- Some features of induction boilers

- Advantages and disadvantages

- Advantages and disadvantages

- Is it true that induction heaters are energy efficient?

- The device and principle of operation of the induction boiler

- What should be guided

- gas boilers

- Electric boilers

- Solid fuel boilers

- Oil boilers

- Induction water heater

- The mechanism of action of heat supply from an induction hob

- Comparison of a heating element and an induction boiler of the same power

- Types of induction boilers

- How to choose a heating device

- Water softening and scale

Some features of induction boilers

We have already said that electric heating is expensive. And consumers need to be prepared for high energy costs. But if it is impossible to build heating on a boiler of a different type, then this will have to be put up with. We note one more fact - with the purchase of an induction boiler, it will not work to save on heating. The thing is that they have no economy of 20-30% compared to heating elements. Therefore, the costs will be the same - very high.

In addition, induction boilers cannot boast of an efficiency of 100% - this simply cannot be. If any manufacturer claims otherwise, then he shamelessly lies.Moreover, some frankly lie about the above efficiency - do not fall for these marketing tricks.

Manufacturers resort to many other tricks. For example, they confidently state that their equipment does not make noise. We dispel the myth - heating elements also work silently. As for compactness, it's true. But the TEN models do not differ in large dimensions.

Advantages and disadvantages

The positive qualities of electric boilers include:

- complete noiselessness during operation;

- there are no odors, fuel ignition hazards or other hazards;

- boilers can be repaired, and the costs for it are much less than for the restoration of other types of units;

- the dimensions of the boilers are small and allow them to be placed at any convenient point in the heating circuit;

- there is no need to allocate a separate room;

- no chimney, passage nodes through walls or ceilings are needed.

The disadvantages of electric boilers are considered to be:

- unit power of more than 5 kW requires the use of a 380 V connection, which is not easy to obtain;

- complete dependence on electricity;

- to connect, you need a separate line with high-quality wiring and circuit breakers;

- The efficiency of electric boilers is relatively low;

- electricity tariffs are high and vary by region.

The efficiency of electric boilers is low, but induction models are an exception - their coefficient reaches 98%.

Advantages and disadvantages

Heating devices such as induction boilers, like other similar units, have their pros and cons. Both their positive and negative sides must be familiarized in detail if you are going to install such equipment in your home.To begin with, let's consider what are good induction varieties of heating boilers.

The main advantage of such units is their reliability. If such products have automation, then they can operate offline, and the owners do not have to constantly monitor them. At the same time, only the absence of a heat carrier can lead to a breakdown of the device - then the core case in the system can overheat too much and, as a result, melt.

Induction boilers are distinguished by high efficiency (over 90%). Of course, the specific value mainly depends on the design of the heat exchanger in the unit and other structural features of a particular model. The advantages of such units include the fact that over the years their efficiency does not fall, so even after a long time you will not notice that your heating system has become less efficient.

Induction heating equipment is not subject to breakdowns - it does not require frequent and expensive repairs. To install such a unit, it is not necessary to additionally build ventilation or a chimney, which often costs users a tidy sum.

Serves such equipment for a long time. If you use these types of heating boilers correctly, they can last more than 30 years, since there is nothing to burn in them, because the inductor is hermetically sealed in the housing and is reliably isolated from contact with the heat carrier. In addition, the coils are not twisted tightly and are filled with a special protective compound. For this reason, the possibility of damage to the coils is minimized.

The liquid in such systems is heated to high temperatures. The minimum value is 35 degrees Celsius.Such units are installed quite simply. Household models are a piece of pipe of small size, which is sealed on both sides. At the same time, there are 2 fittings on the body, which are necessary for connecting the coolant supply and return. There is also a cord to connect the automation. Connecting such systems is not difficult - you can cope with this simple work without the involvement of specialists.

Induction heating systems are characterized by high efficiency. They are characterized by low inertia, so the heating of the heat carrier starts very quickly (immediately after the system is started). Just as quickly, such boilers turn off. In such an apparatus, the spent coolant does not need to be changed too often. It is enough to do this once every 10 years.

Such types of heating devices, as a rule, do not leak, since they do not have detachable internal connections. These units are capable of operating both at direct current and at low voltage in the network. According to experts, harmful scale does not accumulate on the heating element in such devices. This is due to the vibration of the core (because of this, excess particles cannot be deposited on it). In addition, scale will not collect due to the temperature regime of the coolant (not higher than 90 degrees Celsius) and the isolation of the system, in which a limited number of carriers may be present.

