- Very enhanced protection

- Regulatory documents and their requirements

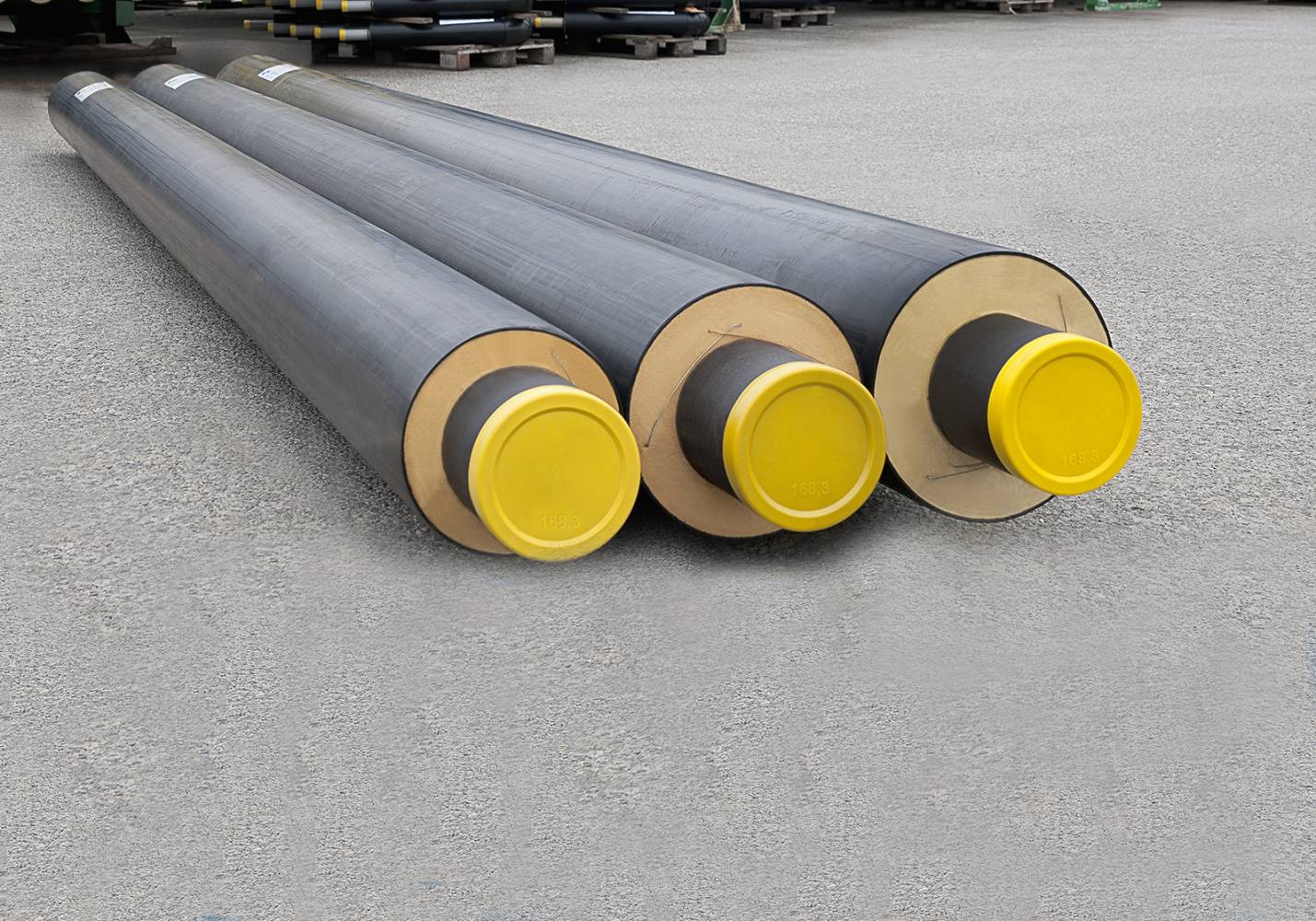

- PPU insulation

- Checking the quality of insulation application

- In the factory

- At the site of installation or repair

- Protective shell

- Highly reinforced steel pipe insulation

- Reinforced insulation according to GOST 9.602-2016

- Types of materials for insulation

- Polymer protective coatings

- Insulation based on bituminous mastics

- Materials for insulating small elements

- Insulation of an underground gas pipeline is necessary in order to protect against the occurrence of local foci of corrosion, the main cause of which is increased soil moisture, and from stray currents.

