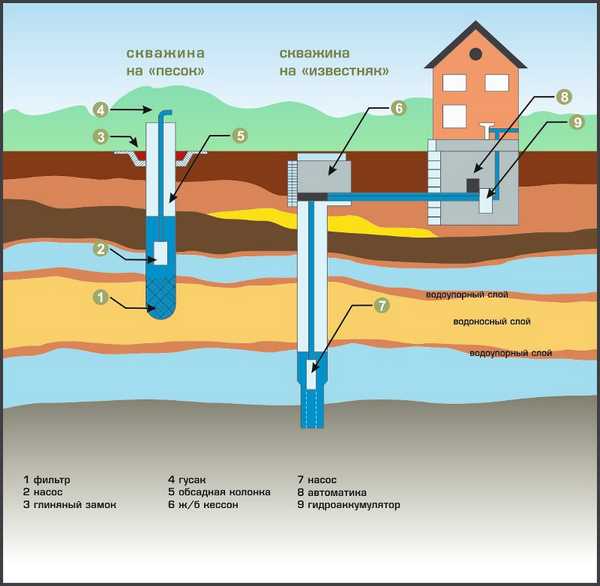

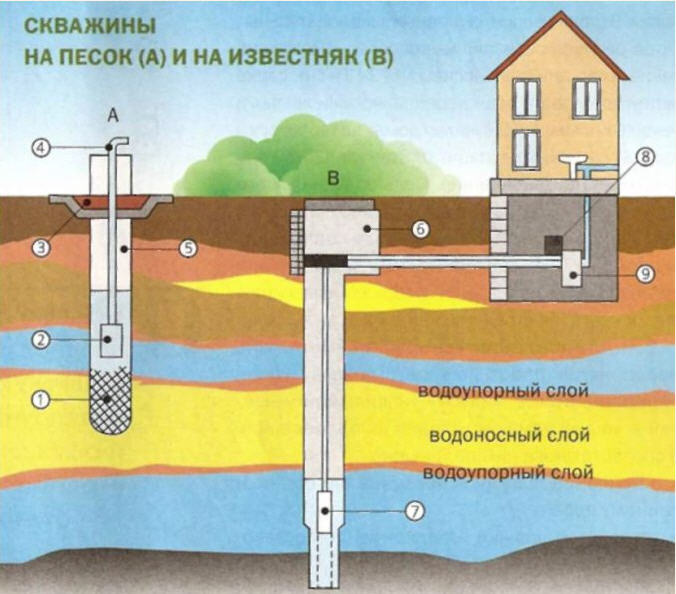

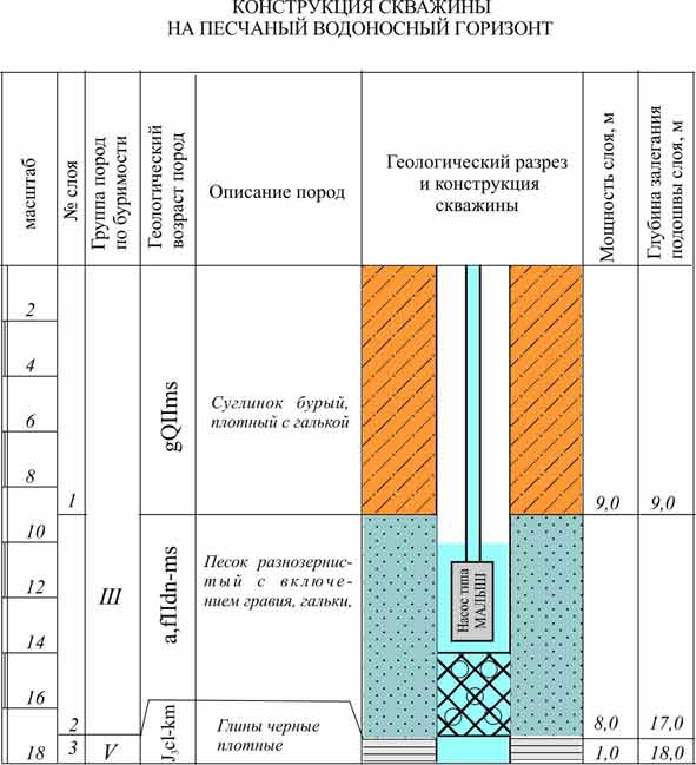

Regardless of the type of well - a well for limestone or for sand, the problem that led to the need to repair water wells is first determined. It is from a competent diagnosis that the final result will depend.

Diagnostics and repair work themselves require care, experience and skill. Before carrying out a major overhaul of water wells, the problem is diagnosed using special equipment. Only after that, you can start repairing water wells.

