- Installation subtleties

- Types of vapor barrier Izospan

- Izospan D

- Izospan D Scope

- Application

- Advantages and disadvantages

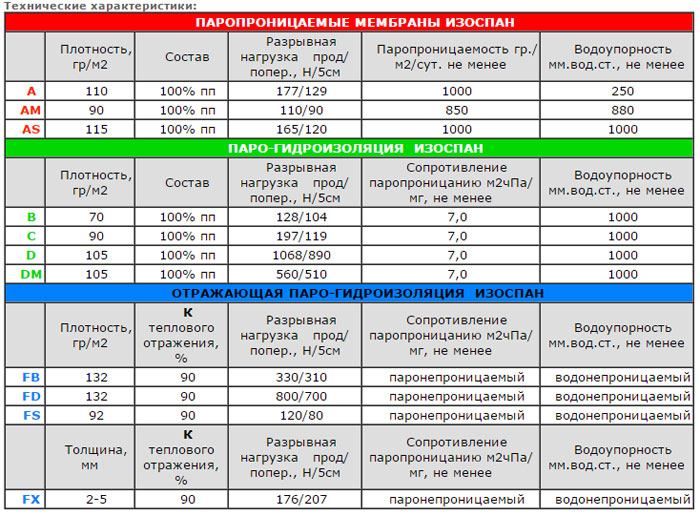

- Types of Isospan (Isospan)

