- The device and principle of operation of the boiler

- Advantages and disadvantages of the device

- Induction heater: scheme and procedure for making your own hands

- crazy hands

- Frame

- Winding

- Core

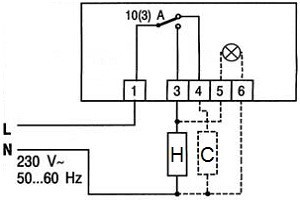

- Power converter

- Making a solid fuel boiler for long burning with your own hands

- Drawing

- materials

- Tools

- We make a boiler with our own hands

- Important notes on installation and use of the boiler

- Equipment selection rules

- Varieties of inverter heating boilers

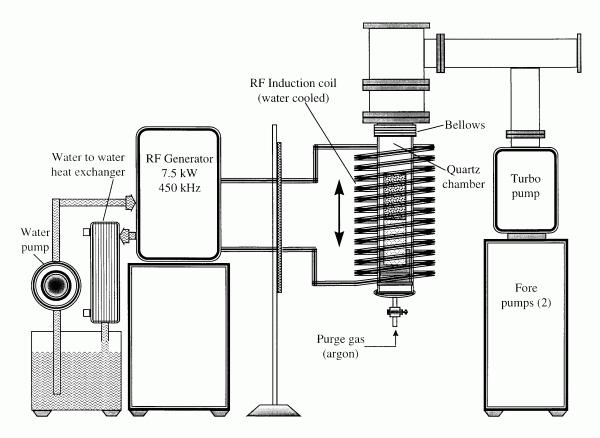

- Induction furnace from a welding inverter - a device for melting metal and for heating the coolant in the heating system

- Internal device

- How to assemble an induction boiler yourself

- Device with a welding inverter and plastic pipes

- Device with transformer

The device and principle of operation of the boiler

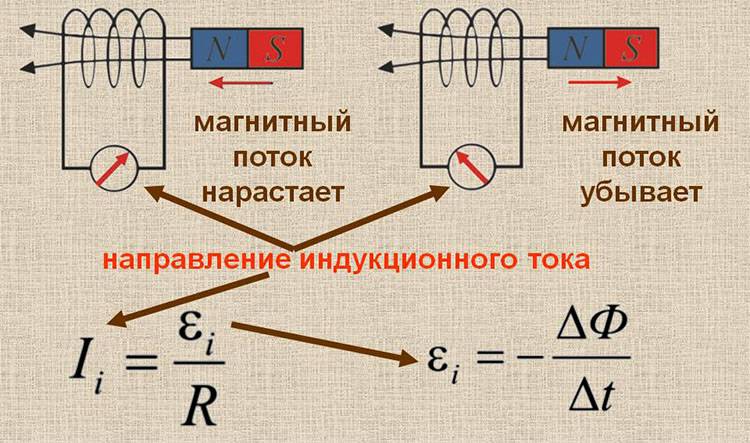

When an electric current is passed through a conductive material, heat is released in the latter, the power of which is directly proportional to the current strength and its voltage (the Joule-Lenz law). There are two ways to cause current to flow in a conductor. The first is to connect it directly to a source of electricity. We will call this method contact.

The second - contactless - was discovered by Michael Faraday at the beginning of the 19th century.The scientist found that when the parameters of the magnetic field crossing the conductor change, an electromotive force (EMF) appears in the latter. This phenomenon is called electromagnetic induction. Where there is an EMF, there will be an electric current, and hence heating, and in this case, non-contact. Such currents are called induced or eddy or Foucault currents.

Heating induction boiler - principle of operation

Electromagnetic induction can be caused in different ways. The conductor can be moved or rotated in a constant magnetic field, as is done in modern electric generators. And you can change the parameters of the magnetic field itself (the intensity and direction of the lines of force), while leaving the conductor motionless.

Such manipulations with the magnetic field became possible thanks to another discovery. As Hans-Christian Oersted found out in 1820, a wire wound in the form of a coil, when connected to a current source, turns into an electromagnet. By changing the parameters of the current (strength and direction), we will achieve a change in the parameters of the magnetic field generated by this device. In this case, an electric current will occur in the conductor located in this field, accompanied by heating.