Now it's time to get acquainted with their cons:

- First of all, a number of disadvantages of such devices include their high price. They are many times more expensive than devices with heating elements. However, the high cost is due to the presence of automation.

- Usually these devices have an impressive weight.For example, a boiler with a diameter of 12 cm and a height of 45 cm will weigh as much as 23 kg.

- These boilers are suitable exclusively for closed heating systems.

- Such units can create wave interference at a short distance. For this reason, experts advise installing them as far as possible from any household appliances.

- If you are going to install an induction boiler in a large house with 2-3 floors, then you will have to additionally mount a high-power circulation pump - this is necessary for the device to work stably.

- Induction units are volatile. If the electricity in your home is turned off, then the heating will also stop working. Of course, such a problem is solvable - you can buy diesel generators, but this will be an additional waste.

Is it true that induction heaters are energy efficient?

The profitability of this type of boiler is achieved only by an initial head start of 5-15 minutes of heating speed. And that, in comparison with heating elements. Because the most economical among electric heating systems is “warm floor”. All arguments about 99 or even 100% efficiency are cunning and counting on mass illiteracy. All electric heaters have the same efficiency.

And the statement that part of the heat from the system is dissipated without reaching the coolant is equally true for heating elements and induction boilers. Given the high cost of the boiler and the mandatory additional equipment for the induction system for a separate amount, savings of 30-50% on electricity are nothing more than a legend and a trade trick.

Durability.Like everything in the world, the core is also subject to destruction, but it will do this, unlike the heating element, much longer - 30 years. The remaining components also have a good margin of safety. Manufacturers give a 10-year warranty on the service of an induction boiler, and they do not lie. If it is equipped with high-quality European electronic controllers, it will serve freely up to 30-40 years.

