- Benefits of using square or rectangular pipes

- PND water pipe: solid advantages.

- Ease of installation.

- biological stability.

- Long service life.

- Metal-plastic pipeline

- How to connect to a common water main

- Bending with a pipe bender

- How to do?

- The use of steel pipes for water supply

- What are the best pipes for plumbing in a private house - an overview of options

- metal-plastic

- Plumbing from polypropylene materials

- Methods for connecting HDPE pipes

- Butt welding

- Electrofusion

- Connection with compression fittings

- Socket connection

- Which way is better

- How to choose flexible pipes

- Types of steel pipes

- Diameter as the main parameter of the plumbing system

- Production of thick-walled metal square pipes

- Where to buy a HDPE water pipe?

- Connection of galvanized water pipes

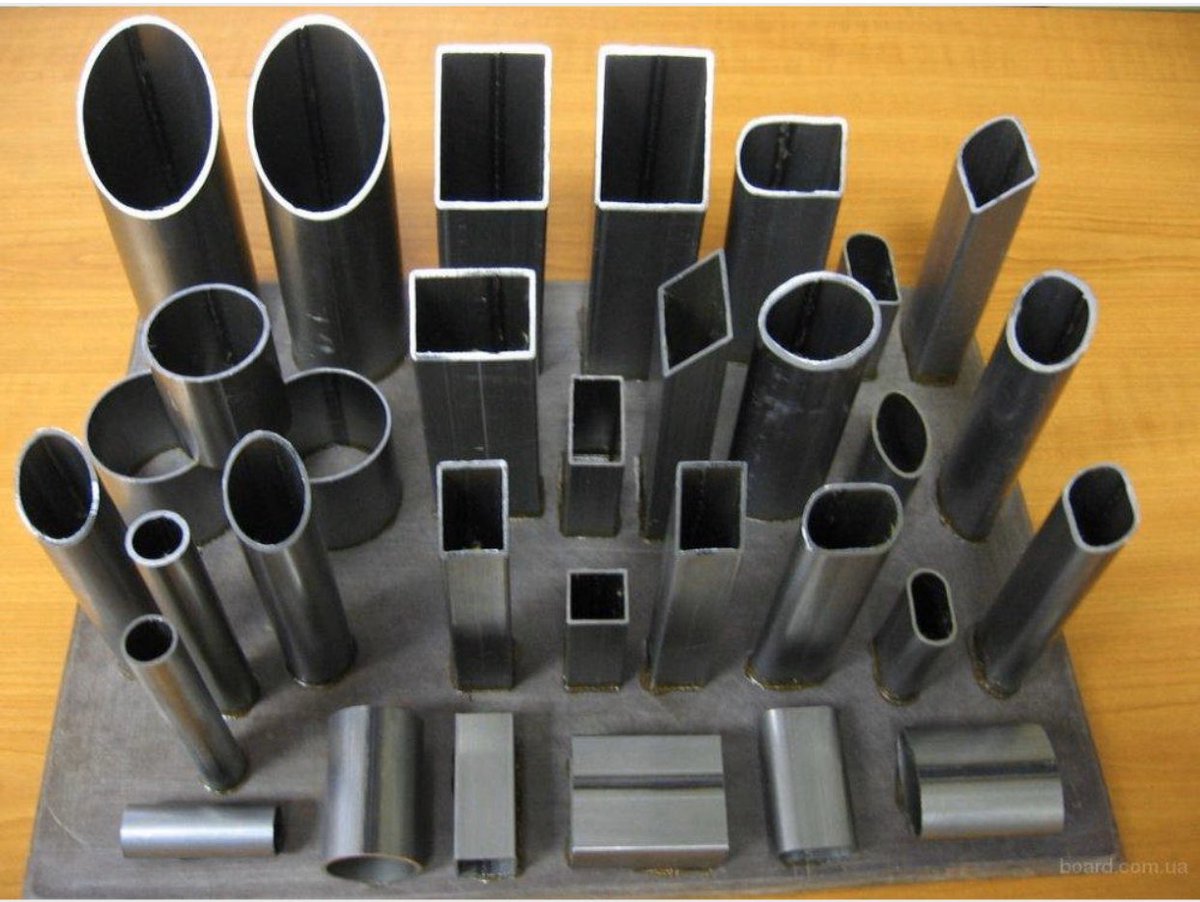

Benefits of using square or rectangular pipes

Scheme of a profile square pipe.

Such a wide distribution is quite understandable, because square and rectangular pipes have sufficient structural rigidity and strength, while their weight and material consumption compare favorably with a metal bar.Suffice it to say that the use of shaped pipes of square and rectangular cross-section makes it possible to reduce the total metal consumption of any structure by a quarter, which significantly reduces its cost. Moreover, the strength of the structure is easy to adjust, using rectangular pipes with different wall thicknesses during installation.