- When is thermal insulation of cold water pipes necessary?

- What materials are used

- Gas pipeline insulation

- How does this happen?

Very enhanced protection

Insulation of a very reinforced type effectively solves the problem of the appearance of corrosive formations on the pipeline. And this problem has always remained acute.

Regardless of the laying option, pipes are always under the influence of water and oxygen. And these are the main factors that cause corrosion formations on the metal. If the pipeline passes underground, then it is also affected by groundwater, and they are often chemically aggressive.

If we consider the following methods of using VUS:

- The traditional option for strengthening steel pipeline systems is their processing with bitumen and bitumen-rubber mastics. A protective or reinforcing coating is applied to such a treatment. The normal level of this processing is the presence of a pair of layers of mastic, the thickness of which is 0.3 cm and a layer of protection from kraft paper.

- With VUS, the mastic is applied in four layers. The second and third layers separate the rolled reinforcing material. Kraft paper acts as the main coating, which is a protection against mechanical influence.

- The next method is an even more enhanced processing, consisting of six layers and a pair of reinforcement layers. The thickness of the protective layers in this embodiment is 0.9 cm.

Video

Regulatory documents and their requirements

There are 3 main documents regulating the organization of protection of gas pipelines. RD 153-39.4-091-01 "Instructions for the protection of urban underground pipelines from corrosion". As the name implies, it does not apply to the insulation of gas pipes with a diameter of more than 83 cm - intercity and international, as well as pipes laid above ground or under water.

GOST 9.602-89 is a related document that contains all the norms and calculations for the protection of underground gas pipelines. If the instruction explains how and from what to equip the insulation, then GOST indicates how much is needed - from meters of material and tools to equipment and labor hours of workers.

GOST R 51164-98 Main steel pipelines. General requirements for corrosion protection. This standard fills a gap in the Instruction regarding main pipelines.Their protection must be especially reliable and has its own specifics, therefore the norms of its organization are placed in a separate document.

As a rule, gas pipelines of national and international importance have a diameter of more than 830 mm, their installation and maintenance is time-consuming and expensive.

These documents regulate the following issues:

- what types of materials are allowed to be used on this type of gas pipeline under these conditions;

- how much reinforced insulation is needed, whether electrochemical protection is needed;

- who and when is obliged to provide the gas pipeline with the necessary protection;

