- How IR film is arranged and works

- Connecting the film to the power supply

- Material Specifications

- Advantages

- Practical Tips

- Features of installation of film underfloor heating

- What is infrared heating and how does it work?

- Preliminary floor heating calculations

- What is new

- Advantages of infrared heating

- No. 4. What to look for when choosing?

- Specifications

- A few words about security

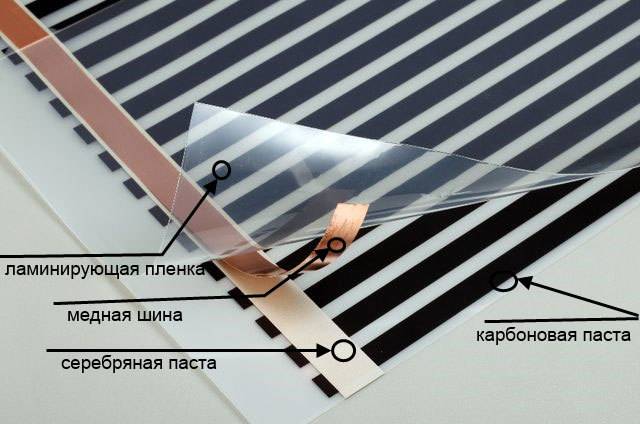

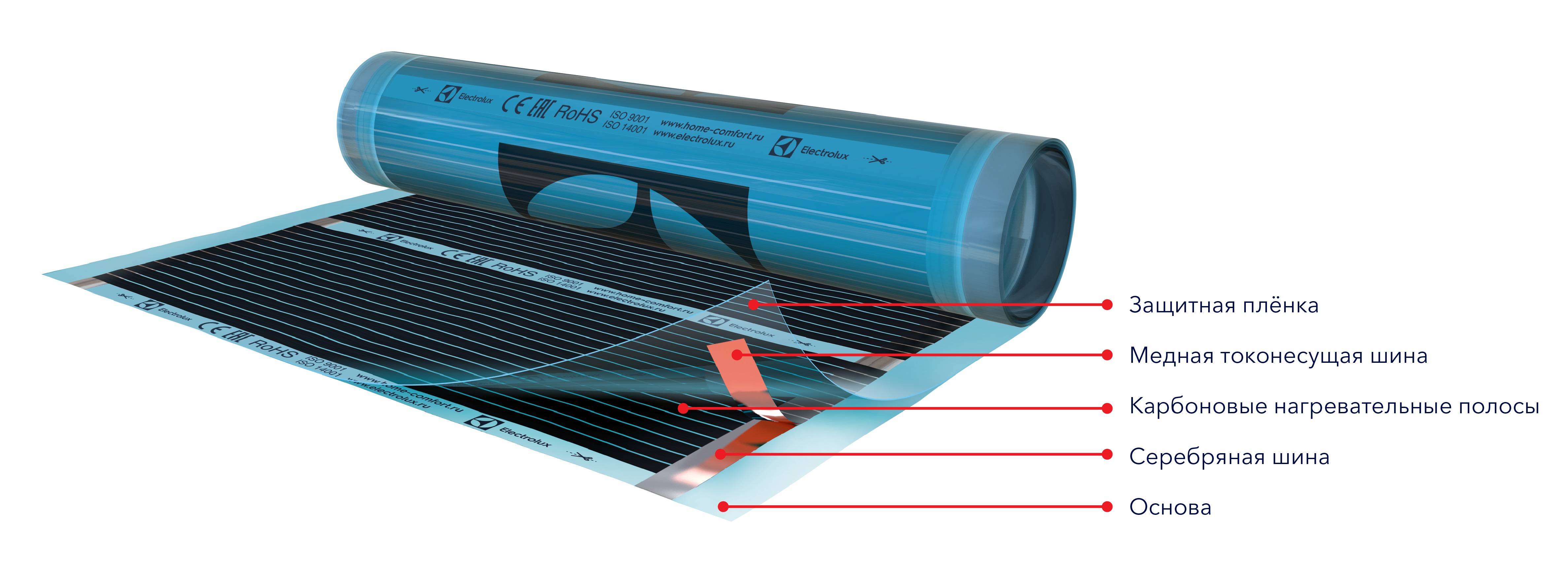

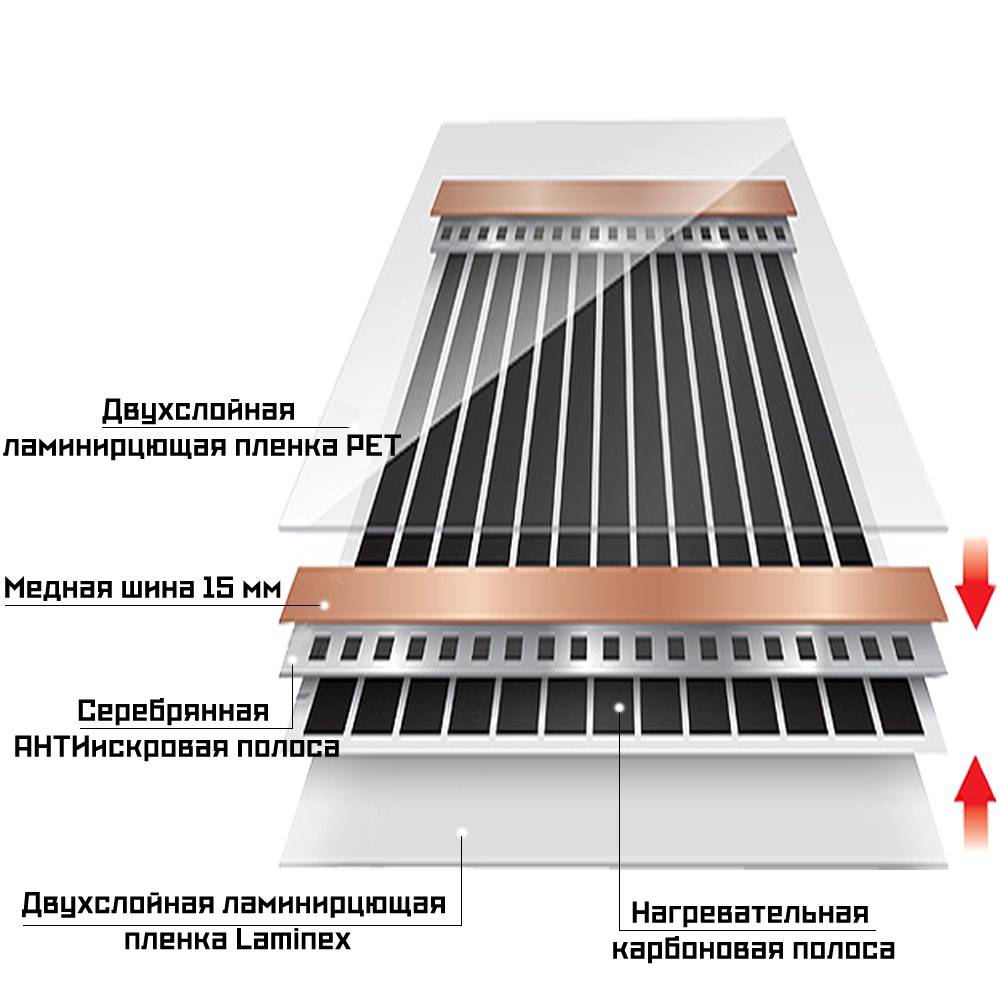

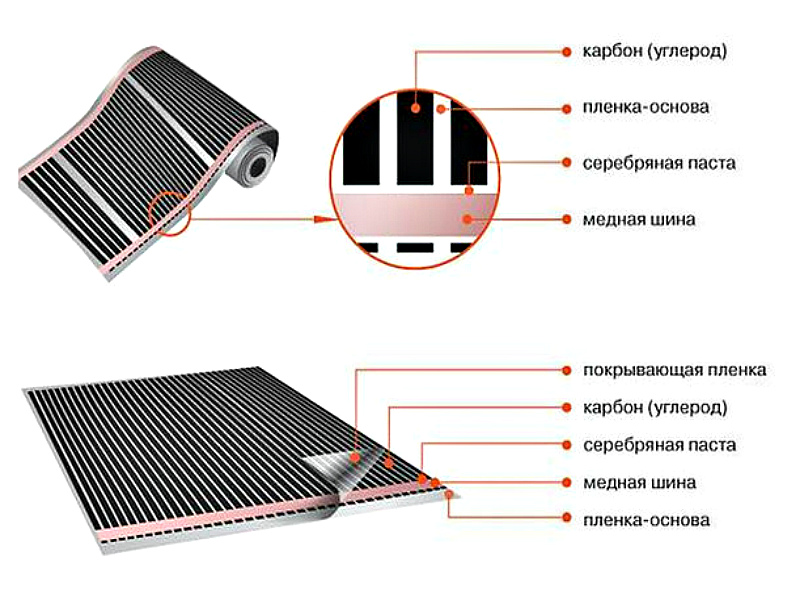

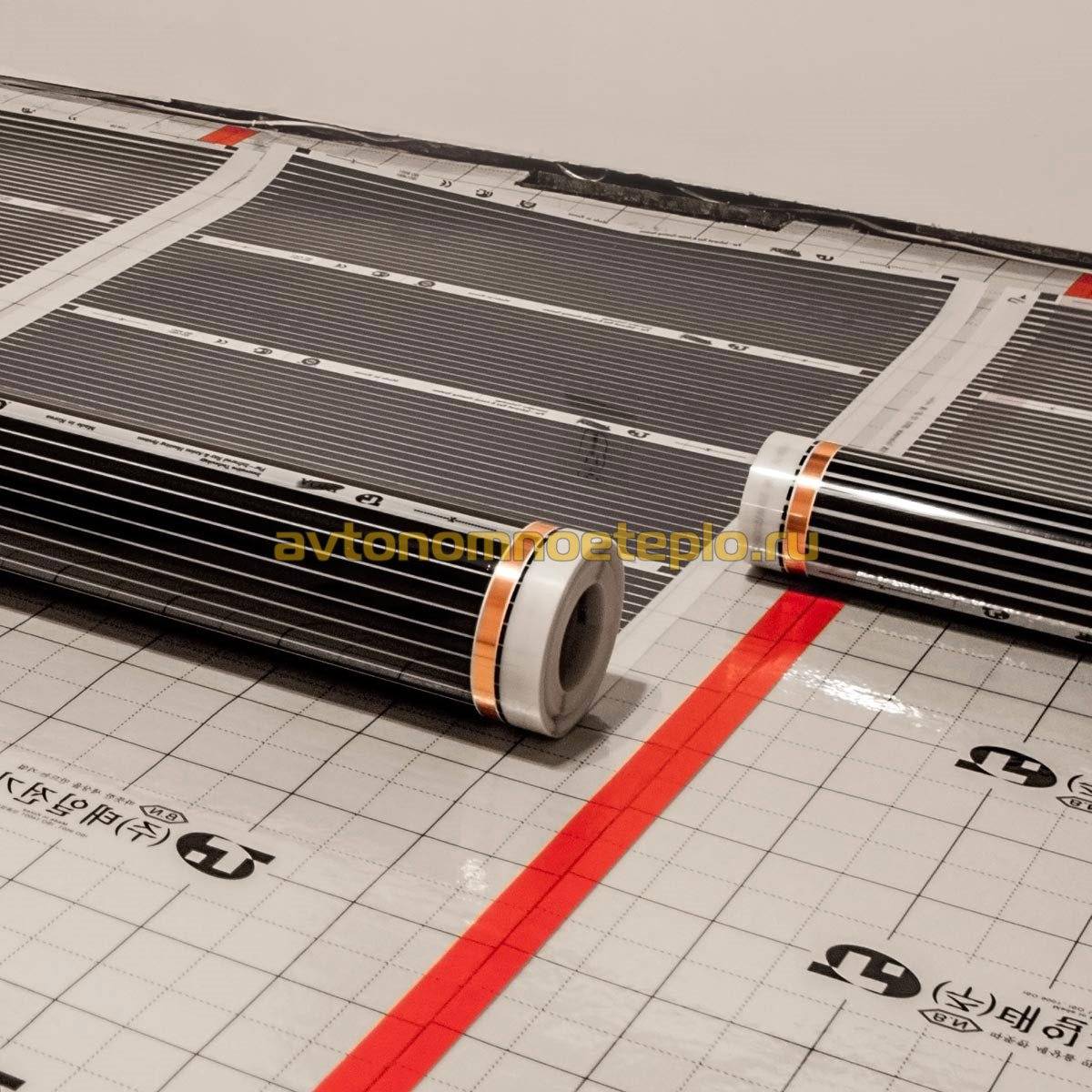

How IR film is arranged and works

We are talking about a very thin product: the film thickness does not exceed 0.22-0.4 mm. The canvas consists of five layers: an inner and outer base made of high-strength polymer material, and three inner layers. A special non-woven material is used to separate the plastic from the heating element. In the middle is the heating element itself, made of copper tracks (tires) and strips of carbon (carbon fiber). This composite material contains polymers and carbon fibers.

Thanks to the carbon atoms that make up the hexagonal lattice, the material, when electricity passes through it, begins to emit infrared radiation invisible to the eye. In the transverse direction to the sheet, heating strips 10-15 mm wide are located.For their fastening to each other, copper current-carrying bars equipped with silver-plated contacts are used.

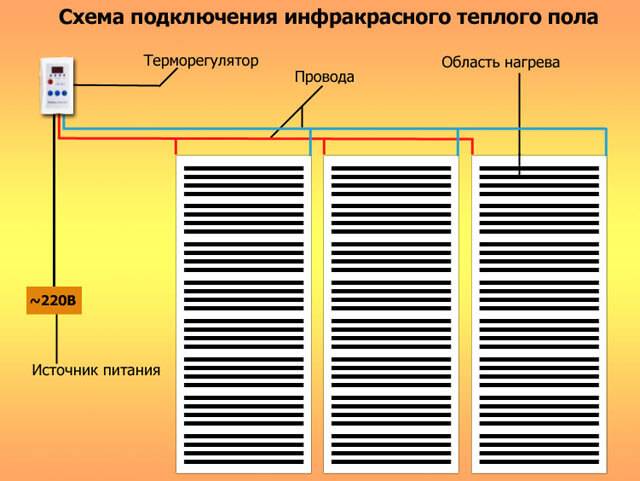

Connecting the film to the power supply

Some sellers recommend using the services of their own installation teams or authorized specialized companies. Only in this case they agree to provide long-term official guarantees when buying film heaters. But these methods are not always suitable.

With the help of the manufacturer's accompanying documentation and the following sequence of actions, you can independently implement projects of various levels of complexity:

- The heater for each room is selected with a certain power (the calculation scheme is given above). Taking into account this parameter, a circuit breaker is installed for one or more rooms in the power circuit circuit.

- In a convenient place on the wall make markings. This is where the thermostat will be installed. In building structures, channels are created for cable installation.

- To connect the power supply of film heaters, the braid and insulation layers are removed from the wire. It is inserted and fixed in the contact clamp with pliers.

- The other side of the clamp is attached to the copper bus of the film heater.

- Contact points are isolated on both sides.

- The wires are connected to the thermostat of the film heater.

- The temperature sensor of the film heater is connected to the dark strip (heating element) from the bottom side.

- After connecting all the elements of the film heater and checking the insulation, a test run is performed. The temperature is set at a level not exceeding +32°C.

- It is recommended to make sure that all film strips are heated.

- An increase in temperature at the points of connection of the clamps, sparking are signs of improper installation. It is necessary to restore the integrity of the contacts of the film heater, to create reliable insulation.

The contact clamp of the film heater is installed between the layers of the laminate

Might be interesting

Material Specifications

The data below on the infrared film for underfloor heating are of an overview, averaged character. The specific characteristics of the product must be specified at the time of purchase.

The proposed data is sufficient for planning the location of the canvases, marking the base, calculating the power. Based on the technical features, you can understand whether the IR system is suitable for operation in specific conditions.

Thermal film indicators:

- Roll width - 50-100 cm. For domestic purposes, as a rule, coatings with a width of 50-60 cm are used. When arranging a bath, office or industrial facility - 70-100 cm. Total energy consumption is almost the same, but wider material will cost more.

- Strip length - 6-50 m. The maximum permissible value is determined by the manufacturer. In a long room, it is advisable to make a separate connection in halves with the installation of two thermostats.

- Power supply from the mains at 220 V. A household single-phase power supply is used.

- Peak power consumption - up to 150-230 Vkv.m. The parameter depends on the manufacturer and type of film. On average, to maintain the temperature in the room at 21-24°C (30°C on the surface of the film), energy consumption will be 25-45 W/sq.m.

- The melting temperature of the thermal film is 210-250 °C. Subject to all the rules for laying a warm floor, the surface temperature of the IR coating will never reach critical values.

After switching on, the film heats up to the maximum temperature in 2-3 minutes.

The efficiency of far infrared rays reaches 90-95%. The efficiency of heating largely depends on the quality of the thermal insulation of the room. In order for the system to warm up the room, the area of the thermal film must be at least 70-80% of the floor surface

Advantages

This method of heating has a number of advantages over other methods of heating a home:

- Simple styling. This will not require the dismantling of the old base, if its condition is more or less normal. As a rule, only additional insulation is carried out so that the thermal energy from the infrared film is redirected inside the dwelling.

- The level of the floor upon completion of the installation of the film remains unchanged. This is very convenient if the house has low ceilings.

- The system does not need additional application of the top concrete layer. Thanks to this, installation activities are not accompanied by a large amount of dirt and dust.

- It is allowed to lay any decorative coating on top of the heating film.

- This type of heating provides uniform heating of the room, which makes it possible to avoid temperature fluctuations in different parts of the room.

- The surfaces of the room heat up at a high rate. The inertia characteristic of other heating systems is absent here.

- The infrared floor is not afraid of mechanical and dynamic influences. This makes it possible to lay it in areas with a high intensity of human flow. We are talking about public buildings, gyms, kindergartens, schools, etc.

- To heat a room with an infrared film, you will need an order of magnitude less energy than in the case of using a traditional electric floor or household heaters. The difference sometimes reaches 40%.

- This heating system, if necessary, can be easily disassembled. Such situations usually arise when moving to another house. The film can be quickly removed and folded, subsequently installed in a new apartment.

- The material is well resistant to any destructive influences. If the connection of one of the sections is broken, not the entire film will turn off, but only one of its areas.

- Not the entire floor can be equipped with infrared heating, but only that part of it that is used most often. Usually, areas near an armchair or sofa, under a desktop or in the center of a children's room are insulated.

- IR film well reduces the intensity of unpleasant odors, ionizes the air without overdrying.

Practical Tips

Warm infrared floors allow you to save up to 30% of electrical energy due to better placement and an improved temperature control system. Professionals recommend choosing elements with a power reserve, this greatly increases their service life. The fact is that when the cold system is turned on, it works with critical loads for quite a long time, a lack of power can cause premature failure of the heating elements.

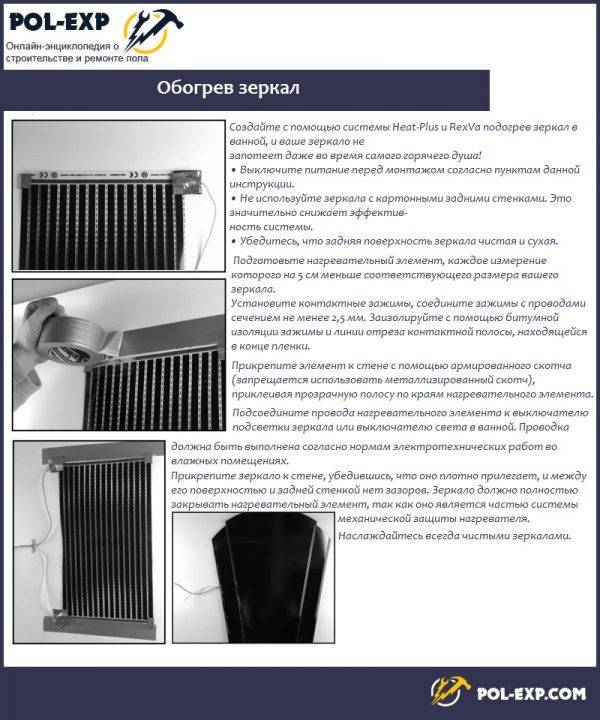

Infrared floor heating is best installed in bathrooms and shower rooms, in rooms with a small area and a minimum amount of furniture.

Heated mirrors

The less often the floor is completely cooled, the longer the system will work. It takes a long time to heat a cold floor to a predetermined temperature; during this period, the system operates with maximum loads. If you need to lower the temperature in the rooms, then it is better to do this with the help of a thermostat, and not by completely turning off the power.

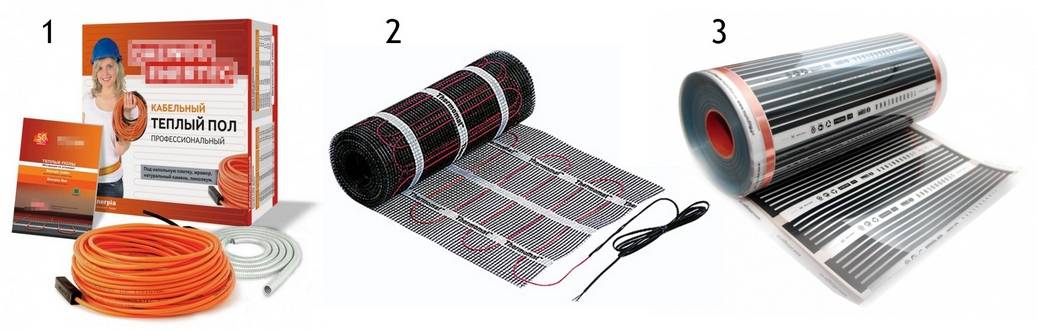

Features of installation of film underfloor heating

The main nuance of installing an infrared underfloor heating is a correct assessment of the capabilities of the electrical network. If a film or rod system is mounted as an additional heat source, then an ordinary outlet is usually enough to connect it. It consumes about 100-200 W / m2 of electricity. For a couple of squares on the floor in a nursery or bathroom, the power in the available sockets is enough.

IR floor under tiles or linoleum

But if the IR film or rods are laid as the main and only heating, then they will have to lay a separate line from the electrical panel. And even a small house with an area of 100–150 m2 will require about 20 kW of power consumption. Are they available?

Up to 15 kW is usually allocated to private cottages. If you have to agree with the power engineers to increase the allocated kilowatts, then this is a lot of wasted time and additional costs.

But without sufficient power, the installation of infrared floor heating cannot be carried out. This is not the installation of plastic windows for which no permits are required. With an electric infrared floor, everything is somewhat more complicated. For example, the same forced ventilation or a borehole pump in a private house is installed without approval.But for a powerful underfloor heating of the type in question, it is most likely that you will need to obtain specifications for additional kilowatts.

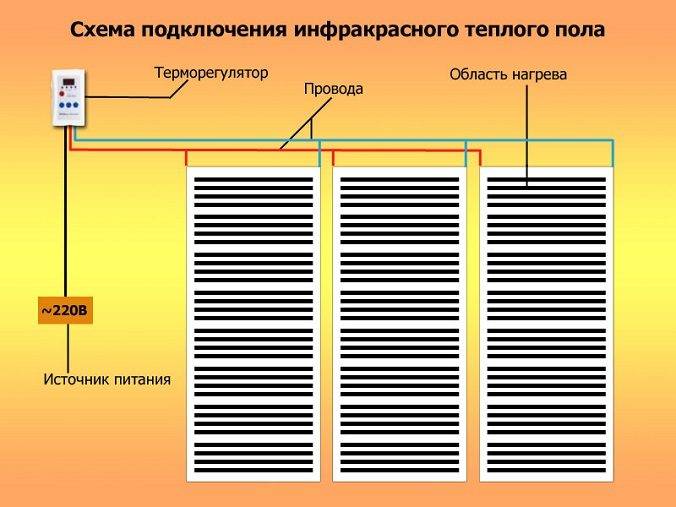

Step by step instructions for laying underfloor heating

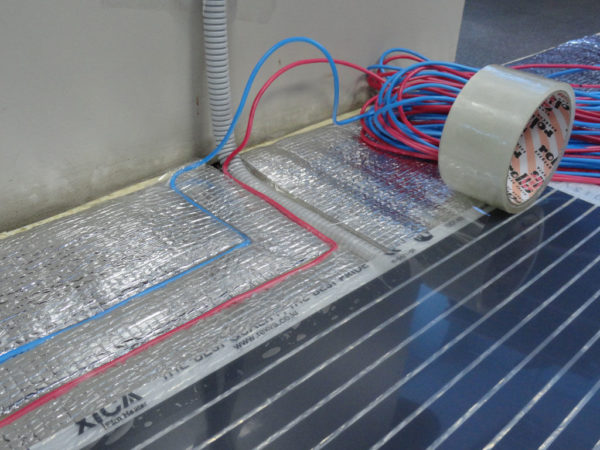

Installation of an underfloor infrared heating system is carried out in six steps:

- Folgoizol or an analogue is laid on a leveled draft base.

- On the active area (where heating is required), the film or rods are laid out.

- The heating elements are tied with wires and special terminals.

- The thermostat is mounted on the wall and the temperature sensor on the floor, and then everything is connected together into a single system with its connection to the mains.

- The heater is being tested.

- Flooring is being laid.

The IR film from the roll is cut exclusively across the strip in specially marked places on it. Damage to carbon elements must not be allowed. And the terminals at the wiring connection points must be covered with bituminous insulating tape.

When properly installed, underfloor heating film is absolutely safe. If the terminals are connected, crimped and insulated properly, the risk of short circuits is minimal. The heating of the carbon elements themselves is carried out only up to 30–45 0С, up to a maximum of 60 0С. They are not capable of melting or setting fire to anything.

Underfloor heating connection diagram

What is infrared heating and how does it work?

The film warm floor consists of two layers of dense polymer, between which there is a heating element - a carbon nanostructure with unique properties. The carbon atoms, formed into a hexagonal lattice several nanometers in size, give the material the ability to emit in the far infrared spectrum.Infrared radiation is a part of the light spectrum invisible to the human eye with a wavelength of 5-20 microns. Such radiation is recognized not only as harmless, but even beneficial to human health. Often this type of radiation used in surgery, dentistry and sports medicine.

Infrared film underfloor heating consists of the following elements. Strips of carbon material about 1.5 cm wide are interconnected by silver-plated copper bars, which conduct electricity. The heating element is laminated on both sides with a dense polymer that does not delay infrared radiation and provides excellent protection against moisture, breakdowns and fire.

Infrared floor heating design

Advantages of the infrared system over other options warm floor:

- This type of underfloor heating is very easy to install. It does not need to be covered with a concrete screed, which will allow you to lay it at any time, even when the repair is completely over.

- The film heat-insulated floor has no restrictions on the choice of a fine floor covering. It can be used under laminate, parquet, carpet, ceramic tiles and any other decorative surface.

- The thickness of the film is usually 0.2-0.4 mm. When using it, the floor level practically does not rise, which allows you to do without steps and thresholds when you decide to arrange a warm floor in only one room.

- Low inertia allows the film to heat up quickly and stop heating just as quickly. This means that you do not have to specifically monitor the readings of the thermometer: if you freeze - turn it on, warm up - turn it off.

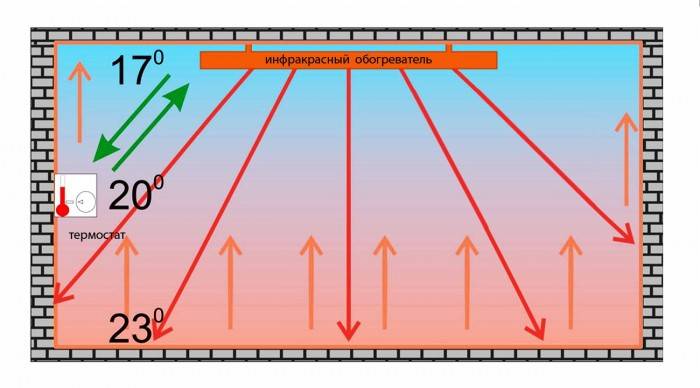

- Infrared radiation heats the room evenly and does not create a temperature difference from the floor to the ceiling.

- The film can be used in areas where there is a significant load on the finish, such as gyms, offices, public areas.

- Due to the special design of the heating element, the installation of an infrared warm floor helps to save a lot. Such heating consumes 25-30% less electricity.

- Easily connects to the smart home system.

- Such a heating film practically does not create an electromagnetic field that adversely affects human health.

It is also important to note that not only installation, but also dismantling of the system is easy. If necessary, you can take it with you when you move.

It is possible to strengthen the infrared film not only on the floor, but also on the wall or ceiling. It can even be used inside a car

Preliminary floor heating calculations

To calculate the infrared floor heating, you need to draw a plan of the room on a piece of paper. Mark the places that will be filled with furniture or household appliances. Be sure to consider a convenient location for the heat regulator. It is to him that power is supplied, wiring from the heating element, as well as a temperature sensor.

Then you need to distribute the strips of the film without overlapping them, but at the same time you need to fill the entire required area as much as possible.

Owners of IR warm film floors claim that this type of space heating can be installed independently in a very short time.And it depends not on the level of skill, but on the installation area. So, for example, a balcony can be insulated in 1 hour. If the floor is not in "potholes", then concrete work will not be required.

In the first case, products are needed, the power of which is from 250 W / sq. m. If the infrared film is planned to be used as an aid, then it is quite possible to choose a model of about 150 W / sq. m. Before starting work, you must carefully study the instructions for installation and operation of the product.

How to calculate infrared floor heating if you need to lay tiles on top? Porcelain stoneware strongly absorbs heat. So that it is not cold, the film model must be of sufficiently high power, at least 220 W/sq. m.

What is new

The optimal temperature regime in the home is the key to its comfort and coziness. This component cannot be replaced by comfortable beautiful furniture or high-quality interior decoration. If it’s cold in the house, you can’t even dream of any good rest. Especially often this problem occurs in cases where the heating season has not yet officially begun, and cold weather has already set in the street. A good solution to this problem is the use of self-contained film floors, which can be turned on as needed.

Installation of other modifications of the "warm floor" is characterized by a significant amount of additional work: as a rule, these systems are built into a concrete screed. These activities are quite laborious and require decent financial costs. It is for this reason that after the appearance on the market of infrared film for underfloor heating, it is becoming more popular day by day.Before purchasing and installing the system, it is recommended to understand its characteristics and installation technology.

Advantages of infrared heating

Among the advantages that show reviews of infrared heating, the following should be noted:

Infrared heaters do not change the humidity of the air and are not able to burn oxygen in the room;

Such heaters are not capable of creating dust and convection air currents, and this is very important for comfort;

Ceiling infrared heating has a compact size, which saves usable free space;

Infrared lamps for space heating do not produce noise during operation, and also do not emit harmful substances into the air;

This heating system not only does not pose a threat to human health, but to some extent it is wellness;

Infrared radiation is not harmful to human health

Infrared radiation is not harmful to human health

- Such home heating with infrared heaters will be more efficient for buildings of this type, such as private houses or country cottages;

- Compared to conventional heating systems, infrared heating is more economical. If we talk about numbers, then such a heating system saves up to 70% of the funds that would be required to pay a receipt for centralized heating;

- Infrared film is characterized by a long service life, which can reach 30 years;

- During the operation of infrared heaters, there is no need to remove combustion products, since they are not emitted at all;

- For infrared heaters, power surges or its emergency shutdown are not terrible;

- Infrared home heating lamps and their rays are not only a good way to heat, they can also help get rid of problems such as humidity, dampness and mold;

- Such devices do not contain elements that heat up above a temperature such as +38 degrees, so they are considered safe in terms of fire safety requirements. In infrared heaters, special devices are built in that will protect the device from overloads;

Temperature distribution in the room with ceiling infrared heater

Temperature distribution in the room with ceiling infrared heater

- The probability of electric shock or fire is at zero level;

- Infrared heaters as the main heating have one of the highest levels of protection and fire safety;

- Such heaters can heat the local area where people are located even in large areas or with high flows;

- IR heaters quickly warm up the area where people are and effectively maintain the optimum temperature there;

- Such heaters are distinguished by ease of installation. Also, their installation does not take much time;

- Ceiling heating plan is very easy to manage and convenient to use. Thanks to such devices, it is possible to maintain any temperature even if the owners of the house are absent;

- Infrared lamps for heating work in automatic mode, they are also compatible with an electronic control system. This allows you to control their work, as well as record and save the main operating system parameters;

- As for the electromagnetic field of such devices, they are at the background level, and compared to many electrical devices, it is rather small.

Infrared heaters can be used to heat a specific area outdoors

Infrared heaters can be used to heat a specific area outdoors

No. 4. What to look for when choosing?

When buying film infrared underfloor heating, it is important to pay attention to the name of the manufacturer, the declared characteristics and the appearance of the film. What should a high-quality film look like, and what performance qualities should it have? When choosing, pay attention to the following parameters:

-

power, on which it directly depends on which flooring the film can be used with. The power consumption of the system ranges from 130-450 W/m2. For laying under linoleum, carpet and other light floor coverings, a film with a power of up to 160 W / m2 will be enough; saunas;

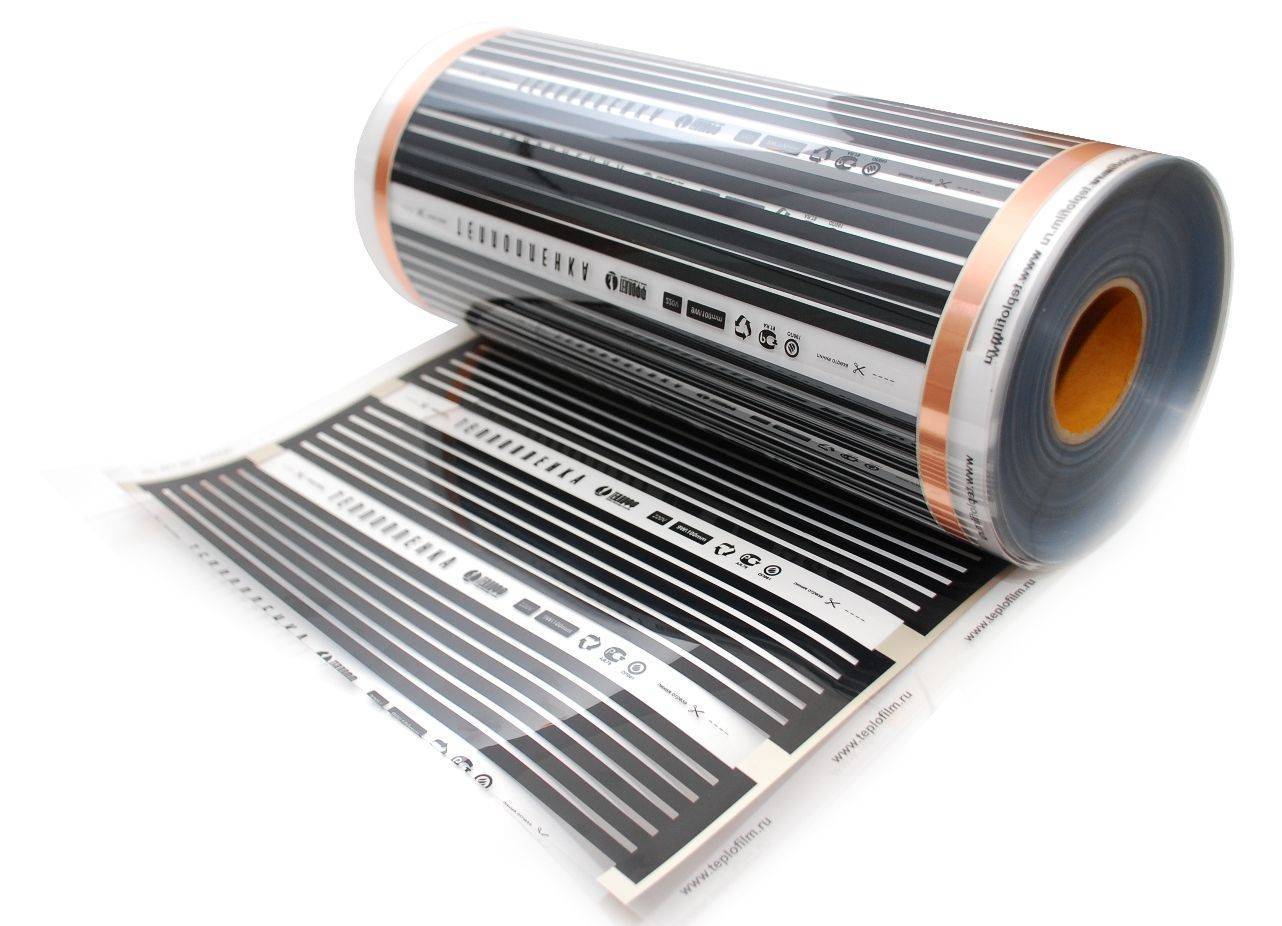

- The film thickness depends on the thickness of the polymer and carbon layers; it ranges from several microns to several millimeters. The minimum allowable thickness is 0.3 mm, the generally accepted thickness is 0.338 mm. The greater the thickness, the more durable and resistant to deformations the protective shell will be. Some manufacturers insist that the film should be as thin as possible so as not to take away the height of the room, but the difference in height when installing the film of 0.3 and 3 mm will be imperceptible, and the durability of the latter is many times higher;

-

film width.The material is produced in rolls with a width of 50, 60, 80 and 100 cm. During installation, the film is mounted so that adjacent sections are as close to each other as possible, but do not overlap. Based on this rule and the parameters of the room, the most suitable roll width is selected to ensure the fastest installation and minimize waste;

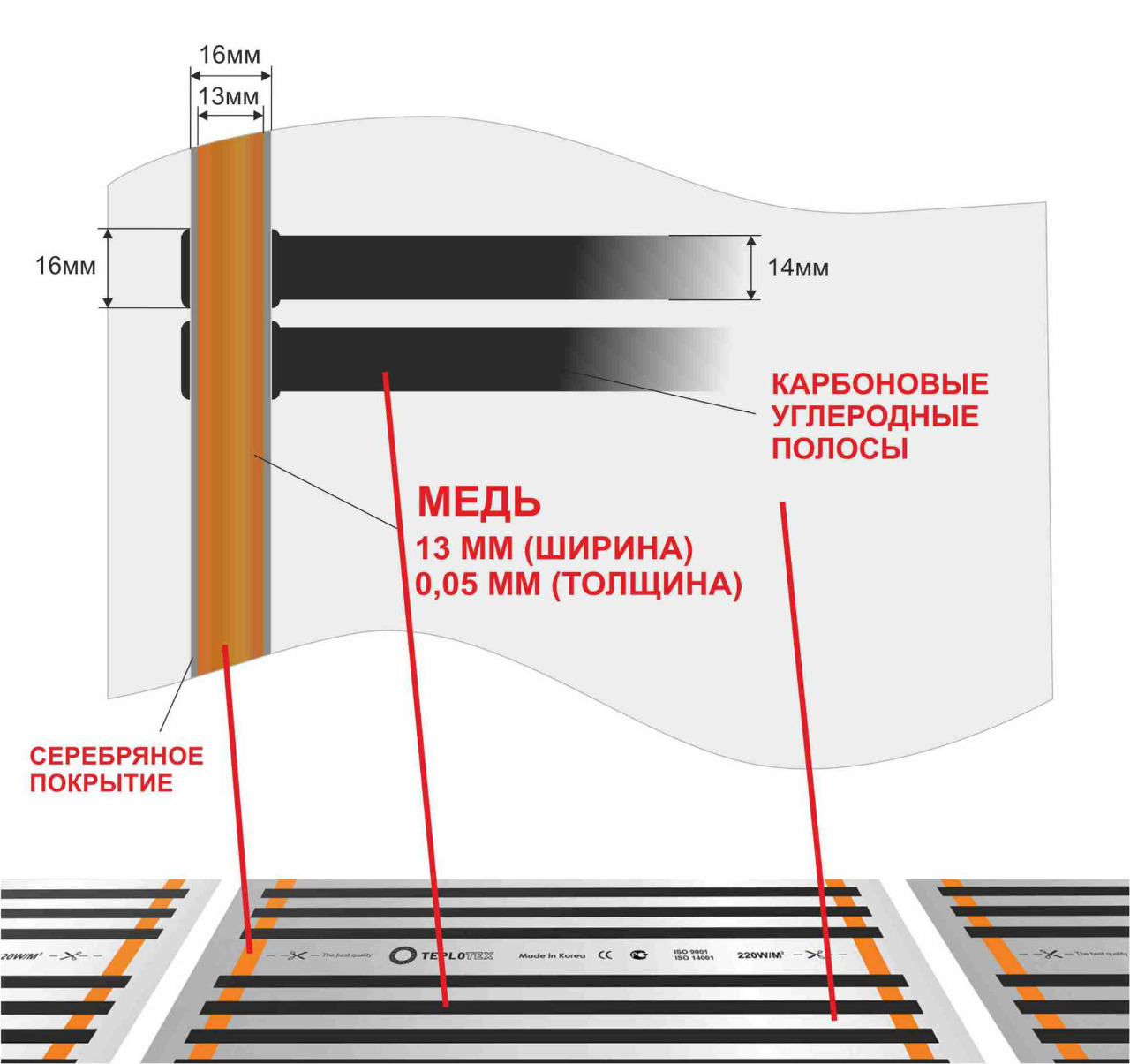

- strips made of silver and copper alloys must have clear contours, not be translucent, not have damage and signs of oxidation. The higher the silver content, the more reliable and less sparkling the film will be. The silver part can be 1.5-2 mm wider than the copper part;

- preference should be given to those films where copper and silver tires are connected by a “dry” contact, which allows minimizing the thickness of the air gap and extending the life of the product;

- the width of the copper bus should be at least 13-15 mm, otherwise we can talk about the low quality of the film. Through copper, carbon strips will not be visible and felt;

- the carbon layer should be applied evenly and not show through. The thicker its layer, the longer the film will last;

-

some manufacturers add silver to the carbon paste to minimize its resistance to current and improve contact with the bus. Over time, a cold tire can peel away from the constantly heated carbon part, resulting in sparking and reduced heating power. Large companies that are constantly improving their products come up with different ways to avoid sparks. The most effective development is the arrangement of a grid of silver stripes at the border of the carbon coating and the copper bus. Such a configuration is called an anti-spark grid;

- the gaps between the carbon strips can be transparent or cloudy - the difference is in the production features. The first option is obtained by using adhesive technology, the second - by lamination. After a few months of use, adhesive strips become brittle, and laminated strips last for years, so give preference to them;

- the heating rate of a high-quality infrared film is 5-10 seconds.

Specifications

Knowing the technical characteristics of the infrared floor heating film is necessary so that you can accurately calculate the required amount of film.

So, we offer you for review the main technical characteristics:

- Sale of an infrared film is carried out in rolls. One roll can be up to 50 m.

- The width of the film can vary from 500 to 1000 mm.

- The thickness of the infrared film of the warm floor can vary from 0.22 to 0.4 mm.

- For one square meter, the power consumption of electricity is about 20–35 W / h.

- The maximum allowable surface temperature is allowed up to 35 degrees.

If you live in a region where the climate is very cold, then this heating system will not be enough for you. It can act as an additional to the main heating system. For example, many people practice infrared heating as an off-season.

It is important to understand the features and principle of operation of this underfloor heating system. Infrared rays do not heat the air! They heat objects, and they, in turn, give off heat to the interior of the room.

Therefore, if there are no certain objects nearby, then the effectiveness of such heating becomes questionable.

A few words about security

Film floors are considered safe for human health.They do not have a negative effect on the body during operation.

But on the other hand, it is important to mount them correctly, insulating all contacts in order to avoid electric shock. Other than that they are completely safe.

Electromagnetic radiation should not be afraid - its level is negligible in order to cause harm.

Infrared warm floor

There is an opinion that due to the presence of such floors in the house, the microclimate improves. And also some note a decrease in the recurrence of the appearance of allergic reactions to anything.