- How to distinguish by name

- 2 Production features

- 2.1 Installation procedure

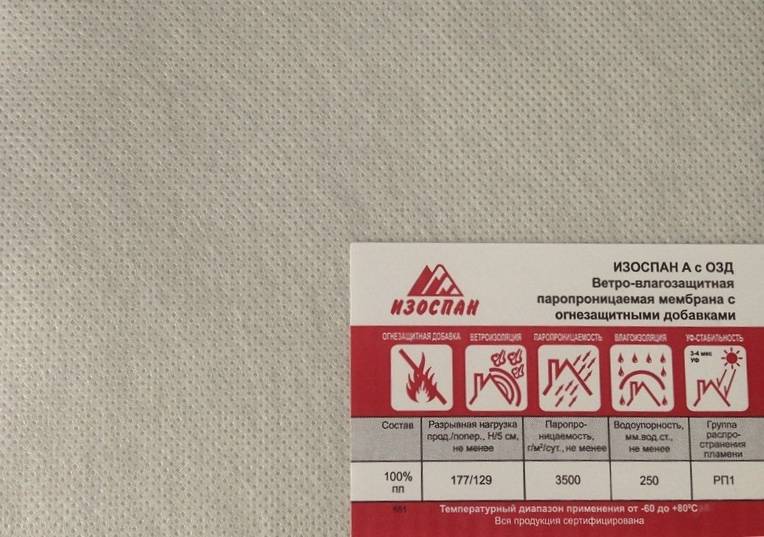

- Varieties of material, their technical features

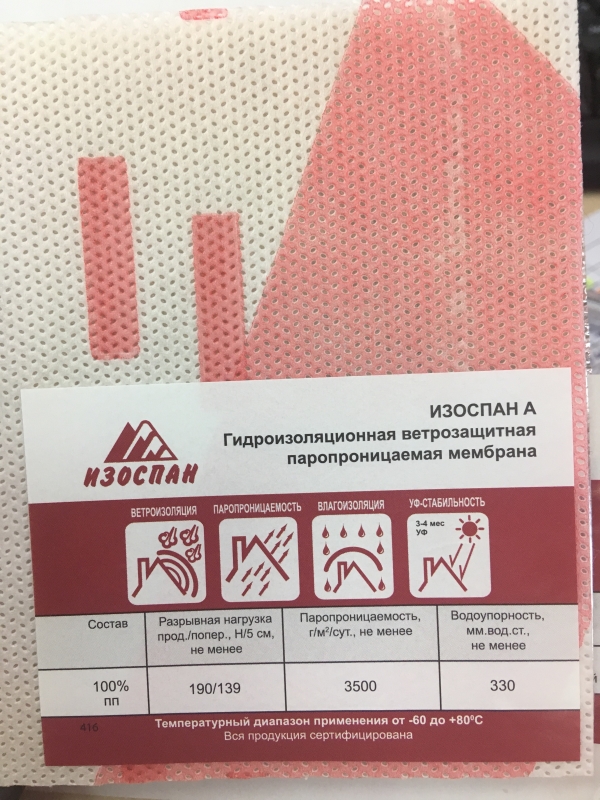

- Isospan A

- Izospan V

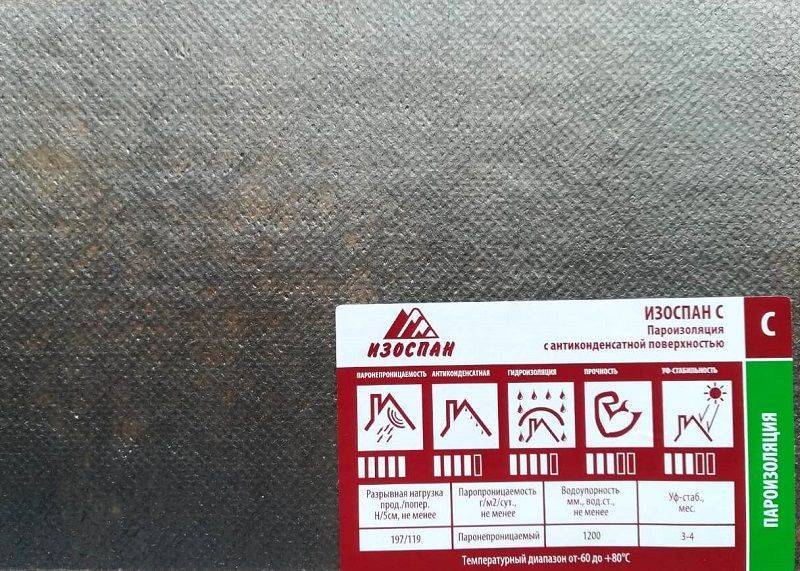

- Izospan C

- Izospan D

- 1 Izospan film features

- 1.1 Differences between materials

- 1.2 Properties and parameters

Installation subtleties

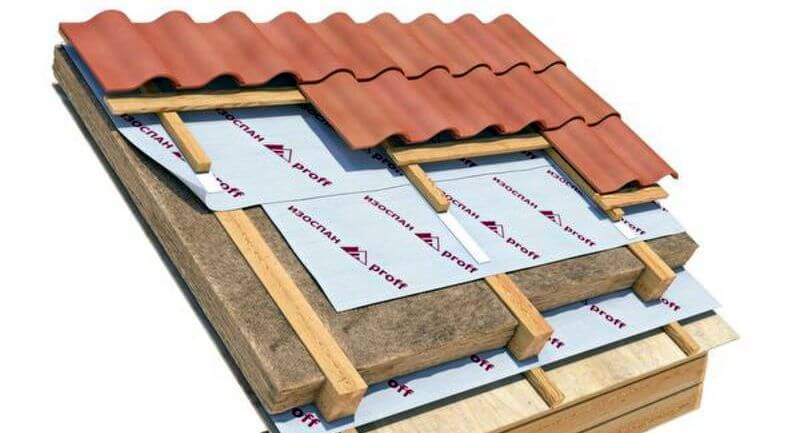

Before using the Izospan film, it is necessary to check the insulation of the gaps between the insulation blocks, if found, eliminate the shortcomings. Carry out sealing of the contact points of the membrane with structural elements, for example, with windows. For vapor barrier walls, Izospan A is used on the outside of the building, and Izospan B is used on the inside. During the construction of walls, Izospan A is laid in layers on their surface. Work is carried out from the bottom up. Fixation is done with a stapler. In this case, it is necessary to exclude sagging of the canvas, otherwise, with a strong wind load on the facade, unnecessary noise (clapping) may appear.

During the installation of the roof, the material is cut directly on the rafters above the thermal insulation. Laying is done horizontally. Start from the bottom of the roof. Fastening is done with nails (sometimes self-tapping screws).It is recommended (but not necessary) to leave a space of about 5 cm between the underside of Izospan and the insulation, and a gap between the membrane and the roof, the width of which is usually equal to the size of the rail.

As noted above, the placement of Isospan begins from the bottom row with horizontal stripes. The overlap must be at least 10 cm. The places where the film adheres to the surface must be glued with mounting tape. This method is suitable for wood veneer.

