- Cesspool made of other materials

- Cesspool made of bricks

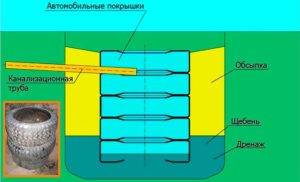

- Cesspool of tires

- Cesspool made of plastic

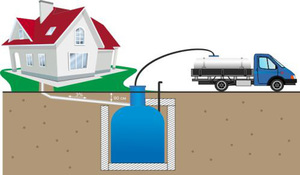

- How to clean a cesspool

- Drainage pit construction technology

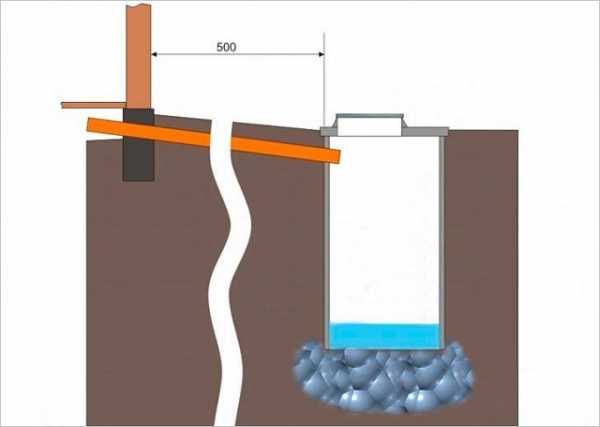

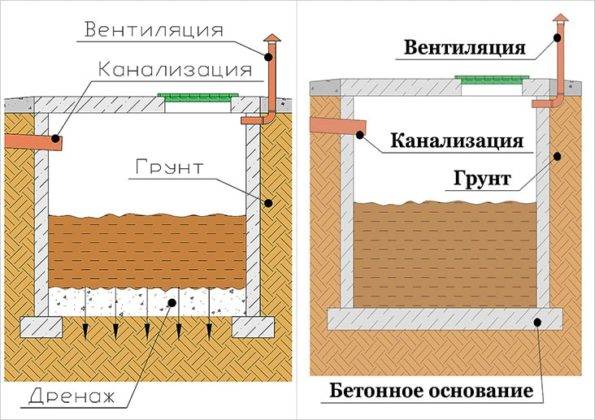

- Pit without a bottom

- We use tires for a cesspool

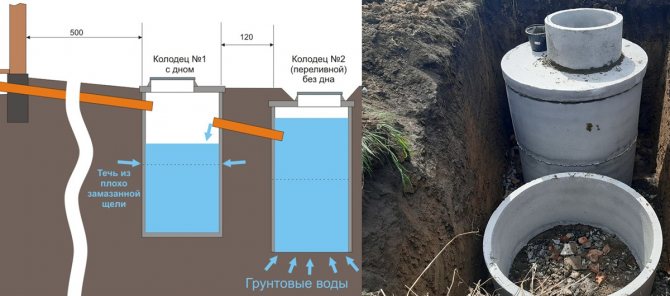

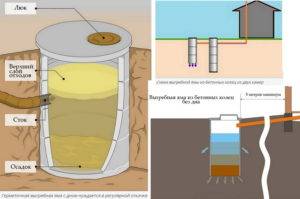

- Pit made of concrete rings

- Sealed cesspool

- Features of the cesspool device in a private house

- Location selection

- Size calculation

- What materials are used?

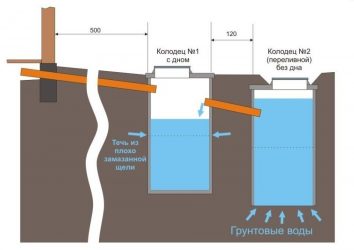

- Pit of concrete rings - detailed diagram, device

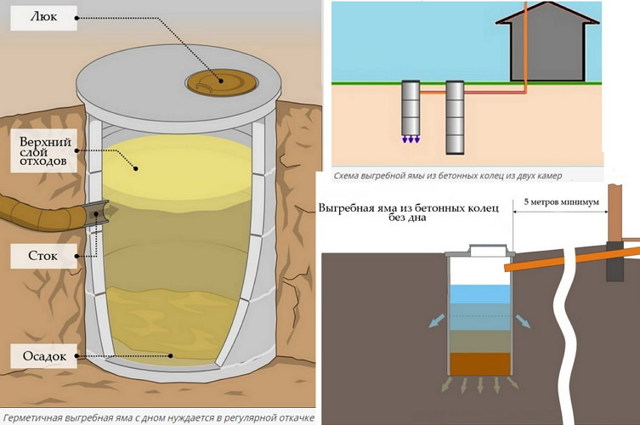

- Sealed pit - detailed diagram, device

- Rubber tires for a cesspool - cheap and cheerful

- Hermetically sealed device

- Basic information

- Purpose and principles of operation

- Types of structures

- Operation of cesspools

- Installation of a cesspool from monolithic concrete

- Sequence of construction work

- Cesspool device

Cesspool made of other materials

In addition to the most common version of a cesspool made of concrete rings, there are many analogues. Some are cheaper but not suitable for permanent residences, some are more expensive but have restrictions on use in certain types of soil.

