- How to choose a self-regulating heating cable for plumbing

- How to determine how much cable power is needed

- Top 5 best manufacturers

- The principle of operation of the heating cable

- Design and scope

- Varieties

- Varieties

- Choosing a cable for a sewer system

- Simple wiring diagram for roof heating

- The principle of operation of the heating cable

- Types of heating cables for plumbing

- Features of assembly and installation of heating cable sections

- outdoor installation

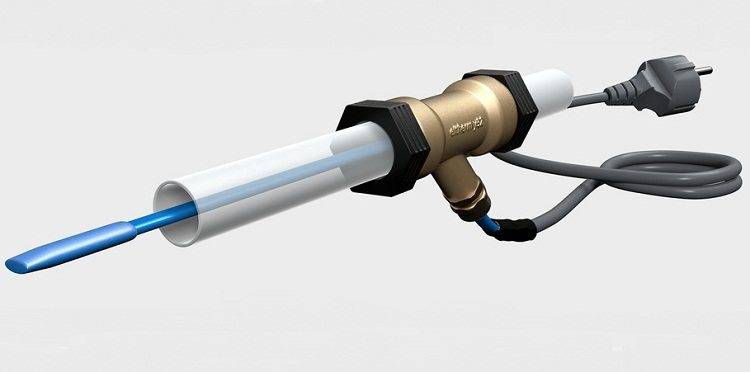

- Internal installation

- Cable types

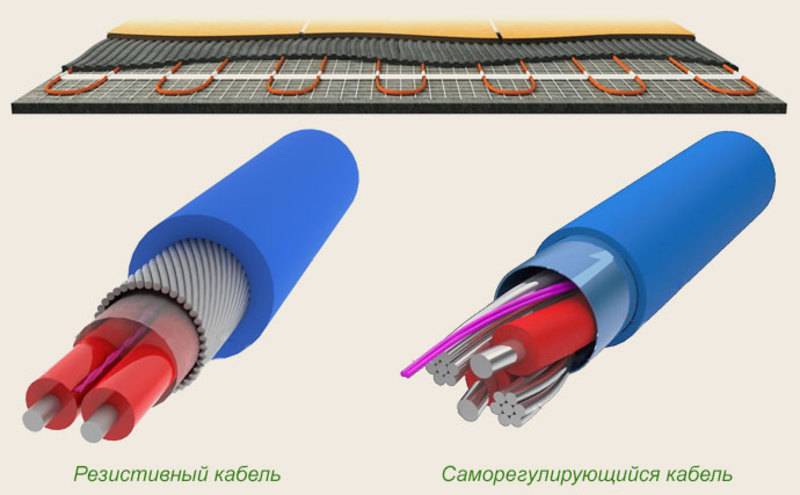

- resistive

- self-regulating

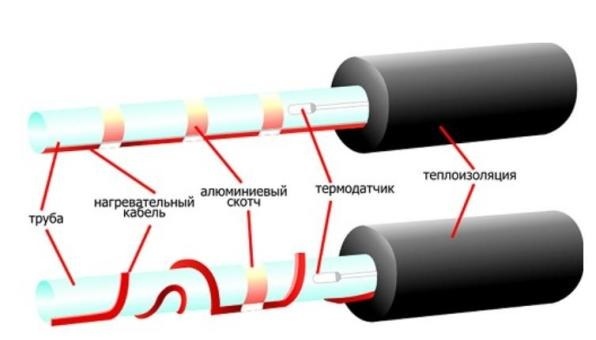

- Mounting methods

- Mounting

- Ways of laying the heating element

- Internal heater installation

- External installation of pipe heating

- Finally

How to choose a self-regulating heating cable for plumbing

Keep in mind that continuous operation of the heating wire is not recommended. The reason is its limited resource. If you turn on the cable for a long time in a relatively warm climate, it will fail prematurely.

A wire with a higher power is used to heat the pipeline when the ambient temperature drops significantly below 0°C. However, even when installing the cable with the maximum load on the power supply, electricity costs will be moderate.

How to determine how much cable power is needed

Determining the power of a heating self-regulating cable:

- For installation inside communications, it is recommended to use the 5 W / m option, and the pipes must pass under the soil layer. Only under these conditions can one count on a sufficient temperature increase with such a wire.

- If you plan to install communications under a layer of soil, but the heat source will be located on the side of the outer walls, you need to use a wire with a power of 10 to 15 W / m. More precisely, you can determine if you know the exact depth of the pipes.

- To heat communications that pass above the ground, it is necessary to use a cable with a power of 20 W or more, since in this case the pipe and its contents are exposed to a stronger effect of low temperatures. In addition, increased air humidity and precipitation contribute to an increase in the negative impact on communications, the likelihood of their icing in this case increases.

The power of a wire is determined by the number of conductive paths in it. The higher the value of this parameter, the colder the pipe can be heated using such a cable. To maintain the temperature of a warm pipe, it is sufficient to use a wire with an average number of conductive paths. For communications with a hot coolant, a wire with a low heat dissipation rate should be used. It is distinguished by the minimum number of conducting paths.

The low-temperature cable is characterized by high elasticity, minimal thickness. This allows you to wrap it more tightly on communications. When choosing, you also need to focus on physical parameters, for example, length.

It cannot be less than 20 cm and more than 100 m, only in this case sufficient efficiency of the heating wire is ensured. If the coiled installation method is chosen, the ability of the cable to bend should also be taken into account.

Top 5 best manufacturers

To install a reliable heating system for communications, you need to use high-quality materials. The wire is constantly in contact with moisture, which increases the risk of breakdown. For this reason, preference is given to a cable of high-quality assembly, which means that materials from common manufacturers are chosen:

- Ensto (Finland);

- Nelson (America);

- Lavita (South Korea);

- DEVI (Denmark);

- FreezStop (Russia).

The principle of operation of the heating cable

The principle of operation of a self-regulating wire is based on a simple property of all classical conductors. The energy passing through the conductor causes it to heat up, which inevitably leads to the release of heat. In this case, the resistance will increase, therefore, with a constant supply voltage, the current decreases, and as a result, the power consumed by the conductor decreases.

