- More about the benefits of the material

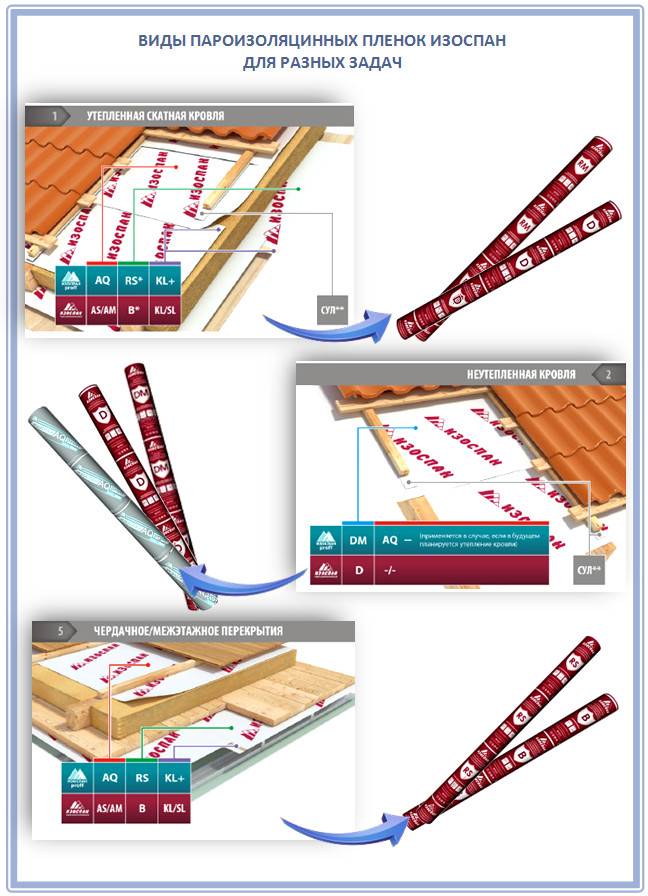

- Varieties of material, their technical features

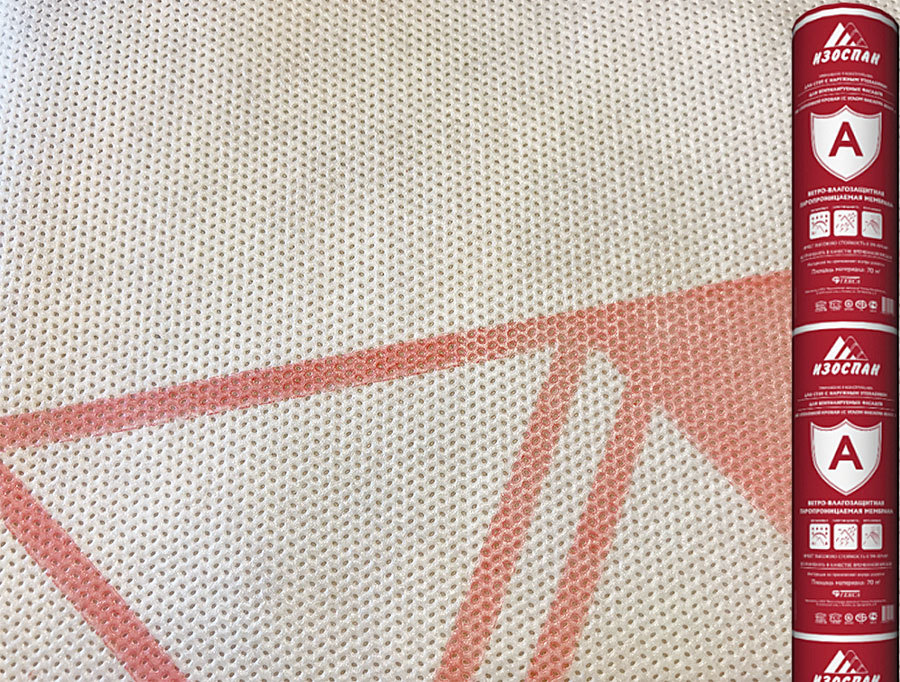

- Isospan A

- Izospan V

- Izospan C

- Izospan D

- General installation rules

- Advantages and disadvantages

- Where is the material applied?