Cesspool made of bricks

To lay out the walls of the well with bricks, it is not necessary to be a bricklayer. It is enough to have minimal knowledge and acquire basic bricklaying skills.To complete the work you will need:

- shovel ordinary bayonet - for leveling the soil in the right places;

- shovel shovel - for collecting and removing excess earth;

- stairs - in order to go down and get out of the pit;

- tape measure - to measure the required dimensions;

- buckets - for carrying mortar and various materials;

- trowel - to apply the mortar to the masonry;

- level - allows you to control the strict verticality of the walls.

Of the materials you will need - brick, cement, sand and water.

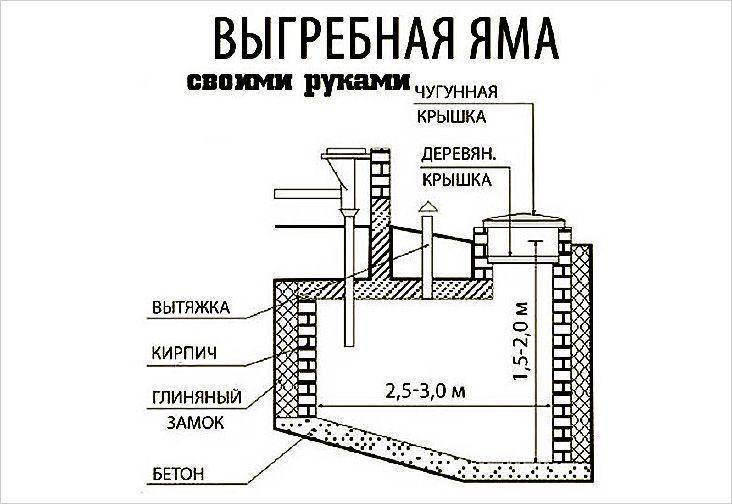

If you are laying a hole with a sealed bottom, then first you need to prepare a concrete base. To do this, it is necessary to make a compacted sand cushion with a thickness of at least 20 cm. After installing the cushion, you can start pouring concrete. The thickness of the concrete bottom should be at least 5-7 cm, it is also possible to reinforce such a base to make it more rigid.

After the concrete has hardened, you can begin the construction of the masonry. At the same time, there are no special requirements for either the quality of the brick or the quality of the masonry itself, the main thing is to maintain the level and the absence of cracks in the masonry. The pit can be either square or round - it all depends on your imagination.

If you are building a sewer without a bottom, then as a brick sole, you need to make a pillow and pour concrete in the form of a ring so that water can escape into the inside.

Cesspool of tires

A cesspool made from waste car tires is distinguished by its low cost and ease of assembly. To install such a pit, you will need old tires of the desired diameter, tires from a passenger car are suitable for a small volume, and for a large one you can take from a truck or even a tractor.

To add usable area, the side parts of the tires must be cut in a circle. You can easily do this with a jigsaw or a grinder. But if they are not available, an ordinary, only very sharp, knife with a rigid blade will do.

The prepared tires are stacked one on top of the other in a pit dug in advance for the diameter of the blanks and fastened together with plastic ties, bolts with nuts, etc. If necessary, the joints between the tires can be sealed with bitumen or other adhesive.

This type of cesspool is often used to collect wastewater in a bathhouse or summer kitchen.

Cesspool made of plastic

The easiest way to make a drain hole is from a ready-made plastic container that you can buy at the store. You just need to dig a pit and install the container itself there.

The indisputable advantages of this method is that you will deprive yourself of an unpleasant smell and be one hundred percent sure that the drains will not fall into the soil and will not mix with groundwater. But as it fills up, you will have to call the sewage equipment for pumping out, which will undoubtedly entail spending money.

Also, restrictions for such containers are imposed by the level of groundwater, since at their high level, the container can be squeezed out of the ground.

How to clean a cesspool

You can pump out the contents of the cesspool by inviting specialists with equipment that should not be less than the volume of your cesspool in volume. The hose of such a sewage machine should be enough to completely lower into the pit, and the entrance to the pit should be convenient.

There are also special products for cleaning cesspools, which are bacteria that are completely safe for nature and process waste products. You can buy such funds at any store for home and garden. Such products remarkably clean even the walls and bottom of the pit, processing solid waste into sludge, gas and water.

Thus, a cesspool in a private house is an economical option for organizing sewage, requiring attention only a few times a year. The indisputable advantage of a cesspool made of concrete rings is its durability, low cost and the possibility of installing such a system with your own hands using minimal equipment.

Drainage pit construction technology

Compliance with the technology of construction of a cesspool is a guarantee of high-quality work, which guarantees an environmentally friendly flow of liquid waste, economical use of the reservoir and its durability. Let us consider in more detail the procedure for creating pits of various varieties.

