- Buy parts on Aliexpress

- The principle of operation of devices

- The principle of operation of devices

- Assembly according to schemes

- Induction furnace from a welding inverter - a device for melting metal and for heating the coolant in the heating system

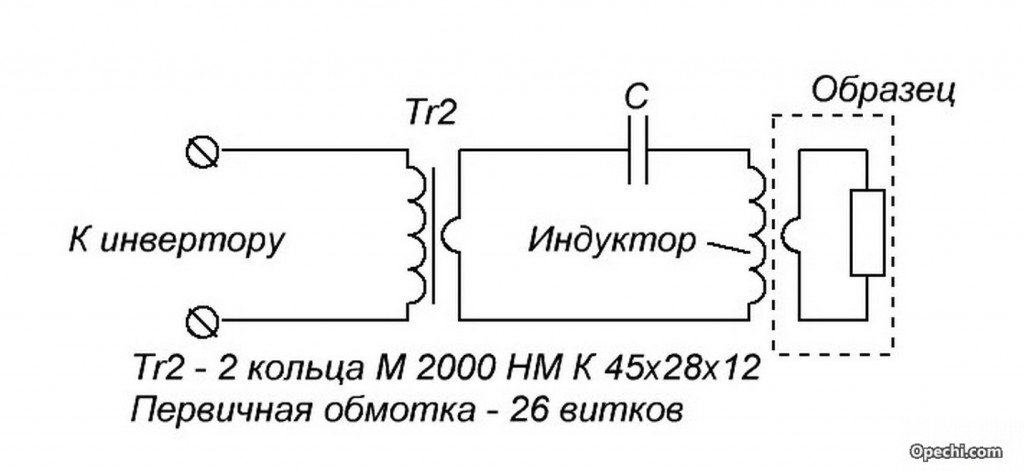

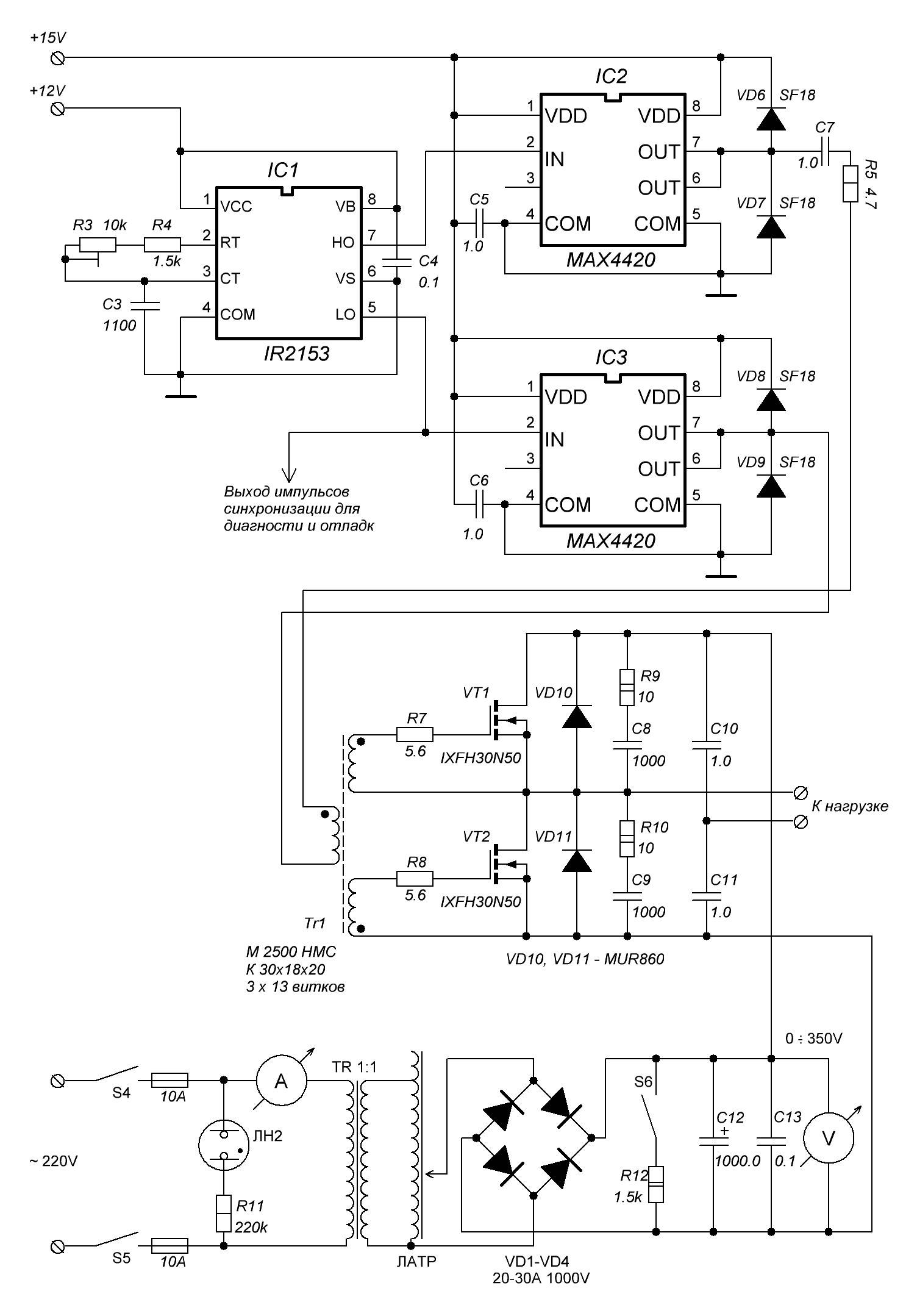

- Diagram of an induction heater

- Advantages and disadvantages of induction heaters

- Operation features

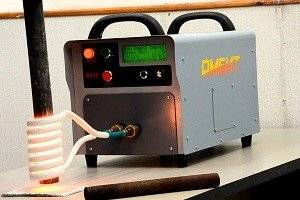

- High frequency induction heaters

- Application:

- Inverter from a device for welding.

- 3 Independent production of equipment

- DIY induction heaters. Homemade induction heater: diagram

- Manufacturing instructions

- Blueprints

- The principle of operation of the induction heater

- Induction welding: working principle

- Step 7: Making a Work Coil

- Conclusion

Buy parts on Aliexpress

|

Appliances that heat with electricity rather than gas are safe and convenient. Such heaters do not produce soot and unpleasant odors, but consume a large amount of electricity. An excellent way out is to assemble an induction heater with your own hands. This saves money and contributes to the family budget. There are many simple schemes according to which the inductor can be assembled independently.

In order to make it easier to understand the circuits and assemble the structure correctly, it would be useful to look into the history of electricity. Methods for heating metal structures with an electromagnetic coil current are widely used in the industrial manufacture of household appliances - boilers, heaters and stoves. It turns out that you can make a working and durable induction heater with your own hands.

The principle of operation of devices

The principle of operation of devices

The famous 19th century British scientist Faraday spent 9 years researching to convert magnetic waves into electricity. In 1931, a discovery was finally made, called electromagnetic induction. The wire winding of the coil, in the center of which there is a core of magnetic metal, creates a magnetic field under the power of alternating current. Under the action of vortex flows, the core heats up.

Faraday's discovery began to be used both in industry and in the manufacture of home-made motors and electric heaters. The first foundry based on a vortex inductor was opened in 1928 in Sheffield. Later, according to the same principle, the workshops of factories were heated, and for heating water, metal surfaces, connoisseurs assembled an inductor with their own hands.

The scheme of the device of that time is valid today. A classic example is an induction boiler, which includes:

- metal core;

- frame;

- thermal insulation.

The features of the circuit for accelerating the frequency of the current are as follows:

- industrial frequency of 50 Hz is not suitable for home-made devices;

- direct connection of the inductor to the network will lead to hum and low heating;

- effective heating is carried out at a frequency of 10 kHz.

Assembly according to schemes

Anyone familiar with the laws of physics can assemble an inductive heater with their own hands. The complexity of the device will vary from the degree of preparedness and experience of the master.

There are many video tutorials, following which you can create an effective device. It is almost always necessary to use the following basic components:

- steel wire with a diameter of 6-7 mm;

- copper wire for the inductor;

- metal mesh (to hold the wire inside the case);

- adapters;

- pipes for the body (made of plastic or steel);

- high frequency inverter.

This will be enough to assemble an induction coil with your own hands, and it is she who is at the heart of the instantaneous water heater. After preparing the necessary elements you can go directly to the manufacturing process of the device:

- cut the wire into segments of 6-7 cm;

- cover the inside of the pipe with a metal mesh and fill the wire to the top;

- similarly close the pipe opening from the outside;

- wind copper wire around the plastic case at least 90 times for the coil;

- insert the structure into the heating system;

- using an inverter, connect the coil to electricity.

According to a similar algorithm, you can easily assemble an induction boiler, for which you should:

- cut blanks from a steel pipe 25 by 45 mm with a wall no thicker than 2 mm;

- weld them together, connecting them with smaller diameters;

- weld iron covers to the ends and drill holes for threaded pipes;

- make a mount for an induction stove by welding two corners on one side;

- insert the hob into the mount from the corners and connect to the mains;

- add coolant to the system and turn on the heating.