- Which side to lay to the heater

- How is the vapor barrier attached?

- Izospan AM: instructions for use

- Izospan positions: characteristics and application features

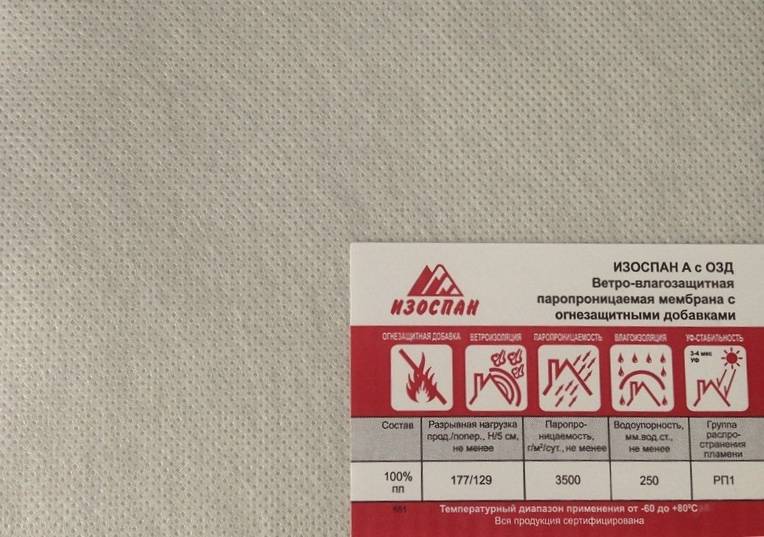

- Range of windproof waterproofing membranes

- Overview of hydro-vapor barriers

- Heat reflective materials

- Izospan insulation range

- Different styling options "Izospan"

- Izospan FB

- 2 Production features

- 2.1 Installation procedure

- 1 Izospan film features

- 1.1 Differences between materials

- 1.2 Properties and parameters

- Helpful Hints

- Waterproof and vapor barrier films

- Conclusion

More about the benefits of the material

Izospan AM has a lot of positive qualities that many people note when buying. That is why it is so popular and has its value. These are the benefits:

- Reduced repair costs. The path for Izospan AM will have to be paid, but it will reliably protect the structure. Moisture is a strong enemy for the house, after which you have to perform a number of works. However, with Izospan AM, you can forget about this.

- Availability. Products can be easily bought, they are not in short supply and are sold on almost all shelves of hardware stores.

- Environmental friendliness.The raw materials from which Isospan AM is made are environmentally friendly and will not harm those living in the house. Waterproofing does not emit toxic substances.

- Good indicators of moisture resistance and vapor permeability. The material will serve as a good barrier to moisture. And since he breathes, the creation of a ventilation gap is not necessary.

- Resistance to UV rays. The material will not shrink and lose its properties over time. Nevertheless, you should not leave Isospan AM in the sun for a long period.

- Small specific weight. This allows you to use products for any construction work. Rolls are easy to deliver to the roof and perform further manipulations.

- Long operating period. Izospan AM does not rot, does not rust, it is not afraid of rodents and insects.

- Good indicators of mechanical strength, due to the substrate.

Izospan AM is produced in rolls, 1.4–1.6 m wide. A roll can be 35–70 m2. As for the scope, it is as follows:

- insulation of sloped roofs;

- for frame walls;

- for walls with external insulation;

- for ventilated facades;

- for attic floors;

- for interfloor ceilings;

- for interior walls.

Varieties of material, their technical features

When choosing products, you need to focus on the presence of isospan quality and safety certificates. Well-known manufacturers coordinate their production plans with legal requirements.

Now, when decorating houses and non-residential premises, 4 main modifications of isospan are used, which have their own characteristics.

Isospan A

This is a film (membrane), which perfectly waterproofs and helps to eliminate moisture, its vapors, from the insulation.This modification is used to protect against wind and water, increases the life of the insulation. It is applied to isolation of private houses, penthouses, garages and any other rooms.

This isospan is resistant to mechanical stress and pressure, completely neutral to bio-impact (mold, bacteria, etc.). Can stretch:

- longitudinally by 190 mm;

- transversely by 140 mm.