Pit without a bottom

A cesspool without a bottom is eternal, one has only to properly equip its bottom and select the appropriate materials for the walls. Following the technology, it is necessary to lay out the bottom with gravel or other small stones and fill it with sand. The purified drain liquid goes into the ground, and the rest of the waste is processed by microorganisms. This is a safe and environmentally friendly method.

The overflow is connected to the sewer system, the sewer is inserted into the pit below the freezing level of the soil.

We use tires for a cesspool

For decades, used car tires have been used in arranging do-it-yourself cesspools in summer cottages.Rubber allows you to make an inexpensive, durable and simple design, the construction of which will be possible even for an inexperienced master. Algorithm of actions when creating a hole:

- Digging a pit.

- Connecting waste tires to each other with waterproof glue.

- Joint sealing.

- Creating a bottom filter.

- Wheel fitting.

- Sewer pipe connection.

- Cover manufacturing.

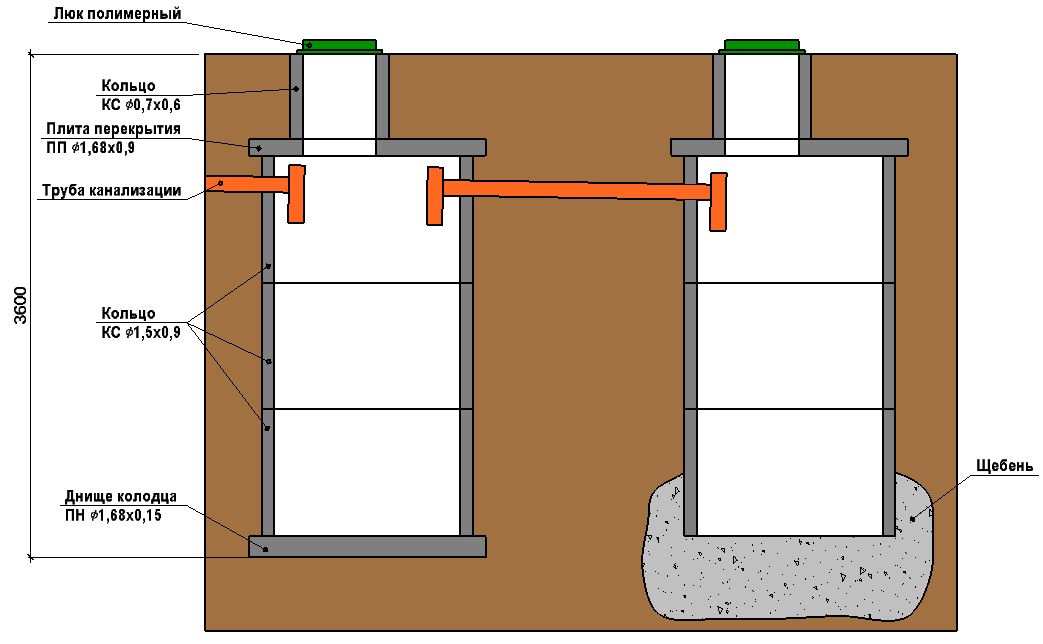

Pit made of concrete rings

Creating a pit from concrete rings is a complex and time-consuming process, however, the expenditure of effort and money is fully justified by the durability and reliability of the tank. Technology for creating a pit from rings:

- Preparation of concrete rings (3 pcs.).

- Digging a pit with a depth of 3 meters, a width, the parameters of which exceed the parameters of the ring by 80 cm.

- Implementation of a concrete screed along the perimeter of the pit (the basis for laying the rings).

- Drilling holes in the lower ring (diameter - 5 cm, distance between holes - 10 cm).

- Laying a filtration layer (1 meter) on the bottom.

- Ring assembly.

- Installation of a plate with holes for the drain pipe and pumping out.

Important!

Installation of concrete rings is carried out using a truck crane with a lifting capacity of up to 5 tons. Truck cranes can be rented by the hour in specialized organizations

