- The principle of operation of the spark arrester for the bath

- Causes of excessive heating of the chimney

- Step by step instructions for making

- Design choice

- Preparatory activities

- Product assembly

- Built-in spark evacuation systems

- Simple Spark Arrestor Circuits

- How to paint iron

- How to make a spark arrester on chimneys?

- We mount the deflector and fasten the finished spark arrester

- Do-it-yourself step-by-step manufacturing and installation of a spark arrester

- Necessary materials and tools

- Drawing and diagrams

- Size calculation

- Mounting Features

- Video: A chimney spark arrester will save your life and property

- What is a spark arrester?

- Where is it used and why is it needed?

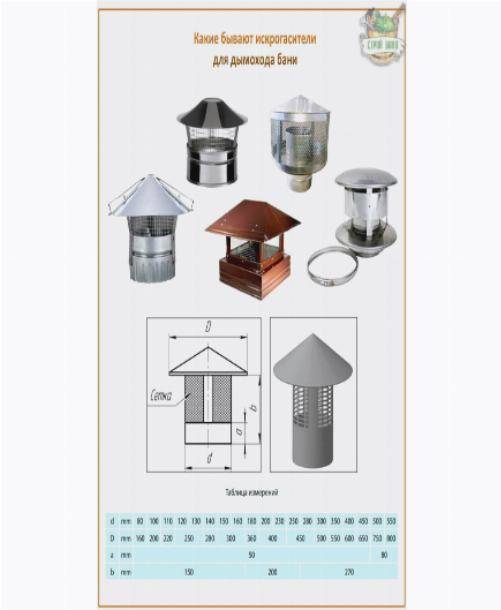

- Varieties of spark arresters

- Where is it sold and how much does it cost?

- Features of the care of the spark arrester

- Spark Arrestor Features

- Sparks from the bath pipe: what to do

- The structure and principle of operation of the spark arrester

- Spark Arrestor Models

The principle of operation of the spark arrester for the bath

To increase the heat transfer of a bath stove, direct chimneys are most often used, which provide increased traction. Due to this, the process of fuel combustion proceeds faster, which reduces the heating time of the room.

The main danger of this design is the removal of sparks through the chimney to the roof surface.For wooden structures, roofs made of combustible materials, this creates a high probability of fire. Therefore, a spark arrester for a bath is vital, especially since its manufacture is quite simple.

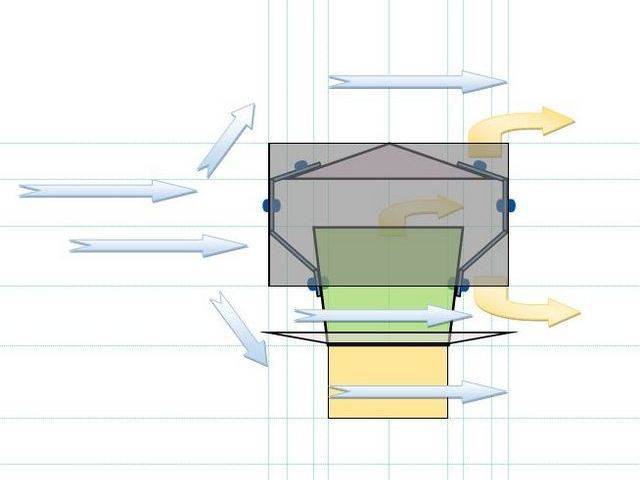

The principle of operation of this design is based on changing the direction of the flow of smoke and creating obstacles, when passing through which sparks are extinguished.

Causes of excessive heating of the chimney

Quite often it happens that the chimney pipe heats up to incredibly high temperatures.

This entails a danger, since the risk of fire increases several times!

In order to minimize it, first of all, you need to isolate all combustible elements nearby.

Next, the insulation is laid around the chimney pipe.

This must be done without fail, because without a high-quality thermal insulation layer around the chimney, you risk your life and health every day.

The reason why the sandwich pipe is heated in the bath is also, most likely, lies in the heat-insulating layer. Perhaps it has worn out over time and needs to be replaced with a newer one. If a new sandwich structure overheats, a defect from the manufacturer is not excluded. This product also needs to be disassembled and replaced with a layer of insulation.

