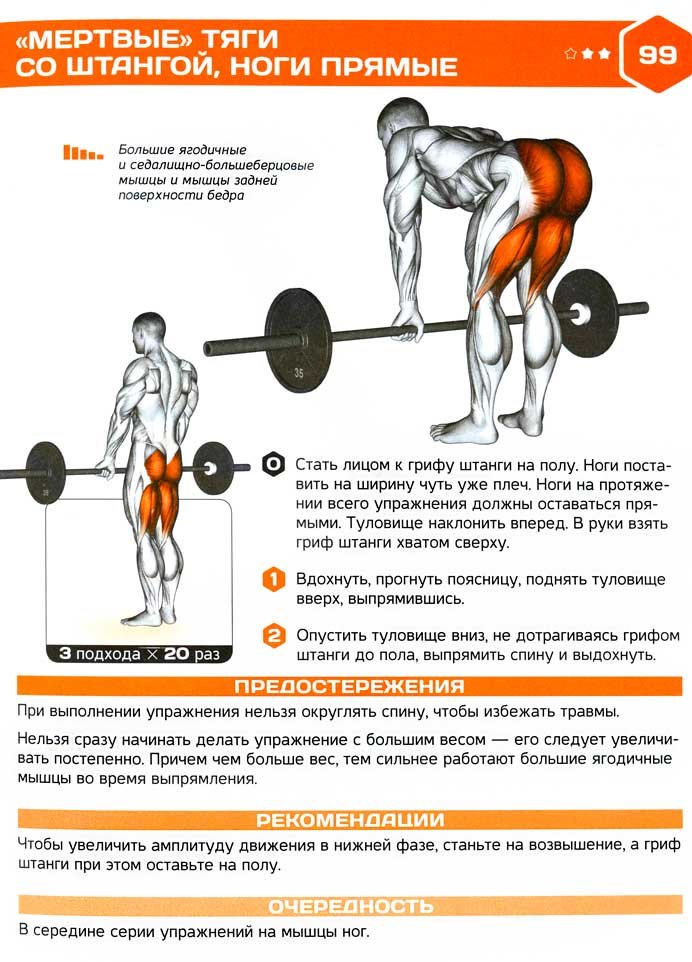

- The device of the deflector-weather vane on the chimney for the furnace

- Types of structures to increase draft in the chimney

- Rotary or rotary turbine

- Vane

- Electric fan

- Stabilizer

- Deflector

- Smoke during kindling

- Other causes of stove smoke

- No draft in the chimney: 6 reasons for reverse draft and how to improve it yourself

- Why is there no draft in the chimney

- Reason 4 - oven wear

- Installing the deflector

- Rotary damper device for the chimney of a sauna stove

- Reverse thrust elimination

- Stabilizers

- Gate manipulations

- Using a draft regulator (stabilizer)

- Ventilation system

- Control and measurement of rarefaction in the chimney

- Thrust calculation

- Traction test

- Why is it smoking

- Checking and determining thrust

- Solving the problem with reverse thrust

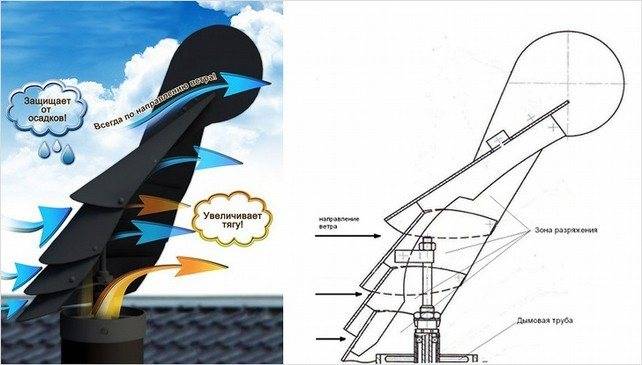

The device of the deflector-weather vane on the chimney for the furnace

There is a new popular type of deflector - a weather vane-deflector.

>

It is (see photo above) a special device in which the body rotates simultaneously with the deflector visors curved on it. Such visors are connected to the bearing assembly. The weather vane, located in the upper part, allows the entire structure to always be located taking into account the direction of the wind.

The operation and arrangement of the deflector-weather vane for the chimney is quite simple and straightforward. The air flow penetrates into the space between the visors, accelerates and thereby creates a rarefaction zone.As a result, the draft in the chimney increases, the fuel in the furnace burns well, and the air exchange also improves.

It is also recommended to create additional ventilation. These chimney wind deflectors are ideal for preventing backdraft, sparking and flame interruption.

You can also make a weather vane-deflector, after which the structure itself should be attached to the cut of the chimney using a ring with a bearing assembly. It is a stable influx of fresh clean air and high-quality removal of combustion products that is the key to the good operation of the furnace.

Types of structures to increase draft in the chimney

Types of structures for the chimney

The installation of technical devices helps to increase the removal rate. Mechanical and electrical devices increase and decrease the speed of movement of smoke, while maintaining optimal pressure in the pipe.

You can increase the draft in the chimney by installing:

- rotary turbine;

- vane;

- electric fan;

- stabilizer;

- deflector.

The solution is selected taking into account the design of the smoke channel, the type of heating equipment. What matters is the height of the pipe above the roof level and the presence of multi-storey buildings in the neighborhood. Any device on the pipe causes the accumulation of soot and condensate inside the channel, so it is better to design and install smoke exhaust channels correctly.

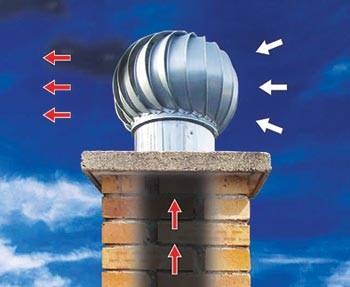

Rotary or rotary turbine

The turbo deflector is driven by air and helps the smoke escape.