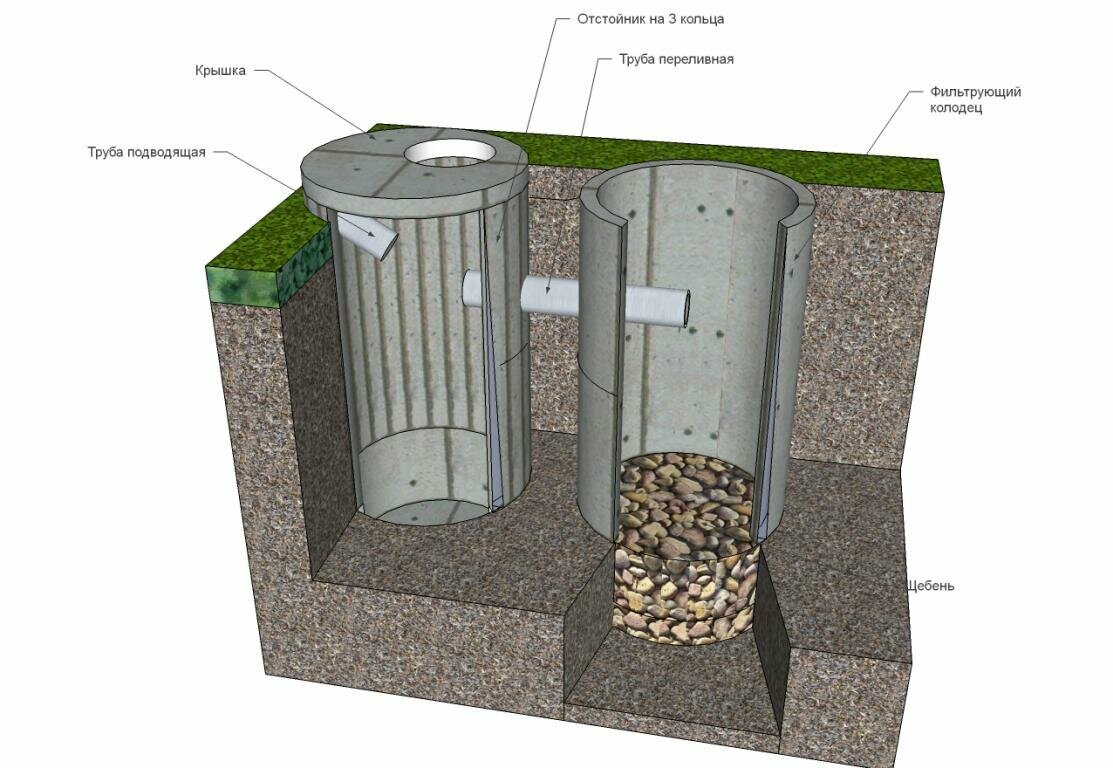

Sealed cesspool

Sealed design - absolutely safe for the environment, does not let in odors. When choosing a sealed design, it is worth considering that its installation is rational only with small amounts of waste, otherwise the pit will need to be cleaned every week.

Homemade tank. A sealed pit can be laid out of concrete rings, it is only necessary to fill the bottom and treat the walls and joints of the rings with sealant (bitumen inside, and clay outside).You can lay out the walls of brick or gas block, and then plaster them. This method requires more labor and time.

When constructing a sealed cesspool, you must immediately consider the location of the hole for the drain pipe.

Finished container. A waste collection device of various capacities can be purchased at specialized stores. Installation of the product involves the following steps:

- Digging a pit.

- Creation of a concrete base.

- Tank installation.

- Connecting waste pipes.

- Burying the container.

Features of the cesspool device in a private house

Location selection

A cesspool is such a container into which domestic wastewater is drained and accumulated in it. To determine the optimal location for its location, you will need to analyze the land and find the most suitable site.

A schematic plan of a private plot can help in this case, in which the locations of the following important elements are necessarily indicated:

- residential building

- Household The buildings

- Water wells

- gas pipeline

- Water supply pipes

Also, on this scheme, the elements of the landscape available on the site should be indicated. For an easier location of the cesspool, it is necessary to put on the plan neighboring buildings and other structures located in neighboring areas, including wells and all communications.

When planning the location of the pit, you need to consider the direction of movement of groundwater. This information can be obtained from the relevant authorities.

At the moment, some sanitary standards have been agreed on the remoteness of this building. from other structures:

- The neighboring building and adjacent buildings - 10-12 m.

- From the boundaries of your site - 1.5 meters

- Own house - 8-10 m.

- Wells for water intake - at least 20 m.

- Water supply networks - at 25 m.

- Ground water - at least 25 m.

- Gas pipes - about 5 meters

When arranging a cesspool, it will be necessary to take into account the condition of the soil in which this structure will be placed. In clay soil, water wells should be at least 20 meters from the pit. With loamy soil, this distance increases by 10 m and will be 30 meters from the cesspool. With sandy or super sandy soil - at least 50 meters.

Also, it is necessary to take into account another extremely important point. Cesspools are strictly forbidden to build along the flow of groundwater, as in this case they may become contaminated.

Size calculation

The first value that needs to be calculated before building a cesspool is its volume, since the efficiency of the entire sewer system and the frequency with which it will be necessary to clean the drain will depend on it. This value can be calculated based on the number of people living on the site. For example, only 4 people live in a private house, 3 of which are adults, and the last is a child.

As a rule, one adult produces at least 0.5 cubic meters of waste, and for a child, this value is reduced by exactly half - 0.25. In the case of connecting water-consuming devices to the drain in the cesspool, they are also taken into account. In this example, they are not involved.

As a result, 1.75 m3 of waste goes to the cesspool (0.5+0.5+0.5+0.25).The resulting number should always be rounded up, which will help to avoid overfilling the waste tanks. In this example, the number will be 2 cubic meters.

The total volume of the cesspool tank should be 3 times the volume of sewage. That is, 3*2=6 m3. This is the optimal pit sump volume for a family of 3 adults and 1 child.

For the construction of a similar structure for a summer cottage, it is necessary to use a different construction scheme. For such a case, you can take 1-2 cubic meters as the optimal value, since such areas are visited not so often and not by very large groups of people. But, in the presence of other circumstances, it is possible to increase the volume of the reservoir for the summer cottage.