The side of the wire that is fixed in the warmer section has a high resistance, the current inside will be less, so the wire will heat up less than in the other section.

At the same time, in cold areas, the wire will have the least resistance (high conductivity), the current will flow in large quantities, which will provide more heating.

After turning on the product installed in the pipeline, it will start working at maximum power, and, as it heats up and reaches the set temperature, the intensity will begin to fall.

Attention! Freezing of water inside the pipes causes it to expand after crystallization, which causes breakthroughs in the system.

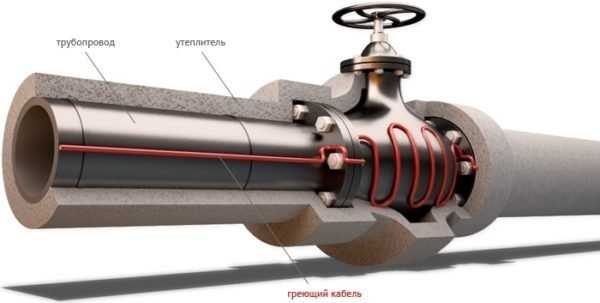

Design and scope

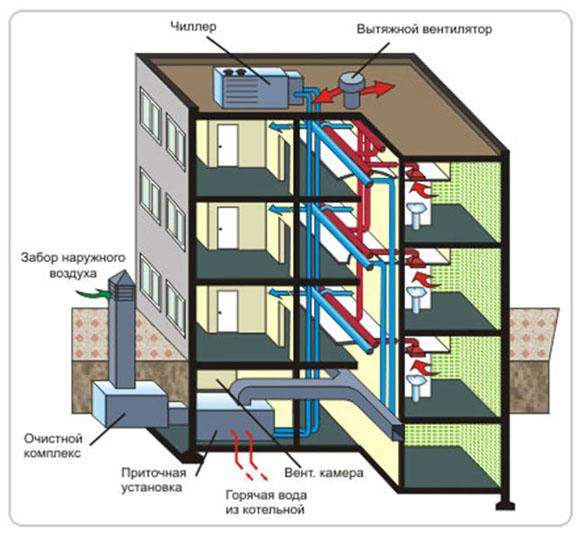

Depending on the type and technical characteristics, heating cables are used to heat drains, water and sewer pipes, tanks. The main purpose is to protect the liquid from freezing by increasing the temperature.

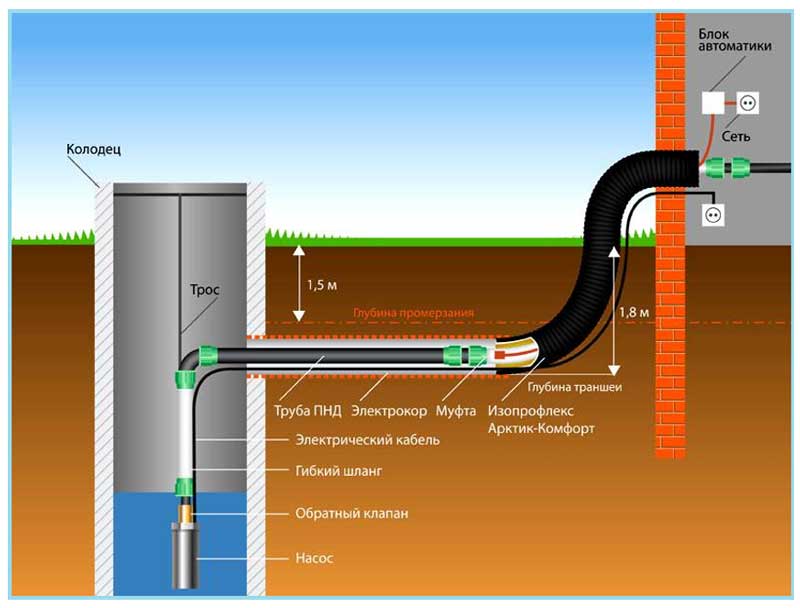

Heating systems are relevant for outdoor communications, that is, for use in the ground or outdoors.

The basis of functioning is the ability of the cable to convert electricity into heat. The wire itself cannot transmit energy, as power counterparts do. He only receives it, and then gives off heat to the pipe (tray, gutter, tank, etc.)

Heating systems have one useful ability - zonal application. This means that you can take a set of elements and assemble a mini-system from it for heating a single area, without connecting to the entire network.

This results in material and energy savings. In practice, you can find miniature "heaters" of 15-20 cm each, and 200-meter windings.

The main components of the heating cable are the following elements:

- Inner core - one or more. Alloys with a high electrical resistance are used for its manufacture. The higher it is, the greater the value of specific heat release.

- Polymer protective shell. Together with plastic insulation, an aluminum screen or copper wire mesh is used.

- Durable PVC outer sheath covering all internal elements.

Offers of various manufacturers may differ in nuances - the alloy of the core or the method of protection device.

Shielded types are considered more reliable, equipped with foil protection and having 2-3 cores instead of one. Single-core products - a budget option, which is good just for assembling systems for small sections of water supply (+)

To improve the performance, the copper braid is nickel-plated, and the thickness of the outer layer is increased. In addition, the PVC material must be moisture resistant and resistant to ultraviolet radiation.

Varieties

Industrial enterprises produce several types of heating cable:

- Self-adjusting. Able to independently adjust to the current weather conditions and control the intensity of heating. As the ambient temperature rises, the cable resistance automatically decreases. This leads to a decrease in current and power. This option is somewhat more expensive than its counterparts, but more than pays off in terms of energy savings.

- Resistive. The resistance and heating power of such a product do not change, which has a positive effect on its cost, but negatively on indicators of durability and efficiency. To increase efficiency, temperature controllers and sensors are additionally installed on the resistive cable.

- Zonal. According to the principle of operation, it is similar to resistive, but it does not function over its entire length, but only in predetermined areas. Such a cable is often used for the insulation of metal containers.

