- Cable types

- resistive

- self-regulating

- Heating cable installation

- Heating cable manufacturers

- The nuances of roof heating

- Heating pipeline installation

- Mistakes when installing heating cables

- Conclusion

- How to choose a heating cable?

- Kolchuginsky

- Cutting and Joining Instructions

- How does a heating cable work?

- Specifications

- Choosing the type of heating cable and calculating the power

- Marking

- How is power calculated?

- What outer insulation should the wire have?

- The principle of operation of a self-regulating cable

- Types of pipeline heating

- Resistive option for heating

- Semiconductor self-adjusting

Cable types

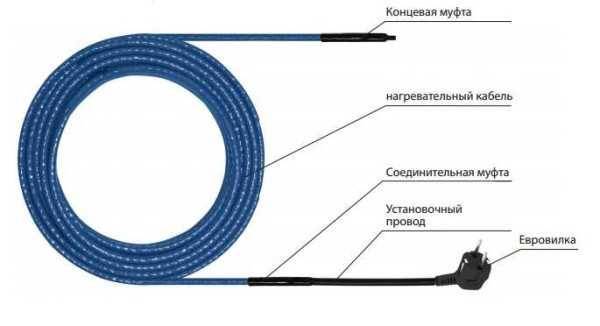

Before installation, it is important to study what heating wires are and how to install them. There are two types of cables: resistive and self-regulating

There are two types of cables: resistive and self-regulating.

The difference between them is that when an electric current passes through the cable, the resistive one heats up evenly along the entire length, and the feature of the self-regulating one is the change in electrical resistance depending on temperature. This means that the higher the temperature of the self-regulating cable section, the lower the current strength will be on it.That is, different parts of such a cable can each be heated to the desired temperature.

In addition, many cables are produced immediately with a temperature sensor and auto control, which significantly saves energy during operation.

Self-regulating cable is more difficult to manufacture and more expensive. Therefore, if there are no special operating conditions, then more often they purchase a resistive heating cable.

resistive

A resistive-type heating cable for a water supply system has a budget cost.

Cable differences

It is divided into several varieties, depending on the design features. Each of them has its own advantages and disadvantages:

| cable type | pros | Minuses |

| single core | The design is simple. It has a heating metal core, a copper shielding braid and internal insulation. From the outside there is protection in the form of an insulator. Maximum heat up to +65°С. | It is inconvenient for heating pipelines: both opposite ends, which are far from each other, must be connected to the current source. |

| Two-core | It has two cores, each of which is isolated separately. An additional third core is bare, but all three are covered by a foil shield. External insulation has a heat-resistant effect. Maximum heat up to +65°C. | Despite the more modern design, it is not much different from a single-core element. The operating and heating characteristics are identical. |

| Zonal | There are independent heating sections. Two cores are isolated separately, and a heating coil is located on top. The connection is made by means of contact windows with current-carrying conductors. This allows you to create heat in parallel. | No cons were found, if you do not take into account the price tag of the product. |

Resistive wires of various types

Most buyers prefer to lay the wire "the old fashioned way" and purchase a wire with one or two cores.

Due to the fact that a cable with only two cores can be used for heating pipes, a single-core version of the resistive wire is not used. If the owner of the house unknowingly installed it, this threatens to close the contacts. The fact is that one core must be looped, which is problematic when working with a heating cable.

If you install the heating cable on the pipe yourself, then experts advise choosing a zonal option for outdoor installation. Despite the peculiarity of the design, its installation will not cause serious difficulties.

Wire design

Another important nuance in single-core and twin-core structures: already cut and insulated products can be found on sale, which eliminates the possibility of adjusting the cable to the optimal length. If the insulation layer is broken, then the wire will be useless, and if damage occurs after installation, it will be necessary to replace the system throughout the area. This disadvantage applies to all types of resistive products. Installation work of such wires is not convenient. It is also not possible to use them for laying inside the pipeline - the tip of the temperature sensor interferes.

self-regulating

Self-regulating heating cable for water supply with self-adjustment has a more modern design, which affects the duration of operation and ease of installation.

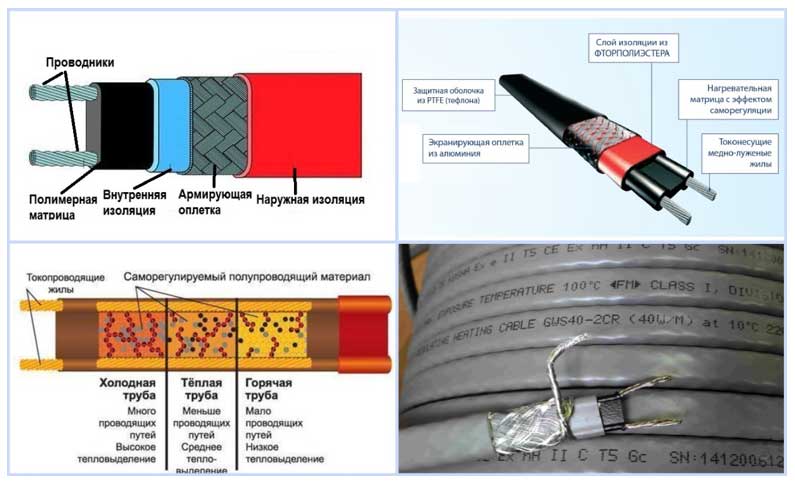

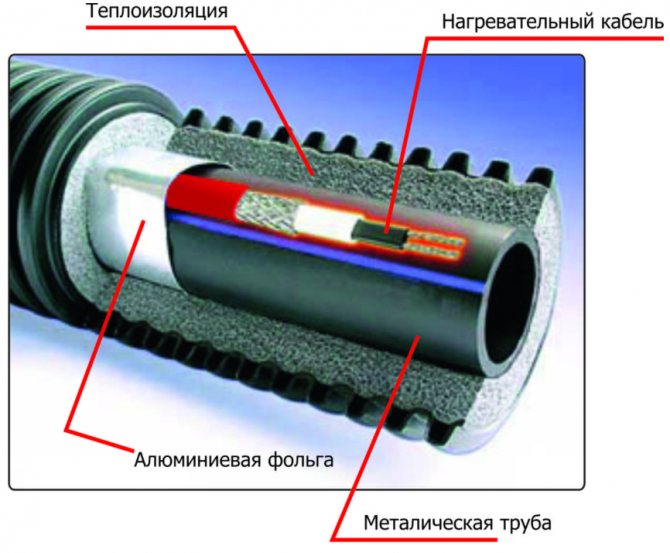

The design provides:

- 2 copper conductors in a thermoplastic matrix;

- 2 layers of internal insulating material;

- copper braid;

- external insulating element.

It is important that this wire works fine without a thermostat. Self-regulating cables have a polymer matrix

When turned on, carbon is activated, and during an increase in temperature, the distance between its graphite components increases.

Self-regulating cable

Heating cable installation

In most cases, the installation of a heating cable is not difficult and anyone can easily cope with it, even if they do not have any experience. The installation method depends on the specific tasks, let's consider the example of pipes (where heating cables are used most often).

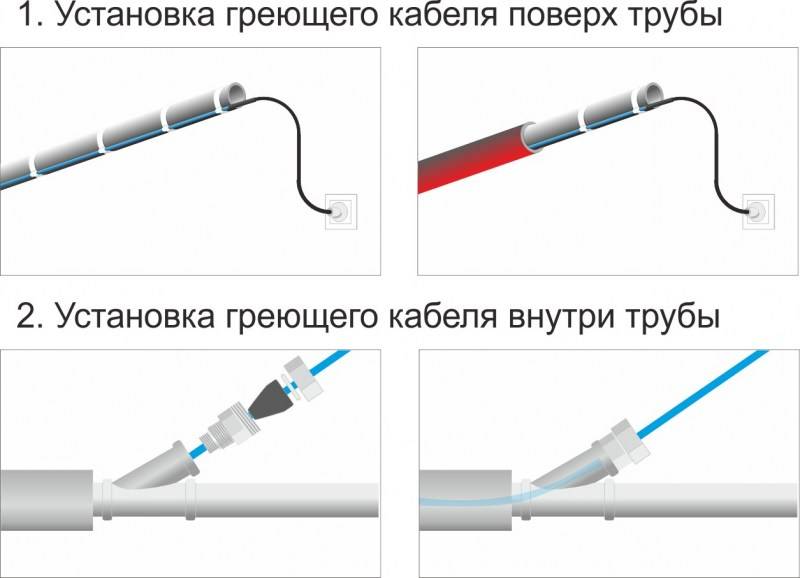

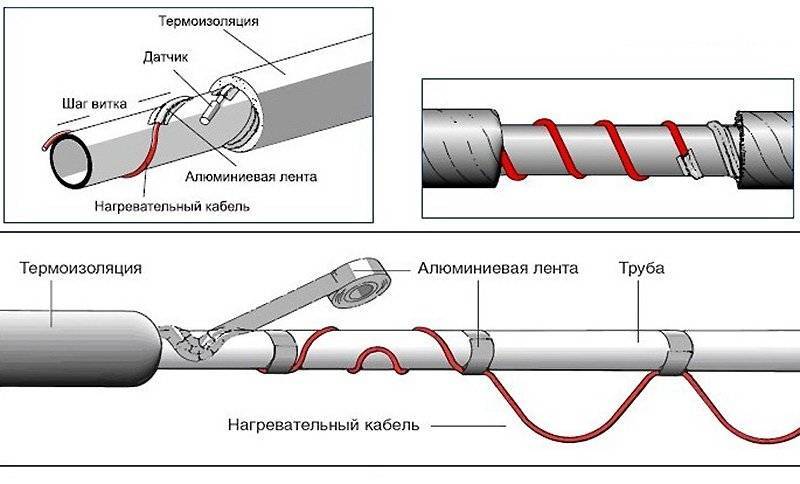

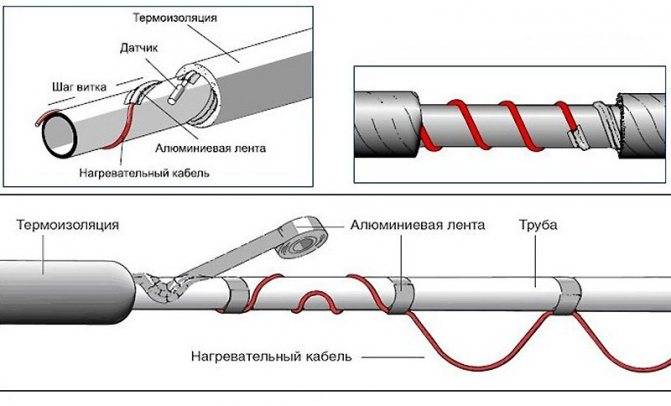

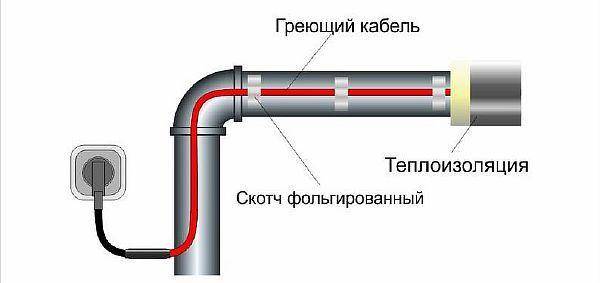

The cable can be pulled outside the pipe, this is one of the easiest options. It can be stretched along and straight, or it can be in the form of a spiral, which will require a longer cable, but it will provide better heating. From above they are wrapped with thermal insulation, in the role of which even ordinary foil can act, which reflects heat. Of course, this method is simple only if the pipe is only to be laid or it is laid outside (not in the ground). And if the pipe is already dug into the ground, then it will have to be dug out, or the second method should be used.

