- The principle of operation of inductors

- Manufacturing instructions

- Blueprints

- How to make such equipment with your own hands

- Advantages and disadvantages

- Nuances

- Inductor device

- Choosing an induction hob

- Prices kitchen induction cookers

- Advantages and disadvantages of the device

- Features of the vortex induction boiler

- Distinctive features of VIN

- How to assemble a vortex induction device?

- Heating control

- Induction heat generator in the heating system

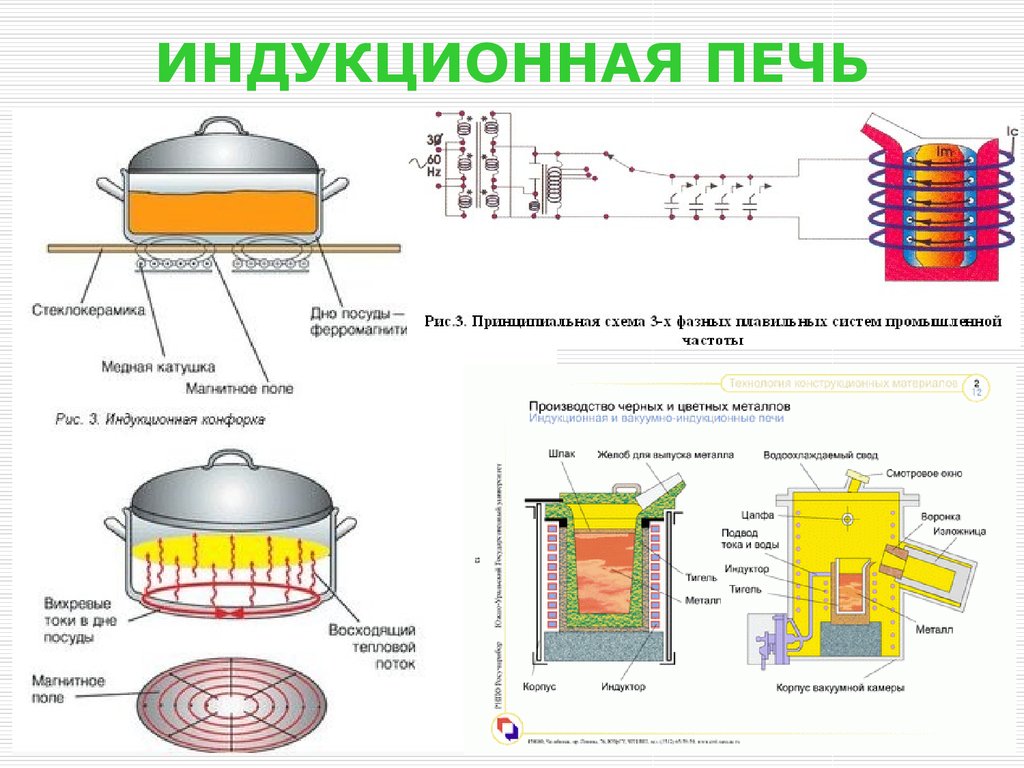

- Induction foundry furnaces

- VIN type water heaters

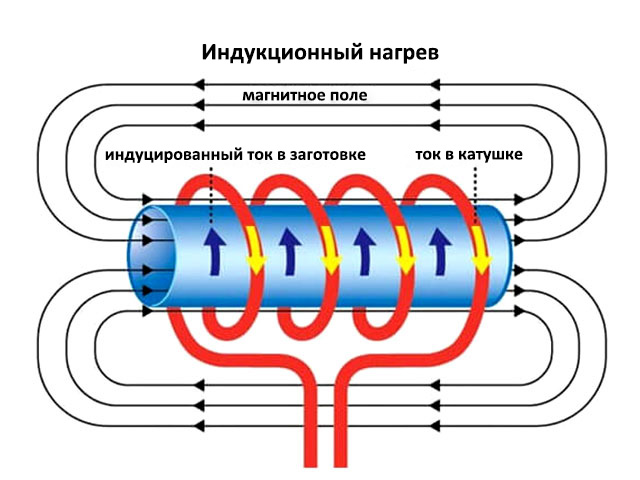

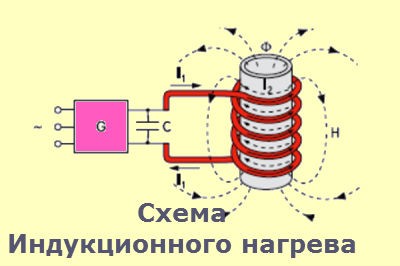

The principle of operation of inductors

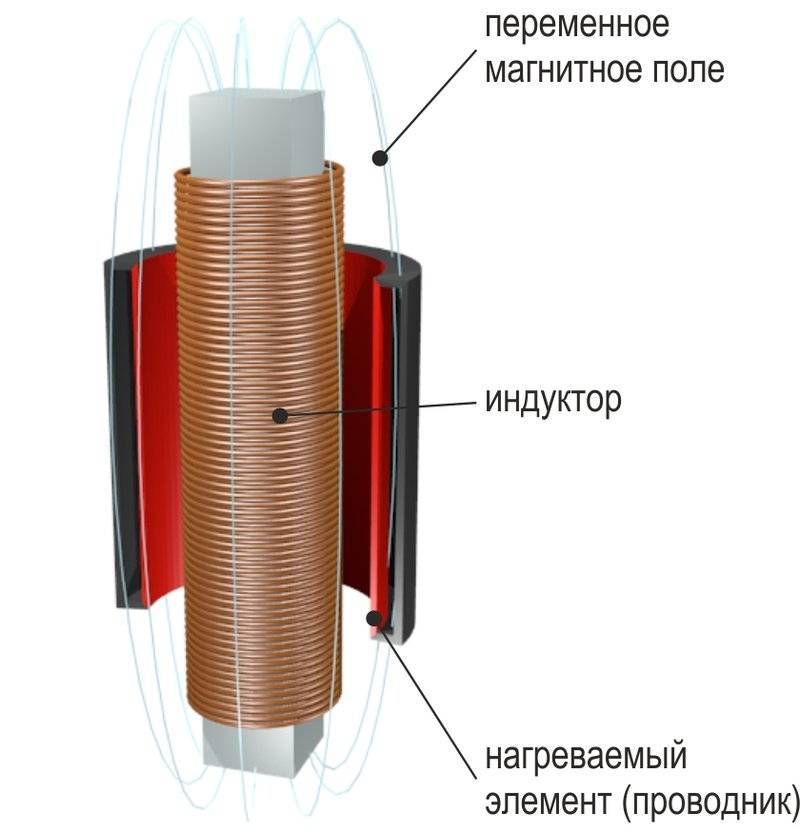

