- Definition, structure, purpose

- metal boxes

- What is an electrical box

- How to choose the right plastic box

- Dimensions of plastic boxes

- Video - Fastening boxes

- Cable channels for electrical wiring: types, types, prices of the most popular standard sizes from different manufacturers

- How to use it correctly

- Method number 3 - "Self-tapping screws with a press washer"

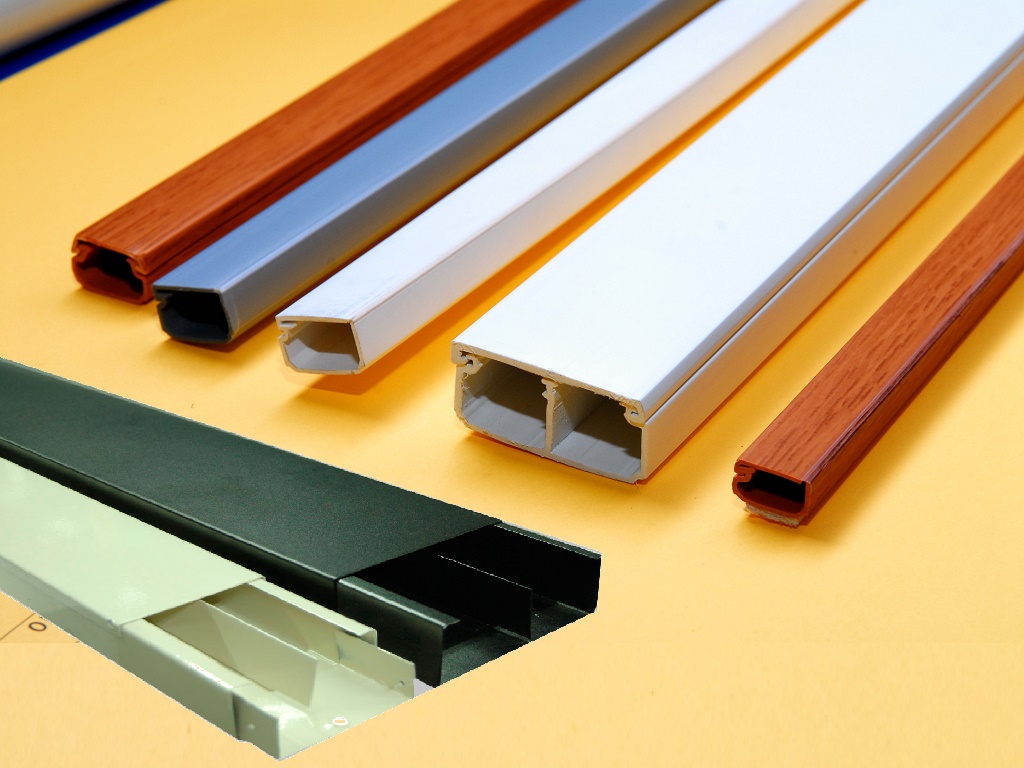

- Materials used for the manufacture of cable channels, their advantages and disadvantages