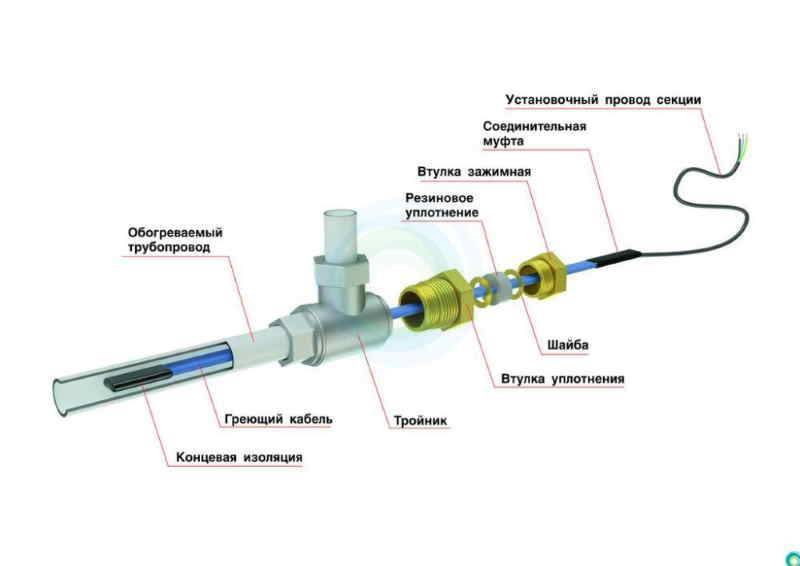

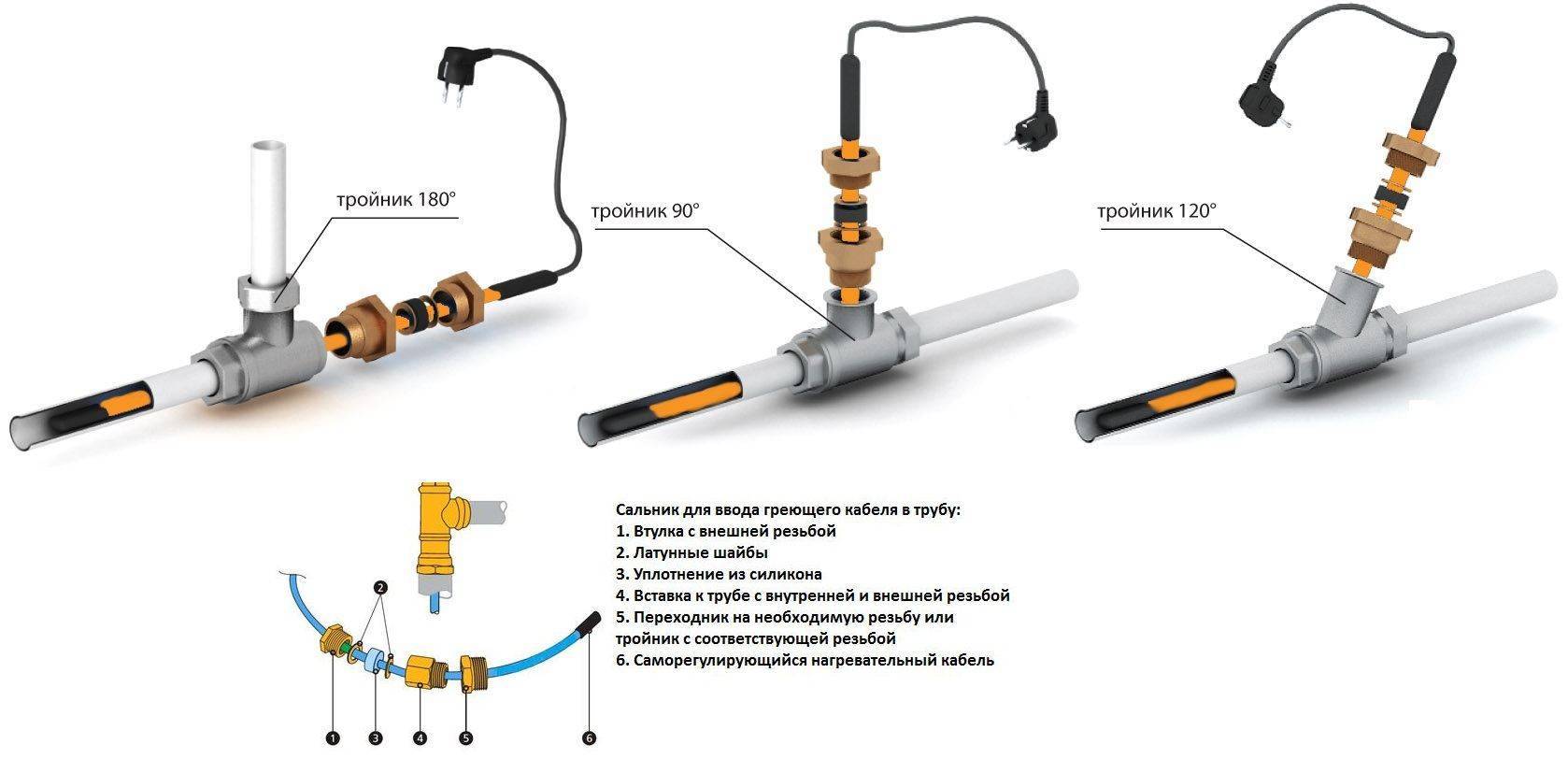

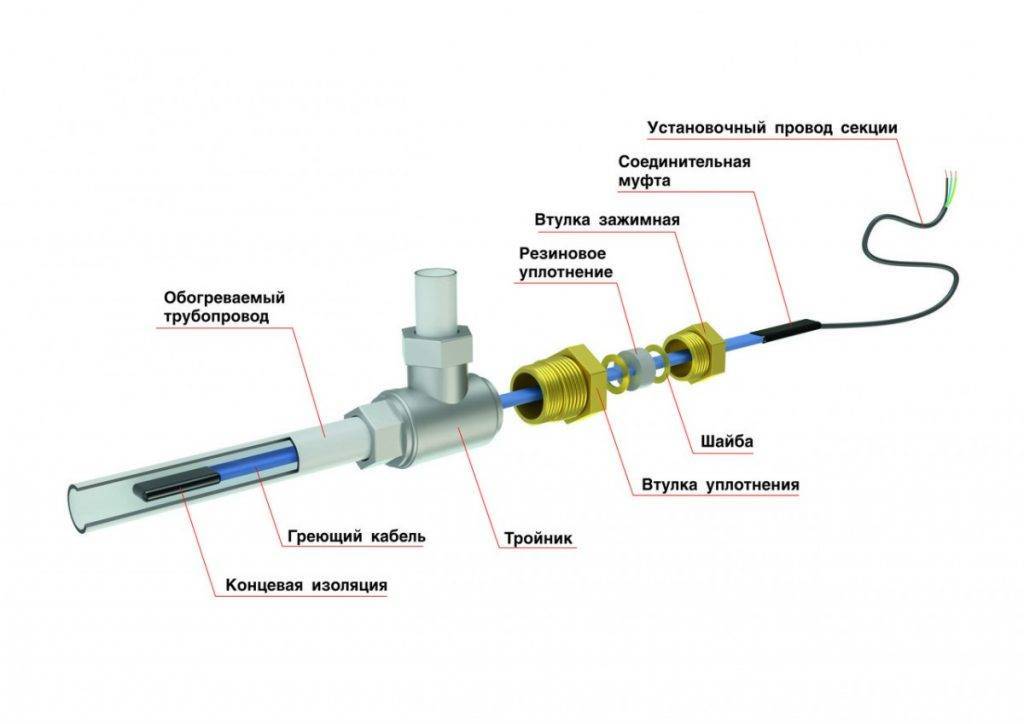

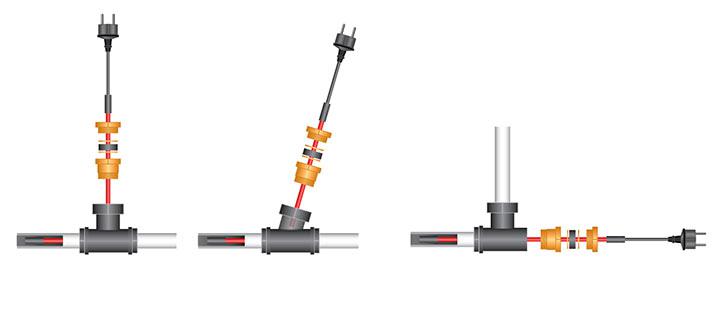

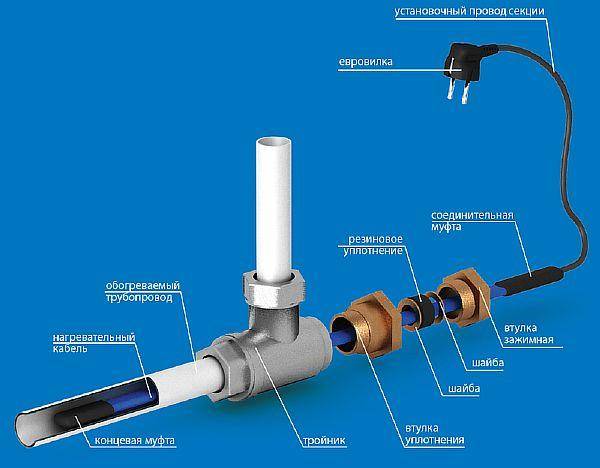

You can also pull the cable inside the pipe. In this case, there are both pluses and minuses. The heating efficiency will be higher, in addition, you can stretch the cable in an already installed pipe. However, the throughput of the pipe will decrease, and in certain cases this can be very important. Also, difficulties may arise if the pipe is very long, here, without special devices stretching the cable will be very difficult. But if the pipe is short, then there will be no difficulties with installing the heating cable.Other things being equal, it is better to choose the option inside the pipe.

Heating cable manufacturers

There are many companies on the world market that are engaged in the production of thermal cables. Below are the most popular, high-quality products:

- Ensto (EFPO10, TASH0.05) — the manufacturing country is Finland. Launches a self-heating cable that meets the latest innovation requirements. The products are easy to install and have an improved design.

- Nelson - the line of models produced by the American company is quite large (CLT; LT; LLT; HLT; SLT-2; QLT; HLT; NC). Products have a long service life, and have constant, improved performance during operation.

- Lavita is a South Korean company. Three main models produced by her:

- HPI 13-2 CT - long, trouble-free operation;

- GWS 10-2 - energy efficient performance;

- VMS 50-2 CX (CT) is a model with increased resistance to external loads.

- DEVI is a Danish company. Large model range (DEVIflex, DEVIsnow, DEVIiceguard, DEVIpipeguard, DEVIhotwatt), all types with a 20-year warranty - replacement and reinstallation of a broken cable. In addition, the products are famous for their high performance and speed. With success it is used both for external, and for internal systems of heating.

- FreezStop is a manufacturer in Russia, these products also cannot be ignored. All models (FreezStop, Freezstop Inside, Freezstop Simple, FreezStop-Lite) are of high quality and suitable for different systems.

