- Repair of induction heaters

- Operation features

- Vortex induction heater

- How to do it yourself?

- From a welding inverter

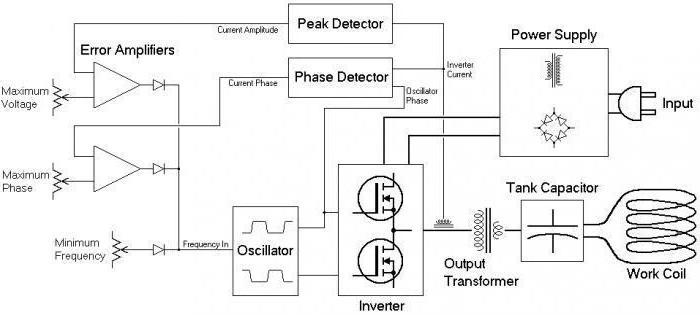

- Principle of operation

- Work principles

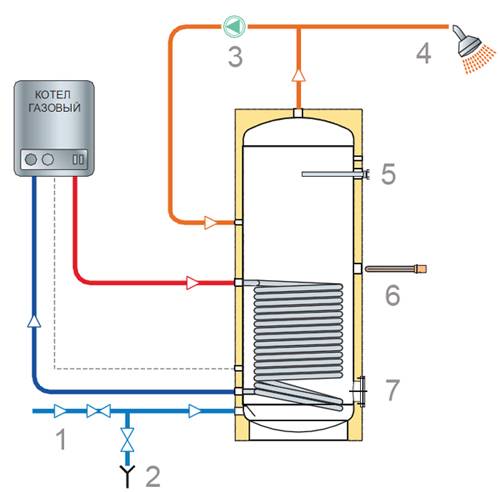

- Components of an induction water heater

- Scheme of a simple induction heater with a power of 1600 W

- Frequency control, inductor, power

- Resonant Capacitor Module

- Working scheme

- High frequency induction heaters

- Application:

- Features of the vortex induction boiler

- Distinctive features of VIN

- How to assemble a vortex induction device?

- Principle of operation and scope

- Production of induction heaters

- Transformer Based

- From high frequency welding machine

- Description and advantages of technology

- Important notes on installation and use of the boiler

- Conclusion

Repair of induction heaters

Repair of induction heaters is made from spare parts from our warehouse. At the moment we can repair all types of heaters. Induction heaters are quite reliable if you strictly follow the operating instructions and avoid extreme operating modes - first of all, monitor the temperature and proper water cooling.

The details of the operation of all types of induction heaters are often not fully published in the manufacturers' documentation; they should be repaired by qualified specialists who are well acquainted with the detailed principle of operation of such equipment.

Operation features

Homemade heater assembly is only half the battle

Equally important is the correct operation of the resulting structure. Initially, each such device poses a certain danger, since it is not able to independently control the level of heating of the coolant. In this regard, each heater requires a certain refinement, that is, the installation and connection of additional control and automatic devices.

In this regard, each heater requires a certain refinement, that is, the installation and connection of additional control and automatic devices.

First of all, the pipe outlet is equipped with a standard set of safety devices - a safety valve, a pressure gauge and a device for venting air. It should be remembered that induction water heaters will work normally only if there is forced water circulation. The gravity flow circuit will very quickly lead to overheating of the element and the destruction of the plastic pipe.

To avoid such situations, a thermostat is installed in the heater, connected to an emergency shutdown device. Experienced electrical engineers use for this purpose thermostats with temperature sensors and relays that turn off the circuit when the coolant reaches the set temperature.

Home-made designs are characterized by rather low efficiency, since instead of free passage, there is an obstacle in the path of water in the form of wire particles. They almost completely cover the pipe, causing increased hydraulic resistance. In emergency situations, damage and rupture of plastic are possible, after which hot water will certainly lead to a short circuit. Typically, these heaters are used in small rooms as an additional heating system during the cold season.

The heating system is an important part of any home. It can be called the "heart" of the home, because it is the heat that creates comfort and atmosphere. The market is replete with various types of gas boilers, because they are considered the most efficient. However, the gas pipeline can be located quite far away, so in this case, electrical equipment comes to the fore. Induction boilers are quite popular. The advantage of this type of heating is that the induction furnace from the welding inverter is made by hand without any problems. On the basis of eddy currents, it is also possible to design an induction heater for metal, taking a welding inverter as a current source.

Vortex induction heater

Due to the economic benefits, today, induction heating has a wide range of applications. The vortex induction heating device is perfect for rooms up to 60 square meters. m, which need to be heated by electricity. So, VIN can be used for heating private houses, production and storage facilities, gas stations, car service centers and other separate facilities.

The main advantages of using VIN as the “heart” of a heating system include the following:

- Heating occurs almost instantly, because heat occurs directly in the part;

- Over the years, the installation works with the same power, its performance does not decrease;

- Compared to conventional electric heating elements, the induction vortex apparatus saves up to 50% of electricity.

That is why today, more and more companies for the production of household appliances and production machines use induction heating. An example of such use, in addition to heating boilers, is an induction electric furnace. The food industry uses an ultrasonic induction heater. In industry, an inverter induction apparatus is used to heat metals, a melting and reduction unit is used for melting non-ferrous metals, an induction electric furnace is used for forging iron and making blanks.

How to do it yourself?