The material is fixed from the outside of the insulation as an additional barrier. For example, when insulating an attic, it is mounted on the roof with an overlap in wide strips.

It is necessary that the membrane lays flat, does not protrude, swell or sag. Izospan A is fixed with wooden slats and nails.

Izospan A can be seen on the picture:

Izospan V

This modification perfectly blocks the way for water vapor, which eliminates the impregnation of the insulation with steam.

Izospan B is two-layer, used:

- On pitched roofs.

- On the walls: external and internal.

- To save floors in the basement, attic (attic).

- In garages and other non-residential premises.

The vapor permeability index is 7, the material can also be stretched: in the longitudinal direction by 130 mm, in the transverse direction - at least 107 mm.

Each layer of this material has its own functions:

- fleecy layer retains moisture and condensate;

- the smooth part allows you to firmly fix the film with insulation.

Unlike the previous modification, isospan B is attached to the inside of the insulation. Fastened from the bottom up and overlapped. In order for the film to capture vapors, condensate, there must be a free space of at least 5 cm above the fleecy layer.

The appearance of the packaging of isospan B can be seen in the photo:

Izospan C

It also consists of two layers, but is used to protect an uninsulated roof, floors between floors, floor insulation. Has high strength.

The film is used for steam and water insulation:

- uninsulated pitched or flat roof;

- frame, load-bearing walls;

- wooden floors parallel to the floor;

- concrete floor.

- Installation of non-insulated roofs (slopes) is carried out with an overlap (with a depth of about 15 cm), also fastened with wooden slats. When arranging the attic at home, this material perfectly insulates the room from moisture from the environment.

- If we talk about wooden floors, then here the film is attached directly to the insulation with a small free space from the floor (4-5 cm).

- When insulating a concrete floor, isospan C is placed directly on the floor and pulled together on it.

Izospan C can be seen in the photo:

Izospan D

This modification is very durable, able to withstand great pressure and loads. It is used in roofing. In terms of waterproofing and protection against condensation, it perfectly withstands even a large crust of snow on itself.

Great for arranging the attic of a house or garage in regions with heavy snowfall. The material protects wooden structures and non-insulated roofs. Isospan D is insulated:

- flat and pitched roofs;

- concrete floors and ceilings at the basement level of the house.

The high strength of the film allows you to protect the living area from wind and moisture, even in cases where the roof passes moisture.

It is also mounted with an overlap horizontally in strips, fixed on the rafters of the roof of the house with the help of rails. Installation on a concrete floor is similar to the previous modification of isospan, because in many respects isospan C and D are similar in their characteristics.

Izospan D can be seen in the photo:

The main modifications of the building material are described above, there are also varieties of these modifications that have different densities or additional qualities, for example, fire retardant additives, which provide greater fire safety and protect against fire.

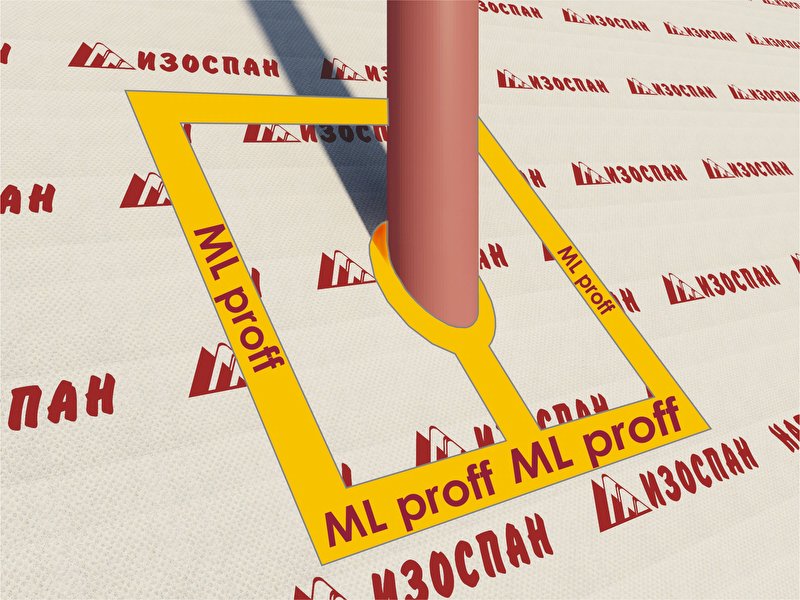

Also, manufacturers timely attended to the creation of additional consumables that allow you to isolate seams and minor damage. We are talking about isospan adhesive tapes - these adhesive tapes allow you to isolate seam lines, uneven surfaces. It is enough that the work surface is dry and clean - isospan FL, SL adhesive tape will provide good impermeability of such places. There is even a metallized tape that has a high resistance index.