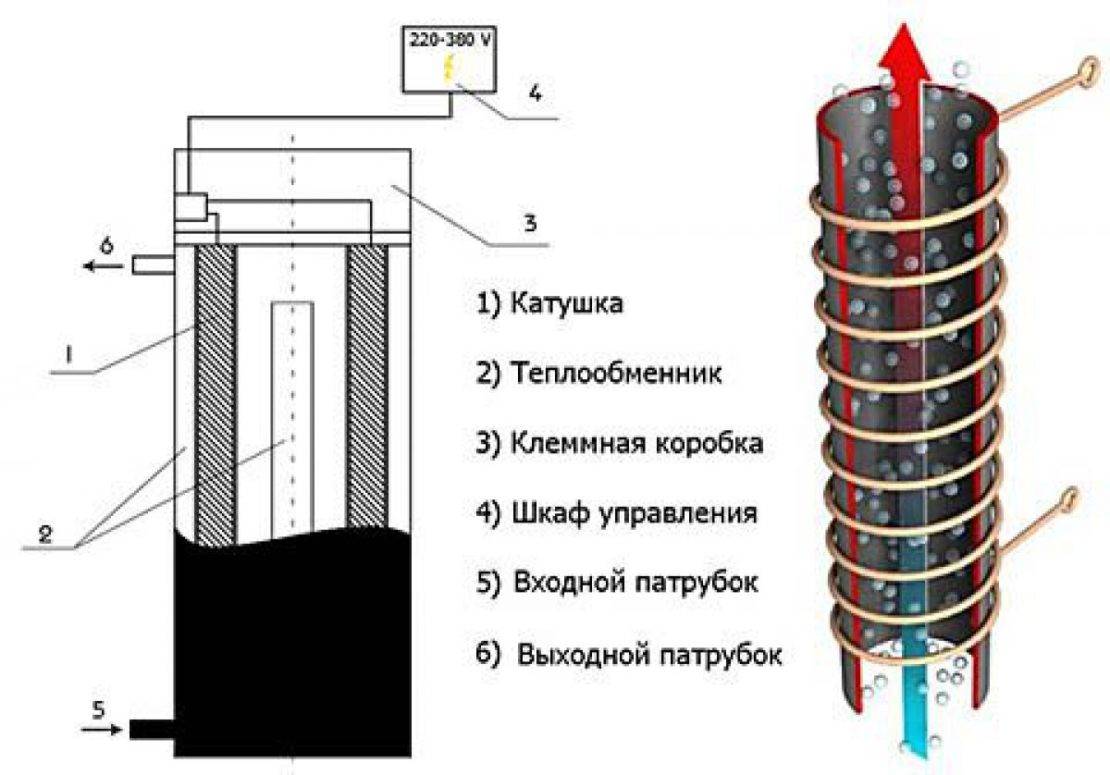

Having become acquainted with this simple theoretical material, the reader must have already imagined in general terms the device of an induction heating boiler. Indeed, it has a rather simple design: inside the shielded and heat-insulated housing there is a pipe made of a special alloy (steel can also be used, but the characteristics will be slightly worse), installed in a sleeve made of dielectric material; a copper bus is wound on the sleeve in the form of a coil, which is connected to the mains.

Boiler induction after installation

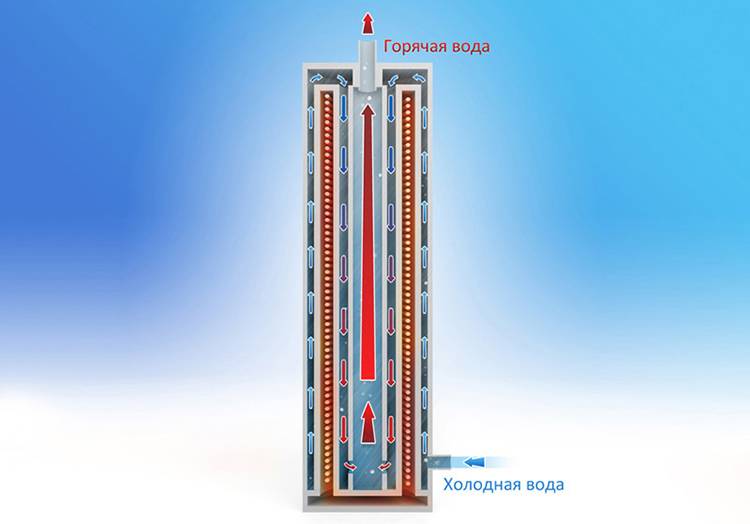

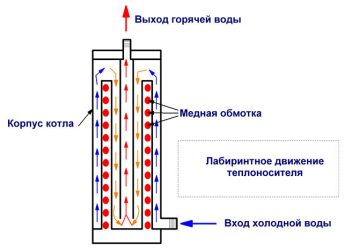

Through two pipes, the pipe cuts into the heating system, as a result of which the coolant will flow through it. An alternating current flowing through the coil will create an alternating magnetic field, which in turn will induce eddy currents in the pipe. Eddy currents will cause heating of the pipe walls and partially of the coolant throughout the entire volume enclosed inside the coil. For faster heating, several parallel tubes of smaller diameter can be installed instead of one pipe.

Readers aware of the cost of induction boilers have, of course, suspected that there was more to their design. After all, a heat generator, consisting only of a pipe and a piece of wire, cannot cost 2.5 - 4 times more than a heating element analogue. In order for the heating to be intense enough, it is necessary to pass through the coil not an ordinary current from the city network with a frequency of 50 Hz, but a high-frequency one, so the induction boiler is equipped with a rectifier and an inverter.