It is very important to lay the material with the right side to the insulation. Before installation, you must carefully read the instructions for use of the canvas

For external insulation of roofs and facades of buildings, it is necessary to use the brands Izospan AND, AM, AS, which provide the necessary protection.

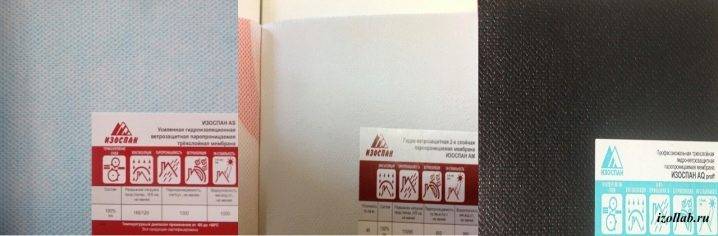

Different variations of Isospan A have different material densities. For model A it is 110 g/m², for AM it is 90 g/m². The AS model has an indicator equal to 115 g/m², and the highest density of the AQ proff is 120 g/m². To create a high-quality hydro- and vapor barrier, experts recommend using an additional Izospan V vapor barrier.

The installation scheme depends on the purpose of the structure. If this is a sloping roof without insulation, then the main structure is mounted, then the vapor barrier layer, and then the wooden flooring.

In the attic, floors are laid first, then vapor barrier, followed by insulation and slats, and lastly, a beam. When using a membrane on a concrete floor, at the first stage, a base is created, then a screed, a film is laid on it, and then only a finish.If you want to achieve good results, you must strictly follow the manufacturer's recommendations, observe the subtleties of using the Izopan material and be sure to take into account the features of the surface on top of which the film layer will be laid.

For fastening to a wooden obreshetka or rafters, a stapler and adhesive tape Izospan KL or SL are used. Izospan brand DM is mainly intended for installation under a metal roof. To ensure the proper level of vapor barrier, Izospan RS, C, DM brands are used. For the installation of underfloor heating, thermal insulation of walls and roofs, it becomes necessary to simultaneously provide hydro- and vapor barrier to prevent heat removal. In these cases, Izospan FD, FS, FX is used.

The use of a membrane is a mandatory requirement for laying insulation in the roof structure. Thanks to it, mineral wool can be protected from steam and condensate. If polyurethane foam is used, then there is no need to use Isospan.

As a waterproofing, it is recommended to use a diffusion-type membrane that allows steam to pass through without blocking it and does not allow humidity in the room. It is necessary that ventilation holes of at least 50 mm remain between the heat-insulating layer and the waterproofing material. The ultimate goal is to remove excess moisture.

For any building, vapor barrier plays an important role. Izospan offers a modern and simple solution to this issue. Moreover, it provides safety to a heater, a roof and walls. The use of the material allows you to significantly insulate the room, although waterproofing is greatly underestimated by the modern consumer.

Izospan products are represented by a wide range of products, each of which will find application for a certain type of work. It is possible to lay the film not only in the roof structure, but also as an insulating material when organizing the foundation, including from crushed stone, sand and soil.

Some types do not allow moisture to pass through at all, so they can only be mounted in rooms with forced ventilation. For a warm floor, you can't find a better film as a reflective lining.

Also see in the video how to use Izospan A:

Types of vapor barrier Izospan

All modern vapor barriers are universal for use on various surfaces. They differ only in their properties: strength, water resistance, UV resistance, vapor permeability.

There are such types of Izospan from the manufacturer Geksa LLC:

Vapor-permeable membranes for protection against wind and moisture Izospan:

- BUT;

- AM;

- AS;

- AQ proff;

Density from 110 g/m2 to 120 g/m2.

This type is used for outdoor work (when insulating roofs and walls). It prevents moisture from accumulating under the roof, allowing condensate to evaporate freely. The structure of the material on the one hand has an effect that repels water, and on the other hand has a rough surface. This feature can extend the life of the insulation layer and the structure itself for many years. The diffusion membrane Izospan is made of polypropylene, which does not have a negative effect on humans. Also, the product is not susceptible to the appearance of mold and any fungi.

Membranes are used in such cases:

- insulation of attics and roofs;

- siding the walls of low houses;

- construction of frame structures;

- as ventilation of an external heater in high-rise buildings.

It is recommended to lay membranes on the roof at an angle of at least 35 degrees.