The traction amplifier contains one or more rotary devices in the design, it is placed at the end of the pipe and operates due to the movement of the wind. The temperature of the outgoing smoke should not exceed 150 - 200°C, depending on the type of turbine.Most often, such devices are placed on gas stoves and boilers.

The device rotates in one direction and by rotation creates an area of reduced pressure above the top of the channel. The nozzle additionally protects the outlet from debris and precipitation.

The disadvantage is the impossibility of working in calm weather. The turbine continues to rotate when the heating is turned off during the summer months and creates increased draft in the room.

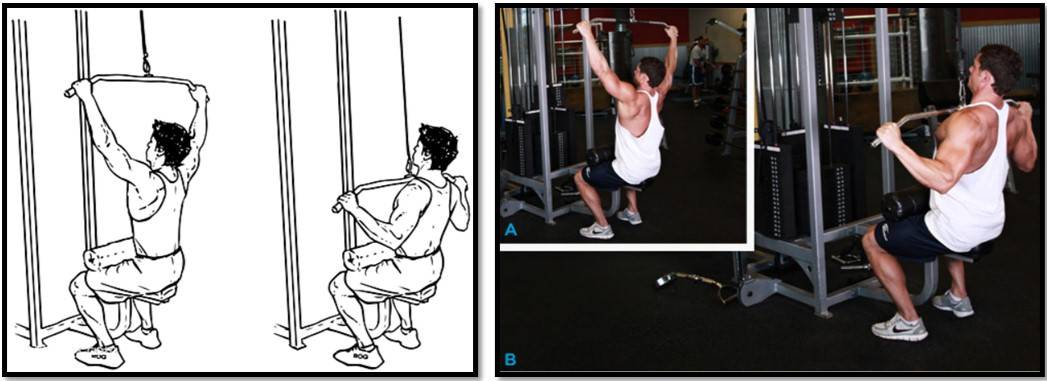

Vane

The weather vane turns against the wind and protects the pipe from blowing out

The nozzle on the chimney to increase the draft is made in the form of a weather vane, which turns against the wind due to a special design. The task of the chimney is to resist back draft and give an aesthetic appearance to the pipe head.

Construction details:

- central axis;

- figure;

- Rose of Wind.

The cap has bearings inside that require regular lubrication. In frost, frost appears on the surface of the body, it needs to be knocked down.

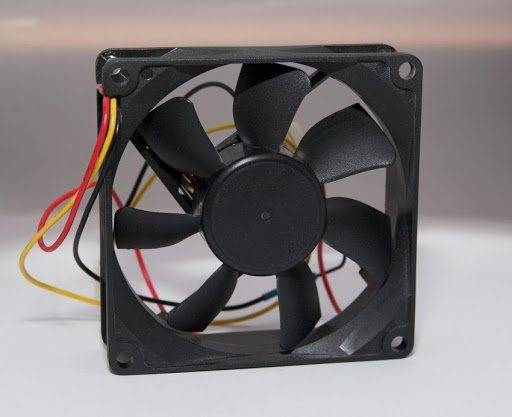

Electric fan

You can increase the speed of the smoke with an electric fan

It is used to extract smoke from solid fuel, gas boilers, stoves in baths and saunas, fireplaces, open hearths, with a temperature of combustion products not higher than 200 ° C, as well as in an air purification system. A chimney fan to improve draft is a draft device to increase heating efficiency. Installing the device allows you to make the boiler furnace and other elements compact, and the combustion process does not depend on the weather.

The rate of circulation of gases increases, the air supply to the burners is organized, the air is distributed evenly over the combustion zones.The use of a fan is not always justified in small household stoves, low power boilers, because they make the design complicated and depend on electricity.

Stabilizer

The device is an interrupter for metered supply of oxygen and maintaining the traction force in the chimney. The design has a safety valve to stop work in case of excessive pressure in the pipe.

The stabilizer is installed on the outlet of the chimney and performs the following functions:

- stabilizes the pressure in the furnace;

- weakens excess draft in the pipe and improves the efficiency of the boiler;

- protects the room from the occurrence of reverse suction of smoke.

A draft sensor is mounted under the umbrella head, which reacts to an increase in the temperature of the combustion products. Smoke accumulates under the dome when the flow is reduced and heats up the controller, which interrupts the gas supply to the burner.

Deflector

A deflector with different nozzle diameters enhances the speed of the smoke

The device is placed at the end of the pipe and converts the energy of the wind flow to reduce the static pressure in the channel. The Bernoulli effect is used, which means that with an increase in wind speed and a decrease in the diameter of the channel, rarefaction appears in the pipe and an additional traction force is created.

The standard version includes three parts:

- the upper cylindrical body, which has an extension at the bottom, it is attached to the base using racks;

- lower metal cup, sometimes asbestos cement or ceramics are used as the material;

- conical cap.

