- Spark arrester value

- Production of various parts for the chimney

- Umbrella

- spark arrestor

- shiber

- Do-it-yourself step-by-step manufacturing and installation of a spark arrester

- Necessary materials and tools

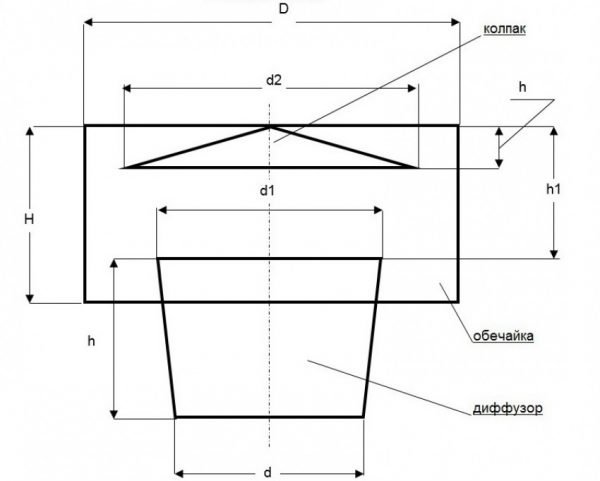

- Drawing and diagrams

- Size calculation

- Mounting Features

- Video: A chimney spark arrester will save your life and property

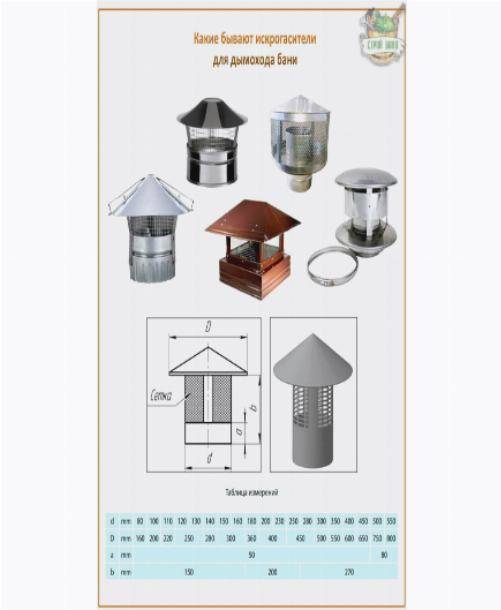

- Kinds

- Varieties of chimney deflectors

- TsAGI

- Grigorovich deflector

- Round Wolper

- H-shaped device

- Vane

- Disc deflector

- Rotating deflector

- spark arrestor

- Purpose of the spark arrester

- Functional purpose

- The simplest spark arresters

- To install a cap or not

- Why do you need a cap on the chimney pipe

- Cap on the chimney pipe - manufacturing materials

- Variety of chimney caps

- How to choose and buy a chimney cap, given its structure?

- Making a visor with your own hands

- Creating a homemade spark arrester

- Tools for the job

- Step-by-step creation of a mesh spark arrester with an umbrella

- Step-by-step creation of a simpler spark arrester from a sheet of metal

- How to make a spark arrester on chimneys?

- We mount the deflector and fasten the finished spark arrester

Spark arrester value

Often, solid fuels are used to kindle sauna stoves. Sometimes there is a difference in the quality of the material, which leads to sparking.A spark is an incandescent particle that did not burn out during kindling. With a stream of hot gases, it goes up the chimney and flies out. Such a phenomenon can lead to unpleasant consequences.

Sparks very often land on the roof or wooden elements of the building. The wind can blow them several meters around, which leads to the appearance of fires. Dry leaves, needles, grass, hay, surrounding structures, trees - all this can catch fire from a single spark. To extinguish a hot particle, it is necessary to ensure its contact with elements and surfaces with a high level of thermal conductivity. So a hot spark will lose its thermal potential even during its movement through the chimney. In other words, it will simply fade.

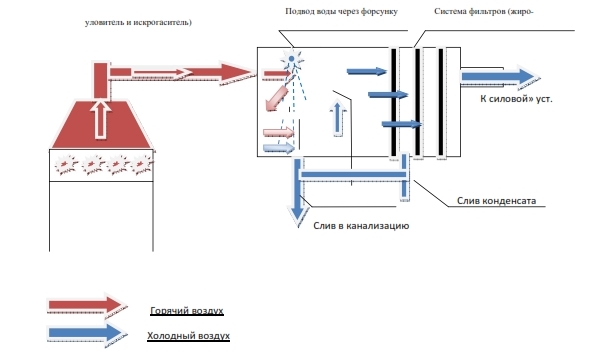

To achieve premature weakening of the spark thermal potential, a spark arrester is installed on top of the pipe. This element allows you to catch sparks when they go outside. A properly made and installed flame arrester reduces the risk of a fire in the bathhouse (sauna) and surrounding buildings.

Installing spark arresters has a number of advantages:

- Provides fire protection when combustible materials are located nearby.

- Prevents sparks from reaching the roof, especially if it is made of flammable materials, a large number of leaves accumulate on it.

- It closes the chimney from precipitation, leaves, birds, which often like to build nests in it.

- Helps to reduce resistance, which eliminates reverse draft and increases the chimney traction force.

Production of various parts for the chimney

Various accessories can be made by yourself.

Umbrella

This element should be made of galvanized steel. The easiest way is to make it in the form of a half-cylinder - then it will be easy to attach racks made from a corner to it.

If the base of the umbrella is round, then it will fit tightly on the chimney and will not let air through at the junction

Another option is to make an umbrella in the form of a 4-sided pyramid. This is also an easy way - a square sheet of steel is simply bent diagonally, but when cutting a workpiece, you will need to provide "lugs" for attaching racks.