- Metal boxes for laying cables: types and features of installation

- Varieties and features of plastic boxes for wires

- Skirting device

- Types of skirting boards with cable channels

- Skirting board design

- Material

- fire safety

- Main varieties

- Advantages and disadvantages of open wiring

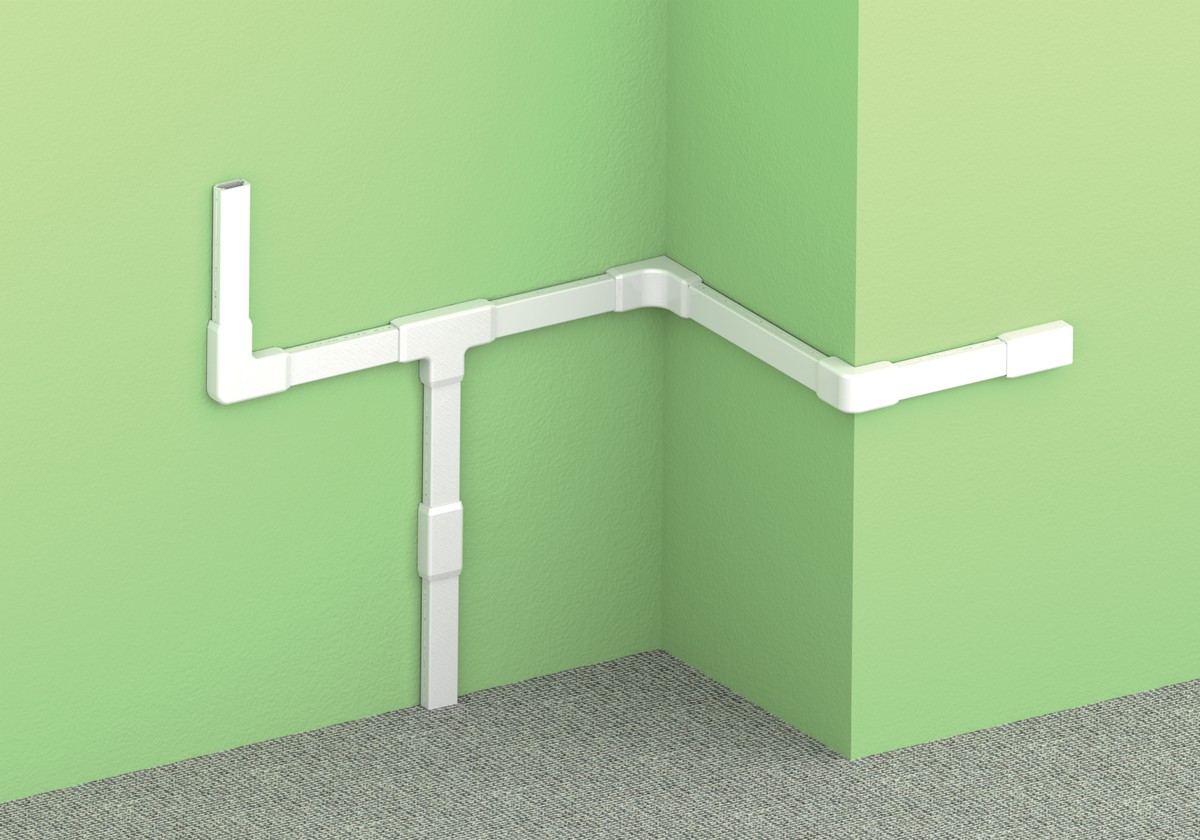

- Installation of cable channels

- Stage number 1 - preparatory

- Stage number 2 - assembly

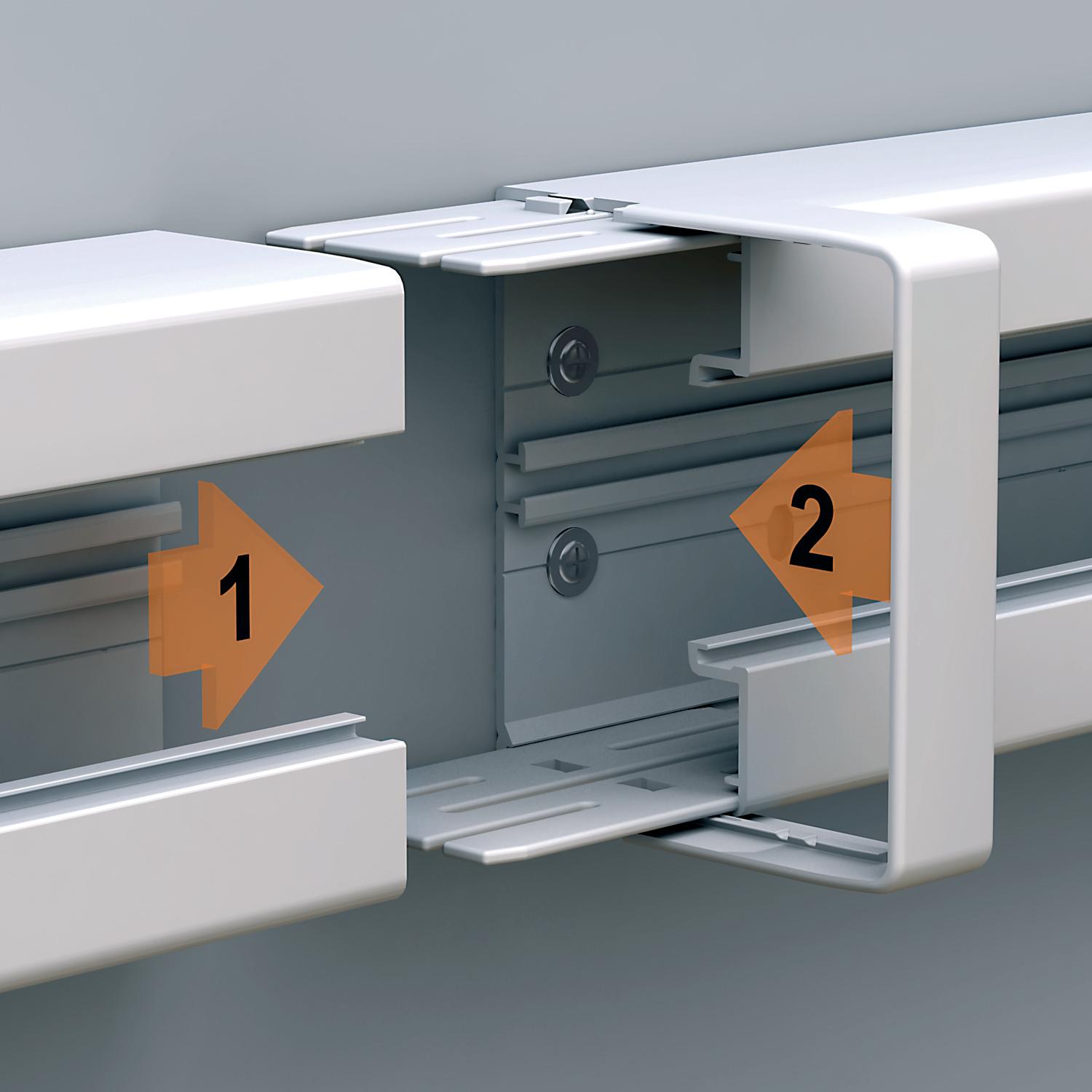

- Making joints

- Cabling

Definition, structure, purpose

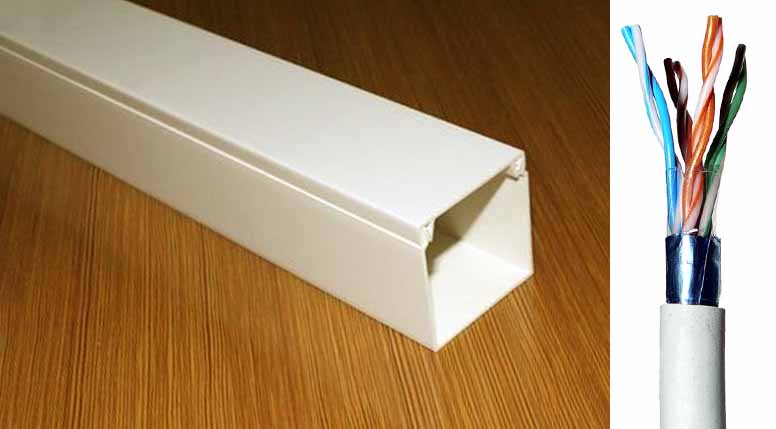

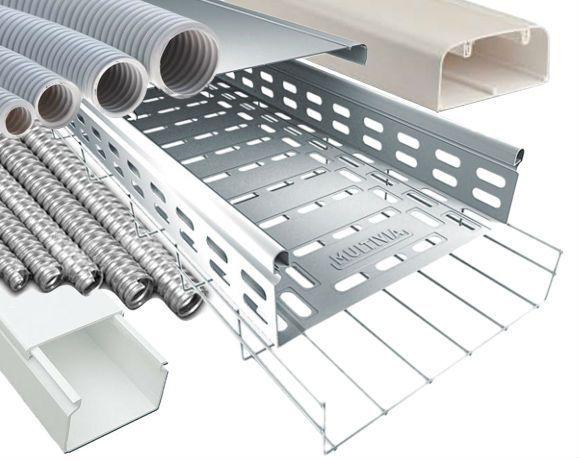

Cable channels are plastic or metal boxes for hidden or open laying of wires and cables. Can be used both outdoors and indoors. They are also called cable trays and boxes, sometimes they add the word "electrotechnical"

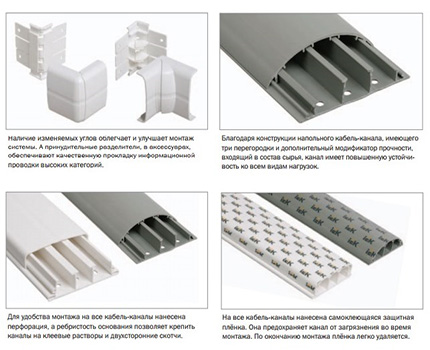

Consists of body and cover.The cross section is mainly rectangular and square, but there are others, more specific (they will also be discussed later). The body can be solid, maybe perforated. Perforated cases are rarely needed, for better ventilation and faster cooling.

The cover and the body of the cable channel are connected with a lock - they snap into place. This cable trays are convenient - you can open, check, lay a new one or remove an unnecessary wire at any time

When buying, pay attention to the structure and quality of the locks - the ease of use depends on them. The best, at this stage, is considered a double lock

It provides sufficient fixation and allows you to repeatedly open / close the lid.

Some types of cable channels can be separated inside by partitions

The internal space of the cable channel can be divided by partitions. This is done in order to be able to separate power (wiring) and low-current (television, Internet, telephone, etc.) cables. It is desirable to lay them separately so that they do not interfere with each other. Some companies have developed a design so that partitions can be installed independently. They are sold separately and are put on the protrusions on the inner wall of the case (an example of such protrusions in the photo on the right).