So, let's look at the main causes of the problem:

- The chimney is made of a single-walled metal pipe without a heat insulator, which is completely unacceptable. It is mandatory to replace single-layer chimney sections with sandwich pipes, or simply supplement them with a heat-insulating layer;

- There may be errors in the design of the sandwich pipe.It should be remembered that this design is installed in such a way that the condensate formed inside cannot get on the outer surface of the chimney.

Step by step instructions for making

For the manufacture of a spark arrester, certain mechanical skills will be required, as well as the ability to choose a product design that is suitable for given conditions.

Design choice

When considering various options for the execution of a spark arrester for a chimney, one should pay attention to a stainless steel product in combination with a classic n-shaped deflector. Also, one should not exclude the possibility of self-production of a special type of deflector equipped with a skirt for extinguishing spark formations.

Preparatory activities

After choosing the type of spark arrester, you should prepare everything necessary for its self-production, including the following set of tools and materials:

- an ordinary hammer, pliers, as well as small clamps and a set of screwdrivers;

- linear measuring devices;

- scissors for cutting metal, a grinder and a drill with a set of drills;

- household welding unit and a set of rivet fixtures.

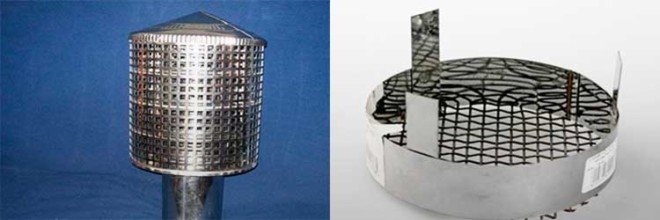

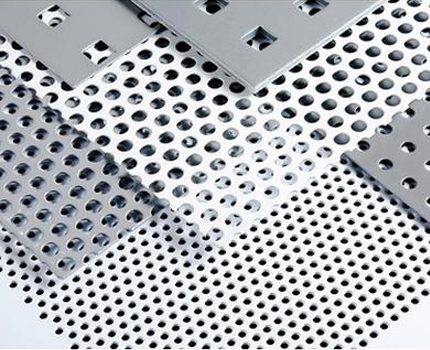

As a material for assembling the system, it is most convenient to choose stainless steel, which has all the necessary protective qualities. The diameter of the bars from which the mesh structures are mounted should be as small as possible (no more than 4 mm). But they should also not be made too thin, because in this case they can quickly burn out from the heat.

Before starting work, you should measure the dimensions of the existing chimney, on the basis of which sketches of the future protective device are then drawn up.For these purposes, it is most convenient to use cardboard blanks used as a kind of stencil.

Based on the sketches obtained, a drawing of the future device should be prepared, in which the exact dimensions of all the elements included in it should be indicated.

Product assembly

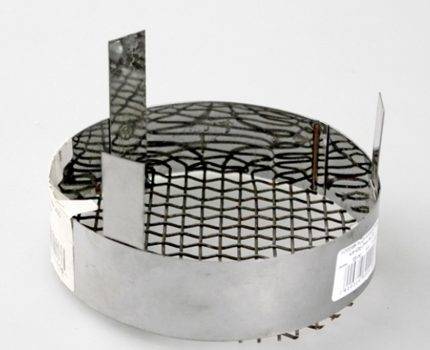

In order to assemble a spark arrester with your own hands, you must follow certain rules. Elements of a mesh fence for a chimney can be purchased ready-made in a store or made independently (rods with a diameter ranging from 1 to 6 mm are suitable for this purpose).

To articulate the individual components of a home-made spark arrester, it is most convenient to use manual welding, after which the resulting seams are carefully cleaned.

The final fastening of all structural elements is carried out using previously prepared rivets.

When using the option of combining a spark arrester with a deflector, a visor of the desired size is first cut out of metal sheet blanks of a certain thickness.

Then a large number of holes are drilled in it, sufficient for the free passage of the flow of exhaust gases. After that, the resulting workpiece is bent at the required angle, and the bending zones are additionally fixed with metal rivets.