The rectifier turns the alternating current into direct current, then it is fed to the inverter - an electronic module consisting of a pair of key transistors and a control circuit. At the output of the inverter, the current becomes alternating again, only with a much higher frequency. Such a converter is not available in all models of induction boilers, some of them still operate at a frequency of 50 Hz. However, the use of high-frequency alternating current can significantly reduce the size of the device.

Principle of electromagnetic induction

In various descriptions, the authors point to the similarity of an induction boiler with a transformer.This is quite true: a coil of wire plays the role of a primary winding, and a pipe with a coolant plays the role of a short-circuited secondary winding and at the same time a magnetic circuit.

Why then the transformer is not heated? The fact is that the magnetic circuit of the transformer is not made of a single element, but of a multitude of plates isolated from each other. But even this measure is not able to completely prevent heating. So, for example, in the magnetic circuit of a transformer with a voltage of 110 kV in the idle mode, no less than 11 kW of heat is released.

Advantages and disadvantages of the device

The “pluses” of the vortex induction heater are numerous. This is a simple circuit for self-production, increased reliability, high efficiency, relatively low energy costs, long service life, low probability of breakdowns, etc.

The performance of the device can be significant; units of this type are successfully used in the metallurgical industry. In terms of the rate of heating of the coolant, devices of this type confidently compete with traditional electric boilers, the water temperature in the system quickly reaches the required level.

During the operation of the induction boiler, the heater vibrates slightly. This vibration shakes off limescale and other possible contaminants from the walls of the metal pipe, so such a device rarely needs to be cleaned. Of course, the heating system must be protected from these contaminants with a mechanical filter.

The induction coil heats the metal (pipe or pieces of wire) placed inside it using high frequency eddy currents, contact is not necessary

Constant contact with water also minimizes the likelihood of heater burnout, which is a fairly common problem for traditional boilers with heating elements. Despite the vibration, the boiler operates exceptionally quietly; additional noise insulation at the installation site of the device is not required.

Induction boilers are also good because they almost never leak, if only the installation of the system is done correctly. This is a very valuable quality for electric heating, as it eliminates or significantly reduces the likelihood of dangerous situations.

The absence of leaks is due to the non-contact method of transferring thermal energy to the heater. The coolant using the technology described above can be heated almost to a vapor state.

This provides sufficient thermal convection to stimulate efficient movement of the coolant through the pipes. In most cases, the heating system will not have to be equipped with a circulation pump, although it all depends on the features and layout of a particular heating system.

Sometimes a circulation pump is needed. Installing the device is relatively easy. Although this will require some skills in the installation of electrical appliances and heating pipes. But this convenient and reliable device has a number of shortcomings, which should also be considered.

For example, the boiler heats not only the coolant, but also the entire workspace surrounding it. It is necessary to allocate a separate room for such a unit and remove all foreign objects from it. For a person, a long stay in the immediate vicinity of a working boiler can also be unsafe.

Induction heaters require electricity to operate. Both homemade and factory-made equipment are connected to a household AC mains.

The device requires electricity to operate. In areas where there is no free access to this benefit of civilization, the induction boiler will be useless. Yes, and where there are frequent power outages, it will demonstrate low efficiency.

In case of careless handling of the device an explosion may occur

If the coolant is overheated, it will turn into steam. As a result, the pressure in the system will increase dramatically, which the pipes simply cannot withstand, they will burst. Therefore, for the normal operation of the system, the device should be equipped with at least a pressure gauge, and even better - an emergency shutdown device, a thermostat, etc.

All this can significantly increase the cost of a homemade induction boiler. Although the device is considered to be practically silent, this is not always the case. Some models, for various reasons, may still make some noise. For a self-made device, the likelihood of such an outcome increases.

In the design of both factory-made and home-made induction heaters, there are practically no wearing components. They last a long time and work flawlessly.

Induction heater: scheme and procedure for making your own hands

The uniqueness of a person lies in the fact that he constantly invents devices and mechanisms that greatly facilitate work in a particular area of labor or life activity.

For this, as a rule, the latest developments in the field of science are applied.

Induction heating is no exception.Recently, the principle of induction has been widely used in many areas, which can be safely attributed to:

- in metallurgy, induction heating is used to melt metals;

- in some industries, special rapid heating furnaces are used, the operation of which is based on the principle of induction;

- in the domestic area, induction heaters can be used, for example, for cooking, heating water or heating a private house. (You can read about the features of induction heating in this article).

To date, there is a great variety of induction installations of industrial type. But this does not mean that the design of such devices is very intricate.

The simplest induction heater is quite possible to make for domestic needs with your own hands. In this article, we will talk in detail about the induction heater, as well as the various ways to handmade.