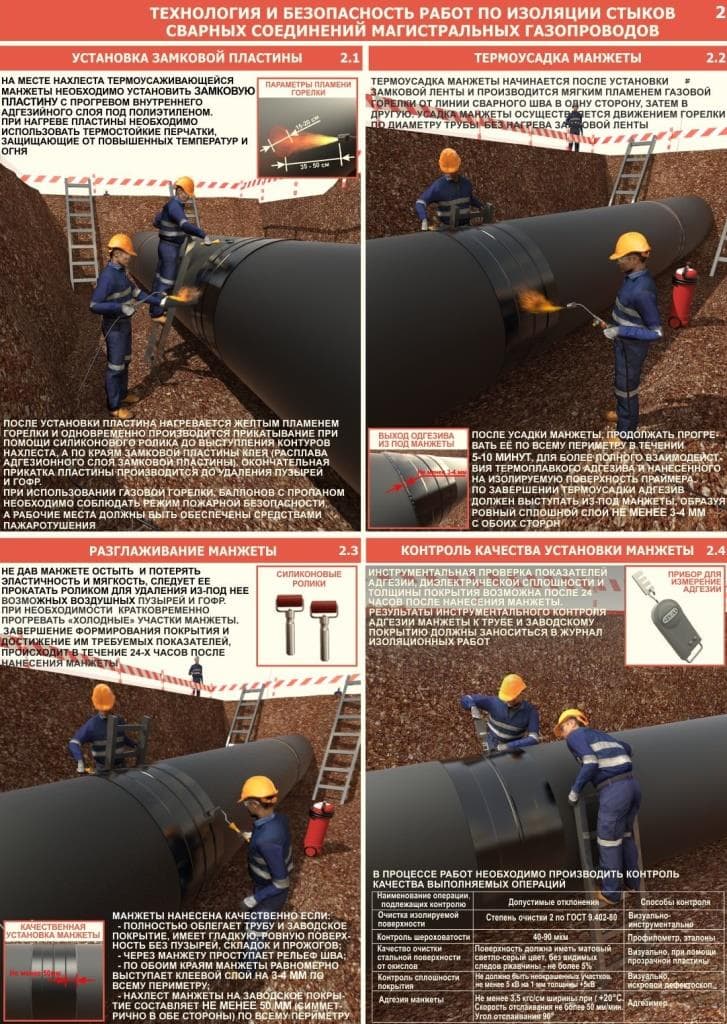

- technology for applying insulation at the factory and in the field, as well as for repairing damage;

- consumption rates of materials and costs of other resources for work;

- the procedure for checking the quality of the coating and the standards for quality indicators for all parameters for each type of insulation.

Thus, in these documents, the entire process of pipe insulation is described step by step, from release at the factory to verification after installation and during operation. There is no room for creativity, because these are security issues.

In the event of damage or poor-quality insulating coating, the steel in the ground rusts rather quickly, and this threatens to leak gas and fire

There are also separate lists that list all recommended materials and manufacturers of insulation for gas pipelines.

Given the complexity of the work and the considerable number of standards that must be observed, do not even expect to cope with the insulation of the gas pipeline on your own, and the gas service will not accept work performed by a third-party master.

PPU insulation

PPU is the name of the material "polyurethane foam".It completely covers the pipe, forming a thick protective layer. From above it is upholstered with a polyethylene or galvanized sheath.

Such pipes are necessarily equipped with an ODK system (operational remote control), which prevents the occurrence of an accident and warns the operator about the appearance of problem areas on the surface of the pipeline.

PPU pipes are much easier to install in the ground, compared to other types. They are more wear-resistant and durable (30 years of operation are guaranteed by manufacturers). They have low thermal conductivity and high mechanical protection.

PPU pipelines are used when conducting heating mains. They successfully transport liquid substances of different temperatures, gases (for heating), chemicals and oil products. The cost of purchasing and laying PPU pipes is much lower than the cost of other types.

Checking the quality of insulation application

The protection of steel gas pipelines is a responsible event, therefore, each operation performed is subject to a thorough check, with the drawing up of an act of concealed work performed and entering them into the pipeline passport. No matter how high-quality and properly selected the insulation material is, it will not cope with the functions assigned to it if the technology of work has been violated.

The main parameters of the finished coating to be checked are thickness, continuity and adhesion to the pipe. They are measured with special electronic devices: thickness gauges, spark flaw detectors and adhesive meters, respectively. They do not damage the coating, so they allow you to control all doubtful points at no extra cost.

In the factory

At factories and production bases, the coating thickness is checked on 10% of the pipes of each batch, in 4 places from different sides in a circle on each pipe, as well as in doubtful areas.

Insulation applied to pipes by the manufacturer is always more uniform, better and more reliable than organized in the field, even when using similar materials

Insulation applied to pipes by the manufacturer is always more uniform, better and more reliable than organized in the field, even when using similar materials

Adhesion, or strength of adhesion to metal and between layers, is also required by regulations to be checked at 10% of the product in a batch or every 100 m.

The continuity of the coating, that is, the absence of punctures, tearing and other through violations, is checked on all insulated products over the entire area.