The principle of operation of a self-regulating cable is based on the properties of certain polymers that can contract and expand with temperature changes.Placed between conductive wires, the polymer expands under the action of heat, moving away neighboring conductor particles and weakening their electrical contact. This leads to an increase in resistance, a drop in current strength and, accordingly, a decrease in heating of the corresponding section of the cable.

Resistive cable, in turn, can be classified by structure into two groups:

- Single core. The cable is a single metal conductor protected by a layer of insulation and shielding material. A current flows through this conductor, as a result of which the metal is heated. The laying of a single-core cable is carried out in loops so that both ends can be brought out to one point for connection to the network. Such a cable is not used for laying inside pipes, since it will be difficult to control its location there, and when the cable sections overlap each other, it can quickly burn out.

- Two-wire. In this design, one of the cores (having high resistance) is used only for heating, while the second one is used as a current conductor. Such a cable does not need to be led to one point - it is powered from one side, while a jumper between the cores is simply mounted at the other end.

Varieties

There are two types of heating cable: resistive and self-regulating. The first model uses the property of the metal to heat up after the passage of electricity. Here there is a gradual heating of the metal conductor. A characteristic feature of a resistive cable is the constant release of the same amount of heat.At the same time, the temperature of the environment is unimportant. Heating will be carried out at full capacity, the amount of electricity consumed will be identical.

To reduce costs in warm seasons, temperature sensors and thermostats are installed (similar to those used in the "warm floor" system). Parts of such a design should not be brought close to each other and crossed, otherwise overheating and failure will occur.

As pluses it is possible to note:

- high heat transfer and the power degree of the circuit, which is considered the main parameter for products with a large diameter, the need for heating numerous components (fittings, adapters, taps);

- ease of use, low cost.

The disadvantages of the system are:

- Additional financial costs for the purchase and installation of temperature sensors, automation and control units.

- A ready-made set of resistive cable is sold in a fixed length, moreover, it is not possible to change the footage on your own. The contact sleeve is made strictly in the factory.

Instances differ in the connection process. So, single-core are connected to the outlet at both ends. The two-core ones are equipped with a plug at one end, and at the other they are fixed with a conventional power cord with a plug for plugging into a 220 V network. Keep in mind that the resistive conductor will cease to function after being cut. When buying a bay larger than necessary, you need to lay it completely.

Self-regulating wire is a metal-polymer matrix. Here, electricity is conducted with the help of cables, and the polymer located between the two conductors is heated.The material has an interesting property: as the temperature increases, the amount of heat generated decreases, and vice versa. These processes take place regardless of nearby wiring nodes. Thus, it independently controls the level of heat, for which it got its name.

This variety has solid advantages:

- the possibility of crossing and fireproof;

- cuttable (there is a marking indicating the cut lines), but then a termination is required.

The only drawback is the high price, but the period of operation (subject to the rules of operation) is about 10 years.

When choosing this type of thermal cable, pay special attention to:

- internal insulation. Its resistance should be at least 1 ohm. The structure must be solid and have adequate thermal conductivity.

- Shielding film in the wire. Thanks to it, the cord becomes stronger and gets zero in weight. In more budget options, the presence of such a "screen" is not provided.

- Type of protective layer. When carrying out installation measures in anti-icing structures, the heating device must be covered with a protective sheath made of thermoplastic or polyolefin, which is resistant to ultraviolet rays. For laying in water supply, experts recommend giving preference to a thermal device covered with an external insulating fluoroplastic layer.

- The use of wires in an aggressive environment will require the presence of a fluoropolymer layer.

- The heating level of the conductors. The heating temperature is 65-190 ° C. Low temperature conductors are intended to heat a pipe with a small diameter.The medium temperature option is suitable for networks with a large diameter, roofs. The high temperature sample is used for industrial purposes.

Choosing a cable for a sewer system

The required heating power is directly related to the heat loss of the heated pipe

It is very important to make the right selection of power for the sewer system of the desired diameter and the conditions for its heat transfer.

Important! Incorrect power selection can lead to:

- If the power is too high, overheating, as a result of which the service life of the heating system will decrease. In the worst cases, plastic drains can melt. (When using a self-regulating heating cable, overheating is completely eliminated).

- If the power is too low, the system will not be able to withstand low temperatures, which will lead to freezing of drains.

- To reduce the economic efficiency of heating.

- Increasing the likelihood of electric shock to a person or animal.

- Reduced service life of both the heating system and the sewage system itself.

When you build a sewer with your own hands, design its heating and thermal insulation, you can be guided by the table below. It displays the average heat loss depending on the pipe diameter, insulation layer and temperature difference.

Figure 6. Selection of specific heat losses of the pipe depending on the diameter and external conditions

Figure 6. Selection of specific heat losses of the pipe depending on the diameter and external conditions

We take the power per unit length equal to or slightly greater than the number that we find at the intersection of the desired thickness and temperature difference. Next, we multiply the length of the pipeline by this number and by a safety factor of 1.3, then divide by the cable power according to the passport - this will be the required length.

Simple wiring diagram for roof heating

The simplest scheme consists of a single thermostat per zone.

It is used for heating small areas.

Roughly speaking, they connected one temperature sensor and unscrewed the regulator knob (PT 330 or another) to the desired temperature, for example, zero degrees Celsius.

It turns out that when this temperature occurs, the anti-icing system will independently start and melt the ice.

The scheme is simple, but has its drawbacks. This system will not understand whether it is snowing outside the window or not.

This means that it will often be useless to heat your roof, burning extra kilowatts to nowhere. This method, although cheap, is not very economical.

Therefore, let's consider a more rational option, using a full-fledged programmable weather station and a combination of all sensors.

The principle of operation of the heating cable

The heating wire must be connected during periods when the ambient temperature drops to +2°С…+5°С. The cable for the water supply, when turned on in low temperature conditions, will require some time to warm up the system. The heating system of the pipeline operates in accordance with the laws of physics: at the moment the electric current passes through the wire, thermal energy is released. At the same time, as the resistance increases, the amount of heat also increases.

The difference between a self-regulating system is the presence of a special coating. When installing such systems, heated water pipes in cooled areas will receive more heat. Self-regulating heating cable for plumbing operates on a similar principle to resistive.