Do-it-yourself induction heating units, as a rule, are usually divided into two main types:

- vortex inductor heaters (abbreviated as VIN), which are mainly used for heating water and heating a home;

- heaters, the design of which provides for the use of various types of electronic parts and assemblies.

The vortex induction heater (VIN) consists of the following structural components:

- a device that converts ordinary electricity into high-frequency current;

- an inductor, which is a kind of transformer that generates a magnetic field;

- a heat exchanger or heating element that is located inside the inductor.

The principle of operation of VIN consists of the following steps:

- the converter transmits high-frequency current to the inductor, which is presented in the form of a cylinder of copper wire;

- the inductor forms an electromagnetic field, which provokes the appearance of vortex flows;

- the heat exchanger located inside the inductor, under the influence of these vortex flows, heats up, and as a result, the coolant also heats up, which then enters the heating system in this form.

Specialist note: since the induction coil is considered the most important element of this type of heater, its manufacture must be approached quite scrupulously: copper wire must be wound in neat turns on a plastic pipe. The number of turns must be at least 100.

As can be seen from the description, the design of the VIN is not complicated enough, so you can safely make a vortex heater with your own hands.

crazy hands

Despite the heaps of misinformation, the induction scheme itself is more than entitled to life. The overestimated market value quite naturally leads to the idea of manufacturing induction do-it-yourself heating boilers. How to do it?

Frame

It should be:

- Dielectric.

- Strong enough.

- Allowing hermetically connect it to the heating circuit.

The simplest and most obvious solution is a polypropylene pipe with a diameter of 40 millimeters. Ideally, with fiber reinforcement, which will have a very positive effect on the strength qualities of the hull.

Fibre-reinforced polypropylene pipe.

Winding

In order to isolate the inductor that heats up when power is applied from thermoplastic polypropylene, it is desirable to stick several textolite strips over the case.What to glue? The simplest and most obvious solution is silicone sealant: it has acceptable adhesion to plastics and tolerates moderate heat well.

The coil itself is wound with copper enameled wire with a diameter of about 1.5 millimeters (section 2.25 mm2). The total length of the winding should be 10-15 meters. It is better to apply coils with a small constant gap.

Coil wound on textolite.

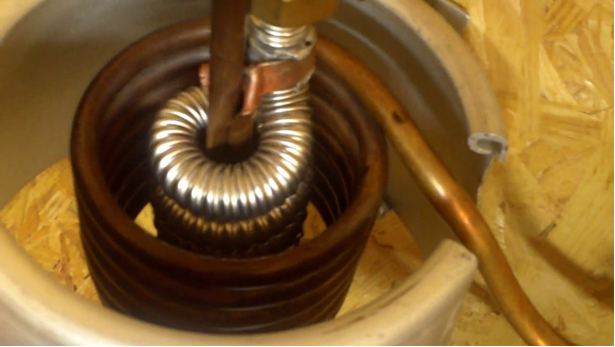

Core

What should it be?

- Conductive. Eddy currents will not be induced in the dielectric.

- ferromagnetic. A diamagnet will not interact with an electromagnetic field.

- Stainless. Corrosion in a closed heating circuit is clearly of no use to us.

Here are some possible solutions.

- Screw auger tightly fitting into the pipe. Moving along the grooves in it, the water will take away the maximum heat.

- Chopped stainless steel wire. It is not very convenient in that the makeshift boiler will have to be limited on both sides with a metal mesh.

- Hedgehogs rolled from nichrome wire, tightly inserted into the pipe.

- Finally, the simplest instruction: in the same way, metal (stainless) washcloths for dishes can be placed in the pipe.

A washcloth made of stainless shavings may well become a heating element for a boiler.

After the core has taken its place, the boiler is supplied on both sides with adapters from polypropylene with a diameter of 40 mm to DU20 or DU25 threads. They will not allow the core to fall out and will allow the boiler to be mounted in any circuit, leaving the connections collapsible.

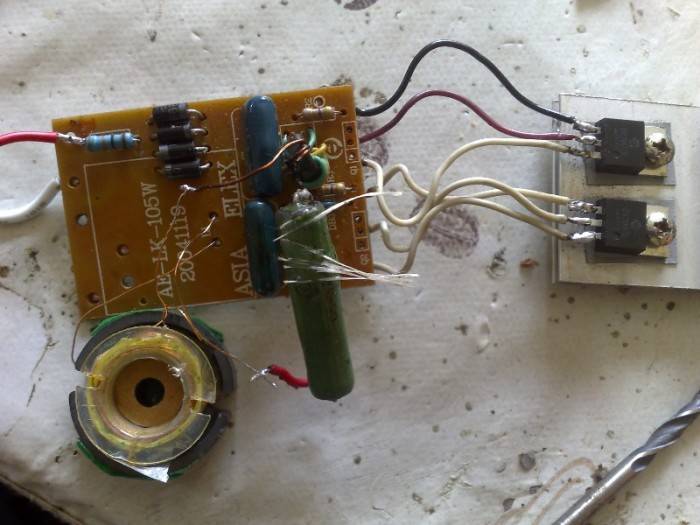

Power converter

What will happen if we simply connect the inductor wound by us to the outlet?