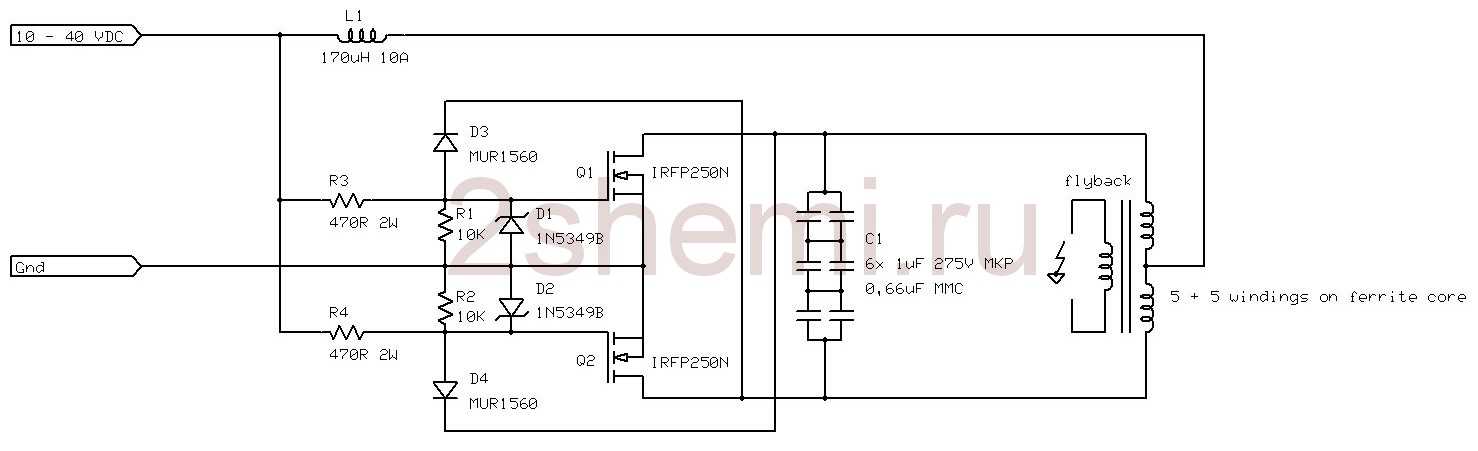

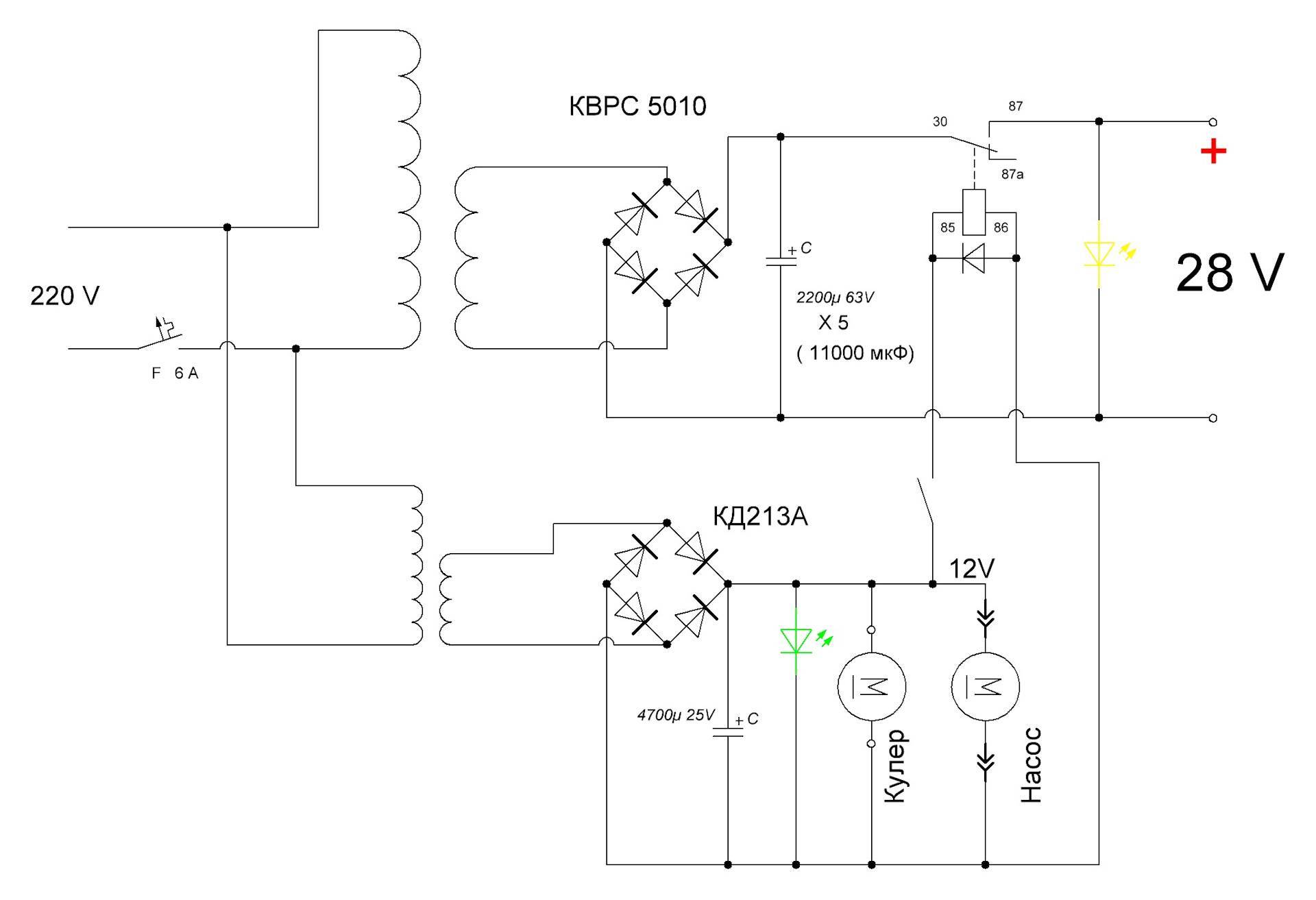

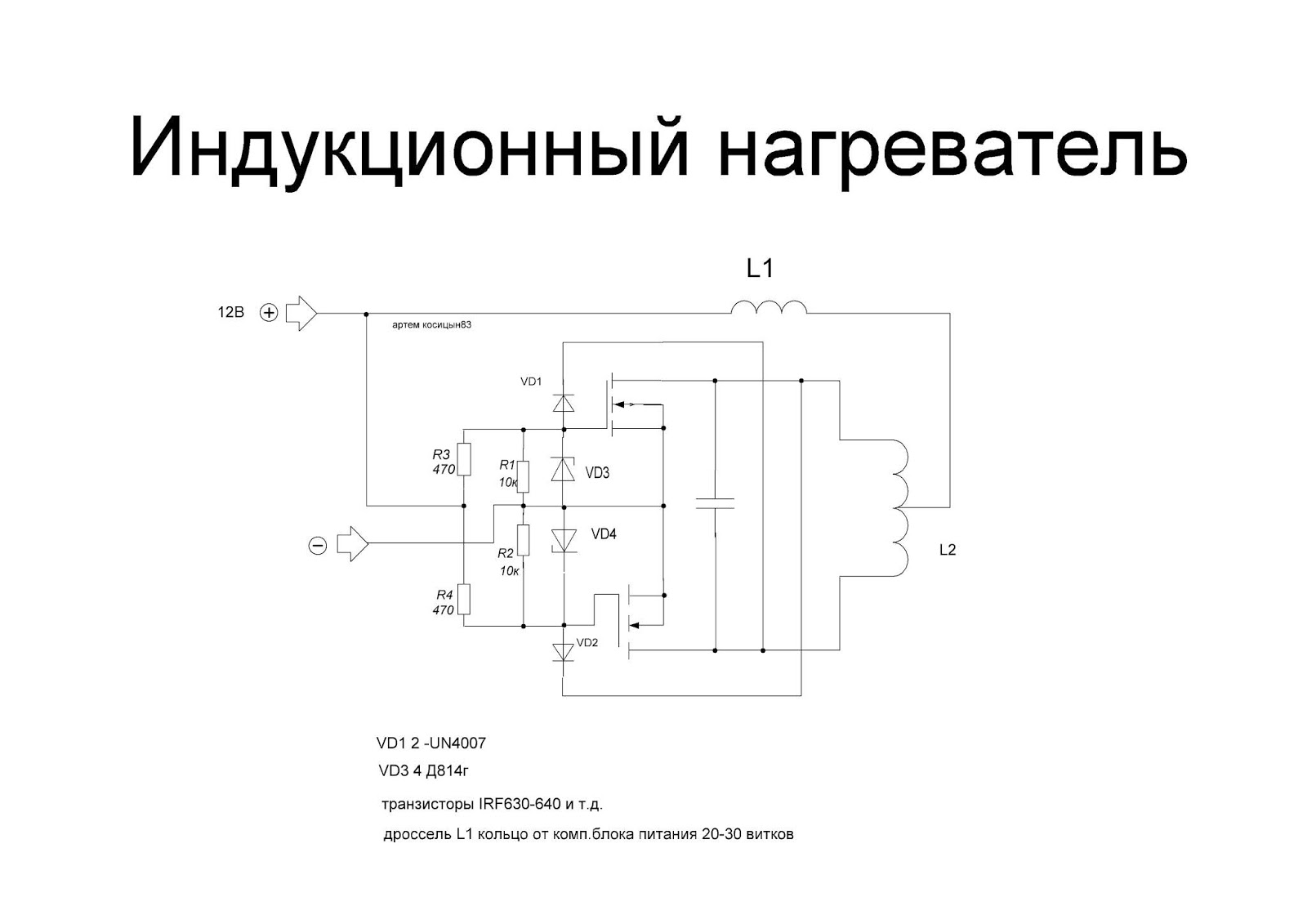

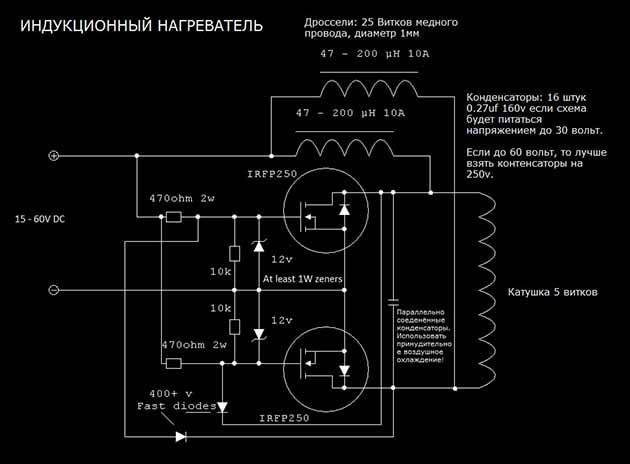

Wiring diagram of the induction heater

Let's say you decide to make an induction heater yourself, for this we prepare a pipe, pour small pieces of steel wire (9 cm in length) into it.

The pipe can be plastic or metal, most importantly, with thick walls. Then, it is closed with special adapters from all sides.

Next, we wind copper wire on it up to 100 turns and place it in the central part of the tube. The result is an inductor. We connect the output part of the inverter to this winding. As an assistant, we resort to a thermostat.

The pipe acts as a heater.

We prepare the generator and assemble the entire structure.

Required materials and tools:

- stainless steel wire or wire rod (diameter 7 mm);

- water;

- welding inverter;

- enameled copper wire;

- metal mesh with small holes;

- adapters;

- thick-walled plastic pipe;

Walkthrough:

- Mode wire into pieces, 50 mm long.

- We prepare the shell for the heater. We use a thick-walled pipe (diameter 50 mm).

- We close the bottom and top of the case with a net.

- Preparing the induction coil. With a copper wire, we wind 90 turns on the body and place them in the center of the shell.

- We cut out a part of the pipe from the pipeline and install an induction boiler.

- We connect the coil to the inverter and fill the boiler with water.

- We ground the resulting structure.

- We check the system in operation. Do not use without water, as the plastic pipe may melt.

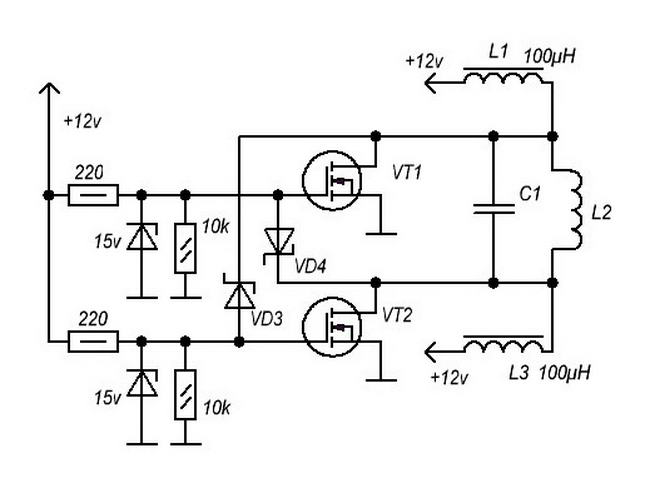

From a welding inverter

The simplest budget option is to manufacture an induction heater using a welding inverter:

The simplest budget option is to manufacture an induction heater using a welding inverter:

- To do this, we take a polymer pipe, its walls must be thick. From the ends we mount 2 valves and connect the wiring.

- We fill the pipe with pieces (diameter 5 mm) of metal wire and mount the top valve.

- Next, we make 90 turns around the pipe with copper wire, we get an inductor. The heating element is a pipe, the generator is a welding machine.

- The instrument must be in high frequency AC mode.

- We connect the copper wire to the poles of the welding machine and check the work.

Working as an inductor, a magnetic field will be radiated, while eddy currents will heat up the chopped wire, which will lead to boiling water in the polymer pipe

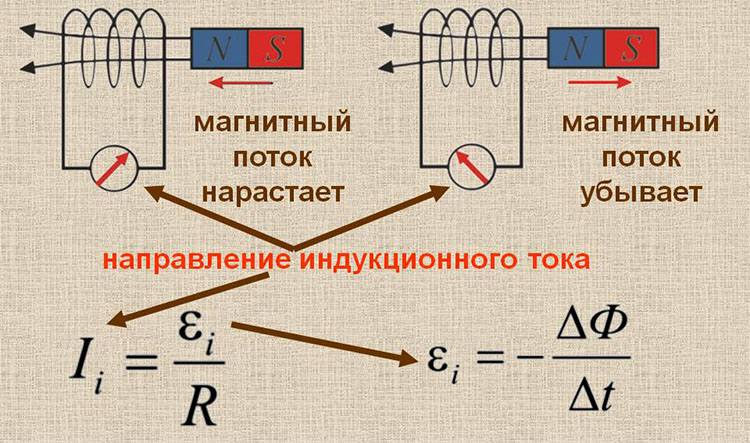

Principle of operation

The operation of all electric heaters, both conventional and induction, is based on the same principle: when an electric current is passed through a certain conductor, the latter will begin to heat up.

The amount of heat released per unit of time depends on the current strength and the resistance value of a given conductor - the larger these indicators, the more the material will heat up.

The whole question is how to cause an electric current to flow? You can connect the conductor directly to a source of electrical energy, which we do by plugging a cord from an electric kettle, oil heater or, for example, a boiler into the outlet. But another way can be applied: as it turned out, the flow of electric current can be provoked by exposing the conductor to an alternating (precisely alternating!) Magnetic field. This phenomenon, discovered in 1831 by M. Faraday, was called electromagnetic induction.

There is one trick here: the magnetic field can be constant, but then the position of the conductor in it must be constantly changed. In this case, the number of lines of force passing through the conductor and their direction relative to it will change. The easiest way is to rotate the conductor in the field, which is done in modern power generators.

Principle of electromagnetic induction

But you can also change the parameters of the field itself. With a permanent magnet, such a trick, of course, will not work, but with an electromagnet - completely.The work of an electromagnet, who forgot, is based on the opposite effect: an alternating current flowing through a conductor generates a magnetic field around it, the parameters of which (polarity and intensity) depend on the direction of the current and its magnitude. For a more tangible effect, the wire can be laid in the form of a coil.

Thus, by changing the parameters of the electric current in the electromagnet, we will change all the parameters of the magnetic field induced by it, up to the change in the location of the poles to the opposite.

And then this magnetic field, which is indeed variable, will induce an electric current in any conductive material located within it. And the material at the same time, of course, will heat up. This is the principle of operation of modern induction heaters.

Looking for the most economical electric water heater? Then take a closer look at the induction water heater. Read about the advantages and disadvantages of the device in the article.

Have you decided to install an electric boiler as a backup heat generator? Read about which model is better to choose here.

The induction furnace is a multifunctional device. It can be purchased at the store, but it is more interesting and cheaper to make it yourself. Through this link you will find device assembly diagram and learn about the features of the operation of the furnace.

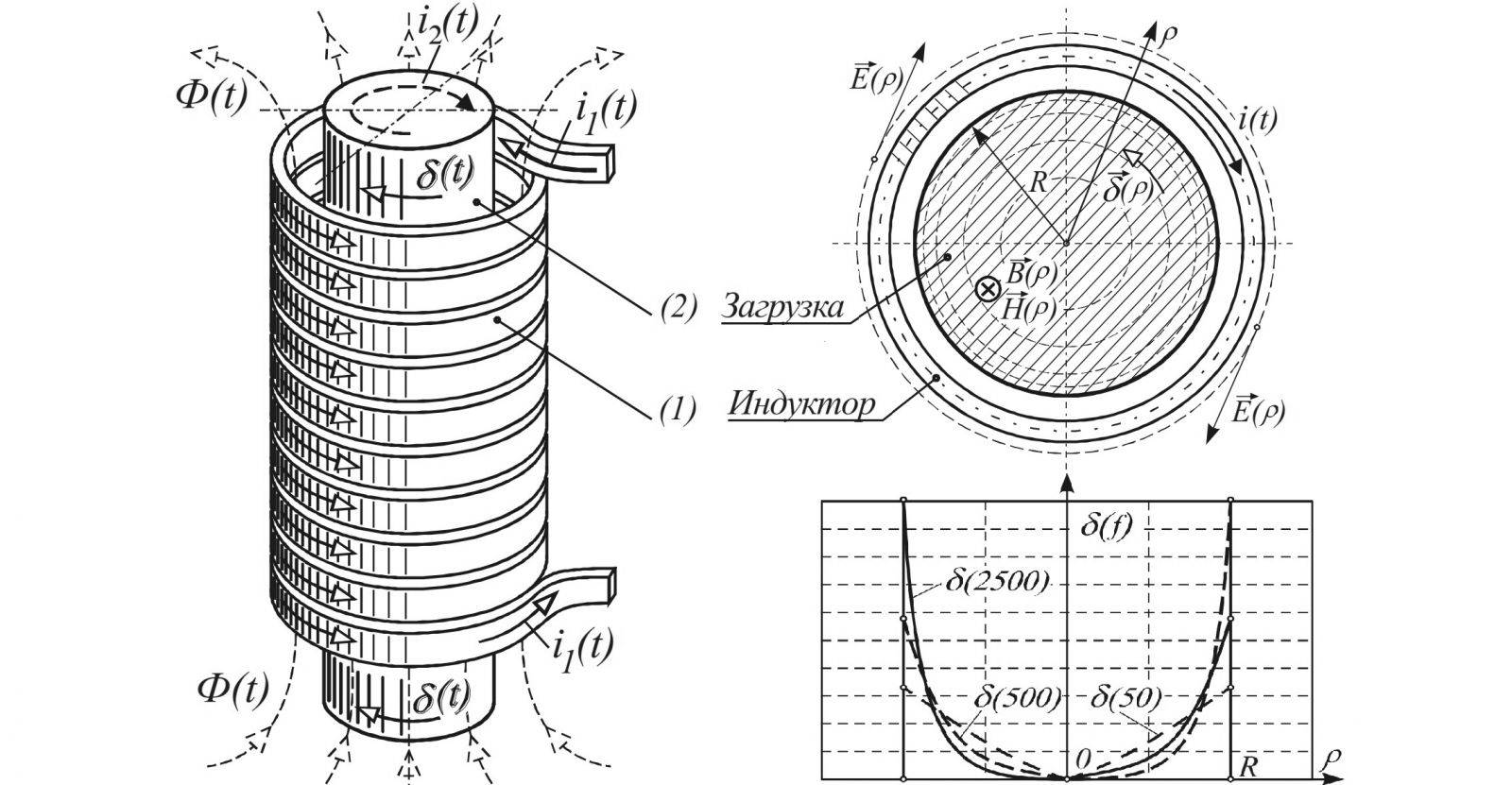

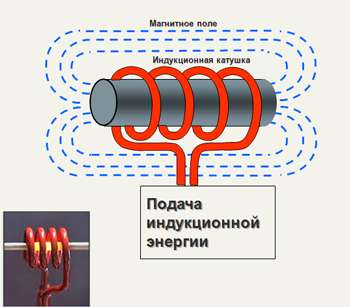

Work principles

To assemble an induction boiler with your own hands, you need to study what it consists of and understand the principles of its operation.

The device heats up due to the energy of the electromagnetic field. The coolant takes it on itself and converts it into heat.

The magnetic field is created in the inductor (this is a cylindrical coil with a large number of turns). Passing through it, electricity creates a voltage around itself.The magnetic flux moves in a vicious circle perpendicular to the electric field. Alternating current creates eddy currents and generates energy into heat. Electricity is transferred to the heater without direct contact.

Induction heat is used efficiently and economically, so water with this method of heating reaches high temperatures in a short period of time. The coolant receives about 97% of the energy.

Components of an induction water heater

The organization of the heating system in your own house with the help of an induction boiler will not require its major redevelopment. The basis uses a transformer consisting of primary and secondary windings.

Vortex flows are formed in the primary winding from electrical energy and create an electromagnetic field. It falls on the secondary, which has the function of a heater.

The secondary winding is the boiler body. It includes elements such as:

- external winding;

- core;

- electrical insulation;

- thermal insulation.

To supply cold water to the device and remove warm water to the heating system, two pipes are installed to the water heater. The lower one is mounted on the inlet section, and the upper one on the hot water outlet part.

The heat generated by the boiler is transferred to the coolant. Most often, water acts as its quality, as it is able to quickly take away heat. Due to the built-in pump, hot water enters the heating system through the pipe. The liquid constantly circulates, so overheating of the equipment is not possible. Cooled water is supplied, and hot water is discharged.

During circulation, the heating fluid vibrates, which prevents scale deposits inside the pipes.You can install an induction water heater in any room, since no noise is created during operation.

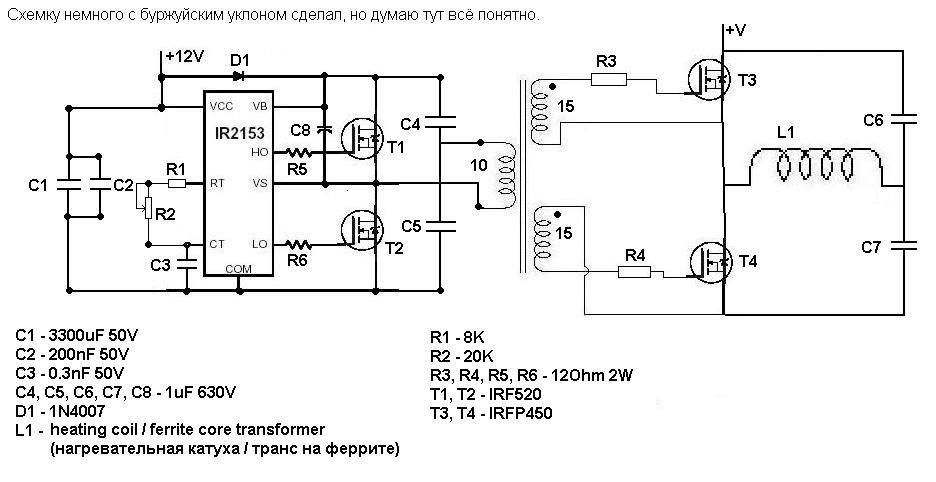

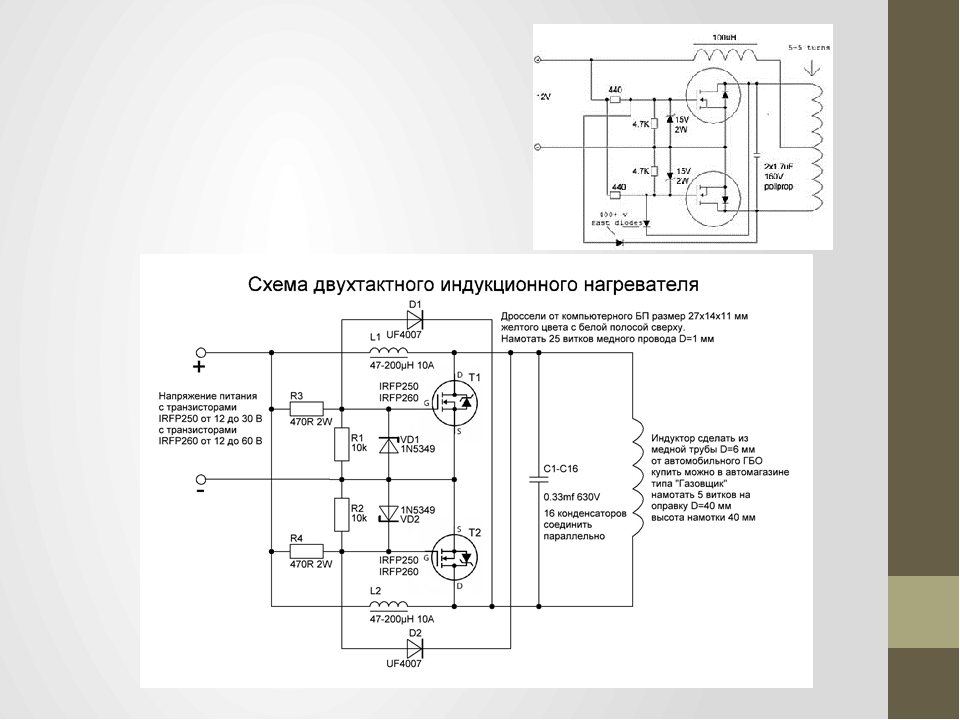

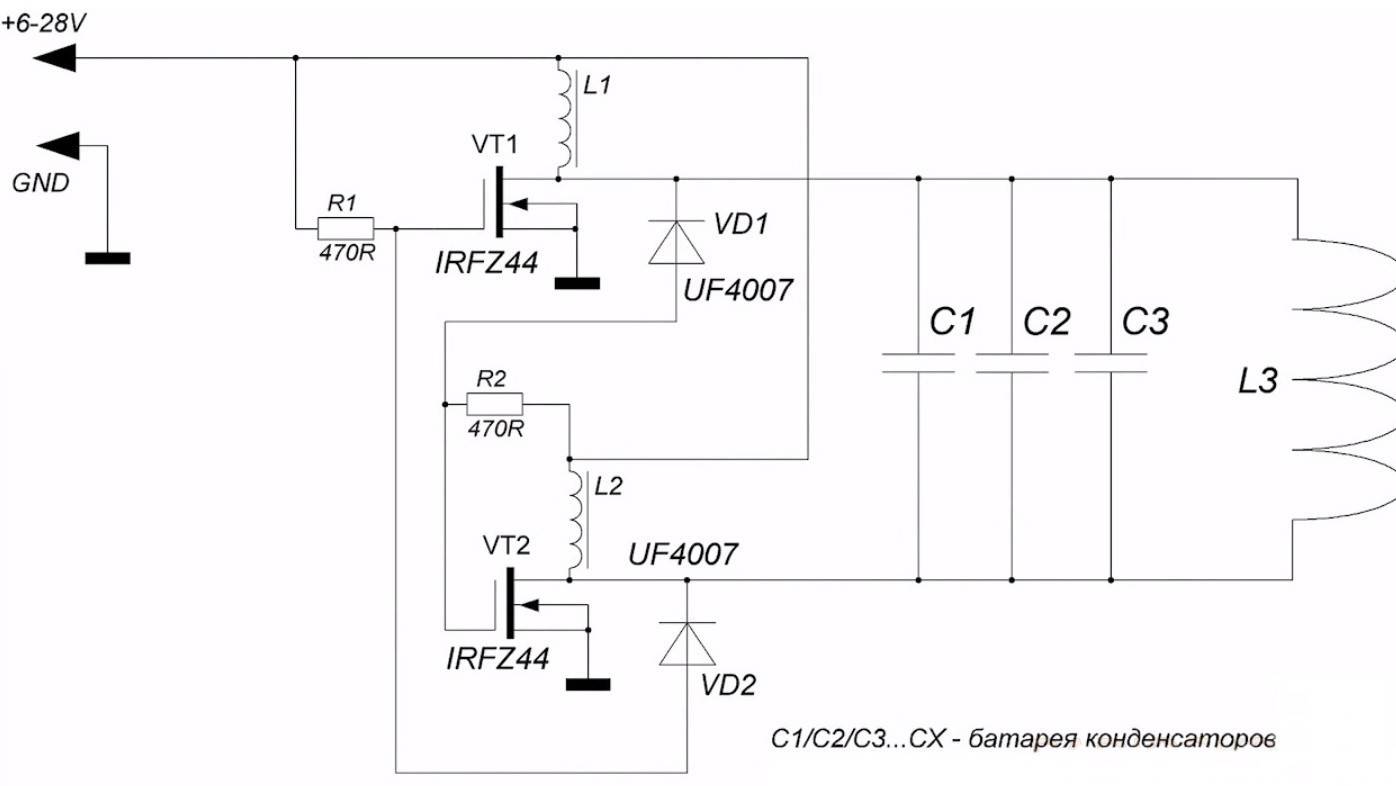

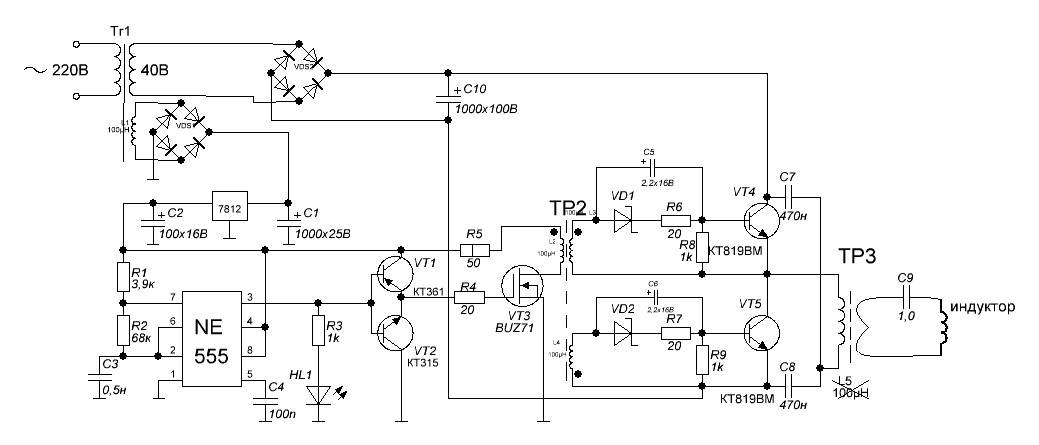

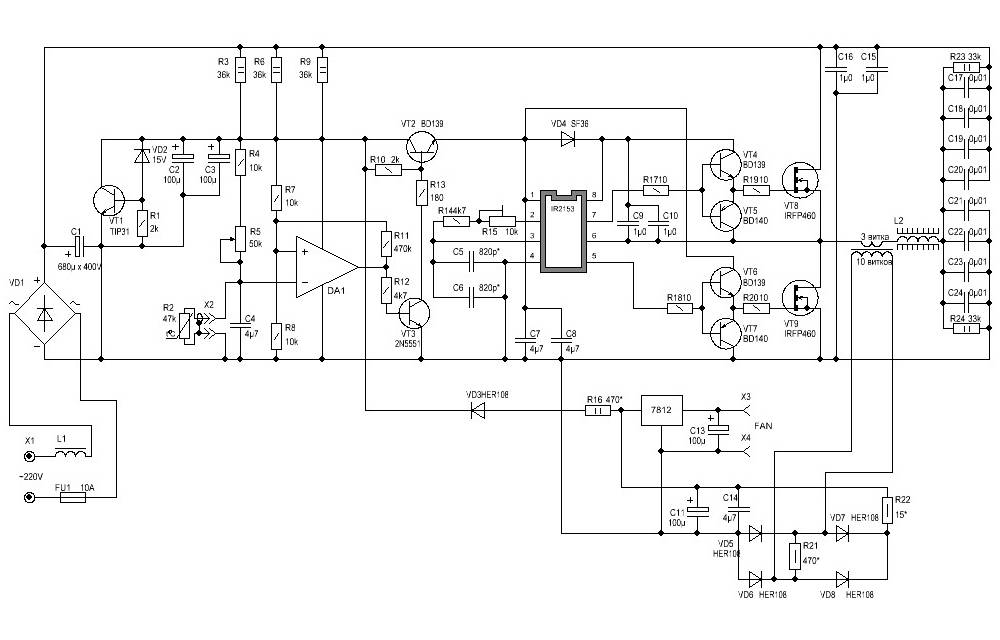

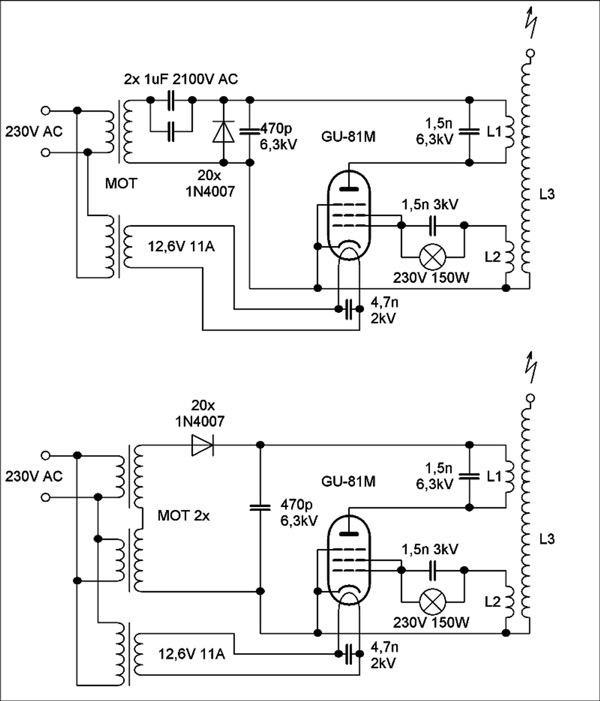

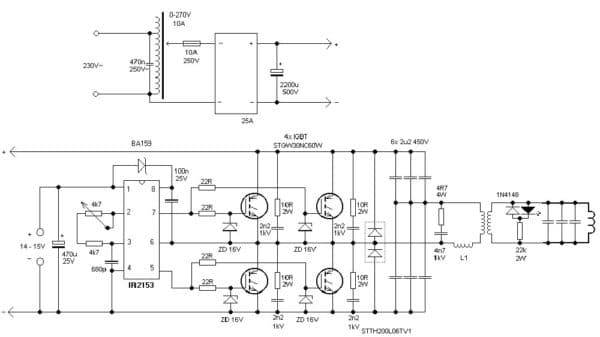

Scheme of a simple induction heater with a power of 1600 W

The presented scheme should be considered rather as an experimental option. However, this option is quite workable. The main advantages of the scheme:

- relative simplicity,

- parts availability,

- ease of assembly.

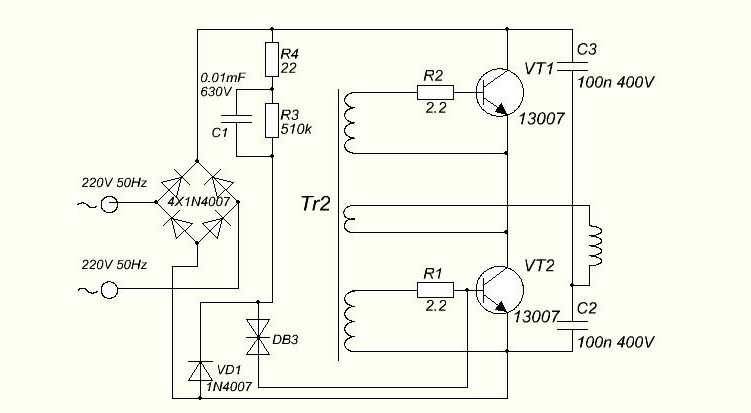

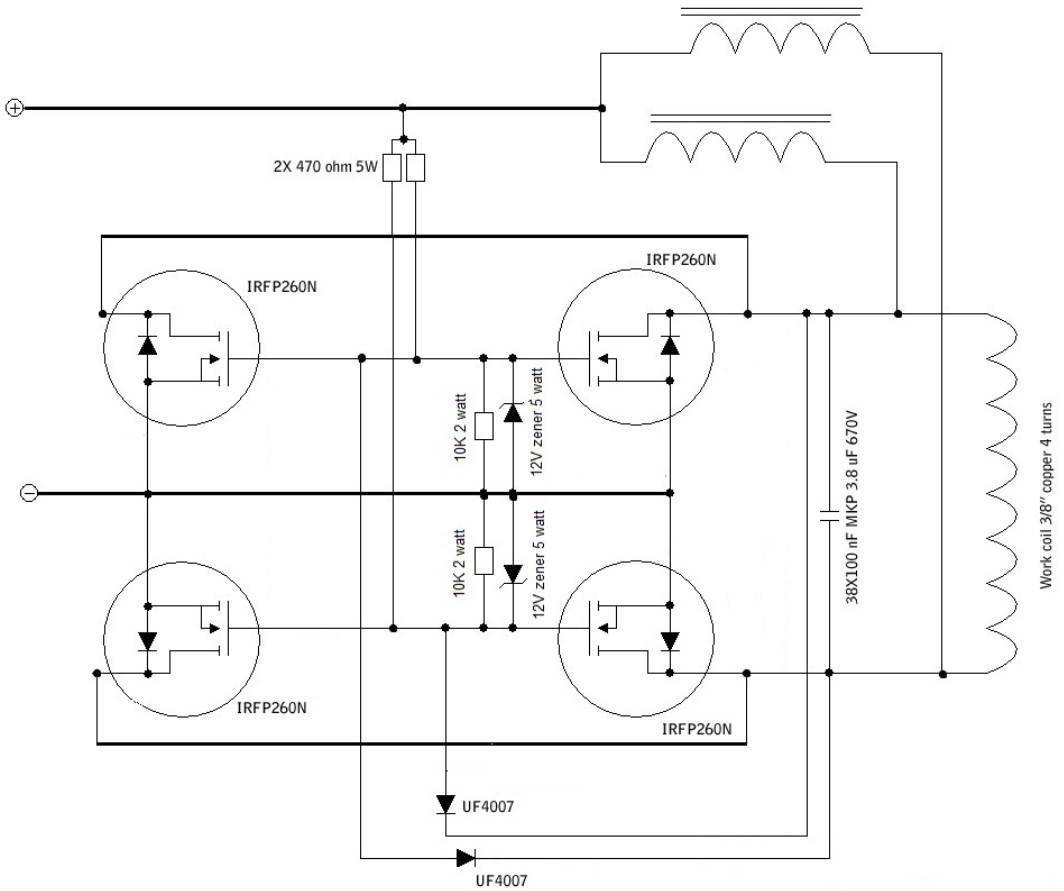

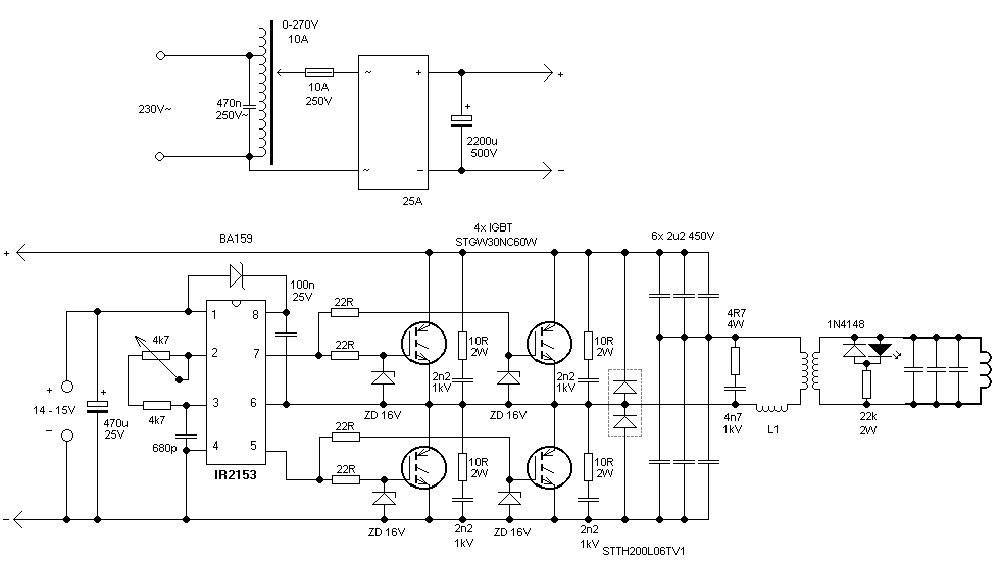

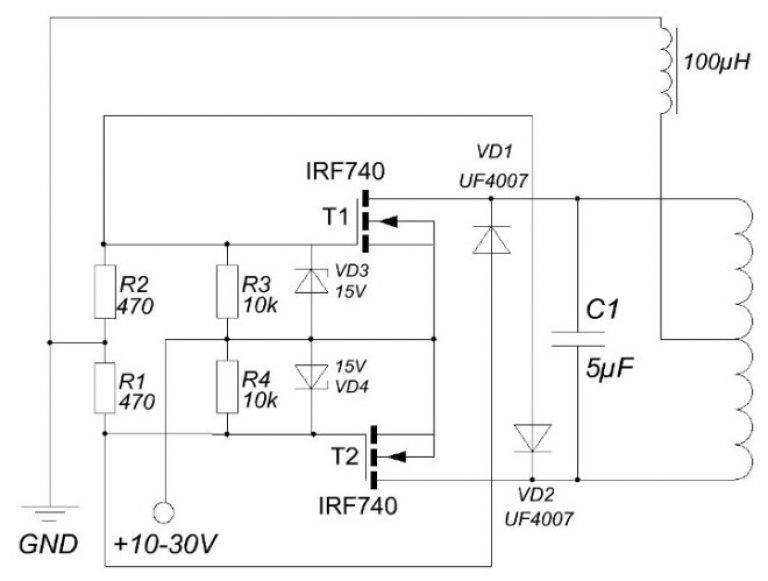

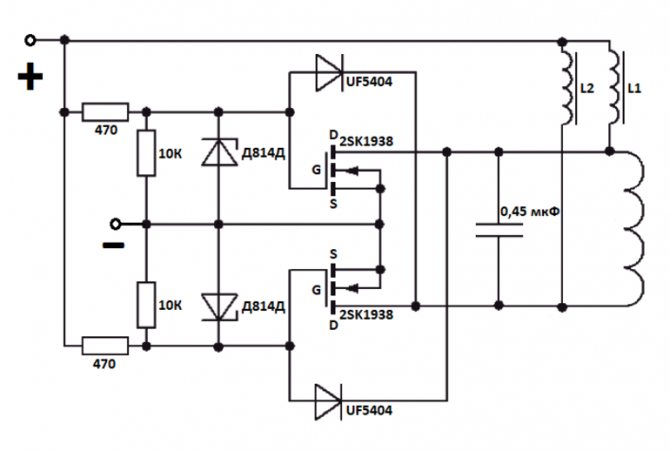

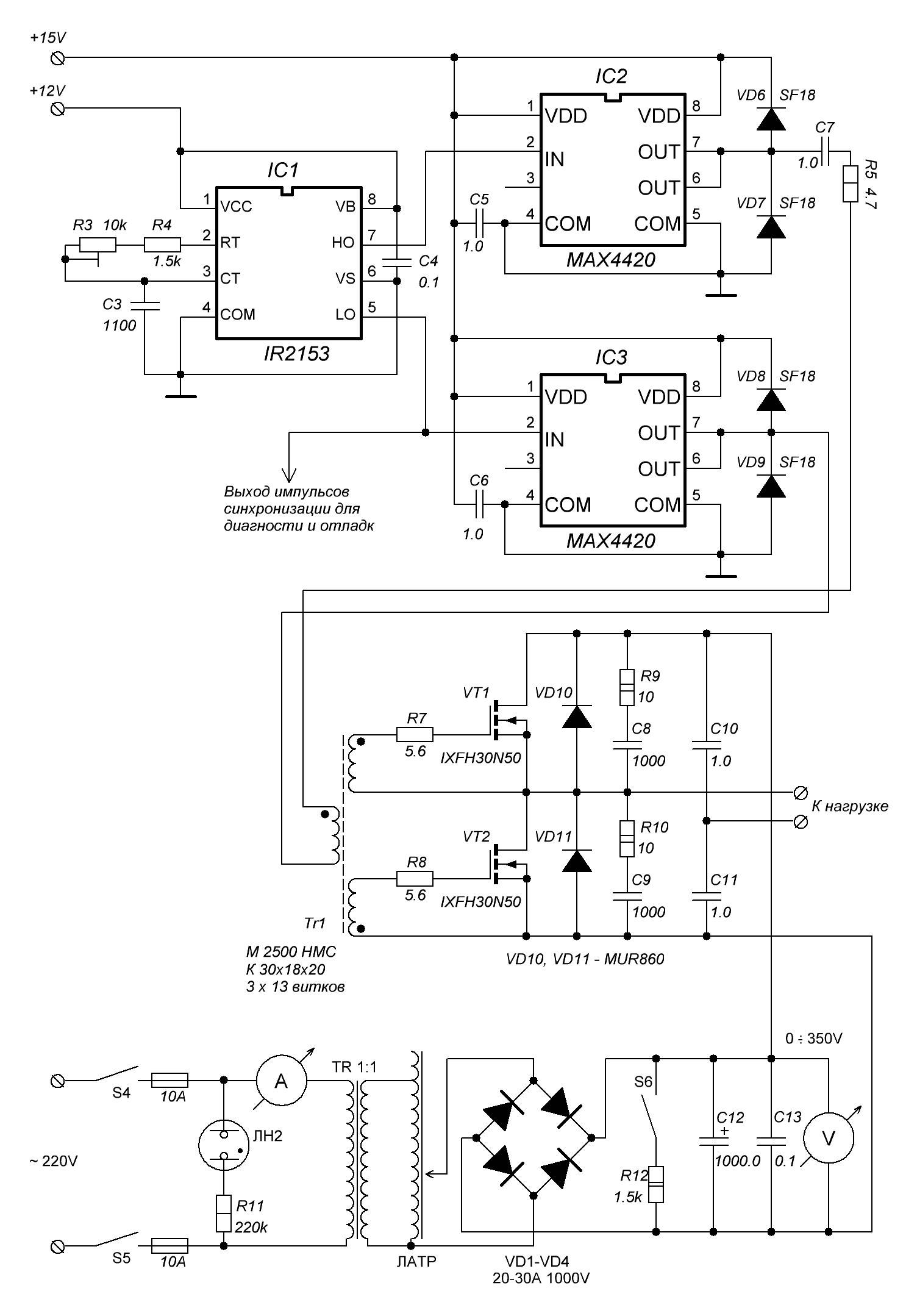

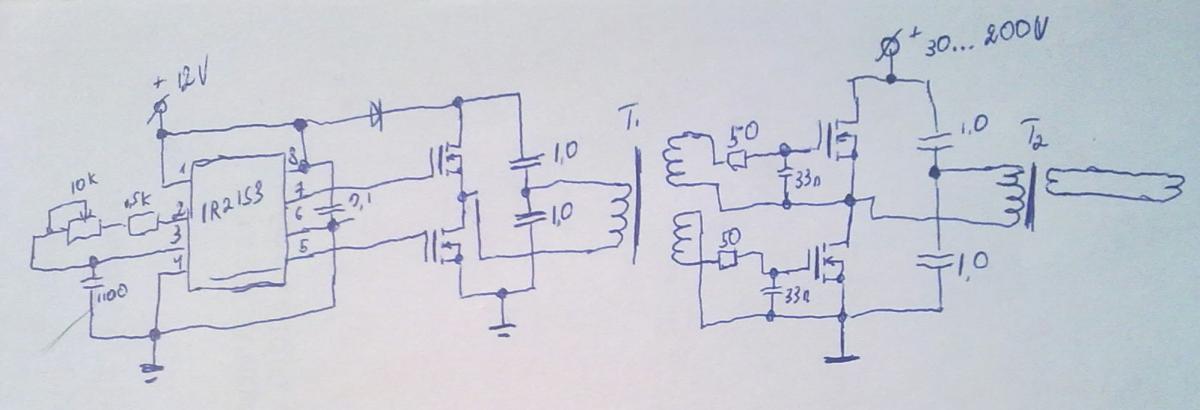

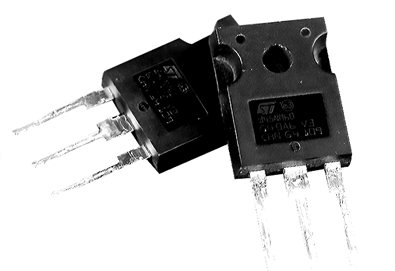

The induction heater circuit (picture below) works on the principle of a “double half-bridge”, supplemented by four power insulated gate transistors from the IGBT series (STGW30NC60W). The transistors are controlled by an IR2153 chip (self-clocked half-bridge driver).

HEATERS

Schematic representation of a simplified low power induction heater, the design of which allows for use in private households

A double half-bridge is capable of delivering the same power as a full bridge, but a clocked half-bridge gate driver is simpler to implement and therefore easier to use. A powerful double diode type STTH200L06TV1 (2x 120A) works as an anti-parallel diode circuit.

Much smaller diodes (30A) will be enough. If you intend to use transistors of the IGBT series with built-in diodes (for example, STGW30NC60WD), this option can be completely abandoned.

The operating resonance frequency is adjusted using a potentiometer. The presence of resonance is determined by the highest brightness of the LEDs.

IGBT TRANSISTOR

Electronic components of a simple do-it-yourself induction heater: 1 - Powerful double diode type STTH200L06TV1; 2 - transistor with built-in diodes type STGW30NC60WD

STTH DIODES

Of course, there is always the possibility of building a more complex driver. In general, the optimal solution seems to be to use automatic tuning. This is usually used in professional induction heater circuits, but the current circuit, in the case of such an upgrade, clearly loses the simplicity factor.

Frequency control, inductor, power

The induction heater circuit provides for frequency adjustment in the range of approximately 110 - 210 kHz. However, the control circuit requires an auxiliary voltage of 14-15V, obtained from a small adapter (the switcher can be switched or conventional).

The output of the induction heater circuit is connected to the working circuit of the coil through a matching inductor L1 and an isolation transformer. The inductor has 4 turns of wire on a core with a diameter of 23 cm, the isolation transformer consists of 12 turns of a two-wire cable wound on a core with a diameter of 14 cm.

The output power of an induction heater with the specified parameters is about 1600 watts. Meanwhile, the possibility of increasing the power to higher values is not excluded.

CAPACITORS

Experimental design of an induction heater, made by hand at home. The efficiency of the device is quite high, despite the low power

The working coil of the induction heater is made of wire with a diameter of 3.3 mm. The best material for the coil is a copper pipe, for which a simple water cooling system can be used. The inductor has:

- 6 turns of winding,

- diameter 24 mm,

- height 23 mm.

For this element of the circuit, a significant heating is seen as a characteristic phenomenon as the installation operates in the active mode. This point should be taken into account when choosing a material for manufacturing.

Resonant Capacitor Module

The resonant capacitor is made in the form of a battery of small capacitors (the module is assembled from 23 small capacitors). The total battery capacity is 2.3 microfarads. The design allows the use of capacitors with a capacity of 100 nF (~ 275V, polypropylene MCP, class X2).

This type of capacitors is not intended for such purposes as application in an induction heater circuit. However, as practice has shown, the noted type of capacitance elements is quite satisfactory for operation at a resonant frequency of 160 kHz. It is recommended to use an EMI filter.

EMI FILTERS

Filter of electromagnetic radiation. Approximately this is recommended to be used in the design of an induction heater in order to minimize interference

The adjustable transformer can be replaced with a soft start circuit. For example, you can recommend resorting to using a simple current limiter circuit:

- heaters,

- halogen lamps,

- other appliances

with a power of about 1 kW, connected in series with the induction heater when first turned on.

Working scheme

The heater consists of the following components:

- Inverter unit, designed for voltage 220 ... 240 V, at a current of at least 10 A.

- Three-wire cable line (one wire is ground) with a normally open switch.

- Water cooling system (it is highly desirable to use water purification filters).

- A set of coils that differ in internal diameters and lengths (with a limited amount of work, you can get by with one coil).

- Heating block (you can use a module on power transistors, which are produced by Chinese companies Infineon or IGBT).

- Snubber circuit with several Semikron capacitors.

The high-frequency oscillation generator is taken to be the same as that of the basic inverter

It is important that its performance characteristics fully comply with those indicated in the previous sections.

After assembly, the unit is grounded, and with the help of connecting cables, the heating induction coil is connected to the inverter power supply.

Approximate operational capabilities of a homemade induction metal heater:

- The highest heating temperature, ° С - 800.

- The minimum inverter power is 2 kVA.

- The duration of the inclusion of PV, not less than - 80.

- Operating frequency, kHz (adjustable) - 1.0 ... 5.0.

- The inner diameter of the coil, mm - 50.

It should be noted that such an inductor will require a specially prepared workplace - a tank for waste water, a pump, and reliable grounding.

High frequency induction heaters

The widest range of applications is for high-frequency induction heaters. The heaters are characterized by a high frequency of 30-100 kHz and a wide power range of 15-160 kW. The high-frequency type provides a small depth of heating, but this is enough to improve the chemical properties of the metal.

High frequency induction heaters are easy to operate and economical, while their efficiency can reach 95%.All types work continuously for a long time, and the two-block version (when the high-frequency transformer is placed in a separate block) allows round-the-clock operation. The heater has 28 types of protections, each of which is responsible for its own function. Example: control of water pressure in the cooling system.

- Induction heater 60 kW Perm

- Induction heater 65 kW Novosibirsk

- Induction heater 60 kW Krasnoyarsk

- Induction heater 60 kW Kaluga

- Induction heater 100 kW Novosibirsk

- Induction heater 120 kW Ekaterinburg

- Induction heater 160 kW Samara

Application:

- surface hardened gear

- shaft hardening

- crane wheel hardening

- heating parts before bending

- soldering of cutters, cutters, drill bits

- heating the workpiece during hot stamping

- bolt landing

- welding and surfacing of metals

- restoration of details.

more

Features of the vortex induction boiler

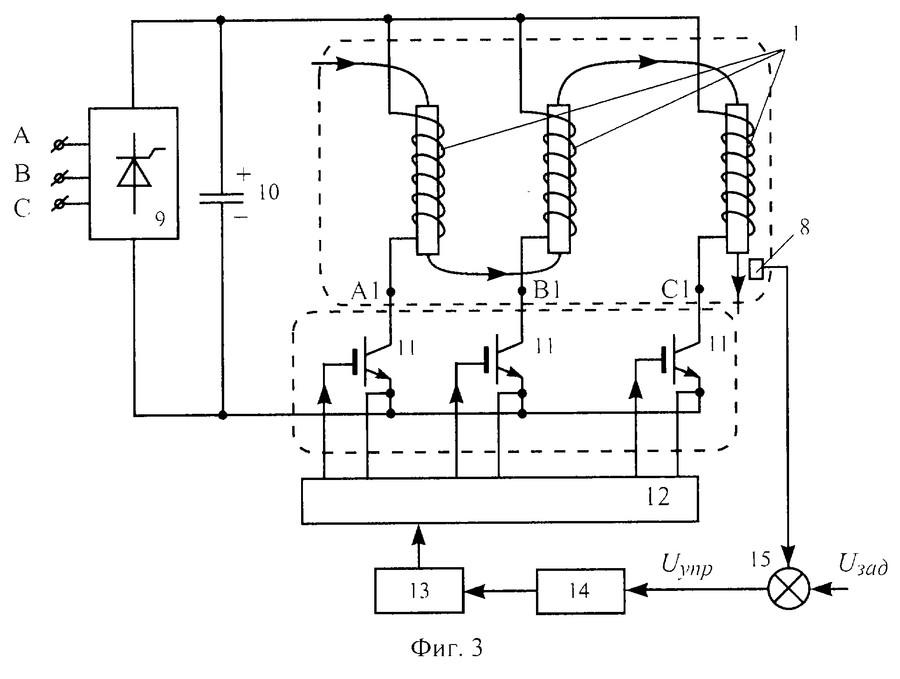

We are already familiar with the principle of operation of an induction heater. There is a variation of it: a vortex induction boiler or VIN, which operates in a slightly different way.

Distinctive features of VIN

Like the induction counterpart, it runs on high-frequency voltage, so it must be equipped with an inverter. A feature of the VIN device is that it does not have a secondary winding.

Its role is performed by all the metal parts of the device. They must be made from materials that exhibit ferromagnetic properties. Thus, when current is supplied to the primary winding of the device, the strength of the electromagnetic field increases sharply.

It, in turn, generates a current, the strength of which is rapidly increasing.Eddy currents provoke magnetization reversal, as a result of which all ferromagnetic surfaces heat up very quickly, almost instantly.

Vortex devices are quite compact, but due to the use of metal, their weight is large. This gives an additional advantage, since all the massive elements of the body take part in heat exchange. Thus, the efficiency of the unit approaches 100%.

This feature of the device must be taken into account if a decision is made to independently manufacture a VIN boiler. It can only be made of metal, plastic should not be used.

The main difference between the vortex induction boiler is that its body acts as a secondary winding. Therefore, it is always made of metal

How to assemble a vortex induction device?

As we already know, such a boiler differs from its induction counterpart, however, making it yourself is just as easy. True, now you will need welding skills, because the device must be assembled only from metal parts.

For work you will need:

- Two segments of a metal thick-walled pipe of the same length. Their diameters must be different, so that one part can be placed in another.

- Winding (enamelled) copper wire.

- A three-phase inverter, it is possible from a welding machine, but as powerful as possible.

- Casing for thermal insulation of the boiler.

Now you can get to work. We start with the manufacture of the body of the future boiler. We take a pipe of a larger diameter and insert the second part inside. They need to be welded one into the other so that there is some distance between the walls of the elements.

The resulting detail in the section will resemble a steering wheel.A steel sheet with a thickness of at least 5 mm is used as the base and cover of the housing.

The result is a hollow cylindrical tank. Now you need to cut pipes into its walls for the pipes for supplying cold and draining hot liquids. The configuration of the pipe and its diameter depend on the pipes of the heating system; adapters may be additionally needed.

After that, you can start winding the wire. It is carefully, under sufficient tension, wound around the boiler body.

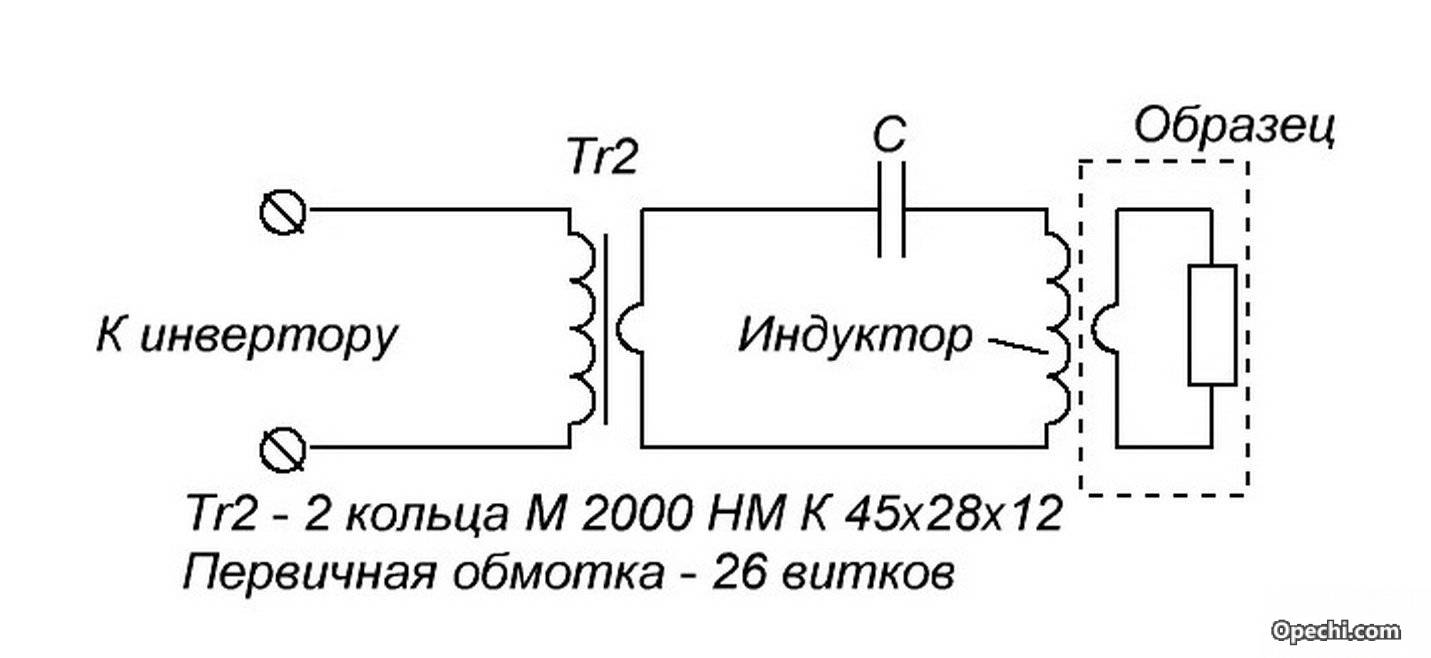

Schematic diagram of a homemade vortex-type induction boiler

Actually, a wound wire will serve as a heating element, so it is advisable to close the device case with a heat-insulating casing. So it will be possible to save maximum heat and, accordingly, increase the efficiency of the device and make it safe.

Now you need to embed the boiler into the heating system. To do this, the coolant is drained, the pipe section of the required length is cut off and the device is welded in its place.

It remains only to power the heater and do not forget to connect the inverter to it. The device is ready for use. But before testing, you need to fill the line with coolant.

You do not know which coolant to choose to fill the circuit? We recommend that you familiarize yourself with the characteristics of various coolants and recommendations for choosing the optimal type of fluid for the heating circuit.

Only after pumping the coolant into the system, carry out a test run.

First you need to run the device at minimum power and carefully monitor the quality of the welds. If everything is in order, we increase the power to the maximum.

On our website there is another instruction for the manufacture of an induction device that can be used to heat the coolant in the heating system. To get acquainted with the process of assembling an induction heater, follow this link.

Principle of operation and scope

The generator increases the frequency of the current and transfers its energy to the coil. The inductor converts high-frequency current into an alternating electromagnetic field. Electromagnetic waves change with high frequency.

Heating occurs due to the heating of eddy currents, which are provoked by variable eddy vectors of the electromagnetic field. Energy with high efficiency is transmitted almost without loss and there is enough energy to heat the coolant and even more.

The battery energy is transferred to the coolant, which is located inside the pipe. The heat carrier, in turn, is the cooler of the heating element. As a result, the service life is increased.

The industry is the most active consumer of induction heaters, as many designs involve high heat treatment. With their use, the strength of products increases.

In high-frequency forges, devices with high power are installed.

Forging and pressing companies, using such units, increase labor productivity and reduce the wear of dies, reduce metal consumption. Installations with through heating can cover a number of workpieces at once.

In case of surface hardening of parts, the use of such heating makes it possible to increase wear resistance several times and obtain a significant economic effect.

The generally accepted field of application of devices is soldering, melting, heating before deformation, HDTV hardening. But there are still zones where single-crystal semiconductor materials are obtained, epitaxial films are built up, materials are foamed into el. field, high-frequency welding of shells and pipes.

Production of induction heaters

Induction heating is not yet as popular as gas and solid fuel boilers. This can be explained by the high cost of such heating systems for private houses. For domestic use, a boiler built on induction technology will cost 30,000 rubles and more. Therefore, it is not surprising that many homeowners refuse to buy factory equipment and make it themselves. If you have the appropriate circuit, inexpensive components and the ability to read technical documentation, you can literally make an effective and completely safe induction heater for a heating boiler in just a few hours.

Transformer Based

It is possible to make high-quality induction heating elements on the basis of a transformer with primary and secondary windings. The eddy currents necessary for the operation of such equipment are formed in the primary winding and create an induction field. A powerful electromagnetic field acts on the secondary winding, which is, in fact, an induction heater and emits a large amount of heat used to heat the coolant.

The design of a home-made induction heater based on a transformer will include the following elements:

- Transformer core.

- Winding.

- Heat and electrical insulation.

The core is made in the form of two ferromagnetic tubes with different diameters. They are welded into each other, after which a toroidal winding is made of durable copper wire. At least 85 turns are made with the obligatory maintenance of an equal distance between them. When electricity is passed through the core and winding in a closed circuit, vortex flows are created that heat the core and secondary winding. Subsequently, the resulting heat is used to heat the coolant.

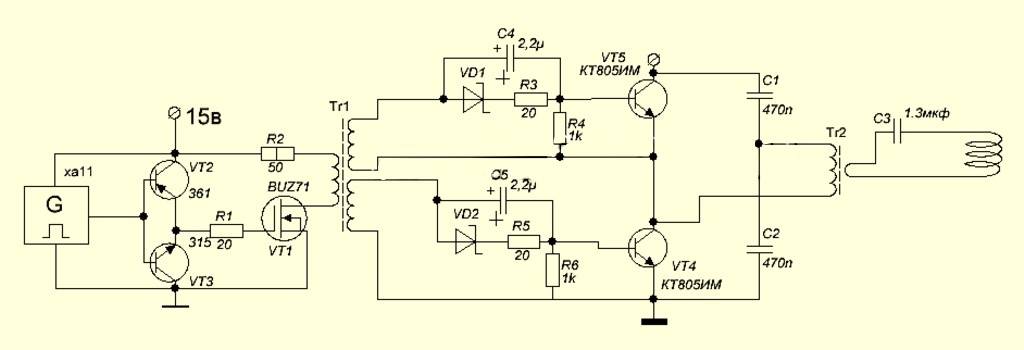

From high frequency welding machine

In a do-it-yourself inductor circuit using a high-frequency inverter, the main elements are an alternator, heating elements and inductors. The generator will be needed to convert a standard voltage with a frequency of 50 Hertz into a high-frequency electric current. After modulation, the current is fed into the inductor coil, which has a cylindrical shape. The winding of the coil is made of copper wire, which allows generating a magnetic alternating field that creates the necessary eddy currents, due to the appearance of which the metal body of the water jacket is heated. The resulting heat is transferred to the coolant.

It is not difficult to make a high-quality heater based on a high-frequency welding inverter. It is only necessary to take care of high-quality and reliable thermal insulation, which will ensure the highest possible efficiency. Otherwise, in the absence of reliable thermal insulation, the efficiency of the heating system is significantly reduced, which leads to a significant consumption of electricity for the operation of the equipment.

There are at least 3 main elements that must be in working order in the heater

There are at least 3 main elements that must be in working order in the heater

Description and advantages of technology

The principle of operation of induction heaters is based on the release of heat by metals when current is passed through them. When voltage is applied to the current-carrying circuit, a magnetic field and an induction current are formed, which generates a large amount of heat. Today, this technology is used to manufacture various electric heaters that combine compact dimensions and excellent power. Due to the simplicity of the design of such installations, it is not difficult to make them yourself.

One of the advantages of this heater is almost 100% efficiency

One of the advantages of this heater is almost 100% efficiency

The advantages of induction heating include the following:

- High power.

- Ability to work in various environments.

- Complete environmental friendliness.

- Possibility of selective heating.

- Full process automation.

- Efficiency at the level of 99%.

- Long service life.

In everyday life, induction heating technologies are implemented in cookers and fully automated heating boilers. Such installations are popular in the domestic market, which is explained by their ease of maintenance, reliable design, efficiency and versatility of use.

The scheme of the device of the induction heater is so simple that it is not difficult to assemble it with your own hands. All you need is minimal experience reading circuits and the ability to work with a soldering iron or similar equipment. You can make both the simplest versions of heaters for heating indoor air, and make a full-fledged boiler for a country house.

In this video you will learn how to make a simple induction heater.

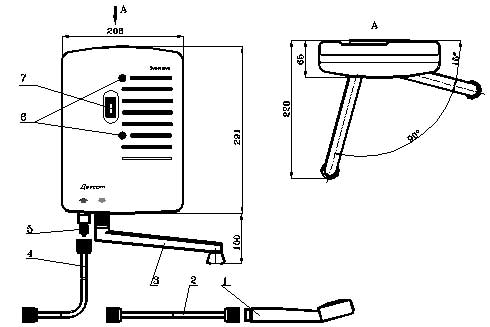

Important notes on installation and use of the boiler

induction heater

Homemade induction boilers are extremely easy to assemble, installation and operation. However, before you start using this kind of heater, you need to know a few important rules, namely:

- homemade induction heating installation is intended for use only in closed-type heating systems, in which air circulation is provided by a pump;Closed heating system

- the wiring of heating systems that will work in conjunction with the considered boiler must be made of plastic or propylene pipes; Plastic pipes for heating

- to prevent the occurrence of various kinds of troubles, install the heater not close to the nearest surface, but at some distance - at least 30 cm from the walls and 80-90 cm from the ceiling and floor.

It is strongly recommended to equip the boiler nozzle with a blast valve. Through this simple device, you can, if necessary, rid the system of excess air, normalizing the pressure and ensuring optimal operating conditions.

Check valve

Thus, from inexpensive materials with the help of simple tools, you can assemble a complete installation for efficient space heating and water heating. Follow the instructions, remember the special recommendations, and very soon you will be able to enjoy the warmth in your own home.

Conclusion

There is a reason to take on the independent manufacture of the device if the household already has an induction panel.The cost of its acquisition is quite high and comparable to the price of an electrode heater. The power of some of these models reaches 10 kW, while making at home an installation with an indicator above 2.5 kW can only be done by a master with the proper level of competence (at a minimum, you need to be able to assemble a frequency converter circuit). Also, before installation, it is necessary to make sure that there are no cracks and holes through which liquid from the heat generator can seep out: such an incident can cause a fire.

An induction heater of a simple design, designed to serve a small area of \u200b\u200bthe room, is easy to make without special training. More powerful and efficient options, for example, with a welding machine or two boards, require the assembler of competencies in the field of electronics. The structural features of these installations necessitate the acquisition of additional controls to ensure safety.