Having the required volume of the tank, it will be necessary to determine its structural dimensions. The depth of the structure is determined by determining the level of groundwater and the features of further maintenance of the cesspool. To periodically clean the tank from accumulated liquid and solid growths on the walls and bottom, you will need to use the services of vacuum trucks.

The hose of the sewer truck rarely exceeds a length of 3 meters, so you should not make the depth of the tank exceeding this value. Otherwise, this may affect the quality of cleaning the cesspool. The most popular pit depths are 2.5 and 2.7 m. The maximum depth of 3 m is used extremely infrequently, but this depth can be compensated with a sand and gravel cushion. This is most relevant for leaky drains.

Also, it is worth remembering that when underground groundwater is above 2 meters, there is no point in arranging a cesspool, as this can lead to filling the reservoir with groundwater. This will mean a drop in the efficiency of the entire sewer.

In this case, septic tanks or barrels of the required size will be the most suitable options, but it will be necessary to protect them with a casing of cement or metal solution.

What materials are used?

Various materials are used to equip a waste pit:

- Brick, concrete blocks and stone. A do-it-yourself brick pit is relatively rarely built. This is due to the fact that bricklaying itself is a very long and laborious process. And not every person has at least the minimum skills of a bricklayer.

- Reinforced concrete rings. A fairly common construction option.

- Barrels made of metal, plastic. On the one hand, they are easy and quick to install, but on the other hand, they have a relatively small volume of about 200 liters. For 1-2 people it may be enough, for a large family it is already not enough. The plastic version is more in demand because it is not afraid of rust.

Pit lined with bricks

Pit lined with bricks

Pit of concrete rings - detailed diagram, device

The advantages of cesspools made of concrete rings are obvious:

- Durability. The design can stand up to 100 years.

- Sustainability. Under the influence of fermentation and decay processes, concrete is not destroyed.

- Ease of installation. Significantly reduces time costs.

- Efficiency. Pollution will never enter the neighboring soil and groundwater.

Due to the fact that concrete rings are so popular and have many useful qualities, we will consider their use in arranging sewers. Inside the concrete is a reinforced mesh that increases the strength of the structure. Water will never penetrate through concrete - except perhaps in the area of \u200b\u200bthe junction of concrete rings. These places are recommended to be treated with cement with water-repellent properties.

- Before installing the rings, the bottom of the pit is covered with rubble and sand. Then a frame of reinforcement is installed, concrete is poured at least 20 cm. This is necessary to prevent sewage from entering the groundwater.

- The process can be accelerated by buying a finished bottom. They are usually sold in the same factories as the concrete rings. The cost will increase, but the time will be significantly reduced.

- The rings are lowered with a crane due to the exorbitant weight of the products. As soon as the first ring has been lowered into the pit, it is necessary to immediately make a seal at the junction with the bottom. For example, using liquid glass, a small amount of which is added to the cement mortar. Do not be lazy to process the seams inside and out. This will strengthen your confidence that the drains will not end up outside the concrete ring.

- After lowering the second element, the joints are processed in the same way. At the final stage, you install a cover equipped with a hatch, metal hooks and ventilation holes.

Pit made of concrete rings

Pit made of concrete rings

Sealed pit - detailed diagram, device

- Light weight.

- Easy installation.

- 100% tight.

A wide range of plastic containers for sewage. They can be purchased at a hardware store.

A wide range of plastic containers for sewage. They can be purchased at a hardware store.

A cesspool made of plastic requires minimal labor costs.It is enough to dig a hole of the desired shape and volume, and then place a tank in it. The concrete pillow is covered with sand, the plastic container is lowered into the pits. After connecting the sewers, the pit is covered with a mixture of concrete and sand in a ratio of 1: 5, and then with ordinary soil. It is completely ready for use.

The layer of turf that was removed from the ground in preparation for work is not thrown away, but put back into place. After some time, it will quickly overgrow, and traces of some actions will remain almost invisible.

Rubber tires for a cesspool - cheap and cheerful

A tire cesspool is a worthy alternative to the first two options described above. Almost every household has unnecessary tires that have long outlived their usefulness. Do not rush to throw them away - you can build a magnificent cesspool.

Rubber wheels are used as a basis. You lay them in the same way as concrete rings. Clamps are used for fixing, and special waterproof glue is used for sealing. Ease, quick installation, low cost (and sometimes even free of charge) - these are the "trump cards" that a cesspool of tires has. The only drawback is that the bottom in such a hole in most cases is not done. Therefore, groundwater is still at risk of pollution.

Used tire pit

Used tire pit

Hermetically sealed device

There are many options for making a cesspool. It is convenient to meet the various needs of summer cottage owners. Use factory products so that the sewer pit will serve you for many years.The scheme of the cesspool of concrete rings involves the use of circles and base plates. Installation is fast. A cesspool in a private house can fully satisfy the needs of residents: concrete rings on the market are sold in a large assortment. You can easily pick up circles with the desired diameter.