Many inductors operate at a power not higher than 2 - 2.5 kW. Such heaters are designed for a room of 20 - 25 m²

If the generator is used in a car service, you can connect it to a welding machine, but it is important to consider certain nuances:

- You need AC, not DC like an inverter. The welding machine will have to be examined for the presence of points where the voltage does not have a direct direction.

- The number of turns to a wire of a larger cross section is selected by a mathematical calculation.

- Cooling of working elements will be required.

Induction furnace from a welding inverter - a device for melting metal and for heating the coolant in the heating system

The idea of using such an induction plant as a metal melting furnace in many ways allows it to be used as a heating boiler for a small room.

The advantage of this application is:

- In contrast to metal melting, in the presence of a constantly circulating coolant, the system is not subject to overheating;

- Constant vibration in the electromagnetic field does not allow sediments to settle on the walls of the heating chamber, narrowing the lumen;

- The principle diagram without threaded connections with gaskets and couplings eliminates the possibility of leakage;

- The installation is almost silent, unlike other types of heating boilers;

- The installation itself, without traditional heating elements, has a longer service life and high reliability;

- There are no emissions of combustion products, the risk of poisoning by fuel combustion products is reduced to zero.

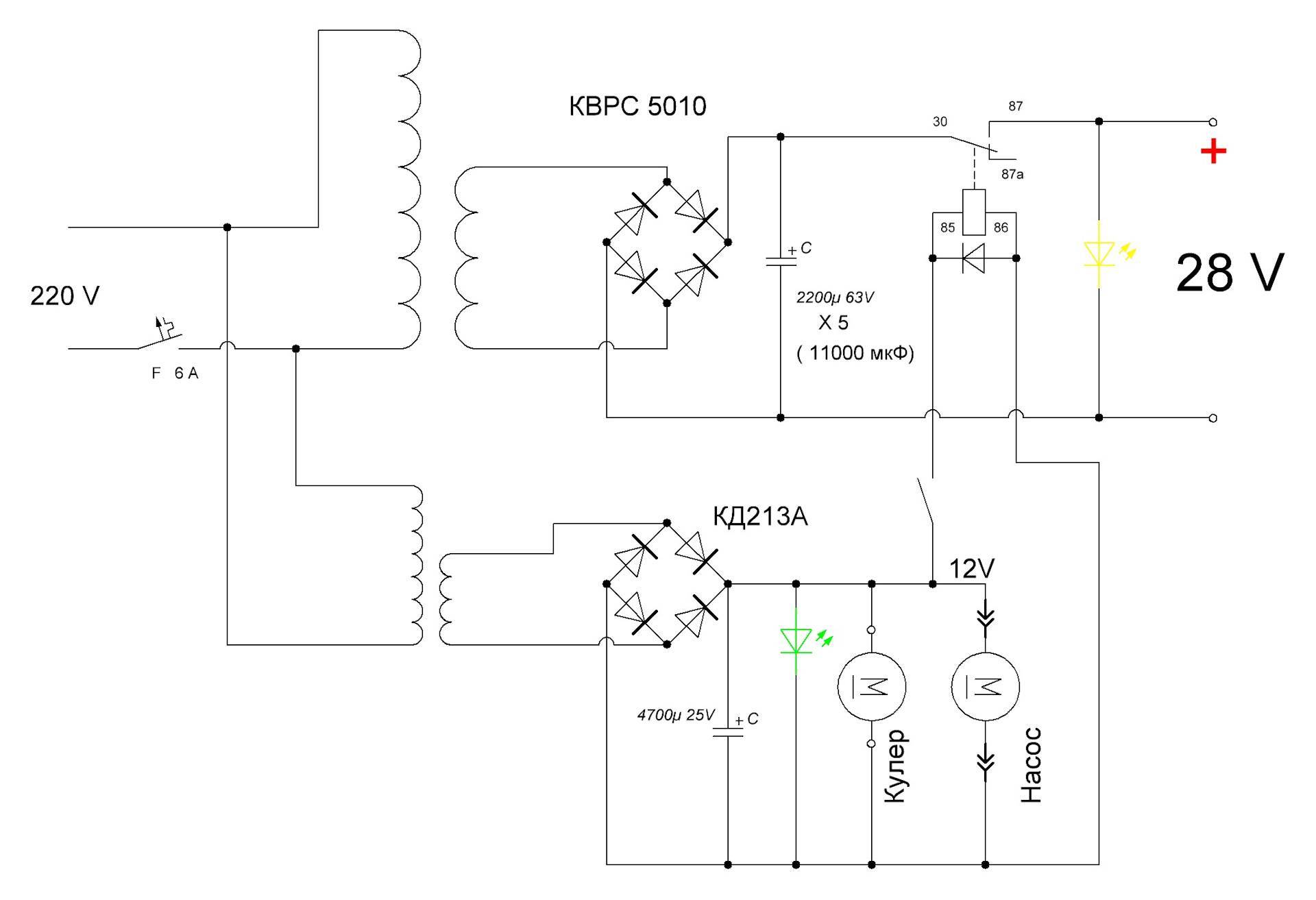

The practical component of the process of creating equipment for space heating using an induction furnace from an inverter welding machine consists of the following steps.

- For the manufacture of the body, a plastic pipe with thick walls is selected and designed for use in pipelines with high temperature and high pressure;

- In order for the metal filler to be constantly in the heater cavity, two covers with a mesh are made so that the filler does not fall out through it.

- A steel wire with a diameter of 5-8 mm is selected as a filler, and cut into pieces 50-70 mm long.

- The pipe body is filled with pieces of wire and connected to the system.

The principle of operation of this device is as follows:

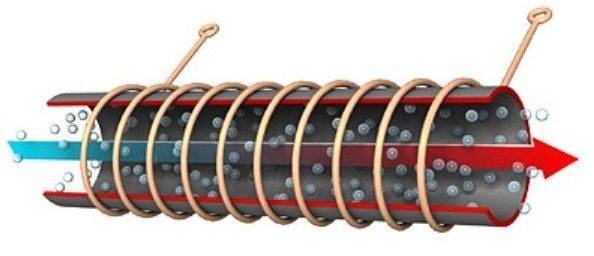

- An inductor made of copper wire with a diameter of 2-3 mm with 90 - 110 turns is installed outside the housing from a plastic pipe;

- The body is filled with coolant;

- When the inverter is turned on, current flows to the inductor;

- In the coil of the inductor, vortex flows are formed, which begin to act on the crystal lattice of the metal inside the case;

- Pieces of metal wire begin to heat up and heat the coolant;

- The coolant flow after heating begins to move, the heated coolant is replaced by a cold one.

Such a schematic diagram of a heating system based on an induction heating element in practical execution has one significant drawback - the coolant must be constantly pushed through by pressure. For this, a circulation pump must be included in the system. In addition, it is recommended to install an additional temperature sensor, this will allow you to control the coolant and protect the boiler from overheating.

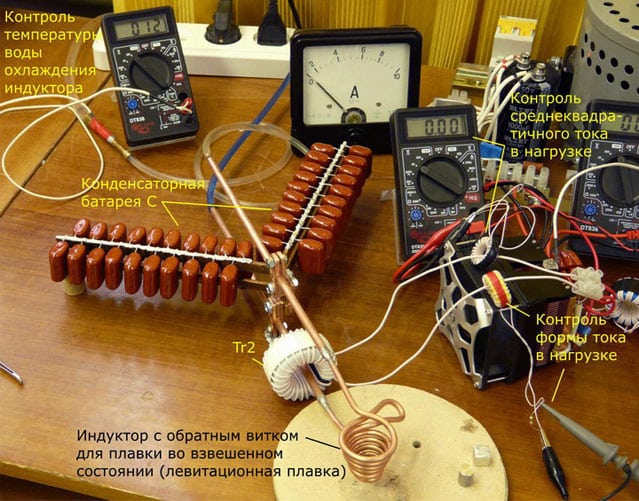

Diagram of an induction heater

Thanks to the discovery of M.Faraday in 1831, the phenomenon of electromagnetic induction in our modern life, many devices have appeared that heat water and other media. Every day we use an electric kettle with a disc heater, a multicooker, an induction hob, since we managed to realize this discovery for everyday life only in our time. Previously, it was used in the metallurgical and other branches of the metalworking industry.

The factory induction boiler uses in its work the principle of the action of eddy currents on a metal core placed inside the coil. Foucault eddy currents are of a surface nature, so it makes sense to use a hollow metal pipe as a core, through which a heated coolant flows.

The principle of operation of the induction heater

The occurrence of currents is due to the supply of an alternating electrical voltage to the winding, causing the appearance of an alternating electromagnetic field that changes potentials 50 times per second at a normal industrial frequency of 50 Hz. At the same time, the induction coil is designed in such a way that it can be connected directly to the AC mains. In industry, high-frequency currents are used for such heating - up to 1 MHz, so it is not easy to achieve device operation at a frequency of 50 Hz.

The thickness of the copper wire and the number of winding turns used by induction water heaters are calculated separately for each unit using a special method for the required heat output.The product must work efficiently, quickly heat the water flowing through the pipe and at the same time not overheat. Enterprises invest a lot of money in the development and implementation of such products, so all tasks are solved successfully, and the heater efficiency indicator is 98%.