Let's do a simple calculation.

- The specific resistance of a copper conductor at +20C is 0.175 Ohm*mm2/m.

- With a cross section of 2.25 mm and a length of 10 meters, the total resistance of the coil will be 0.175 / 2.25 * 10 \u003d 0.7 Ohm.

- Therefore, when 220 volts is applied to the conductor, a current of 220 / 0.7 \u003d 314 A will flow through it.

The result is a little predictable: when a current is applied more than 10 times higher than the calculated one, our conductor will simply melt.

The obvious solution is to lower the supply voltage. The converter must be powerful enough to give at least 2.5 - 3 kilowatts.

A ready-made converter of such power can be a welding inverter with current control. Adjustment will not only protect the winding from overheating, but also allow you to smoothly adjust the effective power of the heating boiler. With an inverter output voltage of 80 volts, the maximum safe power for the winding temperature will be about 2 kW.

For our purposes, the most inexpensive device is suitable: the current requirement will not exceed 30 amperes.

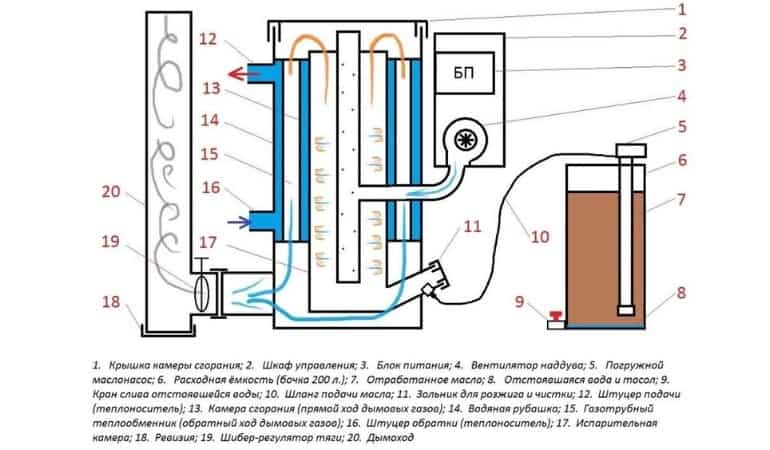

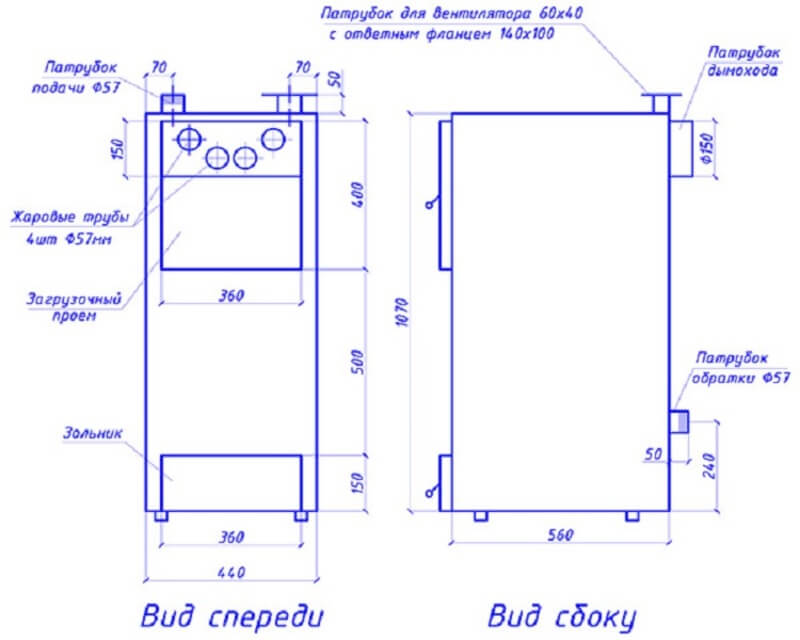

Making a solid fuel boiler for long burning with your own hands

When starting to assemble the boiler, the performer must have the skills of a locksmith, welder and electrician in order to safely complete the production and installation process. He must have protective equipment and pre-prepared materials, tools and devices.

Drawing

Solid fuel boiler drawing

Solid fuel boiler drawing

After How will the type of boiler be chosen?, you will need to have an accurate drawing of parts. It can be performed independently if the master has certain knowledge and drawing skills, you can also take it from a friend who has installed a similar heating boiler for a private house or download it from the Internet.Today, the network has enough options for proven designs of solid fuel boilers of its own manufacture.