Waterproofing and vapor barrier films Izospan:

- AT;

- FROM;

- D;

- DM;

- RS

- RM;

Density from 72 g/m2 to 100 g/m2.

The two-layer material is used to protect both wooden and metal structures from the negative effects of water and moisture. Izospan film is treated with a special water-repellent agent, which makes it possible to use it as an additional layer when pouring cement on the floor. Izospan spreads on the floor with a soft side over the insulation.

Tapes (RM and RS have an additional third layer, which allows them to be used as a vapor barrier in floors between floors).

The purpose of vapor barrier films is as follows:

- arrangement of internal walls;

- protection of the floor from high humidity;

- roof insulation insulation indoors;

- installation of floor coverings.

Vapor waterproofing and heat-shielding materials with the effect of energy saving: isospan fd, isospan fs, isospan fb and fx with a density of 90 g/m2 to 175 g/m2.

The canvases have high vapor barrier properties, which makes it possible to warm up the room faster and save on its heating in winter.

Izospan fb and fd are made of kraft material and lavsan, as a result of which they have increased strength and can maintain their characteristics at temperatures up to +140 degrees.

Foil isospan has reflective properties that reduce heat loss. The main thing to remember is how to properly lay the material on the roof: the metallized side should be facing the inside of the house.Films according to the size of the roll are fastened to the ceiling end-to-end and glued with special adhesive tape.

This type of insulation is used in such cases:

- roof insulation;

- wall cladding at elevated temperatures;

- underfloor heating.

Different types of products are suitable for warming any surface. Izospan characteristics received good feedback from users

Laying the material is not difficult, but it is important to follow the installation rules. The packaging contains information on installing insulation, how to properly install it on walls, floors and roofs.

Here are some rules to follow:

- the wind and moisture protective membrane should fit snugly against the insulation with a small spade along the edges;

- Izospan AQ AS and AM must be overlapped (up to 15 cm) with a white surface to the insulation;

- the joints of the vapor-permeable membrane are fixed with adhesive tape, and fastened along the edges with a stapler;

- two-layer Izospan, when used on roofs and walls, is glued with a smooth side to mineral wool or other insulation, and a rough side inside the house. When installing the floor, everything is done the other way around.

Izospan D

High strength, fully waterproof waterproofing material. Polypropylene cloth with a one-sided laminated polypropylene coating. The versatility of the moisture-vapor-proof material means that it is widely used in construction technologies in the construction of any type of structures.

Izospan D successfully resists moderately strong mechanical loads, is resistant to tearing, withstands strong gusts of wind, and in winter copes with a large snow load. In comparison with other similar films, Izospan D has gained fame as the most durable and reliable option.

Izospan D Scope

In any type of roof, as a barrier preventing the formation of under-roof condensate. Widespread use in the device of hydro- and vapor barrier in the construction of buildings and structures. Protection of wooden structures. The material is largely resistant to negative atmospheric phenomena.

Izospan D is often used at construction sites as a temporary roof covering and installation of a protective wall in facilities under construction. Such a roof or wall can last up to four months. Type D is especially popular when constructing concrete floors that need a waterproofing layer that protects against earth moisture.

Application

- In non-insulated roofs as a protection for wooden structures;

- As protection against under-roof condensate;

- Protection from negative atmospheric phenomena;

- In the arrangement of basement floors;

- Installation of concrete floors.

If there is a task to save the internal parts of the dwelling from the influence of vapors generated as a result of the life of activity, and to extend the life of the insulation, then the right decision would be to use the vapor barrier option with the letter “D”

Recently, more and more owners of country houses understand the importance of the role played by vapor barrier materials, the ever-growing demand is a strong confirmation of this.

Izospan D is spread directly on the rafters directly on the insulated surface of the pitched roof. In this case, the layers of material are the same and you don’t have to be puzzled which side to lay Izospan to the insulation. Installation is carried out horizontally, overlapping, rolls are cut into sheets of the desired size quite easily.

Work is carried out from the lower element of the roof and gradually follows in the direction to the top.Joints, in the process of laying, are glued with SL tape like double-sided tape. Adhesive on both sides, the surface connects two sheets of vapor - waterproofing. The wall-mounted isospan is fixed to the rafters with wooden slats or staples of a construction stapler.