You can install an umbrella made in the form of a house roof on a brick pipe

spark arrestor

The spark arrester is just a metal mesh with a cell of no more than 5 mm, which is installed on the pipe head. It can be made from thin wire or from a plate about 1 mm thick, in which many holes are drilled. The mesh is soldered or riveted to the shell, which, in turn, is attached to the pipe.

The spark arrester must be fastened to a brick chimney with dowels or nails driven into the seam, to a steel chimney - using a clamp covering the shell.

shiber

A damper for a round chimney can be made like this:

- A short piece of pipe of the appropriate diameter is taken.

- Two holes are drilled in it located opposite each other.

- A steel bar about 10 mm in diameter is inserted into these holes, one end of which is bent (this will be the handle).

-

A disc with a diameter slightly smaller than the inner diameter of the pipe is welded to the rod inside the pipe.

To exclude the possibility of completely blocking the chimney by negligence, a sector of ¼ of its area can be cut out in the disk

Do-it-yourself step-by-step manufacturing and installation of a spark arrester

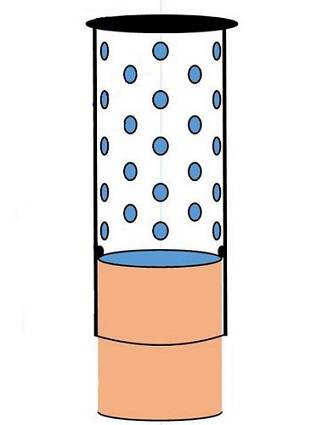

Consider a step-by-step manufacturing option for a spark arrester with a deflector umbrella, consisting of a body, a mesh structure and a deflector cap.

Necessary materials and tools

For self-assembly of such a spark arrester, you will need the following tools:

- measuring instruments (tape measure, level, etc.);

- screwdriver, clamps, pliers and hammer;

- rivets in a set or a welding machine;

- metal scissors, grinder, drill and drill bits.

Drawing and diagrams

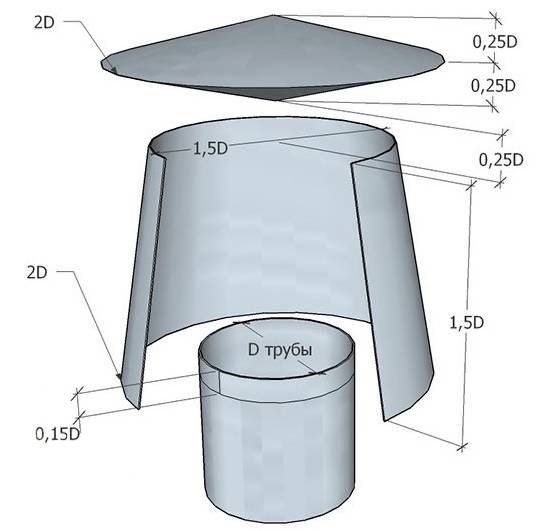

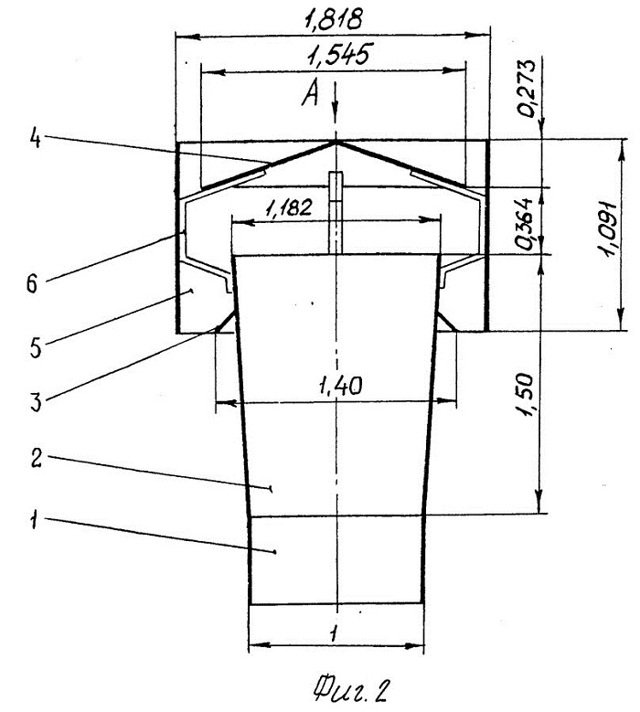

Here is an example of assembling a simple spark arrester based on a common basic drawing.

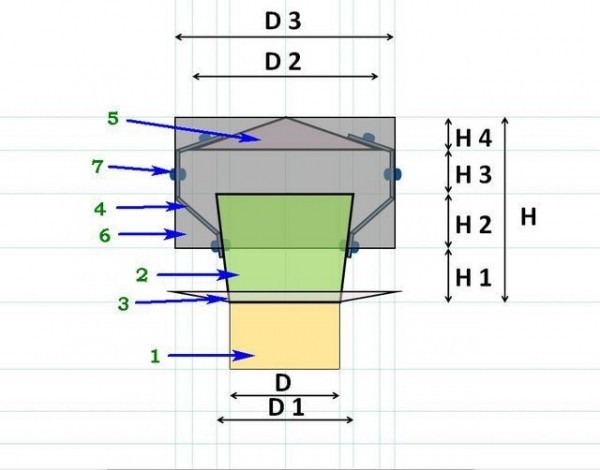

Let's designate the main components and along the way we will tell you how to make them:

- Cylindrical branch pipe - a glass that will be put on the chimney pipe. For the manufacture you need a metal sheet. We cut out a rectangle from it with a length equal to the length of the circle lying at the base (Fig. 2).

You can calculate the required dimensions using the formula: "L \u003d π × D", where L is the length, π ≈ 3.14, and D is the required cylinder diameter. We carefully bend the resulting strip with a pipe, for example, into a cone, combine the edges, drill several holes on them and fasten them with rivets.