Types of heating cables for plumbing

All heating technologies used in water supply heating systems are divided into 2 large groups:

- resistive;

- self-regulating.

Each of them is focused on performing different tasks. For example, a resistive heating wire will be appropriate when equipping short pipes with a small diameter - up to 40 mm. It is more expedient to use self-regulating heating on an extended section.

A resistance heater can be purchased at specialized retail outlets in the form of segments of different lengths. It has a constant resistance, that is, the amount of heat generated is the same throughout the entire length of the wire. The resistive wire can be single-core or two-core.

The standard structure of a single-core conductor assumes the presence of the following components:

- one core;

- double insulation;

- external protection.

The function of the heating element is performed by a core

During the installation of the system, it is important to remember that the connection scheme implies connection from both ends. Visually, this resembles a loop: first you need to connect one end, then stretch (or wind it around the pipe) and connect the second end of the wire

The use of a closed circuit is advisable for equipping roof drains or arranging a "warm floor" system. Although there are also methods of equipping the pipeline. Their feature is the conduction of the heater through the pipe from two sides. The method is only suitable for external use.

For internal laying, a single-core wire is not suitable, since the arrangement of the loop takes up a lot of space. In addition, if it is crossed, overheating will occur.

A feature of a two-core cable is the separation of functions:

- the first core is responsible for heating;

- the second is for the supply of electricity.

It also uses a different connection scheme. There is no need to create a "loop" anymore. It is enough to connect one end of the cable to electricity, and run the other along the pipeline. A two-core system is no less popular than a self-regulating one. The cable for heating a water pipe is used internally with seals and tees. The main advantage of a resistive system is its low cost.

The installation of a thermostat with appropriate sensors will further reduce energy costs. At the moment of fixing the temperature decrease to the level of +2°С, the heating system is automatically activated. When it reaches +6°C, it turns off.

The second group of heating systems is self-regulating. This is a universal type of cable that can perform various functions, such as heating water pipes or roofing elements. In addition, it can be used to heat containers with various liquids, pipes of sewer systems. The peculiarity of the method lies in the ability of the cable to independently regulate the intensity and power of heat supply. When the temperature reaches the set point (for example, +2°C), the system automatically starts heating the pipe.

The main structural difference between a self-regulating cable and a resistive cable is the presence of a heating matrix responsible for the level of heating. The same insulating layers are used. The principle is based on the ability of the wire to increase or decrease the heat supply depending on changes in the level of resistance.

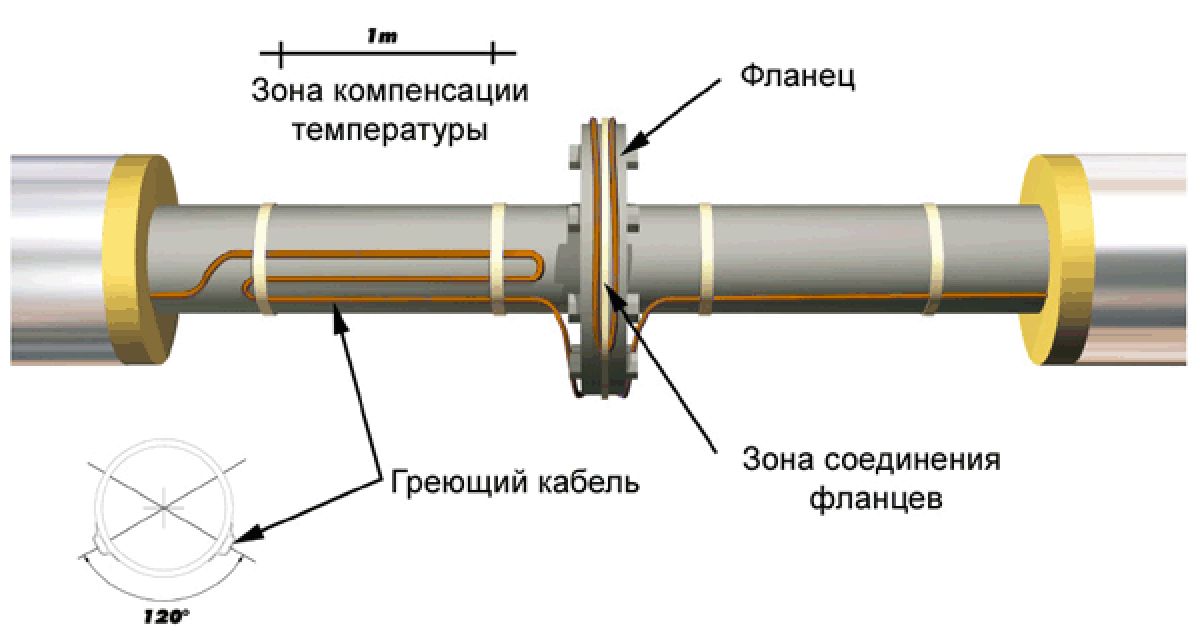

Features of assembly and installation of heating cable sections

Before proceeding with the installation of a heating cable, it is worth deciding on the choice of a specific product model, the use of which will be most appropriate in this case.

There are many types of cable available on the market. Their main characteristic - specific power - can vary in the range from 10 to 40 W/m.

- 10 W/m. Suitable for heating plumbing systems with a diameter of not more than 25 mm.

- 16-17 W/m. Can be used in sewer pipelines with a diameter of not more than 50 mm.

- 30-40 W/m. Such power will be enough to heat a large sewer pipeline with a diameter of 110-160 mm.

The assembly procedure itself is very simple and does not require any special skills from the master. Of the tools, you only need pliers for crimping the connecting sleeves, pliers, a building hair dryer for heating the shrink film, side cutters or a knife for stripping insulation, sealant.

The algorithm of actions can be represented as follows:

- The current-carrying cores, the shielding metal braid and the ground are cleaned (not present in all cable models).

- Pieces of a heat-shrinkable tube of the appropriate length are successively put on the individual cores, the cable under the braid and its outer sheath.

- The adjacent ends of the current-carrying conductors are connected in pairs with the help of sleeves.