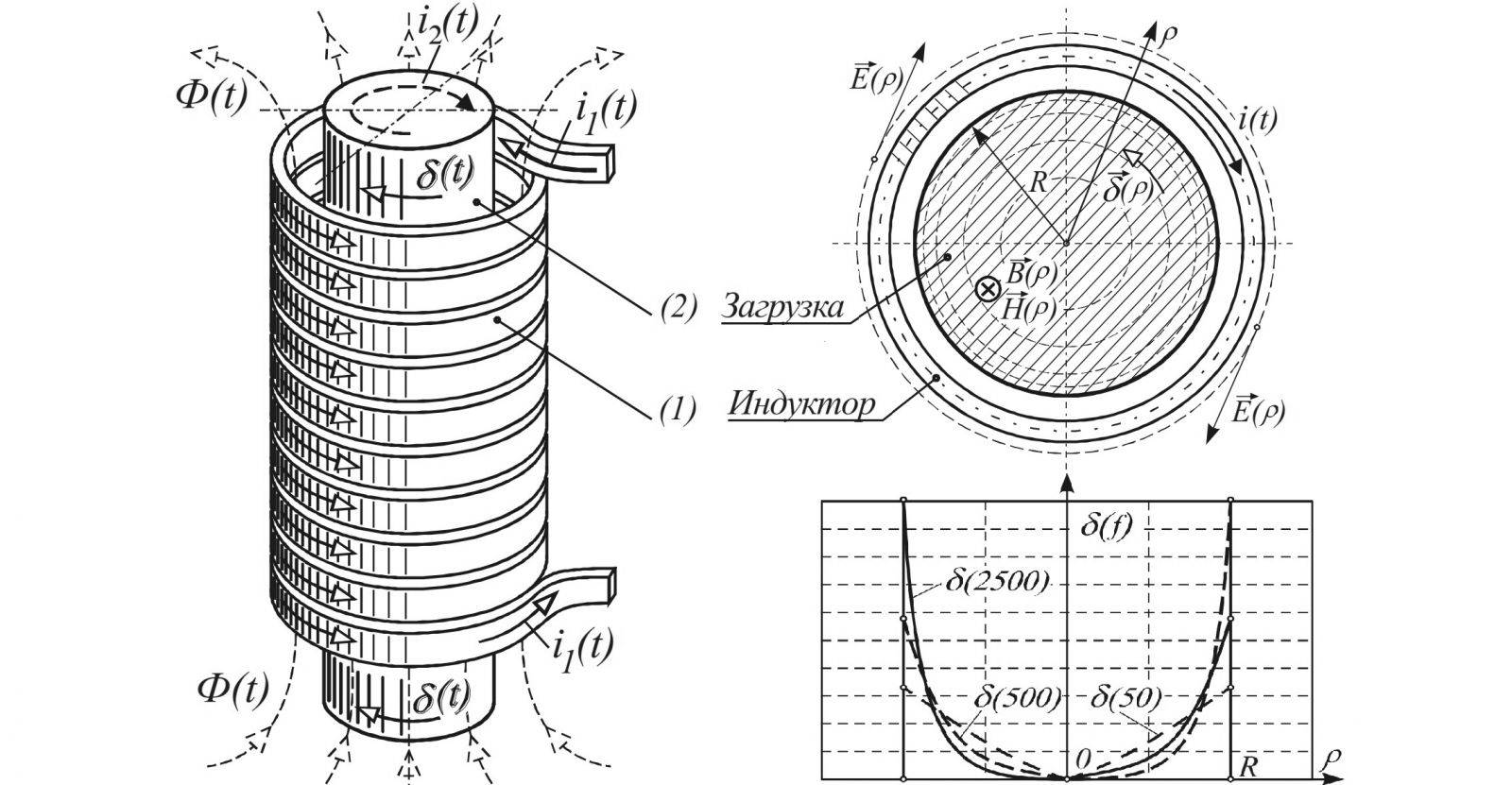

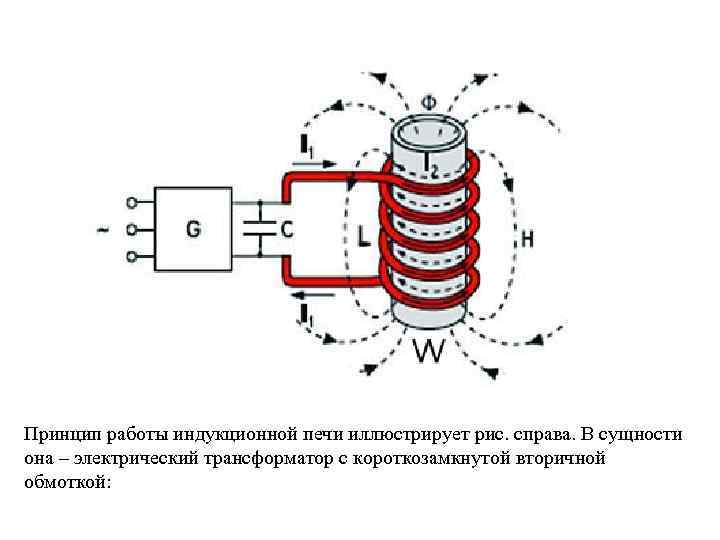

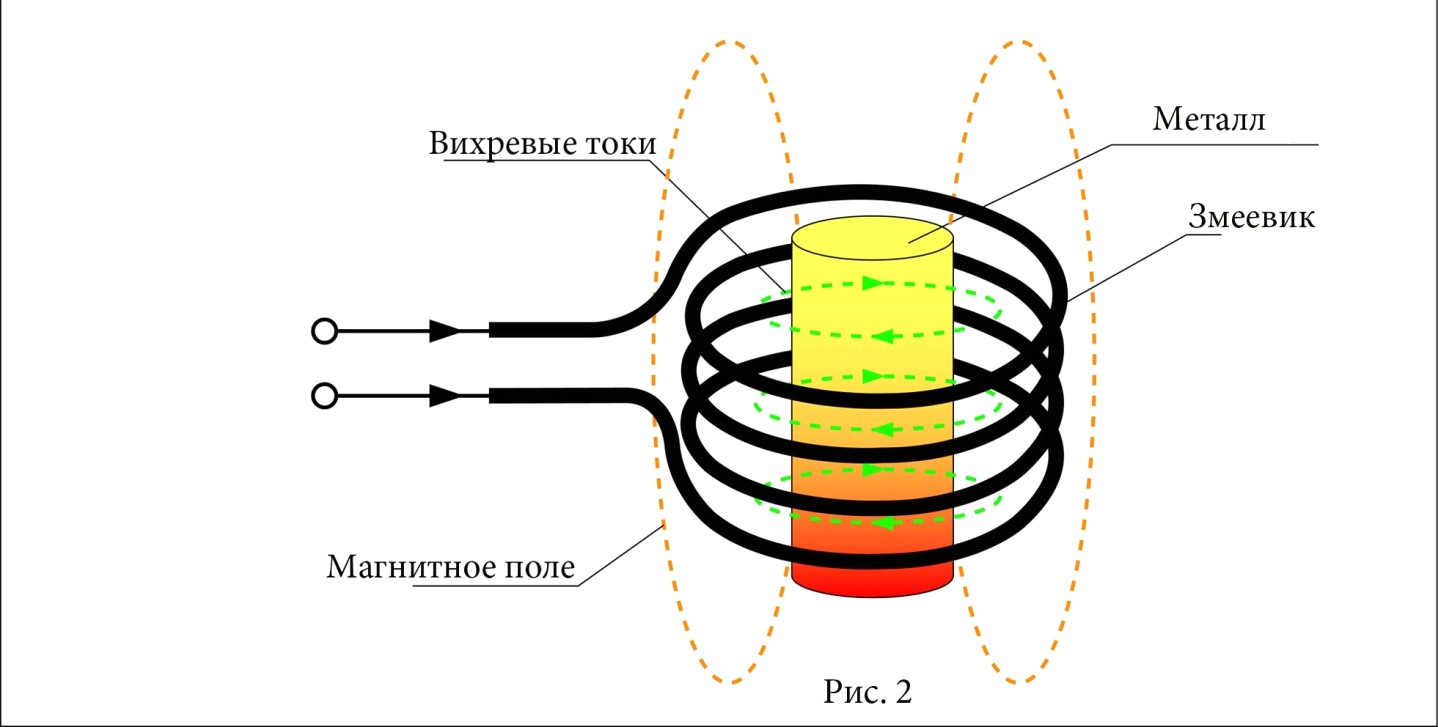

Devices for induction heating of metals operate on a simple principle based on the phenomenon of electromagnetic induction. When an alternating current of high frequency passes through the coil, a powerful magnetic field is formed around and inside it. It causes the appearance of eddy currents inside the processed metal workpiece.

Since the part usually has an extremely low electrical resistance, it quickly heats up under the influence of eddy currents. As a result, its temperature increases to such an extent that the metal becomes softer and begins to melt. It is at this moment that the ends of the workpieces are welded.

