- Advantages and disadvantages of induction heating boilers

- Advantages of using electric induction boilers

- Negatives and weaknesses ↑

- How to make a device yourself

- Necessary tools and materials

- Work order

- How to connect the boiler with your own hands, diagram

- Advantages of induction heating boilers

- Assembling a simple do-it-yourself induction boiler

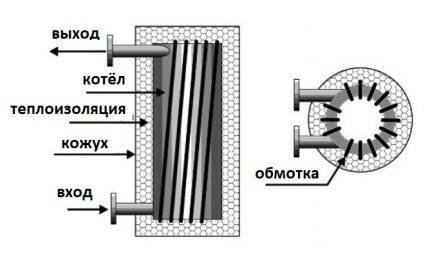

- Device

- Scheme and drawings

- How to DIY

- A more complex version of the induction vortex boiler ↑ ↑

- Principle of operation

- Features of the vortex induction boiler

- Distinctive features of VIN

- How to assemble a vortex induction device?

- Do-it-yourself induction heating boiler

- Buy parts on Aliexpress

- The principle of operation of devices

- The principle of operation of devices

- Assembly according to schemes

- Idea #1 - Simple Vortex Heater

Advantages and disadvantages of induction heating boilers

Creating an induction heating system reduces the cost of electricity consumption. Boilers with induction have many positive aspects, thanks to which they are increasingly being installed in houses without gasification. True, such units are not cheap.

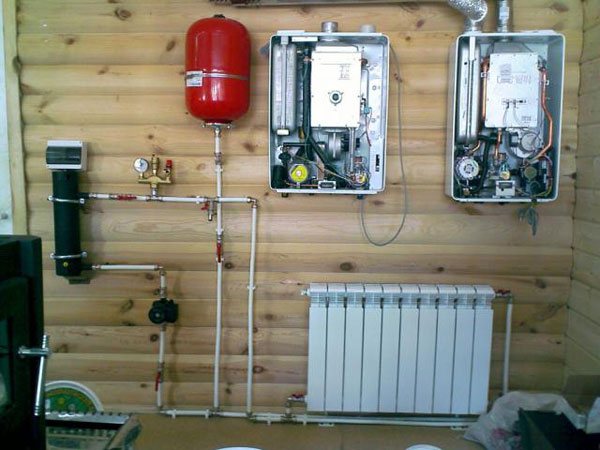

Induction boiler with automatic

Advantages of using electric induction boilers

Like all new technology, this equipment has many advantages:

- With the help of automation, the desired temperature mode of the liquid in the heating system is set. Temperature sensors and relays support the set figures, this makes induction heating boilers autonomous and safe.

- Induction boilers can heat any liquid - water, ethylene glycol, oil and others.

- The efficiency of all electric boilers with induction exceeds 90%.

- The simple design makes these devices very reliable. They can last up to 30 years if properly maintained.

- Due to their small size, it is not necessary to make a separate room, the units can be easily installed in any part of the building and independently introduced into the heating system.

- Due to the constant vibration of the core and the closed system, scale does not form on the heater.

- The induction boiler is economical. It turns on only if the coolant temperature has dropped. Automation brings it to the specified numbers and turns off the device. All this happens very quickly. Working "idle", it consumes little energy due to the low inertia of the system.

The device does not take up much space

Negatives and weaknesses ↑

There are also disadvantages:

- High prices for these relatively new devices. The lion's share of the cost is built into automation, but the better it works, the more energy is saved.

- The interruption of the power supply leads to the shutdown of the heating in the house. A solution to the problem is a diesel or gasoline generator.

- Some models make a lot of noise during operation. These are placed in technical storerooms.

- If a system break occurs and the water does not cool the core, it will melt the body and the boiler mount.If this happens, the shutdown is carried out automatically.

Typical heating system

How to make a device yourself

You can make an induction boiler with your own hands, the main thing is to follow the instructions below.

Necessary tools and materials

- Nippers, pliers.

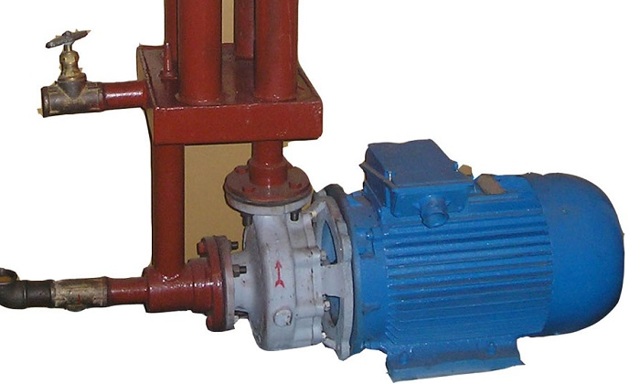

- Circulation pump.

- welding inverter.

- Ball valves and adapters will be required when installing the unit to the heating system.

- Copper, steel or stainless wire. It is better to purchase new materials, since it is better not to use winding from old coils. The cross section of the wire that is suitable for winding the branch pipe is 0.2 mm, 0.8 mm, 3 mm.