Perhaps such a drawing will have to be finalized depending on the available consumables, especially in terms of the manufacture of the housing and the heat exchanger. The main thing that needs to be saved is the estimated thickness of the metal, the minimum allowable dimensions, the heating surface of the heat exchanger, the diameter of the hole for the exit of flue gases so that the boiler does not burn out ahead of time.

materials

Before making a boiler, a workplace is prepared, usually a workshop, and the necessary materials are stored in it. To create a solid fuel boiler, you will need the following consumables:

- steel sheet more than 5 mm for the body, pipe or used gas cylinder;

- stainless steel sheet 5 mm for fuel supply;

- steel corner, with dimensions according to the drawing;

- grate, steel or cast iron;

- water pipes, for high temperature with diameters according to the drawing;

- ash pan door;

- wire, hardware and electrodes;

- air damper or draft regulator.

Tools

The master will need a large list of tools:

- Overalls of the welder with protective equipment;

- welding inverter machine;

- grinder with discs for metal;

- electric drill with drills for metal;

- a set of locksmith tools;

- set of measuring tools.

We make a boiler with our own hands

To complete the corpus long-term solid fuel boiler burning, I chose an old gas cylinder, pre-washed it thoroughly from gas residues, if there is any doubt, I recommend purchasing an already prepared cylinder in the gas service.

Further on the cylinder cut off its upper part below the bend.After preparing the body, the boiler was made according to the following instructions:

- I cut out a circle from a 5 mm stainless steel sheet, with a diameter 20 mm less than the inner diameter of the body, so that it could later move freely along it, advancing the fuel.

- In the middle of the resulting sheet, I drilled a hole of 100 mm with a core drill.

- To this hole I welded a pipe of suitable diameter with a height of 100 mm above the boiler body. Carefully executed the seams so that they are airtight and neat. If it didn’t work out neatly, you can process it with a grinder or a file. Thus, a structure in the form of a piston will be made, which, under its own weight, will move the fuel down the combustion chamber.

- 4 metal corners are welded to the bottom of the piston to create air channels that supply air to the combustion mouth.

- I cut out another circle, but now it is 5 cm larger than the body, in the middle I cut a 100 mm hole for the piston, this part will act as a boiler cover. Dressed on a piston, it hermetically closes the boiler body, thereby creating a combustion chamber.

- The pipe at the top was equipped with a damper to regulate the volume of air supply.

- The edges of the lid were carefully processed with a file.

- I welded special handles for moving to the boiler body, and legs from a metal corner to the bottom of the body.

- At the bottom of the case, I cut out a place for the ash pan door and installed it on hinges.

- The chimney was welded in the upper part of the boiler from a pipe with a diameter of 100 mm.

- Before putting the boiler, it must be put on a flat concrete or tiled surface and connected to the chimney through the gas part.

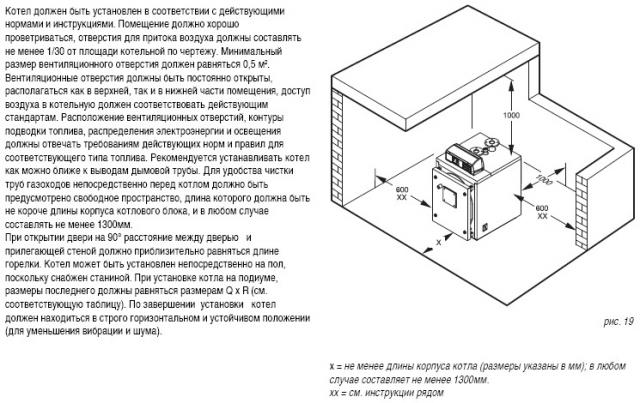

Important notes on installation and use of the boiler

induction heater

Homemade induction boilers are extremely easy to assemble, install and operate. However, before you start using this kind of heater, you need to know a few important rules, namely:

- homemade induction heating installation is intended for use only in closed-type heating systems, in which air circulation is provided by a pump;Closed heating system

- the wiring of heating systems that will work in conjunction with the considered boiler must be made of plastic or propylene pipes; Plastic pipes for heating

- to prevent the occurrence of various kinds of troubles, install the heater not close to the nearest surface, but at some distance - at least 30 cm from the walls and 80-90 cm from the ceiling and floor.

It is strongly recommended to equip the boiler nozzle with a blast valve. Through this simple device, you can, if necessary, rid the system of excess air, normalizing the pressure and ensuring optimal operating conditions.

Check valve

Thus, from inexpensive materials with the help of simple tools, you can assemble a complete installation for efficient space heating and water heating. Follow the instructions, remember the special recommendations, and very soon you will be able to enjoy the warmth in your own home.

Equipment selection rules

When choosing a model of an induction boiler, the main criteria is its power and characteristics of the heated room. It is assumed that for heating 10 sq. m. with a ceiling height of up to 3 meters, 1 kW is required.