- A small layer of sealant is applied to the junction, after which heat shrink is crimped.

- A similar procedure is performed with the ground and the screen, if any.

- At the end of the heating cable, the next steps depend on the type of cable. For a resistive two-core cable, the current-carrying conductors are connected, followed by sealing and insulation of the coupling with a jumper.In a self-regulating cable, all the cores at the far end are cut off and separated by a certain distance, to increase resistance in the event of a violation of the tightness of the coupling.

- The free ends of the shrink film are flattened with pliers.

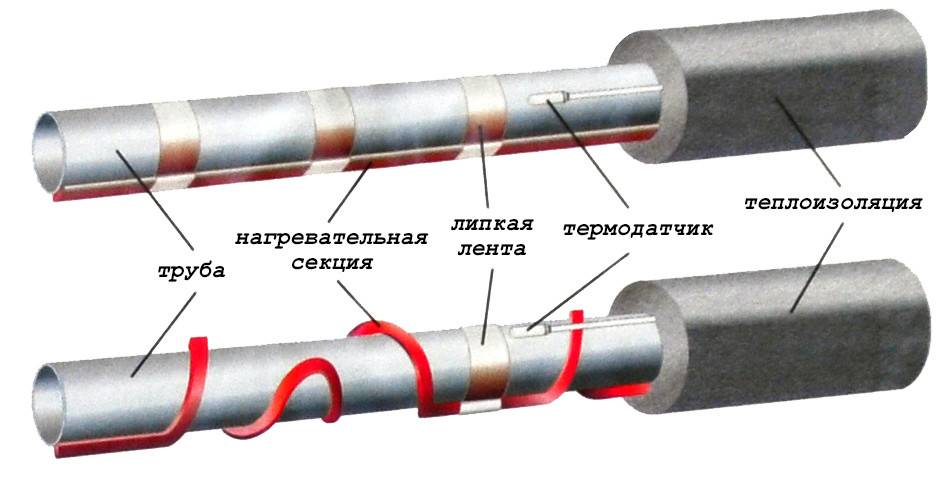

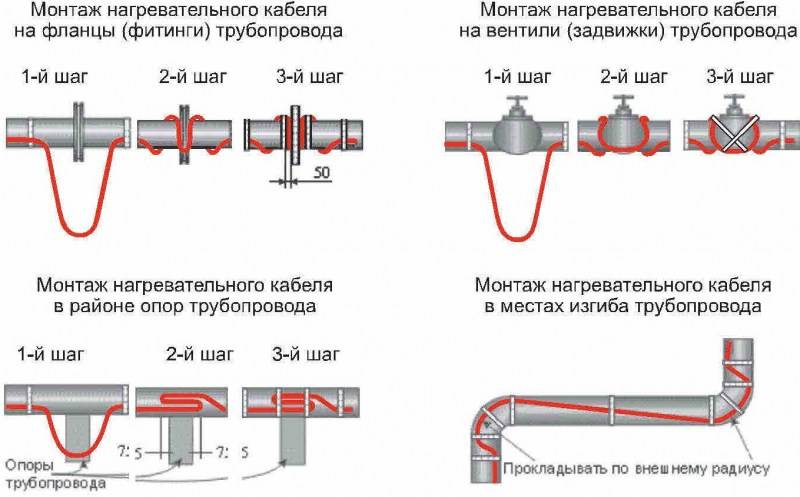

outdoor installation

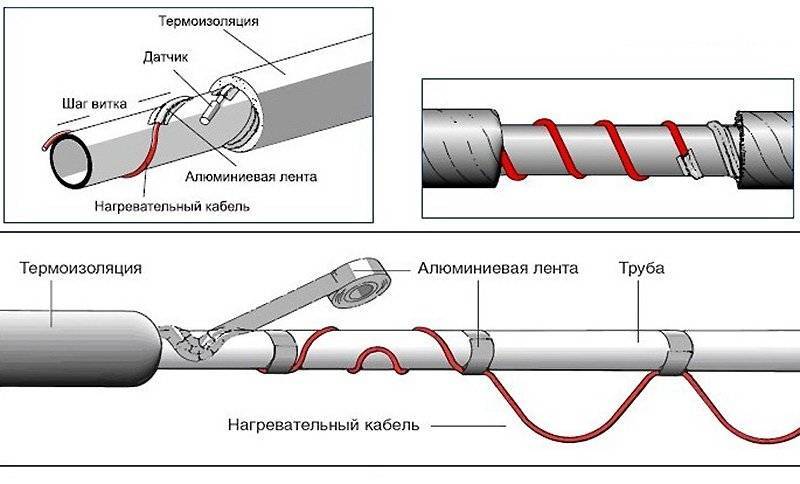

The heating cable is fixed under the pipe with aluminum tape. To improve heat transfer, it should be pressed against the pipe as tightly as possible. Aluminum tape helps to further limit heat loss by partially reflecting infrared radiation.

The cable is fixed with short pieces of adhesive tape at regular intervals (at least 30 cm), after which it is also fixed with adhesive tape along its entire length. For additional reliability of fixation, plastic clamps are often used.

It is allowed to place the cable under a layer of insulation, which will not only provide additional thermal insulation, but also help to fix it securely. It should also be borne in mind that, first of all, horizontal sewerage sections need heating, through which drains move much more slowly than vertical ones.