In addition to high efficiency, the speed at which the medium flowing through the core is heated is especially attractive. The figure shows a diagram of the operation of an induction heater made in the factory. Such a scheme is used in units of the well-known trademark "VIN", produced by the Izhevsk plant.

Heater operation diagram

The durability of the heat generator depends only on the tightness of the case and the integrity of the insulation of the turns of the wire, and this turns out to be a rather long period, the manufacturers declare - up to 30 years. For all these advantages that these devices actually possess, you have to pay a lot of money, an induction water heater is the most expensive of all types of heating electrical installations. For this reason, some craftsmen took up making a homemade device in order to use it in heating the house.

Advantages and disadvantages of induction heaters

The advantages of induction electric heaters include the following performance characteristics and properties:

DIY induction heater

- Eddy currents generate not only heat, but also vibration. Therefore, scale does not settle on the walls of the heating element. Therefore, induction boilers do not need to be cleaned.

- The heating element of such a boiler is an ordinary pipe heated by eddy currents.And with constant circulation of the coolant on demand, it cannot physically burn out, unlike the heating coil of a traditional heating element. That is, you can not even think about replacing or repairing the heating element.

- Even a home-made vortex heat generator is sealed initially. After all, the heat carrier is heated inside an all-metal heating element. Moreover, the energy is transferred to the heater remotely - by means of an electromagnetic field. Therefore, due to the lack of detachable connections, there can be no leaks in induction boilers in principle.

- The boiler does not make noise, although the heating element may vibrate. But the frequency of this vibration is far from the range of sound waves. Therefore, the induction heater operates silently.

- The whole structure is assembled from cheap, readily available parts. Therefore, the induction heater is cheap to the point of obscenity.

In a word, such a heat carrier heating scheme is reliable, durable and very efficient. Moreover, when using an induction boiler, you can even refuse a circulation pump - the coolant will “go” through the pipes under the influence of thermal convection, warming up at the start almost to a vapor state.

And the list of disadvantages of induction heaters should include the following facts:

- Firstly, the alternating electromagnetic field heats up not only the heating element, but also the entire surrounding space, including the tissues of the human body. Therefore, you need to stay away from such a device.

- Secondly, the heating device runs on electricity. And this is not the cheapest source of energy.

- Thirdly, the device is very efficient, and the heat transfer of the heater is simply colossal, so there is always a risk of detonation of the boiler from overheating of the coolant. However, this defect is eliminated by a conventional pressure sensor.

However, if you are ready to put up with the shortcomings, then this heater was created especially for you. And below in the text we will offer you a scheme for self-assembly of such a boiler.

Operation features

Homemade heater assembly is only half the battle

Equally important is the correct operation of the resulting structure. Initially, each such device poses a certain danger, since it is not able to independently control the level of heating of the coolant. In this regard, each heater requires a certain refinement, that is, the installation and connection of additional control and automatic devices.

In this regard, each heater requires a certain refinement, that is, the installation and connection of additional control and automatic devices.

First of all, the pipe outlet is equipped with a standard set of safety devices - a safety valve, a pressure gauge and a device for venting air. It should be remembered that induction water heaters will work normally only if there is forced water circulation. The gravity flow circuit will very quickly lead to overheating of the element and the destruction of the plastic pipe.

To avoid such situations, a thermostat is installed in the heater, connected to an emergency shutdown device.Experienced electrical engineers use for this purpose thermostats with temperature sensors and relays that turn off the circuit when the coolant reaches the set temperature.

Home-made designs are characterized by rather low efficiency, since instead of free passage, there is an obstacle in the path of water in the form of wire particles. They almost completely cover the pipe, causing increased hydraulic resistance. In emergency situations, damage and rupture of plastic are possible, after which hot water will certainly lead to a short circuit. Typically, these heaters are used in small rooms as an additional heating system during the cold season.

The use of induction coils instead of traditional heating elements in heating equipment has made it possible to significantly increase the efficiency of the units with less electricity consumption. Induction heaters have appeared on sale relatively recently, moreover, at fairly high prices. Therefore, craftsmen did not leave this topic without attention and figured out how to make an induction heater from a welding inverter.

High frequency induction heaters

The widest range of applications is for high-frequency induction heaters. The heaters are characterized by a high frequency of 30-100 kHz and a wide power range of 15-160 kW. The high-frequency type provides a small depth of heating, but this is enough to improve the chemical properties of the metal.

High frequency induction heaters are easy to operate and economical, while their efficiency can reach 95%.All types work continuously for a long time, and the two-block version (when the high-frequency transformer is placed in a separate block) allows round-the-clock operation. The heater has 28 types of protections, each of which is responsible for its own function. Example: control of water pressure in the cooling system.

- Induction heater 60 kW Perm

- Induction heater 65 kW Novosibirsk

- Induction heater 60 kW Krasnoyarsk

- Induction heater 60 kW Kaluga

- Induction heater 100 kW Novosibirsk

- Induction heater 120 kW Ekaterinburg

- Induction heater 160 kW Samara

Application:

- surface hardened gear

- shaft hardening

- crane wheel hardening

- heating parts before bending

- soldering of cutters, cutters, drill bits

- heating the workpiece during hot stamping

- bolt landing

- welding and surfacing of metals

- restoration of details.

more

Inverter from a device for welding.