Even compared to ordinary round pipe, rectangular and square section has a logistical advantage, since products of this shape are easy to store and are more compact in transportation, occupying a minimum of volume.

It is also important that it is square and rectangular pipes that are the least laborious for further finishing (priming, painting), which can significantly reduce the amount of consumable material and processing time.

PND water pipe: solid advantages.

The availability of HDPE pipes in comparison with metal counterparts makes them indispensable when equipping residential buildings and private facilities. The products are light weight and easy to transport. Resistant to aggressive environments (alkaline, acidic, salty). True, they can be damaged by contact with nitric acid. They also have other advantages:

Ease of installation.

Their underground installation does not require the use of insulation, protective covers. But when laying on the ground, it is necessary to provide protection from exposure to UV rays.

biological stability.

High ambient humidity will not lead to rotting of pipes or accumulation of microorganisms on their inner and outer walls.

Long service life.

Due to the absence of special maintenance requirements, a HDPE water pipe, subject to correct operating conditions, can properly perform its functions for more than 50 years.Unlike metal and concrete counterparts, they are minimally affected by external influences.

An important advantage of the products is their simple assembly. Connection by welding the ends of pipes or fixing with fittings is carried out quickly. A similar assembly of metal or concrete pipes takes several times longer.

Metal-plastic pipeline

metal-plastic pipes for water supply consist of a thin metal pipe, which is covered with layers of plastics inside and out.

The design of the metal-plastic pipe

Advantages of plastic pipes:

- Quick and easy installation of metal-plastic pipes.

- Good flexibility and ductility.

- Small linear expansion.

- Tolerates high and low temperatures well.

- Ease of repair.

- Small diameter.

Cons of metal-plastic pipes:

- The high cost of fittings and, accordingly, repairs.

- The need for constant maintenance.

- Fear of blows.

- Susceptibility to destruction from ultraviolet radiation, which is why their external use is not always aesthetically pleasing.

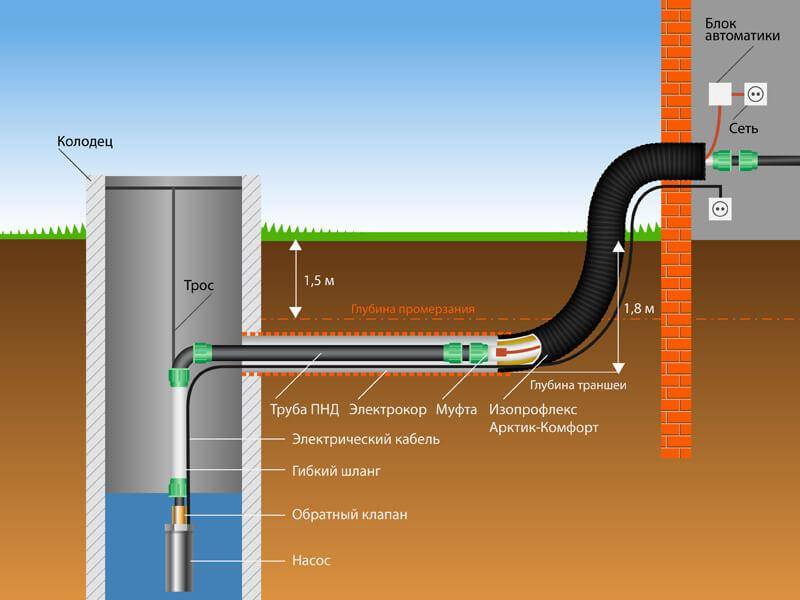

How to connect to a common water main

Before crashing into a water pipe under high fluid pressure, familiarize yourself with three technology options that vary depending on the material of which the pipes are made (they can be polymer (PP), cast iron, galvanized steel).

For a polymer central route, a tie-in into a pressurized water pipe looks like this:

- A trench no less than one and a half meters in size is excavated, the area where the work will be done is exposed, and a trench is being dug from it to the house;

- At the end of the earthmoving work, a saddle is prepared for tapping into the water supply system - this is a collapsible crimp collar that looks like a tee. The straight outlets of the saddle are divided in half, and a valve is installed on the vertical outlet to shut off the pressure. A pipe is drilled through the tap with a special nozzle for tie-in. The most reliable saddle scheme is collapsible welded. It is easy to divide such a clamp into two halves, assemble it over the tie-in section, and weld it to the main route. Thus, the clamp for tapping into the water supply is welded into the body, providing a reliable and absolutely hermetic water supply to the dwelling;

- The pipe is drilled with a conventional drill and an electric drill. Instead of a drill, you can use a crown, but the result is important, not the tool;

- A through hole is drilled until a jet of water comes out of it, after which the drill is removed and the valve is closed. For safety reasons, at the end of the drilling process, the electric tool is replaced with a hand drill or a brace. If you drill a hole not with a drill, but with a crown, then it will automatically ensure the tightness of the drilling site. In addition to these options, there is a solution using a special cutter, which is rotated by an adjustable wrench or an external brace;

- The last stage of the tie-in to the central water supply is the establishment of your own water supply, laid in a trench in advance, and connecting it to the central route with an American compression coupling.