Summing up our review, it remains to add that the manufacturer produces 14 types of such rolled insulation. We have considered only four main types. The buyer, guided by the characteristics of different types, always has the opportunity to buy isospan exactly for their needs. In addition, the manufacturer does not stand still and constantly expands the range of products, for example, there is a version of the film with flame retardant additives.

From our review it can be seen that working with the material does not require complex special skills and is within the power of almost any man. Ease of use and low installation costs make this building material a wide range of uses. The vapor barrier material will fully take over the functions that will ensure the reliability and long service life of your home and industrial thermal insulation.

Wood and moisture are incompatible things. Moisture has a negative effect on any wooden products. Even in small quantities, it gradually penetrates into the structure of the tree and destroys it from the inside, activates the processes of decay, due to high humidity, mold and fungus appear on wooden products over time. When arranging wooden floors in a house - especially if they are laid on the lower floor - you should take care of high-quality vapor barrier.Such a membrane material as Isospan V has proven itself well, instructions for use for the floor in a wooden house of which are presented in this article.

Izospan V: instructions for use for the floor in a wooden house

Izospan V, 70 sq.m.

Advantages and disadvantages

Material advantages:

- strength;

- reliability;

- comes with flame retardant additives;

- multifunctionality;

- environmental Safety;

- ease of installation;

- vapor permeability;

- resistance to high temperatures (suitable for use even in bathrooms and saunas).

Due to its structure, Izospan prevents the penetration of condensate into the walls and insulation, protecting their structure from the formation of fungus and mold. Many positive reviews ensured the popularity of the material for many years. Izospan A is a film membrane impervious to air and moisture. Its use reduces drafts, prevents moisture ingress and helps to improve the quality of the indoor atmosphere. Additional use of a primer before laying the membrane on most building surfaces is not required.

Isopan A is an innovative material that contains components that make it possible to use it on surfaces with elevated temperatures.

This is important in the construction of the roofs of baths and saunas. Unique properties allow to extend the construction season and provide year-round construction of buildings in areas with a cold climate

The product can withstand up to 12 months of direct UV exposure while maintaining the integrity required for long term building projects. The material is lighter in weight than competitive products. This property is irreplaceable when it is necessary to reduce the load on the structure.You can install long sections of the canvas, which will increase the speed of work on the object. The vapor barrier is installed horizontally or vertically, always with a crossing of the canvases by 5 centimeters.

Laying with an overlap avoids the appearance of drafts. The membrane is compatible with various building materials such as gypsum, plywood, OSB, cement board, concrete, CMU, sealant. You can save on the level of heat consumption, which allows you to install and use heating equipment in smaller rooms. Energy costs can be reduced by as much as 40%. The risk of mold and mildew is also reduced.

Among the main disadvantages it is worth highlighting:

- poor moisture resistance;

- small area of application.

If too much water accumulates on the surface of the film, moisture will begin to roll inward. It is not worth using a single-layer film for a roof. In this case, a multilayer membrane is best suited. The manufacturer's instructions indicate that Isospan A can be used in roof construction, but it is desirable that the slope does not exceed 35 degrees. You should not purchase material if you plan to have a metal coating on the roof.

Types of Isospan (Isospan)

Let's start with what Isospan is. This is a trademark under which the Tver enterprise Geksa produces non-woven building materials - films and membranes for various purposes. In short, there are vapor barrier, windproof and waterproof roll materials. There are a lot of materials, so the names, applications and features are summarized in a table. It's easier to navigate that way.

Instructions for use Izospan depends on the area of \u200b\u200bits application

As you can see, all Izospan materials can be divided into three groups:

- Wind protection. This is a group of materials Izospan A and varieties. These are materials that protect the insulation from blowing, keeping warm. At the same time, they remain permeable to steam, but do not conduct / do not pass moisture.

- Steam and waterproofing materials. These are Izospan B, C, R and several of their varieties. They do not let moisture through in any form.

- Energy-saving vapor-waterproofing Izospan F. It is distinguished by the presence of a metallized layer, it does not let moisture through in any form - neither steam nor liquid.

There are also connecting materials - one- and two-sided connecting tapes on a different basis. They are needed during installation, they allow at the joints to avoid deterioration in performance. Some allow you to achieve tight connections.