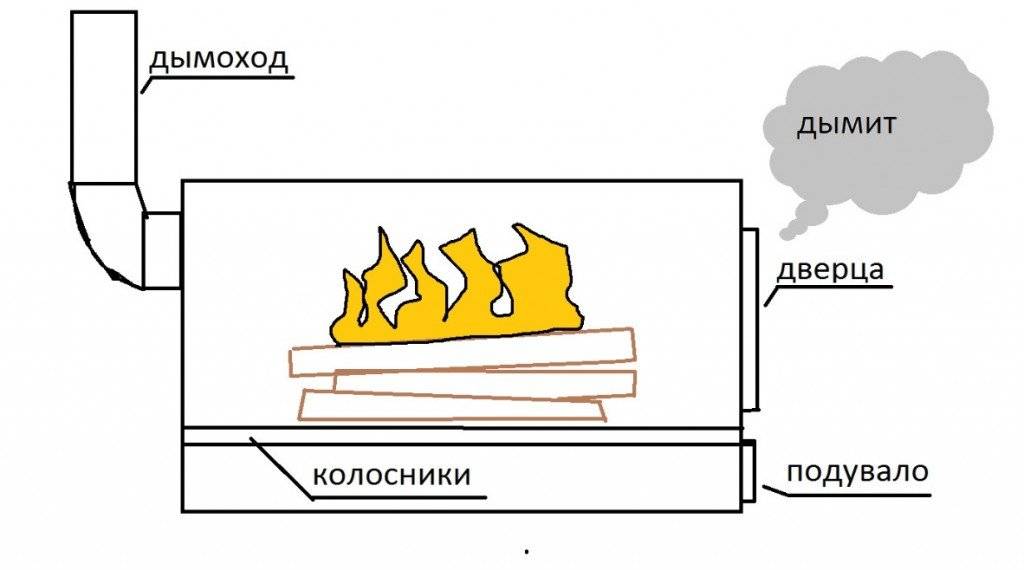

Smoke during kindling

The stove smokes when kindling in the cold season. This problem often occurs with ovens that are used intermittently.For example, the unit is in a bathhouse or a country house. A column of cold air forms a plug in the chimney that blocks the draft. The stove-makers are advised to get rid of it in the following ways:

- bring a burning torch to the smoke collector,

- burn a piece of paper directly near the smoke box.

These techniques allow the cork to warm up, rise up and go out. The problem of cold plugs occurs not only with brick, but also with metal stoves, which are installed in the bath and sauna (heaters). If the house is 2-story, you should be aware that often the cork is collected in the horizontal part of the chimney, if it is on the 2nd floor. According to the masonry technology, the length of this segment (box) should not be more than 2 m.

Other causes of stove smoke

Poor-quality mortar, too thick masonry joints, lack of furnace lining or deformation in it lead to cracks in the furnace body. This causes constant smoke, it is not recommended to operate the unit in this state. Repair is carried out by covering the cracks with special adhesive solutions. If this does not help, you will have to disassemble the case and build the furnace again.

The smoke that enters a heated room from a stove is an unpleasant and dangerous phenomenon, but it is sometimes difficult for an inexperienced person to determine the reasons for its appearance. Why does the stove smoke, possible reasons for such improper operation and tips to eliminate them from an experienced stove-maker, are given below.

Sometimes in calm weather, the stove works normally, but in windy weather it either burns or “releases” smoke into the room from the stove door or valve. The reason for this is most likely a tall tree or a wall located next to the house.The wind, hitting such an obstacle, enters the chimney and prevents the exit of smoke. To fix the situation a cap must be installed on the pipeAn umbrella to protect her from the wind. Such a cap is also needed if the stove is hard to melt in hot weather.

If there are no high wind barriers near the chimney, then a possible reason why the stove smokes may be that the chimney is located below the highest roof level. According to the rules, the pipe must be located above the ridge by at least 25 centimeters.

It is very easy to check if a cap is needed over the pipe if the stove smokes. Two halves of bricks are placed at the corners of the pipe, and a sheet of iron is placed on them. If after 3-5 minutes the stove stopped smoking, then the stove cap is needed.

Another possible reason why the stove smokes may be the destruction of the upper seams of the pipe laying (if it is brick) by rains and flue gases, as a result of which the upper bricks fall out of it. Wind gets into the destroyed places of the chimney, and the stove begins to smoke. The pipe in such a situation must be repaired.

A very possible reason why the Russian stove smokes is the small size of the pipe or views, as well as the poorly closing view door. At the top of the pipe, it is necessary to make laps, which not only create good draft of the furnace, but also improve the appearance of the pipe.

The blower in the Russian stove should be less than the length of the firebox, otherwise the cold air entering the blower in large volumes reaches the back of the firebox and, pushing off from it, displaces smoke from the firebox. If you lay such a blower in half a brick, then the stove will not smoke.

It happens that the stove smokes in any weather, and when the door is opened, the smoke seems to “stretch” after it and enters the room. When this happens, you need to look into the furnace. If there is an oven under the oven stove, then there must be a brick wall between it and the combustion chamber. If it or the cabinet is lower than the top of the door opening, then a clay rim must be made on the wall so that it is higher. The draft in the oven will be excellent even with a difference in height between the side and the stove of several centimeters.

Another possible reason why the stove smokes is that the exit of gases from the furnace occurs below the opening of the furnace door. This situation can be corrected by laying a brick wall across the firebox, the height of which will exceed the height of the door opening.

If the stove smokes and the smoke comes out of the view or valve, then the pipe is clogged with soot or, for example, a brick that has fallen into it. The chimney needs to be cleaned.

Another, quite common possible reason why the stove smokes is clogging the ash blower, and if the stove is a heating and cooking stove, then the oven burns out.

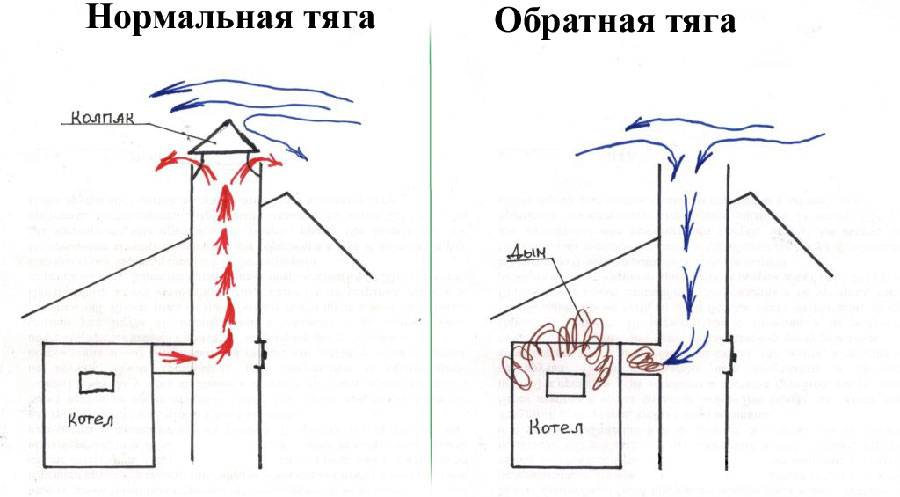

No draft in the chimney: 6 reasons for reverse draft and how to improve it yourself

The unpleasant smell of burning, smoke in the room, poor burning of firewood - all these are the consequences of reverse draft in the chimney. This is a problem faced by many owners of fireplaces, stoves, solid fuel boilers and other wood-fired heating appliances.