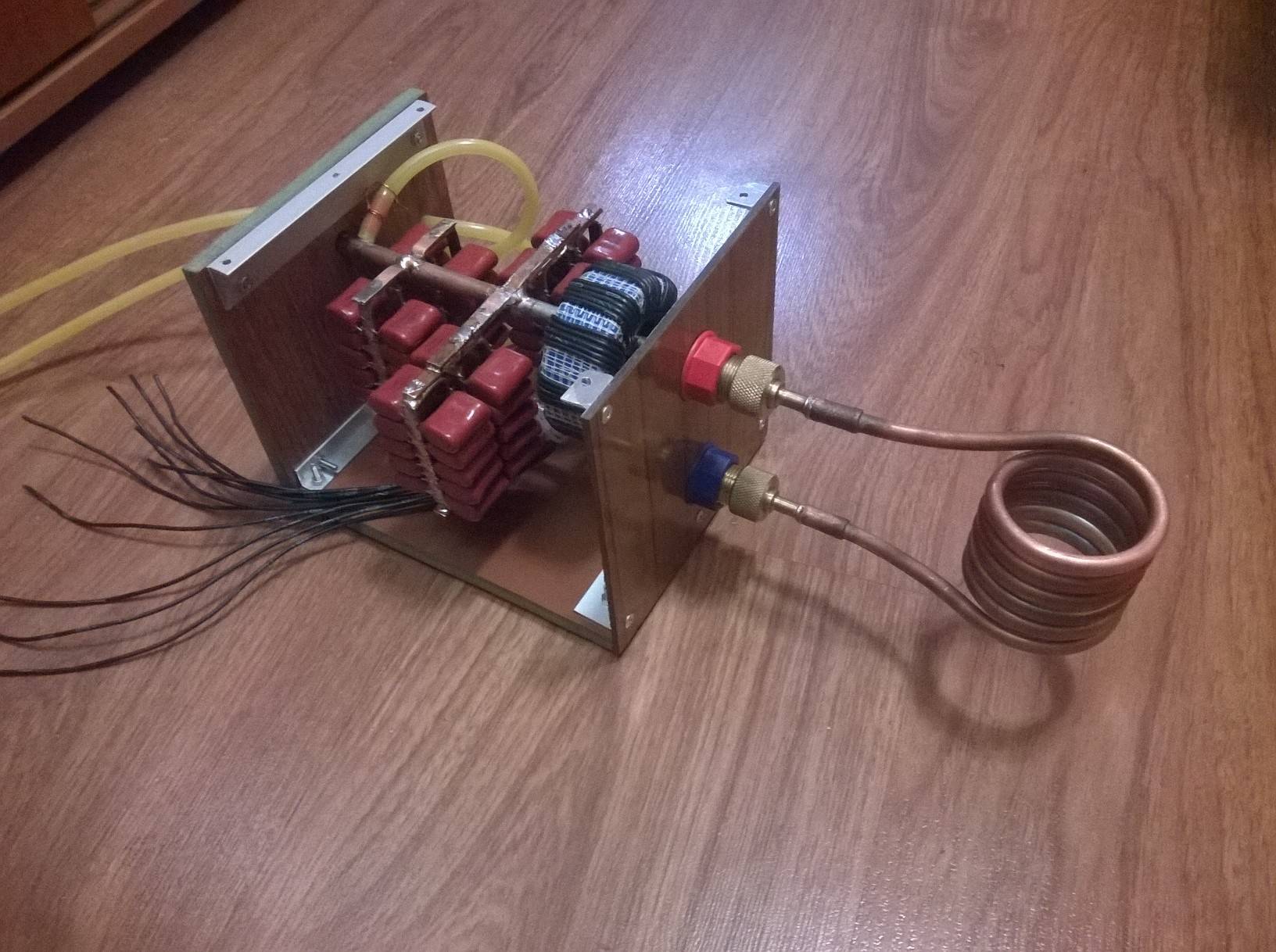

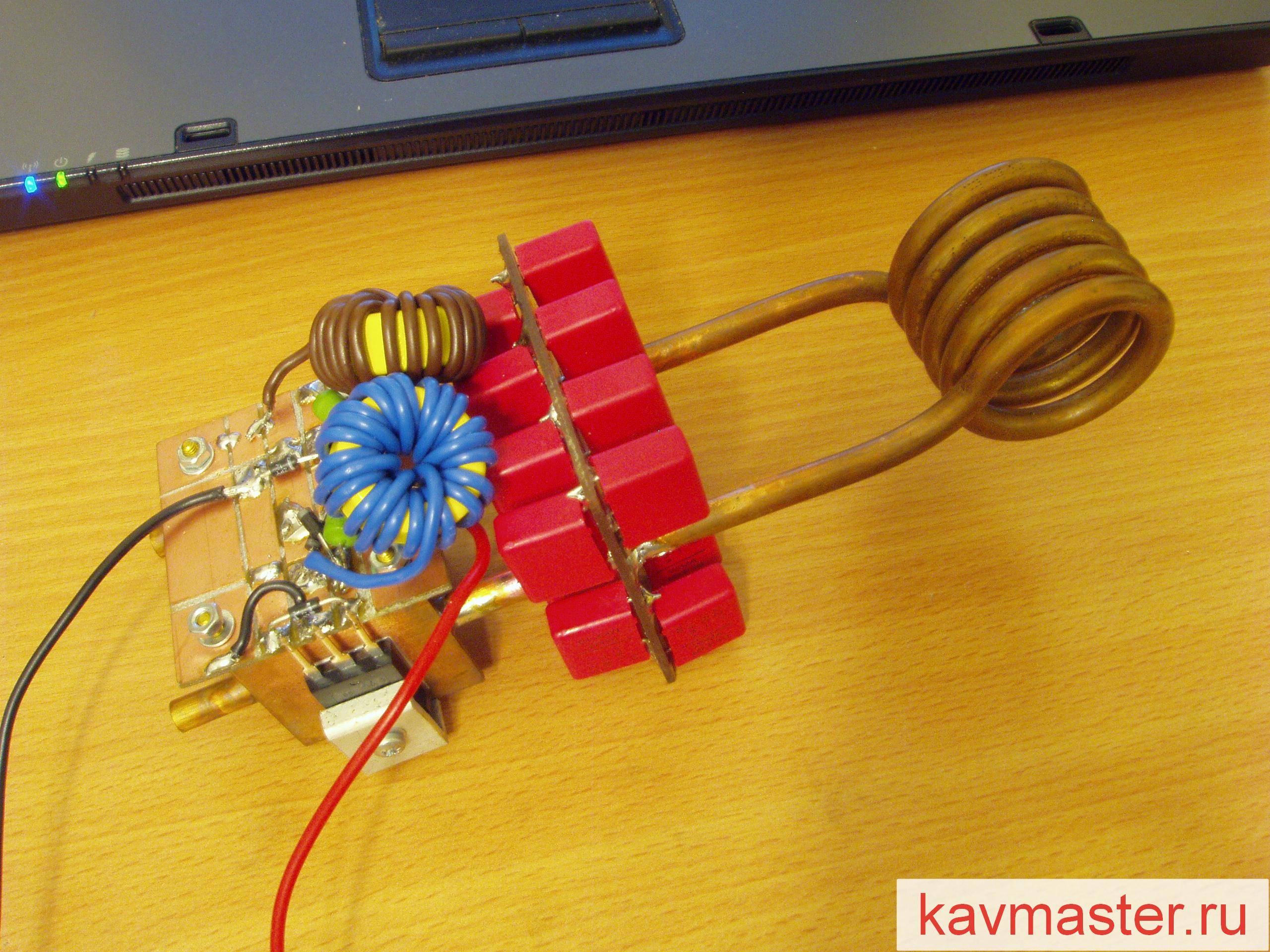

The formation of an electromagnetic field outside the inductor requires a powerful coil with a large number of turns, and bending the pipe is also not an easy task. Therefore, the masters recommend making a semblance of a core out of the pipe by placing it in an induction coil. In general, the body of the device was conceived as metal, but, due to the small size of the inductor, the pipe is replaced with a polymer one with a metal wire inside. After collecting the necessary parts, you can begin to manufacture an induction boiler according to the scheme below

It is necessary to pay attention to the sequence of steps, since the result depends on the observance of the steps.

First you need to fix the metal mesh to one end of the polymer pipe so that the heating wire pieces do not fall during operation.

From the same end of the pipe, an adapter is fixed for further connection to the heating.

Next, you need to cut the wire using wire cutters. The length of the pieces varies from 1 to 6 cm. Then these pieces must be placed as tightly as possible into the pipe so that there is no free space left in it.

The second end of the pipe goes through the same 2 initial stages: installation of a metal mesh and an adapter. Next, the manufacturing stage of the inductor begins: you need to wind the copper wire, while the rate of turns is 80-90 pieces. Connect the ends of the copper wire to the poles of the inverter.

It is necessary to install a circulation pump in the heating system (if it was absent). And finally, the thermostat is connected. It provides automated operation of the heater.

The inductor begins to create an electromagnetic field after starting the inverter. Vortex flows appear, heating the wire inside the pipe, and as a result, the entire coolant.

So, creating an induction heater based on a welding inverter is a fairly simple matter. Moreover, this type of heating has many advantages that result in efficiency, equipment durability and low financial costs.

However, you need to remember the precautions so that you do not have to redo all the work again, select high-quality parts and keep the heater assembly phased.

The modern market for heating equipment is very saturated with all kinds of boiler units.Many experts today advise installing a gas boiler, as it is an effective way to heat a home.

Of course, no one doubts such a statement, but what to do if the building is located far from the gas mains? In this case, the best solution would be to install electrical equipment for heating the house.

To get ahead of the skeptics who, reading these lines, are thinking about the constant rise in the price of electricity, we propose to consider such a type of electric space heating as induction heating. Therefore, in our article we will dwell on the description vortex induction heater, which can be done without much effort with your own hands, while using a welding inverter.

3 Independent production of equipment

A low-power induction heater, which is designed to heat water, can be made on the basis of a simple transformer having a primary and secondary winding. In the first circuit, electricity is converted into eddy currents. A magnetic field is created, which provides powerful induction, directional action. The second circuit of the transformer is responsible for the rapid heating of the coolant.

Necessary tools and materials:

- Transformers or welding inverter.

- Metal pipes of various diameters.

- Welding machine and soldering iron.

- Screwdriver and cutters.

In each case, the necessary components will differ, depending on the selected heater design scheme. It is necessary to remember about the mandatory presence of built-in automation, which will monitor the temperature of the heated water.The presence of a control relay makes it possible to guarantee the trouble-free operation of the device, increasing its safety and preventing the failure of a home-made heat generator.