- A piece of plastic pipe - the body of the structure.

Work order

To assemble a simple induction boiler, you do not need to use complex tools and expensive materials.

All you need is an inverted welding machine. Basic and step-by-step manufacturing steps:

- Cut steel or stainless wire with wire cutters into segments from 5 to 7 cm.

- A plastic pipe for assembling the body of the apparatus with a diameter of 5 cm. The pipe should be tightly filled with cut pieces of wire and laid so that there is no empty space inside.

- A fine-frequency metal mesh is attached to the end parts of the pipe.

- Short pipe sections are attached to the bottom and top of the main pipe.

- Wrap the pipe tightly with copper wire, the number of turns is not less than 90. The same distance should be observed between the turns.

Important! All open sections of copper wire should be insulated with special materials that have good electrical and thermal conductivity. The induction boiler requires mandatory grounding

- Special adapters are connected to the body part of the heater, designed for insertion into heating or plumbing structures.

- The circulation pump is installed.

- An inverting element of 18-25 A is connected to the finished coil.

- The heating system is ready to be filled with coolant.

Attention! Do not start the heating boiler if there is no coolant in the design. Otherwise, the plastic material of the case will start to melt. The result is an inexpensive, uncomplicated unit that will effectively heat the serviced premises.

The result is an inexpensive, uncomplicated unit that will effectively heat the serviced premises.

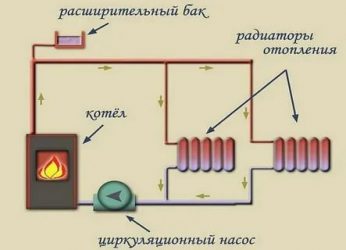

To install an induction system, a closed-type heating structure with a pump is suitable, which will circulate water in the pipeline.

Pipes made of plastic are also suitable for installation work when connecting a home-made heating device.

When installing, be sure to keep a distance from objects that are nearby. According to safety rules, from the heating unit to other objects and walls should be about 30 cm or more, from the floor and ceiling 80 cm or more. It is recommended to install a device for measuring liquid pressure in a closed space and a manual air vent at the outlet pipe.

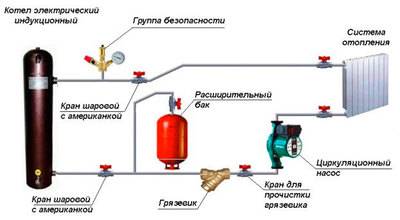

How to connect the boiler with your own hands, diagram

- Source of direct current 220 V.

- Induction boiler.

- Group of safety elements (device for measuring liquid pressure, air vent).

- Ball valve.

- Circulation pump.

- Mesh filter.

- Membrane tank for water supply.

- Radiator.

- Filling and draining line indicator for the heating system.

Photo 2.Scheme of connecting an induction boiler to a heating system. The numbers indicate the parts of the structure.

Advantages of induction heating boilers

Induction boilers have many absolute and comparative advantages, including the following:

- the highest efficiency among all electric boilers;

- invariability of energy characteristics;

- minimum requirements for the coolant;

- increased reliability;

- record long service life;

- ability to work autonomously;

- simple installation without ventilation system;

- automatic control system;

- no need for delivery and storage of fuel:

- heating the coolant up to 95 degrees;

- high level of security.

The device converts electrical energy into thermal energy with an efficiency of 98-99%. It takes 7-10 minutes to heat up the coolant. With a simple design with no moving mechanical parts, the steel alloys used as construction materials make induction boilers record-breaking durable.

Only damage to electrical insulation can disable such equipment. But as the practice of operating transformers, which in their design are in many ways similar to induction boilers, shows, they are really capable of lasting for many decades.

According to manufacturers, units operating due to the effect of electromagnetic induction provide uninterrupted space heating for 100 thousand hours, that is, 30 heating seasons. At the same time, their power does not decrease over time, which cannot be said about electrode and conventional heating boilers.

Induction boilers can be used both as the main and as additional equipment.For example, prepare a coolant for an irregularly used underfloor heating system

The same reasons that determine the durability and increased reliability of induction heaters also reduce the cost of operation. The induction boiler does not need regular maintenance and repair, which saves money.

Compared to many other fuels, using electricity to heat homes remains the most profitable. This is especially true for non-gasified settlements.

The design of the certified induction boiler prevents short circuits. Manufacturers claim that any model has the highest electrical safety class. An induction boiler should not be confused with a microwave oven, since a different frequency of electric current is used for its operation.

Heating of the coolant in the induction boiler occurs evenly - the temperature difference in the system is not more than 30 ° C. That is, there are no local overheatings that can lead to a fire, which makes such units fireproof.

Due to the magnetization of the coolant, fine vibration, imperceptible to others and turbulent eddies, mineral deposits are practically not formed in induction boilers, which favorably affects efficiency. Recall that a thick layer of scale slows down the speed and efficiency of heating the coolant.