Manufacturing instructions

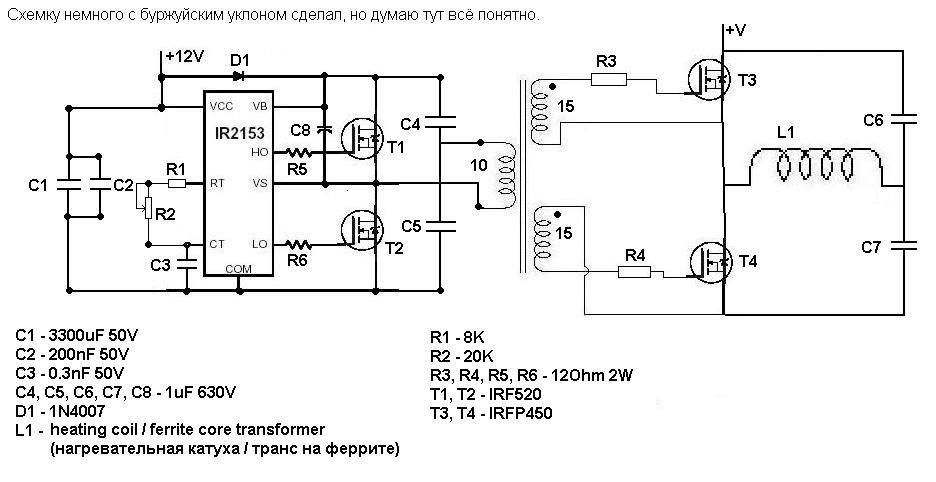

Blueprints

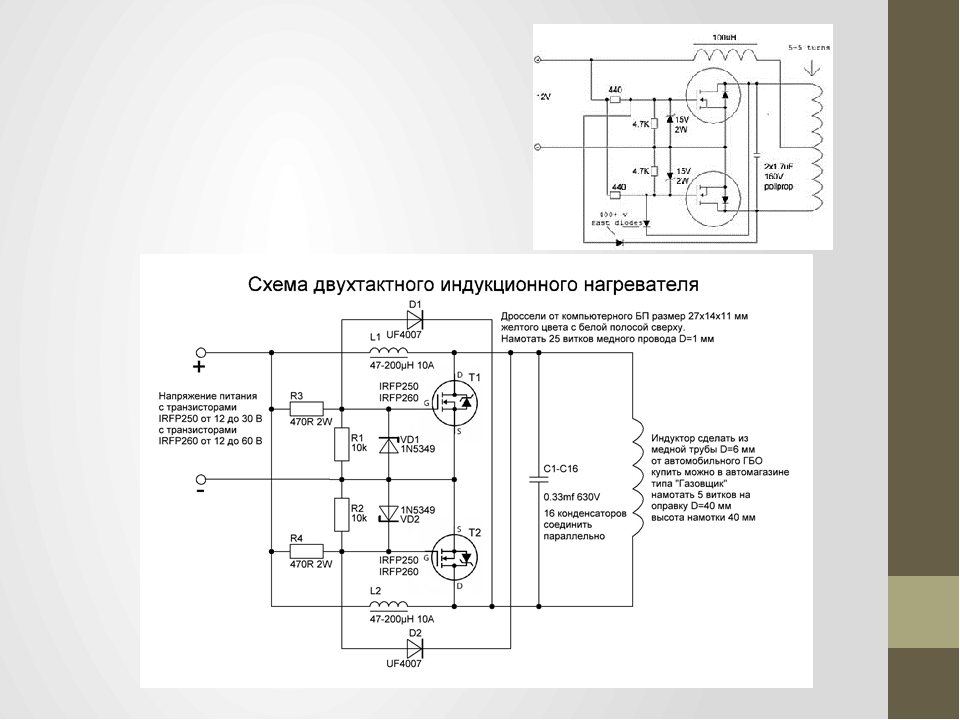

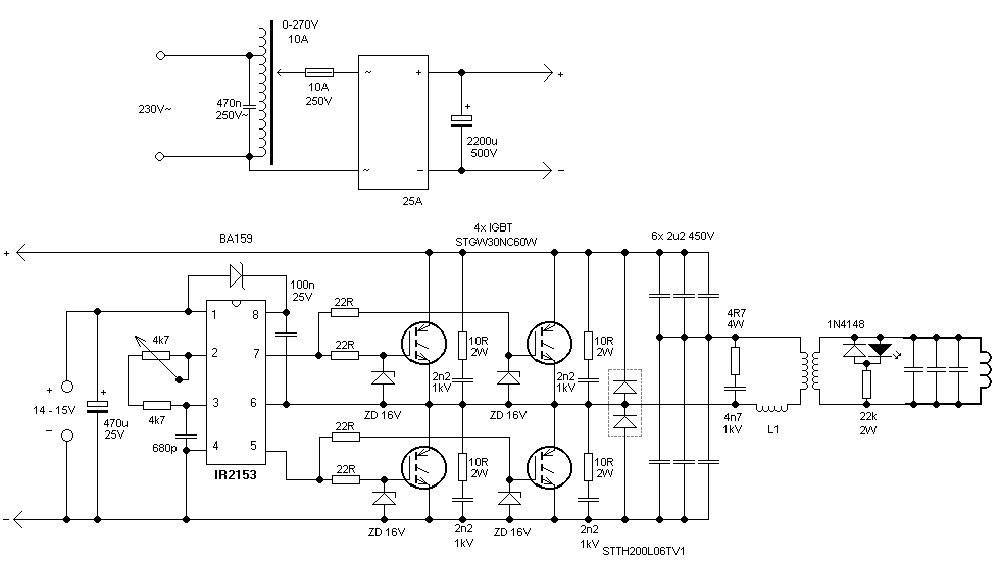

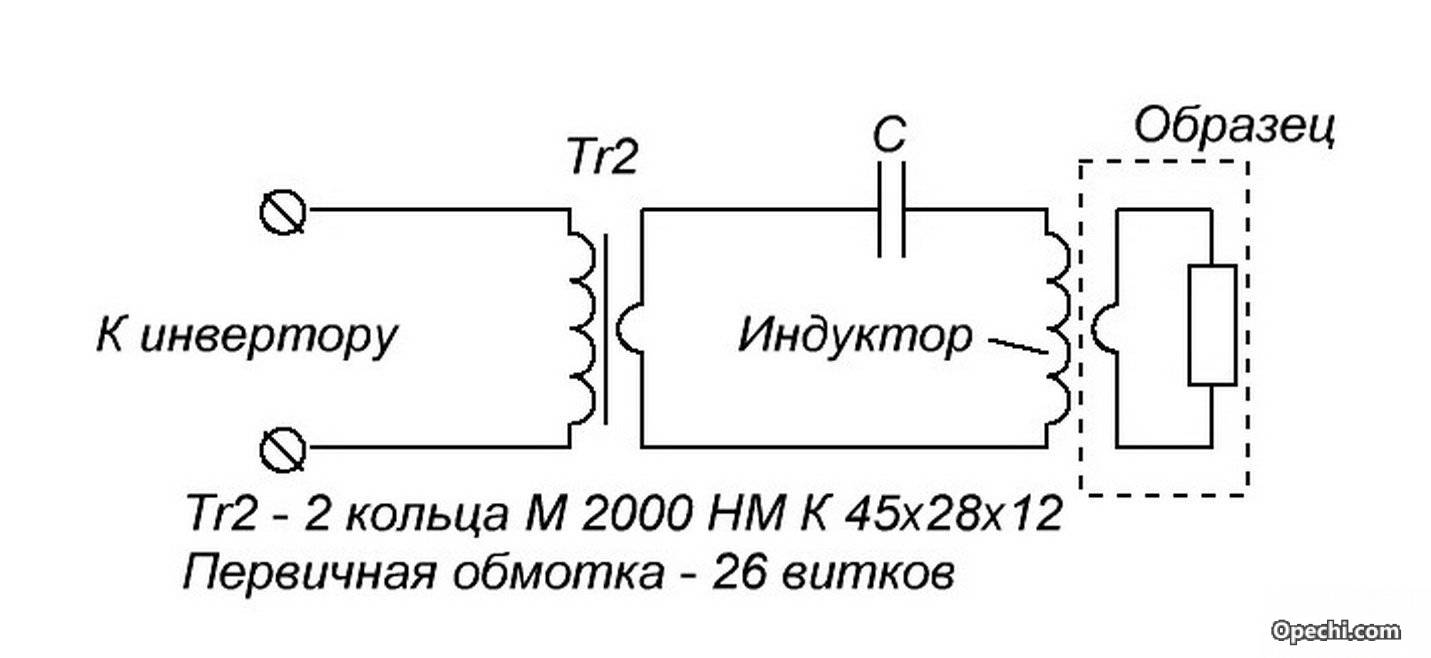