In addition, coating dielectric continuity, impact strength, peel area after cathodic polarization, and other tests can be tested. When insulating with bituminous coatings, a sample for physical properties is taken from each batch of mastic, at least daily.

At the site of installation or repair

In highway conditions, the quality of the insulation is also checked, for continuity - always and completely, and for thickness and adhesion - every 10th insulated weld.

In addition, the width of the overlap on the factory coating is checked, as well as the relief of the insulation - for the absence of corrugations, wrinkles, air cushions and other defects.

With weak adhesion of the insulating tape to the pipe, it will peel off over time, and the pipe will be unprotected from the environment

With weak adhesion of the insulating tape to the pipe, it will peel off over time, and the pipe will be unprotected from the environment

In addition, insulation integrity is regularly checked on existing gas pipelines.To do this, they do not even need to be dug up, and in case of suspicion of damage, the pipes are exposed and checked not only for thickness, continuity and adhesion, but also for the dielectric properties of the insulation.

Protective shell

External insulation of pipelines solves many problems:

only stainless steel products are not subject to corrosion. However, the cost of the latter is very significant, so most communications are recruited from ordinary black pipes. Such an alloy is much more susceptible to corrosion, and the protective shell can greatly reduce damage and extend the life of the product;

Insulation against corrosion

- metal conducts heat, giving it to the air and the earth. To maintain the temperature of the coolant, steel pipes are insulated with polyurethane foam, extruded polyethylene, mastic;

- freezing of liquid in steel pipes is fraught with damage to the latter: water expands upon freezing and breaks metal of any strength. Thermal insulation will avoid this phenomenon;

- the insulating sheath protects steel pipes from mechanical damage, especially with an open installation method;

- prices depend on the complexity and effectiveness of the insulation.

Reliable isolation

Only the simplest options can be carried out manually, for example, applying one layer of mastic.

Highly reinforced steel pipe insulation

Reinforced insulation of steel pipes GOST 9.602-2005 is as follows.

- The traditional option involves surface treatment with bitumen and bitumen-rubber mastic. The normal level is considered to be 2 layers of mastic with a thickness of 0.3 cm and a pad of kraft paper. A protective layer is applied on top of the coating. The prices of the method and materials are the most affordable.

- Very enhanced protection involves at least 4 layers of mastic. At the same time, a reinforcing roll material is placed between the 2nd and 3rd layers. The top shell made of kraft paper protects from mechanical damage.

- The insulation of reinforced steel pipes also suggests another, even more reliable option: 6 layers of mastic and 2 layers of reinforcement. At the same time, their thickness is at least 0.9 cm. In the photo - a protective shell in accordance with GOST.

None of the protection methods involves a manual installation method.

The described methods are offered by GOST 9.602-2005. It is really reliable and durable protection. However, in difficult conditions - a high level of groundwater, channelless laying of steel pipes, this is not enough.

Pipe insulation

Reinforced insulation according to GOST 9.602-2016

Other types of materials are used, although bitumen or bitumen-rubber mastic still acts as the basis.

The university includes the following:

- the surface of the steel pipe is primed;

- reinforced fiberglass is fixed on the product - the first layer;

- then a layer of bituminous mastic is applied, providing protection from water;

- 3 layer - another fiberglass gasket;

- mastic and 1 or 2 protective layers of kraft paper.

This option provides the minimum permeability of oxygen and water, mechanical strength and resistance to the strongest temperature changes. Prices for such insulation, of course, are higher.

GOST suggests another method - again, not a manual method, using polyethylene tape material. The technology is almost the same, that is, the alternation of a polyethylene gasket and layers of mastic. Insulation of steel pipes of reinforced type - in the photo.

The use of polymeric materials guarantees complete insensitivity to moisture in any form and resistance to mechanical damage. The treatment also provides excellent temperature retention: GOST recommends using protection on pipelines where the temperature of the transferred substance ranges from -40 to +60 C.

Types of materials for insulation

Based on the operating conditions and ease of use, there are many types of coatings for insulating gas pipes. It is enough to protect above-ground gas pipelines with 2 layers of primer and 2 layers of paint or enamel.