- Metal mesh - a network with cells. It is best to purchase a ready-made stainless steel mesh base. A cylinder based on it is made in the same way as a glass.

- Protective umbrella cap - the main thing here is to correctly pattern the cone. To do this, we calculate the required workpiece radius using the formula: “C \u003d √ (h² + (D / 2)²)”, where C is the length of the lateral component of the cone, h is the required height, D is the diameter. Carefully fold the finished cut out scan with a cone (Fig. 3)

- Racks for connecting parts into a single structure are made from the same sheet metal. (Rice.4) The length of the posts is determined by the dimensions of the structure, taking into account the required margin from below (approximately 20 mm for 1-2 rivets for attaching to the glass). It is better to place these elements at an angle to the vertical - from the pipe to the edges of the umbrella.

Now about assembly. We attach racks for 1-2 rivets to the “glass” pipe. We insert a mesh cylinder into the space between the racks-holders so that it enters the lower pipe a little and rests on the cone. Now we expose the fungus - we bend the mounting pads of the racks so that they fit snugly against the inside of the cone. We drill through holes through the racks and the umbrella, after which we finally fix the entire structure.

Size calculation

Before starting work, you need to measure the dimensions of the chimney, in accordance with which the sketches of the device will be displayed.

It is equally important to determine the correct size of the cells - they should not be more than 5 mm

Mounting Features

Proper installation depends on the dimensions of the device parts. At the slightest discrepancy between the diameters, it will not work to install a spark arrester on the pipe. A welding machine is used to connect individual elements. The joints obtained after welding must be thoroughly cleaned. For final fixing, you will need rivets or brackets.

Video: A chimney spark arrester will save your life and property

This is interesting: The main fire trucks - general and targeted applications

Kinds

Special spark-extinguishing structures can be manufactured in a variety of designs, differing both in their dimensions, as well as in form. The most common design options for spark arresters are:

- a protective cover made on the basis of a fine mesh;

- a cap of a special shape that performs the function of a spark arrester and a deflector (a device that changes the direction of flow) at the same time.

Due to the fact that spark arresters partially prevent the free movement of combustion products, in their design the effect of reducing draft in the pipe should be minimized.

Based on this requirement, known types of structures (a spark arrester for a potbelly stove, for example) are made in such a way that the crushing of sparks does not cause a slowdown in the smoke flow.

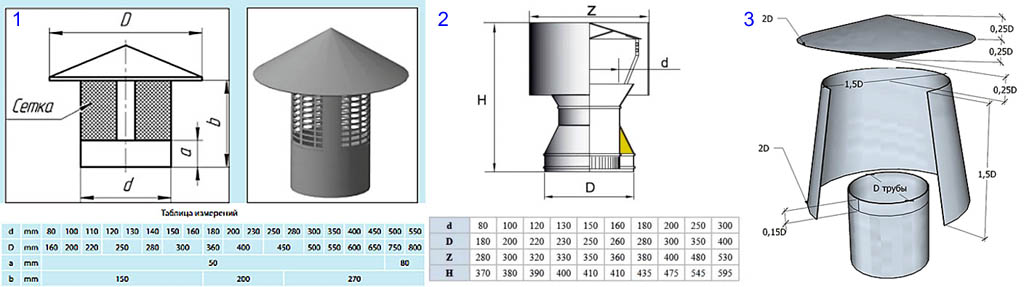

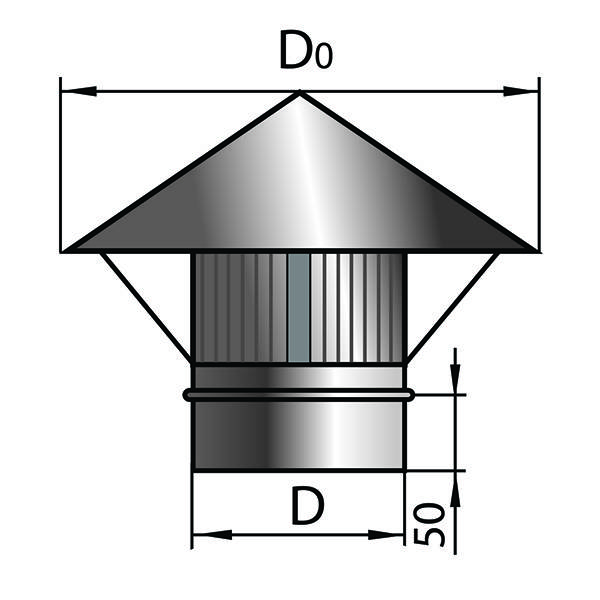

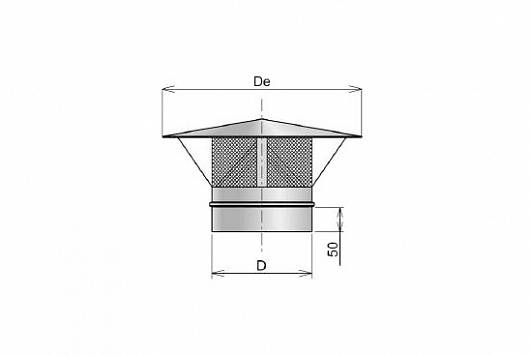

To this end, their sizes are strictly standardized; moreover, the diameters of the deflector or casing in this case (depending on the developed thrust) can vary from 80 to 550 mm. The structural size of the pipe canopy directly depends on the dimensions of the latter.

Of particular interest is a purchased product that combines the functions of a spark arrester and a deflector at the same time (two in one), which can also have a variety of designs.

Varieties of chimney deflectors

Modern deflectors for chimneys are represented by many different designs, the most popular of them are:

- TsAGI.

- Grigorovich deflector.

- Wolper.

- H-shaped.

- Vane.

- Poppet.

- Rotating.