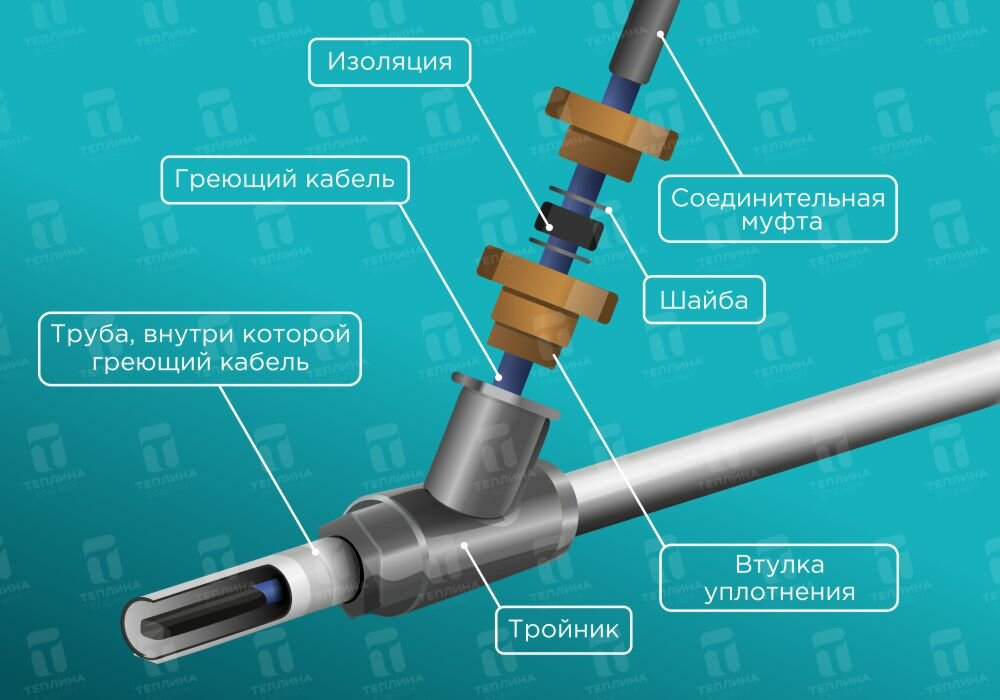

Internal installation

The laying of the heating cable inside the sewer pipes is allowed with some restrictions.

The ring coupling should not be in contact with wastewater passing through the pipes, since they are considered an aggressive environment that can destroy heat shrink in just a few seasons. At the same time, the cable's own insulation is resistant to such influences, and is able to stay inside the pipe for an arbitrarily long time.

Therefore, the ring coupling, as a rule, is taken out of the pipeline. To do this, use special holes in the tee or corner of the structure.

Another indispensable condition is that the cable should be easily removed. Otherwise, during the mechanical cleaning of pipes with wire or plumbing cable, the cable will almost certainly be damaged.

Of course, this method of heating sewers cannot be called cheap. However, given that the pipeline will be reliably protected from any temperature fluctuations and will be able to serve properly for many years, the use of a heating cable will be much more profitable than replacing frozen parts of the system.

Cable types

Before installation, it is important to study what heating wires are and how to install them. There are two types of cables: resistive and self-regulating

There are two types of cables: resistive and self-regulating.

The difference between them is that when an electric current passes through the cable, the resistive one heats up evenly along the entire length, and the feature of the self-regulating one is the change in electrical resistance depending on temperature. This means that the higher the temperature of the self-regulating cable section, the lower the current strength will be on it. That is, different parts of such a cable can each be heated to the desired temperature.

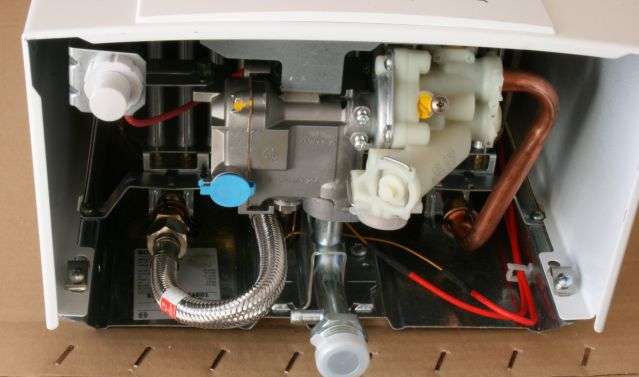

In addition, many cables are produced immediately with a temperature sensor and auto control, which significantly saves energy during operation.

Self-regulating cable is more difficult to manufacture and more expensive. Therefore, if there are no special operating conditions, then more often they purchase a resistive heating cable.

resistive

A resistive-type heating cable for a water supply system has a budget cost.

Cable differences

It is divided into several varieties, depending on the design features.Each of them has its own advantages and disadvantages:

| cable type | pros | Minuses |

| single core | The design is simple. It has a heating metal core, a copper shielding braid and internal insulation. From the outside there is protection in the form of an insulator. Maximum heat up to +65°С. | It is inconvenient for heating pipelines: both opposite ends, which are far from each other, must be connected to the current source. |

| Two-core | It has two cores, each of which is isolated separately. An additional third core is bare, but all three are covered by a foil shield. External insulation has a heat-resistant effect. Maximum heat up to +65°C. | Despite the more modern design, it is not much different from a single-core element. The operating and heating characteristics are identical. |

| Zonal | There are independent heating sections. Two cores are isolated separately, and a heating coil is located on top. The connection is made by means of contact windows with current-carrying conductors. This allows you to create heat in parallel. | No cons were found, if you do not take into account the price tag of the product. |

Resistive wires of various types

Most buyers prefer to lay the wire "the old fashioned way" and purchase a wire with one or two cores.

Due to the fact that a cable with only two cores can be used for heating pipes, a single-core version of the resistive wire is not used. If the owner of the house unknowingly installed it, this threatens to close the contacts. The fact is that one core must be looped, which is problematic when working with a heating cable.

If you install the heating cable on the pipe yourself, then experts advise choosing a zonal option for outdoor installation. Despite the peculiarity of the design, its installation will not cause serious difficulties.

Wire design

Another important nuance in single-core and twin-core structures: already cut and insulated products can be found on sale, which eliminates the possibility of adjusting the cable to the optimal length. If the insulation layer is broken, then the wire will be useless, and if damage occurs after installation, it will be necessary to replace the system throughout the area. This disadvantage applies to all types of resistive products. Installation work of such wires is not convenient. It is also not possible to use them for laying inside the pipeline - the tip of the temperature sensor interferes.

self-regulating

Self-regulating heating cable for water supply with self-adjustment has a more modern design, which affects the duration of operation and ease of installation.

The design provides:

- 2 copper conductors in a thermoplastic matrix;

- 2 layers of internal insulating material;

- copper braid;

- external insulating element.