During installation, the following order must be observed:

- Dig a hole. An excavator is usually hired to perform earthworks;

- Lay the main circle. Install subsequent rings. This work will be handled by experts. This requires the involvement of special equipment. An excavator is needed to set up the bottom, the rings will be lowered down by a crane. It is preferable to use solid products in construction;

- The last circle should rise above the ground by 20 or 30 cm.

The device of a cesspool from concrete rings requires the involvement of experienced professionals and special equipment.

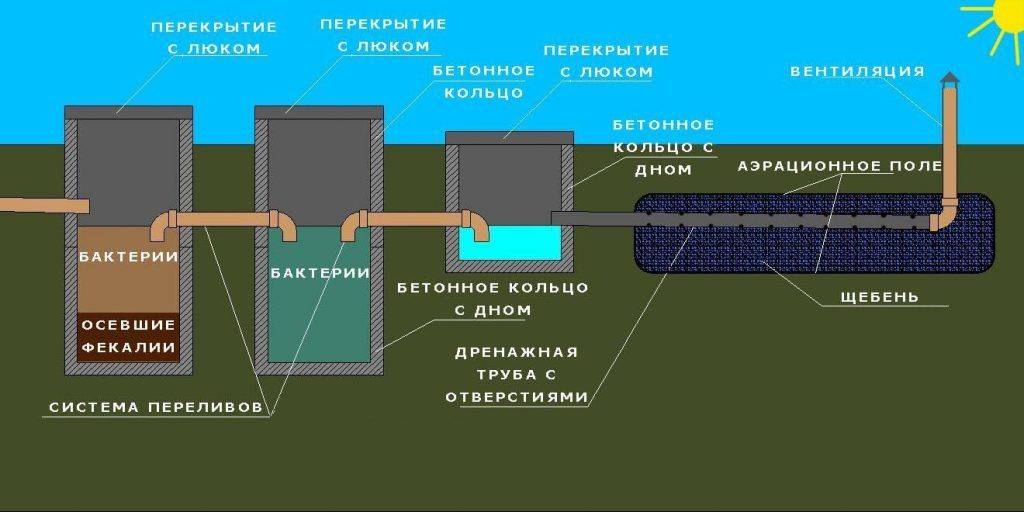

A cesspool with overflow is an excellent replacement for a central sewer in areas where it does not exist. The building has the following advantages:

- rare pumping with the help of sewage equipment;

- the ability to use water a second time to water green spaces;

- no bad odors;

- the ability to use water in large volumes;

- the absence of gurgling and other unpleasant sounds from the sewer system if the pit overflows.

If desired, the master will build a cesspool overflow structure on his own. To do this, you need to understand its device. 2 settling pits are connected to each other with a special pipe in the form of the letter "T".

The first container is connected to the house by a pipeline at an angle of 1.5 or 2 degrees towards the drain. Large particles sink to the bottom of the sump.Wastewater flows through a T-pipe into another container. This sump does not have a bottom. It is filled with geotextiles mixed with layers of sand, as well as rubble with broken bricks. Waste water passes through all layers. After purification, it goes into the ground without harming the environment. Loose or sandy soil makes it possible to fill the second hole with one rubble. Lay geotextile with a layer of black earth on top. Plant plants with a short root system.

The addition of special preparations containing bacteria to the first septic tank helps to improve the breakdown of organic waste. If oxygen enters the container, the biological product works better. Therefore, it is recommended to leave a hole in the lid of the septic tank.

The first sump is built from concrete rings, and the second from red brick. You will need sewer pipes made of plastic and a T-shaped pipe. Instead of the latter, you can take a corner. This is necessary to prevent the entry of sewage from the first container into the second.

If you have to dig a ditch by hand, then use this method. Install the first concrete ring in the place where the settling pit will be. Climb inside the product and dig in a circle. The weight of the ring will cause it to drop. When the concrete product is level with the ground, a second one is installed on it. Keep digging. Unnecessary earth is poured into a bucket, which is lifted by your assistant standing on top. After completing the installation of the rings, bring the pipes to the containers. A chisel and hammer will help you make holes in the concrete rings.

A plastic cesspool is a structure that the master creates without outside help. When installing, avoid pipe drops and sharp turns.When it is impossible to lay a straight pipeline, then make the angle of rotation obtuse. This design avoids blockages. Make sure that it is convenient for the sewer truck to drive up when the drains accumulate and you need to pump out the cesspool. The drawn diagram will help create a competent project for local sewage.

Do-it-yourself sewer pit from used car tires is a budget way to create comfortable living conditions. If the volume of wastewater is small, then this design is ideal: it is affordable and practical. Installation is not difficult. However, to disassemble the structure from do-it-yourself tires difficult. Homemade will last no more than 15 years.

It is difficult to shape a circle on your own from gas silicate blocks. Therefore, it is made in the form of a square or rectangle. Sealing is carried out using a special adhesive or cement mortar.

WATCH VIDEO

Basic information

Purpose and principles of operation

Fundamentals of the principle of operation

Simplicity is considered an important characteristic of the pit. The principle of operation is influenced by the feature of the structure according to its variety.