- Spark arrestor.

TsAGI

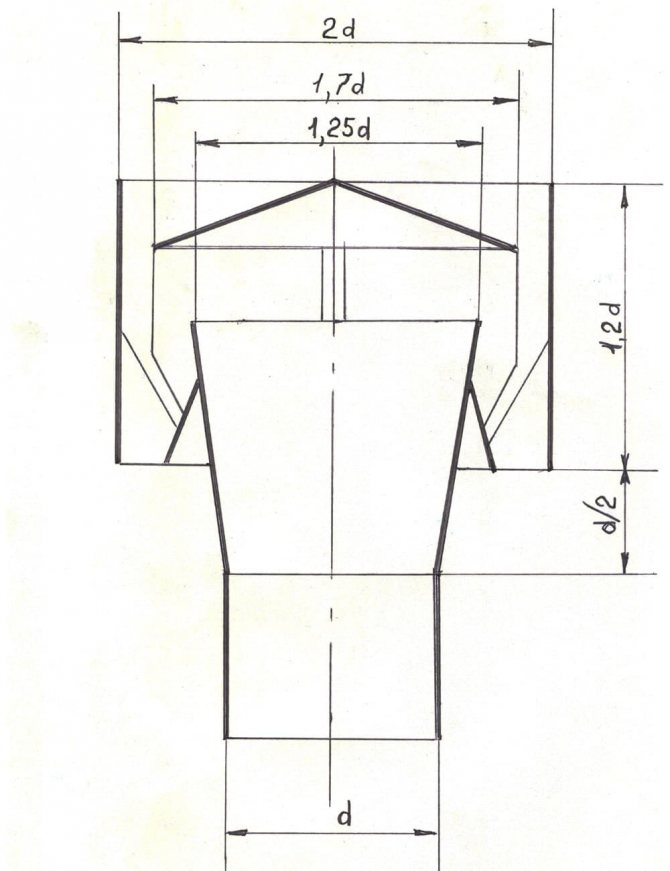

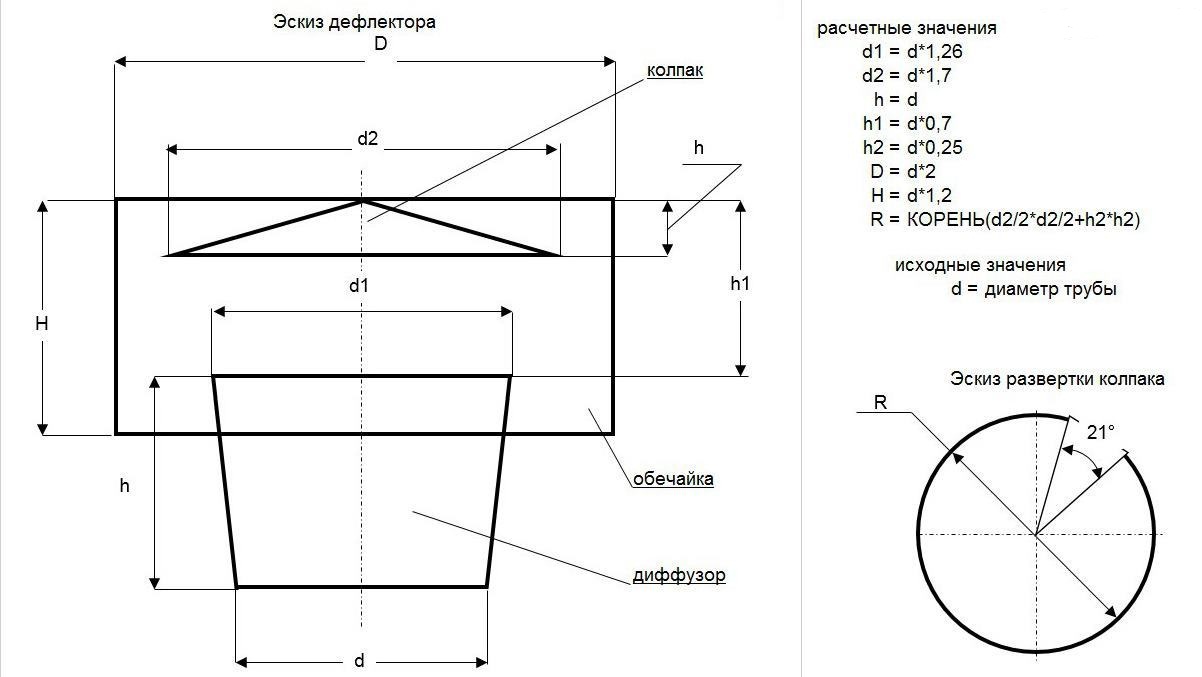

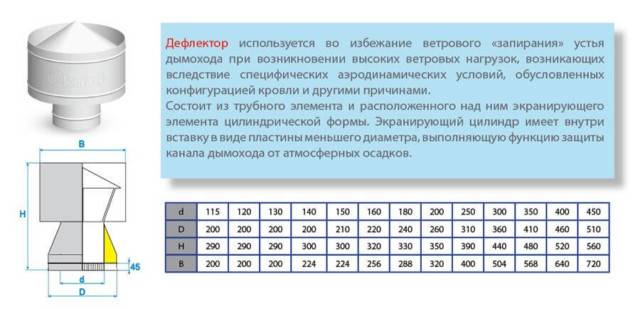

A universal version of the deflectors, developed by the Central Aerohydrodynamic Institute. The structural elements of the device are a pipe fixed on the chimney, a diffuser, a ring and an umbrella.