How to distinguish by name

In the name of the materials, a key letter is affixed, by which it is possible to determine the group and basic properties. So Izospan A with all other indices denotes a vapor-permeable membrane. Izospan B, D, C - hydro-vapor barrier. The difference between the films of this group and the first is that these materials (B, C, D) do not let vapor through. The materials of the first group (A) conduct it (steam), and retain only water. The exception is Izospan A base. It does not retain water and conducts steam.

Instructions for use depends on the type of material

The third group is also hydro-vapor barrier. It differs in that it has a metallized coating. The names of materials in this group contain the letter F: FD, FX, FS, FB, RF. They are used to more effectively retain heat, as heat rays are reflected from the shiny coating. But reflection is possible only if there is an air gap in front of the film of 3.5 cm (or more).

After the first letter in the Izospan marking, there is often a second one. It describes the special properties of the material. It can also be an abbreviation or a short word. For example, the presence of the letter M or S indicates the presence of reinforcement. The prefix fix means that there are strips of glue along the edges, so there is no need to use adhesive tape.

2 Production features

The wind and moisture protection membrane is produced on proprietary equipment in the workshops of Izospan. It is made of dense polypropylene. Moreover, the polymer is used mixed with a bunch of chemical components, as in Izover soundproofing materials.

Just do not be afraid, there is nothing harmful in it. These components only contribute to the strengthening of the material and its durability. So, the Izospan AM model membrane, due to the presence of a separate class of polymers in it, has a much higher density than that of competitor products.

But the AM model is far from the most durable sample from the Izospan line.

One side is waterproof. Mounted outside of the heater. It is smooth and very durable, designed to protect against wind and moisture. The wind is not able to blow through such a polymer, and the water simply flows down it, where it is removed through drainage outlets.

The second side is moisture-retaining, rough. It is she who is directed to face the heater. Its task is to collect condensate, because the membrane is vapor-permeable. On a rough surface, the condensate lingers, and then disappears without affecting the insulation inside.

Actually, this is the unique characteristics of the Isospan film. On the one hand, it completely protects the insulation from moisture. On the other hand, it delays it, preventing it from flowing into the thermal insulation.

This combination was able to win the trust of builders around the world. Only reflective heat-insulating materials are better.

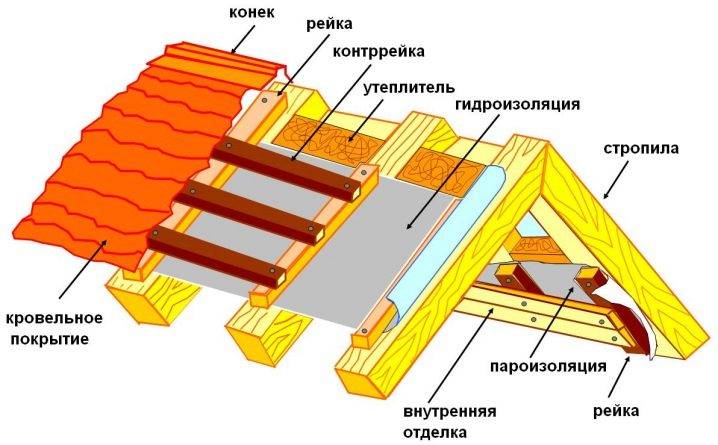

2.1 Installation procedure

Consider the order of laying the membrane. It is worth noting that for each design it is different. Unlike a vapor barrier film, a windshield membrane is vapor permeable, meaning it does not block steam.

It rather serves as an external insulation. A kind of limiter and external fencing for insulation boards.

An example of installing Izospan film on the roof

Accordingly, you need to mount it in a certain place.

Initially, any thermal insulation threshold consists of the following layers:

- Base;

- Vapor barrier;

- insulation;

- Waterproofing;

- crate;

- face material.

It is at the place of waterproofing Izospan A that they mount

But here, too, it is important to note a few nuances.

For example, when finishing facades, the material is mounted directly on the insulation, then covered with special strips or not fixed with a frame at all. You can get by with a thorough fixation with a construction stapler.

But the roofing is already going through a slightly different procedure. Here the membrane must be placed immediately under the cavity of the rafters or panels of the roof structure. Then the frame or the insulation itself is already laid.

Varieties of material, their technical features

When choosing products, you need to focus on the presence of isospan quality and safety certificates. Well-known manufacturers coordinate their production plans with legal requirements.