Built-in spark evacuation systems

It is no secret that the solid fuel used to heat sauna stoves can have different qualities. Quite often, its combustion leads to the appearance of many sparks, that is, incandescent unburned particles, rapidly heading up with a stream of hot gas. These sparks move along the chimney and fly out at great speed, and then scatter in all directions.

Once outside, sparks can get on the roof structure or its individual wooden elements. And in the presence of a strong wind, they can lead to the ignition of dry leaves, grass or needles, which will entail irreparable losses. Timely action is the key to successful fire protection.

In this video you will learn how to make a spark arrester:

To extinguish sparks, it is enough to place special parts with high thermal conductivity in the chimney system. Upon contact with them, hot particles will lose their thermal potential, slowly cool down and become harmless. By the way, many modern sauna stoves already have special units with a quick spark extinguishing function.

The principle of operation of such mechanisms is very simple:

- Air enters the stove through a special door, and into the combustion chamber through the grate.

- The fuel is burned, heating the heater.

- As a result, hot combustion products pass through a special "maze" of jumpers, where active heat transfer occurs. As a result, under the action of centrifugal forces, sparks break out of the general flow, break against the walls of the chambers and are extinguished.

But it is important to understand that at this moment the oven is already heated to high temperatures, so it is often impossible to completely get rid of sparks. Often, owners use curved chimney designs, since in straight sections the probability of sparks is maximum

In this case, the principle of operation remains similar to the previous one - the direction of the flow of sparks with the walls of the chimney system changes.

This device has a simple operation scheme.

This device has a simple operation scheme.

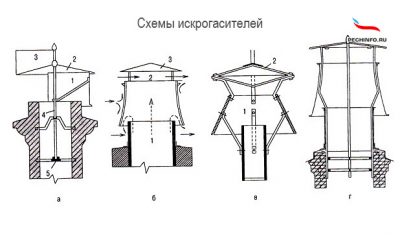

Simple Spark Arrestor Circuits

Of course, if you wish, you can always just go to the market and buy a finished device, having previously measured the dimensions of the chimney, and then install it - but such a spark arrester on the bath pipe will cost a little more. In addition, the design of the spark arrester is quite simple, so it will be almost easier to assemble it at home.

One of the simplest schemes that can be made is a plug in which holes are drilled. A very important aspect in this case is the competent choice of the diameter of the plug - its cross section should be slightly larger than the diameter of the chimney on which it will be installed. This requirement is due to the fact that the assembled device is put on the pipe from above. "How to make a grid on a pipe for stones in a bath - theory and practice."

To make such a design is very simple, but not without problems. The largest of these is the calculation of the number and size of holes that will be drilled in the plug. If the calculation is incorrect, the chimney draft will decrease. In addition, such an external plug becomes covered with soot over time, and an unpleasant odor enters the room.

Another option, which is also often used because of its simplicity, is a spark arrester made of a metal mesh mounted on a pipe with a clamp. This design is also not without drawbacks: firstly, a critical mass of soot will very soon be deposited on the grid, and the thrust will be significantly reduced, and secondly, the efficiency of such a spark arrester in itself is not very high.

How to paint iron

The owners of the baths are constantly faced with rust.

Of course, it is best to make tanks and other furnace components from stainless steel, but in the absence of such an opportunity, various paints and varnishes will come to the rescue.

So, how to paint the stove in the bath? It's best to stop your choice on heat-resistant silicone enamel.

Some of its varieties are able to withstand temperatures reaching 600-700 degrees.

Heat-resistant organosilicon enamel is absolutely not exposed to the negative effects of moisture and sudden changes in temperature.

Therefore, if you want to protect the stove in your sauna from corrosion, heat-resistant silicone enamel will become an indispensable assistant in this matter!

How to make a spark arrester on chimneys?

Making a spark arrester with your own hands is very simple, for this you don’t have to buy expensive materials or tools, almost everything you need is probably in stock with a zealous owner of the house. Before work, it is only necessary to accurately determine the design of the future device, remove all dimensions from the chimney, draw a sketch in compliance with all dimensions, according to which the metal will be cut, and the spark arrester itself will be assembled.

In order to make a spark arrester for a pipe with your own hands, you need to prepare the simplest tools and materials:

Spark arrester device.