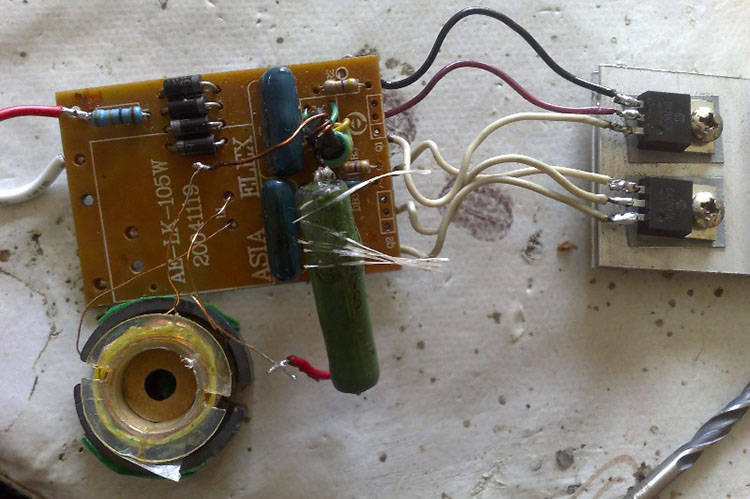

Figure 1. Electrical diagram of the induction heater

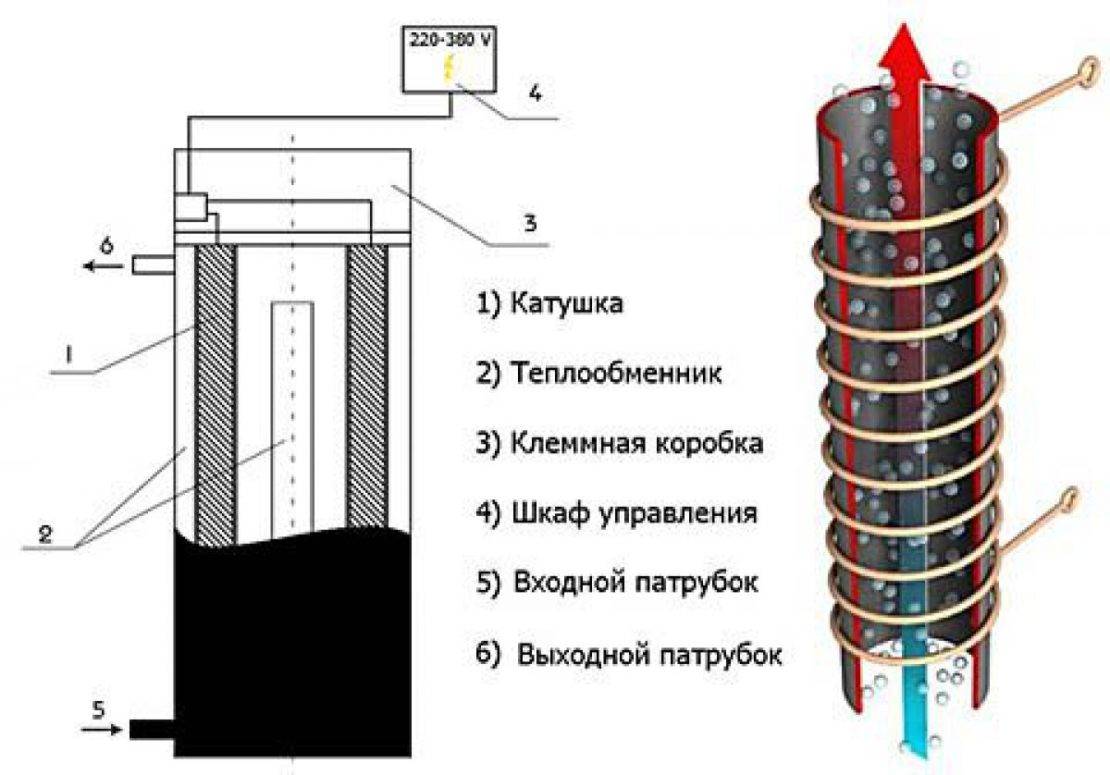

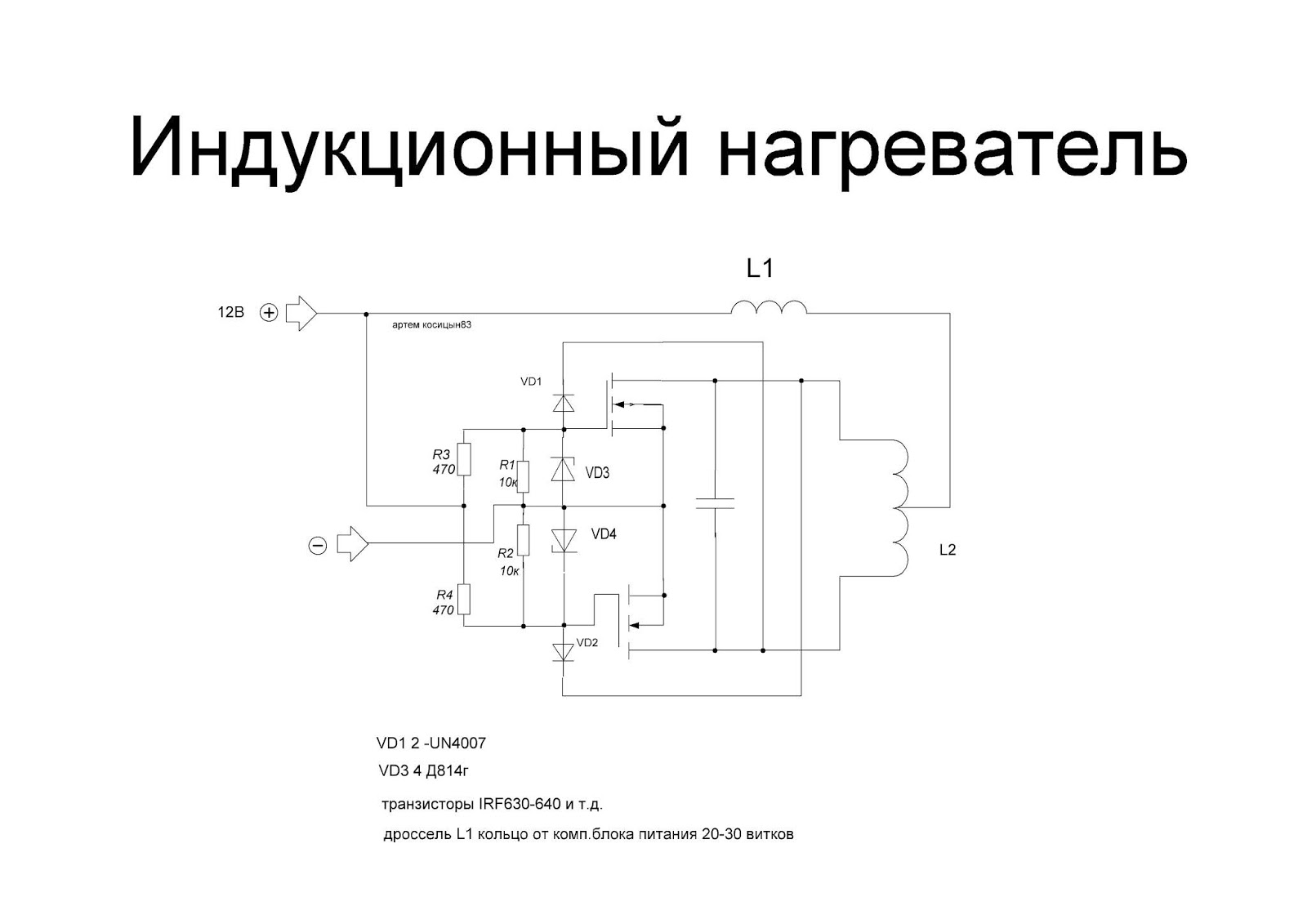

Figure 2. Device.