It should also be noted that the Swedish heater SVK 20 with a power of 1645 W is designed both for underfloor heating and for heating water pipes.

As you can see, the range of self-regulating cables for pipe heating is huge, and it is up to you which model to choose. The main thing is that the product is suitable for the performance of your system.

The nuances of roof heating

To create favorable conditions for the constant thawing of snow and ice on the roof and the drainage system, the heating cable is mounted in the following places:

- on the edge of the roof (preferably around the perimeter);

- in gutters under slopes;

- in drainpipes;

- in valleys.

In open places, the cable is fixed with clamps and brackets, in pipes it is hung on a cable or chain.

Variant of the anti-ice system device:

The final stage is carried out indoors. We install an electric control cabinet and connect the heating system. Then we turn on the thermostat and check how the system works.

Heating pipeline installation

The main requirement for such a connection to the source is the location of the outlet below the freezing depth of the soil. This factor depends on the climatic conditions of the area.

Video

For the Moscow region, it is about 1.8 meters, in the Chelyabinsk region - 1.9. Let's imagine a situation when the supply section should be 10-15 meters long with a trench depth of more than 2 meters (up to 30 cm will be a drainage layer device). At the same time, its width should ensure convenient operation of the excavator. It's time to order an excavator here!

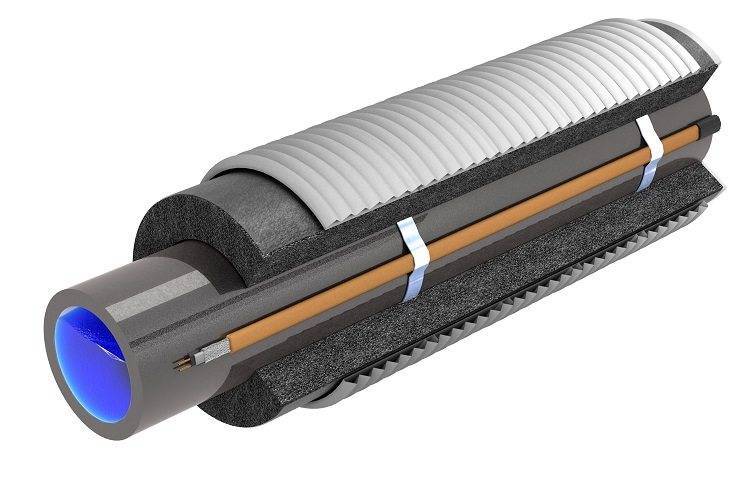

When using heating cable routes, it is enough to dig a ditch up to 50 cm deep and about 30 wide. A drainage device is also necessary.Laying a plastic pipe with a heating cable must be done freely, not stretched.

With this placement of the pipe, its deformations are inevitable due to soil movements, but in the case of using plastic products, they are not dangerous due to the plasticity of the material.

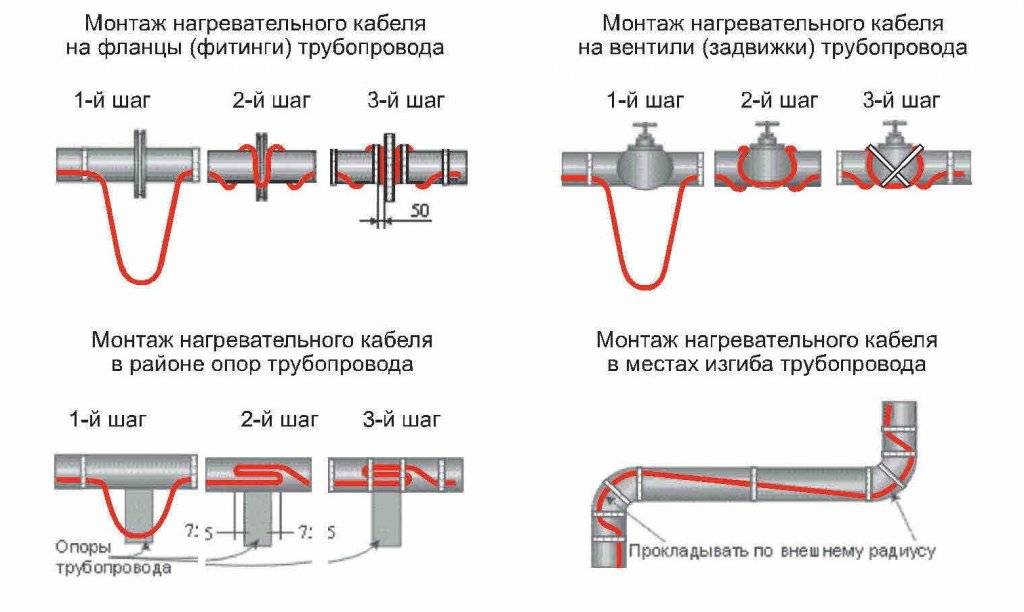

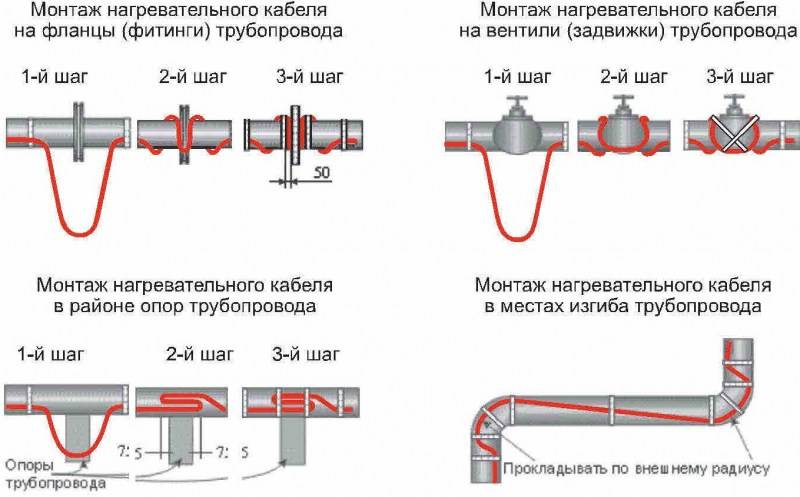

The cable for heating plastic pipes can be placed on it in various ways:

winding on a pipe

This fastening provides the largest contact surface between the object and the heating element. Fastening is carried out with metallized adhesive tape in the transverse and longitudinal directions;

laying the heater along the pipeline wall parallel to its axis

With this arrangement of the heat emitter, one or two threads are used from different sides of the pipe. Mounting is done in the same way;

placement of the heater inside the pipeline. It is better to entrust this operation to experienced specialists, since it is fraught with damage to the wire, which leads to its rapid failure.

