- Mounting Features

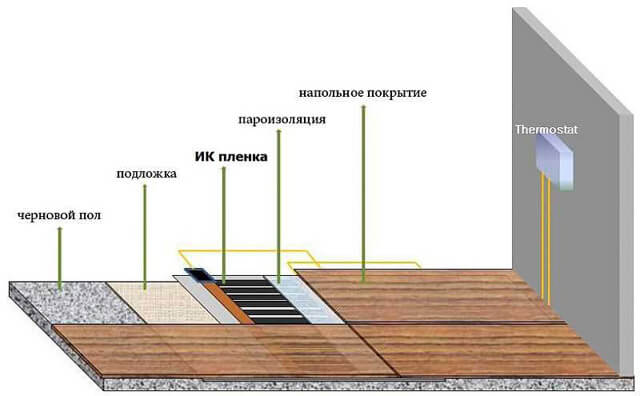

- Substrate preparation for laying infrared film

- Which electric floor is better to choose under the tile?

- Cable

- mats

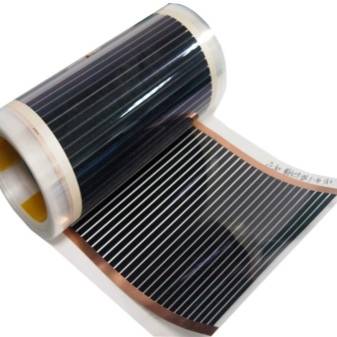

- Film floor heating

- Rod

- Floor finish options

- Advantages and disadvantages of "film" heating

- Where are film systems used?

- Flaws

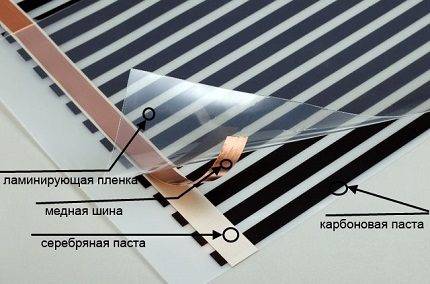

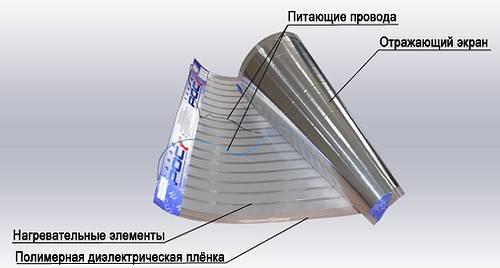

- The device and principle of operation of the IR film

- What is new

- How IR film is arranged and works

- 4 Typical installation errors

- Practical Tips

- Device and characteristics

- Sun on the ceiling

- Installation and its features

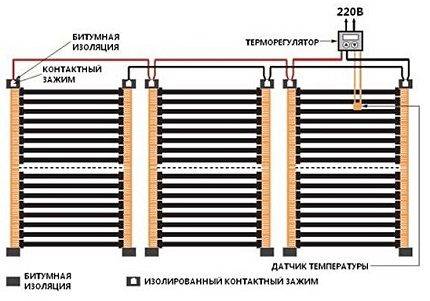

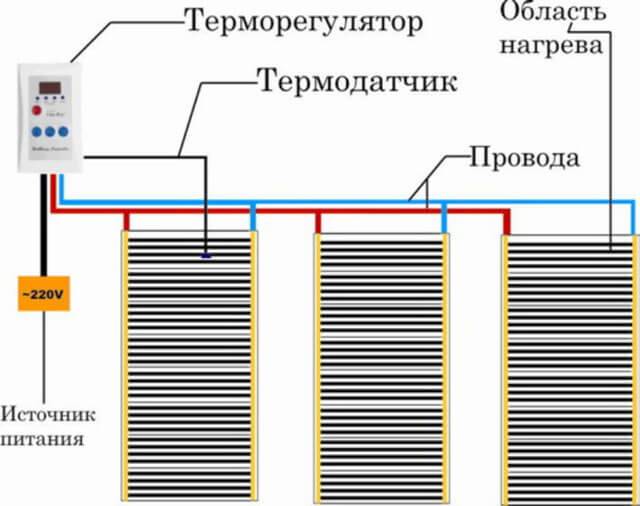

- Mounting diagram

Mounting Features

The contour of the water floor is attached to the walls according to the same principle as on the floor. If such a system is already installed in the floor, you can crash into it, otherwise the water supply will have to be carried out from the boiler. It is best to use metal-plastic pipes so that large mixing units are not created at the joints. The system can be closed with gypsum boards or plaster mortar. Without fail, a heat-insulating layer is arranged, for which isolon is used. After completing the installation, the system is checked under pressure, plaster is applied, not forgetting to install a temperature sensor and a reinforcing mesh that protects the walls from cracking.

Film underfloor heating on the wall is installed in the following way.The panels are pre-assembled into a single network. If a large area is to be heated, rod elements should be installed instead of a film. The finished panel is glued to the insulating layer with a special temperature-resistant adhesive.

The entire assembled structure is fixed on the inside of the drywall sheet, which is attached to the wall in the usual way. To enhance the heat transfer, it is recommended to lay a film with a foil surface on the opposite side of the wall in front of the infrared panels. The efficiency of such heating systems can be improved by wallpapering the walls on a foamed polyethylene substrate.

Rod elements are mounted by analogy with film systems. Due to the fact that a higher temperature is created on the surface, adjacent rods should be installed in increments of ten to fifteen centimeters.

Installing underfloor heating on the wall

Installing underfloor heating on the wall

The difference in the installation of IR film and rods is that the second version of the system sheets is more rigid. But it is possible to pass a large electric power through the rods, which will allow heating spacious rooms.

There are two points that should be taken into account when installing such heating - the power of the safety automation installed in the house, and the installation of a thermostat so that the system does not work all the time.

The easiest way is to arrange electric cable heating systems in the walls. Polyethylene with a foil coating is used as an insulating layer. The heating elements are attached to the reinforced fiberglass with glue.

The cable can be laid with a snake or a snail, a temperature sensor and a protective starting device are installed without fail.From above, the heating system can be covered with plasterboard material.

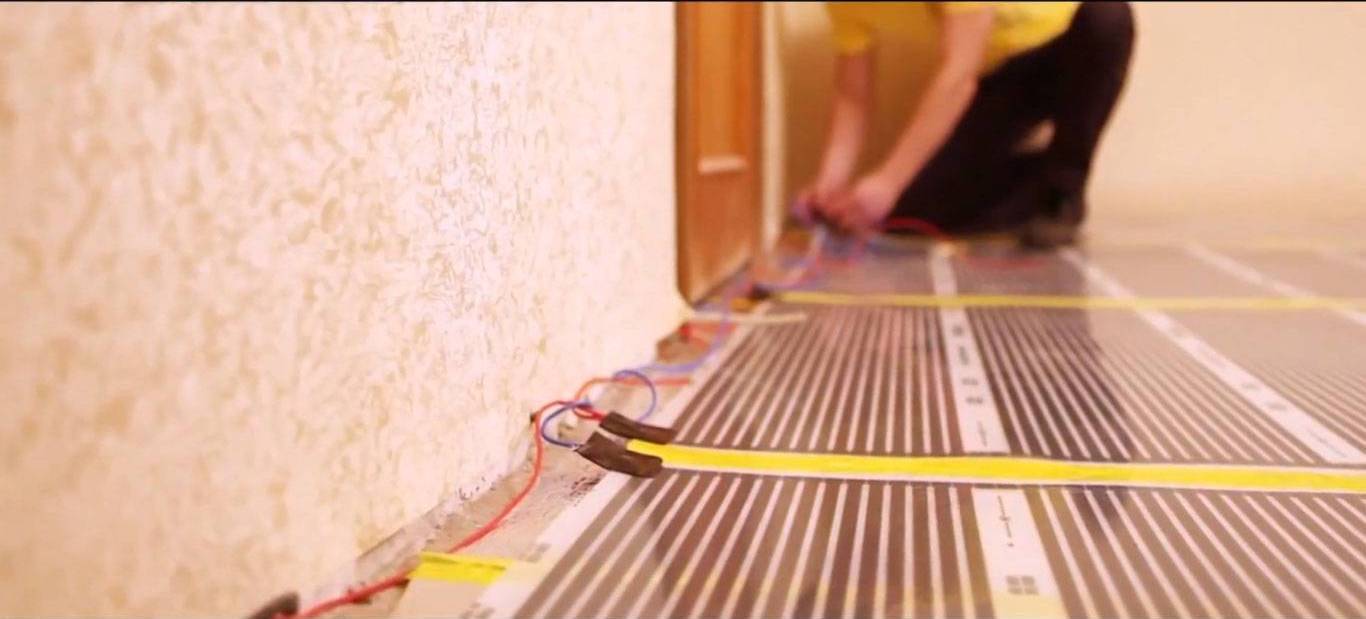

Substrate preparation for laying infrared film

After choosing the laying scheme and purchasing the material, you can proceed to the pre-installation preparatory work. A very important point is the preparation of the base for laying the infrared floor. If the old concrete screed is not even, then it must be dismantled. However, if everything is in order with the screed, it is enough just to clean it of debris and remove dust.

To prevent heating towards neighbors living on the floor below, it is necessary to lay heat-reflecting material for infrared floor heating

In most cases, the base before laying the film has many small cracks, as well as chips. Experts advise to eliminate these defects using cement mortar, or any other suitable composition. In some situations, the owners find that the screed has begun to peel off from the subfloor. This situation requires the removal of the old screed and the organization of a new one.

The joints that form from the connection of the walls to the floor must be carefully leveled and covered over if they have cracks. If this is not done, then the film floor will lose heat through them.

After preparing the base, it is necessary to lay heat-insulating material on the screed. As a rule, a polyethylene foam reflector is used for this purpose. The joints of the individual sheets of the insulator are glued with a mounting tape and this completes the process of preparing for the installation of an infrared warm floor.

Which electric floor is better to choose under the tile?

Electric underfloor heating in stores is offered in four variations:

- cables;

- mats;

- films;

- rods.

Each of these options has its own advantages and nuances of installation. The choice of the most suitable modification for a particular room and the flooring to be laid should be approached wisely and without haste.

Electric floor options

Cable

Warm floors made of heating cables are designed for laying under ceramic tiles and porcelain stoneware. They are mounted in a concrete screed 4–5 cm thick. They are not laid without concrete. If the floors in the house are old and additional overloads are contraindicated for them, then it is better to refuse the cable system.

The heating cable of a similar warm floor under a tile consists of one or two heating cores, which are packed in several layers of heat-resistant plastic. Plus, for strength, such a cord usually has a copper wire braid inside. At the same time, the plastic sheath and electric cores are designed for heating up to 70 0C.

The heating cable is:

- resistive;

- self-regulating.

The first is cheaper, but less efficient. It heats up the same throughout. And in the version with self-regulation, the heat transfer of a particular area depends on the ambient temperature. If there is enough heat in some place, then the veins at such a point begin to warm up less by themselves. This eliminates the appearance of tiles on the floor with local overheating and reduces the overall energy consumption.

Heating mats and cable floor

mats

Mats will cost one and a half to two times more expensive than cable when calculated per square meter of heated surface. However, this type of electric underfloor heating is the most optimal for tiles, it is difficult to find a more correct and better option for tiles.

A thermomat is a reinforcing fiberglass mesh on which the heating cable is already fixed with a snake with an ideal pitch. It is enough to roll out such a heating system on a prepared rough base and simply connect it to the power supply. The tile is then glued on top in the usual way without a screed.

How to lay tiles on heating mats

Film floor heating

If in the first two versions a cable with metal cores acts as a heating element, then the films are arranged completely differently. In the film floor heat, carbon-containing materials are heated, which generate infrared radiation when an electric current is applied. Between themselves, these thermoelements are connected by a copper bus, and from above and below they are closed with a sheath made of polyethylene terephthalate.

The thickness of the thermal film for the floor is only 3–4 mm. And it consumes 20–25% less electricity with identical heat transfer than the cable counterpart. However, it is difficult to call such films an ideal choice for tiling. Not every tile adhesive is suitable for them. There are compounds that can dissolve the film shell.

Manufacturers recommend installing this electric underfloor heating under tiles only with moisture and fire-resistant LSU between them. And this is an additional expense. Plus, the thermal film itself is expensive. The result is a fairly impressive amount per square meter.

Film and rod

Rod

The core heat-insulated floor heats also at the expense of infrared radiation. Carbon rod-tubes connected on both sides with conductive tires act as heating elements in it.Such a system is mounted under ceramic tiles in a thin 2–3 cm screed or in a centimeter layer of tile adhesive.

The main advantage of a rod thermofloor is several times lower power consumption compared to a cable. However, the lucky ones who bought this option, in the reviews, point to its excessive high cost and the gradual failure of the rods. As a result, you pay a lot of money, and after a few months, cold spots begin to appear on the floor.

Instructions for laying and connecting underfloor heating systems

Floor finish options

Almost any floor covering can be used over the IR film - carpet, linoleum, laminate, etc. In some cases, it is allowed to lay plywood, but some of the heat will be lost. It is better to lay the heating film on top of the plywood. When using the system in a kitchen or bathroom under ceramic tiles, it is advisable to use a thin sickle mesh to protect the heating elements.

To level the surface, it is most convenient to use a self-leveling compound. This takes into account the inevitable loss of system efficiency

In the course of laying the decorative coating, it is important to take special care, removing the wiring in a safe place. Most of the malfunctions of the IR film for underfloor heating are due to its incorrect installation or defects in the rough base.

If everything is done correctly, the system will provide reliable heating of the home.

Advantages and disadvantages of "film" heating

In search of an alternative method of space heating, scientists turned their attention to the heat exchange in the environment, which occurs due to the action of infrared rays. Interpretation of the natural process formed the basis for the creation of IR film

The film coating releases thermal energy in the infrared range. Long waves of radiation heat the surrounding objects, which in turn accumulate and transfer heat to the air.

The use of infrared film for arranging a warm floor has become widespread due to a number of advantages:

Versatility. On top of the heating layer, it is possible to lay almost any floor covering. With the help of a film, you can insulate walls and ceilings.

Ease of installation. To create a warm floor system, it is not necessary to dismantle the old base, and the procedure itself can be performed independently. Specialized equipment is not required.

Heating temperature adjustment. A thermostat with a wide range of modes is connected to the heating system. Additional control settings are possible: timer function, dividing the room into different heating intensity zones, etc.

Mobility of a heat-insulated floor. When moving to another place of residence, the structure is easy to remove and spread on another surface.

System compactness

The thickness of the IR coating (up to 0.5 mm) has virtually no effect on the height of the floor, which is especially important for rooms with low ceilings.

Low inertia. The film quickly “turns on” and the effect becomes noticeable after a few minutes.

Uniformity of heating

The room is heated throughout the volume, there are no "hot" and "cold" zones.

Maintaining a healthy microclimate. IR rays do not dry out the air and do not burn oxygen. Manufacturers of "film heating" indicate the therapeutic effect of infrared radiation. The air is ionized and purified from bacteria.

Due to modularity, the failure of one section of the film does not lead to a failure of the entire system.

The heating film withstands significant dynamic loads. It can be mounted in public institutions with high traffic. The service life of the IR heating system is 15-20 years

Innovative technology also has negative qualities:

The electrostaticity of heated surfaces increases, and objects begin to attract more dust.

After turning off the heating system, the room cools down quickly.

When installing, it is important to consider the arrangement of furniture. Where there will be bulky furniture and large appliances, IR film is not laid

Failure to comply may result in system overheating.

The work of a warm floor leads to an increase in energy consumption.

The coating is afraid of moisture and contact with sharp objects.

Laying "film" heating must be carried out carefully and in compliance with safety standards.

Where are film systems used?

The infrared film floor has a wide range of applications. Such material is used as the main or additional heating:

- residential premises;

- public buildings;

- industrial facilities;

- agricultural buildings.

Often infrared film is used for additional heating of an apartment or house. It can be combined with any floor covering. As the main source of heat, such a system is used in rooms where there is no stationary heating or for the period between seasons.

This type of underfloor heating can be used as temporary or emergency heating.

If necessary, such material can be easily dismantled and moved to another location. If the dismantling area is small, it will take several minutes.

An infrared film floor is a great option for heating a public or industrial building. It can be used for additional heating:

- kindergarten;

- hotels;

- hospitals;

- schools;

- sports hall.

By connecting a special control panel, you can control the temperature in different rooms at the same time. Such heating systems are recommended for use in greenhouses and livestock facilities. Often infrared film is used for heating a winter garden or a greenhouse. It is also a great option for a poultry or pig farm.

With the help of an infrared film floor, you can warm up a small room well and maintain the optimum air temperature in a large room. This is a good alternative to a water floor or conventional heaters.

Read more:

How to install an infrared underfloor heating under a tile?

How to choose a ceiling infrared heater?

How to connect a warm floor to electricity - connection diagram

How to install electric underfloor heating under tiles?

How to choose the most economical electric heater for your home?

Flaws

The list of disadvantages of IR film underfloor heating:

- Difficult connection of conductors. To ensure reliable contact, it is necessary to install the terminal on the film on the first attempt. In case of failure, you have to cut off a piece of material to the next terminal pad.

- Sufficiently thick IR systems covered with insulation are characterized by a weak level of air ionization.

- The film can only be laid on a perfectly even base, which implies leveling work, otherwise the material is damaged under dynamic loads.In addition, a thin insulating layer is necessarily laid, which helps to increase the heating efficiency.

- Furniture must not be placed on top of areas decorated with film elements. This is fraught with the occurrence of overheating of the system, with its subsequent failure. There is also damage to furniture and floor finishes.

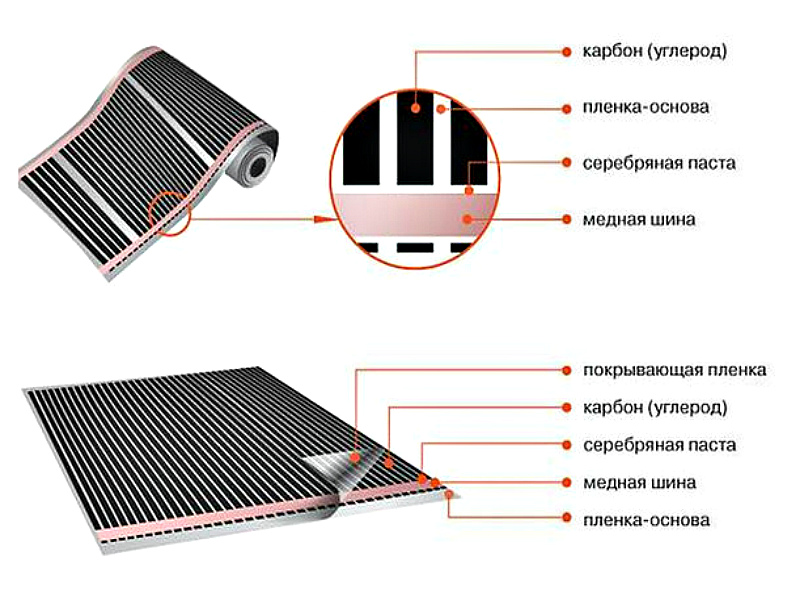

The device and principle of operation of the IR film

The infrared film is made from a durable polymer. During the production process, carbon-graphite strips are applied to the flexible web. The semiconductor sections are connected by copper and silver bars.

The final coating of the material is a laminating film (PET), which protects the components from moisture, breakdowns and fire. Dense polymer does not delay radiation

Functions of the main layers of IR film:

- Carbon paste or carbon fiber cloth is a heating element that converts electricity into heat.

- Foil strips (copper busbars with silver) form a heating circuit and evenly distribute thermal energy over the surface of the film. This element is controlled by a temperature sensor - when heated to the desired temperature, the supply of electricity stops.

- The laminating coating is a protective electrically insulating and heat-resistant layer (the melting point of the material is 210°C).

The carbon nanostructure is distinguished by unique parameters. The atoms of the substance, formed into a hexagonal grid, give the material the ability to emit radiation in the IR spectrum.

Working principle of infrared floor film:

- Electrical current is supplied to the system.

- The current passing through the heating elements (foil strips) is converted into thermal energy.

- Nano-carbon components are heated and generate IR waves, the range of which is 5-20 microns.

- The rays fall on interior items, walls and furniture. From the heated elements, the air in the room warms up.

In addition to the film, the infrared floor heating system includes: a thermostat, a temperature sensor, contact clamps and insulating materials.

The thermostat controls the degree of heating through sensors built into the floor. More complex heating systems are able to change the temperature regime according to a user-defined algorithm

With varieties carbon fiber underfloor heatingused in the arrangement of residential premises, and the features of their installation will be introduced by the following article, which we recommend reading.

What is new

The optimal temperature regime in the home is the key to its comfort and coziness. This component cannot be replaced by comfortable beautiful furniture or high-quality interior decoration. If it’s cold in the house, you can’t even dream of any good rest. Especially often this problem occurs in cases where the heating season has not yet officially begun, and cold weather has already set in the street. A good solution to this problem is the use of self-contained film floors, which can be turned on as needed.

Installation of other modifications of the "warm floor" is characterized by a significant amount of additional work: as a rule, these systems are built into a concrete screed. These activities are quite laborious and require decent financial costs. It is for this reason that after the appearance on the market of infrared film for underfloor heating, it is becoming more popular day by day.Before purchasing and installing the system, it is recommended to understand its characteristics and installation technology.

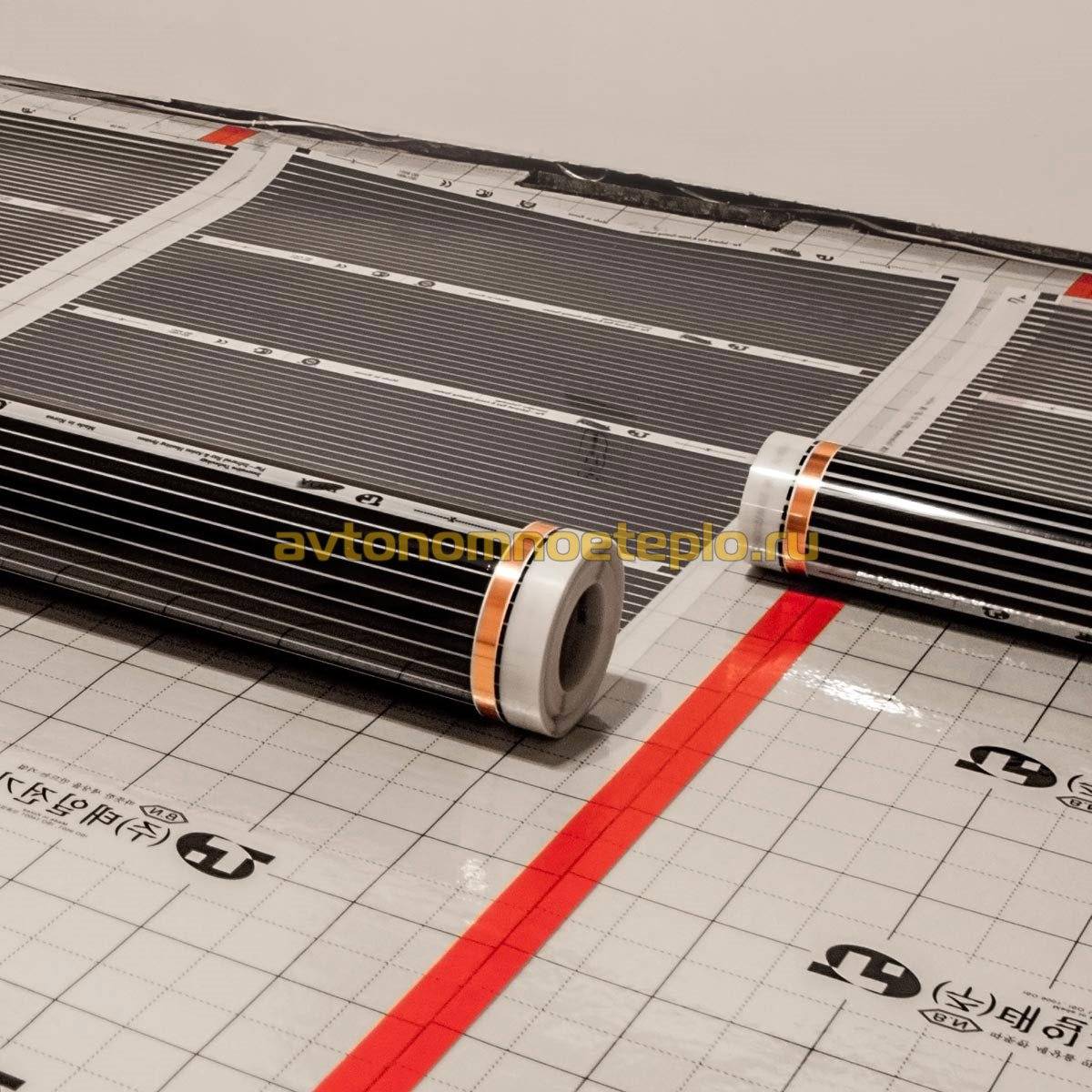

How IR film is arranged and works

We are talking about a very thin product: the film thickness does not exceed 0.22-0.4 mm. The canvas consists of five layers: an inner and outer base made of high-strength polymer material, and three inner layers. A special non-woven material is used to separate the plastic from the heating element. In the middle is the heating element itself, made of copper tracks (tires) and strips of carbon (carbon fiber). This composite material contains polymers and carbon fibers.

Thanks to the carbon atoms that make up the hexagonal lattice, the material, when electricity passes through it, begins to emit infrared radiation invisible to the eye. In the transverse direction to the sheet, heating strips 10-15 mm wide are located. For their fastening to each other, copper current-carrying bars equipped with silver-plated contacts are used.

4 Typical installation errors

The most common mistake when laying a warm floor is considered to be the wrong connection of the film rows. It must be strictly parallel, i.e. it is impossible to lay one part perpendicularly, and the second - parallel to the wall. In this case, heating simply will not be felt, and even a short circuit is also possible.

Many inexperienced repair people spoil the material by cutting the film incorrectly. As we said earlier, it can be cut only in those places that are indicated on the product by the manufacturer. If you ignore this rule and make a cut in another place, a break will form in the electrical circuit.

Another mistake is insufficiently high-quality cleaning of the base.If any debris remains on the subfloor, protruding nail heads, etc., there is a high risk of damage to the tape, which will cause the warm floor to not function.

Before laying such a system, it is very important to prepare the base with high quality - otherwise the film may be damaged and the operation of the warm floor may stop

It is highly recommended to connect the temperature controller only through a separate residual current switch. Of course, you can connect it to a regular outlet, but the first option ensures that the power is turned off in a timely manner in the event of a short circuit in the circuit or a network break. When plugged into an outlet, there is a high risk of fire or personal injury from electric shock.

A common mistake is also the incorrect location of the temperature sensor. If it is located, for example, near a balcony door, it will be additionally cooled or heated by the sun's rays and, therefore, will not record the temperature correctly. If the data is incorrect, the sensor will "command" the increase or decrease in heating, although this is not actually required.

Practical Tips

To improve the operating conditions of a film underfloor heating under linoleum, it is recommended to follow several rules.

Heated floor under linoleum

- Do not heat the material above +26°C. As a result of prolonged heating to high temperatures, linoleum can delaminate, change its original color in places of greatest heating, soften and significantly reduce factory strength characteristics. Increased heating increases the amount of chemical compounds released into the air.

- When laying linoleum, do not use mastics to fix it.In addition to the fact that all mastics become additional sources of harmful compounds, during uneven heating they can form swelling on the surface. It is very difficult to remove such defects later, and in many cases impossible. Linoleum is simply spread over the surface of the floor. If there are concerns about movements, then it is possible to fix the coating with a stapler in several places, the staples are driven in in inconspicuous places, the best option is under the floor skirting boards.

- Do not overlap thermal films. If the configuration of the room is very complex, then it is better to leave a small area of the floor unheated.

- The temperature in the room during the laying of linoleum must be at least + 18 ° C, otherwise hard-to-remove wrinkles may form. But you can not spread it on a hot floor, after testing it must cool to room temperature.

- It is not recommended to use this type of floors as the main heating systems. The fact is that it is possible to heat the premises to comfortable temperature values when the floor is heated to t ° ≥ + 28 ° С, and this should not be allowed in the case of using linoleum.

Adjust the operating modes only after carefully studying the instructions. The first few days of operation of a warm floor, it is desirable to check the reliability of operation more often. As a guarantee, it is recommended to check the floor temperature with an accurate household thermometer. If significant differences are found in the indicators, then it is necessary to make an adjustment during the installation of thermal control.

Device and characteristics

Film infrared heaters (PLEN) are devices that allow you to heat a residential or industrial premises. Their design includes:

- heating element;

- film;

- foil.

Heat transfer occurs due to the release of infrared waves. Their safety and benefits for the human body have been proven by more than a dozen scientific studies.

The main difference between PLEN and more familiar heating devices is that during operation it is not the air in the room that is heated, but the surrounding objects, which subsequently give off heat. This allows you to achieve more comfortable and gradual heating of the air in the room without overdrying it, which is very important in winter.

The advantages of infrared film heaters include the following.

- Flexible temperature control due to the fact that the infrared device can be supplemented with a thermostat.

- Uniform heating of the room. This is achieved due to the special principle of operation of the device.

- Low power consumption. This difference is especially noticeable in comparison with the consumption of classical electric heaters.

- Fast and clear installation. Installation is carried out quickly, does not require special equipment, but this business has its own subtleties that cannot be neglected.

- The shelf life of PLEN is 50 years.

- Wide temperature range. You can use such a heater at temperatures from -40 degrees. In addition, the IR heater is not afraid of temperature changes.

- PLEN does not dry out the air in the room, does not reduce the amount of oxygen, and is also safe for humans and the environment.

- Rapid heating of the room. For example, in order to heat a room with an initial temperature of +10 degrees to a comfortable +20, it will take no more than 50 minutes of operation of the device.

In addition to its advantages, PLEN also has disadvantages.

- In order to achieve normal and stable heating of the room, a large number of IR devices will be required.

- It is irrational to install PLEN in poorly insulated rooms. Before starting the installation of this type of heater, you will first need to take care of eliminating possible heat leaks from the house.

- If the installation technology of the heating film is violated, it can become very hot, thereby giving out an uncomfortable temperature in the room.

- If you install additional thermostats and protective screens to the PLEN, this will lead to a significant increase in the cost of the project.

Sun on the ceiling

Those who had to read "Three from Prostokvashino" in their happy childhood will surely remember that the stove in Uncle Fyodor's house performed purely decorative tasks. To heat the house, he used an electric sun, ordered from some research institute and nailed to the ceiling. Now it is difficult to say whether the creators of ceiling infrared heaters themselves thought of their brainchild or stole this idea from the author of the famous story, but, one way or another, the electric sun turned from a fairy tale into a reality. Unless it has a round shape, but a rectangular one.

What is an IR ceiling film heater and how does it differ from its lamp and tubular counterparts? First of all, the emitter. Instead of metal spirals and ceramic elements, thin carbon threads are used here. which are laid on a polymer film smeared with carbon paste. The thickness of the latter is only 1 micron (0.001 mm), so the whole pizza-like product is placed in a durable fire-resistant shell made of laminated polyester, which plays the role of a reliable electrical insulator.At the edges, both layers of the shell are glued together without laying carbon strands between them. The empty tracks thus obtained are used to mount the heater on the ceiling.

The design of the film ceiling heater

The design of the film ceiling heater

The heater is controlled by a thermostat. installed on the wall at a height convenient for the user, which is usually from 1 to 1.5 m. It is enough to set the desired temperature on this device, and it will turn the ceiling heater on and off at the right time. Simple and cheap thermostats have a mechanical device, more expensive ones are electronic and can be programmed.

All ceiling IR heaters are divided into three categories:

- low-temperature with a wavelength of radiated waves from 5.6 to 100 microns and a heating temperature of up to 600 degrees (the minimum installation height is from 2.5 to 3 m);

- medium temperature with a wavelength of 2.5 to 5.6 microns and a temperature of 600 to 1000 degrees (the minimum height is about 3.6 m);

- high-temperature with a wavelength of 0.74 to 2 microns and a heating temperature of over 1000 degrees (installed at a height of at least 8 m).

IR films are low-temperature long-wave devices; on average, their heating temperature is about 45 degrees.

One square meter of a ceiling IR heater consumes from 130 to 200 W of electrical power, the efficiency of the device is about 95%.

Installation and its features

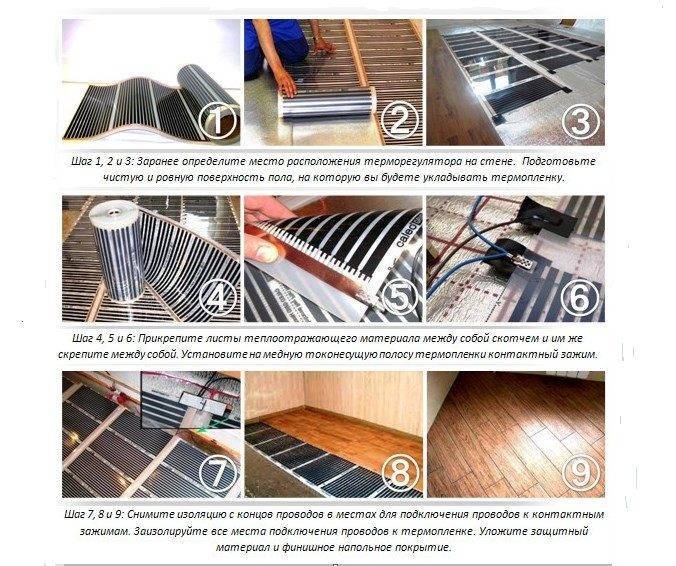

As in any business, when arranging heating with infrared underfloor heating, there are certain principles and rules that you should know and adhere to during the installation process.

The main requirements for the installation of IR equipment for the floor are as follows:

- Infrared floor heating should only be installed on a dry, clean base, and only in places where it is not planned to install heavy furniture without legs.

- If the room does not provide for other heating sources, then the coverage of the infrared heating system should be more than two thirds of the area of the entire room.

- Infrared film underfloor heating should be laid at a distance of 10 to 40 centimeters from the walls.

- The length of the strips of the heating film coating should not exceed 8 meters.

- It is strictly forbidden to lay the film floor heating with an overlap.

- To fix the elements of the infrared coating, it is unacceptable to use nails or screws.

- The location of the air temperature sensor should not be in an open place, otherwise its operation will not be correct enough.

- Do not place the infrared coating near other heating devices or appliances.

- It is very undesirable to install an IR underfloor heating at high humidity or sub-zero temperatures.

- The thermostat should be located at a distance of 10-15 centimeters from the floor.

The most recommended way to connect the thermostat is a stationary version, but it is also possible to connect it like a conventional electrical appliance through a socket. Most of the wires connecting the infrared thermostat should be located under the baseboard.

During installation, one part of the terminal clamps is placed in the external conductive zone, and the other part is in the internal one. It is recommended to use clips from the same manufacturer as the coating itself. They are fixed with pliers or other special tools.

The individual strips of infrared film are joined at the installation site. In the areas where the cuts of the contact busbars are located, insulation is made using a bituminous mixture, which is included in the infrared coating kit.

Mounting diagram

To imagine how to connect an infrared film underfloor heating, you need to draw a laying diagram on a piece of paper.

You should know that the film is not laid under the overall furniture or appliances: wardrobes, walls, chests of drawers, refrigerators and washing machines. Film placed under heavy objects will overheat and stop working. The advantage here is that with a parallel connection it is not so scary: the rest of the underfloor heating area will continue to perform its task. A distance of at least 20 cm should remain from the edge of the film to heavy furniture. The same segment should separate it from the wall. Tape is used for fixation.

The film can be single-sided or double-sided. In the first case, there are special manufacturer's marks that indicate which side to lay it on.

This instruction is very important to follow.