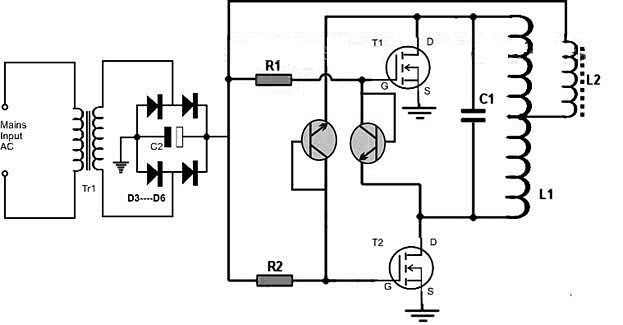

Figure 3. Scheme of a simple induction heater

For the manufacture of the furnace you will need the following materials and tools:

- soldering iron;

- solder;

- textolite board.

- mini drill.

- radioelements.

- thermal paste.

- chemical reagents for board etching.

Additional materials and their features:

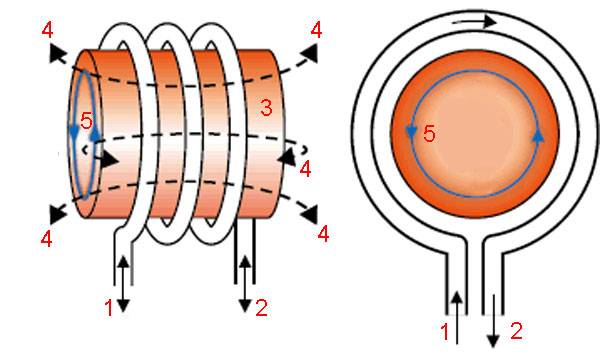

- To make a coil that will emit an alternating magnetic field necessary for heating, it is necessary to prepare a piece of copper tube with a diameter of 8 mm and a length of 800 mm.

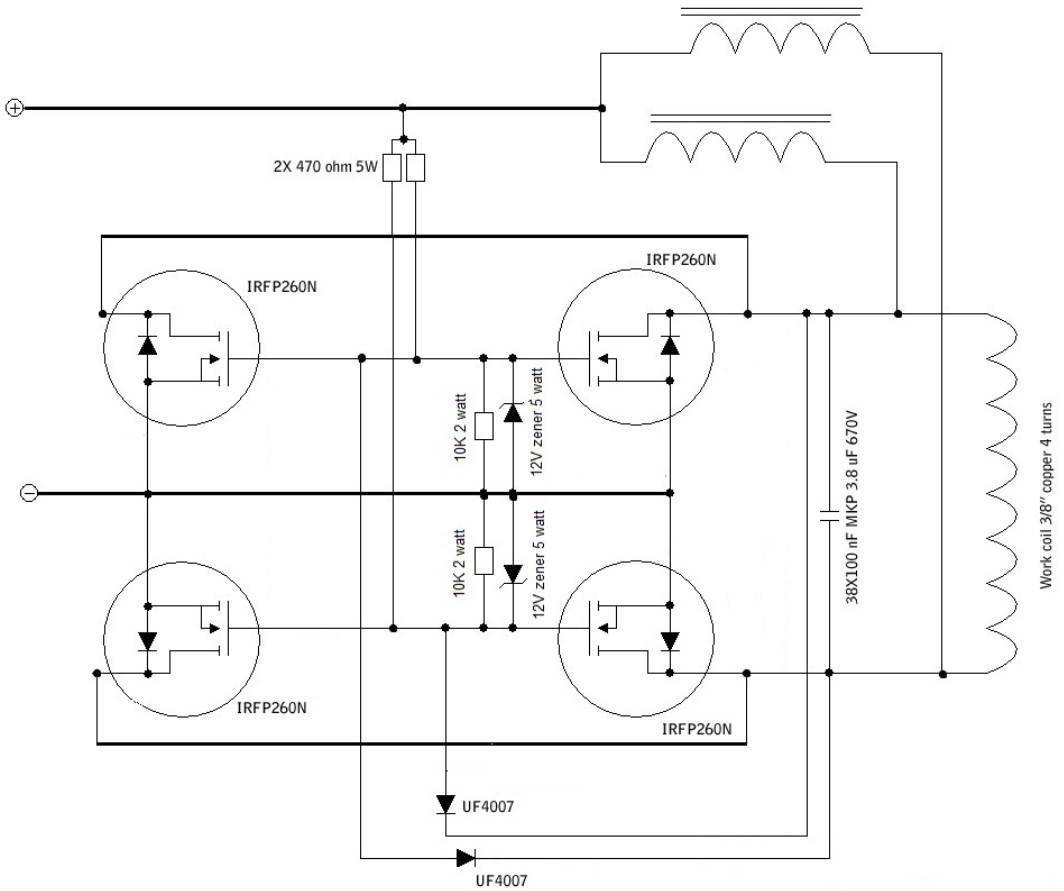

- Powerful power transistors are the most expensive part of a homemade induction setup. To mount the frequency generator circuit, it is necessary to prepare 2 such elements. For these purposes, transistors of brands are suitable: IRFP-150; IRFP-260; IRFP-460. In the manufacture of the circuit, 2 identical of the listed field-effect transistors are used.

- For the manufacture of an oscillatory circuit, ceramic capacitors with a capacity of 0.1 mF and an operating voltage of 1600 V will be needed. In order for a high-power alternating current to form in the coil, 7 such capacitors are required.

- During the operation of such an induction device, the field-effect transistors will be very hot and if aluminum alloy radiators are not attached to them, then after a few seconds of operation at maximum power, these elements will fail. Putting transistors on heat sinks should be through a thin layer of thermal paste, otherwise the efficiency of such cooling will be minimal.

- The diodes that are used in the induction heater must be of ultra-fast action. The most suitable for this circuit, diodes: MUR-460; UV-4007; HER-307.

- Resistors used in circuit 3: 10 kOhm with a power of 0.25 W - 2 pcs. and 440 ohm power - 2 watts. Zener diodes: 2 pcs. with an operating voltage of 15 V.The power of the zener diodes must be at least 2 watts. A choke for connecting to the power outputs of the coil is used with induction.

- To power the entire device, you will need a power supply unit with a capacity of up to 500. W. and a voltage of 12 - 40 V. You can power this device from a car battery, but you will not be able to get the highest power readings at this voltage.

The very process of manufacturing an electronic generator and coil takes a little time and is carried out in the following sequence:

- A spiral with a diameter of 4 cm is made from a copper pipe. To make a spiral, a copper tube should be wound onto a rod with a flat surface with a diameter of 4 cm. The spiral should have 7 turns that should not touch. Mounting rings are soldered to the 2 ends of the tube for connection to the transistor radiators.

- The printed circuit board is made according to the scheme. If it is possible to supply polypropylene capacitors, then due to the fact that such elements have minimal losses and stable operation at large amplitudes of voltage fluctuations, the device will work much more stable. The capacitors in the circuit are installed in parallel, forming an oscillatory circuit with a copper coil.