- metal bars with a diameter of up to six millimeters (preferably one mm so that gases can freely pass through the grate). Instead of bars, you can use a piece of metal mesh;

- a sheet of metal with a thickness of one millimeter;

- grinder, metal scissors;

- simple pencil, ruler;

- steel rivets (aluminum will not give reliable fixation);

- welding machine and clamps for fastening the material before welding.

It is better to carry out all work on a horizontal surface, first measure the dimensions from the chimney. It is recommended to immediately decide on the design, draw a sketch with the exact dimensions, which will be necessary when cutting the material, assembling the device itself for installation on the chimney.

The process of installing spark arrester equipment is very simple:

- First, a sketch is drawn for the future device.

- After that, steel up to 1 mm thick is cut according to the project (depending on the size of the chimney itself).

- A metal mesh with 5 mm cells is also cut according to the dimensions of the installed chimney. This can be done with the help of prepared wire cutters or scissors for metal.

- A pipe with a diameter suitable for a chimney is cut in such a way that a base for installing a grid is obtained from it.

Further work on the manufacture of a spark arrester includes:

- Bars that are placed parallel to each other on the grid, leaving a part for attaching to the pipe. We press them with a hammer, all joints are welded with a welding machine.

- The resulting mesh should be wrapped around the pipe, pressed with clamps. You need to tap on the grid with a hammer - this way the stress will be removed from the metal.

- After bending, all edges and joints are welded.

You can take a ready-made, previously purchased piece of mesh, which is attached to the base pipe in the same way.

We mount the deflector and fasten the finished spark arrester

Now we make a deflector for the pipe. We cut out a visor in the form of a circle from a sheet of metal, bend it (all folds are attached from above with rivets), we get a small cone with a diameter larger than the diameter of the main pipe. This will be our visor.

The deflector is attached to the grid and the base of the spark arrester using metal strips welded or fixed with ordinary steel rivets. The ready-made spark arrester can be installed on chimneys using various mounting options for this (depending on the material of the chimney itself). These can be self-tapping screws, bolts, it is necessary to provide for the possibility of dismantling for.

Spark arresters are an additional element that are equipped with pipes to protect buildings from fires, they are placed on the top of the chimneys. This is a specially installed mesh and a deflector that prevent sparks from reaching the roof surface. All of them, passing through the grate, are simply extinguished on its cells.

It is recommended to install such a device for baths, saunas, when covering the house with flammable materials. In addition, the spark arrester keeps birds, foreign material, twigs, and other debris out of the chimney, greatly reducing the frequency of chimney sweeps. Installing a spark arrester ensures the greatest possible safety. You can make such a device with your own hands, for this you need the simplest materials and tools, the installation itself takes a minimum of time.

Do-it-yourself step-by-step manufacturing and installation of a spark arrester

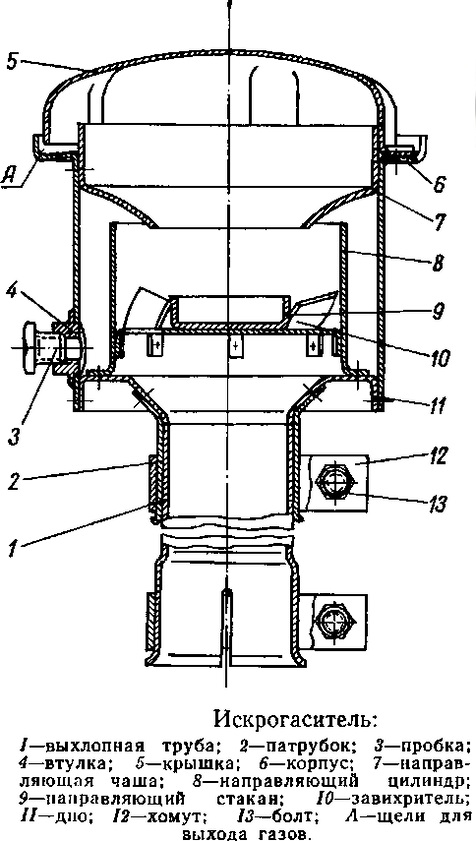

Consider a step-by-step manufacturing option for a spark arrester with a deflector umbrella, consisting of a body, a mesh structure and a deflector cap.