To prevent heat loss to the environment, heated pipes are in all cases equipped with an additional heat-insulating layer of detachable insulators, winding of porous sheet insulators or ordinary rolled insulation. To protect it, various materials are used from roofing felt to metal foil.

Cable installation in plastic pipes with an internal location is not used for heating spillway sewers. Such drains often contain chemically active substances that can cause significant damage to the highway in a short time.

It is not uncommon for heating cables to be used to thaw drainpipes to prevent them from collapsing. In this case, more powerful heat emitters are used at the rate of 30 - 50 W per meter.

The cable for defrosting plastic pipes of drainage systems should also have the same power.

Mistakes when installing heating cables

Consider typical errors in the construction of heating systems:

- the installation of heaters at a laying depth of wiring below the level of soil freezing, this can be considered as non-productive costs. In this case, it is sufficient to install local heating in places of increased risk, where the system is not deep enough. Such a place, as a rule, is the point of entry into the house;

- some consumers believe that the heating system is able to replace the insulation of the pipeline, which is not true. In the absence of external insulation, they receive an inefficient heating system that does not save from freezing;

- the belief that the heating line should work continuously is erroneous, often this is not necessary, and the consumption of electricity at a consumption rate of 18 W per meter can be a significant amount. Additional costs for automatic switching on / off of heating using temperature sensors in this case will pay off in the shortest possible time.

Video

The cable for defrosting plastic products is installed, as a rule, for a preventive purpose in order to avoid the formation of ice plugs in places of increased risk, in particular, at the outlet of the drain system from the house.

Not the fact that it will be used constantly, but in any climate extreme operating conditions may occur. In this case, the additional possibility of heating / defrosting pipes will not be superfluous.

Conclusion

The costs incurred for the heating cable for plastic pipelines and its installation will significantly reduce the cost of construction work and reliably protect the consumer from climatic vicissitudes.

How to choose a heating cable?

The choice of product depends on the application:

- For roof edges and gutters experts advise buying a resistive cable with a power of 12 to 22 watts per linear meter or self-regulating with indicators from 20 to 40 watts. The second option is suitable for small areas and saves electricity. Such a heating cable fits perfectly into the pipe.

- To remove ice on steps and platformsIf the cable is laid in a screed, the recommended resistive wire power is 26 to 30 watts. If the product will be in the sand, and not in the screed, then the power should be chosen no more than 20 W per linear meter.

- For plumbing or tank heating with liquids, it is better to use a self-regulating cable, for plastic pipes with a power of 10 watts per linear meter, and for metal pipes up to 20 watts.

Kolchuginsky

Today it is the largest manufacturer of heating cable in Russia. The company is located 100 km from Moscow. The organization's products are available in 65 cable macro sizes. In 2011, the company was included in Cable Alliance Holding LLC. This also includes the joint-stock associations Sibkabel, as well as Uralkabel.

The list of partners of the holding and the organization includes Russian Railways, installation and construction companies and firms that work in the field of machine and shipbuilding.The cable channel manufacturer's products are available at the Bushehr nuclear power plant located in Iran and at the Eastern Siberia oil pipeline in the Pacific Ocean.

Address: Moscow, st. Bolshaya Ordynka, 54 p. 2.