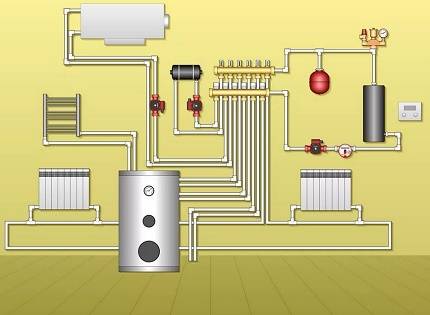

To increase power, a cascade of three or more induction boilers with a common control cabinet can be used. This solution will help to heat a two-story mansion

If you follow the operating rules specified in the instructions, then after installation and setting the temperature regime, you can not remember the boiler throughout the entire heating season. Unlike solid fuel "brothers", induction appliances do not require regular loading of firewood and coal and ash removal. Pipe cleaning is not required, which distinguishes them from other types of electric boilers.

The boiler itself and its accessories take up little space and can be installed in a small area. The components of the control system allow the use of induction boilers in one bundle with other climatic equipment.

Induction boilers can be integrated into an intelligent home equipment control system called “Smart Home”

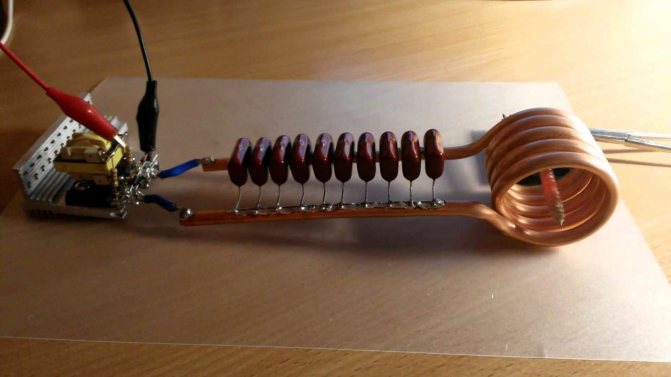

Assembling a simple do-it-yourself induction boiler

For greater savings, you can assemble an induction boiler with your own hands. However, it should be borne in mind that this is not an easy task, and one cannot do without minimal skills. You will need knowledge in both assembly and installation, and in electronics. Ideally, it is necessary to carry out accurate calculations so that the result is a device that will fully satisfy your needs and will not fail the first time you turn it on.