General installation rules

In order for the material to function as expected, it is important to study the instructions well before starting work with it. Otherwise, it is easy to make mistakes when laying and, thus, there will be no sense from Izospan B, and the owner of the house will consider that he threw money away

In order for the material to work as expected, the following rules must be observed during operation:

- it is necessary to fix the material from top to bottom when working on inclined or vertical structures;

- individual webs of material are fastened with an overlap of at least 15 cm;

- the joints between the canvases must be glued with special adhesive tape;

- Izospan V is laid in such a way that its fleecy side is turned towards the insulation;

- You can fix Izospan with the help of small bars, a stapler, clamping strips.

Izospan in floor vapor barrier

Advantages and disadvantages

Material advantages:

- strength;

- reliability;

- comes with flame retardant additives;

- multifunctionality;

- environmental Safety;

- ease of installation;

- vapor permeability;

- resistance to high temperatures (suitable for use even in bathrooms and saunas).

Due to its structure, Izospan prevents the penetration of condensate into the walls and insulation, protecting their structure from the formation of fungus and mold. Many positive reviews ensured the popularity of the material for many years. Izospan A is a film membrane impervious to air and moisture. Its use reduces drafts, prevents moisture ingress and helps to improve the quality of the indoor atmosphere. Additional use of a primer before laying the membrane on most building surfaces is not required.

Isopan A is an innovative material that contains components that make it possible to use it on surfaces with elevated temperatures.

This is important in the construction of the roofs of baths and saunas. Unique properties allow to extend the construction season and provide year-round construction of buildings in areas with a cold climate

The product can withstand up to 12 months of direct UV exposure while maintaining the integrity required for long term building projects. The material is lighter in weight than competitive products. This property is irreplaceable when it is necessary to reduce the load on the structure. You can install long sections of the canvas, which will increase the speed of work on the object. The vapor barrier is installed horizontally or vertically, always with a crossing of the canvases by 5 centimeters.

Laying with an overlap avoids the appearance of drafts. The membrane is compatible with various building materials such as gypsum, plywood, OSB, cement board, concrete, CMU, sealant. You can save on the level of heat consumption, which allows you to install and use heating equipment in smaller rooms. Energy costs can be reduced by as much as 40%. The risk of mold and mildew is also reduced.

Among the main disadvantages it is worth highlighting:

- poor moisture resistance;

- small area of application.

If too much water accumulates on the surface of the film, moisture will begin to roll inward. It is not worth using a single-layer film for a roof. In this case, a multilayer membrane is best suited. The manufacturer's instructions indicate that Isospan A can be used in roof construction, but it is desirable that the slope does not exceed 35 degrees. You should not purchase material if you plan to have a metal coating on the roof.

Where is the material applied?

This group "B" (B) is considered universal, therefore it has a rather multifaceted scope. The only installation restriction is internal installation. For external insulation "Izospan" B is not suitable, there are other groups for this. With internal insulation, the material is used to isolate such surfaces:

- Wall structures.

- Internal partitions.

- Interfloor ceilings.

- Floors in rooms with high humidity.

- Substrate for parquet or laminate.

- Roof insulation.

This demand is due to the fact that the thermal insulation cake will not cope with its functions without a vapor barrier film.

Which side to lay to the heater

According to the official instructions:

- For roofing.Smooth side to the heater.

- For walls. Smooth side to the heater.

- Attic floors. The film is laid between the finishing material of the living room ceiling and the sub-ceiling (smooth side to the sub-ceiling).

- Ground cover. Rough side to the insulation.

How is the vapor barrier attached?

Fixing the membrane to the walls, floor or ceiling can be done with wide-head nails or a construction stapler. However, the best choice would be the use of counter rails.