It is important that this wire works fine without a thermostat. Self-regulating cables have a polymer matrix

When turned on, carbon is activated, and during an increase in temperature, the distance between its graphite components increases.

Self-regulating cable

Mounting methods

The choice of installation method depends on the location of the plumbing system and the specific type of heating cable.

-

The most common is installation on top of the pipe.

To do this, the cable is pre-stretched along the entire length of the required section of the water supply. You can place it in different ways - in one straight line, in zigzags (wavy line) or wrap the pipe in a spiral.

If it is planned to install a temperature controller, the sensor must be placed in the coldest place of the pipeline, for which it may be necessary to make the necessary measurements.

The sensor is installed at the maximum distance from the heater - diametrically opposite, with its additional thermal insulation from the cable. If this requirement is not met, the automatic control system will lose its meaning.

The cable is firmly attached to the body of the pipe with strips of adhesive tape, best of all - aluminum tape.

On top of the laid and fixed cable, thermal insulation is installed - mineral, polystyrene foam, polyurethane, etc., and a protective casing that will protect the entire mounted system from external mechanical influences, atmospheric and soil moisture.

-

There is a way to lay a cable in the body of a water pipe.

This is very justified if it is impossible to carry out installation on top. In addition, this method is the most economical - you can use a cable of lower power, since heat transfer is carried out by direct contact with water.

Not all types of cables are suitable for the implementation of this method - this should be specified immediately upon purchase. In the kit, special couplings are purchased that ensure the tightness of the plumbing system and secure cable fastening.

When installing, remember that the cable should not rest against bends, tees, should not interfere with the operation of gate valves and taps.

Such cables are completely safe both electrically - they have very reliable insulation, and from an environmental point of view - the material of their outer coating does not in any way affect the quality of drinking water.

Mounting

Ways of laying the heating element

The heating cable for heating pipes can be installed in several ways, depending on the installation requirements and the diameter of the water supply.

There are three of these methods:

- laying inside the pipe;

- installing it outside with the location along the pipe in a straight line with fixing with adhesive tape;

- external mounting around the pipe in a spiral.

When laying a heater inside a pipe, it must meet several requirements. Its insulation must not be toxic and must not release harmful substances when heated. The level of electrical protection must be at least IP 68. Its end must end in a tight coupling.

When laying outside the pipe, it must fit snugly against it, secured with adhesive tape, and polyurethane thermal insulation must be put on top of the pipe.

Scheme of the device of the resistive heating cable for pipes

Internal heater installation

The first method is the most difficult from a technical point of view. For this purpose, special types of heating cable with food-grade fluoroplastic outer insulation are used, which do not contain harmful substances and have an electrical protection level of at least IP 68.

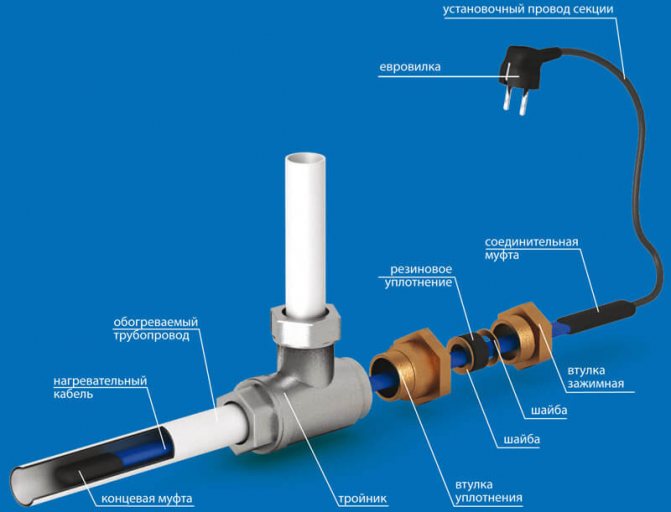

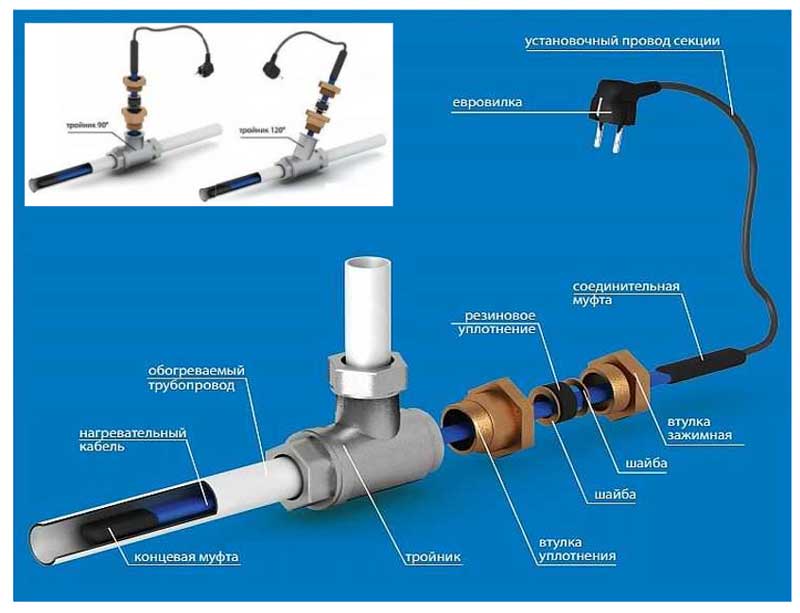

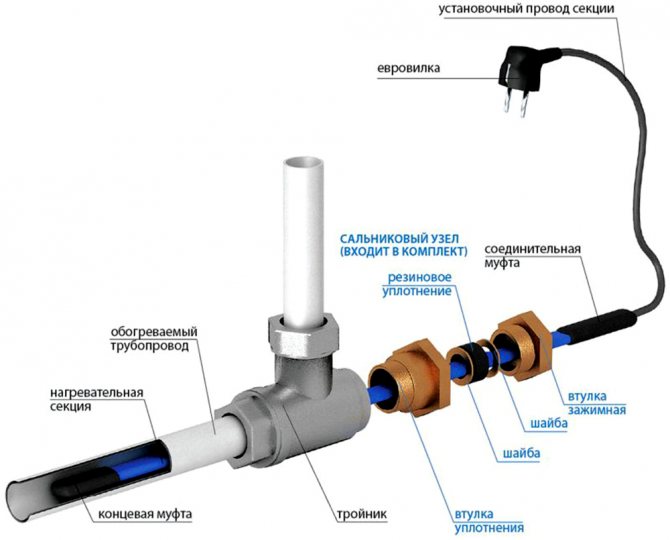

In this case, its end must be carefully sealed with a special sleeve. For this installation method, a special kit is produced, which consists of a 90 or 120 degree tee, an oil seal, as well as a standard kit for connecting to the electrical network with an end sleeve.