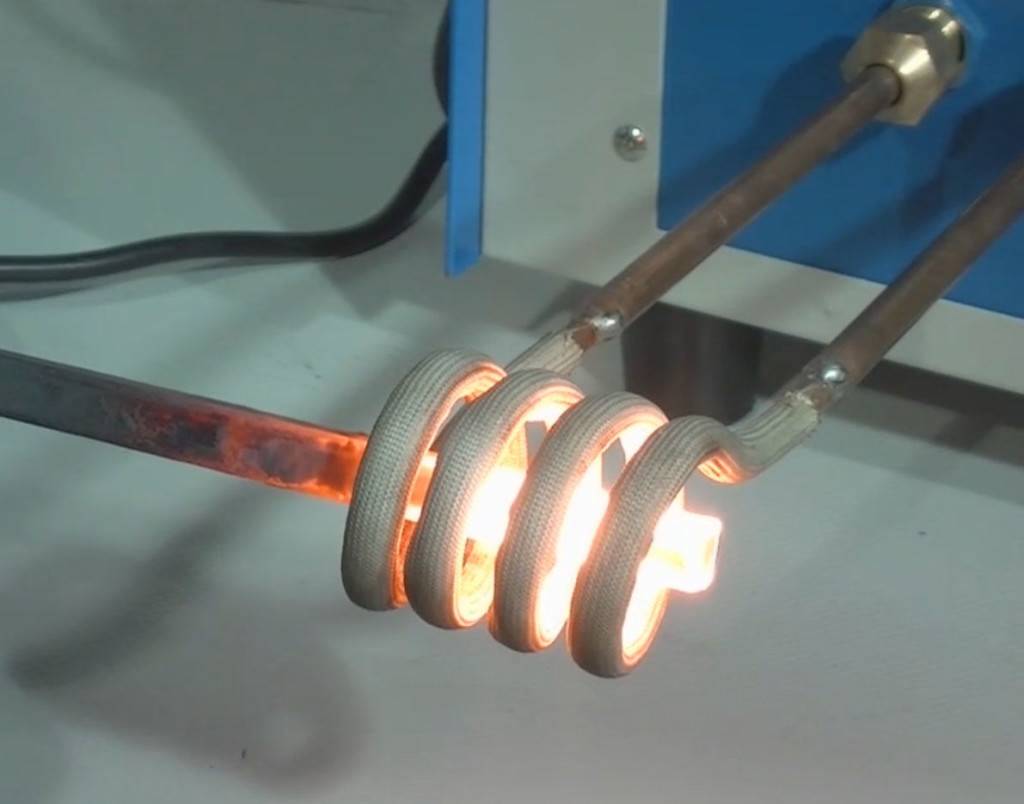

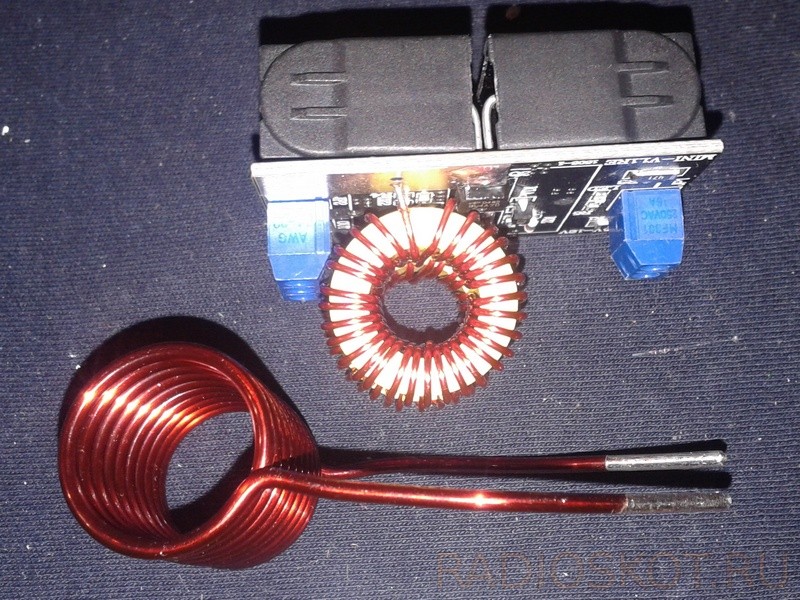

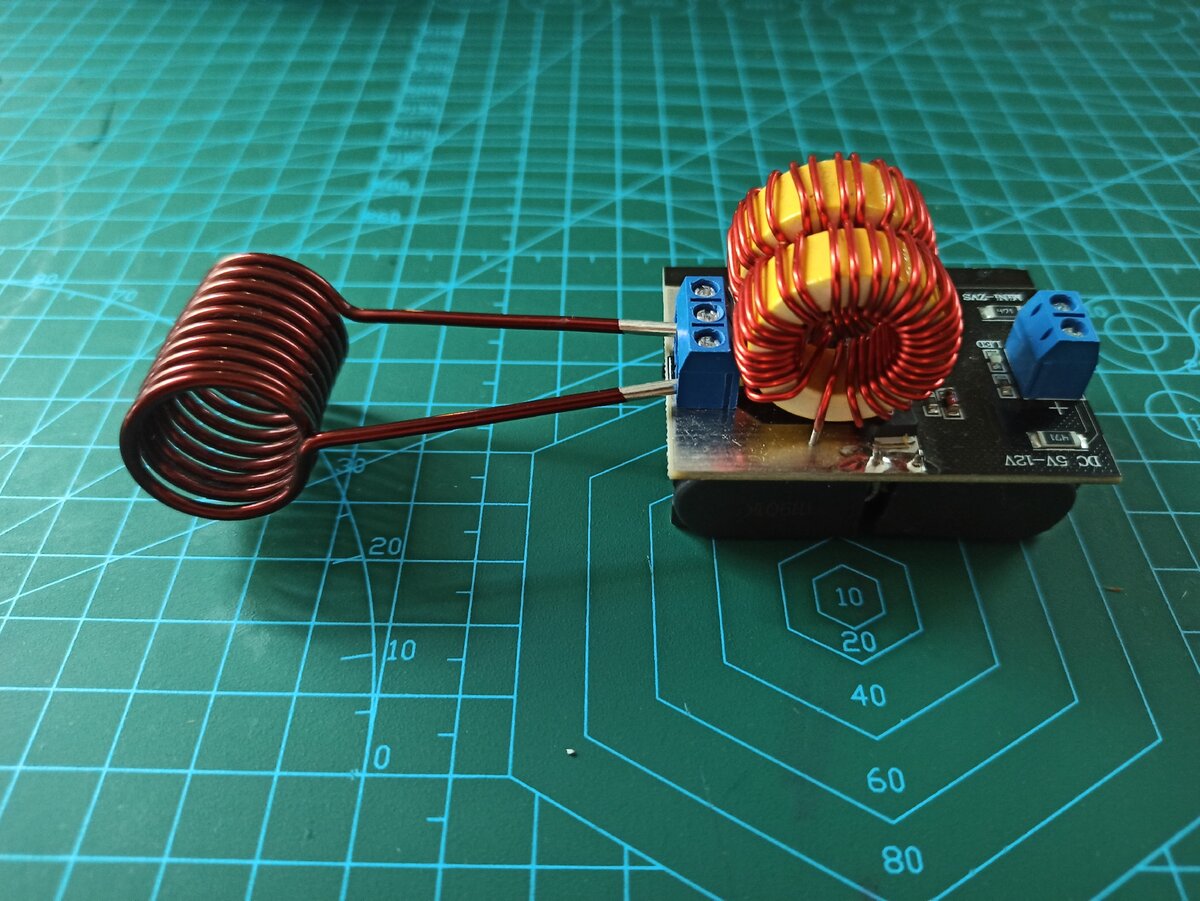

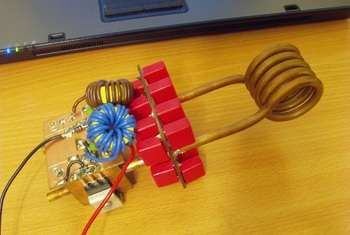

DIY induction heaters. Homemade induction heater: diagram

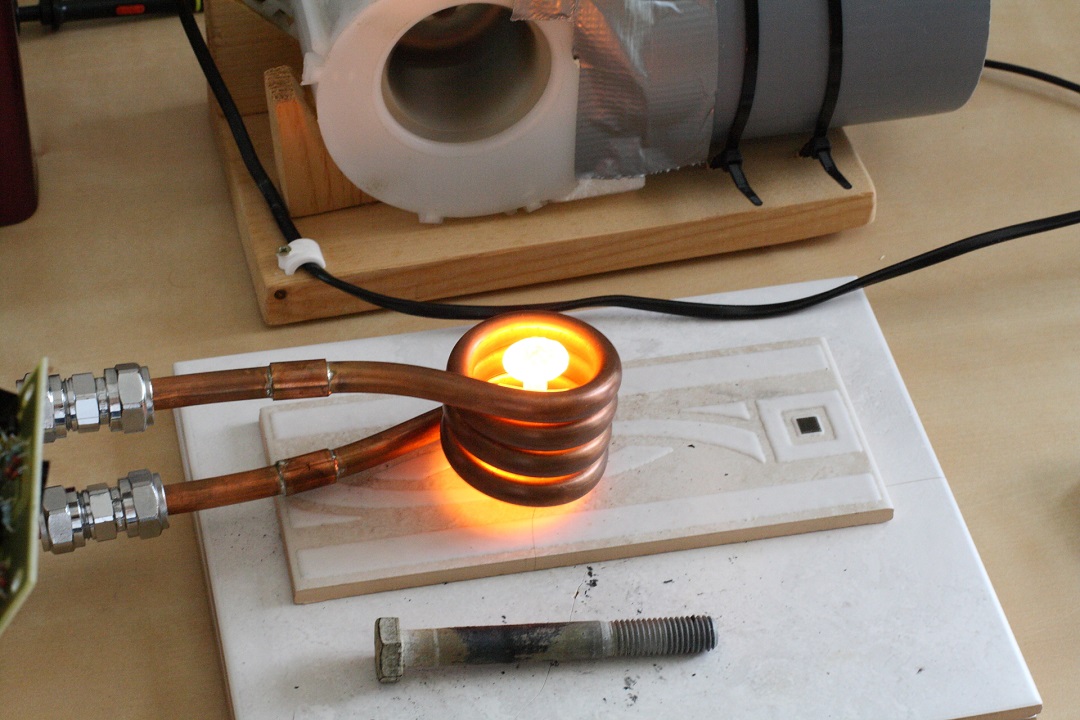

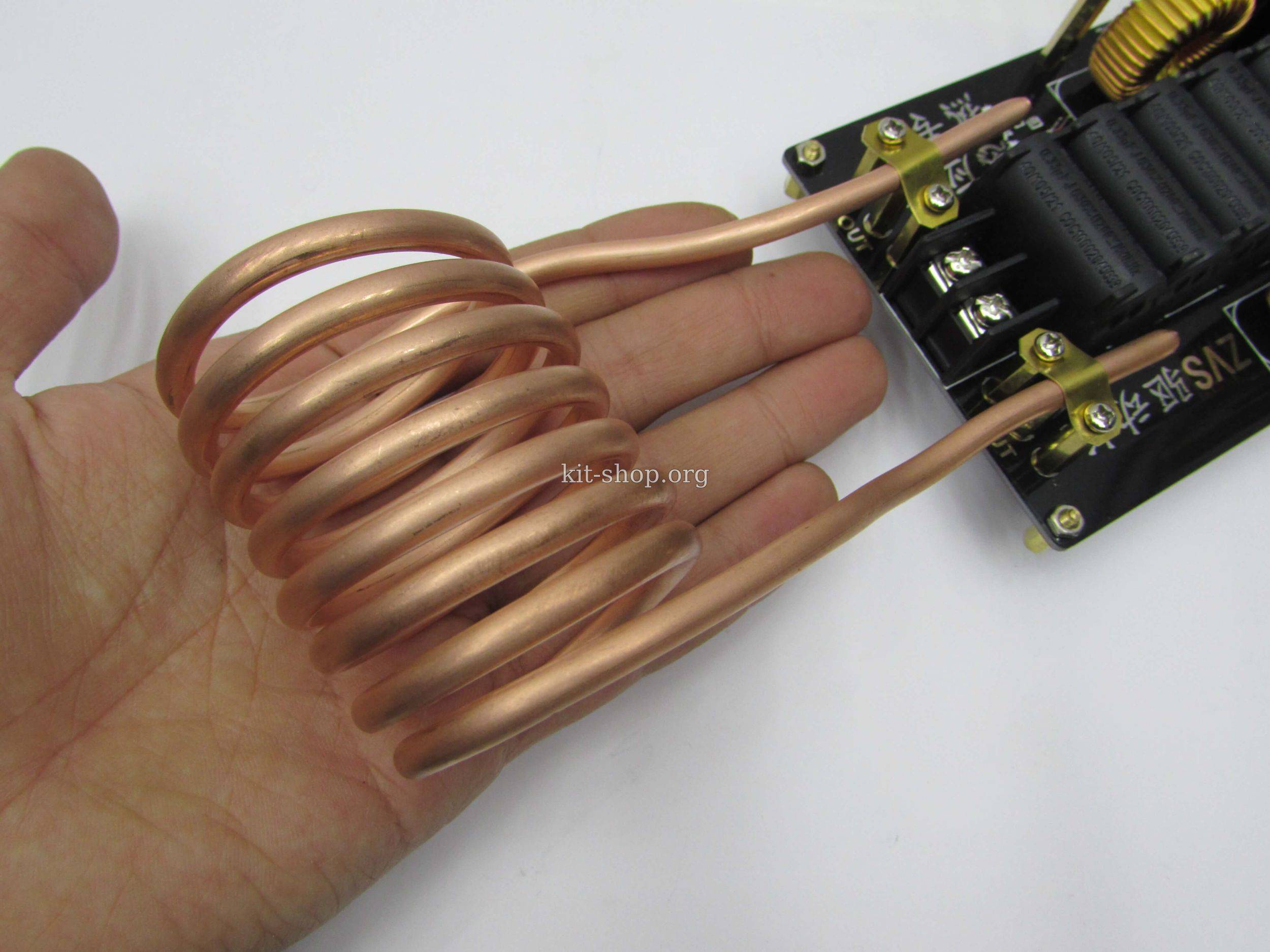

Such a heater can often be seen on a video, or in photographs, where, after applying power, a metal product or just a piece of iron placed in a coil of copper tube immediately starts to heat up to red. In this article, we will consider the circuit and assembly of an induction heater.