For complete control of the insertion point, it is advisable to equip a revision above it - a well with a hatch. The well is equipped as standard: a gravel-sand cushion is made at the bottom, reinforced concrete rings are lowered into the trench, or the walls are laid out with bricks.Thus, even in winter it will be possible to shut off the water supply if it is necessary to repair it in the house.

For a central water supply pipe made of cast iron, a saddle tie-in looks like this:

- To tap into a cast-iron pipe, it must first be thoroughly cleaned of corrosion. At the very place of drilling, the top layer of cast iron is removed by a grinder by 1-1.5 mm;

- The saddle is built into the pipeline in the same way as in the first paragraph, but to completely seal the joint between the pipe and the crimp, a rubber seal is laid;

- At a further stage, a shut-off valve is attached to the clamp nozzle - a valve through which the cutting tool is inserted.

- Next, the body of the cast iron pipe is drilled, and do not forget about the need to cool the cut site, as well as change the crowns in a timely manner.

- A hole is drilled for tapping into the main water supply with a hard-alloy victorious or diamond crown;

- The last step is the same: the crown is removed, the valve is closed, the insertion point is scalded with special electrodes.

A steel pipe is slightly more ductile than a cast-iron pipe, so the tie-in of the pipes is carried out according to a technique similar to the solution with a polymer line, but the saddle is not used, and before making a tie-in into a galvanized steel water pipeline, the following steps are implemented:

- The pipe is exposed and cleaned;

- A branch pipe of the same material as the main pipe is immediately welded onto the pipe;

- A shut-off valve is welded or screwed onto the pipe;

- The body of the main pipe is drilled through the valve - first with an electric drill, the last millimeters - with a hand tool;

- Connect your water supply to the valve and the pressurized tie-in is ready.

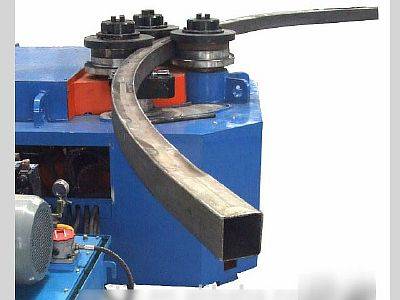

Bending with a pipe bender

If large-diameter professional pipes are used for the manufacture of a greenhouse, then it will be difficult to bend it manually. We suggest that you familiarize yourself with the instructions on how to make a standard pipe bender yourself, its design is a drive wheel (it moves along the edges bending the pipe at the right angle), a station, a conveyor and clamping elements.

Pipe bender happens:

- Manual - designed for a small amount of work. The workpiece is placed in the conveyor and clamped by a roller. The wheel is rotated by the handle, as a result, bending occurs.

- Electric - the equipment is recommended for professional pipes with a large thickness. The device is powered by electricity, and the wheel rotates electrically, so you do not have to waste your strength. The principle of operation is similar to the previous one, the profile is refueled into the conveyor, it, passing through the pressure zone, bends.

When using this device, the corners inside and outside the pipe experience equal pressure, so the bend is of high quality and does not burst.

How to do?

In the best case, the strapping belt is mounted immediately after the supports are installed. This recommendation is due to the fact that during the service, the marking of the piles shifts under the influence of the weight of the house and the movements of the soil masses.

When the supports are installed, they proceed directly to the installation of the grillage from the pipe:

- The ends of the metal piles are cut off at the design height.

- Heads are welded to the tops of all beams.

- Profiled pipes are assembled between piles protruding above the ground into a single structure by electric arc welding.

- Attach the harness to the piles with bolts and rivets.

- Clean all seams and apply a layer of anti-corrosion coating.

Other methods of fastening are also used - rivets and bolts. However, each technology necessarily provides for the cleaning of seams, followed by application with a special composition to protect against corrosion.

Tying for piles can be done in two ways:

- pipes are mounted around the perimeter of the outer base in several rows below the heads;

- the jibs are erected diagonally between the piles crosswise or obliquely.

An additional advantage of the first method is that the beams can be used as the basis for a future decorative plinth that improves the exterior of the house. After the strapping is installed, finishing panels are mounted on it, imitating facade masonry.