Thus, it is enough to divide the area of the heated room by 10 and as a result, the required nominal power of the electric boiler will be obtained. For example, for a house of 100 sq. m. required induction heater 10 kW.

If there is no desire to calculate the required boiler power with high accuracy, you can use a simplified version. According to him, induction boilers with a capacity of only 3-4 kW are able to heat a room with an area of 30-40 m²

In order not to overpay for unnecessary power and not to freeze in case of its lack, it is necessary to evaluate the specific characteristics of a house or other object, including wall materials, window area, thermal insulation, etc., and choose heating equipment based on these data.

It does not hurt to ask the seller about the power factor, that is, the ratio of the active and total power of the selected model. This indicator is called the cosine phi (Cos φ) and is measured in volt-amperes. It helps to determine what proportion of the consumed electricity is spent directly on heating the coolant, and what proportion is used to generate a magnetic field.

The power factor values are in the range from 0 to 1. For well-designed induction boilers, Cos φ is 0.97-0.98 kVA, which is considered an excellent indicator, since almost all of the electricity consumed is spent on heating the working fluid.

A variety of models allows you to choose an option for use as a main or backup heat source. Powerful boilers operating on 380 V voltage are able to independently heat houses, large commercial and industrial facilities.

For operation in the country or in the garage, an effective induction boiler can be made with your own hands. With detailed guidance for assembling useful homemade products will introduce the next article.

Varieties of inverter heating boilers

Electric double-circuit boiler for water supply and home heating

There are two types of inverter-type heating equipment - industrial and domestic. Industrial boilers are impressive in size, since there are volumetric heat exchangers inside. In addition, the system for converting electric current in them is quite complicated. The same applies to the cylindrical winding. All this provides significant power of the device and the possibility of its use for industrial purposes and for space heating. When choosing power, it is taken into account that 1 kW of thermal energy is enough to heat 2 cubic meters of industrial premises.

Household inverter boilers are designed for heating private houses. They are equipped with a toroidal coil, which can be powered both from a common network and from uninterruptible power supplies. Household units are more compact in size and cost less. To select a boiler in terms of power, they follow the rule that 1 kW of thermal energy is enough to heat 10 m² of a room with a height of no more than three meters.

Induction furnace from a welding inverter - a device for melting metal and for heating the coolant in the heating system

The idea of using such an induction plant as a metal melting furnace in many ways allows it to be used as a heating boiler for a small room.

The idea of using such an induction plant as a metal melting furnace in many ways allows it to be used as a heating boiler for a small room.

The advantage of this application is:

- In contrast to metal melting, in the presence of a constantly circulating coolant, the system is not subject to overheating;

- Constant vibration in the electromagnetic field does not allow sediments to settle on the walls of the heating chamber, narrowing the lumen;

- The principle diagram without threaded connections with gaskets and couplings eliminates the possibility of leakage;

- The installation is almost silent, unlike other types of heating boilers;

- The installation itself, without traditional heating elements, has a longer service life and high reliability;

- There are no emissions of combustion products, the risk of poisoning by fuel combustion products is reduced to zero.

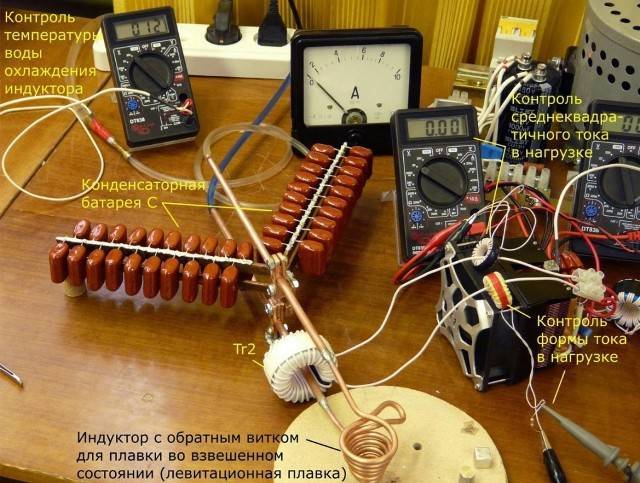

The practical component of the process of creating equipment for space heating using an induction furnace from an inverter welding machine consists of the following steps.

- For the manufacture of the body, a plastic pipe with thick walls is selected and designed for use in pipelines with high temperature and high pressure;

- In order for the metal filler to be constantly in the heater cavity, two covers with a mesh are made so that the filler does not fall out through it.

- A steel wire with a diameter of 5-8 mm is selected as a filler, and cut into pieces 50-70 mm long.

- The pipe body is filled with pieces of wire and connected to the system.