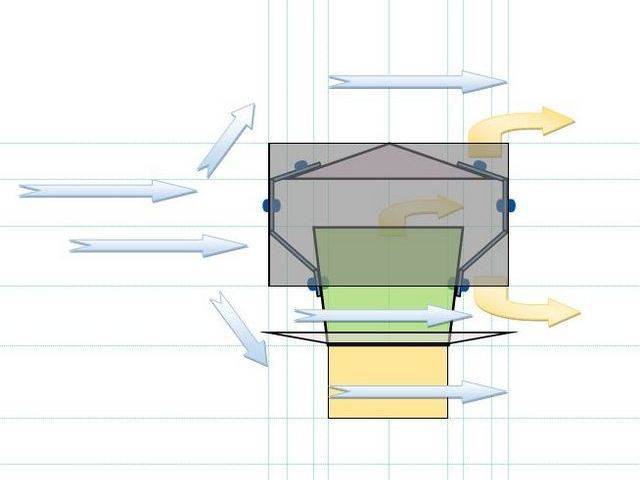

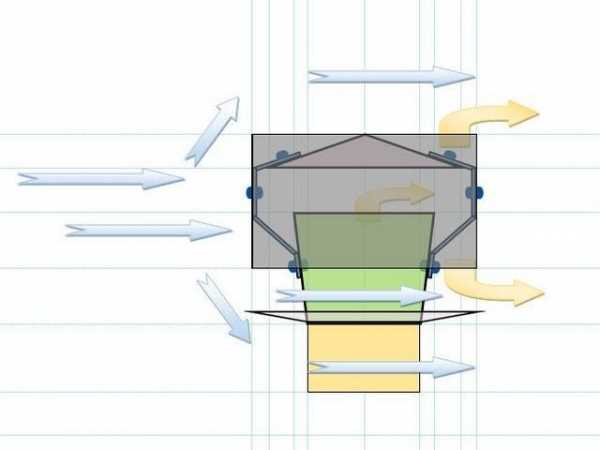

The main advantage of TsAGI is the convenient location of the umbrella, when warm air masses are removed through the ventilation duct, which leads to an increase in traction.TsAGI is used to protect the ventilation and chimney systems.

This design effectively cuts the incoming air flow to quickly remove smoke from the chimney. At the same time, the umbrella is located inside the cylinder, therefore it provides maximum protection against the negative effects of precipitation.

A significant drawback of the design is the complexity of production, so it is quite difficult to assemble the TsAGI deflector at home.

h3 id="deflektor-grigorovicha">Grigorovicha deflector

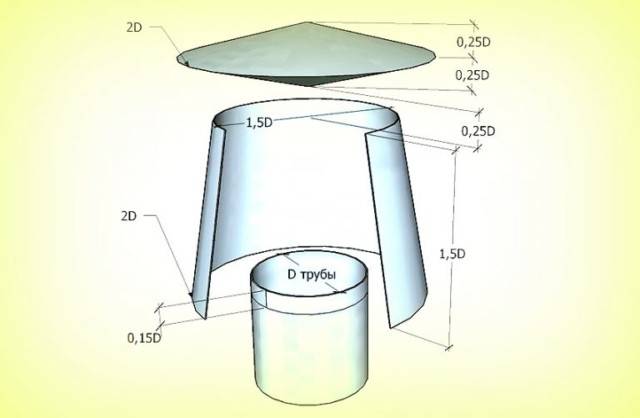

The most affordable version of the device, which can be made independently from improvised materials. The design consists of an upper cylinder, a lower cylinder with nozzles, a cone and mounting brackets.

The Volpert-Grigorovich deflector is successfully used to protect the hood and chimney. The main advantage of the device is the simplicity of design, and the disadvantage is the high location of the umbrella in relation to the diffuser, which leads to smoke blowing on the sides.

In general, such a device does not effectively increase traction, but prevents the penetration of precipitation into the pipe.

Round Wolper

Such a device is almost identical to the TsAGI deflector, but with the only difference - there is a visor for protection against precipitation and pollution, located above the diffuser.

H-shaped device

The H-shaped deflector provides for the use of pipe sections, therefore it is able to withstand extreme wind loads. The main structural elements are mounted with the letter H, excluding the ingress of precipitation and pollution into the pipe due to the horizontal branch pipe.

Lateral vertical elements contribute to an increase in internal draft, which leads to the simultaneous removal of smoke in different directions.

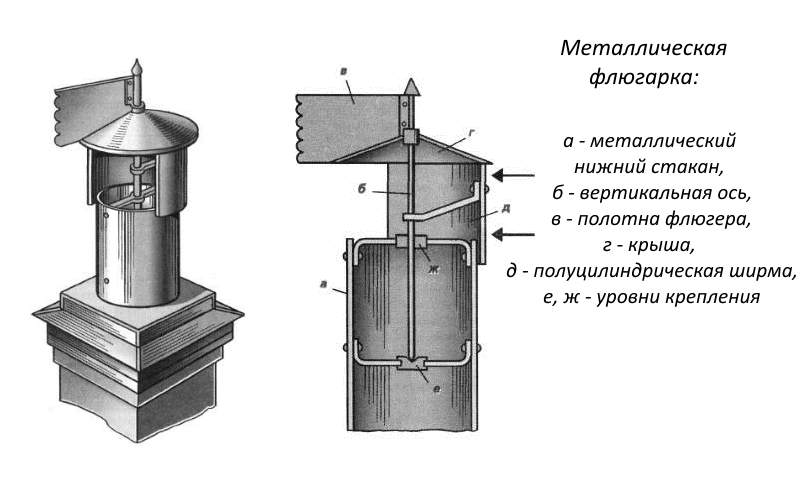

Vane

Another version of the chimney deflector, which is represented by visors connected to each other, rotating in a circle. To ensure constant movement under the influence of air masses, a special weather vane is installed in the upper part of the structure. Many designs are equipped with a small arrow pin that determines the direction of the wind.

By cutting through the air currents, the visors lead to increased draft in the chimney. In addition, they protect the boiler or stove from possible contamination from outside.