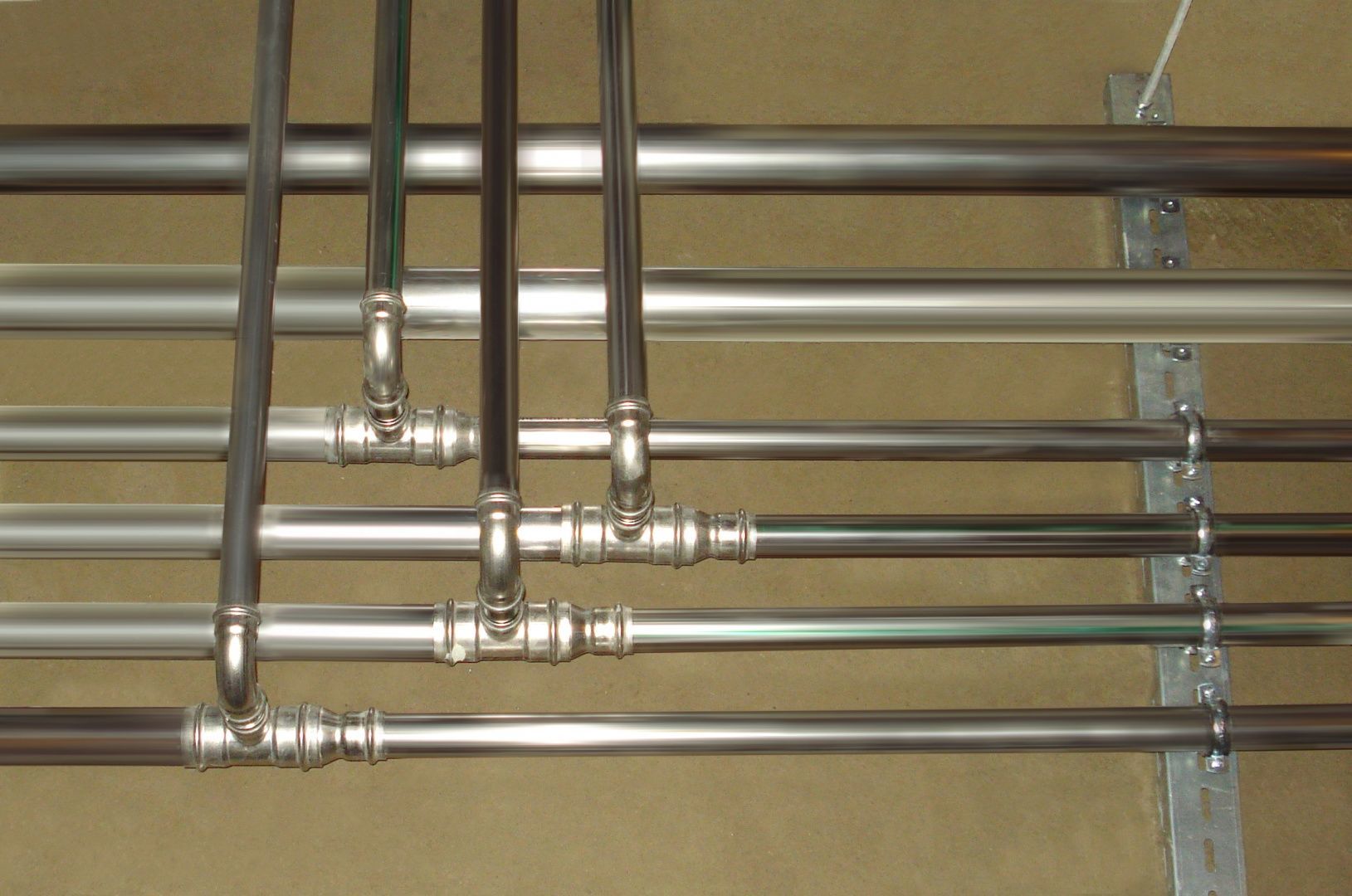

The use of steel pipes for water supply

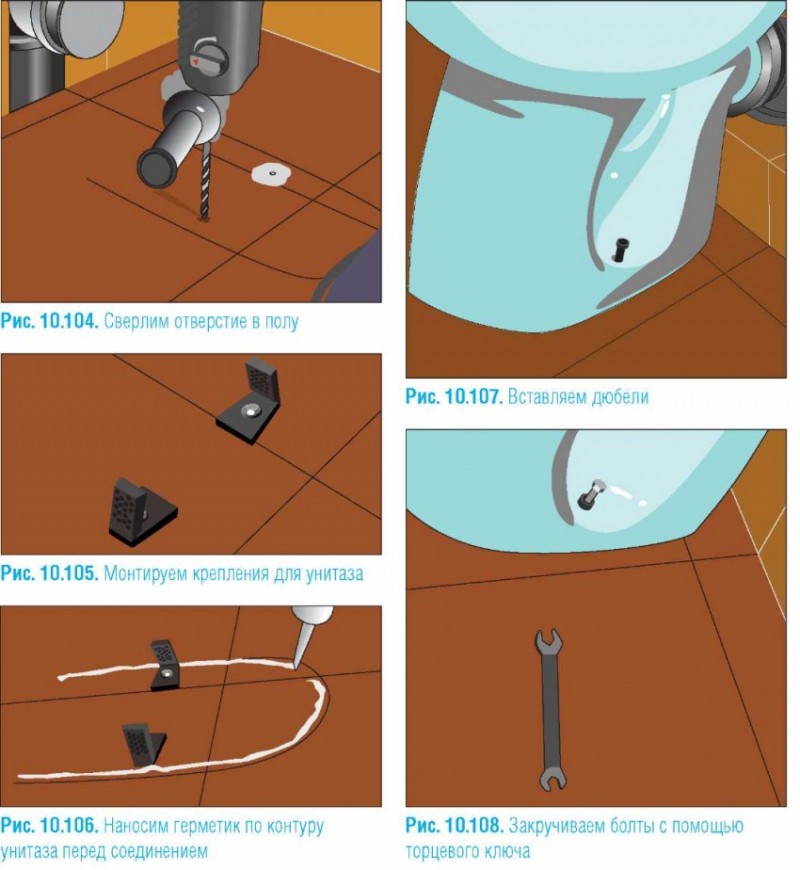

Steel pipes are divided, depending on their coating, into galvanized (galvanized inside and outside) and uncoated. Steel pipes for water supply are mounted by means of threaded connections using tees, spurs, couplings, or by welding.

Steel water pipes

Advantages of steel pipes:

- High degree of strength and rigidity.

- Durability.

Steel pipes have a number of significant disadvantages:

- High labor intensity of installation.

- The need for very careful sealing of seams.

- Rust on pipes.

- Tendency to form on the walls of inorganic and organic deposits.

If a galvanized pipe is chosen for water supply, then experts recommend sealing the threaded connections during their installation with flax soaked in paint or drying oil.The use of synthetic materials for sealing threads is strongly discouraged.

What are the best pipes for plumbing in a private house - an overview of options

To live in a private house, it is impossible to do with just one pump that will pump water from a well or well. The water supply system must be organized in such a way that the residents are provided with the necessary amount of water. Pipes for water supply in a private house are selected from a material that is resistant to corrosion and to the loads that occur with high water pressure.

When solving the problem, which pipes for water supply are better, it must be remembered that the water supply system must be functional, durable, reliable, and have a long service life. And such that its undesirable repair did not hit the pocket too hard.

To decide which pipes are best for plumbing in a private house, the following factors must be considered:

- chemical constituents of water;

- operating conditions of pipelines;

- working pressure inside the pipes;

- route length.

A few years ago, the choice was small and was reduced only to the installation of cast-iron or steel pipelines. Today, the construction market offers various models of pipes for plumbing in a private house - which ones are better to choose? We will talk about this in this article, as well as go over the technical characteristics of materials and installation methods for several options.

metal-plastic

Manufacturers of metal-plastic pipes guarantee the quality work of their products for a period of 25 years or more. Ease of installation is the main feature of these pipelines.The plumbing system made of this material is essentially a constructor, which is assembled quickly and easily with the help of connecting fittings. The unique design has special reliability and durability.