Further in the article, we will consider the main causes of poor draft in the chimney, and also give simple recommendations for elimination this problem.

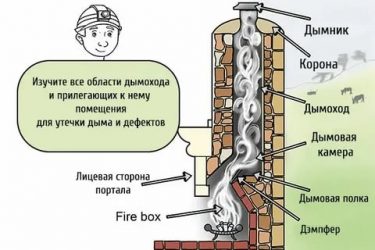

Why is there no draft in the chimney

Chimney clogged with soot

Perhaps this is the most common and main reason for the deterioration of traction.

When wood is burned, soot is formed. It is particles of combustion products that stick together and settle on the inner walls of the chimney, which leads to a narrowing of its diameter. As a result, the movement of air becomes difficult.

Therefore, the soot must be removed regularly. So you will not only improve traction, but also increase the efficiency and fire safety of the heater. To make the walls of the chimney less polluted with soot, you can use fuel wood briquettes, which contain less moisture and other harmful impurities.

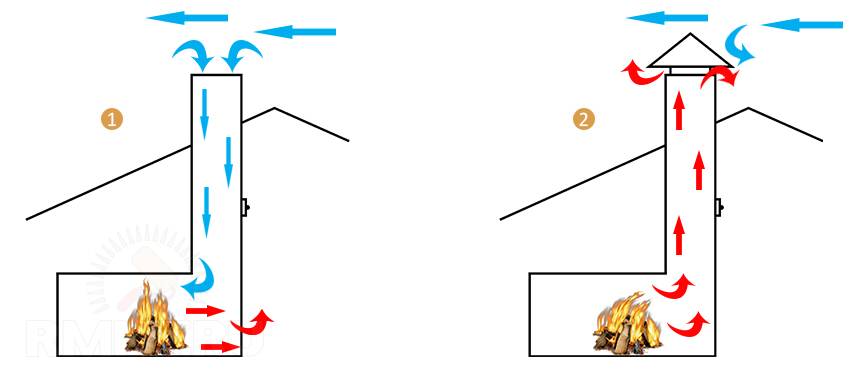

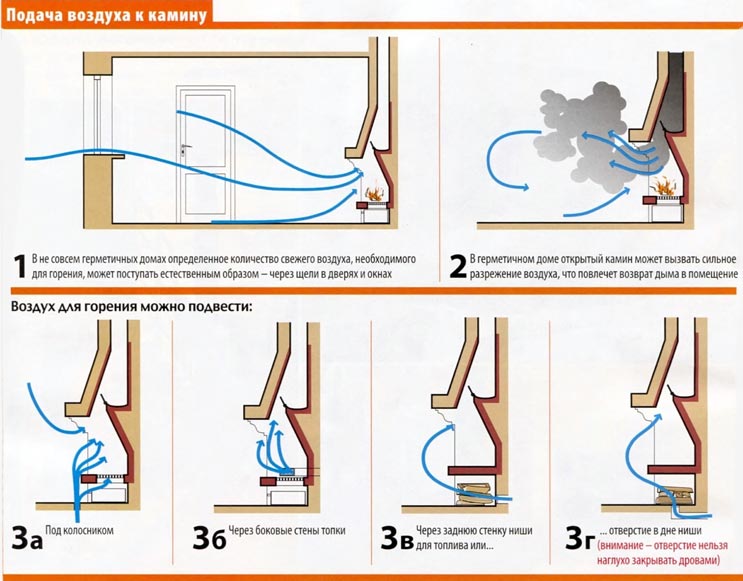

Insufficient air supply

When burning firewood, it is necessary that the air moves “from bottom to top”. That is, from the room to the chimney and to the street. To do this, in the room where the heater is installed, air flow - draft must be provided.

If all the windows are closed, if the ventilation is malfunctioning, then the smoke begins to move in the opposite direction - from the chimney to the room. That is, there is a backlash.

The easiest way to solve this problem is to create the right air movement in the room. For example, open a window before lighting a fire and close it 10-15 minutes after the flame flares up.

Cold outdoor air pressure

The draft in the chimney may deteriorate due to a decrease in the outside temperature. Since cold air is heavier than warm air, it sinks down and “presses” inside the pipe. This problem is especially often manifested in the presence of the previous two - the lack of air flow and a clogged chimney. It enhances their influence.

Therefore, the solution is: insulating the chimney, removing soot and creating an air flow.

The presence of a visor on the chimney

Often a hood is installed on chimneys, which can prevent smoke from escaping from the chimney.As a result, an air "plug" of smoke is formed and traction deteriorates.

In such cases, the visor should be replaced with a higher one or removed.

Incorrect chimney design

Backdraft can occur as a result of improper chimney design: narrow diameter, too high a height, a large number of bends or narrowings.

To eliminate problems of this kind, you will have to rebuild the chimney, which will entail a significant investment of time, effort and money.

brick collapse

Due to the constant heating-cooling process of a brick chimney, it can collapse. Bricks will fall off, fall down and clog the chimney.

To avoid such a situation, the chimney must be insulated. This will also solve the cold air pressure problem.

So, how to increase traction in the chimney? Here are a few simple steps that do not require much time and money:

- Clean the chimney of soot. This is the first thing to do. You can do it yourself, with minimal time, effort and money.

- Ensure air flow. Open a window for 5-10 minutes before starting a fire. This will create the correct movement of air in the room "bottom-up". The window can be closed after the fire flares up.

- Insulate the chimney if it is not insulated. This will reduce the influence of cold air and also extend the life of the chimney.