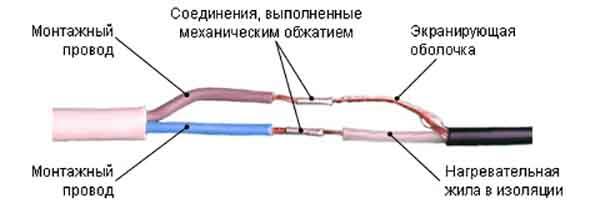

Cutting and Joining Instructions

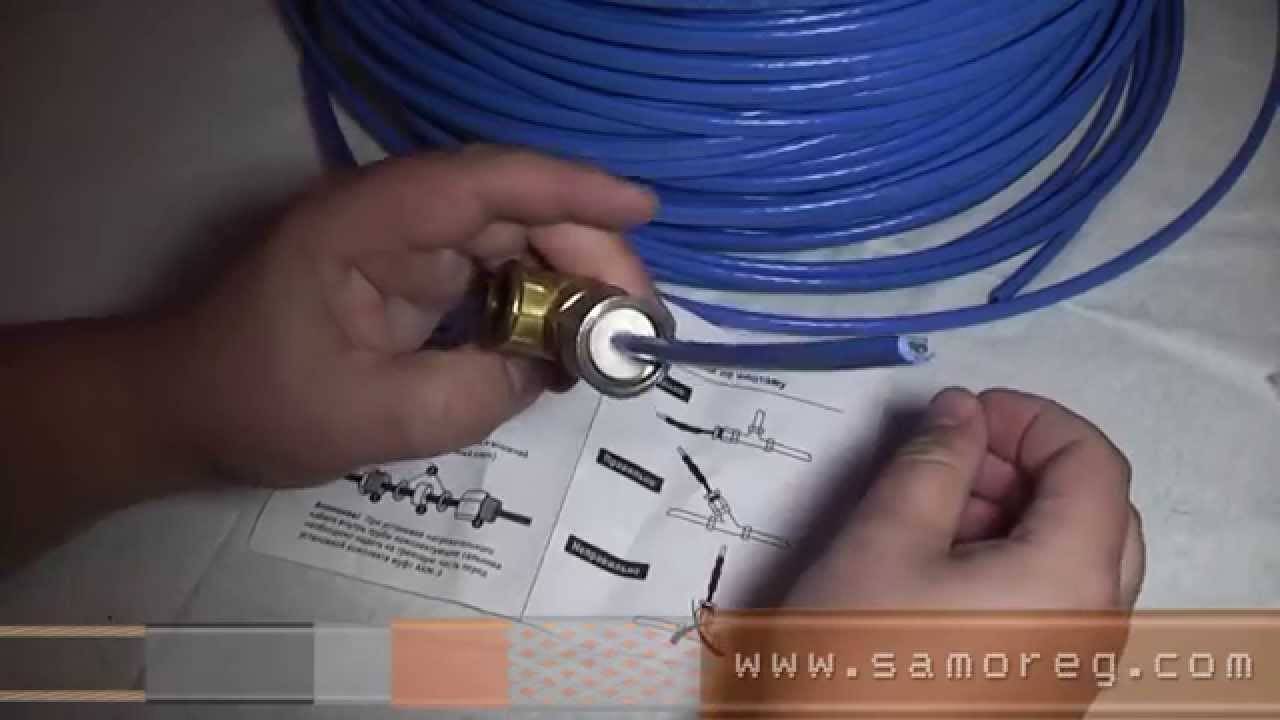

We decided to pay special attention to this point, because no home-made twists are suitable for joining such cables. To make the contact reliable and tight (after all, the supply voltage is 220 Volts), you need to connect the power wire to the heating wire using a special kit

It is purchased separately and consists of heat shrink sleeves of various diameters and metal crimp lugs.

The step-by-step docking procedure looks like this:

- Carefully cut and remove the top layer of insulation from the end of the heating cable to a length of 45 mm. Separate the strands with a knife, cutting the semiconductor matrix along.

- Put protective tubes of different lengths on the ends (the thinnest ones included). Heat them up with a blow dryer to shrink them. Cut off the short-sheathed strand so that it protrudes 9-10 mm, and then expose both contacts by stripping the insulation to the heat shrink tubing.

- Install the sleeves on the bare cores and crimp them on one side with pliers or wire cutters. Take 2 tubes with an adhesive layer and put them on the prepared ends of the cable.

- Having previously removed the insulation, alternately pull the large and medium cover from the kit onto the power wire. Bend the ground wire (yellow) to the side, and expose the remaining two.

- Insert the ends of the power cord into the sleeves and crimp them on the other side. Move the small tubes previously put on to the contacts and blow dry them.

- Slide a medium-sized cover over the connection and heat with a hair dryer to shrink.Repeat the operation with the largest tube. On this sealed joint is ready.

To terminate, a termination (sold separately) must be installed on the second end of the heating wire. To do this, divide its wires with wire cutters to a length of 2 cm and remove the sheath from one of them, and then put on the sleeve and treat it with a hair dryer to shrink. The operation is clearly shown in the video:

How does a heating cable work?

A heating or hot cable is a heating system for pipes laid in the ground. The electrical cable in the insulating sheath is fixed on the pipe and connected to the power supply. The pipe heats up, as a result, the wastewater acquires a consistently high temperature, which reliably protects it from freezing.

There is a cable for external heating of a pipe or internal. The first is laid outside the structure, and the second - inside. It is believed that outdoor installation is easier to produce than internal, so it is more in demand. In addition to the external cable, a heating film is also used.

Heating with a film for sewer systems is not often used. The material has to be wrapped around the entire pipe, which complicates installation, but ensures uniform heating

This material is completely wrapped around the structure, then it is fixed. The film gives a more uniform heating of the pipe than the cable, it has less power, which allows you to somewhat reduce operating costs.

Three types of cable can be used for heating pipes:

- self-regulating;

- resistive;

- zonal.

A self-regulating cable is considered an extremely convenient option, since it can automatically change the heating temperature depending on climatic conditions.Cable resistance decreases if the ground heats up more and increases as the temperature drops.

Self-regulating cable is most in demand in modern conditions, since it is easy to lay, it is more reliable and does not require additional elements for installation.

This change in operating mode reduces the overall power of the system, i.e. allows you to save energy. Moreover, the change in resistance may be different in individual sections of the pipeline. The result is a better heating quality, the self-regulating cable itself will last longer, and there is no need to install thermostats.

A resistive cable does not have such abilities, but differs in comparison with self-regulating systems by a more reasonable price. When installing this type of cable, you will need to install a set of temperature sensors and thermostats to ensure that the operating mode of the system changes when the weather changes.

Resistive cable costs less than self-regulating counterparts. If this option is selected, a suitable power density must be carefully calculated to prevent overheating.

If this requirement is neglected, the risk of overheating of the cable and its breakage increases. The zonal cable also does not have the ability to regulate resistance, but this system does not generate heat along its entire length, but only in certain sections. Such a cable can be cut into separate fragments, which is convenient when installing pipelines of complex configuration.

It is also widely used in the installation of metal sewers or for heating tanks. It should be noted that the heating of structures buried in the ground is not the only area of \u200b\u200buse of a heating cable.It is also used to heat pipes laid on the surface or in rooms that are not heated.

Sometimes the cable is used only for certain sections of the pipeline, for example, parts that go to the surface. Systems that are mounted inside the pipe are used relatively rarely. Most often they are used if the pipeline is already laid in the ground, and the installation of an external cable would require extensive excavation.