The advantages that distinguish metal-plastic pipes from other products of this type:

The photo shows the structure of metal-plastic pipes

- do not give in to corrosion;

- greater resistance to high and low temperatures;

- high plasticity of the material, allowing the installation of the most complex structures;

- there is no accumulation and deposition of mineral salts inside the pipelines;

- ease of installation that does not require special tools and skills (applies to installation with collapsible compression fittings, press tongs are required for press fittings);

- aesthetic appearance;

- affordable cost.

Attention: When purchasing metal-plastic water pipes, pay attention to the presence of a certificate that allows these products to be used for transporting drinking water.

The inner diameter of metal-plastic pipes is relatively small, but the water flow does not become less. In addition, these products can easily withstand high water pressure.

Do-it-yourself installation of a metal-plastic pipe for a water supply system in a private house is greatly simplified due to the light weight of the products. By the way, if necessary, the metal-plastic plumbing system can be dismantled, and then reassembled (when using collet fittings). The reliability and quality of the system will not deteriorate from this.

How and with the help of what water treatment is organized for private houses, read in a separate material.

And how to make a shower in the country with our own hands, we told in another article on the site.The choice of location, materials and sequence of work.

Plumbing from polypropylene materials

Recently, polypropylene water pipes are becoming more and more popular.

For operation under certain conditions, polypropylene pipes are produced and classified under the following markings:

- for cold water - PN10;

- for hot (not more than 60 degrees) water, as well as cold - PN16;

- for cold and hot water (up to 95 degrees) - PN20;

- for heating systems, hot and cold water - PN25.

What pipes are best for plumbing underground? There can be only one answer - polypropylene. Due to its resistance to corrosion, polypropylene pipes can also be installed in rooms with high humidity and in aggressive environments. Their non-separable sealed connections are created by soldering with a special soldering iron, which does not require special skills to work with.

An important advantage of polypropylene pipes is their perfectly smooth inner surface, which eliminates the formation of fatty deposits on their walls. Since these products began to be produced less than a century ago, it is difficult to say exactly about the duration of their operational period.

Estimated time is about 50 years.