Material - metal or plastic

If you choose plastic cable channels, please note that it must be non-flammable or non-combustible (read in the description). Ideally, if it also gives out little smoke - just in case

metal boxes

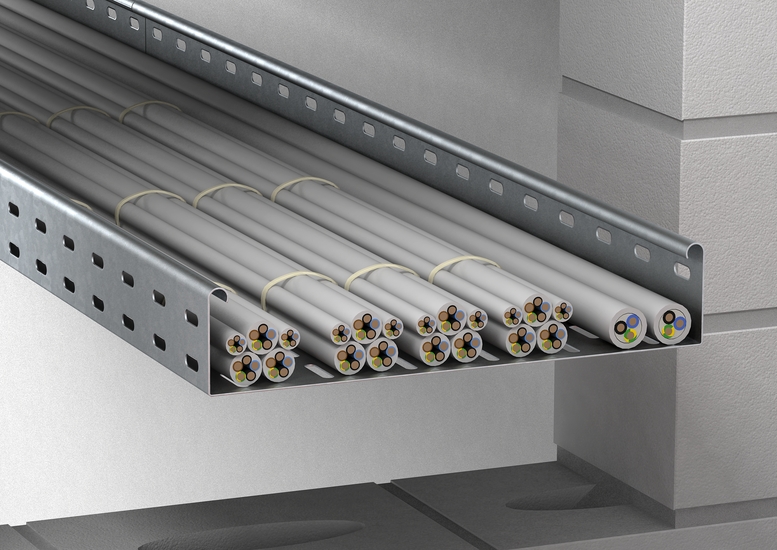

They are also called trays. Since metal boxes are very rarely used in domestic conditions, they can be described briefly.Are intended for carrying out cables in and outside of rooms. The main task is to protect the cable from mechanical damage and arrange many of them into one route. Trays are made of galvanized steel, have the shape of a U-shaped profile, covered with a lid.

Types of metal trays (from left to right): smooth, perforated and ladder

They are perforated and smooth. Perforated products are lighter, they are easier to mount with fasteners, smooth ones are installed on special supports. The boxes are used when laying power cables in industrial premises, raised floors or false ceilings. As well as plastic boxes, they have a lot of accessories for arranging turns and attaching them to ceilings.

Metal tray construction

What is an electrical box

The use of hidden wiring in the house can cause a lot of inconvenience when repairing its individual sections or if it is necessary to completely replace the cable route. To do this, you have to violate the integrity of the wall covering.

The wires laid in the boxes can be changed or repaired at any convenient time.

New technologies have saved the owners of the premises from such "dirty" and expensive work by offering special products for laying open electrical wiring. Let's highlight their advantages over the hidden method of laying cables:

- easy access to wiring anywhere in the circuit;

- reliable protection against mechanical damage and moisture;

- safety.

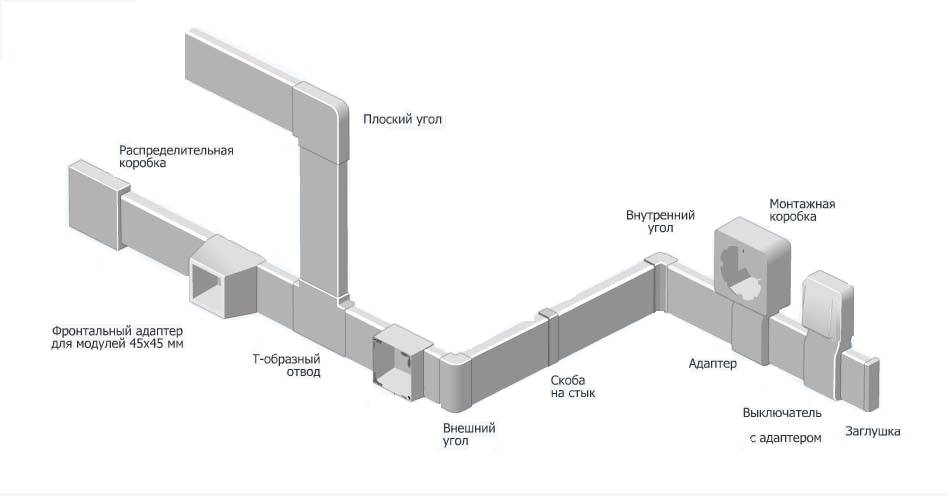

The electrical box is made in the form of elements of square or rectangular section and can have different lengths, widths and volumes. Additionally, you can purchase all the necessary accessories: corner connectors, tees, plugs, etc.

The presence of various connecting and decorative elements allows the use of cable channels for laying networks of any configuration

The electrical box consists of:

- grounds. In cross section, it resembles the letter "P", which is formed by the bottom and side walls. On the bottom there are holes for attaching the product to the surface. If they are not enough, you can drill your own in any convenient place. To fix the upper part, there are latches on the walls;

- top (lid). It resembles the base, but has a lower height of the side walls, in which recesses are made for the latches on the counterpart. The front surface is smooth, plain or with a pattern. Fixation to the base occurs until it clicks. The electrical box consists of a base and a cover, which are connected with latches

This is interesting: How to connect LED strips to each other - solderless option (connector, connectors) and how to solder + video

How to choose the right plastic box

So, we have already understood that all boxes are different from each other. What principles should be followed when choosing a particular solution? We will talk about this in this chapter.