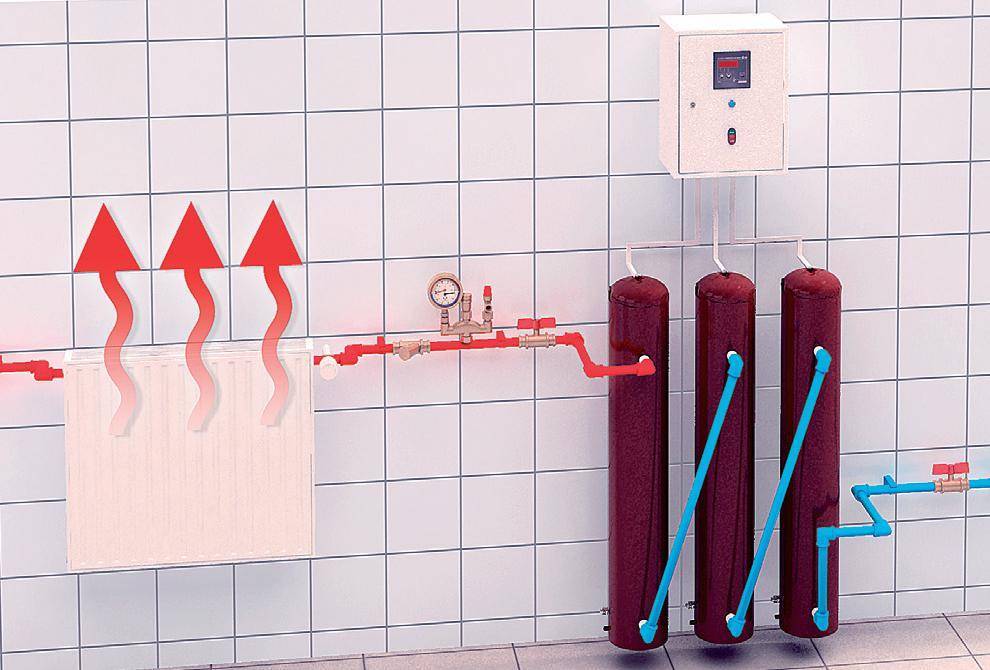

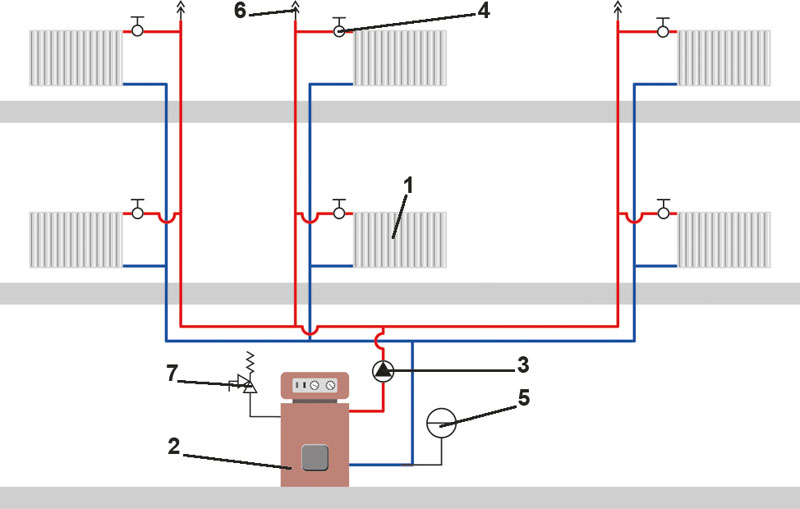

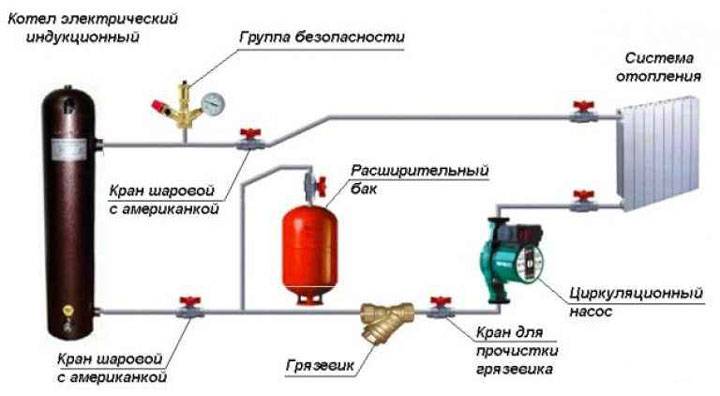

Photo 2. Induction boiler connected to a closed heating system. It is additionally equipped with a controller, an expansion tank and a pump.

Given the above, the owner of an induction boiler will find savings compared to heating elements only in the long term - after five years of using the system. But, compared to the initial installation costs, it may not be significant.