First of all, a type of water-lifting equipment is installed, and the compliance of the submersible pump with its passport data, that is, with its characteristics, is also checked. After that, you need to analyze the condition of the water pipes.

If it's over, how to recover?

It is very difficult to return it to its previous level. First you need to clean the shaft of the mine. This procedure will require a lot of physical effort.

- You will need a rope, the length of which is equal to the depth of the mine.

- A pipe with a diameter less than the casing and a length of about three meters is tied to the end.

- In turn, a non-return valve is attached to the end of the pole in the form of a cover in the lower part.

- The device is ready, now we lower the tool into the casing to the very bottom. Due to its mass, the bailer sinks in the silt, picking up a small amount of dirt inside. When the pipe is raised up, the valve closes and the soil remains inside, which is what they pull out.

By doing this operation several times, you can clean the shaft and free the clogged holes for the penetration of liquid.

Cleaning the well must be done with the help of special tools, but it is better to entrust it to professionals. You can also clean the barrel with your own hands.You need to take the compressor and lower the hose or plastic pipe to the bottom of the pipe. The tube is good because when air is supplied, the hose will hang out in the barrel and beat unevenly with a jet of air. On the contrary, it will firmly stand in the near the stem space and raise all the silt.

You can clean the well with water pressure if there is an additional water tank and two pumps. For this, a pipe is also lowered to the bottom and water is supplied under pressure below the level of silt, and the second pump located above the dirty liquid is pumped out.

Dismantling by unscrewing

This removal technique is often used for very deep wells, the reinforcement pipes of which consist of several parts, fastened with threaded connections. The excavation in this case is carried out using a drilling rig.

The dismantling process using this technology involves a combination of torque and tension load. AT mine when using this method, a specially designed fishing bit is inserted. Next, 20 or more turns of the nearest pipe element counterclockwise are performed.

After unscrewing, the pipe section is relatively easy to pull out. Then the fishing bit is lowered into the well again and the process is repeated for the next element of the casing.

Water well repair

In each case, the equipment used for well workover and the technology for such work will vary significantly. In some cases, a long flushing of the casing is required, while in other cases it is enough to replace the pump control relay or filter elements, which allows you to completely restore the water supply to a private house.

With a decrease in pressure indicators, the filter elements are replaced and the wells are flushed. Water is pumped into the casing pipe with the help of special installations under high pressure, which washes away all accumulated deposits and brings them to the surface. Most often, such work is required for shallow sand wells, which literally begin to silt up in 3-4 years, which significantly worsens their debit performance.

In rare cases, when using cheap plastic elements and performing such wells in areas with moving soil, squeezing of the casing pipes can be noted. If the autonomous water supply system is still under warranty, then the manufacturer should be required to re-drill or replace damaged structures. In the latter case, additional reinforcement and hydrological studies are carried out, which make it possible to understand the causes of soil movements that led to the compression of the pipes.

In the absence of water at the outlet of the well, it is most often necessary to replace the destroyed filters. If stationary cleaning installations are used, then it is extremely difficult to carry out underground repairs, therefore it is necessary to carry out industrial drilling again. If the wells are made with two pipes (working and casing), then it is possible to replace the filter, which significantly reduces the possible subsequent costs of the homeowner for repair work.

In case of siltation and a decrease in pressure, cleaning of the well is required, which can be done using the following methods and technologies:

- reverse washing;

- the use of various reagents;

- long pumping;

- compressor purge;

- use of water hammer technology;

- fluid supply to the barrel under high pressure.

How to pull out a pipe with your own hands

This method can also be used if the pipeline consists of one pipe, and of several connected to each other. Dismantling is carried out according to this technology approximately as follows:

- a clamp is fixed at the end of the pipe;

- cables are attached to the clamp;

- pull the pipe with a jack until it breaks;

- take out the torn part out;

- a special tool is lowered into the mine for capture;

- using a jack, pull out the next part of the pipe.

Most likely, it will not be possible to get a pipe from a too deep well using this method. But you can still try to dismantle it at a medium-depth mine with your own hands, using interference technology.

The upper part of the pipeline in this case is also pulled out using a crimp collar. The lower part in such wells is usually perforated for filtration. You can capture it, for example, with a home-made tool that works on the principle of a "fish hook" and consists of:

- strong steel rod;

- rope loops;

- two "whiskers" located at the bottom on both sides of it, movable in a vertical plane, the total length of which in the expanded state slightly exceeds the diameter of the shaft.

When leaving the well, the "whiskers" of such a device will turn around and enter the holes of the pipe filter. This, in turn, will allow you to raise the structure to the surface. You can try to make such an exciting tool yourself from improvised materials.