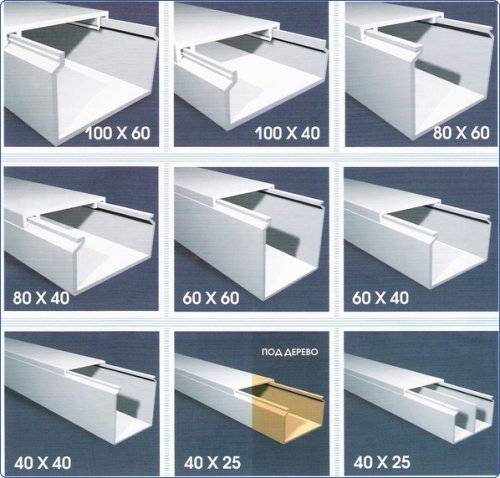

Dimensions of plastic boxes

This box holds a lot of wires.

This box holds a lot of wires.

According to GOST from 2007 61084-1, the minimum length of the outlet section must be 2 m. The manufacturer is obliged to indicate the cross-sectional area of the internal part in the marking so that the consumer knows exactly the usable internal space. The width of the box is selected depending on the number of wires and their cross section.

There are many sizes of cable channels, here are some of them:

- Wall mini boxes are available from 10*10 mm to 80*60 mm.Naturally, the smallest are designed to accommodate one or more very thin wires.

- Floor boxes can be 160*65 mm; 50*12mm; 92*20mm and 75*17mm.

- Main-type plastic boxes can be small 20 * 10 mm and large - 100 * 60 mm, there are also intermediate values.

Plinth cable channel

Plinth cable channel

- The plinth options have an irregular shape, so it’s a little more difficult to choose the inner area here. It is worth focusing on the width of the cover and the depth of the internal groove. It is also worth remembering that cables can be passed above and below the inner box.

- Corner systems of triangular type have much less usable area than rectangular ones with the same wall dimensions. The best option would be 40 * 40 - it may well fit up to 3 wires

Corrugation for laying electrical wiring

Corrugation for laying electrical wiring

Flexible corrugated hoses, which also belong to this class of products, come in the following diameters: 50, 25, 20 and 16 mm - the distance between the inner walls is taken into account. The smallest option is used for telephone cables, 20 mm is ideal for laying wires to electrical outlets in rooms, 25 mm is used between electrical panels, 50 mm is used in industrial activities.

Video - Fastening boxes

A very important characteristic of a plastic box is the thickness of its walls. This affects not only the strength, but also the flexibility of the product.

Variants according to specifications - from 0.7 mm to 2.4 mm. If you choose a cable channel on the wall, then you can buy a cheaper model, but for the same plinth and floor box you need something stronger, as damage is possible.

Cable channels for electrical wiring: types, types, prices of the most popular standard sizes from different manufacturers

To buy cable channels of the desired size at a bargain price, you should familiarize yourself with the offers. With the same shape and size, products can differ significantly in cost, depending on who is the manufacturer of a particular model. Overpaying for a brand is not always a profitable solution. Among the products of domestic manufacturers, you can find offers that have optimal quality and cost.

We offer you to get acquainted with the types, sizes and prices of cable channels offered by various manufacturers. The length of one product is 2 meters:

How to use it correctly

Before laying communications, it is advisable to draw up a wiring plan for future wiring. You need to weigh all the options so that later you do not regret wasted time and money. Then the necessary cable channels are bought, and then it is recommended to proceed as follows:

- Unpack cables and box.

- Apply markings to the surface involved in the installation.

- Cut off blanks.

- Remove the cover from the box.

- Install the box.

- Level up.

- Make holes for fastening.

- Fasten the box.

- Lay the wires in the channel.

- Close the lid.

Note! After completing the work, it is recommended to write down where and where this or that cable is laid. According to the current rules, all cables are placed strictly horizontally or vertically.

According to the current rules, all cables are placed strictly horizontally or vertically.

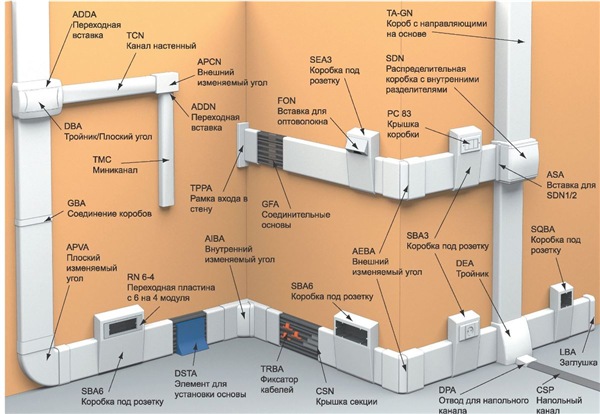

Elements of cable channels

Elements of cable channels

The advent of cable channels has greatly simplified the installation of wiring.There was no need to create recesses for wires in painted and plastered walls with subsequent sealing. Cable channels are easy to install and maintain, aesthetic and durable.