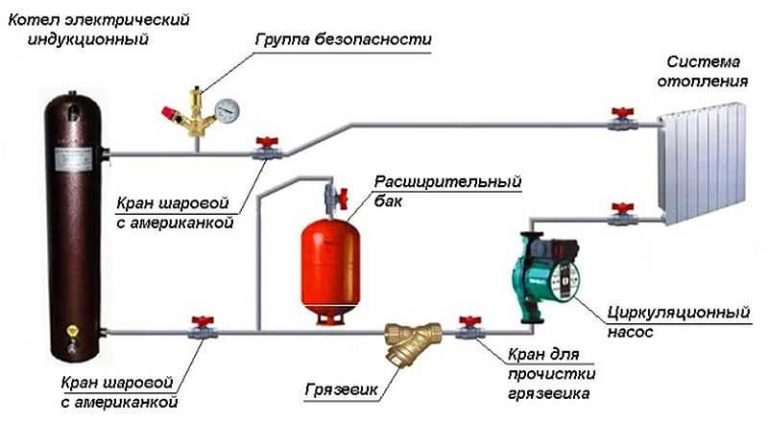

The device and principle of operation of the induction boiler

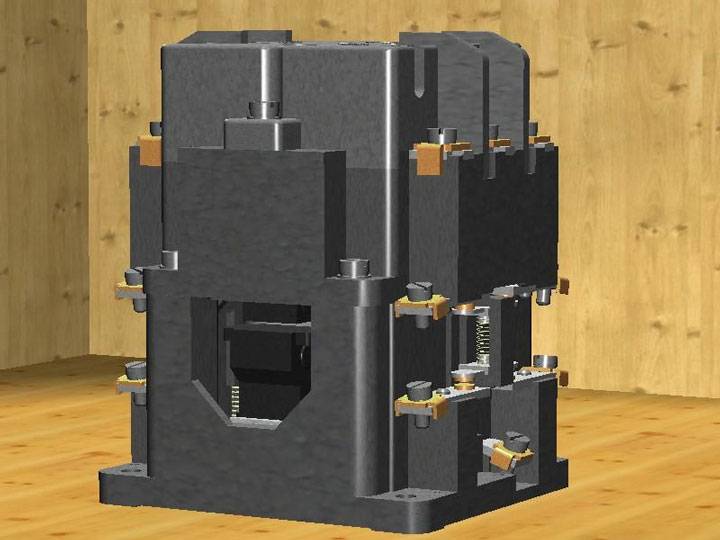

The induction boiler consists of the main elements:

- Corps;

- induction coil;

- core.

The principle of operation of induction units is extremely simple: passing through the coil, an electric current generates a strong electromagnetic field. In accordance with the Joule-Lenz law, under the influence of electromagnetic waves, the tubular core is intensely heated, giving off thermal energy to the coolant circulating inside it.

The performance of such systems is evidenced by the fact that, since the 1930s, the principle of electromagnetic heating has been successfully applied in metal-smelting furnaces.

What should be guided

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we distinguish several types of boilers.

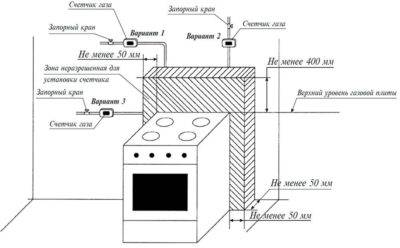

gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive, it is available to a wide range of consumers. What are gas heating boilers? They differ from each other depending on what type of burner - atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products leave through a special pipe with the help of a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall mounted gas boiler

As for the method of placing the boilers, the choice of a heating boiler assumes the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to conduct hot water, then you can install modern wall-mounted heating boilers. So you will not need to install a boiler for heating water, and this is a financial savings. Also, in the case of wall-mounted models, combustion products can be removed directly to the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall models is their dependence on electrical energy.

Electric boilers

Next, consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. Such types of heating boilers are small in size, so they can be used in small houses, as well as in cottages from 100 sq.m. All combustion products will be harmless from an environmental point of view.And the installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and prices for it are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as spare appliances for heating.

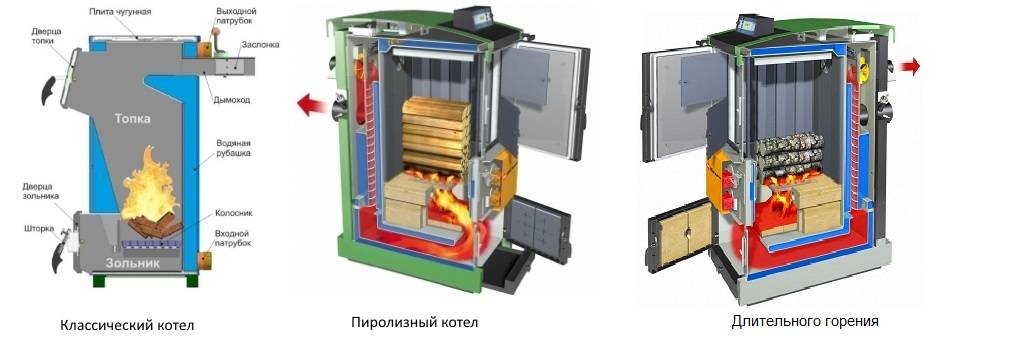

Solid fuel boilers

Now it's time to consider what solid fuel heating boilers are. Such boilers are considered the most ancient, such a system has been used for space heating for a long time. And the reason for this is simple - fuel for such devices is available, it can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to work offline.

Gas generating solid fuel boiler

Modification of such boilers are gas generating devices. Such a boiler differs in that it is possible to control the combustion process, and the performance is regulated within 30-100 percent. When you think about how to choose a heating boiler, you should know that the fuel used by such boilers is firewood, their humidity should not be less than 30%. Gas-fired boilers depend on the supply of electrical energy. But they also have advantages in comparison with solid propellant ones. They have a high efficiency, which is twice as high as solid fuel appliances. And from the point of view of environmental pollution, they are environmentally friendly, since the combustion products will not enter the chimney, but will serve to form gas.