Methods for connecting HDPE pipes

The finished project presents a plan of the backbone network: length, turns, connections. At the design stage, even before the purchase of materials, they determine the method of attaching the sections to each other and form the final list of equipment and materials, calculate the estimated cost of laying.

Butt welding

For a strong, reliable HDPE connection, butt welding is used. The method is convenient and inexpensive, except for the cost of the welding machine. On average, the price of such equipment is from 180 thousand to 2 million rubles. If you do not have a goal to purchase a machine for welding HDPE pipes, it is better to entrust the joining of sections to a specialized team.

If you are planning to lay the plumbing yourself, I will tell you how to do it. The welding machine consists of the following elements:

- centralizer;

- hydraulic unit;

- welding mirror;

- trimmer.

Assembly consists of the following steps:

- Fix the HDPE pipes in the centralizer on both sides with fixing nuts.

- A manual with a formula is supplied with the welding machine, through which the pressure is calculated for a specific pipe diameter. Having learned the necessary parameters, set them in the hydraulic unit.

- Degrease the edges of the HDPE pipe with alcohol wipes.

- Align the joints with a trimmer so that there are no burrs.

- Heating the welding mirror, install it between the pipes. Apply pressure to the centralizer until the ends melt by 1 centimeter. Reset the pressure to zero and wait the time indicated in the instructions.

- Remove the heating element, connect the pipes.

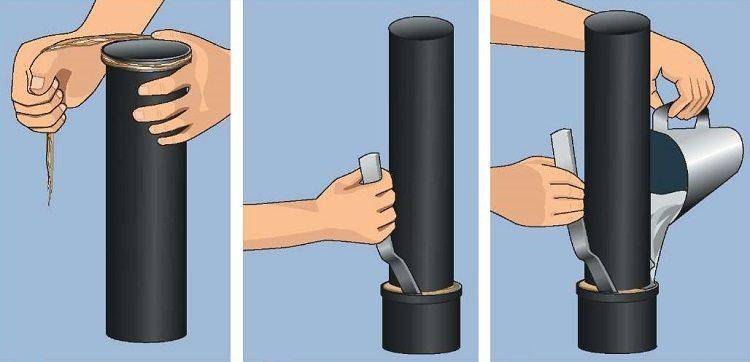

Electrofusion

The method of electrofusion connection is suitable for repairing an existing HDPE plumbing. But it can also be used to weld a new system in hard-to-reach places. You will need an electrofusion welding machine and couplings. The cost of couplings depends on the diameter, starts from 200 rubles.

Before starting work, they try on the coupling to pipe segments and make serifs with a white marker.From the point of cut to the notch, the pipe is cleaned with a scraper from the protective oxidative coating and degreased.

The electrocoupling is a sleeve with grooves for the contacts of the welding machine. A barcode is glued on the coupling body, which is read by a laser pointer included in the device. If for some reason the reading did not occur, then the data can be taken from the coupling passport. The barcode is needed so that the machine automatically selects the welding mode.

Having connected the pipes in the coupling, connect the contacts. On the apparatus give the command "start". The current is supplied to the mains located on the inside of the coupling. The pipe starts to melt. The process is considered completed when beacons appear on the surface of the sleeve and the device gives a signal.

Connection with compression fittings

Less reliable methods include connection with fittings. Leaks can form at the joints, so it is better to use this method for outdoor plumbing systems of small diameters.

To connect the water supply from HDPE pipes with compression fittings, no additional equipment is required. It is allowed to connect only HDPE pipes of the same diameter, grade and wall thickness by welding and an electric coupling, and the variety in fitting models allows you to assemble elements of different sections.

Unscrew the blue clamping nut from the fitting, put it on the pipe. A white ring is attached next. The cleaned and degreased pipe is inserted into the fitting, the ring and nut are tightened, and tightly tightened.

Socket connection

Before couplings and fittings became available in the construction markets, the gasket pipeline, the connection method was widely used into the socketThe technology consists in arranging pipes of different diameters: one pipe is inserted into another and the joint is sealed. For sealing, a rubberized sleeve is used, previously put on a wide section of the pipe.

Which way is better

For underground plumbing it is better to use the butt welding method. Such a connection guarantees a long operation of the system without leakage. The pipe welding process is fast, one person can handle the job.

How to choose flexible pipes

Turning to a specialized store for bending tubes, you need to rely on the following selection options:

Product material. For the street and cold unheated rooms, metal-plastic, steel, PVC are suitable. If the pipeline section will be additionally subjected to mechanical stress, it is better to choose stainless steel. For interior work, it is desirable to use polypropylene.

Tube section. Must match the diameter of the main pipeline.

Material for the manufacture of the main line. It is desirable that the flexible pipe and the rest of the plumbing be made from the same polymer or metal. This will eliminate uneven linear expansion of the network under the influence of temperature fluctuations.

Purpose of the highway

It is necessary to pay attention to the permissible temperature indicators for the transported medium for each type of flexible elements.