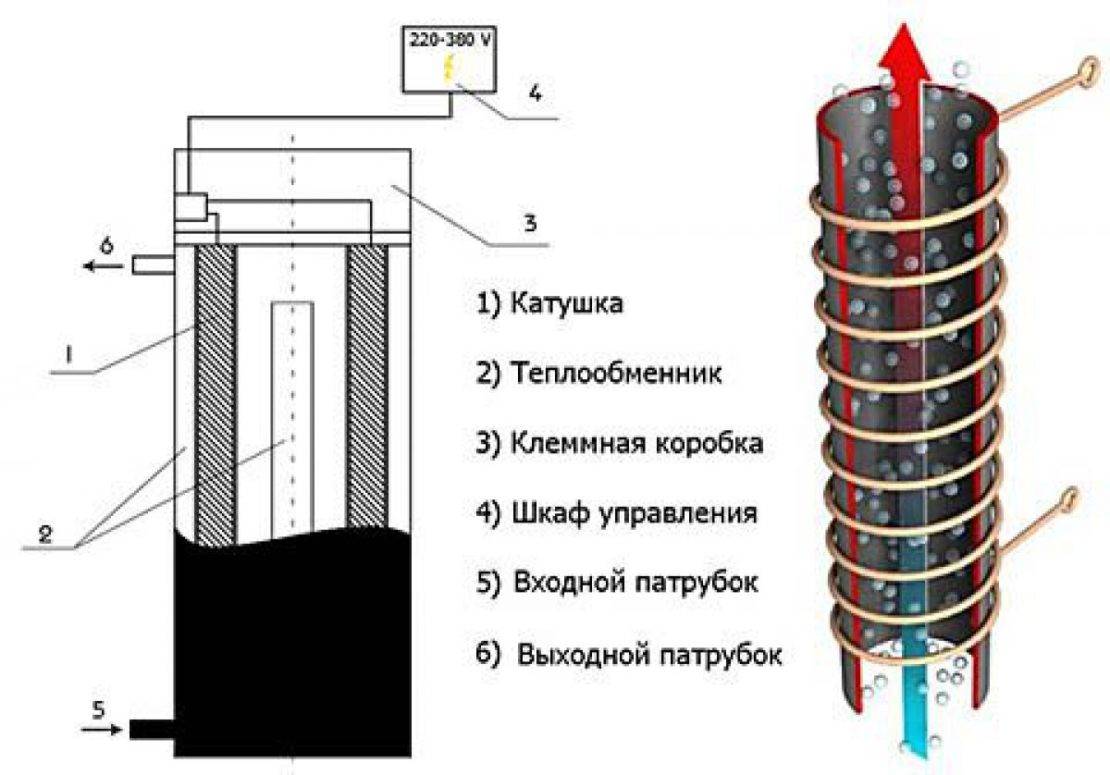

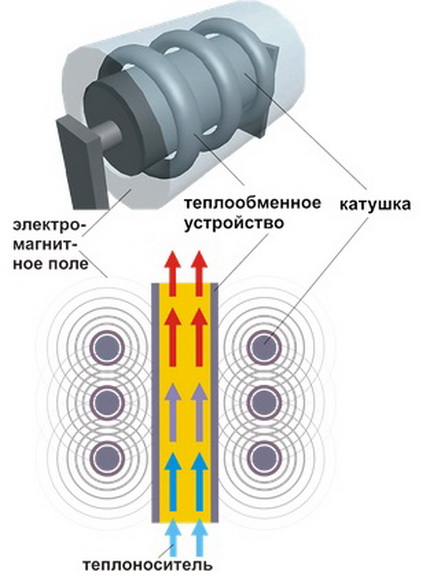

Device

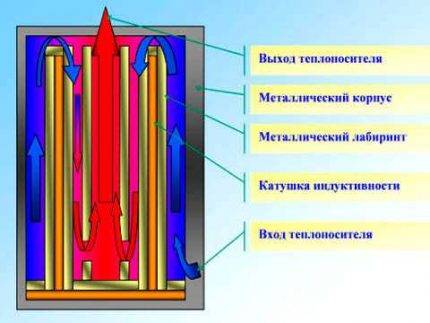

As the name implies, such boilers operate on the basis of the emerging electromagnetic induction, which, in turn, contributes to the formation of eddy currents.

The simplest induction boiler includes the following elements:

- coil;

- heat exchanger;

- terminal box;

- control cabinet;

- inlet and outlet pipes.

In industry, an induction boiler is usually represented by a heat exchanger acting as a core, with a winding connected to a high-frequency converter.

Inside the heat exchanger, a coolant is necessarily located, the heating of which occurs under the action of eddy currents. Connecting the pump allows you to avoid exactly the difference between the temperatures of the inlet and outlet pipes for the coolant - thanks to it, the natural circulation of the coolant in the boiler occurs.

Almost any liquid can be used as a coolant. Antifreeze and oil are often poured in, however, in order to save money, ordinary water can also be used for this purpose. Even with this, it is not necessary to subject it to any cleaning, since the system constantly vibrates at high frequencies, and the scale simply does not have the opportunity to settle. The same applies to other impurities.

As an outer shell, it is best to give preference to metal, without saving on insulation: both thermal and electrical.

There are no restrictions on the shape of the boiler. Compared to electric ones, there is no need to install a tank in induction ones, which is why they differ in their modest size.

Scheme and drawings

Skilled hands have long been fond of assembling induction boilers at home. They went through a lot of variations, many of which, although interesting, do not have the proper benefit or safety. Nevertheless, successful models quickly gained popularity on the Internet.

They are preferred not only by those people who are fond of assembling boilers for the sake of hobby, but also by those for whom it is important to use the device for its primary purpose - to heat the house. The most popular options are:

- Using power from a welding inverter. This is considered a simple option for self-assembly of an induction boiler, however, you will need to pay a lot of attention and effort to the high-frequency converter - this is exactly how the welding inverter is used.

- Based on an induction hob. This method is beneficial to use if you have an unnecessary induction cooker. Acquiring it for such a purpose is clearly irrational. To do this, you need to disassemble it and get the copper wire - it will serve as a winding in the induction boiler. The control panel is reconfigured for the boiler so that it can be used to adjust the output.

How to DIY

You can assemble a simple induction boiler without using an inverter or stove. They, in fact, only replace some elements.

To make it work, you need to strictly adhere to the algorithm of actions:

Cut stainless steel wire with a diameter of 7–8 mm into pieces of 5 cm.

Pick up a plastic pipe with a diameter of about 50 mm. It will be required to assemble the case.

Install a fine-mesh metal mesh at the bottom of the pipe.

Fill the tube with chopped wire (this will act as a metal labyrinth), also cover the top with a net

At the same time, it is important to choose materials so that the wire does not crawl through the mesh cells.

Wrap at least a hundred turns of copper wire tightly around the pipe. Winding must be as accurate as possible!

Attach pipes to the heater, which will subsequently connect it to the heating and plumbing systems of the house.