- The heating of the metal occurs inside the coil, after the circuit is connected to a power supply or battery. When heating the metal, it is necessary to ensure that there is no short circuit of the spring windings. If you touch the heated metal 2 turns of the coil at the same time, then the transistors fail instantly.

How to make such equipment with your own hands

Due to the high cost of the device, many owners decide to make a heating system with their own hands.You can, having worked hard, find a diagram of how to make an induction heater with your own hands. There are plenty of articles on the internet on this topic. Here I would like to describe the principle how to make the most simple home appliance.

For the simplest system, you will need a small set of tools: a screwdriver, a soldering iron and wire cutters. And the instructions for making it look like this:

- we take a 7 mm stainless steel wire and cut it into pieces of about 5 mm;

- we prepare a pipe, made of plastic or metal, it does not matter. We look to the thickness was about five millimeters. This thickness is necessary to protect against overheating;

- fill the pipe with pieces of wire;

- close the holes at the ends of the pipe with a mesh so that the wire cuts do not accidentally spill out;

- then take the copper wire and wind it around the pipe with a spiral, about 80-90 turns;

- cut a rectangular hole in the pipe.

- insert into this hole, the manufactured device.

- for the next step, you need a high-frequency inverter, which can be purchased at the store.

Advantages and disadvantages

According to the reviews of VIN owners, the use of a heater of this type has a number of advantages, which include the following important points:

- small overall dimensions allow the unit to be used in any premises;

- high efficiency;

- VIN service life is more than 30 years;

- does not require additional care;

- high level of fire safety;

- this type of boiler operates silently;

- scale does not settle on the inner walls, because eddy currents also create vibration;

- complete tightness of VIN prevents any kind of leakage;

- the boiler control process is fully automated;

- during the operation of the unit, no harmful combustion products are emitted, in other words, this type of heater is completely environmentally friendly;

- the ability to connect to an existing heating system;

- various liquids can be used as a heat carrier, for example, water, antifreeze, oil, etc.

You might be interested in an article on how to own induction heater hands.

An article on how to make an induction boiler with your own hands, read here.

For greater persuasiveness of the advantages of this type of boiler unit, we give as an example the technical characteristics of the VIN-15 model heater:

- required voltage - 380V;

- power consumption is 15 kW/h;

- amount of generated heat - 12640 Kcal/h;

- the boiler can fully heat a room with a volume of 500–700 m3;

- the diameter of the inlet and outlet pipes is 25 mm.

It is hard not to agree that these are quite positive characteristics of the boiler of this model.

The main negative aspects of using a vortex induction heater include the following:

- the electromagnetic field heats up not only the heat exchanger, but also all surrounding objects, including human tissues;

An important point: a person should not be near the induction heater for a long time!

if a ferromagnetic product is in the field of action of the electromagnetic field, this will inevitably lead to overheating of the boiler due to additional magnetization;

a high level of heat transfer creates a risk of detonation of the propeller from overheating.

Expert tip: to prevent detonation, you can optionally install a pressure sensor.

Watch the video, which shows the features of the VIN vortex induction heater, as well as reviews about this equipment:

Nuances

- When conducting experiments on heating and hardening metals, the temperature inside the induction coil can be significant and amounts to 100 degrees Celsius. This heating effect can be used to heat domestic water or to heat a house.

- The heater circuit discussed above (Figure 3), at maximum load, is capable of providing the radiation of magnetic energy inside the coil equal to 500 W. Such power is not enough to heat a large volume of water, and the construction of a high power induction coil will require the manufacture of a circuit in which it will be necessary to use very expensive radio elements.

- A budget solution for organizing induction heating of a liquid is the use of several devices described above, arranged in series. In this case, the spirals must be on the same line and not have a common metal conductor.

- A stainless steel pipe with a diameter of 20 mm is used as a heat exchanger. Several induction spirals are “strung” onto the pipe, so that the heat exchanger is in the middle of the spiral and does not come into contact with its turns. With the simultaneous inclusion of 4 such devices, the heating power will be about 2 kW, which is already enough for the flow heating of the liquid with a small circulation of water, to values \u200b\u200ballowing the use of this design in supplying warm water to a small house.

- If such a heating element is connected to a well-insulated tank that is located above the heater, then the result is a boiler system in which the heating of the liquid is carried out inside the stainless pipe, the heated water will rise up, and colder liquid will take its place.

- If the area of \u200b\u200bthe house is significant, then the number of induction spirals can be increased to 10 pieces.

- The power of such a boiler can be easily adjusted by turning off or turning on the spirals. The more sections that are simultaneously turned on, the greater the power of the heating device operating in this way will be.

- To power such a module, you need a powerful power supply. If a DC inverter welding machine is available, then a voltage converter of the required power can be made from it.

- Due to the fact that the system operates on a direct electric current that does not exceed 40 V, the operation of such a device is relatively safe, the main thing is to provide a fuse box in the generator power circuit, which, in the event of a short circuit, will de-energize the system, thereby eliminating the possibility of a fire.

- , provided that batteries are installed to power induction devices, which will be charged using solar and wind energy.

- Batteries should be combined in sections of 2, connected in series. As a result, the supply voltage with such a connection will be at least 24 V., which will ensure the operation of the boiler at high power. In addition, series connection will reduce the current in the circuit and increase the battery life.

Inductor device

Equipment for induction heating of metals has a prefabricated structure. It consists of two main units - the inductor itself, as well as a generating plant that generates high-frequency current pulses.

The inductor is an ordinary inductor, consisting of several turns of a copper conductor. For the production of these components, only oxygen-free copper is used, in which the content of foreign impurities should not exceed 0.1%. This device can have a different diameter (from 16 to 250 mm depending on the model). The number of turns varies from 1 to 4.

The generator that generates pulsed currents for the induction heating coil has quite impressive dimensions and weight. It can be performed according to any scheme for generating high-frequency pulses. For example, in modern industry, generating units based on multivibrators, RC generators, relaxation circuits, etc. are often used.

If the equipment is primarily used for heating small parts, the pulse frequency must be at least 5 MHz. These units are developed on the basis of electronic tubes. If the technique is used to heat large metal workpieces, it is advisable to use induction units with an operating frequency of up to 300 kHz, built on the basis of inverters based on IGBT circuits or MOSFET transistors.

Choosing an induction hob

In order to choose the right panel, personal preferences must be taken into account.

The first step is to deal with the burners, or rather with their number.If you do not plan to cook meals for several people every day, then a miniature version with two burners will suffice. What is the point of paying money for the extra part of the hob? If the family consists of more than three people, then the purchase of a full-fledged appliance with four burners is already required. The purchase of a solid panel without burners is advisable as a replacement for the first option, because such surfaces are of medium size.

Medium size induction

The shape and appearance of the structure play an important role in the case of interior design in the same style. In addition, it is necessary to pre-measure the place for the installation of a ceramic-metal structure. If there is no suitable place, then it is better to look at portable models.

You should pay attention to the energy efficiency of the device, which should not be lower than class "A". Otherwise, the device will consume more electricity.

The cost of equipment also differs from the number of temperature modes, so if you do not plan to cook culinary delights, then purchase a panel with a minimum set of modes. In other cases, it is better not to skimp and purchase an expensive stove, which involves more than 15 modes.

Induction cooker "for a bachelor"

Prices kitchen induction cookers

Kitchen Portable Induction Cooker

Decide if you need a "booster" function. It is not available on all models of appliances and is responsible for the rapid heating of dishes. For example, it allows you to bring water to a boil in a matter of minutes.

It is worth considering whether the auxiliary capabilities of the tile will be required.Modern appliances are equipped with a large number of additional functions, including automatic shutdown (when boiling), a timer, defrosting food, and storing programs. Choose a panel with such benefits only when you really intend to use them, otherwise it is just a waste of money.