Such a heater can often be seen on a video, or in photographs, where, after applying power, a metal product or just a piece of iron placed in a coil of copper tube immediately starts to heat up to red. In this article, we will consider the circuit and assembly of an induction heater.

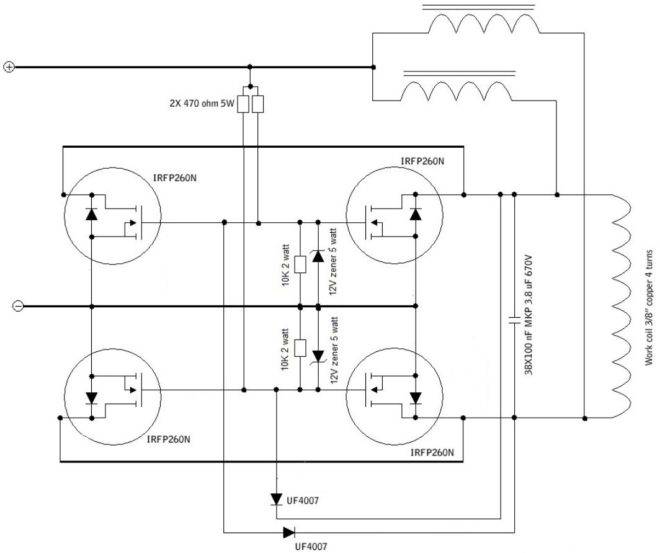

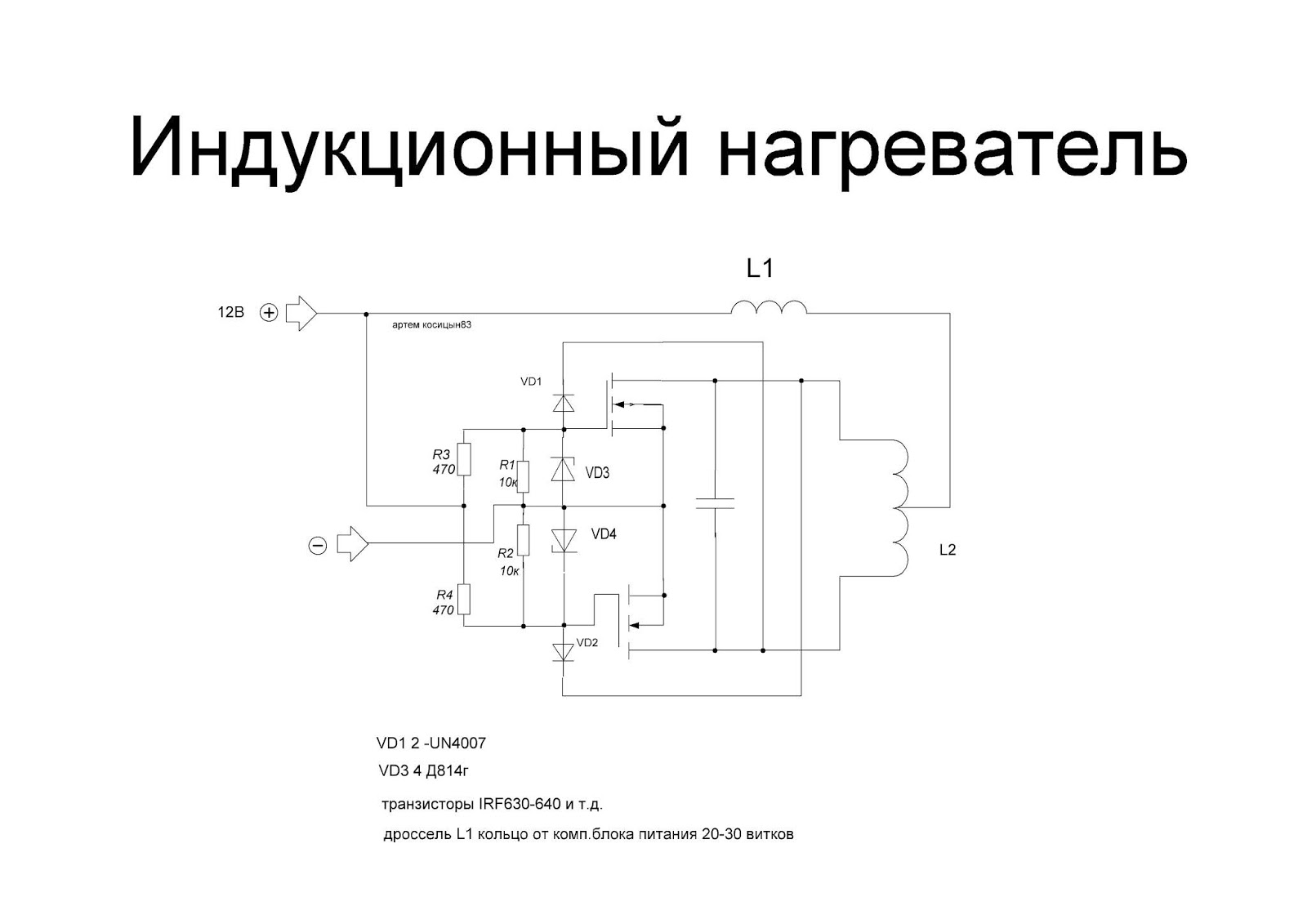

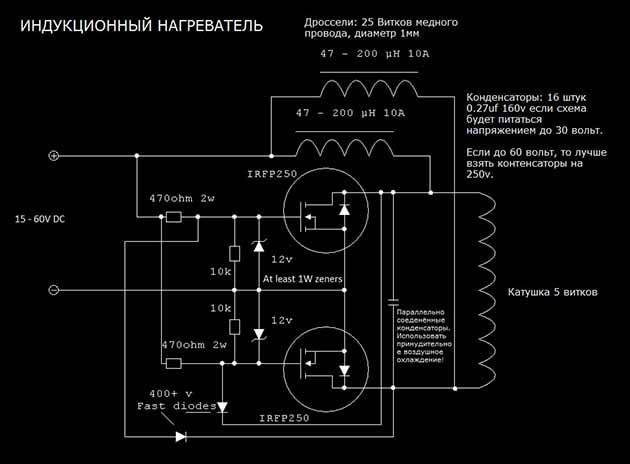

Device Diagram:

Diagram of a 500-watt induction heater that you can make yourself! There are many similar schemes on the Internet, but interest in them disappears, since basically they either do not work or work but not as we would like. This induction heater circuit is fully operational, proven, and most importantly, not complicated, I think you will appreciate it!