Master skills. Easier to install PVC and polypropylene pipes

Steel and metal-plastic require more experienced actions.

The budget is not the last criterion when buying plumbing elements. Here the master is guided by his capabilities.

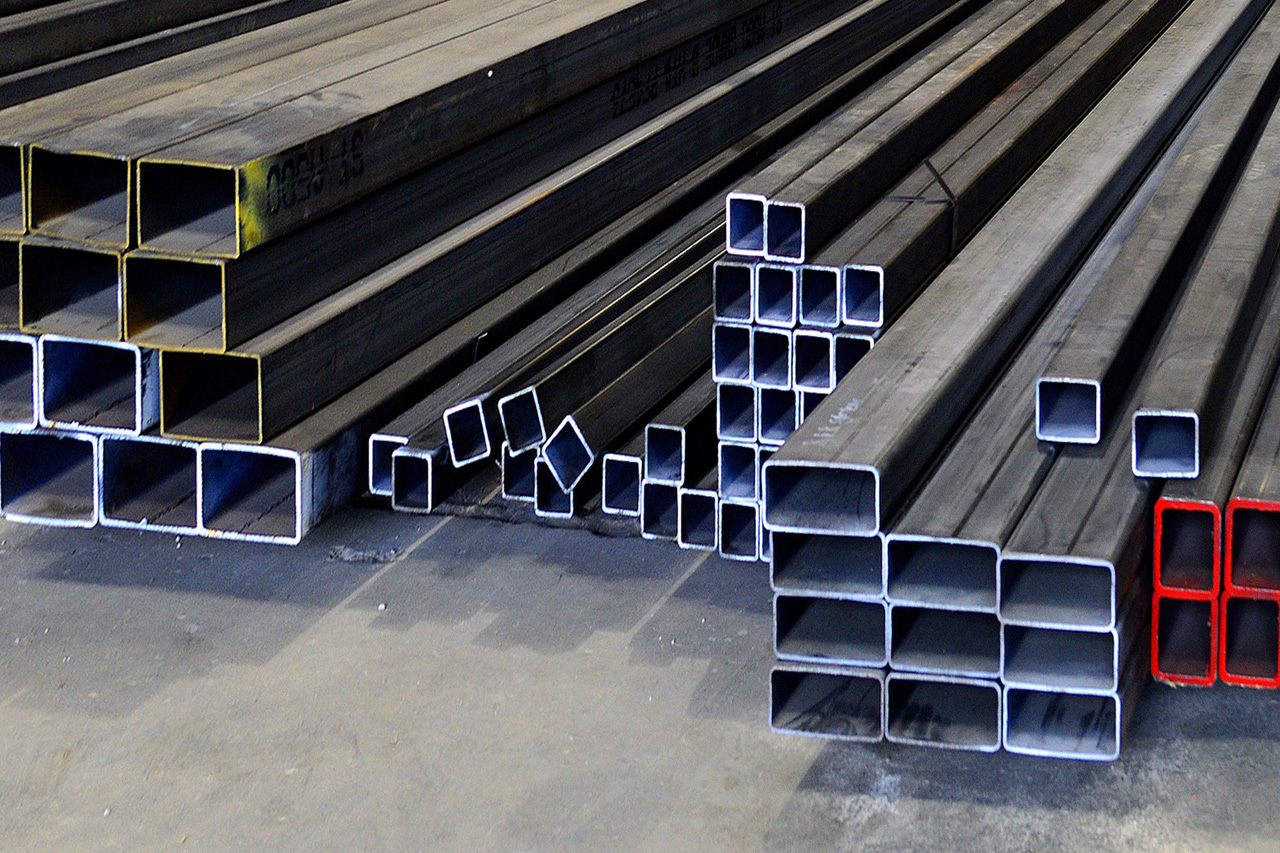

Types of steel pipes

Types of steel pipes for water supply are provided below.The most common classification is the division according to the specifics of manufacture, thus, they are divided into:

Types of steel pipes for water supply are provided below.The most common classification is the division according to the specifics of manufacture, thus, they are divided into:

- Galvanized. This category consists of products that have been finished with zinc on both sides. This protective layer greatly increases the anti-corrosion capabilities of products.

- Profile. They are made from carbon steel. These options are widely used to create buildings with increased stability and metal frames.

- Seamless. Hot-formed products are a line of pipe products that do not have a helical or longitudinal welding fastening (seam). The production technology in this case consists in finishing hot-deformed types under the influence of high temperature.

- Electrowelded. For production in this case, low-gelated and carbon steel is used. Most often in the form of a sheet or strip. Electrowelded products are widely used for laying heating networks, in the construction of other networks and structures.

- Water and gas pressure. A very significant moment for them is the ratio of the inner and outer diameter, which depends on the wall thickness. Based on the wall thickness, this type of pipe assortment is conditionally classified into: reinforced, standard and light.