Necessary materials and tools

For self-assembly of such a spark arrester, you will need the following tools:

- measuring instruments (tape measure, level, etc.);

- screwdriver, clamps, pliers and hammer;

- rivets in a set or a welding machine;

- metal scissors, grinder, drill and drill bits.

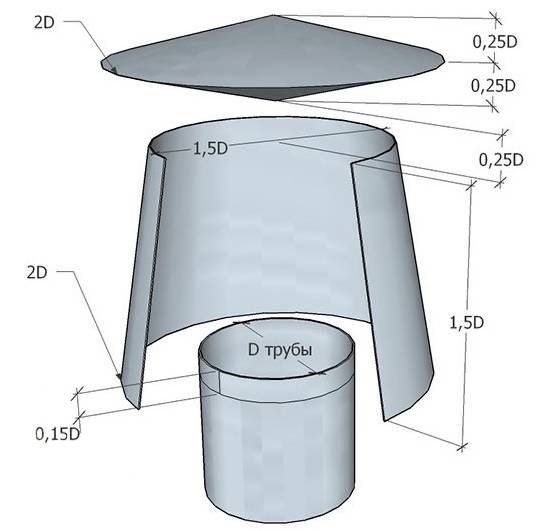

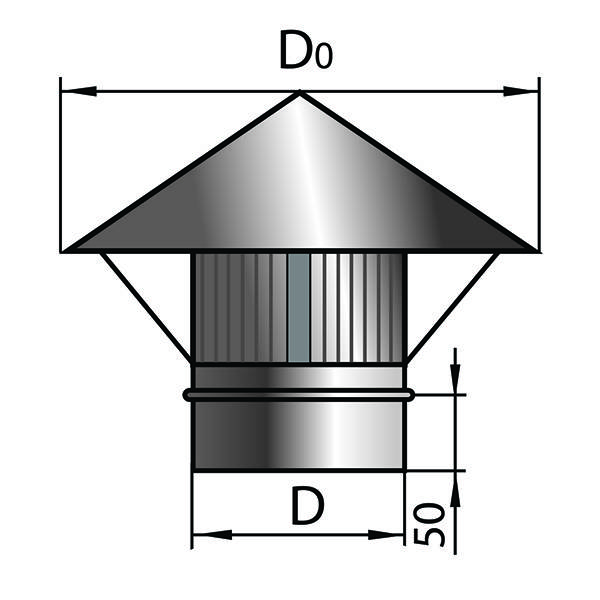

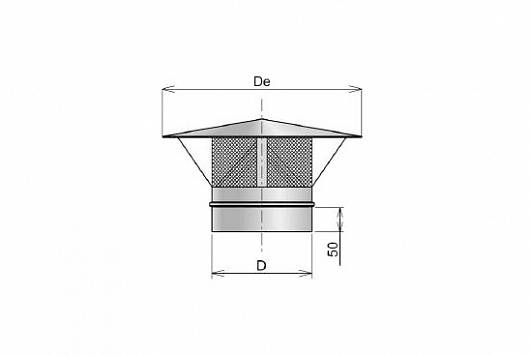

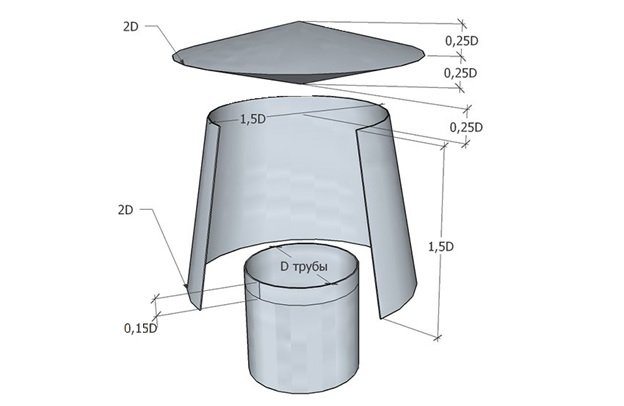

Drawing and diagrams

Here is an example of assembling a simple spark arrester based on a common basic drawing.

Let's designate the main components and along the way we will tell you how to make them:

- Cylindrical branch pipe - a glass that will be put on the chimney pipe. For the manufacture you need a metal sheet. We cut out a rectangle from it with a length equal to the length of the circle lying at the base (Fig. 2).