So installing an internal cable will be much cheaper. But such cables are usually recommended to be used only inside small diameter pipes, since their power is low.

It varies between 9-13 W / m, which is usually not enough for large sewer pipes. The length of such a cable, for obvious reasons, should be equal to the length of the pipe. The internal heating cable is made only of a self-regulating type.

Specifications

Choosing the type of heating cable and calculating the power

In accordance with various consumer properties, there are three main types of temperature-controlled wire in terms of power and purpose of heat consumption.

- Cable with a maximum temperature of up to 70 degrees

- up to 105 degrees

- up to 135 degrees

The increase in power and temperature height is achieved through the use of copper cores of various diameters.

Marking

- D - used for marking the low-temperature version

- Z - medium temperature

- Q - option with maximum temperature (usually additionally marked with red insulation)

- F - anti-corrosion treatment

Refractory polyethylenes and fluoroethylene are used for the insulating coating.

About working with copper wire. Copper is an ideal conductive material, copper wire is ductile and flexible.

Therefore, when working with a cable with a copper core, it is important to prevent kinks and the possibility of physical abrasion.

How is power calculated?

According to the rated power, voltage class and heat transfer class. That is, you can see the table of power and energy consumption for each type of cable.

Sectional view of self-regulating cable devices

Heat dissipation linear type for self-regulating wire from 6 to 100 watts per meter.

If you count offhand, according to average parameters in practical use, heating 1 meter of wire will cost about 30 watts. It is highly desirable to connect through a separate transformer.

What outer insulation should the wire have?

The internal insulation of conductive wires is not as important as the external one. From the external depends on the conditions in which it will be possible to use the product. For example, if it is necessary to run a wire inside a water pipe, then the insulation must be made of food-grade fluoroplast, which will not affect the taste of water or change its chemical composition. Moreover, dust and moisture protection should be according to the IP68 standard.

For installation on a roof or downpipe, it is important that the insulation withstand long-term exposure to UV rays. It is usually made from a fluoropolymer

The product may not indicate the material of the shell, but only the phrase "protection from UV rays" is written. But for sewerage, a cable with a polyolefin sheath is intended. Although this information is usually written in the specifications for each product, it is better to check with the seller so as not to make a mistake and buy the right wire.

The principle of operation of a self-regulating cable

The polymer matrix connecting the conductive wires is the main heating element. Its heating is carried out continuously. A cable with such “insides” can be cut into separate fragments from 20 cm long. The main feature of the matrix is a spontaneous change in heat transfer depending on the external temperature. How it works? With an increase in external temperature, the resistance of the matrix polymer increases proportionally, and the heat transfer, accordingly, decreases.

Heating cable

Heating cable

The property of self-regulation is manifested in various sections of the pipeline. So, the underground part of the pipeline, under favorable conditions, will not heat up, without preventing the heating of open sections of the pipe by the same cable.

To turn on the heating of the water supply when the temperature drops, just plug the cable into the socket. They turn on the cable when it gets cold up to + 5 °, in order to be prepared for sudden night frosts.

The heating cable is very easy to use. With proper installation, its service life is unlimited. Reliable protection against overheating makes the cable absolutely safe.

Advice. For drinking water supply, the use of such a cable is quite acceptable.

Types of pipeline heating

Heating wires are classified according to the heat dissipation scheme into self-regulating and resistive systems. Each of them has its own characteristics.

Resistive option for heating

The principle of operation of such a cable is to heat an insulated metal core, and it is important to monitor the temperature in order to prevent combustion of the heating element. According to the type of construction, such a cable can be with one or two cores.The first option is rarely used, as it requires the circuit to be closed. When heating pipes, such a system is sometimes impossible at all.

When heating pipes, such a system is sometimes not possible at all.

Resistive cable device

A two-core wire is more practical - one end of the cable is connected to the network, a contact sleeve is installed on the other, which ensures closure. One conductor can serve as a heat source, then the second one serves only for the necessary conductivity. Sometimes both conductors are used, increasing the power of the heating itself.

The conductors are protected by multilayer insulation, which has a grounding in the form of a loop (screen). To protect against mechanical damage, the outer contour is made of a PVC sheath.

Cross section of two types of resistive cable

Such a system has its positive and negative sides. The first ones include:

- High power and heat transfer, which is necessary for a pipeline with an impressive diameter or with a considerable number of style details (tees, flanges, etc.)

- Simplicity of design at an affordable cost. Such a cable for heating a water pipe with a minimum power costs 150 rubles per meter.

The disadvantages of the system include the following:

- For correct operation, it is necessary to purchase additional elements (temperature sensor, control unit for automatic control).

- The cable is sold with a certain footage, and the end contact sleeve is mounted in production conditions. Do-it-yourself cutting is prohibited.

For more economical operation, use the second option.

Semiconductor self-adjusting

This self-regulating heating cable system for plumbing is completely different in principle from the first option. Two conductors (metal) are separated by a special semiconductor matrix, which acts as a heating source. This ensures high current conductivity at low temperatures. At the same time, when the temperature rises, the consumption of electricity decreases markedly.

Installation option

Such features allow you to achieve the highest temperatures in more vulnerable areas. Such a cable system for heating water pipes has its advantages:

- Energy savings increase, as the system reduces power when the ambient temperature rises.

- You can buy the required length, cut places are provided in increments of 20 or 50 cm.

There is also a negative side - the high cost of the cable itself. Even for simple varieties, the price is about 300 rubles per meter, and the most “advanced” models are estimated at over 1000 rubles.

Sectional variant with self-regulating heating wire

Any system can be installed inside or outside the pipe. Each technology has its own characteristics that should be considered during installation. So, for an external structure, it is better to choose models with a flattened section, since a large surface of the cable will be in contact with the pipe, which will increase heat transfer. The power limit is wide, you can pick up from 10 to 60 watts per linear meter.