Pipes that will serve on the seabed are covered with a layer of concrete on top of the main insulation, for weighting and additional protection.

Next, we will talk about the means of protecting steel pipes underground.

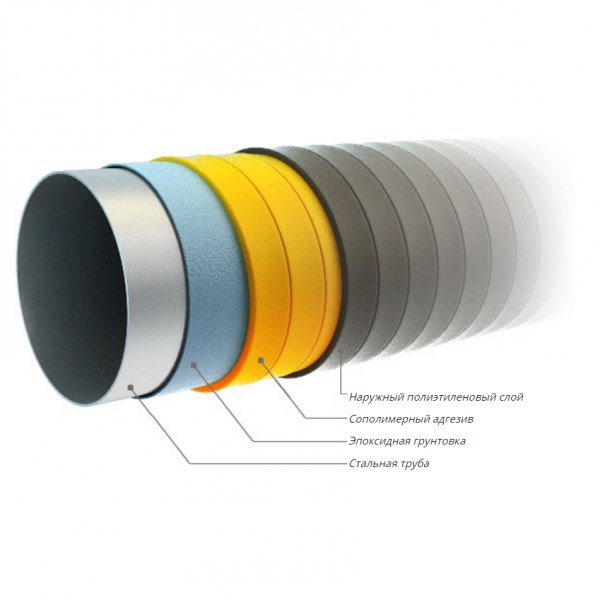

Polymer protective coatings

Extruded polyethylene is the most advanced and versatile protection. It is used on pipes with a diameter of 57 - 2020 mm, it adheres tightly, forms an ideally uniform continuous layer, protects against thermal and mechanical influences, and is also convenient to use.

In such a coating, a steel pipe is practically not inferior in terms of protection characteristics to polymer analogues. This protection consists of only 2 layers - a hard gluing adhesive and, in fact, polyethylene. Despite this, such a coating of a very reinforced type on pipes of large diameter can reach 3.5 mm.

Extruded polypropylene is specific for its high mechanical strength: it can be used to pull pipes through wells, for closed laying methods, and not worry that the insulation will be damaged from friction or catching on stones and soil.Outwardly and in structure, this type of insulation does not differ from polyethylene, only 0.3 - 0.5 mm thinner.

Polymer adhesive tapes are polyethylene and PVC, while the former is preferable, since they stick 4 times stronger and better protect pipes. More often sticky PET tapes are used for repairing and insulating joints of pipes coated with extruded polyethylene, but there are also pipes wrapped with them at the factory along the entire length.

If necessary, polymer adhesive tapes allow you to completely replace the protection of the pipe in the field - but this requires a special automated installation

If necessary, polymer adhesive tapes allow you to completely replace the protection of the pipe in the field - but this requires a special automated installation

There is also a combined PET coating, in which the primed pipe is first wrapped with an adhesive polymer tape, and then protected with a layer of extruded polyethylene on top. It is used on pipes with a diameter of up to 53 cm, and the total thickness does not exceed 3 mm.

Insulation based on bituminous mastics

Such insulation is fundamentally different in composition and properties, primarily in the method of application. The adhesion of bitumen to both the pipe and the layers to each other is ensured by heating and melting the material itself, and not by an adhesive primer, as is the case with PET.

Such a coating is applied to a special bituminous primer, and consists of 2-3 layers of mastic, each of which is reinforced, and an outer protective paper wrapper. As a result, a continuous coating is formed, completely repeating the shape of the pipe, where the reinforcing fiberglass or mesh is, as it were, soldered into the thickness of the protection.

As a reinforcing material, fiberglass, fiberglass or non-woven polymer fabric is used.Fiberglass tapes are wound with a slight overlap to form a continuous layer

As a reinforcing material, fiberglass, fiberglass or non-woven polymer fabric is used.Fiberglass tapes are wound with a slight overlap to form a continuous layer

The mastic itself, in addition to bitumen, contains various inclusions - polymer, mineral or rubber - providing different properties of the material. Modifying additives and plasticizers are also added to it, which add elasticity, flexibility, resistance to critical temperatures and durability in addition to natural hydrophobicity and adhesion ability.