Method number 3 - "Self-tapping screws with a press washer"

If it became necessary to fasten the cable channel to metal, less than 2 mm thick or to an aluminum profile, then we advise you to use metal self-tapping screws, also called "bugs", for fastening. By the way, the correct name for bedbugs is self-tapping screws with a press washer. They do not require pre-drilling a hole. There is nothing difficult in installing an electrical box on a metal surface, the main thing is to choose good self-tapping screws and charge a screwdriver.

There is also a special gun with which you can independently attach the cable channel to concrete. The video provides a detailed description of the installation:

Materials used for the manufacture of cable channels, their advantages and disadvantages

For the manufacture of cable channels for electrical wiring, various materials are used. This determines not only the appearance of manufactured products, but also their technical characteristics. Do not think that the wire boxes perform an exclusively decorative function. Their main purpose is to protect people inside the building from the consequences of an emergency, such as a short circuit. Given the load on the electrical network, plastic products are most often installed inside residential premises, and in industrial enterprises. Each type has its own distinctive features, which you should definitely familiarize yourself with before buying.

Choices must be made on an individual basis.

Metal boxes for laying cables: types and features of installation

The appearance of metal boxes for electrical wiring can hardly be called attractive. However, in terms of safety, they are significantly superior to plastic counterparts. They can be open and closed.

Metal products are highly durable

When laying a power supply system in an industrial enterprise, open steel products are often used, mounted on walls or fixed directly under the ceiling. This metal wiring box is wide enough to fit thick cable bundles inside.

Open models are popular in industrial plants

The use of closed products is abandoned because of the inevitable heating of the cable due to the meeting of the magnetic fields of adjacent wires. This can cause ignition of the electrical wiring and shutdown of the automation. In open systems, natural ventilation provides timely heat dissipation.

Metal is a good conductor. To guarantee the safety of people nearby, when installing electrical steel boxes, grounding is mandatory.

Related article:

Grounding is mandatory

Another type of metal cable ducts are anodized aluminum products. They are mainly used in the laying of power supply systems in industrial enterprises. Sometimes they are used in home interiors decorated in Hi-Tech style. They consist of a box with a lid, a column, polycarbonate mounts and wiring.

The advantages of such products include:

- Possibility of protection against electromagnetic influence;

- High impact strength;

- UV resistance;

- fire resistance;

- The ability to withstand significant temperature fluctuations without loss of geometric shape.

The disadvantages include the complexity of the installation work. Dowels are used to fasten the box and cover, which greatly complicates installation and requires a special tool.

Anodized aluminum box

Varieties and features of plastic boxes for wires

Plastic boxes for electrical wiring cost much less than their metal counterparts. They can be open and closed. Considering that plastic is not among the electrically conductive materials, grounding is not provided for when installing plastic systems.

Plastic products are presented in a wide range

For their manufacture, self-extinguishing PVC is used, which eliminates the possibility of flame spread in the event of an emergency. In closed products, the lid fits snugly against the channel. This also contributes to an increase in the level of safety, since full combustion becomes impossible due to limited oxygen access.

Plastic plinth will hide the wires

Despite the fact that the PVC cable channel can be purchased at a relatively low price, their use in industrial enterprises is limited. Due to low strength characteristics, such products have a limited service life. Open models are purchased when laying a small amount of cables.

Closed plastic cable channels are widely used in the installation of household wiring. Manufacturers offer products of various colors, shapes and sizes, and therefore choosing the right option for a particular room will not be difficult.

A wide range of sizes will allow you to choose the right option

Skirting device

The plinth floor for laying of a cable is mounted on the basis of a wall. Inside it passes one or more cable channels. This allows you to carry out almost any communications to equipment, lighting fixtures. After laying the wire, the entire system is closed with a decorative panel.

Regardless of the model and purpose, such designs include several main components. These include a frame, a decorative connecting bar. Also, when installing the structure, connectors of external and internal corners are used. The entire system is covered by a decorative outer panel.

The frame must be mounted on the base of the wall right next to the floor. For this, self-tapping screws are used. The remaining structural elements are assembled manually. For this, you do not need to use a special tool. This greatly simplifies and speeds up installation. Such work is easy to do on your own, even if you do not have high qualifications in the field of repair work.

Types of skirting boards with cable channels

Let's start with materials. Wall plinths with cable channels are made of several types of material. Products made of PVC plastic are well known, there are metal products (aluminum and alloys, you can find copper and brass). Not so long ago, skirting boards with channels for cables made of polyurethane appeared.