A significant drawback of the design is the fragility of the bearing that ensures the movement of the visors.

Disc deflector

A simple and affordable option for protecting the chimney system, providing high traction. The main structural elements create a special visor to protect the chimney from pollution and precipitation.

At the bottom, the visor is equipped with a cap directed towards the pipe. The air masses entering the deflector create a narrow and rarefied channel, which makes it possible to double the internal thrust.

Rotating deflector

Such a device can rotate due to air masses in one direction, so in calm weather it is absolutely motionless. When there is heavy ice, the turbo structure becomes useless, therefore, it requires heating or periodic cleaning.

The turbo deflector reliably protects the chimney system from clogging and the negative effects of precipitation. If a gas boiler is used as a heat generator, then it would be rational to use such a chimney.

spark arrestor

There are models of devices for the safe extinguishing of sparks. Usually they are structures equipped with a cylinder and an umbrella with a fine mesh.

The spark arrester on the chimney works according to the following principle: the mesh traps the residual combustion products that are contained in the smoke

As a result, the sparks falling on the deflector are completely attenuated, this is especially important if the chimney system is located near flammable objects or green spaces.

The only drawback of the design is the likelihood of a decrease in traction if the device is improperly assembled.

h2 id="naznachenie-iskrogasitelya">Spark arrester assignment

A spark arrester is a device that is necessary to cool particles that enter the chimney during the combustion process. It is installed on the head of the chimney pipes.

Note! The combustion of solid fuels produces heat, water and carbon dioxide. Heat turns water into steam

Impurities in the fuel lead to its incomplete combustion, due to which other combustion products and unburned incandescent particles are formed. The latter are sparks flying out of the pipe under the action of thrust.

High quality fuel has the least amount of non-combustible particles. Low quality fuel is the greatest. The danger of sparks is that they do not cool down when moving along a flat pipe. Hot particles, getting outside, can ignite sections of the roof, trees, grass, walls of the house. In this case, the risk of fire increases.

The designs of modern chimneys provide for several stages of spark cooling. To do this, create obstacles, turbulent flows and horizontal branches.Their main purpose is to ensure contact of hot particles with the pipe wall.

In this case, the sparks transfer their heat to the chimney, and they themselves are cooled. The problem is that the pipe heats up quickly and loses its ability to cool the solids. In addition, the turbulent flow inside the pipe reduces the chimney draft.

An additional obstacle to the way of sparks to the outside is a spark arrestor. It does not reduce the draft in the chimney, but cools the particles rising up. The spark arrestor mechanically traps sparks and cools them. This reduces the risk of them spreading outside the chimney and causing a fire.

Functional purpose

At first glance, it may seem that a canopy mounted on a chimney is nothing more than home decoration. But in fact, the canopy performs many useful functions. Mainly by diverting the flow, it helps to increase the air draft in the pipe. In addition, the visor performs protective functions, preventing the ingress of precipitation. In addition to the properties already mentioned in the paragraph, there are others:

- Debris protection. The wind can bring foliage, feathers, which clogs the chimney, because of which there is a threat of smoke in the room.

- Increasing the efficiency of a fireplace or stove. Increases the power of the hood by about 20%, the deflector helps to maintain the fire and not let it die out. In turn, during the downtime of the stove in the sauna, natural ventilation appears. It helps to get rid of the smell of dampness and quickly drain the room.

- Strengthening the pipe. If the chimney is made of fire-resistant brick, then a cap on it will help prevent premature destruction of the structure.

In addition to the above, this spark arrester on the chimney pipe prevents swirl and turbulence in the chimney. This means that the residents of the house will not hear incomprehensible noises that appear due to pipe vibration.

All this indicates the significant importance of the product and its choice, manufacture must be approached with all seriousness.

One of the important elements of the deflector is a drip. It provides high-quality water drainage from the chimney pipe. If this detail is neglected, then icing and destruction of brickwork is possible.

And also pay attention to the material from which the element is made. It should easily tolerate dampness, be resistant to high temperatures, withstand ice in winter

The simplest spark arresters

In practice, several simple structures are used:

- When using a metal chimney, it is necessary to close its upper end with a steel plug. After that, it is necessary to drill a series of holes in a checkerboard pattern around the circumference of the pipe with a diameter of about 3-5 mm. When smoke passes through these holes, most sparks are extinguished. The simplicity of the design has one drawback - the draft of the furnace is significantly reduced. In addition, drilled holes quickly become clogged with soot or tar.

- In some cases, a standard deflector installed at the top of the pipe can replace the spark arrester with a chimney. This device prevents reverse thrust in high winds and extinguishes a significant amount of sparks. When choosing this option, keep in mind that the deflector is not designed to extinguish sparks, so its reliability is limited.

To install a cap or not

From a technical point of view, a cap is a special metal device that protects the chimney outlet from the negative effects of atmospheric factors. It should not in any way affect the design parameters of the draft, not distort the initial conditions for the movement of air flows, etc. The presence of other more complex devices on the chimney should be provided at the heating design stage.

Chimney cap

As you noticed, not all chimneys have caps, since the owners of the building have their own beliefs, they are often contradictory, but everyone has the right to life. Before making a final decision, you should familiarize yourself with the point of view of opponents and supporters of such structures.