The vapor barrier is laid with an overlap with an overlap of at least 10 cm. After the vapor barrier is fixed, the joints are glued with special adhesive tape or vapor barrier tape.

Izospan AM: instructions for use

Now we can move from theory to practice. Another important plus of Isospan AM is the ease of installation. Anyone can cope with this task if you follow the safety rules and instructions. The first thing to do is to prepare all the appropriate tools and materials for the job. We will need:

- self-tapping screws;

- wooden slats;

- construction stapler;

- metallic profile;

- scissors to cut material;

- construction tape at the joints;

- roulette;

- Izospan AM itself in the right amount.

Advice! When buying products, it is better to take them with a margin of 10%. So it will be calmer and you will not have to go to the store again.

Now you can get to work. According to the instructions, Izospan AM must be laid directly on the insulation. This ensures proper moisture removal. It is better to lay the membrane with the red side inside. The white layer of Isospan AM is slightly stronger and will protect the material from external factors.

The roll is laid in a horizontal position, gradually moving upwards. The weak point is the joints. That is why, in order to ensure high-quality waterproofing, the sheets must be laid on top of each other with an overlap of 15 cm on each side. The film is fixed to the rafters using a construction stapler. And to make the joints even tighter, they are glued with construction tape.

Note! When laying Isospan AM, it is necessary to ensure that the sheets do not sag, but are slightly stretched, and no defects form on the surface.

Once the membrane is fixed, it can be additionally fixed with wooden or plastic slats. They need to be fixed to the surface of the wall or rafters with nails. The mounting step of the rails is 30 cm. These rails will act as a ventilation gap.

When Izospan AM is laid, it is already possible to lay roofing material on top of it. As for the work inside, it remains to close the insulation with vapor barrier material using the same technology and, if necessary, finish inside the attic. That's it, job done.

Izospan positions: characteristics and application features

Geksa has developed a wide range of vapor barrier membranes. Without construction experience, it is difficult to navigate the choice and determine the optimal material. The main selection criterion is the purpose, scope of use. Conventionally, all types of film insulation can be divided into three categories: hydro and wind protection, vapor and waterproofing, reflective materials to increase heat saving.

Range of windproof waterproofing membranes

These are hydro-wind barriers that protect the insulation, structural elements from wind, condensate, and moisture from the outside.At the same time, the materials allow steam to pass through - moisture does not accumulate in the heat-insulating layer, but is vented into the atmosphere.

The product line is represented by the following items:

- Izospan A. Density - 100 g / sq. m, vapor permeability - more than 2000 g / sq. m / day. The action of the membrane - moisture quickly comes out, but does not seep inside. Installation from the outside of the heat insulator, under the cladding, a ventilation gap is required.

- Izospan AM. Density - 90 g / sq. m, steam permeability - from 800 g / sq. m / day. A three-layer membrane, we allow installation without a ventilation gap - air circulates in the gaps between the layers of the film.

- Izospan AS. Technical indicators: density - 115 g / sq. m, vapor permeability - 1000 g / sq. m / day. Three-layer diffuse material, more resistant to stretching than type AM.

- Izospan AQ proff. Reinforced material with a density of 120 g / sq. m - a three-layer structure with reinforcement. The film is well resistant to mechanical damage, UV rays. Izospan AQ is indispensable for protecting the insulation of the roof, walls, if for some time the structures will be without an external coating.

- Izospan A with OZD. A membrane with flame retardant additives is recommended if welding is to be performed near the insulation.

The listed wind protection films are applicable in the arrangement of frame walls, ventilated facades, thermal insulation of pitched roofs with a slope of 35 °.

Overview of hydro-vapor barriers

This category is designed to protect internal structures from moisture. Scope of application:

- installation of an insulated roof - suitable for a flat or pitched roof;

- waterproofing of floors - films are applicable to protect the base, under the laying of laminate, for the floor in a wooden house;

- hydrobarrier of garret, socle, interfloor overlappings.

Characteristics of hydro-vapor barrier Izospan:

- Izospan V. Two-layer film, density - 70 g / sq. m., water resistance - more than 1000 mm of water. Art. The material is in demand due to its universal properties and affordable price. The membrane acts as a vapor barrier for indoor walls, for ceilings with interfloor, basement ceilings and attics under a heat-insulated roof.