They can be of two designs:

- The recess for cables is formed in the "body" of the plinth and is covered with a cover made of the same material. These are options for a small number of cables. Cable laying in a plinth with a cable channel: one of the types

- With removable top cover.They consist of two parts: a rear strip with formed recesses for laying conductors and a decorative cover. The material doesn't have to be the same. Sometimes the color is different, sometimes even different materials are used.

This electrical plinth has a removable front panel

Both options are viable and successfully exploited. But they have different mounting methods. In the first case, the plinth is attached to the wall through a cable channel, in the second, the back part is fixed to the wall, and the front part is put on after installation.

Skirting board design

By design, electrical skirting boards are similar to each other: they consist of a plate that is attached to the wall, a cavity or shelves where the cable is laid, and a front panel. But there are models that contain only one recess, where 3-5 cables lie. The outer panel is a protective plate that is held on by latches, meaning you attach it without tools.

It is possible to lay wiring in an electrical plinth not only in an apartment, but also in a country house or in a wooden house. This is due to the fact that the installation is fast, convenient and cost-effective, while the electrical wiring will be hidden from prying eyes.

Material

Plinth floor for cable laying can be made of different materials. Most often, plastic, wood and aluminum are used for such structures. This determines the main performance characteristics of the plinth.

Plastic structures are mounted at the base of the floor. The cable channel in them is located in the center. Connectors can be removed outside the profile. For this, special output sections are used.There are separators on the profile rail, which involve laying several types of wires inside the structure.

Much less often you can find wooden skirting boards with a cable channel inside. Most often, these products are made to order. Only one wire can be laid inside such a product. It must be distinguished by a high class of insulation. Otherwise, there is a high probability of ignition of the wiring during operation.

The aluminum plinth differs in the greatest fire resistance. It can accommodate many different wires that have high power.

fire safety

Most electrical cables are made of plastic, which raises questions about fire safety. If you do not take into account very cheap options from the market, all the rest are made of plastic, which does not support combustion and does not spread. More serious manufacturers also use "low-smoke" material. Such an electrical plinth from the point of view of fire safety is an acceptable option.

Electrical safety is guaranteed if the operating conditions of the cables are observed

Well, to be sure of fire safety, take also cables with a margin in cross section and in non-combustible sheaths. And it is cables, not wires, when it comes to wiring. The difference is not only in price.

Main varieties

Depending on the modification, the dimensions of the cable channels, their shape, material of manufacture and technical indicators differ. In everyday life or for wiring in offices, the most common are:

| Name | Peculiarities | Applications |

| Mini | Box with a small section. They fit up to 3 small cables. Installation of mini cable channels is carried out using self-tapping screws.When turning the wires, the joints are poured at an angle of 45 ° or plugs are placed. Typical dimensions vary from 10x10mm to 60x80mm | Most often used in the conduct of the Internet, television and telephony. |

| Flattened floor | Oval profile, which is used if it is not possible to run cables around the perimeter of an office or apartment. When installing, one edge of the box is fixed to the floor with screws, then closed with a lid and plugs are placed at the joints. Made of aluminium, galvanized or hard plastic. Size variations: from 16×6.5 cm to 7.5×1.5 cm. Among the colors are white, black gray, brown and a natural wood option. | They are laid in offices where it is necessary to lower the wire to office equipment or a workplace in the center of the wall. Suitable for one or more medium size cables. |

| Parapet guides | The main (parapet) boxes are made of plastic. There are several variations depending on the type of profile: similar to the “P” cloak without a partition, to “W” - with three sections, to “G” for corners, figured and universal. The main advantage is the ability to adjust the angle of rotation in the range from 7 to 45 ° using adapters. Dimensions from 10×6 cm to 1×2 cm. | They are used in any domestic premises. |

| Perforated with open access | Made of plastic or metal, 30-40% lighter than conventional options with easier installation. They provide good air circulation, have constant access to the wire in different parts of the network and can be installed on curved surfaces. | They are used to connect wires to each other when entering electrical panels or in production shops, where the appearance of the wiring is not important. |

| Skirting floor | This type of cable channel is fastened with self-tapping screws to the walls or floor. By design, they resemble hollow sections with a lid on top. The main selection parameter is the width of the diagonal wall (5 and 7 cm). The advantages include versatility for residential and office premises, variability in color performance and immunity to ultraviolet rays. After dismantling the plinth cable channel, it can be reused. | Offices, administrative buildings, apartments and private houses. |

| Flexible | Prefabricated structures made of metal or plastic. They are available in different colors, there are corrugated models. Such cable channels protect against mechanical damage, vibration or chemical reactions with the external environment. Such a box is flexible, able to reduce noise levels and give free access to wiring. At the same time, it is easy to replace a single element, and installation does not take much time. By diameter, the following subtypes can be found:

| When connecting wires to machines and other equipment in production. |

| Corner ceiling | Installation of the corner cable channel is carried out at the joint between the wall and the ceiling. The triangular shape of the design fits perfectly into a flat corner. The maximum dimensions of the internal cavity are 4 by 4 cm. Simple installation and light weight design are among the positive sides of the box. Such cable channels are fixed only under the ceiling due to their fragility. | Any office and residential premises. |

| Transparent with backlight | Outwardly similar to the corner ceiling models.They have a fully transparent lid tilted at an angle of 45°. They have built-in lighting. | They are used to decorate the lighting system under the ceiling, frame kitchen cabinets and other decorative elements. |

| Industrial wire | Made from metal wire. They provide free air circulation, quick access to wires and do not accumulate dust inside the structure. | They are mounted in warehouses and workshops, as well as behind stretch ceilings. |

The types of cable channels listed can be divided according to the degree of rigidity, the presence of a cover or the type of locks at the joints. However, the installation of ducts for wiring in an apartment is carried out according to the same principle and with general rules.

Advantages and disadvantages of open wiring

The advantages include the following points:

- Ease of installation. Compared to the flush-mounted method, the open one takes less time and allows you to equip the system with your own hands.

- Price. The cost of laying is much less, since multiple chasing around the perimeter of the room is excluded.

- Planning mobility. At any time, if the need arises, you can move the switch or socket to another place without effort.

- Availability. In the event of a malfunction, the replacement of a non-working element or assembly is carried out without difficulty.

The disadvantages are as follows:

- Appearance. Not everyone will like the lines of wires laid through the house, with the exception of preconceived design decisions.

- Fire safety. If the wiring is supervised, it can be replaced very quickly. The main thing is to be careful and prevent damage to it.In addition, fire safety in wooden houses requires special vigilance from the owners.

Installation of cable channels

It would seem that the installation of plastic boxes is not a very complicated matter, but there is one point here, on which the quality of the installation depends. This is the quality of the surfaces on which the boxes will be installed and fixed. That is why the installation process is divided into two stages.

Stage number 1 - preparatory

First of all, the installation surfaces must be leveled. Their curvature is the gaps between them and the back of the panel, this is the curvature of the boxes themselves, which will simply be impossible to align. Therefore, the main requirement for a presentable appearance of installed fixtures is a flat surface.

A sharp knife is suitable for cutting the cable channel

The preparatory stage includes the preparation of tools. What do you need for this?

- For trimming, you can use a hacksaw, a jigsaw, a grinder, a sharp knife. That is, the tool that you work with the most. If you have chosen a grinder, then keep in mind that a lot of dust is released during its operation, so do not forget to wear goggles and a respirator.

- For marking, it is best to use a simple pencil.

There are certain nuances with the mounting tool. For example, if the walls in the house are already aligned and wallpaper is pasted on them, if the wall is wood, drywall, fiberboard or chipboard, then the best option is to put wire boxes on liquid nails. You can use other adhesives. But keep in mind that it is impossible to lay the wires in the box until the adhesive is completely dry.

Stage number 2 - assembly

If the wall is a tree, then it is better to fix the box on self-tapping screws.And for this you need either a screwdriver or a screwdriver. In some boxes, the rear mounting plate is made of thick plastic, so the self-tapping screw may not cut through it. So, you will need a drill with a thin drill bit for metal.

If the walls are brick or concrete, then the installation is done with self-tapping screws on plastic dowels.

- First, holes are drilled in the back panel.

- It is installed on the wall, marking is made through the holes with a pencil.

- According to the markings, holes are drilled with a drill, where plastic dowels are inserted.

- Fastening with self-tapping screws.

The best option for attaching a plastic box, if the base allows it, is liquid nails

Let's face it, this is the most troublesome option, so some masters drill in the mounting panel and in the wall in one operation, setting the panel to the wall and drilling one hole in them right away.

Making joints

This operation must be brought to a separate stage, because, as the wizards say, this is the most difficult moment in the entire installation process. Most often, joints are the connection of horizontal and vertical circuits of electrical wiring. Here the main goal is to create a transition without gaps and gaps so that it looks presentable.

It is for these purposes that the accessories are used. If it is not, you will have to use different methods of fitting. For example, cut the back panel and cover at 45º, and then join the two sections at a right angle. By the way, for corner adjustment, it is necessary to take into account the fact that horizontally and vertically installed boxes must be the same size.

Scheme-image of accessories for cable channels

Cabling

It seems to be a simple process, but even here there are nuances.We recommend choosing cable boxes with longitudinal baffles in their design. You can easily lay cables in them, so to speak, floor by floor, so that they do not interfere with each other

If the cable channel is a box without partitions, then pay attention to the quality of the cover fastening

It is important here that it is not squeezed out under the pressure of the weight of all the laid wires.