You can calculate the required dimensions using the formula: "L \u003d π × D", where L is the length, π ≈ 3.14, and D is the required cylinder diameter. We carefully bend the resulting strip with a pipe, for example, into a cone, combine the edges, drill several holes on them and fasten them with rivets.

- Metal mesh - a network with cells. It is best to purchase a ready-made stainless steel mesh base. A cylinder based on it is made in the same way as a glass.

- Protective umbrella cap - the main thing here is to correctly pattern the cone. To do this, we calculate the required workpiece radius using the formula: “C \u003d √ (h² + (D / 2)²)”, where C is the length of the lateral component of the cone, h is the required height, D is the diameter. Carefully fold the finished cut out scan with a cone (Fig. 3)

- Racks for connecting parts into a single structure are made from the same sheet metal. (Fig. 4) The length of the posts is determined by the dimensions of the structure, taking into account the required margin from below (approximately 20 mm for 1-2 rivets for attaching to the glass). It is better to place these elements at an angle to the vertical - from the pipe to the edges of the umbrella.

Now about assembly. We attach racks for 1-2 rivets to the “glass” pipe.We insert a mesh cylinder into the space between the racks-holders so that it enters the lower pipe a little and rests on the cone. Now we expose the fungus - we bend the mounting pads of the racks so that they fit snugly against the inside of the cone. We drill through holes through the racks and the umbrella, after which we finally fix the entire structure.

Size calculation

Before starting work, you need to measure the dimensions of the chimney, in accordance with which the sketches of the device will be displayed.

It is equally important to determine the correct size of the cells - they should not be more than 5 mm

Mounting Features

Proper installation depends on the dimensions of the device parts. At the slightest discrepancy between the diameters, it will not work to install a spark arrester on the pipe. A welding machine is used to connect individual elements. The joints obtained after welding must be thoroughly cleaned. For final fixing, you will need rivets or brackets.

Video: A chimney spark arrester will save your life and property

This is interesting: The main fire trucks - general and targeted applications

What is a spark arrester?

Spark arrester - a special "superstructure" with an umbrella, which is located on the chimney. It serves to prevent the exhaust of flammable sparks, soot and other combustion products. In design and function, the spark arrester differs from the deflector, which accelerates the air flow to increase traction.

The principle of operation of the spark extinguisher is as follows:

-

Smoke, together with the combustion products contained in it (ash, sparks, tar, soot, etc.) goes up the chimney to the spark arrester cover.

-

The cover changes the direction of the smoke so that it passes through the side screens.To do this, the structure is made in the form of a cone or dome so that the smoke is directed sideways.

-

The metal mesh extinguishes sparks and filters hot ash. Because of this, like any filter, the spark arrester must be cleaned periodically.

The grid is made of stainless steel and is firmly attached to the chimney or to the nozzle on it. The mesh openings of the grid should preferably not exceed 5x5 millimeters in size.

The umbrella is also made of stainless steel, and performs an additional protective function: it prevents debris, precipitation and birds from entering the chimney. Garbage is highly flammable and causes a fire: fallen leaves, branches, pieces of paper that have accidentally flown in and other flammable objects should not be in the chimney. Birds can get stuck in the net and die by disrupting the spark arrester. Also, the umbrella prevents precipitation from entering the pipe, disrupting its operation.

Where is it used and why is it needed?

Spark arresters can be useful for the pipe channel of any furnace: for a bathhouse, a country house, a cottage, a garage, a workshop and other buildings.

Stoves used for heating and other purposes (fireplace, potbelly stove, bakery oven, etc.) - need a spark extinguisher to avoid a fire.

Varieties of spark arresters

There are several options for creating a spark arrester:

-

The spark-extinguishing mesh is welded directly into the chimney. Unreliable design, clogs very quickly, but its manufacture requires a minimum of time and effort. It may be suitable for one season, after which it will need to be changed, or for rarely used rooms (for example, baths).

-

Elbow on the pipe.It reduces draft, sparks do not fly out as quickly (they can be extinguished better) and a more restrained flow of smoke provides additional heat. Minus - it can be implemented only at the stage of construction of the chimney.