The structure may not have a bottom, or it may have a sealed base. Drains are split naturally, when sewage reaches a certain level, the pit should be pumped out through the services of sewers.

If the structure is sealed, then the drains should not fall into the ground. The walls of the structure are made, as a rule, of brick, of concrete rings. The base is filled with cement. In order for the effluents to decompose quickly, biological preparations are introduced into the pit, but from time to time the pit needs to be pumped out.

The absorption pit type consists of a traditional filter pit without a bottom.The base is covered with layers of sand, gravel, gravel. This construction is economical, processed liquid effluents go into the soil, so sewage will rarely have to be pumped out. This type of construction is suitable if groundwater flows deep.

Types of structures

There are different classifications of drives. It depends on the design, type of material, frequency of use. With infrequent use, you can install the simplest design.

Concrete rings for the pit

To install a pit of concrete rings with your own hands, you will have to hire special equipment or use a tripod, because they are heavy. A concrete solution is poured to the bottom, which can be reinforced. Next, the rings themselves are installed on the base. The positive features are the possibility do-it-yourself constructionalso low price. The disadvantages include the large weight of the rings that must be delivered to the site.

To install a pit of concrete rings with your own hands, you will have to hire special equipment or use a tripod, because they are heavy. A concrete solution is poured to the bottom, which can be reinforced. Next, the rings themselves are installed on the base. The positive features are the possibility do-it-yourself constructionalso low price. The disadvantages include the large weight of the rings that must be delivered to the site.

Sealed construction

A sealed type pit is considered safer to use. But it must often be pumped out of sewage. It is convenient to use designs with one or more chambers, where wastewater undergoes mechanical treatment.

The structure is filled entirely with concrete. Cement mortar is suitable for both walls and bottom. If you perform reinforcement in a circle, then the device will acquire maximum strength and tightness. The advantages include ease of manufacture, the disadvantages - the regular pumping of wastewater.

Pump-down design

Pits that do not require sewage pumping do not imply the absence of any maintenance. Such cesspools process effluents almost completely. A drain pit is used to collect sufficiently clean effluents, for example, waste water after a bath.Structures can be placed on sandy soils that absorb moisture well. The advantages of the design include easy installation, low cost and subsequent maintenance. The disadvantages include the possibility of runoff getting into the soil, its pollution.

Drain building made of bricks

A pit made of bricks is considered a primitive construction. It can have a bottom and be airtight, or not have a bottom, while having a base with a thick layer of drainage pad.

Brick structures collect and process waste with high quality. To equip the pit, professional skills are not needed. The soil on the site affects the structural features, as well as the number of people who constantly use the pit. The advantages include ease of installation, low price. The pit has flaws, they are affected by the structural features of the pit.

Septic tanks

In the country, you can install septic tanks manufactured at the factory. The devices have differences in the material of manufacture, size, design. Drains are collected in a septic tank, split into technical liquid and sediment, which falls to the bottom.

These facilities are considered superior. Waste is broken down by beneficial bacteria. Industrial water at the outlet of the septic tank can be used on the farm, watering the garden. The best option for water disposal is the organization of drainage into the ground. Benefits include not having to build do-it-yourself construction. Among the shortcomings, high prices for some models of septic tanks are distinguished.

Pits with the addition of biological products

Operation of cesspools

periodic pumping.biologics for cesspools to decompose solid sludge

Therefore, it is worth considering the costs even before the start of all work. Financial costs will decrease if several holes are made at the bottom of the collector and plastic tubes are inserted into them, the upper ends of which protrude 70–80 cm above the bottom.

If during operation it turned out that the volume of the pit is insufficient, you should not start all work again. It is much easier to dig nearby and equip another hole by connecting it to the first one with pipes. A cesspool can degrade the appearance of the site. It can be masked with a flower garden. Suitable and flowers in tubs, arranged around the perimeter of the hatch. If you use your imagination, you can come up with other options.

Installation of a cesspool from monolithic concrete

For example, we can consider how a drain pit is built without pumping out of monolithic concrete. Such structures are strong and durable, and when the walls are treated with special compounds, they become waterproof. The installation of such a structure is somewhat longer than when using concrete rings, since it takes time to gradually harden, but it has certain advantages:

- easier transport of materials,

- no need to use lifting equipment (it is impossible to lower heavy rings into the pit manually).

Scheme of a two-chamber cesspool with overflow, which, in fact, is already a septic tank

Once the optimal volume of the structure is determined, the question of its depth, which determines the capacity along with the surface area, should be decided. There are some limitations in this regard.The sewer pipe is located at a depth of at least 1 meter underground in order to avoid freezing during the cold season. Taking into account the diameter of the pipe itself, the need to indent from the upper edge of the tank to the place of its entry and the margin for installing the cover and backfilling the structure with soil, the depth of the pit can be up to 3 meters, but no more.

A two-chamber septic tank is much more efficient than a single-chamber one. When installing a cesspool, the chambers are made adjacent, that is, the pit is divided into two parts, and the partition is also made of monolithic concrete.

Sequence of construction work

- In the excavated pit, the bottom is leveled and tamped, after which, at the installation site of the first chamber, a solution for the foundation is poured into the formwork.

- After the mortar has hardened, a formwork is built for the side walls and partitions to a height of 50 cm. It does not make sense to arrange it higher, since the mortar is poured in stages, as the mortar solidifies. Old boards, plywood, etc. can be used as formwork material. The partition can be made both simultaneously with the walls and after their installation is completed. The hardening time of each "step" of 50 cm is at least a day.

Concrete cesspool without pumping out - the device diagram assumes the presence of formwork for pouring cement

- Tees are installed at the installation level of the inlet pipe and the place where drains flow from the chamber to the chamber. A piece of pipe can also be used for overflow, however, the tee will ensure the movement of partially purified water from below, which reduces the likelihood of solid particles entering the second chamber, which linger at the tee due to their inertia.The overflow pipe from the first chamber to the second must be located lower than the inlet pipe in the first chamber.

Tees for sewer pipes of a septic tank

- The “floor” of the second (smaller in volume) chamber of the septic tank is covered with rubble. Layer height 30-50 cm.

- For the upper part of the tanks, floor slabs can be poured or finished products can be used, however, in any case, the “lids” of the tanks must have openings for inspection hatches (one for each chamber) and for installing a ventilation pipe.

- The structure is left to set the strength of the solution and dry completely.

- Manhole openings in the upper part are equipped with opening covers, a ventilation pipe is installed.

Installation of hatches and ventilation

- The structure is covered with earth.

Read about the construction of a septic tank of their reinforced concrete rings on this page of the site.

There are various ways to improve the performance of a structure during construction.

- Covering the walls of the cesspool from the inside with a waterproofing layer (home-made bituminous composition, special mastic or primer) will increase its sanitary safety. Concrete in its "pure" form is not completely waterproof. The coating can also be done on both sides, however, in order to be able to apply it to the outer surface, it will be necessary to dig a pit, which will have an area much larger than necessary, which will significantly increase the labor intensity of the work. For external waterproofing, a polymer film is often used, lining a hole with it before installing walls and partitions.

- The strength of the floor and vertical structures can be increased using the principle of reinforcement.Ready-made metal reinforcing mesh, broken brick or scrap metal can be used as reinforcing elements.

The use of reinforcing materials to strengthen the concrete structure is recommended.

- It is recommended to use a solution with the following proportions for pouring: for every 200 kg of Portland cement, 300 kg of fine river sand and 100 liters of water are taken. It is recommended to add a plasticizer, the amount of which is determined by the instructions.

Cesspool device

Having decided on the volume and location of the cesspool, you can begin to build it. First, they dig a pit. This can be done manually or with a rented excavator. The bottom of the dug pit must be prepared depending on the type of cesspool chosen. If a decision is made on how to make a cesspool of concrete rings without a bottom, then it is necessary to arrange a crushed stone pillow. If a sealed design is chosen, then the bottom of the well must be concreted or a special ready-made ring with a bottom should be used.

The dimensions and geometry of the hole dug by the excavator will be much larger than required, which will entail the consumption of crushed stone for backfilling voids

After the concrete at the bottom of the pit hardens, you can begin to lay the rings. Since concrete rings are quite heavy, a winch or a crane is used for their installation. Rings must be installed exactly butt to butt. After installing the rings, the sewer pipe is taken out of the house into the drain pit.

From above, the entire structure is covered with a concrete slab with a maintenance hole. A cast-iron manhole with polymer insulation is installed in the hole for tightness

Particular attention should be paid sewer waterproofing. To do this, perform penetrating and coating (with liquid glass and mastics) waterproofing of the rings

The joints between the rings are filled with cement mortar with the addition of liquid glass. The construction of the cesspool is completed by backfilling the pit with layer-by-layer compaction.

In the case when a cesspool is made in a private house, the scheme of which provides for two chambers, then the first container of concrete rings is waterproofed and the bottom is made, and during the construction of the second ring they are laid either on the ground or on a pillow of gravel and sand without sealing joints.

Sewerage arrangement for a private house can be done independently or you can order a team of builders to install a cesspool from concrete rings. The installation price in the latter case will depend on the scheme and dimensions of the structure. For example, a drain pit of three KS-10-9 rings will cost about 25,000 rubles. The same pit, but complete with a drainage well of two rings, will cost 35,000 rubles.

Sewerage arrangement for a private house can be done independently or you can order a team of builders to install a cesspool from concrete rings. The installation price in the latter case will depend on the scheme and dimensions of the structure. For example, a drain pit of three KS-10-9 rings will cost about 25,000 rubles. The same pit, but complete with a drainage well of two rings, will cost 35,000 rubles.

Experts believe that cesspools made of concrete rings can last 100 years. Their arguments are based on the fact that concrete is a very durable building material and remarkably withstands the processes of decay and fermentation that take place in wastewater.

How a do-it-yourself drain pit is made of concrete rings is shown in the video: