- Film floor installation

- Manufacturers of IR underfloor heating for heating

- The principle of operation of heating with a warm infrared floor

- Types of warm infrared floors

- Option #1 - rod systems

- Option #2 - film systems

- Preparatory activities

- Tools and materials

- Calculation of the required material

- Project preparation

- Why Choose Electric Heaters

- Problems of infrared underfloor heating

- Rapid floor cooling

- Poor thermostat performance

- Film damage under linoleum

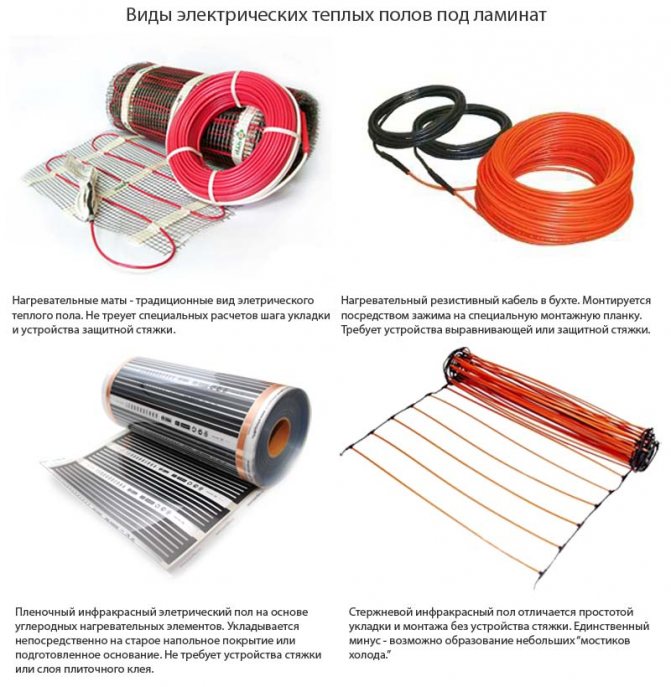

- Types of carbon floor

- Film floors

- Rod floor

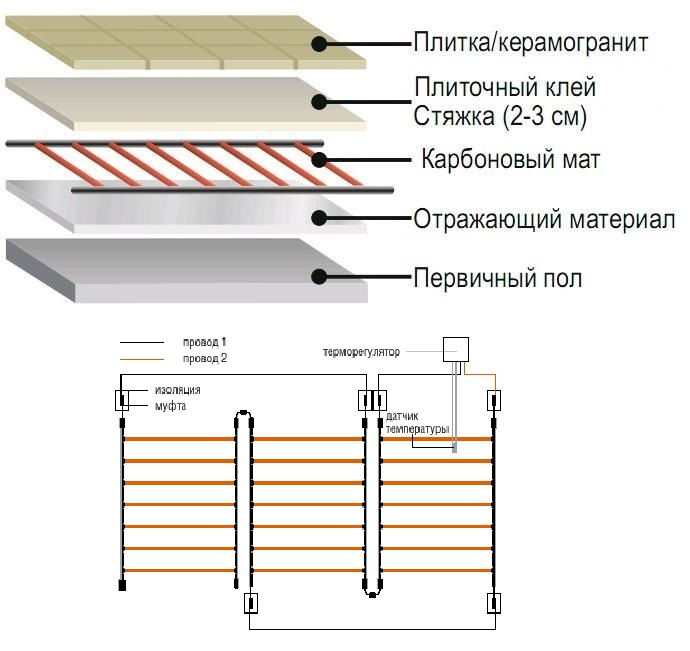

- Features of the device IR floor under the tile

- Device and principle of operation

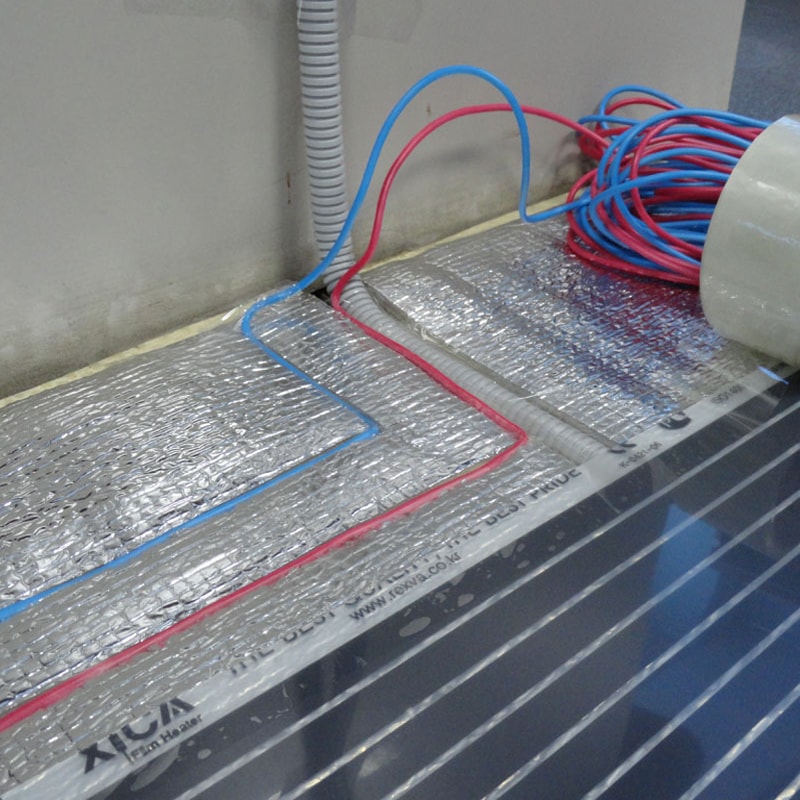

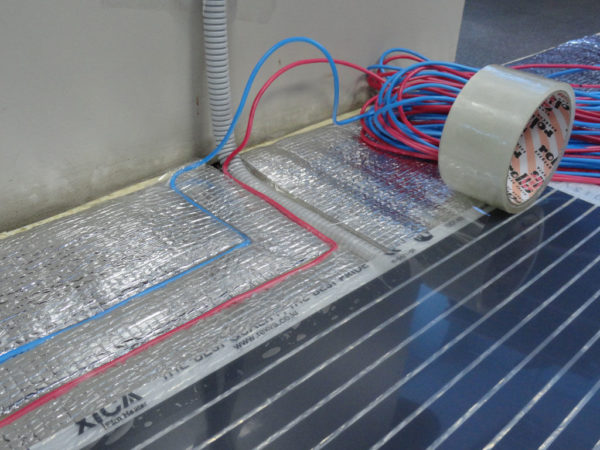

Film floor installation

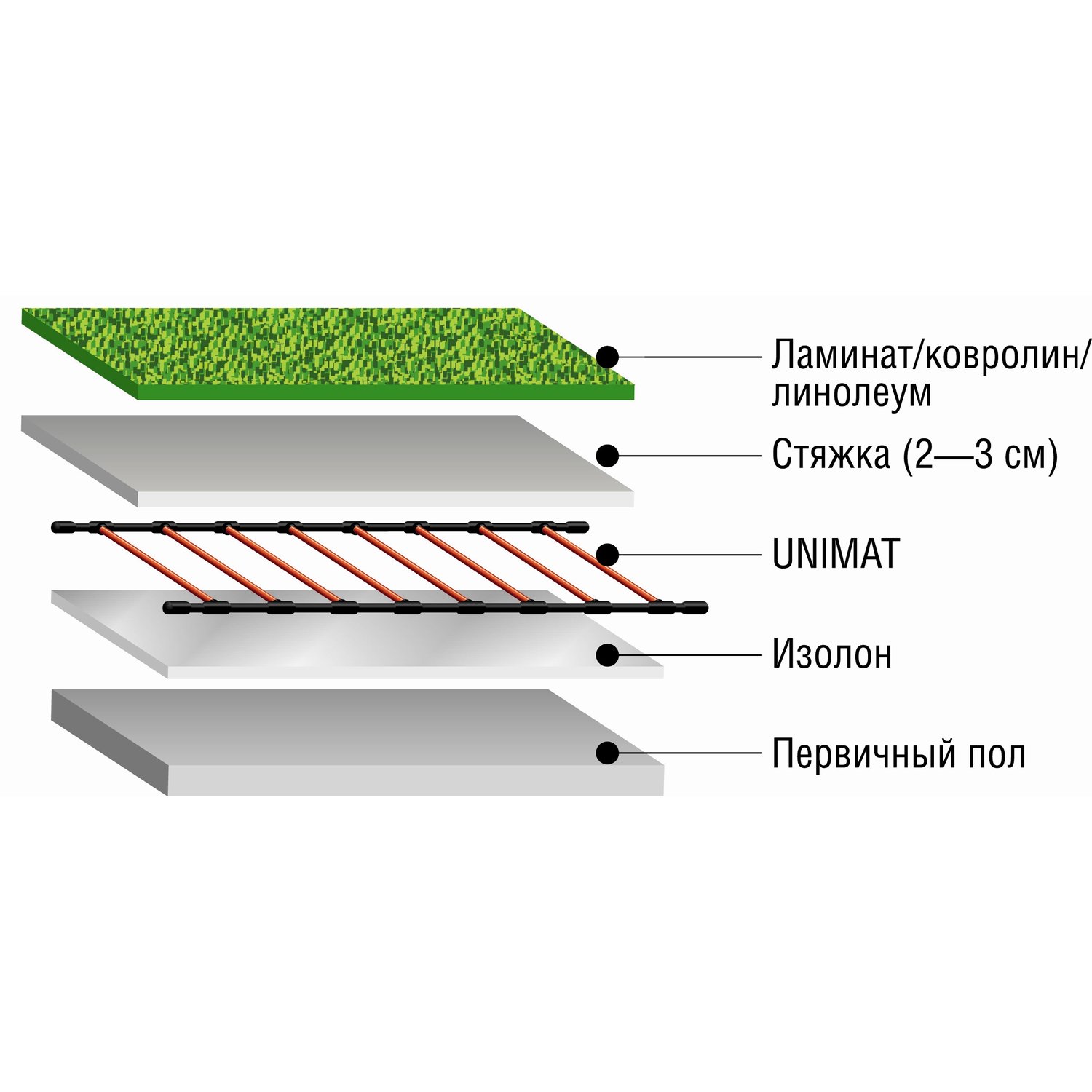

All carbon systems are laid on a flat surface. The base is recommended to be leveled. Differences of 1 mm per 1 linear meter are allowed. m. Thermal film and rods heat the entire surface around: not only the floor covering, but also the lower base, the foundation. In order for warm air to pass upwards, thermal insulation and a reflective screen are laid on the base. In the future, the installation of a thermal film is carried out.

On the floor, the boundaries of the "warm floor" are marked. From the wall and from furniture, the film is placed at a distance of at least 5 cm. The gap between the strips is 2 cm

Pay attention to the width of the roll. If the width is 50 cm, then the length of the tape should not exceed 13 m.The larger the width of the roll, the smaller the allowable length of the tape will be: width 80 cm - length 10 m; width 100 cm - length 7 m

The film is recommended to be pre-marked and divided into separate tapes.

There is space for a thermostat on the wall. Make a hole into which a plastic cup is inserted. It will contain the entire electrical part of the system and the control unit. The control panel is left on the wall surface.

Thermal film tapes are laid according to the marking. They are connected with adhesive tape.

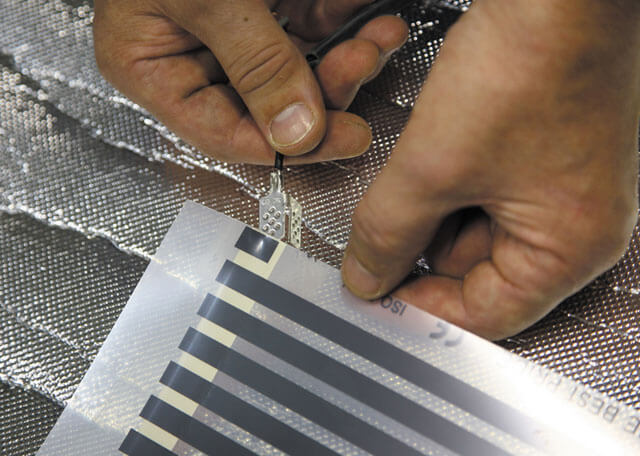

Contacts are connected to each sheet. The terminals are installed in the area of the copper and silver bus. Strengthen the terminals with pliers.

Install wiring; connect terminals. The connection scheme is parallel.

The joints are isolated with bituminous tape. Insulation covers the places of cuts in the area of \u200b\u200bmetal tires. So that the joints do not stand out on the surface and do not experience a large load from the floor cladding, a recess is made for them in the substrate or in the reflective screen.

A temperature sensor is installed on one of the tapes. A distance of 60 cm is maintained from the wall to the sensor, and 10 cm from the edge of the film. A niche is cut out under the sensor in the substrate.

All wires are led into a corrugated tube, which is connected to a thermostat. For the pipe, a groove is made in the floor and in the wall, which is then sealed with mortar.

The system is being tested. With a positive result, the carbon floor is covered with a substrate and a laminate is laid.

To lay the tiles, use tile adhesive.

The larger the width of the roll, the smaller the allowable length of the tape will be: width 80 cm - length 10 m; width 100 cm - length 7 m. It is recommended to pre-mark the film and divide it into separate tapes.

There is space for a thermostat on the wall. Make a hole into which a plastic cup is inserted. It will contain the entire electrical part of the system and the control unit. The control panel is left on the wall surface.

Thermal film tapes are laid according to the marking. They are connected with adhesive tape.

Contacts are connected to each sheet. The terminals are installed in the area of the copper and silver bus. Strengthen the terminals with pliers.

Install wiring; connect terminals. The connection scheme is parallel.

The joints are isolated with bituminous tape. Insulation covers the places of cuts in the area of \u200b\u200bmetal tires. So that the joints do not stand out on the surface and do not experience a large load from the floor cladding, a recess is made for them in the substrate or in the reflective screen.

A temperature sensor is installed on one of the tapes. A distance of 60 cm is maintained from the wall to the sensor, and 10 cm from the edge of the film. A niche is cut out under the sensor in the substrate.

All wires are led into a corrugated tube, which is connected to a thermostat. For the pipe, a groove is made in the floor and in the wall, which is then sealed with mortar.

The system is being tested. With a positive result, the carbon floor is covered with a substrate and a laminate is laid.

To lay the tiles, use tile adhesive.

Manufacturers of IR underfloor heating for heating

The construction market currently has many models of infrared warm coatings from various manufacturers. At the same time, many of them are little known to a wide range of consumers, and therefore the reliability and efficiency of such products are not guaranteed.

If you want to buy quality products from well-known companies, then the lion's share of the market is occupied by branded products from South Korean manufacturers, although there are also products made in other countries, including Russia. Some of the more well-known brands can be briefly reviewed below.

Caleo is a manufacturer of infrared underfloor heating from South Korea

The products of this company have earned popularity due to their high quality and efficiency, however, there is an essential point that must be considered when choosing it: due to its very small thickness (0.42 mm), infrared film requires great care and accuracy when laying

Marpe High Quality is an innovative infrared coating from the South Korean company Green Industry. Differs in high efficiency and economic power consumption, has a warranty period in 15 years.

Teplofol-nano - infrared film floors of German-Russian production. They are an innovative development: they are only 0.2-0.4 mm thick, and aluminum serves as a heating element in them. The warranty period is 7 years.

RexVa is another South Korean brand whose products are of high quality. Warm floors of this company are reliable and have an affordable price, which is why they are popular in Russia and the CIS countries.

Slim Heat - film underfloor heating, produced by a group of Russian companies "Special Systems and Technologies". The warranty period of operation is 7 years.

Heat Plus is another South Korean manufacturer whose products are very widely represented on the Russian market. Warm floors of this company are characterized by economical energy consumption, reliability and safety. The warranty period is 10 years.

Of course, infrared heat-insulated floors, with all their advantages, are far from the only option for efficient and convenient arrangement of heating in the house. There are many other very practical heating systems: water floor heating, central heating, heating mats, cables, etc. All of them have their advantages and disadvantages, a comprehensive assessment of which determines the choice of the best option in each specific situation.

The principle of operation of heating with a warm infrared floor

Most of the film materials used on the Russian market for organizing underfloor heating are of South Korean or domestic origin.

Most of the film materials used on the Russian market for organizing underfloor heating are of South Korean or domestic origin.

We will understand the principles of functioning of the IR underfloor heating. The work of the structure is in many ways similar to the action of the Sun. When connected to the network, the electric current begins to move along the heat-conducting fibers of the working surface of the warm floor. As a result, infrared rays appear, the strength of which is directed to objects located in accessible areas. That is, heat is transferred to furniture, a person, and other objects that fall into the field of view of IR rays.

The film floor can be successfully used as the main heating of an apartment or house, however, it is necessary that at least 70% of the floor be covered with this material.

The film floor can be successfully used as the main heating of an apartment or house, however, it is necessary that at least 70% of the floor be covered with this material.

Other types of heaters heat according to a different principle. First, heat is transferred to the air masses, after which it is transferred to objects around. At the same time, the laminate practically does not heat up. Even at high temperatures, the heating of the flooring is very slow. Because of this, a lot of energy is wasted.

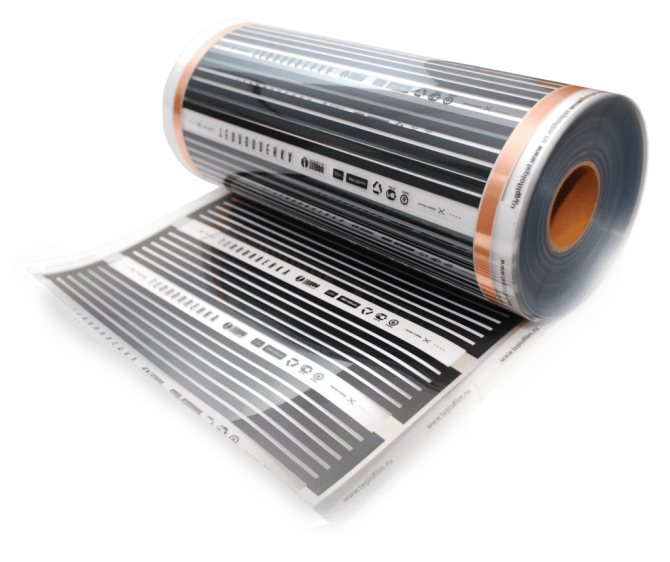

The infrared film is supplied in rolls, the width of the material can be from 50 to 100 mm, and the price largely depends on the characteristics and popularity of the brand.

The infrared design of the floor allows you to quickly warm up all the objects and the person in the room. In a short time period, comfortable conditions for being in the room are provided. At the same time, energy losses are minimal, since all resources go to useful heating. You will only pay for your own heating, not air heating.

If for some reason the central heating system is out of order, but electric energy is supplied to the house, with the help of a warm floor it will be possible to maintain in the living quarters, if not a comfortable temperature, then acceptable for normal life and protection from hypothermia.

If for some reason the central heating system is out of order, but electric energy is supplied to the house, with the help of a warm floor it will be possible to maintain in the living quarters, if not a comfortable temperature, then acceptable for normal life and protection from hypothermia.

Film structures can be installed in any room. They are suitable for use in homes, schools, offices and other institutions. At any time of the year, you can independently turn on and off the system, regardless of the main lines, so many users are starting to switch to such a heating system.

Types of warm infrared floors

Today, two types of warm floors with infrared radiation are produced - rod and film. Each has its own specific installation and use.

Option #1 - rod systems

They are mats of graphite-silver rods hidden in a copper protective sheath and interconnected by stranded wires. This system is powered by electricity. The current heats the rods and the carbon material inside them. He begins to emit heat in the IR spectrum. It rushes up and warms the room.

Rod cable floors are sold in ready-made coils and in the form of individual cables. The second option is cheaper, but requires proper soldering and connection.

Rod cable floors are sold in ready-made coils and in the form of individual cables. The second option is cheaper, but requires proper soldering and connection.

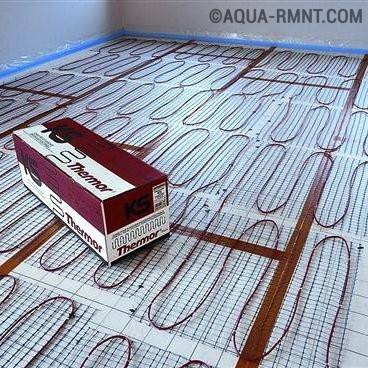

- first, a heat-reflecting substrate is laid, which will prevent infrared rays from going down and heating the neighbors' ceiling;

- then the mats are evenly rolled out and connected to each other into an integral system;

- fix the mats with masking tape;

- connect the sensor and thermostat, check the quality of work by powering the system from the mains;

- after making sure that the connection is correct, the rods are poured with a thin 3-centimeter screed.

When laying, the mats are rolled out so that they lie end-to-end or at some distance from each other. Overlapping them is prohibited!

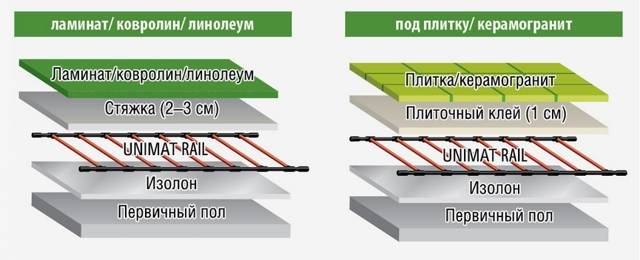

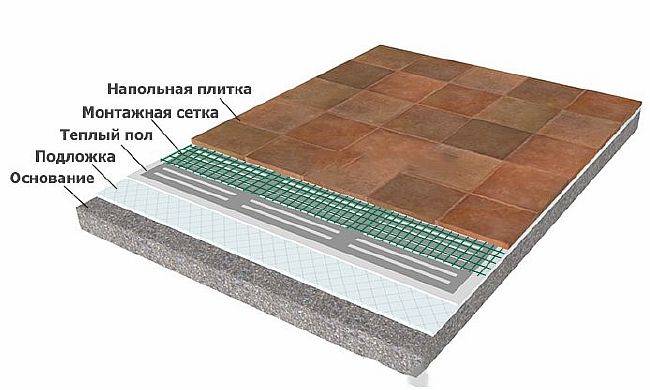

When laying carbon mats, you can want a thin screed or embed the cables in tile adhesive (depending on the finish)

Option #2 - film systems

An easier-to-install option is film infrared floors. In them, carbon is also the main conductor of heat, only it is placed not in rods, but in strips inside the polymer film.

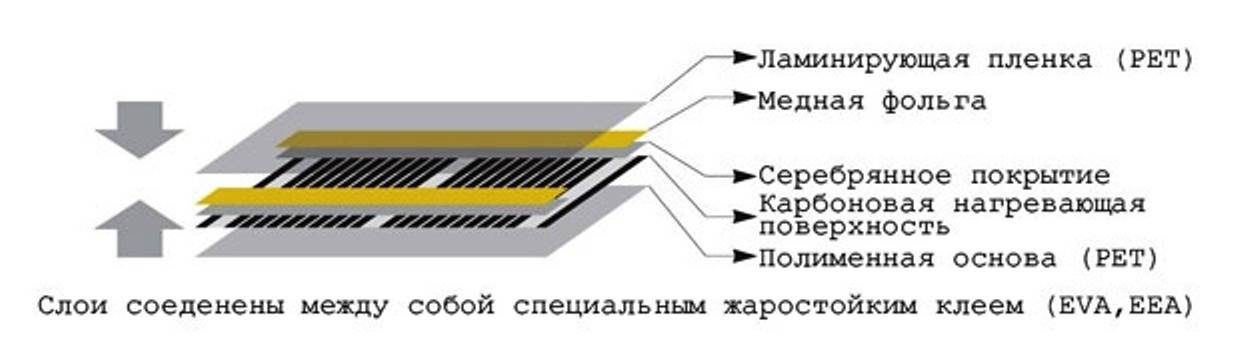

The heating elements in it are tightly laminated, so they are not afraid of moisture, accidental dents and punctures, although the total thickness of the film floor is only 0.4 cm. Carbon strips come in increments of about 1-1.5 cm so that the surface warms up evenly.

The heating elements are laminated with polymer material on top and bottom to isolate them as much as possible from accidental ingress of water and dust.

Film floors are laid without a screed (the so-called "dry" installation), laying a heat-insulating substrate from below so that all the heat rushes up. The finish coat is laid directly on the film.

So that delicate materials, such as laminate or linoleum, do not warp from temperature changes, a thin protective film is placed between the IR film and the finish coat.

So that delicate materials, such as laminate or linoleum, do not warp from temperature changes, a thin protective film is placed between the IR film and the finish coat.

Today, film is already being produced that is completely covered with carbon material, and not stripes. It is called continuous. And if in striped carbon material is applied by spraying, then in solid it is rolled out over the surface in the form of a paste.

Such a floor is more expensive, but it conducts heat better, since it does not have “dead zones” at the junctions of the sheets and between the strips.

Preparatory activities

Before starting the installation of a warm water floor under the tiles, it is necessary to prepare the material, tools and project of the future structure.

Watch the video

Tools and materials

To install the heating structure, it is necessary to prepare the following tool: a screwdriver, a tape measure, an open-end wrench, a puncher and a rule for leveling the screed.

In addition, you should purchase material:

- pipes and elements for their fixation;

- pump and valves;

- reinforcing mesh;

- hydro and thermal insulation material;

- construction livestock;

- fasteners.

Each type of pipe has its pros and cons.

Therefore, when choosing, you should take into account not only the characteristics of the product and the room in which they will be installed, but also your requirements and financial capabilities.

Calculation of the required material

To calculate the length of the pipeline, the characteristics of the tubular product and the features of the heating system should be taken into account. An online calculator can be used to facilitate calculations.

The program produces averaged data, therefore, a correction factor is applied for correction, which is influenced by a number of parameters. You will need to enter the size (diameter) of the pipes, laying step, information about the material of the contour, finish coating and screed.

To calculate the size of the pipeline, you can use the following formula:

L=S/n*1,1+k,

wherein:

- L is the length of the heating circuit;

- S is the area of the room;

- n is the laying step;

- 1.1 is the average safety factor for bending;

- k is the distance of the collector from the floor.

There is a simpler formula - each of the two adjacent sides of the room is multiplied by the laying step and the results are summed up. This is the length of the contour, only the distance to the collector should be added.

Project preparation

To make a project, you can use a sheet from a regular notebook in a cage. It is necessary to strictly adhere to the scale of the room in which the laying is planned.

You need to start the drawing by drawing the general outlines of the room, marking the areas where the doors, windows and the outer wall are located. With a large area of \u200b\u200bthe room, it is necessary to equip decompression seams, which are also reflected in the plan. Underfloor heating pipes should not be placed on these seams. But if the contour crosses them, then it is protected by a corrugated pipe.

Then, on the diagram, areas are marked where it is planned to install furniture that will fit snugly against the floor. There is no point in laying heating elements. The place of installation of the manifold cabinet is determined. After that, the laying scheme of pipes is reflected on the plan.

Two main schemes that are used when laying:

- "Snake" - the pipeline is laid along the wall with a certain step, that is, in one half of the room the pipes will be hotter than in the other, this method is recommended for small rooms;

- "snail" - pipes with hot coolant are placed parallel to those through which cooled water circulates, so surface heating is more uniform.

When drawing up a diagram, you must adhere to a number of rules:

- the length of one circuit is not more than 120 meters;

- all highways should be approximately the same - the difference is not more than 15 meters;

- standard pitch 150 mm, in the presence of a harsh climate, it can be slightly reduced;

- it is necessary to lay the heating element with an indent from the walls of 150 - 300 mm;

- the contour must be solid.

If you are not sure that you can do the project and calculate the material correctly, then it is better to use the services of professionals.

Why Choose Electric Heaters

New products are created taking into account the shortcomings of old designs. In this case, a comparison with liquid heat carriers would be appropriate.

The features of these traditional underfloor heating systems are listed below:

- They are installed in a relatively thick screed, which is limited by the diameter of the pipes. This design reduces the height of the ceilings.

- Special equipment is used to heat the liquid. If the boiler is fuel-fired, a separate chimney must be installed. In some multi-family buildings, current regulations cannot be met or would be prohibitively expensive.

- The increased complexity of equipment increases the risk of breakdowns.

- When leaks occur, the scale of the accident may be too large. In addition to personal losses, one has to compensate for the consequences of flooding neighbors.

- The water circuits must be emptied if the building is not in continuous use during the winter. In any case, measures are necessary to protect against the appearance of ice plugs inside the pipes.

In general, the system does not work effectively enough. Here, a coolant is used to transfer heat to a certain area. Losses occur in the process of its movement. Heating adjustment is allowed only in individual circuits, but not along the length of the route. High inertia degrades the accuracy of automated control systems.

Separately, it should be noted that the condition of the pipeline and the components of the system is negatively affected by:

- the liquid itself

- mechanical, chemical and biological pollution;

- pressure drops.

These shortcomings are eliminated with the help of electric heating.

The figure shows a set for a typical "electric floor heating" system. A conductor is inserted into the polymer sheath, which heats up when current passes through it. To adjust the operating parameters, you can use the data on the air temperature in the room, in the depth of the floor covering. The power is turned on instantly, so energy resources are spent rationally.

Problems of infrared underfloor heating

Incorrect selection and installation of underfloor heating film can subsequently lead to problems and system interruptions. This may be due to the poor quality of the purchased material, poor maintenance or improper installation. The main thing before buying is to study all the problems that may arise in order to be immediately ready to solve them.