Advantages and disadvantages of the device

The “pluses” of the vortex induction heater are numerous. This is a simple circuit for self-production, increased reliability, high efficiency, relatively low energy costs, long service life, low probability of breakdowns, etc.

The performance of the device can be significant; units of this type are successfully used in the metallurgical industry. In terms of the rate of heating of the coolant, devices of this type confidently compete with traditional electric boilers, the water temperature in the system quickly reaches the required level.

During the operation of the induction boiler, the heater vibrates slightly. This vibration shakes off limescale and other possible contaminants from the walls of the metal pipe, so such a device rarely needs to be cleaned. Of course, the heating system must be protected from these contaminants with a mechanical filter.

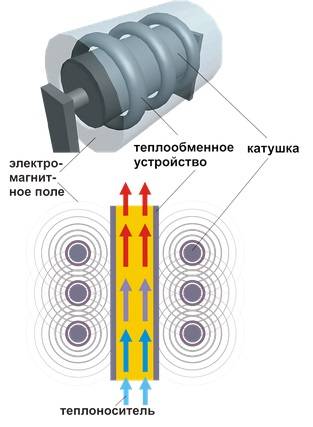

The induction coil heats the metal (pipe or pieces of wire) placed inside it using high frequency eddy currents, contact is not necessary

Constant contact with water also minimizes the likelihood of heater burnout, which is a fairly common problem for traditional boilers with heating elements.Despite the vibration, the boiler operates exceptionally quietly; additional noise insulation at the installation site of the device is not required.

Induction boilers are also good because they almost never leak, if only the installation of the system is done correctly. This is a very valuable quality for electric heating, as it eliminates or significantly reduces the likelihood of dangerous situations.

The absence of leaks is due to the non-contact method of transferring thermal energy to the heater. The coolant using the technology described above can be heated almost to a vapor state.

This provides sufficient thermal convection to stimulate efficient movement of the coolant through the pipes. In most cases, the heating system will not have to be equipped with a circulation pump, although it all depends on the features and layout of a particular heating system.

Sometimes a circulation pump is needed. Installing the device is relatively easy. Although this will require some skills in the installation of electrical appliances and heating pipes. But this convenient and reliable device has a number of shortcomings, which should also be considered.

For example, the boiler heats not only the coolant, but also the entire workspace surrounding it. It is necessary to allocate a separate room for such a unit and remove all foreign objects from it. For a person, a long stay in the immediate vicinity of a working boiler can also be unsafe.

Induction heaters require electricity to operate. Both homemade and factory-made equipment are connected to a household AC mains.

The device requires electricity to operate. In areas where there is no free access to this benefit of civilization, the induction boiler will be useless. Yes, and where there are frequent power outages, it will demonstrate low efficiency.

An explosion may occur if the device is not handled with care.

If the coolant is overheated, it will turn into steam. As a result, the pressure in the system will increase dramatically, which the pipes simply cannot withstand, they will burst. Therefore, for the normal operation of the system, the device should be equipped with at least a pressure gauge, and even better - an emergency shutdown device, a thermostat, etc.

All this can significantly increase the cost of a homemade induction boiler. Although the device is considered to be practically silent, this is not always the case. Some models, for various reasons, may still make some noise. For a self-made device, the likelihood of such an outcome increases.

In the design of both factory and homemade induction heaters Virtually no wearing parts. They last a long time and work flawlessly.

Features of the vortex induction boiler

We are already familiar with the principle of operation of an induction heater. There is a variation of it: a vortex induction boiler or VIN, which operates in a slightly different way.

Distinctive features of VIN

Like the induction counterpart, it runs on high-frequency voltage, so it must be equipped with an inverter. A feature of the VIN device is that it does not have a secondary winding.

Its role is performed by all the metal parts of the device. They must be made from materials that exhibit ferromagnetic properties.Thus, when current is supplied to the primary winding of the device, the strength of the electromagnetic field increases sharply.

It, in turn, generates a current, the strength of which is rapidly increasing. Eddy currents provoke magnetization reversal, as a result of which all ferromagnetic surfaces heat up very quickly, almost instantly.

Vortex devices are quite compact, but due to the use of metal, their weight is large. This gives an additional advantage, since all the massive elements of the body take part in heat exchange. Thus, the efficiency of the unit approaches 100%.

This feature of the device must be taken into account if a decision is made to independently manufacture a VIN boiler. It can only be made of metal, plastic should not be used.

Main difference swirl induction boiler lies in the fact that its body acts as a secondary winding. Therefore, it is always made of metal

How to assemble a vortex induction device?

As we already know, such a boiler differs from its induction counterpart, however, making it yourself is just as easy. True, now you will need welding skills, because the device must be assembled only from metal parts.

For work you will need:

- Two segments of a metal thick-walled pipe of the same length. Their diameters must be different, so that one part can be placed in another.

- Winding (enamelled) copper wire.

- A three-phase inverter, it is possible from a welding machine, but as powerful as possible.

- Casing for thermal insulation of the boiler.

Now you can get to work. We start with the manufacture of the body of the future boiler.We take a pipe of a larger diameter and insert the second part inside. They need to be welded one into the other so that there is some distance between the walls of the elements.

The resulting detail in the section will resemble a steering wheel. A steel sheet with a thickness of at least 5 mm is used as the base and cover of the housing.

The result is a hollow cylindrical tank. Now you need to cut pipes into its walls for the pipes for supplying cold and draining hot liquids. The configuration of the pipe and its diameter depend on the pipes of the heating system; adapters may be additionally needed.

After that, you can start winding the wire. It is carefully, under sufficient tension, wound around the boiler body.

Schematic diagram of a homemade vortex-type induction boiler

Actually, a wound wire will serve as a heating element, so it is advisable to close the device case with a heat-insulating casing. So it will be possible to save maximum heat and, accordingly, increase the efficiency of the device and make it safe.

Now you need to embed the boiler into the heating system. To do this, the coolant is drained, the pipe section of the required length is cut off and the device is welded in its place.

It remains only to power the heater and do not forget to connect the inverter to it. The device is ready for use. But before testing, you need to fill the line with coolant.

You do not know which coolant to choose to fill the circuit? We recommend that you familiarize yourself with the characteristics of various coolants and recommendations for choosing the optimal type of fluid for the heating circuit.

Only after pumping the coolant into the system, carry out a test run.

First you need to run the device at minimum power and carefully monitor the quality of the welds. If everything is in order, we increase the power to the maximum.

On our website there is another instruction for the manufacture of an induction device that can be used to heat the coolant in the heating system. To get acquainted with the process of assembling an induction heater, follow this link.

Heating control

The core of an induction soldering iron is made of copper (not a magnetic material), and the back of it is coated with a ferromagnetic material (an alloy of iron and nickel). The front part serves as a sting, the core itself is called a cartridge.

The heating of the copper tip is adjusted as follows:

- when an alternating voltage is applied, and hence the field, Foucault currents are generated in the coating, which heat up the material;

- heat is transferred to copper;

- as soon as the temperature of the coating reaches the Curie point, the magnetic properties disappear and the heating stops;

- in the process of working with an induction soldering iron, the copper tip gives off heat to the part and cools down, the ferromagnetic coating also cools down;

- as soon as the coating cools down, the magnetic properties return, and heating resumes instantly.

The maximum heating of an induction soldering iron depends on the properties of the magnetic alloy and the core. Such control is called smart heat.

You can change the temperature for specific soldering conditions by installing a temperature sensor that is connected to the station control unit, or by changing the cartridges (core with a tip) that are inserted into the handle of the induction soldering iron.

The first option is cheaper than the second, so not only professionals use it today. But the second method is more accurate and reliable.

Induction heat generator in the heating system

The induction water heaters used in heating circuits have both advantages common to all electric heaters and inherent only to them. Let's start with the first group:

- In terms of ease of use, electric heaters are ahead of even gas equipment, since they do without ignition. In addition, they are much safer: the owner does not have to be afraid of fuel leakage or combustion products.

- Electrical equipment does not need a chimney and maintenance in the form of removing carbon deposits and soot.

- The efficiency of an electric heater does not depend on its power. It can be set to the very minimum, and at the same time the efficiency of the unit will remain at the level of 99%, while the efficiency of a gas or solid fuel boiler in such conditions will be significantly lower than the passport one.

- In the presence of an electric heat generator, the heating system can operate in the lowest temperature mode, which is very important during the off-season. In the case of using a gas or solid fuel boiler, the “return” temperature drop below 50 degrees is not allowed, since in this case condensate forms on the heat exchanger (when using solid fuel, it contains acid).

- And the last thing: when using electric heating, you can do without a liquid coolant, however, this does not apply to induction heaters.

Simple induction heater

Let's move on to the advantages of directly "inductors":

- The contact area of the coolant with a hot surface in induction heaters is thousands of times greater than in devices with tubular electric heaters. Therefore, the environment warms up much faster.

- All elements of the "inductor" are mounted only from the outside, without any tie-ins. Accordingly, leaks are completely excluded.

- Since heating is carried out in a non-contact way, an induction type heater can work with absolutely any coolant, including all types of antifreeze (a special one would be needed for a heating element electric boiler). At the same time, water can contain a relatively large amount of hardness salts - an alternating magnetic field prevents the formation of scale on the walls of the heat exchanger.

For every barrel of honey, as you know, there is a fly in the ointment. Here, too, it could not have done without it: not only is electricity itself quite expensive, but also induction heaters are among the most expensive type of electric heating equipment.

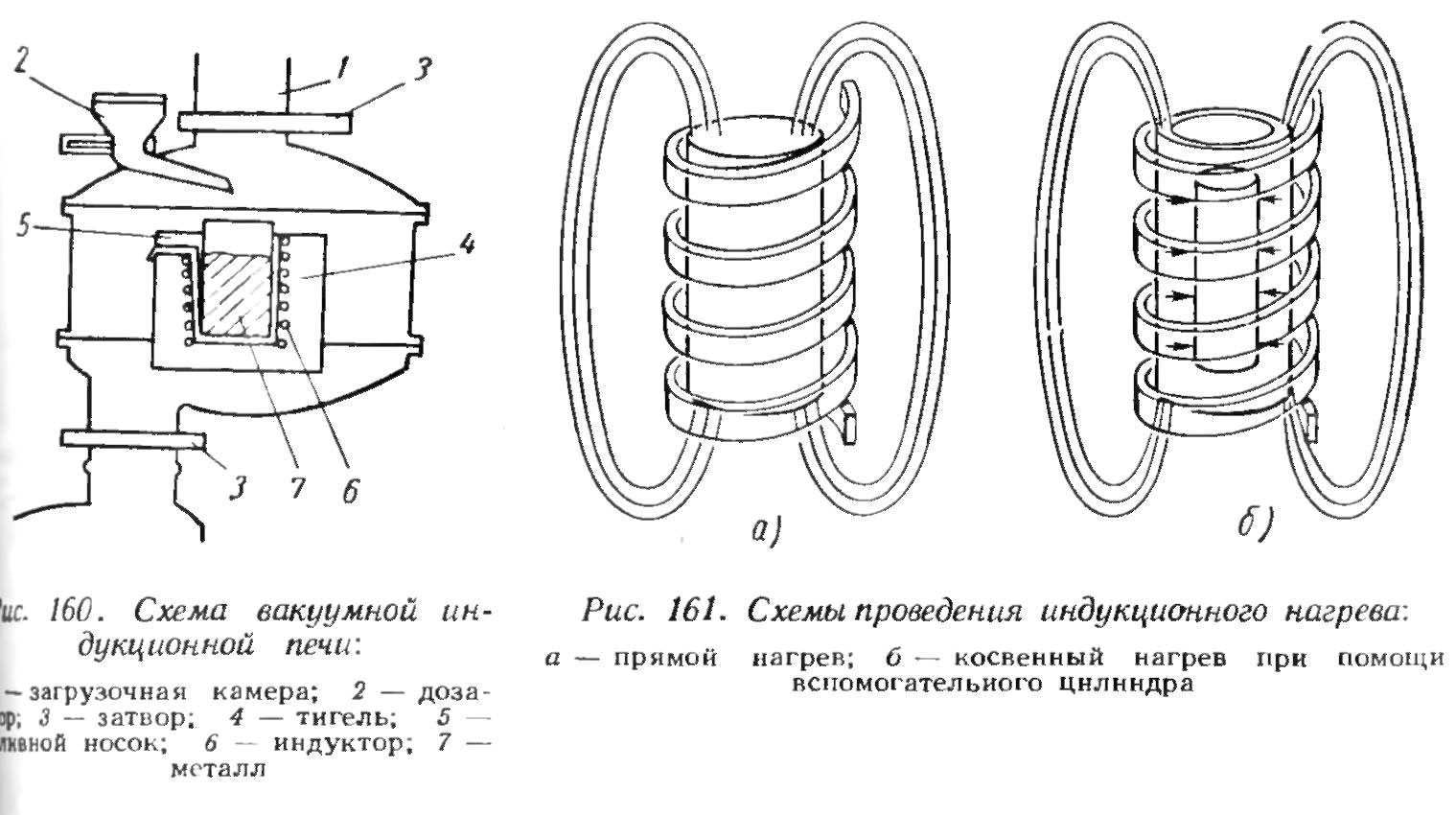

Induction foundry furnaces

Each induction casting furnace can be equipped with two types of converters, as a rule, a thyristor converter is cheaper and is equipped with high power furnaces, and a transistor converter is more economical in terms of power consumption:

Thyristor frequency converters are used to power induction foundry furnaces, they work according to the usual two-stage principle:

- - the rectifier converts the alternating current of the network into direct current;

- - the inverter converts this direct current again into alternating current, but already at the desired frequency.

Thyristor converters can work with high current and voltage and at the same time withstand continuous load.Their efficiency is higher than that of IGBT converters.

Transistor frequency converters. Transistor frequency converters are used to power induction furnaces, in which up to 200 kg of non-ferrous metals and up to 100 kg of ferrous metals can be melted, in furnaces of the IPP type. Such furnaces are most often used in laboratory conditions for experimental melts, when there is a need for a quick change of alloy.

Among the undoubted advantages of transistor converters are compactness, ease of operation and quiet operation.

VIN type water heaters

The heart of the unit is a coil, consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical body in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed from above and below by welded covers, terminals for connecting to the electrical network are brought out. A cold coolant enters the vessel through the lower branch pipe, which fills the entire space inside the vessel. The water heated to the required temperature goes into the heating system through the upper pipe.

Heat carrier heating scheme

Due to its design, when connected to the network, the heat generator constantly operates at full capacity, since it is not rational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown / on with a water temperature sensor. It is only necessary to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the hot water induction element when it is reached.After the time has elapsed and the water has cooled down by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the winding of the heat generator provides for a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying cables of a large cross section, which in itself is very expensive. To increase the power, it is enough to put three water heating installations in a cascade and apply a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each cascade device, the photo shows a similar example of induction heating.

Heating with induction boilers

Design features of Sibtechnomash heaters Using the same effect of electromagnetic induction, another company develops and manufactures water heaters of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial form and spreads from it in all directions. If in the VIN units the coolant passes inside the coil, then the Sibtechnomash induction boiler device provides for a spiral heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the coils of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- heat exchanger piping is available for flushing and maintenance.

Example of connecting an induction boiler

Despite the differences in the design of the heat generator, its efficiency is 98%, as in heaters of the VIN type, this efficiency value is declared by the manufacturer himself. The durability of the units in both cases is determined by the performance of the coils, or rather, the service life of the winding and electrical insulation, this indicator is set by manufacturers within 30 years.