-

Spark arresters are made in the chimney, and the end is tightly welded. Such a design can be made from a pipe cut and simply placed on top of the chimney so that in the future it can be changed without touching the “main” chimney.

-

The head-deflector is installed together with the spark arrester on the chimney. It serves to accelerate thrust and counteracts the creation of reverse thrust. If the weather in the area is mostly calm, and strong wind is rare, then its presence is not necessary.

According to the principle of action, you have to choose only from two options:

-

Standard spark arrestor.

-

Spark arrester with deflector.

The difference between them is significant only if the house is located in an area with frequent thunderstorms, strong winds (mountains, coastal areas, fields) and the pipe runs straight vertically. The deflector then accelerates the air in the pipe and throws sparks through the spark arresters at a higher speed, preventing back draft that can cause a fire. The functionality of the spark extinguisher suffers somewhat.

In forests or near towns, there is no need for a deflector, and only a spark arrestor can be installed (or add a knee to the chimney to slow down smoke and save wood, if it is just being built). The design for extinguishing sparks must be placed on straight chimneys, especially if the roof is made of combustible materials.

Where is it sold and how much does it cost?

Similar products can be found ready-made, in stores that sell stoves and heating boilers.They can also be offered by companies that design and build chimneys.

Spark arrestor on the chimney

Approximate cost:

-

a simple "grid" that is inserted into the chimney: from 100-200 rubles;

-

spark arrestor with an umbrella, mounted on top of the chimney: from 700-900 rubles.

Features of the care of the spark arrester

The complexity of maintaining a spark extinguisher installed on a chimney depends on the model chosen by the building owner.

The first option is a hat made of metal mesh. In this case, it is necessary to periodically check its condition - it can become clogged with combustion products, other debris brought by the wind.

Such a grid, especially when fuel with a high resin content was used for the firebox, needs to be cleaned of soot and burning quite often. Also, if the material for manufacturing was chosen cheaper, it will soon be necessary to replace the spark arrester with a new one.

When cleaning a structure in which the mesh is installed as a damper designed to collide with sparks, the structure will have to be disassembled. And this is a certain inconvenience.

Frequent walks to the roof to clean the mesh can also hardly be called a pleasant experience. Yes, even when from time to time you need to change the metal mesh on the chimney. Therefore, it is better to immediately select a better material for the manufacture of a spark arrester.

The second option is a deflector with a mesh inside. Here, it will also be necessary to periodically clean the metal cells of the grid, which are clogged with combustion products. After all, the more debris the mesh element of the device collects on itself, the more difficult the process of removing smoke will become.And this is fraught with big troubles.

The third option is a deflector with a skirt. Here it is necessary to periodically check that leaves, butterflies and birds do not close small holes designed to remove water from rain and melted snow. It is not necessary to remove the device from its workplace and clean it. This is the easiest model to maintain.

The fourth option is spark arresters made of metal alloys that are susceptible to corrosion. Such products will quickly become unusable. This must be taken into account at the stage of material selection.

To protect yourself from having to build a spark arrester every year, it's best to choose good quality 5mm stainless steel right away. The same applies to the metal mesh - it must be wear-resistant, preferably stainless steel.

The grid for the manufacture of the spark arrester must be heat-resistant, wear-resistant with a thickness of partitions up to 5 mm

Checking the spark arrester is carried out without fail when cleaning the chimney.

Spark Arrestor Features

The spark arrester installed on the pipe of the boiler room has a number of characteristic features that are unique to these devices:

- All spark arresters are designed for installation on chimneys connected to solid fuel heating systems;

- The size of the spark arrester cells cannot exceed 5 mm;

- It is imperative to install a spark arrester on a pipe if the roof is made of combustible or flammable materials;

- The installation of spark arrestors is also mandatory if the chimney design does not have turns and bends (such systems are found in saunas, baths, etc.);

- In addition to protecting against fire, spark arresters also protect the structure from external factors - for example, from birds mistaking the chimney for a nest.

- The spark arresting mesh is best made removable - it is actively clogged, so it must be regularly cleaned of dirt;

- A spark arrester (if necessary) is always included in the project, according to which the smoke exhaust system is being equipped. “What should be the chimney of a boiler room - types, features, standards and advantages of options.”