- Izospan S. Density - 90 g / sq. m. Scope of application is similar to type B film, can be used for concrete floors.

- Izospan D. High-strength woven fabric, density - 105 g / sq. m. Izospan D withstands significant mechanical stress. The main purpose is the waterproofing of the base of the floor, flat / pitched roof, basement. Can be used as a temporary roof covering.

- Izospan RS/RM. Three-layer insulation reinforced with PP mesh, density - 84/100 g / sq. m respectively. Application - arrangement of a hydro-vapor barrier for ceilings, floors, wall ceilings, roofs of any kind.

During production, high-strength fabrics of the D, RS, RM series are coated with water-repellent compounds. Hydrophobic films can be used as a waterproofing material when installing cement screeds on concrete, arranging earthen floors.

Heat reflective materials

Reflective hydro-vapor barrier with a heat-saving effect - complex films with a metallized coating. The canvases simultaneously protect the internal structure of the roof, insulation, ceilings and walls from wet vapors from inside the house, and also reflect heat radiation back into the room.

Izospan coating options differ from each other in the composition that determines the scope of their application.

Popular markings:

- FB - construction cardboard with lavsan coating and aluminum coating; used for cladding walls / ceilings of baths;

- FD - polypropylene sheet + metallized coating, the material is suitable for installing water / electric underfloor heating;

- FS - similar in composition to FD, but here is a double metallized film; used as a heat vapor barrier for sloping roofs;

- FX - the basis of the canvas - foamed polyethylene + metallized lavsan film; scope of application - a substrate for a laminate, a hydro-vapor barrier for walls, an attic, ceilings.

The thermal reflection coefficient of Izospan sheets reaches 90%

Izospan insulation range

- Wind and waterproofing Izospan. Membranes A, AS, AM AQ proff, A with OZD protect the insulation from moisture from the external environment and prevent the formation of condensate. A good choice for roofing or ventilated facades.

- Hydro and vapor barrier film Izospan. Materials of the B, C, D, DM series protect the insulation of the internal structures of floors and roofs from the penetration of condensate and steam from inside the room.

- Reflective fabrics with energy saving effect. Films FX, FB, FD, FS have a metallized coating that reflects heat and prevents it from escaping from the room.

- Connecting tapes. Metallized adhesive tape SL will help you install quickly and with a high degree of tightness.

Different styling options "Izospan"

The technical characteristics of Izospan AM allow it to be used for various purposes. For example, the material can act as a hydro and wind protection of the heat-insulating layer of the roof when installing an insulated pitched roof. In this case, the top layer will be the roofing, followed by Izospan.It is laid on a counter-lattice, under which there is a layer of insulation. Before this, Izospan B is laid, but the first and second layers will be the interior trim and rafters, respectively.

Sometimes this material is also used in the construction of ventilated facades, walls with external insulation and frame walls. In this case, the Izospan AM vapor barrier is used as a water and wind protection. The bottom layer will be the interior finish, followed by the Izospan vapor barrier, followed by the insulation, and then the vapor barrier described in the article, on which the counter-lattice is stuffed and the outer skin is laid.

You can also use such protection in a wall made of timber, which is closed with a heater and the described vapor barrier, on which a counter-lattice is sewn. The entire system is covered with an outer casing. Instructions for use of "Izospan AM" may provide for the laying of a vapor barrier on a load-bearing wall. It is closed by elements of the mounting system, followed by a heat-insulating layer, which is closed by hydro and wind protection, described in the article. The final layer will be the outer finish.

Izospan FB

Izospan fb is a completely new class of protective materials that began to be created not so long ago. It has such parameters as zero hydro and vapor permeability, as well as heat reflection by more than 90%. Such characteristics make this brand effective in insulating special rooms in which there is a need to maintain high temperatures with high humidity.

Isospan fb consists of kraft paper covered with one layer of metallized lavsan. This makes it an indispensable component in the arrangement of saunas and baths.While any other vapor barrier only prevents moisture from entering the insulation, this material helps to retain steam inside and reduce heat transfer due to infrared radiation.

Able to withstand temperatures up to +140 degrees.