Rapid floor cooling

This problem is especially pronounced if the electricity is often turned off.Heat quickly leaves the film, therefore, during installation, a heat-insulating substrate is usually laid between the subfloor and the heating elements. She will not allow the heat to go away, but rather will delay it.

Underlay to keep warm

Poor thermostat performance

All floor heating devices use special thermostats. They are necessary to automatically turn on and off the infrared floor heating. The device independently monitors when it is necessary to stop and resume the heat supply using special sensors.

Thermostat for underfloor heating

However, during an emergency and sudden power outage, problems with this equipment may occur. In some models, thermostats cannot continue their work on their own, because their automatic system is out of order. To prevent this from happening, it is best to choose infrared heated floors with a battery in the thermostat.

Film damage under linoleum

Installation of an infrared floor can be carried out even under linoleum. However, some models of this flooring, which are very thin and flexible, may cause the device to fail. Heavy furniture that will be placed on the surface, or jumping children - any mechanical impact can damage the infrared film.

Underfloor heating installation

That is why it is recommended to choose a denser coating, which will ensure the reliability and safety of the infrared floor. If it is not possible to purchase dense materials, then it is better to lay the existing linoleum in two layers.

Types of carbon floor

Now two types of carbon floors are produced - film and rod. They differ not only in structure, but also in the way of laying, and also have different technical characteristics.

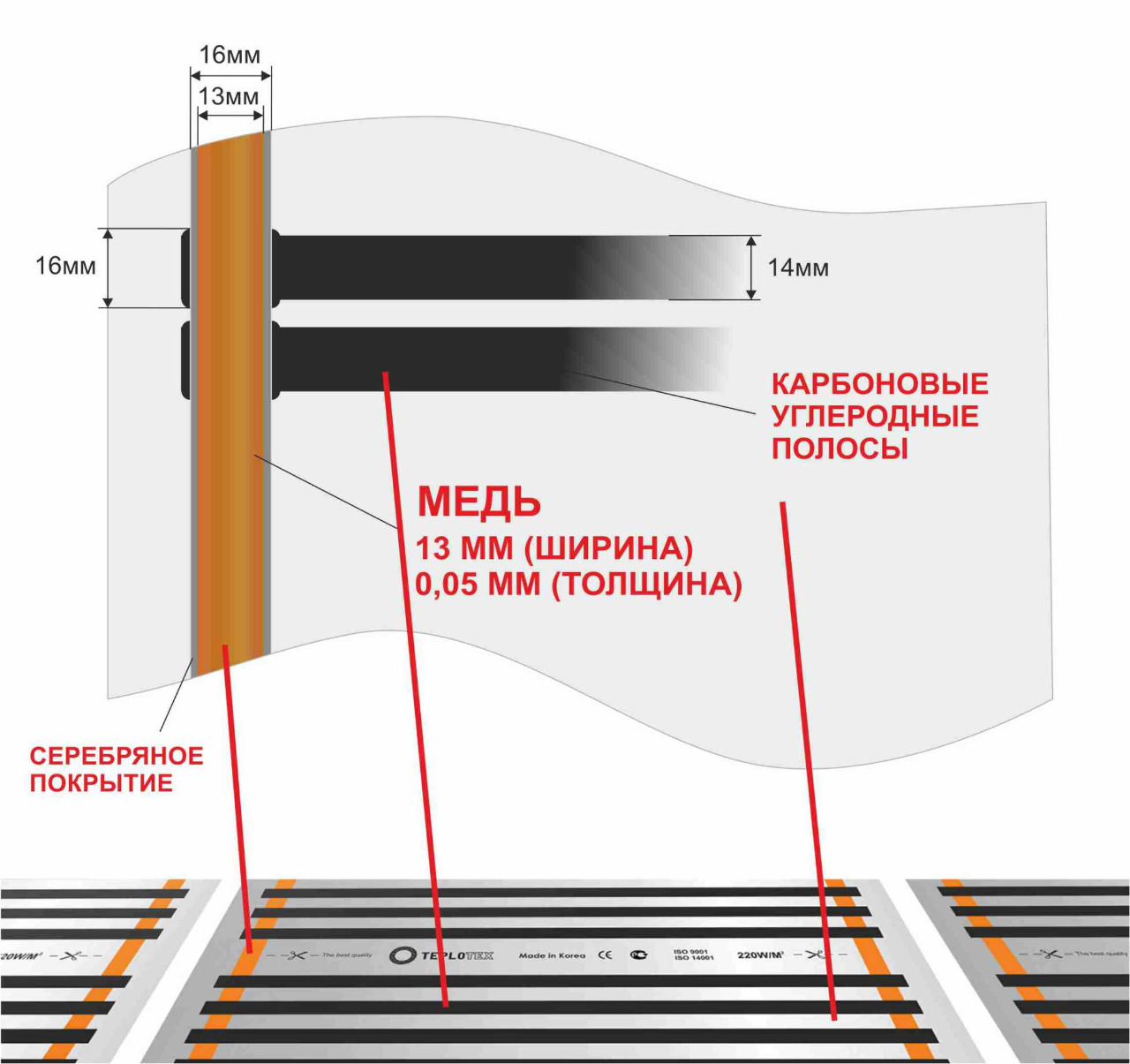

Film floors

A thermal film, or a solid warm floor, is a sheet of strips soldered together with heating elements, which are pure carbon or a mixture of carbon and graphite. The composition is applied by spraying onto a base of heat-resistant polypropylene, and then covered on both sides with a two- or three-layer protective film. The polymer shell is able to withstand heating up to 120°C without changing its characteristics, has high tensile strength and resistance to other negative influences. Copper bars are used for soldering strips.