The rating of heating boilers shows that single-circuit gas-generating boilers cannot be used to heat water. And if we consider automation, then it is great. You can often find programmers on such devices - they regulate the temperature of the heat carrier and give signals if there is an emergency danger.

Gas-fired boilers in a private house are an expensive pleasure. After all, the cost of a heating boiler is high.

Oil boilers

Now let's look at liquid fuel boilers. As a working resource, such devices use diesel fuel. For the operation of such boilers, additional components will be needed - fuel tanks and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this, replaceable burners or special burners are used, which are capable of operating on two types of fuel.

Oil boiler

Induction water heater

Induction water heaters have a housing and an original electric inductor (transformer) inside it, and its secondary winding is the metal pipe itself with water, in the form of a short-circuited coil.

As a result of the flow of significant electrical currents in it, from the electrical voltage inductively induced in it, this pipe is intensively heated and heats up the water in it with its heat.

In a nutshell, how does an induction heater work?

this is a step-down transformer that is installed in a pipe

At first I decided that if the word “induction” is present in the name, then heating occurs with high-frequency currents such as in a microwave, it turned out that it was not.

There is no high frequency at all, powered by a 220/380 volt power frequency 50 Hertz.

The technology is actually very simple - there is an ordinary coil in a shielded pipe - this is, as it were, the primary winding of a transformer, if we draw an analogy with a transformer.

The role of the secondary winding, and at the same time the magnetic circuit, is performed by a metal heating pipe!

The mechanism of action of heat supply from an induction hob

The design of the boiler is based on electric inductors, they include 2 short-circuited windings. The internal winding modifies the incoming electrical energy into eddy currents. In the middle of the unit, an electric field appears, which then enters the second turn.

The secondary component acts as the heating element of the heat supply unit and the boiler body.

It transfers the energy that has appeared to the heat carrier of the system for heating. In the role of heat carriers that are intended for such boilers, they use specialized oil, filtered water or non-freezing liquid.

The internal winding of the heater is affected by electrical energy, which contributes to the appearance of voltage and the formation of eddy currents. The received energy is transferred to the secondary winding, after which the core is heated. When the heating of the entire surface of the heat carrier has occurred, it will transfer the heat flow to the heating devices.

Comparison of a heating element and an induction boiler of the same power

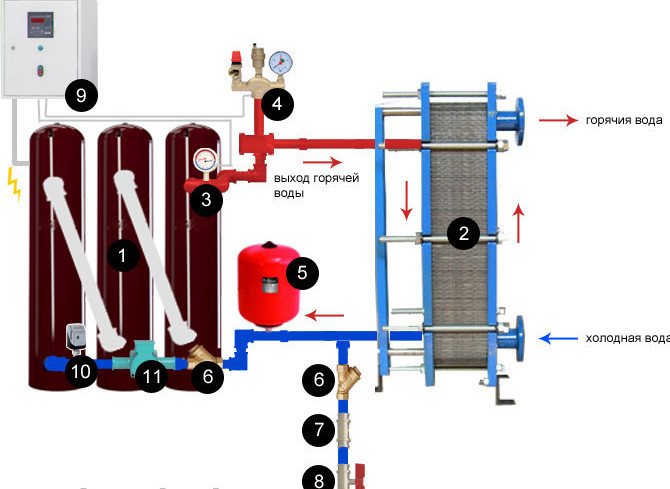

But the most important point for comparison is, of course, the final cost of products and how much it will cost to maintain one or another heating system.

But the most important point for comparison is, of course, the final cost of products and how much it will cost to maintain one or another heating system.

Let's really compare two models of approximately the same power:

induction 25 kW (price ~ 85 thousand rubles at the end of 2017)

heating element 24 kW (price ~ 46 thousand rubles at the end of 2017)

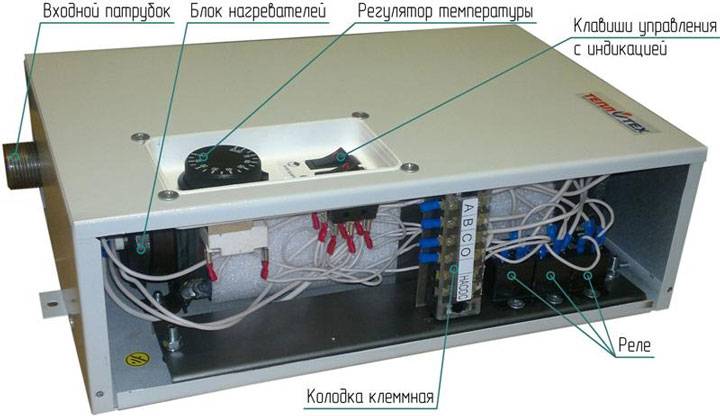

For the first model, the package includes:

pump

flow sensor

security group

control cabinet

temperature sensor

shut-off control valves

The weight of an instance per 25 kW is about 80 kg.