There are also tapes that connect bitumen as an adhesive and special polymer tapes. The main 2 types of such coatings are PALT, with heat-shrinkable tape, and LITKOR, made of polymer-bitumen tape. The latter, in particular, is necessary to protect connections between pipes with different types of insulation.

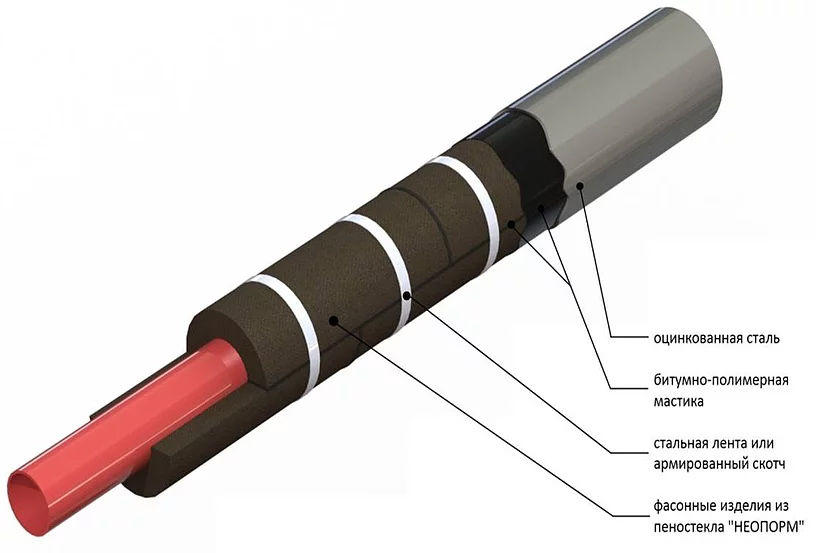

Materials for insulating small elements

Socle conclusions, corners, knees, condensate collectors and other shaped elements of gas pipelines also need protection.

It is more convenient to isolate small parts at the installation site, but the factory coating is preferable, because it is more uniform and reliable

It is more convenient to isolate small parts at the installation site, but the factory coating is preferable, because it is more uniform and reliable

For this, there are special coatings: PAP-M105 and Polur. The first is two layers of cured polyester resin reinforced with fiberglass.

Polur consists mainly of polyurethane, supplemented with technological additives and divided into the main component and the hardener. With the help of these two compositions, shaped joints are insulated both at the factory, and in workshops, and directly on the track.

Insulation of an underground gas pipeline is necessary in order to protect against the occurrence of local foci of corrosion, the main cause of which is increased soil moisture, and from stray currents.

Such currents are formed in the ground if engineering networks are laid close to power cables, highways, railways. The induced electric current that enters the gas pipes leads to a decrease in their durability. Steel pipes are damaged so quickly that gas leakage can occur as early as the first year of operation. Since the loss of tightness of the gas pipeline leads to an emergency, it is necessary to think in advance about the protection of the underground pipeline from the adverse effects of the environment. A promising and modern way to insulate underground gas pipelines are PPU pipes, a wide selection of which is offered by the Ural Pipe Insulation Plant.

Features of insulation of underground gas pipelines with polyurethane foam

There are two methods for insulating a gas pipe: pre-applying an insulating layer at the factory, or protecting the gas pipeline after installation.

Pre-coated insulated pipes are considered the most durable. To increase the level of waterproofing during underground laying, the top layer of the protective sheath is made of polyethylene. This provides optimal protection when laying in the ground without the construction of channels and tunnels. The absence of channels and communication wells can significantly reduce the cost of gas pipeline insulation, since PPU pipes can be laid directly into the trench.

Another advantage of PPU insulation is the possibility of electronic monitoring of the state of the gas pipeline. In this case, the occurrence of a malfunction immediately becomes known to the maintenance personnel.