Now, when decorating houses and non-residential premises, 4 main modifications of isospan are used, which have their own characteristics.

Isospan A

This is a film (membrane), which perfectly waterproofs and helps to eliminate moisture, its vapors, from the insulation. This modification is used to protect against wind and water, increases the life of the insulation. It is applied to isolation of private houses, penthouses, garages and any other rooms.

This isospan is resistant to mechanical stress and pressure, completely neutral to bio-impact (mold, bacteria, etc.). Can stretch:

- longitudinally by 190 mm;

- transversely by 140 mm.

The material is fixed from the outside of the insulation as an additional barrier. For example, when insulating an attic, it is mounted on the roof with an overlap in wide strips.

It is necessary that the membrane lays flat, does not protrude, swell or sag. Izospan A is fixed with wooden slats and nails.

Izospan A can be seen in the photo:

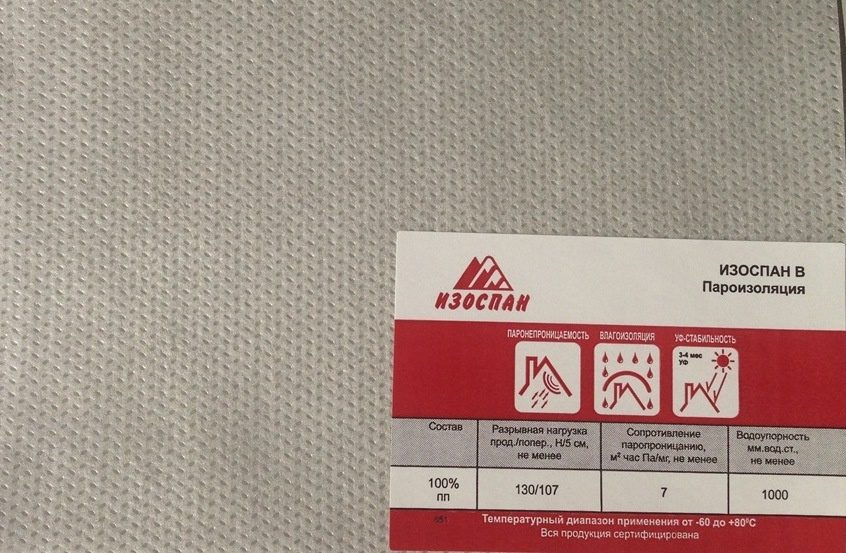

Izospan V

This modification perfectly blocks the way for water vapor, which eliminates the impregnation of the insulation with steam.

Izospan B is two-layer, used:

- On pitched roofs.

- On the walls: external and internal.

- To save floors in the basement, attic (attic).

- In garages and other non-residential premises.

The vapor permeability index is 7, the material can also be stretched: in the longitudinal direction by 130 mm, in the transverse direction - at least 107 mm.

Each layer of this material has its own functions:

- fleecy layer retains moisture and condensate;

- the smooth part allows you to firmly fix the film with insulation.

Unlike the previous modification, isospan B is attached to the inside of the insulation. Fastened from the bottom up and overlapped.In order for the film to capture vapors, condensate, there must be a free space of at least 5 cm above the fleecy layer.

The appearance of the packaging of isospan B can be seen in the photo:

Izospan C

It also consists of two layers, but is used to protect an uninsulated roof, floors between floors, floor insulation. Has high strength.

The film is used for steam and water insulation:

- uninsulated pitched or flat roof;

- frame, load-bearing walls;

- wooden floors parallel to the floor;

- concrete floor.

- Installation of non-insulated roofs (slopes) is carried out with an overlap (with a depth of about 15 cm), also fastened with wooden slats. When arranging the attic at home, this material perfectly insulates the room from moisture from the environment.

- If we talk about wooden floors, then here the film is attached directly to the insulation with a small free space from the floor (4-5 cm).

- When insulating a concrete floor, isospan C is placed directly on the floor and pulled together on it.

Izospan C can be seen in the photo:

Izospan D

This modification is very durable, able to withstand great pressure and loads. It is used in roofing. In terms of waterproofing and protection against condensation, it perfectly withstands even a large crust of snow on itself.