Table. Pros and cons of installing hoods

| Functions performed | Brief Description of Actual Specifications |

|---|---|

| Closes the chimney outlet from wind blowing | On the roof of buildings, the direction of the wind changes depending on the size, location and angle of slopes. To prevent the occurrence of reverse thrust, special engineering calculations of heating are made, which regulate the height of the chimney depending on its location and distance from the ridge. The wind on level ground never blows downwards, only eddies from the roof can give it such a direction. Another reason for reverse draft is the complete absence of natural air flow into the room or too powerful forced exhaust ventilation. A hood, if properly sized and typed, breaks up the airflow and ensures proper draft in the chimney. |

| Protects the chimney from rain and snow, prevents mechanical pollution and bird nesting | There is one problem here - only the net protects from birds, the visor must be protected around the entire perimeter. Frozen condensate may appear on the grid and critically reduce traction. It is useless to clean, water under certain climatic conditions will freeze again. Sometimes you have to go up to the roof in winter, remove the grid and thus restore traction. This is undesirable, doing any work on the roof in winter is very dangerous. |

| Increases the life of the chimney cap | Completely correct statement. But for this you need not a complex decorative product, but only one of its elements - a cap. |

| Improves the appearance of the building | A beautiful cap of the original design really has a positive effect on the appearance. There are exclusive projects that allow emphasizing the prestige of the building and the solid financial position of their owners. |

As you can see from the list, the number of positive and negative consequences from installing the cap is approximately equal, hence the conclusion - make your own decision. But remember one universal requirement of regulations: all nozzles and fixtures should not interfere with the free exit of smoke and not worsen the calculated performance.

Kinds chimney caps

Why do you need a cap on the chimney pipe

First of all, the chimney is installed in order to increase traction through the divergence of air flows. There are several functions of the device:

- Protects the device from penetration of water and snow. With heavy rains, a huge amount of precipitation can accumulate in the structure, which, when in contact with flue gases, form acidic compounds. The cap on the chimney, in turn, protects the mouth of the pipe from the ingress of unwanted moisture;

- Prevents unwanted objects from entering the structure;

- Improves traction. For this purpose, deflectors of various variations are thought out.

Cap on the chimney pipe - manufacturing materials

For trouble-free functionality of the device, it is necessary to responsibly approach the selection of material for direct production. One of the most popular materials is copper because it is durable and has an aesthetic appearance. If the cap on the chimney pipe is made of some other building material, then all mounting elements must be brass.

The weather vane on the chimney, made of stainless steel or galvanized, looks spectacular. The most popular is the device made of stainless steel with polymer sheathing. The service life of such a device reaches 20 years. The polymer coating makes it possible to choose a cap to match the roof.

Beautiful forged weathercocks will become a real decoration of the roof

Variety of chimney caps

The type of wind vane is based on the structure of the pipe and the external shape.

Types of chimneys:

- Generally accepted. This type of wind vane looks like a hut on top of the pipe. This kind of design can have a variety of configurations;

- European fixtures for chimneys. A key feature of the structure is a cap with a rounded shape. The main task of the product is to prevent the formation of condensate and ventilate the room;

- A device with a multi-pitched dome. The advantage of the design is the presence of two slopes. This kind of product contributes to the maximum saving of the pipe from precipitation;

Chimney with multi-pitched hood

Weather vane for brick chimney

- With opening lid.This structure allows you to quickly perform all the necessary manipulations regarding the maintenance of the pipe. The key purpose is overall ventilation;

- With deflector. This design can be additionally equipped with a swinging lid. Provides direct impact on traction power.

Related article:

How to choose and buy a chimney cap, given its structure?

When choosing a product, it is necessary to take into account the direct structure of the chimney. The ideal option is a three-layer device from modular sandwich panels. With such a device, you can not worry about protecting the chimney from precipitation. Since, all the moisture that gets inside the structure is collected in the collection.

When it comes to gas appliances, in this case, the nozzle is most preferable. The best option for a solid fuel system is a weather vane deflector.

There are no contraindications for brick pipes in conjunction with a solid fuel system and you can give preference to any cap you like.

Installation diagram of the chimney system

Making a visor with your own hands

To properly make a do-it-yourself chimney cap, you should use the drawings of simpler samples.

The following tools and materials are required for work:

- Galvanized steel, copper or stainless steel;

- Scissors for metal;

- Pliers, mallet, vise.

Swivel caps made of galvanized steel

Work execution algorithm:

- Making a visor must begin with measurements of the chimney.

- Formation of the scheme on paper. It should be borne in mind that the device must be worn freely on the pipe. Therefore, a gap of about 2-3 mm is added to the existing dimensions of the pipe.

Scheme of the cap on the chimney

- The finished drawing must be transferred to the building material and cut out;

- The sides of the workpiece along the dotted line "a" are bent to an angle of 90 degrees. Then a similar procedure must be performed with straight lines marked with the letter "d". At the attachment points, it is necessary to make 3 through holes (15-20 cm step) and fix the structure with rivets;

Drawing of an apron-dropper with markings

Apron design options

Creating a homemade spark arrester

It is not always possible to find a product of the desired shape and desired design. In such cases, you can solve the problem by making a spark arrester yourself.

To create a spark arrester with your own hands, you only need a minimal set of knowledge and skills.

The most important rule is that the size of a square grid cell should not exceed 5x5 millimeters. Making less than 2x2 millimeters is also not recommended: combustion products and furnace soot will accumulate, which will quickly clog the mesh, and smoke will pass through it worse.

Tools for the job

To make a homemade spark extinguisher, you will need the following material and tools:

-

grinder or scissors for metal;

-

welding machine (not always required);

-

metal sheets and 3 strips 10-15 mm wide (stainless steel, galvanized iron);

-

metal mesh (the thickness of the rods is not more than 6 mm, the mesh sizes are 5x5 mm);

-

pencil, ruler, hammer, pliers;

-

as a template, you will need a chimney with the same diameter as the chimney.

Step-by-step creation of a mesh spark arrester with an umbrella

The first and most important task in creating any design is a sketch.It allows you not to keep in mind the dimensions, and use it as a visual aid. Therefore, before starting work, you need to decide exactly how the product will look like.

Further points:

-

Wrap the chimney pipe with a metal mesh with an overlap of about 10-15 mm, then cut off a piece of the desired diameter.