The principle of operation of this device is as follows:

- An inductor made of copper wire with a diameter of 2-3 mm with 90 - 110 turns is installed outside the housing from a plastic pipe;

- The body is filled with coolant;

- When the inverter is turned on, current flows to the inductor;

- In the coil of the inductor, vortex flows are formed, which begin to act on the crystal lattice of the metal inside the case;

- Pieces of metal wire begin to heat up and heat the coolant;

- The coolant flow after heating begins to move, the heated coolant is replaced by a cold one.

Such a schematic diagram of a heating system based on an induction heating element in practical execution has one significant drawback - the coolant must be constantly pushed through by pressure. For this, a circulation pump must be included in the system. In addition, it is recommended to install an additional temperature sensor, this will allow you to control the coolant and protect overheating boiler.

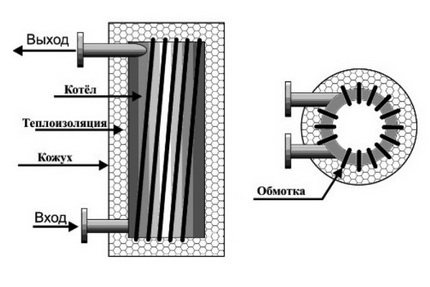

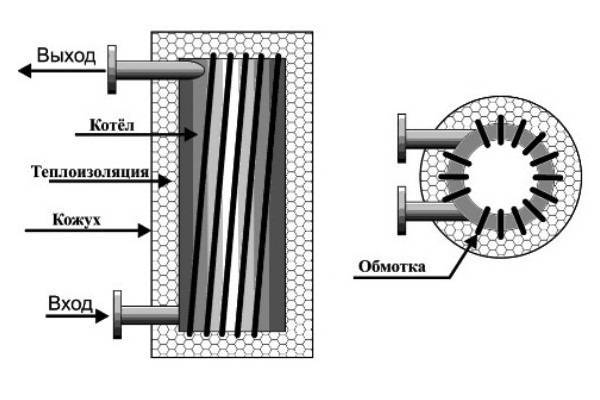

Internal device

Structurally, the induction electric heating boiler is a transformer enclosed in a welded metal shell. Under the casing is a heat-insulating layer. The coil is located in a separate compartment, hermetically isolated from the working space. Such placement is safe, because it completely eliminates contact with the coolant. The core consists of thin steel tubes with a toroidal winding.

Please note that an induction hob heating boiler does not have heating elements, which is fundamentally different from traditional heat generators equipped with heating elements. Its design features ensure uninterrupted, highly efficient operation of the heating system for a very long period of time.

How to assemble an induction boiler yourself

The modern market for heating devices represents a large selection of different models of induction heaters for both domestic and industrial use. Despite the fact that today such equipment has not reached the level of widespread use in heating systems, its cost is high. Price for household boilers start from 25,000 rubles, and for industrial ones - from 100,000 rubles.

To save money, make induction heater can be hands. Even a non-specialist can do such work.

Device with a welding inverter and plastic pipes

All materials and components that are used for assembly are available and are often at hand. What is needed for this:

- wire rod or stainless steel wire (diameter up to 0.7 cm);

- copper wire;

- metal grid;

- a fragment of a plastic pipe with thick walls for the heater body (inside diameter 5 cm);

- welding machine;

- adapters for mounting the boiler to the heating system;

- tools;

- pump to circulate water.

stainless steel wire steel should be cut into pieces 0.5-0.7 cm long. Fill the plastic pipe tightly with them and close it on both sides. It should not have free space. A metal mesh is installed at the bottom of the tube, which allows you to keep the steel particles inside.

Next, you should make the main heating component - an induction coil. A copper pipe is wound onto a plastic pipe. wire. It is necessary to make at least 100 neat turns at the same distance from each other. Then the induction coil is connected to the individual heating system. The boiler is installed in any part of the pipeline.To pump water, you need to build a pump.

A home-made device is connected with an external copper winding to the inverter. Mandatory electrical and thermal insulation works boiler. All open areas are covered with special material. Basalt wool is used for insulation. This is necessary in order to heat the pipe without losing heat energy to the air.

Device with transformer

This option is easier to assemble than the previous one. What you need to make your own hands:

- three-phase transformer with the possibility of mounting;

- welding machine;

- copper winding.

It is necessary to insert the pipes one into the other, weld. The sectional design should resemble the shape of a donut. It performs two tasks at the same time - a heating element and a conductor. Then the heater body is wrapped with copper wire and connected to the transformer. To prevent heat loss during operation, a protective casing can be built on the boiler.

Induction heating is a good alternative to standard heating systems. Its efficiency is about 97% efficiency. Such systems are economical, operate on any liquid, operate silently, do not emit harmful substances.

If the assembly rules are followed, the boilers are safe to operate. They are durable. But if any element becomes unusable, replacing it will not be difficult. All materials are easily replaceable and available.

![A simple DIY induction boiler [life hack]](https://fix.housecope.com/wp-content/uploads/7/8/d/78d32b8bd71848da4ba2ae9798a1557f.jpeg)