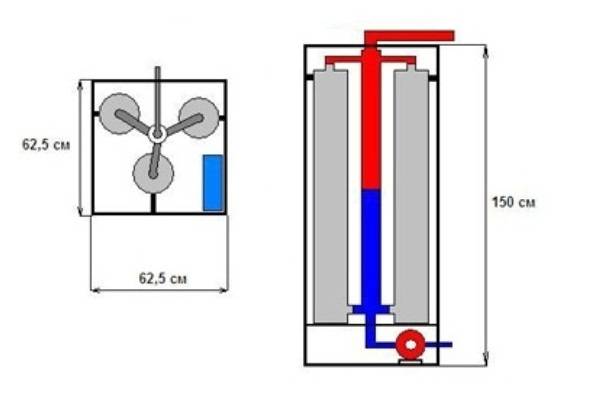

A more complex version of the induction vortex boiler ↑ ↑

In order to make this homemade induction boiler, you will need skills in working with a welding machine and a three-phase transformer, it is desirable that it be equipped with fasteners.

The design consists of two pipes welded into each other. If you look at them from above, then the pipes welded together will resemble a donut. It simultaneously performs the function of a core (a conductor of energy generated by a magnetic field) and works as a heating element.

The winding is wound on the boiler body, which increases productivity with relatively small dimensions and weight.

For the supply and output of the coolant circulating in the heating system, the inlet and outlet pipes are welded into the housing.

It is recommended to eliminate the loss of thermal energy received during the operation of the device and current leakage, to place a thermal boiler made by oneself in an insulating casing.

The coolant is heated by direct contact with the winding according to the standard scheme for induction equipment.

An induction heating system can only be installed in a closed heating network with forced circulation provided by a pump.

It is permissible to include the device in a heating system with a plastic pipeline.

A distance of at least 30 cm must be observed between the surface of the walls, other appliances and the induction boiler, and a distance of more than 80 cm from the plane of the floor and ceiling.

It is recommended to install a safety group behind the outlet pipe: pressure gauge, automatic air vent, blast valve.

Of course, with the manufacture of the latter option, you will have to tinker a lot, but the result and the economic effect will no doubt be a pleasure.Factory induction equipment has been running like clockwork for three decades without requiring repairs. A home-made device will last at least 25 years, and if you make every effort, then more.

It is possible that initially hand-made production of an induction vortex boiler may seem rather time-consuming and complicated. But there will be many benefits from it. In addition to the expense for the purchase of expensive factory equipment, which is tangible for the family budget, thanks to useful home-made work, the cost of expensive electricity will also be significantly reduced.

Would you like to furnish your home with efficient yet cost-effective heating? Then be sure to pay attention to modern induction boilers. Such units are characterized by high performance and at the same time have an extremely simple design, so you can easily handle the assembly of an induction heating boiler with your own hands.

The operation of the equipment in question is based on the use of induction electrical energy.

Such boilers are absolutely safe and environmentally friendly. During their operation, no by-products are released that can harm a person and the environment.

Contents of step by step instructions:

Principle of operation

Such units are similar to heating elements. They convert electricity into heat.

Thanks to the design of an electric induction heating boiler, the heating of the coolant occurs much faster.

For its arrangement, it is not necessary to re-equip the heating system of the building.

Video lesson:

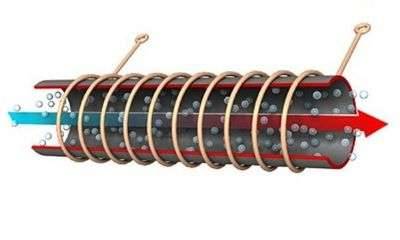

The simplest design of a heat generator assembled on the principle of induction is an electric inductor consisting of a primary and secondary winding:

- The primary winding converts electrical energy into eddy currents, which redirect the electromagnetic field created by them to the secondary winding;

- A metal heating pipe acts as a secondary winding.

The induction electric boiler works on the principle of a transformer, the pipe with water passing inside the coil is very hot, but the heat, due to the circulation of water, is removed to the heating system, so overheating is excluded.

The process of heating a home seems to be one of the most important for any person.

When building a house, overhauling, renewing the pipeline, it is very important to accurately determine the source of heating. If the homeowner lives in a gasified area, then there will be no unnecessary questions with the choice of a heating boiler

A gas appliance is the optimal solution, available in terms of quality and cost.

Features of the vortex induction boiler

We are already familiar with the principle of operation of an induction heater. There is a variation of it: a vortex induction boiler or VIN, which operates in a slightly different way.

Distinctive features of VIN

Like the induction counterpart, it runs on high-frequency voltage, so it must be equipped with an inverter. A feature of the VIN device is that it does not have a secondary winding.

Its role is performed by all the metal parts of the device. They must be made from materials that exhibit ferromagnetic properties.Thus, when current is supplied to the primary winding of the device, the strength of the electromagnetic field increases sharply.

It, in turn, generates a current, the strength of which is rapidly increasing. Eddy currents provoke magnetization reversal, as a result of which all ferromagnetic surfaces heat up very quickly, almost instantly.

Vortex devices are quite compact, but due to the use of metal, their weight is large. This gives an additional advantage, since all the massive elements of the body take part in heat exchange. Thus, the efficiency of the unit approaches 100%.

This feature of the device must be taken into account if a decision is made to independently manufacture a VIN boiler. It can only be made of metal, plastic should not be used.