-

Wrap the pipe used for the template with the resulting mesh.

-

In the place of overlap, it is required to attach a metal strip 10-15 mm wide, protruding at the top beyond the edges of the grid 3-5 mm.

-

The strip is welded to the mesh (either a riveting machine is used, or it is bolted).

-

Reinforce additional 2 strips at an equal distance from the overlap of the mesh - these strips with ledges will become the holders of the umbrella. You should get a cylinder of mesh with three protruding metal strips-props.

-

A circle is drawn on a sheet of metal, approximately 100 mm larger than the diameter of the pipe. It must be cut with scissors, grinder or other tool.

-

Next, you need to cut the corner: for this, the radius of the circle is taken, and an angle of 15-25 degrees is marked from the center, and cut out of the sheet.

-

The resulting circle with a cut off corner must be rolled into a cone with an overlap of 10-15 mm. Can be fastened by welding or riveting. Alternatively, you can cut 4 equilateral triangles from a sheet and weld them into a pyramid.

-

Fasten the two resulting elements: the mesh cylinder and the lid cone. There should be no free space between the roof and the mesh through which sparks can escape. It is best to fasten with a welding machine. The result is a finished spark extinguisher.

The structure is installed on the chimney in two ways. The first is with a clamp sold in hardware stores.

The second option is to make your own clamp from a metal strip. It is better not to weld it: you can make holes in the pipe and install the spark arrester on the bolts.

Step-by-step creation of a simpler spark arrester from a sheet of metal

There is an easier way to create a homemade spark arrester. In this case, only a thin sheet of stainless steel is needed for work. The width of the sheet should be 10-15 cm larger than the diameter of the chimney (for overlapping). Length - about 20-30 cm.

Sheet spark arrester

Separately, you will need another piece of metal - for the end cap.

The creation process looks like this:

-

We bend a sheet of metal and wrap it around the pipe, with an overlap of 10-15 cm.

-

We fasten the bent sheet (we will get a pipe) by overlapping - using bolts or welding.

-

We close one of the ends of the resulting pipe with a second piece of metal and weld it.

-

We cut slots in the pipe or make holes of small diameter (5-10 mm). You can do this with a drill.

-

We install the resulting structure on the chimney and fix it (with bolts or welding).

In terms of manufacturing, this is a simple and fast option, but in operation it is far from the best. The disadvantage is that an inexperienced craftsman will probably not be able to accurately calculate the number and diameter of holes. As a result, chimney draft can be worsened.

Also, such a spark arrester will quickly become dirty, and it will have to be removed more often for cleaning. Therefore, this design may be suitable as a temporary replacement, or for buildings in which the furnace is used infrequently.

How to make a spark arrester on chimneys?

Making a spark arrester with your own hands is very simple, for this you don’t have to buy expensive materials or tools, almost everything you need is probably in stock with a zealous owner of the house. Before work, it is only necessary to accurately determine the design of the future device, remove all dimensions from the chimney, draw a sketch in compliance with all dimensions, according to which the metal will be cut, and the spark arrester itself will be assembled.

In order to make a spark arrester for a pipe with your own hands, you need to prepare the simplest tools and materials:

Spark arrester device.

- metal bars with a diameter of up to six millimeters (preferably one mm so that gases can freely pass through the grate). Instead of bars, you can use a piece of metal mesh;

- a sheet of metal with a thickness of one millimeter;

- grinder, metal scissors;

- simple pencil, ruler;

- steel rivets (aluminum will not give reliable fixation);

- welding machine and clamps for fastening the material before welding.

It is better to carry out all work on a horizontal surface, first measure the dimensions from the chimney. It is recommended to immediately decide on the design, draw a sketch with the exact dimensions, which will be necessary when cutting the material, assembling the device itself for installation on the chimney.

The process of installing spark arrester equipment is very simple:

- First, a sketch is drawn for the future device.

- After that, steel up to 1 mm thick is cut according to the project (depending on the size of the chimney itself).

- A metal mesh with 5 mm cells is also cut according to the dimensions of the installed chimney. This can be done with the help of prepared wire cutters or scissors for metal.

- A pipe with a diameter suitable for a chimney is cut in such a way that a base for installing a grid is obtained from it.

Further work on the manufacture of a spark arrester includes:

- Bars that are placed parallel to each other on the grid, leaving a part for attaching to the pipe. We press them with a hammer, all joints are welded with a welding machine.

- The resulting mesh should be wrapped around the pipe, pressed with clamps. You need to tap on the grid with a hammer - this way the stress will be removed from the metal.

- After bending, all edges and joints are welded.

You can take a ready-made, previously purchased piece of mesh, which is attached to the base pipe in the same way.

We mount the deflector and fasten the finished spark arrester

Now we make a deflector for the pipe. We cut out a visor in the form of a circle from a sheet of metal, bend it (all folds are attached from above with rivets), we get a small cone with a diameter larger than the diameter of the main pipe. This will be our visor.

The deflector is attached to the grid and the base of the spark arrester using metal strips welded or fixed with ordinary steel rivets. The ready-made spark arrester can be installed on chimneys using various mounting options for this (depending on the material of the chimney itself). These can be self-tapping screws, bolts, it is necessary to provide for the possibility of dismantling for.

Spark arresters are an additional element that are equipped with pipes to protect buildings from fires, they are placed on the top of the chimneys. This is a specially installed mesh and a deflector that prevent sparks from reaching the roof surface. All of them, passing through the grate, are simply extinguished on its cells.

It is recommended to install such a device for baths, saunas, when covering the house with flammable materials. In addition, the spark arrester keeps birds, foreign material, twigs, and other debris out of the chimney, greatly reducing the frequency of chimney sweeps. Installing a spark arrester ensures the greatest possible safety. You can make such a device with your own hands, for this you need the simplest materials and tools, the installation itself takes a minimum of time.