Isospan fs has a similar effect, however, it has a lower temperature threshold and is more used as a reflective screen in ordinary rooms.

The model is environmentally friendly, characterized by high strength and durability.

The advantages of the FB brand include its following characteristics:

- does not pass moisture;

- does not get wet;

- holds steam;

- has increased strength.

Isospan fb is laid in parts, having previously cut even canvases. The foil side should look inside the room, that is, it should be located towards the thermal radiation. The overlap between the layers can be up to 20 cm. Be sure to leave a gap between the reflector and the finish of 4-5 cm. To increase the tightness, the joints between the sheets are glued with FL tape.

2 Production features

The wind and moisture protection membrane is produced on proprietary equipment in the workshops of Izospan. It is made of dense polypropylene. Moreover, the polymer is used mixed with a bunch of chemical components, as in Izover soundproofing materials.

Just do not be afraid, there is nothing harmful in it. These components only contribute to the strengthening of the material and its durability. So, the Izospan AM model membrane, due to the presence of a separate class of polymers in it, has a much higher density than that of competitor products.

But the AM model is far from the most durable sample from the Izospan line.

One side is waterproof. Mounted outside of the heater.It is smooth and very durable, designed to protect against wind and moisture. The wind is not able to blow through such a polymer, and the water simply flows down it, where it is removed through drainage outlets.

The second side is moisture-retaining, rough. It is she who is directed to face the heater. Its task is to collect condensate, because the membrane is vapor-permeable. On a rough surface, the condensate lingers, and then disappears without affecting the insulation inside.

Actually, this is the unique characteristics of the Isospan film. On the one hand, it completely protects the insulation from moisture. On the other hand, it delays it, preventing it from flowing into the thermal insulation.

This combination was able to win the trust of builders around the world. Only reflective heat-insulating materials are better.

2.1 Installation procedure

Consider the order of laying the membrane. It is worth noting that for each design it is different. Unlike a vapor barrier film, a windshield membrane is vapor permeable, meaning it does not block steam.

It rather serves as an external insulation. A kind of limiter and external fencing for insulation boards.

An example of installing Izospan film on the roof

Accordingly, you need to mount it in a certain place.

Initially, any thermal insulation threshold consists of the following layers:

- Base;

- Vapor barrier;

- insulation;

- Waterproofing;

- crate;

- face material.

It is at the place of waterproofing Izospan A that they mount

But here, too, it is important to note a few nuances.

For example, when finishing facades, the material is mounted directly on the insulation, then covered with special strips or not fixed with a frame at all. You can get by with a thorough fixation with a construction stapler.

But the roofing is already going through a slightly different procedure. Here the membrane must be placed immediately under the cavity of the rafters or panels of the roof structure. Then the frame or the insulation itself is already laid.

1 Izospan film features

Izospan has been producing insulation materials for a very long time. In the market, they have managed to prove themselves from the best side for the entire time of their existence. Therefore, there is no doubt about the quality of their products.

The main product line from this manufacturer is a special protective film. There is a film Isospan A, Isospan B, Isospan C, etc.

There is a difference between these materials and you need to pay attention to it.

Although it is worth noting an interesting fact, there are practically no visual differences between the films of model A and C. They are also the same size.

It remains to rely on the technical characteristics and the scope of the destination itself. If we evaluate the insulation from the side of its properties, the differences between different materials become obvious.

1.1 Differences between materials

So, the Isospan A film is wind and moisture protective as a vapor barrier Isospan B, that is, it acts as a heater limiter. Do not be mistaken, arguing that the wind protection of thermal insulation is not needed. Just the opposite.

Wind is a very serious irritant. Unlike ordinary moisture or steam, it constantly affects the surrounding structures.And modern heaters (the same mineral wool or polystyrene) do not have sufficient density, therefore they are subjected to external loads.

Slowly but surely the wind will undermine the strength of the material until it is completely destroyed.

With moisture, the situation is different, but this is certainly clear to everyone. A waterproof film is a real must. After all, it is moisture-proof insulation that allows you to limit the insulation from the ingress of water into it.

And water, by the way, is extremely difficult to remove from already installed insulation boards. If your structures are not ventilated, then it is completely impossible. As you can see, the windshield film performs extremely useful functions.