It is worth saying that in order to connect the heater and to install it inside the pipe, you must have basic knowledge of plumbing and electrical installation. And the sequence can be described as follows. In the presence of all components: an oil seal, a tee, as well as the necessary set of tools, we begin with the installation of a tee on the water supply system, which must be protected from freezing in winter.

The tee is installed on the pipe using a threaded connection with a seal with FUM tape or tow with paint. In the second outlet of the tee intended for the stuffing box, we insert the heating cable prepared for installation for plumbing with a washer put on it, a polyurethane stuffing box and a threaded stuffing box.

After installing it in the water supply, the gland is installed. In this case, it is necessary to ensure that the connecting sleeve between the heating and electric cables is outside the pipeline by about 5-10 cm from the stuffing box. It is better to purchase a kit for internal installation from cable suppliers, since all gland gaskets are made for its cross section. This will allow in the future during operation to protect yourself from water leaks from the stuffing box.

For internal pipes, special types of heating cable are used with food-grade fluoroplastic outer insulation, which does not contain harmful substances, has an electrical protection level of at least IP 68

External installation of pipe heating

Heating of external pipes with a cable

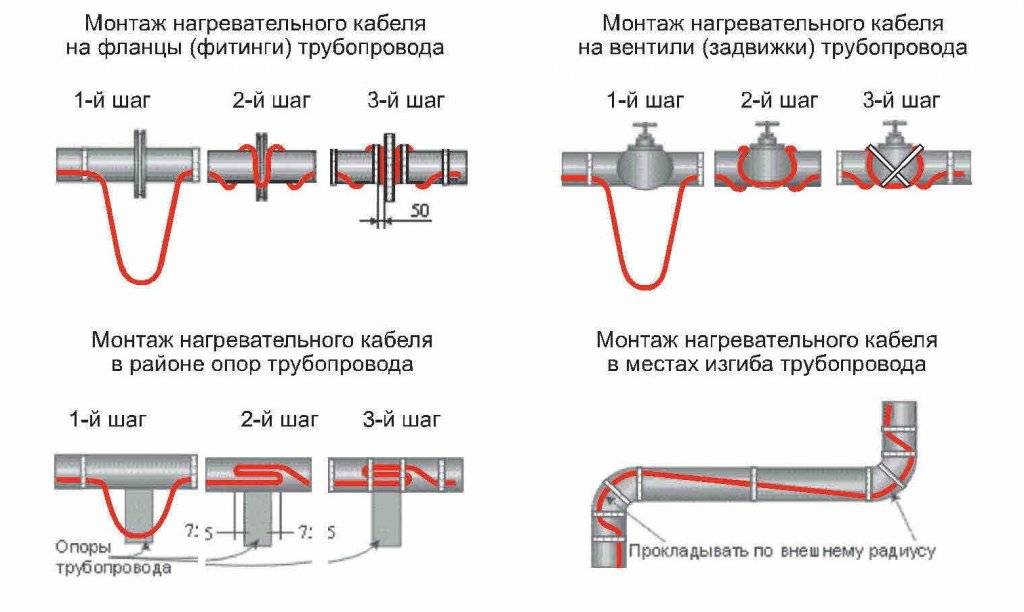

Installation of heating outside the water supply is much easier. It is laid along the pipe, fixed along the entire length with aluminum tape every 30 cm. If possible, it is attached to the bottom of the pipe so that the heating is optimal - from the bottom up.

The considered method refers to water pipes of small diameter, with large diameters it is selected more powerful and the laying is performed in a spiral around the pipe. Shut-off valves such as valves, taps, filters are wrapped with a cable in any form.

If it is self-adjusting, then the shape of the winding around the valves is not important for it, even a crosshair is allowed. Regardless of the type of installation - inside or outside, along the pipe or in a spiral - all water pipes must be insulated. There is a very convenient polyurethane shell for different diameters.

Since the protection of sewers from freezing is just as important as the protection of water pipes, sewer outlets are heated in the same way. The only difference is that the sewer pipes have a diameter of 150 mm or more and the heating system is mounted on them outside in a spiral.

Pipe cable heating: system components

Finally

The problem of uninterrupted water supply to a private house remains relevant today. When laying pipelines, everyone thinks that he has done everything so that the water in the pipes does not freeze, but winter comes and it becomes clear that not everything is thought out to the end. Heating in pipes in the most vulnerable places is a kind of insurance for all occasions. As a rule, each winter is characterized by certain periods when sub-zero temperatures reach peak values. Therefore, heating can be turned on precisely during such peak periods, turning off at the rest, and the temperature can be monitored on the Internet according to the weather forecast. As a rule, most of the forecasts are absolutely real, so you can always rely on them.To be safe, you can turn on the heating only at night, and in the daytime, when the temperature rises, the heating can be turned off. In this case, you will not have to pay a lot for electricity, but water will be supplied to the house on an ongoing basis.

As for colder regions, when cold frosty weather lasts for a long time, this problem becomes more urgent. In such conditions, heating of water pipes is indispensable. Under such conditions, the earth freezes deep enough, so it makes no sense to dig too deep, especially since in any case you will have to bring water into the dwelling, and this is already a big risk. The best option to protect the water supply system from freezing is the organization of pipe heating and reliable thermal insulation. The main thing is to do everything correctly and in a timely manner.

How to choose a heating cable inside a pipe

Watch this video on YouTube