The galvanized steel water pipe deserves special attention. Such a coating significantly extends the service life and reliability of the line. These products are universal and widely used in everyday life and in industry.

Compliance with the requirements of GOST becomes a solid guarantee of high anti-corrosion properties, reliability and durability.

Diameter as the main parameter of the plumbing system

Many are wondering how to choose the diameter of the pipe due to the fact that it is responsible for an important parameter of the system. This is the capacity of the pipeline. The choice and installation of system elements directly depends on it. A pipe with a cross section of 25 mm passes - 30 liters per minute. If the pipe has a diameter of 32 mm, then its throughput is 50 liters per minute

At the same time, it is worth paying attention to another important element in the water supply system. This is a mixer

Its throughput does not exceed 5 liters per minute.

It is worth correctly calculating the required size of pipes, their cross section and throughput, depending on how many devices are connected to the system, and the number of free water outlets (through mixers). Installing plumbing in a private house is different from wiring in an apartment. Your own home may have more bathrooms, more equipment that consumes water. If the calculations are not correct, the last of their output points will receive the minimum amount of water. For example, when you turn on the water in the kitchen, the water in the bath will stop flowing. To prevent this from happening, you need to be able to calculate the throughput.

Production of thick-walled metal square pipes

Thick-walled products have walls with a thickness of at least 10% of the diagonal size. In the range of reinforced metal pipes, the largest wall thickness among pipes of domestic manufacturers is 12 mm. The method of manufacturing reinforced metal pipes does not differ significantly from the principle by which thin-walled products are produced.Reinforced profile pipes are formed from thick steel sheet and are hot-rolled products.

Like thin-walled, reinforced square steel pipes are not seamless. In the case of thick-walled ones, the presence of a seam affects strength only with a deviation of 10-12%. This insignificant indicator does not impair the ability of a thick-walled rectangular structure to withstand high loads.

In the production of this type of profile pipes, the main emphasis is on reliability. Reinforced steel pipes are usually hidden among utilities, so they do not require control over the aesthetic component. Defects left after welding a seam are usually not processed, which keeps the cost of a rectangular thick-walled pipe acceptable.

Both welded and seamless square steel pipes have both a number of positive qualities and a certain number of disadvantages. The choice of metal pipes for the installation of hull structures depends on the requirements for a particular type of structure. To do this, you need to familiarize yourself with all the options that the assortment of each manufacturer offers.

Where to buy a HDPE water pipe?

So, you have decided to buy a HDPE pipe and are now looking for a reliable supplier. The choice may not be so easy. Price is the determining factor, but there are other things to consider. Since we are talking about a water pipe, a GOST certificate of conformity should be required. Sometimes, under the guise of a water pipe, they sell a technical pipe. It's pretty easy to tell the difference: on cable conduit no blue stripe. But this is if we are talking about a conscientious manufacturer. In the face of fierce competition, small businesses go to different tricks.Most often - the use of recyclables, which is prohibited by GOST for water supply. Therefore, it is highly desirable to know that the pipe manufacturer has a good reputation and binding documents. You can safely buy a HDPE pipe for water from us: the reviews of our regular partners speak for themselves. You can buy the right amount in Moscow, from a factory in the Moscow region, or order delivery to any corner of Russia. Drink water only from quality pipes!

Connection of galvanized water pipes

The connection of the galvanized pipeline is possible by welding or threading. It is obvious that the violation of the integrity of the protective layer leads to corrosion and the joints are subject to such a risk to a large extent, so the installation of these systems requires a special approach.

The threaded connection is used for the installation of round galvanized pipes. A steel pipe product with factory-made threads at the ends after diffusion galvanization is fully protected and ready for threaded connection using galvanized fittings (couplings, nipples, reductions, plugs, adapters, corners, etc.).

The joint is sealed by winding tow with painting. During hot-dip galvanizing, the threads often swim and have to be restored again. Docking with a thread, made in accordance with all the rules, is reliable and tight, safe for water supply, does not corrode, and is convenient for further replacement and repair.

However, today there are several methods for welding steel products in galvanized steel without damaging the protective coating. The welding method is suitable for the installation of all types of pipes, both round and profile pipes of any section.

The basis of welding galvanized products is the task of preventing the evaporation of zinc from the surface of the steel. To do this, a layer of flux is applied to the pipes at the junction, which prevents the protective layer from burning out.

The filler rod is melted by the torch flame, forming a weld. Zinc melts, but does not burn out, then solidifies again. This type of connection is used for the installation of a water supply system, the flux residues inside are gradually washed out with water without harming the drinking qualities.

Also, during welding on a semi-automatic device, liquefied food carbon dioxide is used as a protective medium to preserve zinc. In the seam zone, the zinc layer is cleaned, since its oxides contribute to the spattering of the electrode, which makes the seam porous.

For gas electric welding of thin-walled galvanized pipes (up to 5 mm), overhead copper rings are used, which are then removed, while maintaining the integrity of the zinc coating.