The main difference between the vortex induction boiler is that its body acts as a secondary winding. Therefore, it is always made of metal

The main difference between the vortex induction boiler is that its body acts as a secondary winding. Therefore, it is always made of metal

How to assemble a vortex induction device?

As we already know, such a boiler differs from its induction counterpart, however, making it yourself is just as easy. True, now you will need welding skills, because the device must be assembled only from metal parts.

For work you will need:

- Two segments of a metal thick-walled pipe of the same length. Their diameters must be different, so that one part can be placed in another.

- Winding (enamelled) copper wire.

- A three-phase inverter, it is possible from a welding machine, but as powerful as possible.

- Casing for thermal insulation of the boiler.

Now you can get to work. We start with the manufacture of the body of the future boiler.We take a pipe of a larger diameter and insert the second part inside. They need to be welded one into the other so that there is some distance between the walls of the elements.

The resulting detail in the section will resemble a steering wheel. A steel sheet with a thickness of at least 5 mm is used as the base and cover of the housing.

The result is a hollow cylindrical tank. Now you need to cut pipes into its walls for the pipes for supplying cold and draining hot liquids. The configuration of the pipe and its diameter depend on the pipes of the heating system; adapters may be additionally needed.

After that, you can start winding the wire. It is carefully, under sufficient tension, wound around the boiler body.

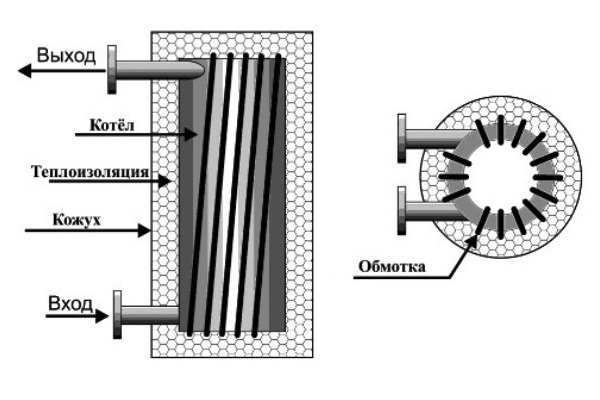

Schematic diagram of a homemade vortex-type induction boiler

Schematic diagram of a homemade vortex-type induction boiler

Actually, a wound wire will serve as a heating element, so it is advisable to close the device case with a heat-insulating casing. So it will be possible to save maximum heat and, accordingly, increase the efficiency of the device and make it safe.

Now you need to embed the boiler into the heating system. To do this, the coolant is drained, the pipe section of the required length is cut off and the device is welded in its place.

It remains only to power the heater and do not forget to connect the inverter to it. The device is ready for use. But before testing, you need to fill the line with coolant.

You do not know which coolant to choose to fill the circuit? We recommend that you familiarize yourself with the characteristics of various coolants and recommendations for choosing the optimal type of fluid for the heating circuit.

Only after pumping the coolant into the system, carry out a test run.

First you need to run the device at minimum power and carefully monitor the quality of the welds. If everything is in order, we increase the power to the maximum.

On our website there is another instruction for the manufacture of an induction device that can be used to heat the coolant in the heating system. To get acquainted with the process of assembling an induction heater, follow this link.