It is easy to assemble and install a spark arrester on a pipe with your own hands - it is much more difficult to choose materials that are optimally suited for this device and will allow you to achieve maximum efficiency. A bad example is ferritic steel or zinc-coated metal - these materials wear out very quickly, so you will have to think about repairing the structure very soon.

Sparks from the bath pipe: what to do

The spark arrestor does its job as long as the sauna chimney is functioning properly. Violation of the rate of smoke circulation leads to the fact that sparks begin to fly from under the cap. The first step is to figure out where they come from. Sparks are small particles of fuel that have not had time to burn in the furnace. With normal draft, they manage to burn out in the furnace, and some of them smolder inside the pipe on the way to the exit from the chimney.

With a decrease in smoke circulation, the fire in the furnace goes out. If the thrust is higher than normal, the opposite effect occurs. The fuel quickly flares up, crumbles into particles that do not all have time to burn. A strong draft of the air stream picks up these particles along with smoke and throws them out through the pipe into the street in the form of a beam of sparks.

The problem of sparks is inherent in a direct-flow pipe, which is the only drawback of such a chimney design. The fire from the furnace immediately enters the vertical pipe. If the chimney channel of the bath has knees, bends, horizontal sections, the smoke circulation is weakened. Even with strong traction, the sparks hit the walls of the pipe at turns, scatter into smaller parts, and have time to burn out before departure. However, curvilinear chimneys quickly become clogged with soot. For a bath with knees, a pipe is not the best option.

The problem is solved by reducing the speed of the smoke circulation of the once-through pipe. The draft is regulated by dampers, dampers, blower door. If positive results cannot be achieved, the residence time of smoke with sparks in the pipe is increased by increasing the length of the chimney channel. After the thrust is normalized, rarely flying sparks are caught by the spark arrester.

Attention! You have to be careful with traction. A decrease in smoke circulation below the norm leads to gas contamination of the bath with carbon monoxide, which is deadly to humans

Reducing the smoke circulation below the norm leads to gas contamination of the bath with carbon monoxide, which is deadly to humans.

The structure and principle of operation of the spark arrester

The spark arrester device of different models has distinctive design elements. Appearance is different. Common is the presence of a housing, a spark-extinguishing element made of steel mesh or sheet, as well as a cover that delays the escape of sparks.

All models of spark arresters work on the same principle:

- After igniting the sauna stove, hot combustion products are formed inside the furnace, consisting of gas, smoke, air, and small particles of unburned fuel. The draft air flow directs them through the chimney of the bath to the street.

- At the top of the pipe, hot air collides with the tip. The smoke freely escapes into the atmosphere, and the particles of burning fuel hit the extinguishing element made of mesh or sheet metal, the housing, the deflector cover.

- A burning spark that hits a metal element loses its heat capacity and quickly dies out.

The spark arrester most often traps large fuel particles. Small sparks sometimes slip through. If sparks fly strongly from the bath pipe, it is necessary to reduce the draft by closing the dampers. Another reason may be the burning of the spark arresting grid.

Spark Arrestor Models

Models of spark arresters differ in design, method of trapping and extinguishing sparks, and auxiliary features. Conventionally, the elements are divided into the following groups:

- Dynamic models deposit burning particles by gravity. From contact with a cold deflector and a grid of heat-intensive metal, the spark loses energy.

- Filtration models extinguish sparks and purify gases passing through the cellular filter partitions. For a bath, such a spark arrester is rarely used. More often it is found on the exhaust pipe of a car, tractor, combine.

- Liquid locks are a special type of spark arresters. The combustion products pass through the water, where 100% of the sparks are extinguished, soot settles. Cold air without the smell of burning comes out of the chimney outside.

A dynamic model is most often put on the pipe. However, even such a bath head has different modifications.

The simplest in design is considered a model in the form of a casing. Its main task is to capture sparks. More from the casing should not be expected. The deflector is more complicated. The spark arrester is equipped with an additional element for redirecting air flows.For some models, the weather vane rotates. In addition to extinguishing sparks, the deflector enhances the draft in the pipe.

This is interesting: Do-it-yourself floor in a chicken coop - you need to know this