Pipes with factory-applied polyurethane foam insulation have already found wide application in various fields, as they perfectly protect engineering networks not only from heat loss, but also from high and unstable humidity, external corrosion and premature failure. An additional advantage of using such pre-insulated pipes is their relatively low cost.

Operational and consumer characteristics of PPU steel pipes

High resistance to corrosion and loss of premature failure due to the unique properties of foamed polyurethane. Its main quality is low thermal conductivity, therefore, a small layer of this material is sufficient to significantly reduce heat losses. The service life of the foam polymer exceeds 30 years, while maintaining all its technical characteristics, that is, the operational life of the PPU protection is comparable to the service life of the underground pipeline itself.

Such products are highly resistant to atmospheric and ground moisture - their water absorption is less than 2%, in addition, they can operate in a wide temperature range, their operating pressure should not exceed 1.6 MPa.

PPU has high adhesion to steel, so the insulation is seamless, in the form of a single monolithic sheet. Polyurethane foam insulating material is highly durable and resistant to mechanical damage and shock, and also tolerates contact with aggressive environments. All these qualities make PPU steel pipes an effective means of protecting not only heating networks and hot heat supply, but also gas pipelines of high, medium and low power.

The installation of such pipes is not difficult, and their design is simple and reliable - a water-gas or main steel pipe, polyurethane foam insulation, and a protective sheath.

UZTI, products for gas engineering networks

The Ural Pipe Insulation Plant offers pipes of various diameters with all the necessary components for laying a gas pipeline. The plant also offers coating services for pipes of the required size. Three production lines for pouring the insulator produced at the plant make it possible to produce 2,000 meters of pipes of various sizes daily, in the range of more than 9,000 product items. All products manufactured by the plant are manufactured in strict accordance with the technological regulations, this guarantees high quality products and a long service life without replacement and repair.

When is thermal insulation of cold water pipes necessary?

Insulation for cold water pipes is carried out to protect them from external breakthroughs and freezing, prevents corrosion and condensation.

What causes condensation and where does it form? Pipe fogging refers to the moisture that occurs on them, which usually appears:

- On cold parts of the surface.

- As a result of contact with warm air, greater humidity. Steam, which is part of the warm air, when cooled, is converted into moisture in the form of precipitation on a cold pipeline.

Condensation is formed as a result of:

- Too cold piping coming into contact with warm ambient air.

- Increased humidity of the external environment.

- Insufficient ventilation of the room.

- Water supply failures.

Consequences of condensation:

- The unaesthetic appearance of a misted pipe.

- The accumulation of puddles under them.

- High humidity.

- The appearance of mold in combination with a heavy smell.

- Corrosion of metal pipes.

If the pipe is small in diameter, the use of specially designed pipe shells made of thermally insulating porous foam is best suited. This type of insulation can be installed with your own hands, having previously selected the desired size - the inner diameter of the shell must correspond to the outer diameter of the pipe.

The shell is cut along the entire length, put on a pre-dried pipe, the resulting seam is sealed with adhesive tape or glue. The result is an aesthetic appearance combined with reliable protection of the pipeline.

To install the insulation of a large diameter pipeline, it is necessary to use flat sheets, rolls of different thicknesses with the addition of an adhesive layer and aluminum foil.

Seams and joints are connected:

- glue;

- self-adhesive rubber and aluminum tapes;

- clips.

With their help, tightness and reliability of insulation are achieved.

What materials are used

This type of insulation is made of thin-sheet galvanized steel in the form of cylinders or shells of different diameters, from which you can choose the right option for any external pipeline.