Moisture protective membrane Izospan A in the package

The film moisture-proof membrane Isospan B, like Isospan AM, is already concentrating on slightly different tasks. Here, the main emphasis is on protecting the thermal insulation from the penetration of steam. Its thickness is usually less, but the cost is also significantly lower.

Many are interested in the question of whether there is a difference between Isospan A and AM insulation. Indeed, if you look only at the technical properties, the materials seem identical.

However, there are still certain differences. It is enough to look at the product certificate, where the full technical characteristics and purpose of the material are indicated.

Initially, the Isospan A membrane has a high density and is additionally protected from damage during installation. Therefore, the manufacturer recommends using it mainly for wall decoration. Especially for work in ventilated insulation frames.

But Izospan AM is slightly weaker in terms of strength, which forces the user to use it in places with less load.As a result, the AM model is almost ideally suited for roofing.

1.2 Properties and parameters

Now it is worth evaluating directly the technical characteristics of Izospan insulating membranes, as well as its interesting nuances. But first, we note that all the properties described below are those when you use products that have received a certificate.

A certificate of conformity is available for all Izospan products. Therefore, when buying, you have the right to demand a certificate from the seller, thereby wanting to make sure that they are not trying to slip a fake on you.

The certificate of conformity is issued by government agencies and contains information about the product, its quality mark, etc. Also, the certificate allows you to make sure that the ingredients declared on the packaging are actually present in the membrane.

It would seem, why such excessive caution? After all, it's just isolation. But in fact, you need to understand that insulation has no less weight in the structure than the same insulation.

Rough surface of the membrane Isospan AM

You can buy expensive mineral wool insulation and decorate all structures with it, hoping for a miracle. But if you do not install at least a conventional wind and moisture-proof membrane, then after a few years serious problems may begin.

Helpful Hints

The use of the material is quite simple, but the process should be approached responsibly. There are some tips for laying the membrane:

- Try to ensure a natural outflow of moisture from the insulation. To do this, do not close the bottom edge of the canvas.

- Since the material is sold in large sizes, it will have to be cut. You can do it at a construction site. Moreover, the material should be spread directly on the insulation.

- Try to use this product carefully, despite its strength.

- The membrane should not be used as a permanent or even temporary roof covering. It won't last long in direct sunlight. And the real roof is more reliable.

Please note that you will be doing the work at height, so all actions must be performed as carefully as possible. You need to take care of your own safety (wear comfortable shoes that will not slip). It is undesirable to work in windy or rainy weather, as this may lead to a fall from a height. For greater security, tie yourself to the rafters. That's all the recommendations for laying this material. Good luck with your installation!

Waterproof and vapor barrier films

Waterproof and vapor barrier film is designed for indoor installation. It is used to protect insulation and structures from moisture, which increases the thermal conductivity of the thermal insulator, contributes to the destruction of wood and metal.

The use of films that do not allow steam and condensate to pass through prolongs the service life of insulation and building structures, if the correct installation has been performed.

Scope of application of hydro and vapor barrier films:

- arrangement of the base of the floors;

- installation of an insulated roof (protection of a material that insulates a flat or pitched roof);

- insulation of enclosing structures from the side of the room, sound insulation of partitions;

- protection of floors - basement, interfloor, attic (serves as a waterproofing barrier);

- laying wood-based or wooden floor coverings (parquet boards, floor laths, laminate).

hyperstroy

redline5036

stroiluxe22

isospan_gexa

stroiluxe22

skrusles

teplokarkas

artberesta

Conclusion

Among the advantages of the material are the following:

- Strength and durability.

- Increase the life of the heater.

- Good protection of the floor or other structures from the harmful effects of moisture.

- Environmental Safety.

- Izospan B is able to prevent the development of such unpleasant consequences of moisture as fungus and mold.

- The product does not allow the penetration of insulation elements into the room.

- There is no need to have certain skills in working with this material.

- Ease of installation of isospan B. Ordinary scissors are used to cut the web. At the same time, it does not tear during bending and stretching.

- Low cost with excellent technical qualities of the product.

- Light weight, which allows you to use the film to protect any premises.

- Thanks to special fire-fighting additives, the canvas is able to go out on its own during a fire.

- Possibility of application in a brick and wooden house.