When dismantling long pipes from deep wells using this technology, another device called a chalka is additionally used. With this tool, the pipe is picked up at the moment the clamp is moved.

What is a casing pipe

A water well is similar to a conventional well. Its characteristic differences are a small diameter and a large depth, which can reach tens of meters. The casing pipe is a cylindrical structure, the installation of which is carried out in a drilled well. It is needed in order to protect the walls of the well from possible collapse of the soil. An operating pipe is inserted inside it, which allows the water to remain fresh and clean.

Kinds

Casing strings, depending on the material of manufacture, are metal, plastic and asbestos-cement. The choice of a specific type of product depends on the depth of the well, the characteristics of the land (i.e. soil) and other indicators. The casing type product must have good resistance to soil pressure, durability and comply with sanitary and hygienic standards if the column is used for installation in a drinking water source. Detailed description of the species:

- Steel casing labor. The most durable, durable, but also expensive. It can perform its functions even at high ground pressure. It has poor resistance to the negative effects of corrosion. Over time, well water can taste rusty. This will entail additional costs for the arrangement of filters. Depending on the production method, it can be seamless and welded seam. The first option is characterized by excellent strength indicators and a high price.The second product is somewhat cheaper, but less durable. In some cases, steel casing is made with a protective coating or improved materials to resist rust. There are three main types of such products: galvanized, stainless and enamelled.

- Asbestos cement casing pipe. More fragile than steel, but quite high quality and relatively inexpensive. Experts do not recommend using it for drinking purposes, because. it is capable of releasing harmful impurities into the water, for example, carcinogens. Modern industry offers a choice of types of such pipes made of modified material. When buying, it is recommended to study the sanitary certificate of asbestos-cement casing products in order to be sure that they are suitable for drilling water wells.

- Plastic casing pipe. A relatively new product, which is stronger than asbestos-cement and cheaper than its steel counterpart. Has a low weight. In recent years, plastic casing products have become very popular. For their manufacture, polymers such as polyethylene, polypropylene, polyvinyl chloride are used. Plastic products are environmentally friendly, corrosion resistant, cheap, easy to install, excellent tightness and durability (service life reaches 50 years). True, plastic products have poor resistance to mechanical stress and a limited depth of application - no more than 50-60 m.

- Sterilization of jars in the oven of electric and gas stoves. Temperature for sterilizing jars in the oven

- Who suits caramel hair color and how to achieve this shade

- Cystitis - home treatment with folk remedies and medicines

What is a casing pipe

A water well is similar to a conventional well. Its characteristic differences are a small diameter and a large depth, which can reach tens of meters. The casing pipe is a cylindrical structure, the installation of which is carried out in a drilled well. It is needed in order to protect the walls of the well from possible collapse of the soil. An operating pipe is inserted inside it, which allows the water to remain fresh and clean.

Kinds

Casing strings, depending on the material of manufacture, are metal, plastic and asbestos-cement. The choice of a specific type of product depends on the depth of the well, the characteristics of the land (i.e. soil) and other indicators. The casing type product must have good resistance to soil pressure, durability and comply with sanitary and hygienic standards if the column is used for installation in a drinking water source. Detailed description of the species:

- Steel casing labor. The most durable, durable, but also expensive. It can perform its functions even at high ground pressure. It has poor resistance to the negative effects of corrosion. Over time, well water can taste rusty. This will entail additional costs for the arrangement of filters. Depending on the production method, it can be seamless and welded seam. The first option is characterized by excellent strength indicators and a high price. The second product is somewhat cheaper, but less durable. In some cases, steel casing is made with a protective coating or improved materials to resist rust.There are three main types of such products: galvanized, stainless and enamelled.

- Asbestos cement casing pipe. More fragile than steel, but quite high quality and relatively inexpensive. Experts do not recommend using it for drinking purposes, because. it is capable of releasing harmful impurities into the water, for example, carcinogens. Modern industry offers a choice of types of such pipes made of modified material. When buying, it is recommended to study the sanitary certificate of asbestos-cement casing products in order to be sure that they are suitable for drilling water wells.

- Plastic casing pipe. A relatively new product, which is stronger than asbestos-cement and cheaper than its steel counterpart. Has a low weight. In recent years, plastic casing products have become very popular. For their manufacture, polymers such as polyethylene, polypropylene, polyvinyl chloride are used. Plastic products are environmentally friendly, corrosion resistant, cheap, easy to install, excellent tightness and durability (service life reaches 50 years). True, plastic products have poor resistance to mechanical stress and a limited depth of application - no more than 50-60 m.