Installation of galvanized protective shells is carried out on a previously fixed heat-insulating material:

- polyurethane foam. This insulator has a low thermal conductivity, hygroscopicity, durability, good adhesion to steel and sheath material, applied by spraying.By agreement with the customer, pipes in polyurethane foam insulation (PPU) are equipped with a system of ODK (operational remote control). It allows real-time information about damage to the steel pipe and casing, the appearance of places of moisture in the heat-insulating layer, violations of the signal wire;

- PPU shells are products made of foamed polyurethane, made in the form of split cylinders, semi-cylinders, prefabricated elements. Are fixed on a pipe on a coupler;

- foam polymer mineral. The material has a low water absorption coefficient, retains heat well in the line. The cost of foam polymer-mineral insulation (PPM) is lower than other options for heat insulators;

- extruded polyethylene. Pipe insulation using extruded polyethylene is considered reinforced (RH). It is applied in the factory, forms a completely waterproof layer, resistant to temperature extremes and the effects of various chemical compounds and aggressive environments;

- rubber-bituminous mastic. Performs the function of waterproofing metal pipes without affecting the reduction of their thermal conductivity. The technology of insulation with rubber-bitumen mastic involves the application of several layers: a primer that increases the adhesion of metal surfaces, polymer-bitumen mastic and a non-woven fabric for reinforcement. To wrap the insulated surface of pipes, a polymer film or galvanization is used.

Gas pipeline insulation

To insulate pipes transporting gas, various types of insulators are used. For example, it is possible to insulate a gas pipeline using special paint or varnish, but in most cases modern protective materials are used.

What requirements should an insulator for gas pipes meet:

first of all, the insulator for the gas pipeline must be able to be uniformly, monolithically mounted on the pipe;

and it is also very important that the insulating material for the pipeline has a low water absorption coefficient and generally high waterproofing properties;

The material for insulating gas pipes must have high moisture resistance

- also, high-quality protective material must be highly resistant to corrosive effects and the effects of any other aggressive chemical compounds;

- the insulator must be strong enough to protect the gas pipeline from mechanical stress;

- the coating must not have any damage (cracks, chips, etc.).

Consider the main types and types of insulation of gas pipelines:

bituminous mastics. Such heat insulators are produced with various additives that are mixed with the base material - bitumen. Additives can be of three types:

- Polymer.

- Mineral.

- Rubber.

Such additives provide protection against the appearance of cracks and, in addition, improve adhesion to the surface of the gas pipe. It is also worth noting that bitumen mastics have proven themselves well at low temperatures.

tape materials. Insulating tapes are usually made of polyethylene or polyvinyl chloride (PVC). At the production stage, an adhesive material is applied to one of the sides of such a tape, through which the tape is mounted on the gas pipeline.

Depending on the design features of the pipeline and the region in which it is laid, the following types of tape insulation are used:

- Normal.

- Reinforced (US).

- Highly Reinforced (VUS).

Today, to protect gas pipelines, tape insulation is often used, which is wound around pipes using a special device.

The last type of insulation is the most reliable and effective and is most often used to protect pipelines in populated areas. VUS is resistant to aggressive corrosive influences and active chemicals.

VUS is produced using the extrusion method. Pipe insulation with extruded polyethylene is carried out to increase the protective functions of the pipeline. Pipe insulation with extruded polyethylene is a very reliable protection option. Extruded tapes have excellent waterproofing performance and are installed on pipes that are laid even in adverse climatic conditions.

How does this happen?

The construction technology provides for pipe insulation exclusively in the factory. The application of protection in the locations is permissible only during the overhaul and current repairs of the gas pipeline. In the field, these works are completely mechanized. The process of applying an insulating coating is provided by cleaning and insulating machines (combines). The manual isolation method is used only when protecting individual joints or small sections of the gas pipeline.

It is important to prepare the pipe for insulation. With the help of pipe cleaning machines and special brushes, the gas pipeline is cleaned to a metallic sheen from contaminants and products.

Then a primer a tenth of a millimeter thick is applied to the gas pipeline, and after it dries, hot bituminous mastic is applied. It is applied in several layers - depending on the requirements for insulation. Next - the turn of the film.She wraps the pipe in a spiral so that it fits as tightly as possible - without wrinkles and folds (corrugation). After that, the thickness and continuity of the protective coatings are checked by the method using thickness gauges, spark flaw detectors and other measuring instruments.