As a rule, these simple actions are enough to increase the draft of the chimney. If the problem is related to the design features of the chimney channel, then more serious resources will be required to solve it.

No draft in the chimney: 6 reasons for reverse draft and how to improve it yourself What to do if there is no draft in the chimney? The article discusses the main causes of poor traction, as well as tips for improving it.

Reason 4 - oven wear

It happens that the stove served faithfully for many years, but over time it began to gradually smoke. And the further, the more. In this case, the reason is the aging of the structure. Soot and ash gradually accumulate in the chimney and narrow the cross section. It is possible that the internal masonry of the chimney collapsed. Depressurization of the masonry also happens, that is, cracks appear in the walls, hog or chimney.

To eliminate this cause, you can clean the oven yourself. It is necessary to remove soot in all accessible places, free the chimney from collapsed masonry elements, seal all the cracks that led to depressurization of the furnace with furnace mortar. If all the measures taken did not restore traction, then you can not do without the help of a qualified craftsman. He will professionally inspect the stove and chimney and find a way to eliminate the defect.

Installing the deflector

Once installed, the deflector is bolted to the roof to prevent it from being blown away by the wind.

A home-made and purchased model is assembled into a finished product below, before being mounted on a pipe. The aerodynamic structure is bolted to a round metal, asbestos pipe, usually 3 holes are made in the pipe for this. If there is a slight play, a wrapping collar is used.

An adapter is used for mounting the deflector in a brick rectangular or square tube sections. The device is tested after installation. The spark arrester is made independently from thin metal mesh or sheet of stainless steel.

Rotary damper device for the chimney of a sauna stove

An important role in regulating the traction force is played by the gate device, which is a special horizontal plate, which, due to its position, increases or decreases the cross section of the chimney. There is a small hole in this plate, which does not allow the damper to completely seal the chimney. This is necessary to comply with fire safety regulations. Often a horizontal damper is mounted in brick ovens, but can also be installed in steel chimneys. Turning, chimney damper is a plate that is attached along the axis. Its adjustment is made by turning. The only drawback is that welding burns occur at the rotary gate, and such an unpleasant phenomenon has recently been observed very often.

An important role in regulating the traction force is played by the gate device, which is a special horizontal plate, which, due to its position, increases or decreases the cross section of the chimney. There is a small hole in this plate, which does not allow the damper to completely seal the chimney. This is necessary to comply with fire safety regulations. Often a horizontal damper is mounted in brick ovens, but can also be installed in steel chimneys. Turning, chimney damper is a plate that is attached along the axis. Its adjustment is made by turning. The only drawback is that welding burns occur at the rotary gate, and such an unpleasant phenomenon has recently been observed very often.

Both types of damper have certain differences: a chimney damper, i.e. a horizontal damper, allows you to adjust the flow area, and the throttle only shows whether the chimney is open or closed. In extreme cases, you can fix with a chain.

In order to choose the right damper for the chimney, you need to decide on the type of furnace and take into account some more features. The damper is installed on all types of furnaces, except for some new models, where the combustion process is already being adjusted by controlling the supply of fresh air, for which a deflector is used. In a gas stove, it is recommended to use a rotary damper, which can completely eliminate the risk of completely closing the chimney, and the flame will not accidentally jump out through the ash pan.If, nevertheless, a damper is used, then it is necessary to ensure that there is always a gap of at least 30-40% of the cross-sectional area of the chimney. Rotary dampers for a bath stove with intermittent action should not be installed, because the damper always allows steam to pass in the closed state when it is supplied. But there is an opinion that when the rotary gate is in the open position, then the pipe located below is quite difficult to clean afterwards.

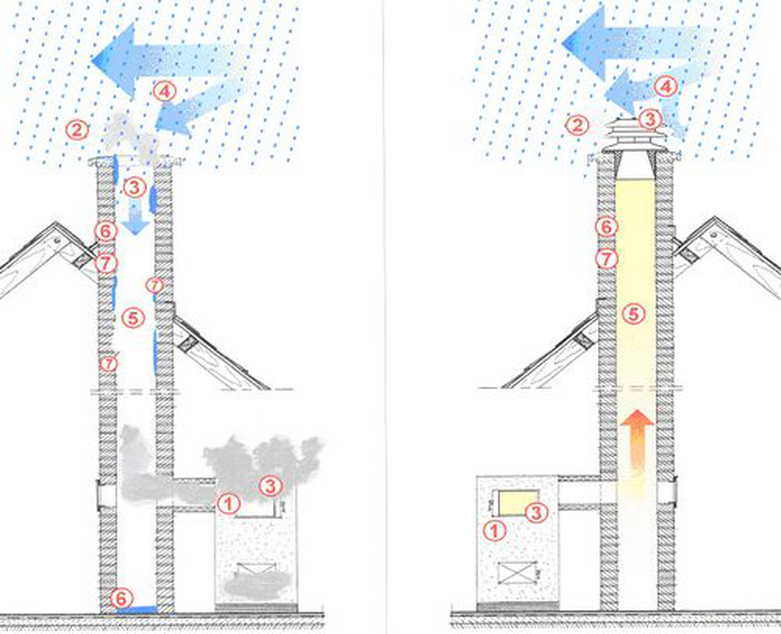

Reverse thrust elimination

In some cases, when the reverse draft is in the chimney, elimination can be done by hand.

- This applies to cleaning the chimney from soot and removing foreign objects. You will need a ruff and a weight with a cable.

- If there is a lack of air, you need to open the window for 10 minutes to ventilate.

- Chimneys in the outer wall or remote need to be insulated.

- Sometimes in wet weather or after a long break in the operation of the heater, it is enough to burn a piece of newspaper in the firebox to resume traction.

A good means of eliminating the possibility of reverse thrust is the use of various devices. These can be gate valves, deflectors (pictured), chimney weathercocks, smoke fans.