Great for arranging the attic of a house or garage in regions with heavy snowfall. The material protects wooden structures and non-insulated roofs. Isospan D is insulated:

- flat and pitched roofs;

- concrete floors and ceilings at the basement level of the house.

The high strength of the film allows you to protect the living area from wind and moisture, even in cases where the roof passes moisture.

It is also mounted with an overlap horizontally in strips, fixed on the rafters of the roof of the house with the help of rails. Installation on a concrete floor is similar to the previous modification of isospan, because in many respects isospan C and D are similar in their characteristics.

Izospan D can be seen in the photo:

The main modifications of the building material are described above, there are also varieties of these modifications that have different densities or additional qualities, for example, fire retardant additives, which provide greater fire safety and protect against fire.

Also, manufacturers timely attended to the creation of additional consumables that allow you to isolate seams and minor damage. We are talking about isospan adhesive tapes - these adhesive tapes allow you to isolate seam lines, uneven surfaces. It is enough that the work surface is dry and clean - isospan FL, SL adhesive tape will provide good impermeability of such places. There is even a metallized tape that has a high resistance index.

1 Izospan film features

Izospan has been producing insulation materials for a very long time. In the market, they have managed to prove themselves from the best side for the entire time of their existence. Therefore, there is no doubt about the quality of their products.

The main product line from this manufacturer is a special protective film. There is a film Isospan A, Isospan B, Isospan C, etc.

There is a difference between these materials and you need to pay attention to it.

Although it is worth noting an interesting fact, there are practically no visual differences between the films of model A and C. They are also the same size.

It remains to rely on the technical characteristics and the scope of the destination itself.If we evaluate the insulation from the side of its properties, the differences between different materials become obvious.

1.1 Differences between materials

So, the Isospan A film is wind and moisture protective as a vapor barrier Isospan B, that is, it acts as a heater limiter. Do not be mistaken, arguing that the wind protection of thermal insulation is not needed. Just the opposite.

Wind is a very serious irritant. Unlike ordinary moisture or steam, it constantly affects the surrounding structures. And modern heaters (the same mineral wool or polystyrene) do not have sufficient density, therefore they are subjected to external loads.

Slowly but surely the wind will undermine the strength of the material until it is completely destroyed.

With moisture, the situation is different, but this is certainly clear to everyone. A waterproof film is a real must. After all, it is moisture-proof insulation that allows you to limit the insulation from the ingress of water into it.

And water, by the way, is extremely difficult to remove from already installed insulation boards. If your structures are not ventilated, then it is completely impossible. As you can see, the windshield film performs extremely useful functions.

Moisture protective membrane Izospan A in the package

The film moisture-proof membrane Isospan B, like Isospan AM, is already concentrating on slightly different tasks. Here, the main emphasis is on protecting the thermal insulation from the penetration of steam. Its thickness is usually less, but the cost is also significantly lower.

Many are interested in the question of whether there is a difference between Isospan A and AM insulation. Indeed, if you look only at the technical properties, the materials seem identical.

However, there are still certain differences.It is enough to look at the product certificate, where the full technical characteristics and purpose of the material are indicated.

Initially, the Isospan A membrane has a high density and is additionally protected from damage during installation. Therefore, the manufacturer recommends using it mainly for wall decoration. Especially for work in ventilated insulation frames.

But Izospan AM is slightly weaker in terms of strength, which forces the user to use it in places with less load. As a result, the AM model is almost ideally suited for roofing.

1.2 Properties and parameters

Now it is worth evaluating directly the technical characteristics of Izospan insulating membranes, as well as its interesting nuances. But first, we note that all the properties described below are those when you use products that have received a certificate.

A certificate of conformity is available for all Izospan products. Therefore, when buying, you have the right to demand a certificate from the seller, thereby wanting to make sure that they are not trying to slip a fake on you.

The certificate of conformity is issued by government agencies and contains information about the product, its quality mark, etc. Also, the certificate allows you to make sure that the ingredients declared on the packaging are actually present in the membrane.

It would seem, why such excessive caution? After all, it's just isolation. But in fact, you need to understand that insulation has no less weight in the structure than the same insulation.

Rough surface of the membrane Isospan AM

You can buy expensive mineral wool insulation and decorate all structures with it, hoping for a miracle.But if you do not install at least a conventional wind and moisture-proof membrane, then after a few years serious problems may begin.