Do-it-yourself induction heating boiler

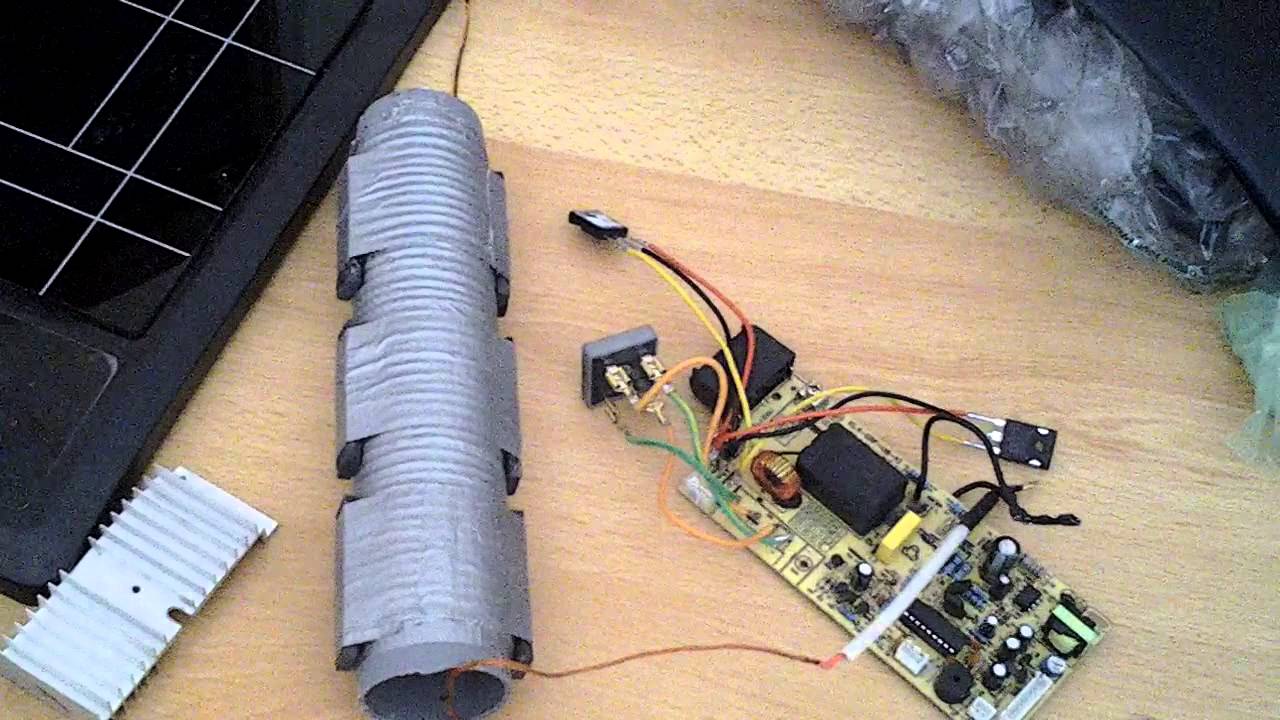

At home, the heater can be made from a welding inverter or transformer.

Boiler from a welding inverter

Before proceeding directly to the assembly, you must stock up on the following materials:

- Stainless wire with a diameter of 5-7 mm;

- A piece of plastic heat-resistant pipe, approximately 500 mm long, with an outer diameter of not more than 50 mm and a wall thickness of at least 5 mm;

- Perforated or woven stainless steel mesh with a window no larger than 4x4 mm. The size of the mesh must completely cover the cross section of the plastic pipe and provide the possibility of reliable fastening;

- Enamelled copper wire with a diameter of 1.2-1.5 mm. It will take approximately 5m to wind the coil;

- Two adapters for connecting the boiler to the heating main;

- The welding inverter allowing to carry out smooth adjustment of current strength.

After all the necessary components have been prepared, you can begin to assemble the induction boiler. The assembly consists of several stages:

1. Stainless wire is cut into pieces 5-6 cm long in the amount necessary to completely fill the pipe.

2. One side of the pipe is closed with a mesh, after which the pieces of wire are backfilled and the other side is sealed.The internal cavity of the pipe is filled completely, and the presence of a fencing mesh on both sides prevents pieces of wire from entering the pipelines of the heating system.

3. 90-100 turns of copper wire are wound onto the filled pipe. In the process of winding, it is necessary to ensure uniformity and the same distance between the turns. The entire coil must be equidistant from both ends of the pipe.

4. Adapters are hermetically installed on the ends of the pipe, and a tie-in is made into the existing heating main.

5. Both coil leads are connected to the welding inverter.

6. The heating circuit installed in this way is filled with coolant, after which the system is ready for operation.

It is strictly forbidden to connect the device to the mains until the system is completely filled with coolant.

7. Using the inverter, the required temperature is set.

Such a design of an induction device with your own hands can effectively heat an area of 50–60 m2. If the heated area is larger, or additional power is required for autonomous hot water supply, there is a second option.

Induction boiler using a transformer

When using a transformer, the role of the heating element is played by the body of the device, inside which the coolant circulates. For the manufacture of the unit, in addition to the skills of the welder, you will need:

- Two metal pipes placed one inside the other so that a cavity forms between them.

- Two flat rings for sealing ends;

- welding inverter;

- Three-phase transformer;

- Metal pipes for inlet and outlet pipes.

1. At some distance from the ends, pipes are welded into the hollow cylinder, which ensure the circulation of the coolant.

2. By winding copper wire around the body, the primary winding is formed;

3. To slow down cooling and reduce the dissipation of thermal energy, the product is placed in a special case, and the resulting cavity is filled with heat-resistant heat-insulating material.

Security

To prevent accidents, when installing home-made induction boilers intended for heating a private house, you must follow several rules:

- When connecting the product to the heating system, the distance from the wall must be at least 30 cm, and from the floor and ceiling at least 80 cm;

- Devices can only be installed in closed circuits with forced circulation of the coolant;

- A pressure gauge and a safety valve should be installed on the outlet pipe.

The use of the phenomenon of electromagnetic induction in the manufacture of heating boilers can significantly reduce the dimensions of products, ensure high performance and long service life of the equipment.

Buy parts on Aliexpress

|

Appliances that heat with electricity rather than gas are safe and convenient. Such heaters do not produce soot and unpleasant odors, but consume a large amount of electricity. An excellent way out is to assemble an induction heater with your own hands. This saves money and contributes to the family budget. There are many simple schemes according to which the inductor can be assembled independently.

In order to make it easier to understand the circuits and assemble the structure correctly, it would be useful to look into the history of electricity. Methods for heating metal structures with an electromagnetic coil current are widely used in the industrial manufacture of household appliances - boilers, heaters and stoves. It turns out that you can make a working and durable induction heater with your own hands.

The principle of operation of devices

The principle of operation of devices

The famous 19th century British scientist Faraday spent 9 years researching to convert magnetic waves into electricity. In 1931, a discovery was finally made, called electromagnetic induction. The wire winding of the coil, in the center of which there is a core of magnetic metal, creates a magnetic field under the power of alternating current. Under the action of vortex flows, the core heats up.

Faraday's discovery began to be used both in industry and in the manufacture of home-made motors and electric heaters. The first foundry based on a vortex inductor was opened in 1928 in Sheffield. Later, according to the same principle, the workshops of factories were heated, and for heating water, metal surfaces, connoisseurs assembled an inductor with their own hands.

The scheme of the device of that time is valid today. A classic example is an induction boiler, which includes:

- metal core;

- frame;

- thermal insulation.

The features of the circuit for accelerating the frequency of the current are as follows:

- industrial frequency of 50 Hz is not suitable for home-made devices;

- direct connection of the inductor to the network will lead to hum and low heating;

- effective heating is carried out at a frequency of 10 kHz.

Assembly according to schemes

Anyone familiar with the laws of physics can assemble an inductive heater with their own hands. The complexity of the device will vary from the degree of preparedness and experience of the master.

There are many video tutorials, following which you can create an effective device. It is almost always necessary to use the following basic components:

- steel wire with a diameter of 6-7 mm;

- copper wire for the inductor;

- metal mesh (to hold the wire inside the case);

- adapters;

- pipes for the body (made of plastic or steel);

- high frequency inverter.

This will be enough to assemble an induction coil with your own hands, and it is she who is at the heart of the instantaneous water heater. After preparing the necessary elements you can go directly to the manufacturing process of the device:

- cut the wire into segments of 6-7 cm;

- cover the inside of the pipe with a metal mesh and fill the wire to the top;

- similarly close the pipe opening from the outside;

- wind copper wire around the plastic case at least 90 times for the coil;

- insert the structure into the heating system;

- using an inverter, connect the coil to electricity.

According to a similar algorithm, you can easily assemble an induction boiler, for which you should:

- cut blanks from a steel pipe 25 by 45 mm with a wall no thicker than 2 mm;

- weld them together, connecting them with smaller diameters;

- weld iron covers to the ends and drill holes for threaded pipes;

- make a mount for an induction stove by welding two corners on one side;

- insert the hob into the mount from the corners and connect to the mains;

- add coolant to the system and turn on the heating.

Many inductors operate at a power not higher than 2 - 2.5 kW. Such heaters are designed for a room of 20 - 25 m²

If the generator is used in a car service, you can connect it to a welding machine, but it is important to consider certain nuances:

- You need AC, not DC like an inverter. The welding machine will have to be examined for the presence of points where the voltage does not have a direct direction.

- The number of turns to a wire of a larger cross section is selected by a mathematical calculation.

- Cooling of working elements will be required.

Idea #1 - Simple Vortex Heater

First of all, get acquainted with how this heating option works and what are its advantages over alternative boiler options. All questions will be answered by the video below!

Description of the advantages and principle of operation of induction water heaters

From the materials for making homemade products you will need:

- plastic pipe with an internal diameter of not more than 50 mm;

- steel wire, with a diameter of not more than 7 mm;

- 2 adapters for connection to the heating system (pipes);

- metal mesh with small cells;

- copper enameled wire;

- high frequency inverter;

- insulating material.

Prepare all the materials, you can proceed to the installation of the induction boiler with your own hands. First of all, cut the steel wire into 5-centimeter pieces. After that, close one side of the plastic pipe with a mesh and put the chopped wire inside. The amount of material should be such that the volume of the homemade product is completely “clogged” with wire. Further, the second end is closed with a metal mesh, which will prevent the wire from spreading through the heating system.

When the filling is prepared, it is necessary to independently make connection points for a home-made whirlpool boiler to the heating main. To do this, adapters are fixed on both sides of the pipe by welding or threaded connection.

Next, you need to create the heating element of the device yourself - an induction coil. All that is needed is to wind about 90-100 turns of copper wire over the pipe. Be sure to observe the pitch between the turns so that the homemade unit works evenly. After complete winding, the ends of the copper wire are connected to the inverter and, finally, the boiler body can be assembled and insulated with a suitable thermal and electrically conductive material.

Starting a home-made heater must be done only after connecting to the coolant - water. If you turn on the inverter without water in the case, the pipe will instantly melt and all your efforts will be in vain.

That's the whole instruction for assembling an induction boiler from improvised means at home. Such a home-made product can be installed on any part of the heating system, but due to its not very attractive appearance, we recommend hiding it further from the eyes.

You can clearly see the principle of operation of the device in this photo:

As you can see, the core inside is red-hot, which is due to the influence of an electromagnetic field. We advise you to view the tests of the assembled device on a video example:

The action of the electromagnetic field