The deflector is always available for sale. The price ranges from 550 to 3800 rubles. The manufacturer provides instructions for use.

Safe and efficient operation of heating units is possible if there is draft in the chimney. At the first sign of reverse thrust formation, it is necessary to check chimney and ventilation ducts. The entry of combustion products into the home is fraught with health risks and can threaten people's lives.

Stabilizers

During the existence of heating, many devices have been invented that improve the flow of gases in the chimney (see photo):

rotary turbines - consists of a nozzle and a housing mounted on the chimney head. Under the influence of wind, the nozzle rotates and creates an increase in the flow of exhaust gases due to the created rarefaction;

electric smoke exhauster, or smoke fan. With forced draft, you don’t have to worry about tipping over - this is an almost ideal smoke outflow regulator, however, maintenance of the device on the roof is quite difficult, and the installation of such a design should be calculated even at the drawing stage;

all kinds of caps are also able to slightly improve the outflow;

chimney weathercocks, often mounted on wood-burning stoves.

Gate manipulations

Shiber - a damper that affects the strength and direction of thrust. Usually, during the construction of a stove or fireplace, two gates are installed. One is in the chimney, the second is in the stove or in its door. "Play" with the position of these flaps, often this increases traction, and the problem is solved by itself.

Using a draft regulator (stabilizer)

This is a special device that creates air currents in the chimney and controls their strength. It stabilizes draft and, among other things, contributes to fuel economy, and also prevents combustion products from entering the room.

Ventilation system

Often a situation arises when everything is fine with the chimney, but there is still a reverse draft in the chimney, what to do then? What is the reason? Most likely, the matter is in the ventilation system, which works according to certain natural patterns.

The density of warm air flows is significantly lower than the cold masses, so warm air rushes up.If at this time the doors or windows are open in the room, then the air masses will go exactly into the open openings, and not into the chimney of the heater. Therefore, you need to ensure that when you turn on the device, all doors and windows to the street are closed.

Also, the internal architecture of the structure has a huge impact on traction. If there are many doors or windows in the building, there is a passage to a balcony or stairs to another level, then a draft will certainly occur. Therefore, it is impossible to keep open windows and doors located above the level of the combustion chamber.

It often happens that all openings are locked, but when the heating device is kindled, the low-pressure zones attract fresh air flows from the chimney, and as a result, the thrust is overturned. You can solve the problem by creating the necessary air circulation.

For this you need:

- install in-wall supply valves;

- equip windows with supply valves;

- install a forced ventilation device in the window glass;

- slightly open the door, window or window.

The implementation of one of the proposed measures will lead to a decrease in atmospheric pressure in the room and, accordingly, the disappearance of reverse thrust.

If a gas column is used as a heating device, then there are some nuances:

- the combustion chamber draws air flows from the room;

- oxygen deficiency begins to be felt in a fairly short time;

- air from the chimney will begin to flow back, which will lead to the extinction of the flame and smoke.

In this case, it is worth carefully checking the efficiency of the ventilation system.