Manufacturing instructions

Blueprints

Figure 1. Electrical diagram of the induction heater

Figure 2. Device.

Figure 3. Scheme of a simple induction heater

For the manufacture of the furnace you will need the following materials and tools:

- soldering iron;

- solder;

- textolite board.

- mini drill.

- radioelements.

- thermal paste.

- chemical reagents for board etching.

Additional materials and their features:

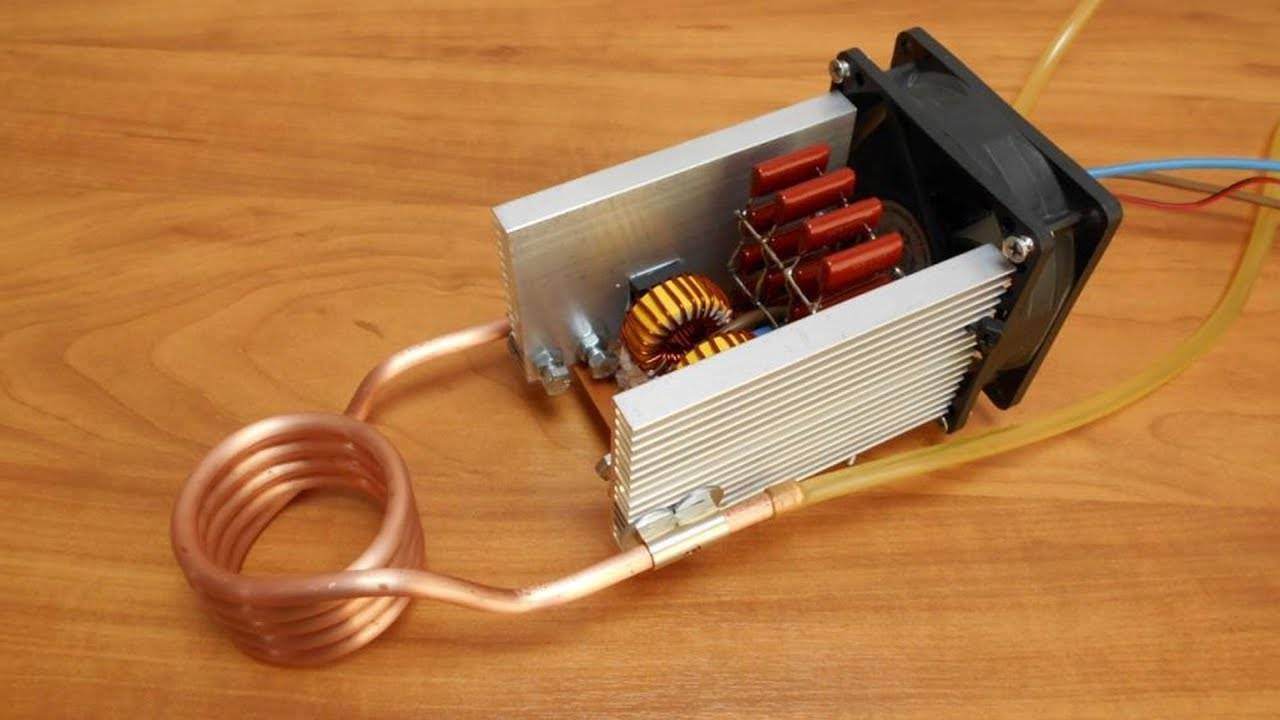

- To make a coil that will emit an alternating magnetic field necessary for heating, it is necessary to prepare a piece of copper tube with a diameter of 8 mm and a length of 800 mm.

- Powerful power transistors are the most expensive part of a homemade induction setup. To mount the frequency generator circuit, it is necessary to prepare 2 such elements.For these purposes, transistors of brands are suitable: IRFP-150; IRFP-260; IRFP-460. In the manufacture of the circuit, 2 identical of the listed field-effect transistors are used.

- For the manufacture of an oscillatory circuit, ceramic capacitors with a capacity of 0.1 mF and an operating voltage of 1600 V will be needed. In order for a high-power alternating current to form in the coil, 7 such capacitors are required.

- During the operation of such an induction device, the field-effect transistors will be very hot and if aluminum alloy radiators are not attached to them, then after a few seconds of operation at maximum power, these elements will fail. Putting transistors on heat sinks should be through a thin layer of thermal paste, otherwise the efficiency of such cooling will be minimal.

- The diodes that are used in the induction heater must be of ultra-fast action. The most suitable for this circuit, diodes: MUR-460; UV-4007; HER-307.

- Resistors used in circuit 3: 10 kOhm with a power of 0.25 W - 2 pcs. and 440 ohm power - 2 watts. Zener diodes: 2 pcs. with an operating voltage of 15 V. The power of the zener diodes must be at least 2 watts. A choke for connecting to the power outputs of the coil is used with induction.

- To power the entire device, you will need a power supply unit with a capacity of up to 500. W. and a voltage of 12 - 40 V. You can power this device from a car battery, but you will not be able to get the highest power readings at this voltage.

The very process of manufacturing an electronic generator and coil takes a little time and is carried out in the following sequence:

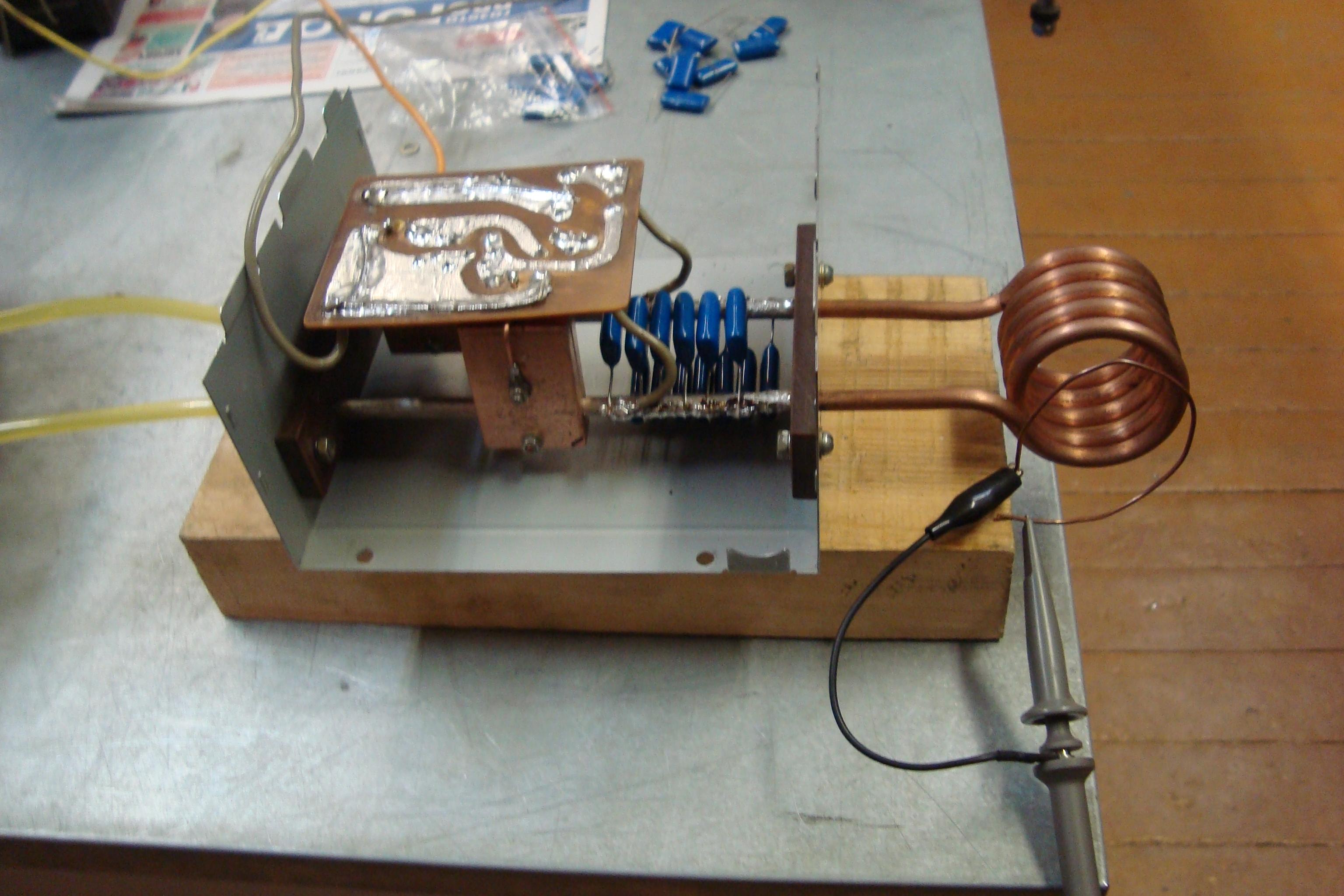

- A spiral with a diameter of 4 cm is made from a copper pipe.To make a spiral, a copper tube should be wound onto a rod with a flat surface with a diameter of 4 cm. The spiral should have 7 turns that should not touch. Mounting rings are soldered to the 2 ends of the tube for connection to the transistor radiators.

- The printed circuit board is made according to the scheme. If it is possible to supply polypropylene capacitors, then due to the fact that such elements have minimal losses and stable operation at large amplitudes of voltage fluctuations, the device will work much more stable. The capacitors in the circuit are installed in parallel, forming an oscillatory circuit with a copper coil.

- The heating of the metal occurs inside the coil, after the circuit is connected to a power supply or battery. When heating the metal, it is necessary to ensure that there is no short circuit of the spring windings. If you touch the heated metal 2 turns of the coil at the same time, then the transistors fail instantly.

The principle of operation of the induction heater

Induction heating is not possible without the use of three main elements:

- inductor;

- generator;

- heating element.

An inductor is a coil, usually made of copper wire, that generates a magnetic field. An alternator is used to produce a high frequency stream from a standard 50 Hz household power stream.

A metal object is used as a heating element, capable of absorbing thermal energy under the influence of a magnetic field.If you connect these elements correctly, you can get a high-performance device that is perfect for heating a liquid coolant and heating a house.

Image gallery

Photo from

Regardless of the design complexity, dimensions and tasks to be solved, its main components are an inductor, an eddy current generator and a heating element.

The undoubted advantage of induction heaters is a quick warm-up with significantly lower power requirements compared to other heating devices.

A significant disadvantage of induction heaters is the mandatory need for an energy source. Without electricity, the device is completely useless.

If a home-made induction heater is installed on a metal heating pipeline, then it will not only effectively heat the coolant, but also stimulate the movement of the heated fluid along the circuit

In order for the inverter to work normally in a circuit with an induction coil, it is connected through a thermostat. Rectifier diodes are connected to the outputs, otherwise the system will work like an electromagnet, and not like an induction heater.

The simplest generator of induction currents for a homemade heater is an inverter, usually used in electric welding.

An induction coil that generates eddy currents is connected to the poles of the inverter, when turned on, thermal energy immediately begins to be generated in the network.

The principle of induction is used not only in the preparation of the heat carrier and the heating of sanitary water for hygienic purposes. It is used in metal smelting

Assembly of the simplest induction heater

Rapid heating by eddy currents

Mandatory access to a source of energy

heating metal tube

Conventional Inverter Upgrade

Using the inverter as a generator

Induction coil connection points

The use of induction in metal smelting

With the help of a generator, an electric current with the necessary characteristics is supplied to the inductor, i.e. on a copper coil. When passing through it, the flow of charged particles forms a magnetic field.

The principle of operation of induction heaters is based on the occurrence of electric currents inside conductors that appear under the influence of magnetic fields.

The peculiarity of the field is that it has the ability to change the direction of electromagnetic waves at high frequencies. If any metal object is placed in this field, it will begin to heat up without direct contact with the inductor under the influence of the created eddy currents.

The high-frequency electric current flowing from the inverter to the induction coil creates a magnetic field with a constantly changing vector of magnetic waves. The metal placed in this field heats up quickly

The lack of contact makes it possible to make energy losses during the transition from one type to another negligible, which explains the increased efficiency of induction boilers.

To heat water for the heating circuit, it is enough to ensure its contact with a metal heater. Often, a metal pipe is used as a heating element, through which a stream of water is simply passed. Water simultaneously cools the heater, which significantly increases its service life.

The electromagnet of an induction device is obtained by winding a wire around a core of a ferromagnet.The resulting induction coil heats up and transfers heat to the heated body or to the coolant flowing nearby through the heat exchanger

This is interesting: Circulation pump for heating - selection models and installation rules

Induction welding: working principle

A heater of this type can be created by having certain parts.

Most often, its structural components include:

- An inductor, which is made from the required amount of copper wire. It is she who will provide a kind of magnetic field.

- Element yes heating. Most often it is made from a copper pipe, which is located inside each inductor.

- Generator. It will convert household-type energy into high-quality current.

All these components interact with each other and work on the principle of an induction type heater.

The induction heater, in turn, presents 4 important points:

- A generator that will generate current and transfer it to a copper coil;

- An inductor receiving current will create an electromagnetic field;

- The heating element will heat up under the influence of the flow, and create vector changes;

- The heat carrier during the heating process will transfer its energy directly to the heating system.

This action of the induction unit provides a number of advantages.

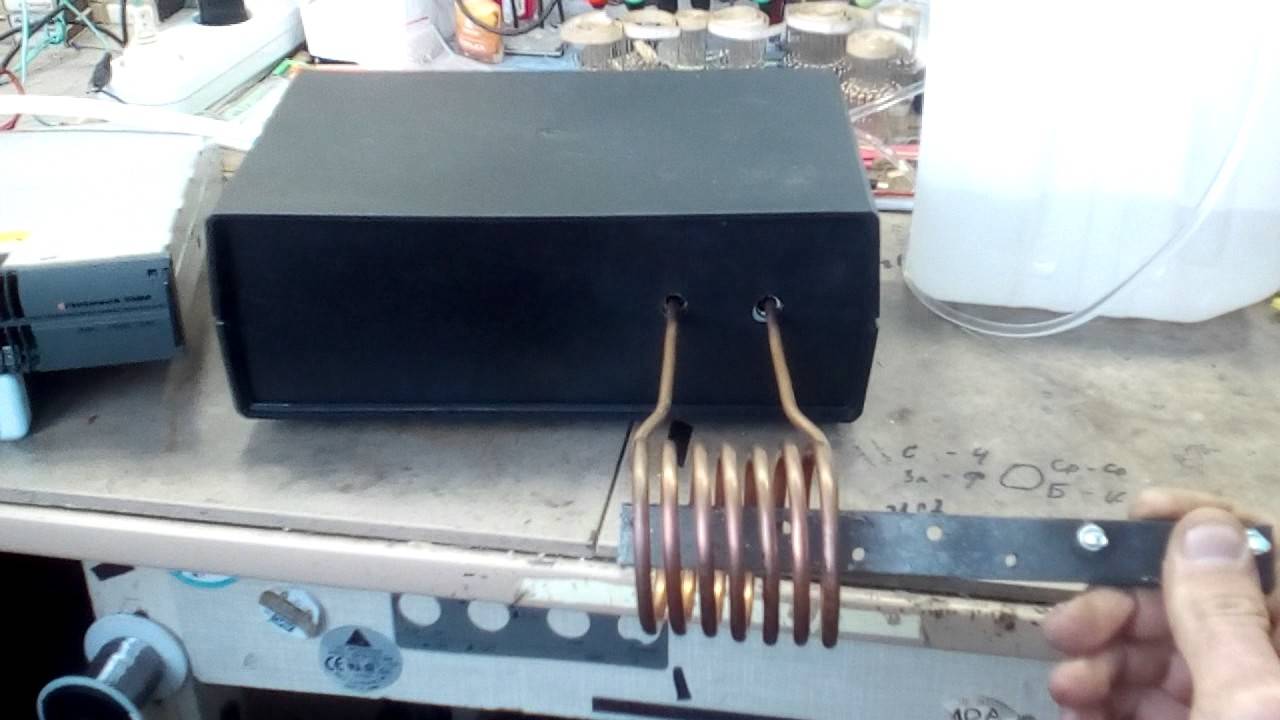

Step 7: Making a Work Coil

One of the questions I've often been asked is, "How do you make such a curved coil?" The answer is sand. The sand will prevent the tube from breaking during the bending process.

Take a copper tube from a 9mm refrigerator and fill it with clean sand. Before doing this, cover one end with some tape, and also cover the other after filling with sand.Dig a pipe of the appropriate diameter into the ground. Measure the length of the tube for your spool and start winding it slowly around the tube. Once you make one turn, the rest will be easy to do. Continue winding the tube until you get the number of turns you want (usually 4-6). The second end must be aligned with the first. This will make it easier to connect to the capacitor.

Now remove the caps and take an air compressor to blow out the sand. It is advisable to do this outdoors.

Please note that the copper tube is also used for water cooling. This water circulates through the capacitance capacitor and through the working coil.

The work coil generates a lot of heat from the current. Even if you use ceramic insulation inside the coil (to keep the heat in), you will still have extremely high temperatures in the workspace heating up the coil. I will start with a large bucket of ice water and after a while it will become hot. I advise you to prepare a lot of ice.

Conclusion

Boilers and heaters of the induction type are characterized by high efficiency, since all the electricity used is converted into heat. Before making any device yourself, we strongly recommend that you carefully study the diagram and analyze the working conditions. This will avoid mistakes at the preparation stage.

Electrician of the 6th category Panteleev Sergey Borisovich, work experience - 17 years: “To heat my house, I chose a very simple scheme of induction heating. First, I chose a section of the pipe and cleaned it. He made insulation from electrical fabric and an induction coil from copper wire. After isolating the system, I connected the inverter.The only drawback of this scheme is the electromagnetic field, which adversely affects the body. Therefore, the device had to be installed in the boiler room, where people rarely appear.