The weight of an instance per 25 kW is about 80 kg.

What is the difference between a high-quality heating element boiler? First, it weighs almost 40kg less.

In addition, all the electronic filling is hidden inside it. This means that there is no need for a bulky control cabinet that takes up additional space.

In addition to the above equipment for the induction boiler, which is also initially present in the heating element, it includes additional functional units:

automatic power selection in several steps of 2kW

This is good because the boiler itself can choose the power at which it currently needs to work. The temperature outside changes smoothly, and with a large number of steps, you can flexibly select the required power to avoid frequent on-off.

You will observe with your own eyes the constant blinking of light during such switching. And yet, powerful electrical contactors with their pops and clicks can really make you jump every time in surprise.

In heating elements, quiet relays are installed, or a contactor of compact dimensions, you can hear their work only when you are directly near the unit.

weather-compensated automation

It is she who is engaged in switching steps. As soon as the boiler “sees” that the heating rate is going too fast, it drops one step, then another, and so on. If the temperature is less than the set one, it adds this step.

In this case, not all 24 kW are turned on at once, but a gradual, smooth increase in power from the minimum value. You can't see it with your eyes, by blinking the lights.

thermal protection for overheating and freezing

low water pressure sensor

If your system is leaky and there is a leak somewhere, then the boiler simply will not turn on. In induction, the heating of the core will continue.

error indication

You can always approach the boiler and very quickly determine the malfunction due to which it “got up” by the error code.

expansion tank

mechanical or electronic pressure gauges

possibility of connecting a boiler

Moreover, this possibility is already automated. All you have to do is set the temperature of the water, and the boiler will do the rest.

Working at 40 degrees and switching to the boiler, it will independently accelerate to 80C, heat the titanium and then return to the previous mode.

If the same automation is included in induction boilers, then at P = 25 kW they would cost not 85 thousand, but a hundred thousand more. Indeed, in the original version, all control in them is carried out according to the temperature of the duct.

The question of whether to buy or not to buy an induction boiler, or to make a choice in favor of a heating element, of course, everyone decides for himself. But many are becoming more and more convinced that an induction boiler is not the heating unit that should be installed in individual private houses and cottages.

Of course, it is impossible to do without induction heating in some structures, production and work areas. For example, heating the environment in chemical production, which must remain sterile.

Therefore, it is better to leave this type of heating there, and do not drag it to your home. There is no need to suffer with a complex, heavy, overall unit, if you can get by with other very elegant solutions.

Types of induction boilers

Induction heating boilers differ in the frequency of the voltage applied to the working heating element. Standard modifications of the SAV are connected to a household AC network with a frequency of 50 Hz and a voltage of 220 or 380 V (for products with increased power).

Vortex-type equipment (VIN) is equipped with a converter that generates high-frequency alternating current (10,000 Hz and higher). The use of high-frequency currents makes it possible to reduce the weight of the equipment, but negatively affects the cost of products.

An additional difference is the material of the heat exchanger. Budget models are equipped with steel nodes, voltage is applied to the winding mounted on the heating element.

Currents are induced in metal elements, which provide heating of the parts and the liquid inside. The design of the boiler provides for an adjustable pump driven by an electric motor, which circulates the coolant through the heating circuit.

Vortex type boilers. Source

Vortex type boilers. Source

Swirl-type boilers are used to heat the coolant of a pipeline made of ferromagnetic material. A ferromagnetic circuit is used as a magnetic circuit and a secondary winding, as well as structural elements of the product case.

The set of equipment includes a microprocessor control unit, a circulation pump is provided for pumping the working fluid. The additional pump is designed to circulate the heat carrier through the pipes of the heating circuit installed in the building.

How to choose a heating device

When choosing an inverter boiler for heating, it is worth considering many factors.