Control and measurement of rarefaction in the chimney

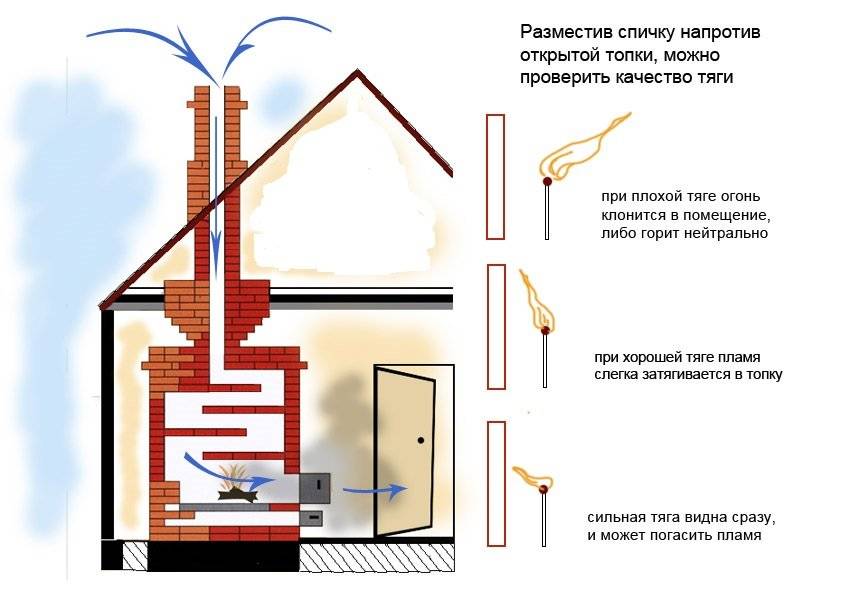

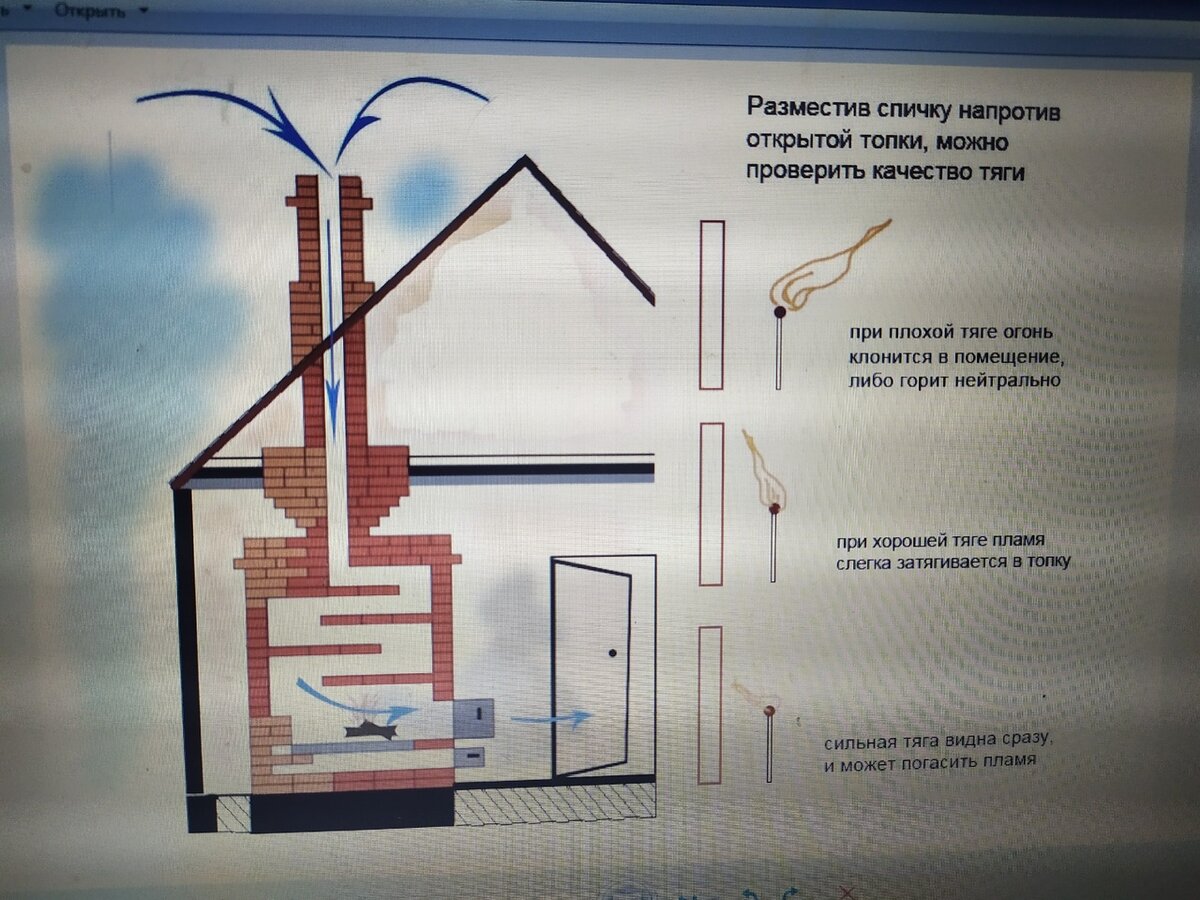

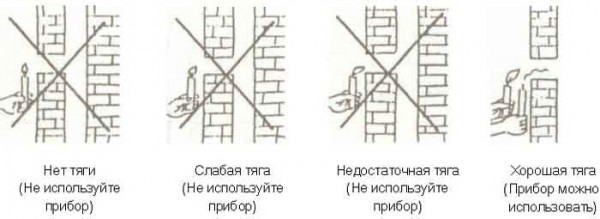

The usual way to check if the chimney is functioning is to substitute a lit match or lighter to the chimney channel. Sometimes a piece of toilet paper and a smoking cigarette are used instead.

If a light or smoke is directed inside the chimney, there is a rarefaction of the air. If the flame is completely motionless, then this means that there is no thrust.

Too much traction can even extinguish a burning match

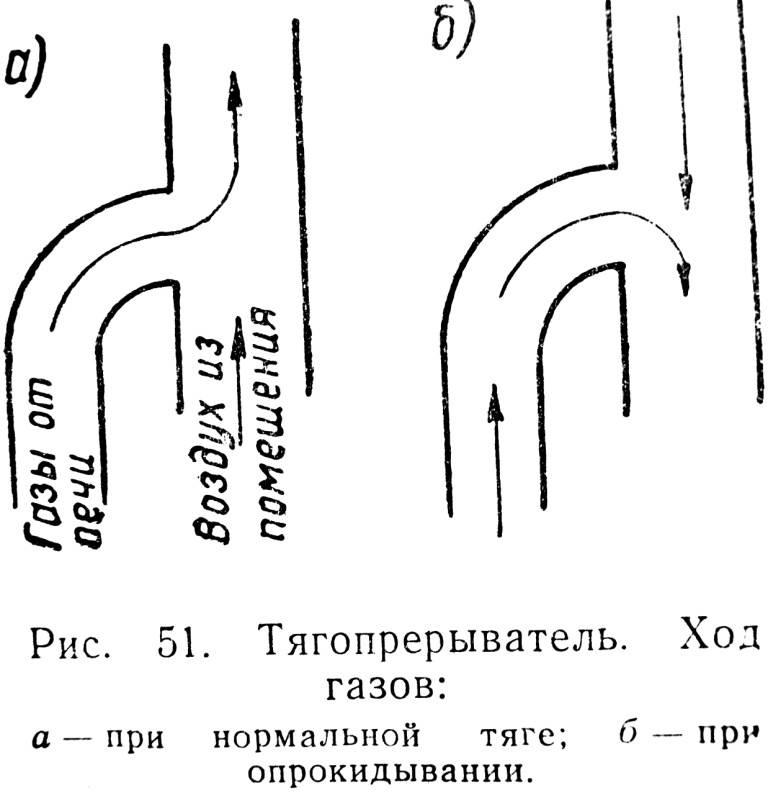

If a light or smoke is directed away from the channel, that is, into the house, it is recognized that there is rarefaction of the air, but it is violated. This phenomenon is called overturned draft, which adversely affects the operation of the heating system.

The normal course of gases when the thrust is overturned is violated

Thrust calculation

Since the thrust is created due to the pressure difference, it is calculated by the formula ∆P = C∙a∙h (1/T0 - 1/Ti), where ∆P is the pressure difference in Pa, a is the atmospheric pressure in Pa, h is the height of the pipe in metres, T0 is the absolute outside temperature in K, and Ti is the absolute inside temperature in K. C is a coefficient which is assumed to be 0.0342 in the calculations.

Depending on the obtained value of ΔP, the following levels of air rarefaction are distinguished:

- less than 2 Pa - 1st, 2nd or 3rd;

- exactly 2 Pa - 4th;

- more than 2 Pa - 5th or 6th.