Mounted film carbon fiber underfloor heating

Laying film floors is carried out on a dry, even surface directly under the finish coating, that is, there are no wet processes. This significantly speeds up installation and allows, if necessary, to easily dismantle the system and reuse it. There are certain restrictions when choosing floor coverings for such floors:

- felt-based linoleum, carpet, carpet tiles - materials with low thermal conductivity reduce heating efficiency by several times;

- tiles, porcelain stoneware, self-leveling floor - installation of the coating includes "wet" processes;

- natural parquet, solid board - can be used provided that the operating temperature of the system does not exceed 28 ° C.

Laminate - the best flooring for underfloor heating

The film floor can, if necessary, be cut into pieces to fit the size of the room.If during operation one of the sections fails, this will not affect the overall functioning of the system, and the floor will work as before.

Main characteristics of the film system

| Technical specifications | Values |

|---|---|

| Film thickness | 0.23-0.47mm |

| Power consumption | 130 W/m2 |

| Energy consumption per m2 | 25-35 Wh |

| Maximum heating temperature | 33°C |

| Roll length | 50 m |

| Roll Width | 50-100 cm |

Rod floor

The core floor has a more complex design. It is a system of flexible rods with a parallel connection scheme. The rods are made of a heat-resistant polymer and filled with a carbon mixture, and the elements are connected using a stranded copper wire in a protective sheath. The design also includes a thermostat and a special temperature sensor. Thanks to the parallel connection scheme, the system functions stably even if one or more heating elements burn out.

A feature of this system is the ability to self-regulate: when the temperature rises in a separate area (for example, under furniture), the power consumption of the heating elements drops, which eliminates the overheating of the system. Conversely, where the surface cools quickly, the rods heat up more, increasing the power consumption. Such unique properties allow you to lay the floor in any room without restrictions and install objects with a large contact area on top - cabinets, cabinets, beds.

Resistant to heat trapping and can be stowed under furniture

Rod underfloor heating RHE

The rod system is laid in a screed or a layer of tile adhesive with mandatory thermal insulation of the rough base.As a heat-insulating substrate, it is recommended to use materials with a metallized coating that is resistant to the negative effects of the screed components. Foil coatings in the mortar layer break down rather quickly, so they are not suitable for carbon floors.

Carbon underfloor heating has a self-regulating effect and changes its consumption downwards during operation

Main characteristics of the core floor

| Technical specifications | Values |

|---|---|

| Power consumption | 125-170 W/m |

| Energy consumption per m2 | 20-50 Wh |

| Energy consumption per m2 | 20-50 Wh |

| Step between heating elements | 10 cm |

| Construction width | 83 cm |

| Maximum allowable laying length | 25 m |

| Thickness | 3.5-5mm |

| Maximum heating temperature | 60°C |

Features of the device IR floor under the tile

The only feature in the design of such a “pie” with tiles is that it is not “dry” installation that is used, but tile glue is used or a self-leveling floor is made.

If preference

given to the "wet" method, when constructing film floors, it should be taken into account

a number of features:

- Slight adhesion - in connection with this,

simply pouring such floors with cement mortar is not recommended, since

the structure will be floating. If something falls on such a surface

heavy, then the screed may crack, and it will be difficult to eliminate these flaws.

Some try to increase adhesion by

notching the product, but experts do not advise resorting to such

way. These places are difficult to isolate, thereby leakage of current is possible.

The film does not tolerate alkali -

the alkali contained in the cement slurry will have a negative effect on

IR floors.This will lead to their rapid failure.

If, nevertheless, you decide to install the underfloor heating film under the tiles with your own hands, then during the installation process you should adhere to certain technological conditions, which are described in detail below.

Device and principle of operation

Warm carbon fiber floor refers to electric heating devices. Heating of a floor covering is carried out at the expense of infrared radiation. The range of operating waves is 5 - 20 microns.

Such a process in the system occurs due to its design, which consists of heating strips or rods filled with a carbon mixture. Each element is held together by copper conductors through which an electric charge flows.

All wires and heating parts are wrapped in a protective polypropylene sheath. Therefore, carbon heating equipment is not afraid of moisture. Due to the parallel type of connection, the IR heating system is able to function even if its individual sections are damaged.

The infrared radiation emitted by the electric carbon device allows you to evenly heat the entire floor area. In this case, heat is distributed to surrounding objects. Thanks to these properties, the air in the room does not dry out and a favorable microclimate is created.

Carbon warm film floor