First of all, you need to pay attention to its power. Throughout the life of the boiler, this parameter remains unchanged. It is taken into account that 60 W is needed to heat 1 m2

Making the calculation is very easy. It is necessary to add the area of \u200b\u200ball rooms and multiply by the specified number. If the house is not insulated, then it is better to choose more powerful models, as there will be significant heat losses.

It is taken into account that 60 watts are needed to heat 1 m2. Making the calculation is very easy. It is necessary to add the area of \u200b\u200ball rooms and multiply by the specified number. If the house is not insulated, then it is better to choose more powerful models, as there will be significant heat losses.

An important factor is the features of the operation of the house. If it is used only for temporary residence, then there is no need to constantly maintain the temperature in the premises at a given level. In such cases, you can completely get by with a unit with a power of not more than 6 kW.

When choosing, pay attention to the configuration of the boiler. Convenient is the presence of an electronic program unit with a diode thermostat. With it, you can set the unit to work for several days and even a week in advance

In addition, in the presence of such a unit, it is possible to control the system from a distance.This makes it possible to pre-heat the house before arrival.

With it, you can set the unit to work for several days and even a week in advance. In addition, in the presence of such a unit, it is possible to control the system from a distance. This makes it possible to preheat the house before arrival.

An important parameter is the thickness of the walls of the core. The resistance of the element to corrosion will depend on this. Thus, the thicker the walls, the higher the protection. These are the main parameters that should be considered when choosing a device and constructing a heating system. If the price is not acceptable, then you can use analogues or build a boiler yourself. To do this, you just need to have certain knowledge and skills.

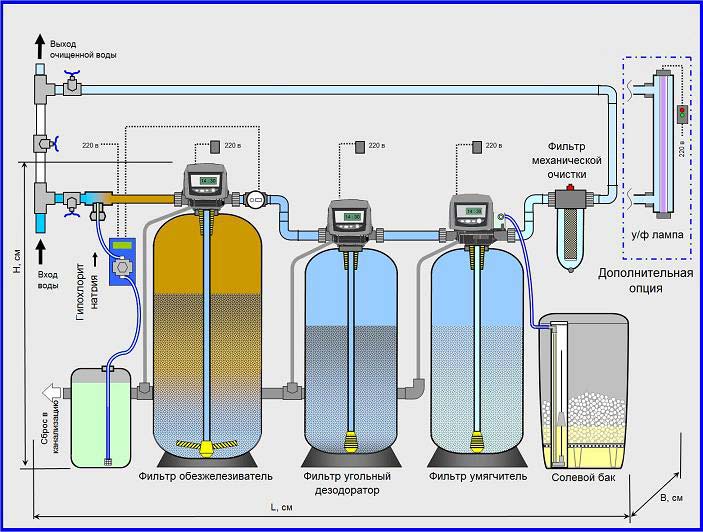

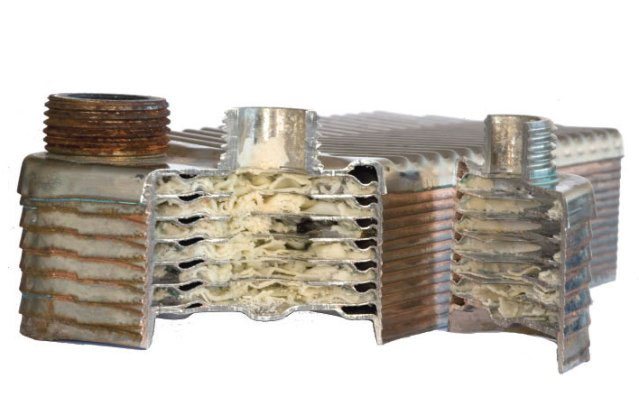

Water softening and scale

The third point - with poor water preparation and heavy load, scale forms on the surface of the heating elements. In induction, scale is excluded.

Firstly, the very scale, as many imagine it, based on the example with a kettle, is not in heating systems. Since the liquid does not boil there.

But deposits, of course, are always and everywhere. Moreover, in any systems - gas, heating, wood, induction, etc.

"scale" in a gas boiler

These are exactly the impurities that are present in any water. Pour water into a clean glass, let it evaporate and you will see a thin film on the walls.

Therefore, the presence of an impurity or its absence is not a disadvantage or an advantage, but a given of any heating system.