Trying to find out for yourself what the traction force is is not worth it. It is better to use heating equipment so that there is no need to check according to formulas and devices.

Traction test

Installing a deflector on the pipe allows you to increase air circulation and increase traction

The anemometer device determines the traction force when the smoke moves at a speed of 1 m / s or more.In the off-season, the device shows unreliable results due to the small difference in the temperatures of the external and internal environment and the low flow rate. The advanced gas analyzer measures tractive effort in pascals (Pa) and is accurate but expensive. A reading of 10 - 20 Pa is considered sufficient.

The color of the fire in the furnace shows the traction force:

- yellow and golden tongues indicate a normal flow rate;

- white flame and hum indicate that the thrust is excessive;

- dark shades indicate insufficient speed.

Why is it smoking

Smoke in the bath is not only unpleasant. It is also very dangerous. Any schoolchild knows: in the process of combustion, carbon monoxide is formed - a strong toxic substance. So you need to carefully ensure that in the room where you like to have a good time, only steam and heat remain, and not smoke at all.

So, for what reason does the stove smoke in the bath and what to do about it?

- The simplest reason (it may arise if you did not design and install the bath and stove equipment) is that the stove does not “pull” due to the too small inner diameter of the chimney. If this indicator is less than 120 mm. - change the pipe.

- This reason is more difficult to eliminate (and most likely, you will not be able to master the process yourself), but you still have to do something: if a metal sauna stove smokes at the first fire, it is highly likely that you incorrectly installed the unit or made errors in the design

- However, don't panic! Perhaps the point is not in the design of the furnace, but in the pipe, and then it will be relatively easy to correct the situation.

Checking and determining thrust

These two processes are necessary for those people who want to optimize the heat output from burning wood and minimize heat loss. Such owners must use special devices.

In the past, its strength was determined using an anemometer. It made it possible to check the thrust force when the air moved in the chimney at a speed greater than 1 m / s. Today there are better devices. They make very accurate calculations. True, they cost a lot.

Also, the calculation of the speed of movement of carbon monoxide can be carried out by making an assessment of the flame. So, you can check if the traction is normal or very strong.

In addition to these methods, there are folk ones. They involve the use of a sheet of paper or a match. The first is brought to the chimney. The position of the paper must be perpendicular to the channel. If the sheet begins to deviate from its original position, then air moves through the chimney. The amount of deflection depends on the speed of air movement. The calculation will not be very accurate, however, sufficient for making further decisions.

A white flame indicates excessive speed. There is also noise coming from the chimney. If a dark red color is visible, then the analyzed indicator is weaker than the norm. A golden fire indicates good traction.

The match is lit and blown out. Then they quickly move it into the furnace and observe the direction of smoke movement. This check is very simple.

Solving the problem with reverse thrust

Now you need to check the traction. You can use a special device that measures the speed of air flow - an anemometer. Often there is no such device, then you can use folk methods, for example, bring a burning match or a sheet of paper and see the direction of air movement.Besides, draft quality can be determined by the color of the flame in the furnace:

- white or very light color - a sign of insufficient traction;

- if the flame is of an even golden color, the draft is normal;

- dark shades of orange color - insufficient.

If the stove is inside the house, the draft will be better than if it is located at the outer wall.

Basic ways to solve problems with traction:

- Improving the quality of the chimney.

First of all, to improve the draft of the chimney. To do this, it is necessary to check the entire channel for soot sticking and leaks in the joints. Everything needs to be cleaned and fixed. If this does not help, move on to the next method.

- Installing a deflector at the end of the pipe.

The method is good when the air currents around the pipe are constant and strong. The deflector perfectly increases traction, however, without wind, the deflector is useless. In some cases, it can even reduce thrust due to the creation of additional resistance to the movement of air from the channel.

- Chimney extension.

Simple and fast solution. The main thing is the correct calculation of the location of the channel relative to the ridge of the building, as well as an analysis of the likelihood of air flows at the installation site. After all, even a chimney 10 meters long, installed in the wrong place, will not solve the problem.

- Installing the draft regulator.

The device compensates for the lack or excess of internal pressure in the channel relative to the external one. The regulator allows you to maintain the optimum temperature in the furnace by controlling the air supply to the furnace. With it, the air flow rate is constant, which means that the thrust is stable and does not depend on external factors (wind, pressure changes, etc.).

Another important concept is reciprocity.It occurs when the resistance in the chimneys is too high (due to the proximity of the ridge of the building, standing next to tall buildings, etc.). In this case, the air from the fire goes along the path of least resistance, that is, into the room, that is, the thrust we need disappears altogether.

There is also the term “thrust overturning” - moving air changes its direction only for a certain time. The first signs of a possibly imminent draft tipping are the formation of a large amount of smoke during combustion, which, when the stove is opened, bursts into the room. This means that the thrust has deteriorated, which means that it may even become reversed.

In this case, the air from the fire goes along the path of least resistance, that is, into the room, that is, the thrust we need disappears altogether. There is also the term “thrust overturning” - moving air changes its direction only for a certain time. The first signs of a possibly imminent draft tipping are the formation of a large amount of smoke during combustion, which, when the stove is opened, bursts into the room. This means that the thrust has worsened, which means that it can completely become reversed.

The methods for eliminating reverse thrust are the same as for improving thrust. In fact, reverse draft is the extreme and most unpleasant degree of bad draft, the smoke in the room is unpleasant and even dangerous. Therefore, in a critical case, it makes sense to turn to specialists. They will quickly analyze all the factors and fix the problem.

The safety and efficiency of stove heating depends on sufficient draft in the chimney. When the first even minor problems are detected, it is necessary to conduct a full check of the system to identify the causes of problems and find ways to increase traction. Most repair and restoration work you can do it yourself, but if there is no self-confidence, you need to invite a specialist.

Related video: