- The history of the production of ZIL refrigerators

- Refrigerator ZIL 64

- Refrigerator repair ZIL 64

- ALUMINUM WINDING: PLUSES AND MINUSES

- "ZIL-63" KSh-260/26**

- The legend of the automotive industry - ZIS 5 "Zakhar Ivanovich"

- Device Options

- Reasons for the popularity of ZiLs

- "OCEAN" COMES FROM THE FAR EAST

- Who "wels" on our extravagance

- Start of car production.

- ADVENTURES OF ITALIANS IN SARATOV

- The best compressor unit

- Refrigerators "ZIL" - ups and downs ... Part I

- Brand "Saratov"

- ATLANTS HOLD THE MARKET?

- Brand "Crystal"

- Video about legendary refrigerators

The history of the production of ZIL refrigerators

The starting point for the start of the production of domestic freon-powered compression refrigerators is the Decree of September 07, 1949, by order of which a design bureau was created at the Moscow plant named after J.V. Stalin.

It was here that drawings were developed and prepared for the manufacture of small 85-liter Saratov units and more capacious 165-liter ZiLs.

For the first time, the famous refrigerators left the assembly line in April 1950, but since their "native" automobile plant was named after Stalin, the logo of the devices was formed from the abbreviation "ZiS-Moscow", and since 1956, when the enterprise was renamed " Plant named after Likhachev, its products became the ZIL brand

The prototype for the first refrigerator "ZiS-Moscow" was a sample of pre-war production in the United States. One of the "premier" devices, by the way, was presented to Brezhnev and was highly appreciated by him. But in the difficult post-war period, the people were not able to purchase expensive equipment - at first, the plant had serious sales problems, but after a couple of five-year plans, the line for production was scheduled for many years to come.

More than 5 million ZiLs were assembled at the Likhachev plant, but after the collapse of the Union, foreign manufacturers appeared on the market, with which domestic equipment could not compete due to interruptions in funding for new developments and incorrect marketing policies. In order to stay afloat, the management began to reduce the quality of products, “turn a blind eye” to various defects, which immediately affected consumer demand.

Today, only a few buildings remain on the territory of the former multi-kilometer industrial zone of the enterprise, which were reconstructed and turned into a car center with showrooms

In 2016, the legendary plant named after Likhachev celebrated its centenary, but there is no talk of restoring its production facilities - most of the workshops were demolished for the construction of a new residential microdistrict.

Refrigerator ZIL 64

The developers of the ZIL 64 ksh devices, manufactured in 1988, pleased the owners with significant technical improvements.

- Automatic defrosting.

- The presence of a pipeline for the removal of melt water from the chambers.

- Increased temperature up to -18 degrees.

- Larger freezer.

- Improved insulating properties.

- Improved internal layout.

- Equipped with wheels for moving.

- Hanging the door.

A positive quality is the automatic defrosting and removal of moisture in the freezer compartment.

The disadvantage of the model is the manual control of defrosting when the ambient temperature rises above + 30 degrees. The thermostat must be set to 0. The device turns on only after complete defrosting in automatic mode.

Refrigerator repair ZIL 64

A characteristic feature of the ZIL brand is the durability of the nodes. A lot of old equipment works without significant repairs for 30-50 years. In most cases, relays fail. Replacement is not difficult. Dismantling old models of equipment is very easy. On the back wall of the cabinet below, it is necessary to unscrew the condenser (2 bolts) and the entire unit (4 bolts). Then pull the mechanism towards you, release the relay from the spring mount and two wires. Pull the part out of the slots.

ALUMINUM WINDING: PLUSES AND MINUSES

Aluminum is a light and soft metal, it also has good conductivity compared to other metals. But in addition to the conductivity of electric current, aluminum is also characterized by increased thermal conductivity, that is, it heats up much faster and stronger than copper, and this negatively affects the output power of the electric generator. One of the features of aluminum is its increased resistance to corrosion. In contact with air, aluminum oxide immediately forms, which covers the wire with a thin layer. This quality is indispensable in the manufacture of cases of various units, but, unfortunately, it has a negative effect in the winding. The fact is that the oxide film makes it difficult to solder, so the connected aluminum parts are not very strong and not resistant to wear.Have you noticed how easy it is to break an aluminum wire by twisting it in your hands? The aluminum winding will also crack easily. So, in the advantages of aluminum winding, we have only cheap cost and light weight.

And the cons should be counted:

1. Current conductivity is lower than that of copper. 2. Rapid heating (generator output drops when loaded). 3. Poor strength (generator resource decreases). 4. Cools down slowly.

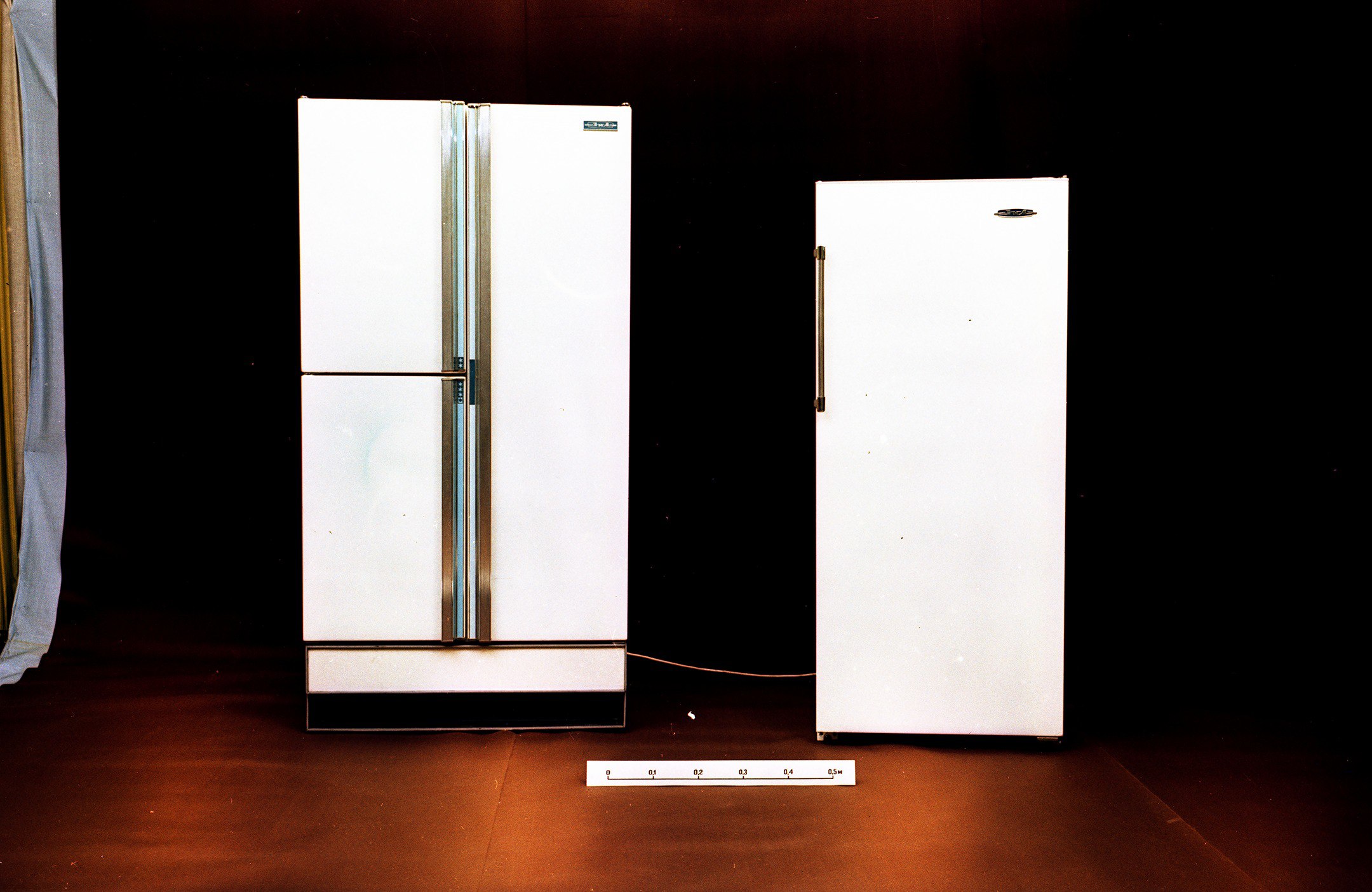

"ZIL-63" KSh-260/26**

In the seventies, buyers had the opportunity to purchase more efficient and convenient refrigerators of the second generation of the competing brands "Minsk" and "Oka", manufactured using new technologies. Demand for the products of the ZIL plant began to fall, prompting the plant management to think about creating a three-chamber refrigerator with increased comfort and a volume of 400 liters.

Soviet specialists and American colleagues began to develop a new refrigerator model, but already at the initial stage of work it became clear that the domestic industry would not be able to quickly reorganize to produce the planned model. In this situation, the management decided to start production of the transitional model of refrigerators "ZIL-63" KSh-260/26 **. The manufacturer eliminated most of the shortcomings, which contributed to another increase in demand for the plant's products. Moscow buyers have created a queue for five years ahead. The minimum cost of organizing production paid off in less than three months. Despite the huge profit of the enterprise, the management of the plant did not want to invest in the modernization of the refrigerator model being produced, arguing that there was sufficient demand for products and the absence of the need to increase the cost of products.The production of the ZIL-63 model took the working capacity of the enterprise for 12 years. Buyers appreciated the following advantages in the ZIL-63 KSh-260/26 refrigerator:

- The adjustable height of the shelves made it possible to place dishes of various sizes for cooling. Simplified cleaning process in the refrigerator.

- In the kit there were special containers for products.

- Added the ability to change the direction of the door opening and the door opening limiter.

- Transport rollers appeared on the bottom wall of the refrigerator.

In the transitional model, some shortcomings remained due to insufficient funding for the project:

- The obsolete, but reliable and durable compressor still made too much noise.

- Fiberglass insulation took up a lot of space between the walls of the refrigerator.

- Manual defrosting and heavy weight are preserved.

The exterior of the refrigerator was updated with a new longer chrome door handle and a redesigned trademark emblem. Many suggestions for improving comfort, proposed during the production of ZIL-63 refrigerators, have remained relevant in our time and are used in the production of modern refrigerators.

The reliability and versatility of some units of ZIL refrigerators simplified post-warranty maintenance. The power of the compressors was calculated according to the maximum standards, because of which they were often used to make home-made cooling units in ship galleys and to lower the temperature in cellars.

The ZIL-63 refrigerator surpassed foreign counterparts in terms of reliability and durability, was in high demand in hot countries and was repeatedly awarded various awards.

The legend of the automotive industry - ZIS 5 "Zakhar Ivanovich"

In 1933, the car that later became a milestone for the automobile plant, the famous ZIS 5 (commonly known by the nickname "Zakhar Ivanovich", or even simply "Zakhar"), saw the light of day. Until 1948, only at the Moscow ZIL plant, more than 500 thousand copies of this car were produced, capable of carrying loads weighing up to 3,000 kilograms. On the whole, taking into account the production capacities of the factories in Ulyanovsk (UlZIS, the future UAZ) and Miass (UralZIS), the circulation of the issue exceeded one million copies.

The car received a lot of changes and improvements compared to the previous model - AMO 3. The carrying capacity was increased to three tons, the power of the 5.6-liter engine reached 73 liters. With. The truck was equipped with mechanical brakes, and on a number of modifications, primarily produced during the Great Patriotic War, the brakes were installed only on the rear wheels. Based on the ZIS 5 model, a wide variety of ZIL modifications have been produced over the years, including vehicles with a gas generator and a gas cylinder, as well as variations of the ZIS 11 and 12 with an extended base.

In 1937, the Moscow plant produced the first prototype of a new generation of freight transport - the ZIS 150. The estimated carrying capacity of the new vehicle was five tons when driving on a good road and 3.5 tons - off-road or primer.

Distinctive features of the new truck.

| Aspects | Numerical indicators |

| All metal cab. | For three places. |

| Fuel tank. | Volume 100 l. |

| Engine. | Power was boosted to 82 hp. With. (similar to the already produced buses of the ZIS 16 brand). |

Prototypes of the new model were produced several times even before the start of the Great Patriotic War, but the new truck entered mass production only in 1947. In the first years after the war, ZIL 150 cars had a cabin made partly of wood, because there was a huge problem with metal in the country. The carrying capacity was reduced to four tons, but the power of the 5.6-liter propulsion system was increased to 90, and later to 95 horsepower.

Device Options

When buying a new device, a potential buyer needs to consider many parameters. These are dimensions, useful volume, number of cameras of the device and other characteristics. One of them is the weight of the refrigerator. Many people consider this parameter unimportant. But it will be of particular interest to the owner when transporting equipment, so it should be considered when buying. Modern models do not differ in large mass. But still, at least two people will be needed to transport any unit.

Some nutritionists believe that the dimensions of the refrigerator can affect the weight of its owner. The larger the useful volume of equipment, the higher the likelihood of gaining excess mass.

Reasons for the popularity of ZiLs

The main secret of the longevity of Soviet refrigerators is the high quality of all parts, from case materials to all components.

For a long time, these devices belonged to elite equipment, not accessible to everyone: a third of the output was exported, the same amount was sold in Moscow, and the rest was sold according to orders for high ranks from various cities of the Union.

Advantages of ZIL refrigerators:

- stylish (at that time) appearance;

- quality assembly;

- thick-walled strong case;

- durable, height-adjustable, non-absorbent and easy-to-clean shelves;

- loyalty to voltage drops in the network;

- easy disassembly and high maintainability.

Each product has undergone strict quality control. Even a fully serviceable device could be rejected if there were only small scratches or minor irregularities on the welded material of the case.

But at other factories producing refrigerators, such nuances were not considered defects.

High standards were set for every detail. There are cases when entire wagons with blanks were rejected, on which spots or deviations in the color of the surface were found.

Components that did not pass the control were redirected to other, less “fastidious” factories. Such a tough position was the main reason why the ZiL brand has long been considered the manufacturer of the most reliable refrigerators in the Union.

"OCEAN" COMES FROM THE FAR EAST

In the Primorsky Territory in the city of Ussuriysk, the Okean plant is located. More than 30 thousand units of products under the well-known brands LG, DAEWOO and OCEAN roll off its conveyors every month. OCEAN is the plant's own brand, successfully revived from the once very popular brand of refrigerators "Ocean" in the Far East of Russia.

The range of "Oceans" is small, only 4 models, but it is interesting: all refrigerators are equipped with the No Frost system, 1 model is a combi, 3 models are with a top freezer. (See tables for details). The appliances use R134a refrigerant. Warranty - 3 years.

In 2009, the plant received a certificate of compliance of the quality management system with the requirements of international standards ISO 9001-2001 in relation to the production of refrigerators.

Refrigerators under the OCEAN brand are known to consumers not only in the Far East region, but also in Siberia, Novosibirsk and Irkutsk regions, as well as Transbaikalia.

Who "wels" on our extravagance

Of course, double chamber models equipped with two compressors contain more copper. If you are not too lazy to extract it, you can get up to 1.5 kg of non-ferrous metal at a time. True, you will have to mess around longer, but you won’t have to give “free” money to collectors.

Masters, bringing old household appliances to their base, are not lazy to disassemble them. From each household electrical appliance, whether it be a hair dryer, a washing machine or a refrigerator, they remove the metal and, immediately handing it over, put our hard-earned money in their pocket. And they get a lot in a day! Knowing how much copper is in the compressor from the refrigerator, you can approximately calculate how much money they will have in their pocket if at least three refrigerators and a couple of washing machines are scrapped in a day, even if taken at a minimum - this is about 1000 rubles.

Those who are interested can watch a video of disassembly and measurements.

Start of car production.

In 1917, 432 trucks were assembled at the plant, the following year - 779, and 108 cars in 1919.

But, at the same time, the plant was not completed for the manufacture of its own cars. The reason for this is the October Revolution and the war. Nationalization turned the unfinished enterprise into several large workshops specializing in the repair of cars and other equipment. From the beginning of 1920, the AMO took part in the Soviet tank program. In the period from February to July, 24 tank engines of the Russian Renault tank were manufactured here.

April 30, 1923 The plant received the name of the communist Ferrero, an Italian killed by the Nazis.But only in March 1924, the plant received a government order to produce the first batch of Soviet trucks.

In 1925, the plant was given the name of the 1st State Automobile Plant. In 1927, I.A. became the director of the plant. Likhachev. The plant was subordinate to the auto trust, which decided to start its reconstruction.

Production picked up pace. 1930 was marked by the purchase of a license for an American Autocar-5S truck with a payload of 2.5 tons. The plans were to produce trucks using the conveyor method.

The launch of the reconstructed plant took place in 1931, and on October 1 of the same year, it was named after Stalin (Plant named after Stalin, ZIS). October 25, 1931 is the launch date of the first Soviet automobile assembly line, which produced the first batch of 27 AMO-3 trucks.

During the first five-year plans, in accordance with the General Plan for the Reconstruction of Moscow, housing construction was launched. The workers of the factories "Dynamo" and "Amo" were placed in the village of Dubrovka, which was under construction.

Since 1932, the production of minibuses AMO-4 (aka ZIS-8) began.

On August 21, 1933, the Council of People's Commissars of the USSR decided to make a second reconstruction of the plant, which was aimed at expanding the range of cars.

After undergoing reconstruction in 33-37, ZiS made a new modification - ZIS -5, which was given the nickname "Zakhar". Since 1934, ZIS-6 trucks and ZIS-8 buses began to be produced. Cars ZIS-101 began to roll off the assembly line in 1936. Special vehicles based on ZIS and AMO were produced by many enterprises. Ambulances began to be produced in the late twenties. For them, the AMO-F-15 cargo chassis was used. Experimental models of thermo-vans were built in 1932-33 on the basis of Shissy AMO-4.The Aremkuz plant in the same year produced bread vans on the AMO-3, ZIS-5 chassis. The Leningrad Dairy Plant began to produce isometric milk tanks in 1934.

ADVENTURES OF ITALIANS IN SARATOV

The Saratov Electric Unit Production Association was founded on May 14, 1939. In 1951, the production of household refrigerators was launched there. But this is not the main direction of the enterprise, but only one of the departments of a huge plant. In 2009, "Saratov" expanded its range by releasing 4 models of freezers. SEPO manufactures 200 types of products for the needs of Russian aviation, automation, and the military industry. This is one of the largest enterprises in Russia for the production of electronic and complex electrical products, for example, multifunctional control systems and electronic controllers for aircraft engines for all modern aircraft and helicopters.

But although refrigerators are only a small part of the overall assortment of the enterprise, great attention is paid to their quality, which is why SARATOV is a real brand that has managed not only to successfully survive the difficult times of the nineties, but also competes in the market with many Russian and foreign manufacturers of economy refrigerators. -class

Since 2005, a new line of the Italian concern "Afros" has been operating, which allows the production of refrigerators with the design of "soft lines". The partner of the Saratov refrigerator plant is the Italian company ILPEA, a leader in the design of seals and magnetic inserts for refrigerators, which are more elastic and durable in terms of their technical composition. In the production of refrigerators, the compressor motor of the famous Italian concern ACC is used.Most models of Saratov refrigeration household appliances use R134a refrigerant.

In total, the assortment includes 14 models of household refrigerators and freezers: a two-compressor combi (with a bottom freezer), two models of two-chamber refrigerators with a top freezer, three models of one-chamber refrigerators with a freezer compartment, two models of one-chamber refrigerators without a freezer compartment, six models of upright freezers .

The two-compressor combi is the highest in the Saratov assortment - 195 cm, the width and depth are standard for Russian cuisine - 60x60 cm, which allows you to fit the refrigerator even into a room with a small footage. Refrigerators with a top freezer are even more compact: their width is only 48 cm, and the standard depth is 60 cm. The highest Saratov single-chamber refrigerator is 148 cm, the lowest is 87.5 cm. At the same time, their width / depth is only 48x59 cm. Manufacturer offers the highest freezer (among Russian), as tall as a large refrigerator - 195.8 cm. The smallest freezer, like the smallest refrigerator, is only 87.5 cm high.

Naturally, the compact dimensions of most models are due to the peculiarities of national housing and imply that the internal volume of the devices is not very large. For a two-chamber combi refrigerator compartment for 210 l combined with a 125 l freezer. AT top freezer refrigerators its volume is 30 liters, and the volume of the refrigerator compartment can be selected: 165 or 122 liters. For single-chamber refrigerators, the volume of the refrigerator compartment varies from 185 to 107 liters, and the freezer compartment can be 25 or 15 liters.

At the same time, it is Saratov that offers consumers a huge 304-liter freezer. In addition, there are models for 135 and 125 liters.

All Saratov refrigerators are white. The model is guaranteed for 3 years.

In 2009, "Saratov" expanded its range by releasing 4 models of freezers.

The best compressor unit

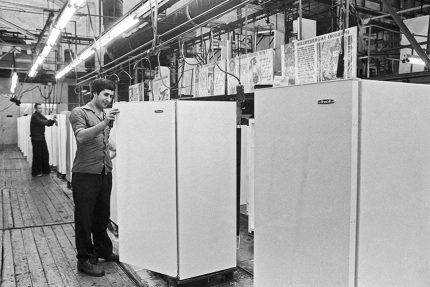

The real legend among the Soviet cooling appliances was the ZIL refrigerator. This is a compression unit, the mass production of which was organized in 1949-1951. at the Moscow Automobile Plant.

The first models of such refrigerators were developed by the Design Bureau of the enterprise. They were called "ZIS-Moscow". The first sample of such a refrigerator had a volume of 165 liters.

A year after the organization of a workshop for the production of household household cooling appliances, a pilot batch of 300 units saw the light. These were the first compression refrigerators that had a volume sufficient for the consumer.

consumer market

In 1969, a new domestic rectangular refrigerator appeared. They became the unit of the ZIL-62 KSh-240 model. Such a refrigerator easily fit into the interior of a standard kitchen. In addition, the designers for the first time used a magnetic seal for its doors. This made it possible to operate the refrigerator in areas not only with a temperate, but also with a tropical and subtropical climate.

Refrigerators "ZIL" - ups and downs ... Part I

December 31, 2010

Refrigerators of the brand "ZIL" retained unconditional leadership within the country from the beginning of the organization of production and until the 80s as the most spacious, most reliable, comfortable and prestigious. There was no advertising or marketing service at the plant. Refrigerators were advertised by buyers.The word "marketing" did not exist in the vocabulary of workers. The assessment of demand and needs was carried out by technical specialists with the involvement of the Ministry of Trade.

Starting with the second model, 30% of the total output of refrigerators was exported, 30% was sold in Moscow, the rest went to Leningrad, Kyiv and - according to orders - to other cities for local leaders. The elite contingent of buyers determined the highest requirements for the plant's products. Each refrigerator was checked for compliance with technical conditions much more strictly than required by GOST. Good refrigerators were rejected if there was a mote, a small scratch or a barely noticeable bump on the front surface. In other factories, this was not considered a defect.

Fig. 1 Chief designer of refrigerators "ZIS" Kamishkirtsev Sergey Mikhailovich with the team, 1959

Equally high demands were placed on components. There were cases when cars of aluminum blanks for evaporators with deviations in surface color were rejected. In the absence of official confirmation from the engineering services that the stains do not affect the strength and hygienic qualities, the car was returned to the supplier. The unification of dimensions allowed the supplier to redirect a wagon with rejected blanks to another refrigerator plant. Such a tough position could not arouse love for Muscovites, but was supported by the leaders of the country and contributed to maintaining the high image of the ZIL brand as the most reliable refrigerator in the Soviet Union.

The starting point in the history of the creation of domestic production of freon-12 compression household refrigerators can be considered the Decree of the Government of September 7, 1949 with instructions to the Ministries of the Automotive and Aviation Industry.According to this Decree at the plant. I.V. Stalin, the head design bureau was created.

For the first time, the specialists of the plant came into contact with refrigeration production and did not know about its nuances. Despite this, the development of refrigerators was carried out in the shortest possible time thanks to everyone's enthusiasm and the desire to create a better life after the end of the war. In a few months, design bureau designers prepared drawings of refrigerators with a volume of 165 liters for ZIL and 85 liters for the Saratov plant.

The first model "ZIS-Moscow" DX-2 with a volume of 165/12 liters (165 liters - total volume and 12 liters - low-temperature compartment, NTO) was produced from 1951 to 1960. The prototype was an American sample of pre-war production. L.I. Brezhnev had one of the first ZIS-Moscow refrigerators.

Fig. 2 "ZIS-Moscow" DH-2.

In the difficult post-war period, Soviet people were not ready to buy refrigerators. Small quantities of products at low ambient temperatures were stored by ordinary citizens in nets outside the window. In the Asian republics, it was believed that meat was best stored "on the legs." Therefore, in the early 50s, the plant had serious sales problems that gave rise to jokes.

The first ZIS-Moscow refrigerator had a number of undoubted advantages: the metal chamber was not only strong and durable, but also hygienic; stainless steel evaporator and steel condenser guarantee maximum reliability and durability of the refrigeration unit; the smooth forms of the cabinet and door were pleasing to the eye and ensured the safety of the owners.

However, the lack of experience and imperfect technologies gave rise to serious shortcomings: it was impossible to maintain a normalized temperature in the refrigerator and LTO, and the production “ate up” a huge amount of metal and was extremely laborious. The temperature in the NTO "ZIS-Moscow", by the way, did not fall below -6ºС.

Brand "Saratov"

In addition to absorption refrigerators in the Soviet Union, production of compressor household refrigerators was also launched at many industries. Plant No. 306 became one of these enterprises. Initially, aircraft engines were produced here. In 1951, the Saratov refrigerator rolled off its assembly line. Contemporaries said about this model that it was "badly tailored, but soundly sewn." A similar characterization could be given to many goods produced during the building of socialism.

Refrigerator "Saratov" had a body made of steel. They covered such devices with white enamel. The internal shelves of the freezer, as well as the evaporator, were stamped from stainless steel. Chrome was used in the decoration of the refrigerator.

The first models of these devices were single-chamber with a volume of 85 liters. The thermal insulation of the unit was provided by the use of glass or mineral wool. Somewhat later, the plant launched the production of two-chamber refrigerators, the operation of which was carried out on freon that is safe for human health.

Refrigeration units "Saratov" were successful not only among consumers of the Soviet Union. The plant's products were exported to thirty-three countries of the world, including Germany and France, Italy, Belgium, England and others. And today, the old Soviet refrigerators of this brand serve as a real example of technology that corresponds to the slogan of those times, calling for "building for centuries."

ATLANTS HOLD THE MARKET?

Refrigerators "ATLANT" are not entirely ours, Russian, they are produced in Belarus, but, according to various studies, "Atlant" occupies from 16 to 20% of the Russian market. . In general, the Minsk plant annually produces more than a million refrigerators. 70% are exported to the CIS countries, the European Union, the Middle East, and even Australia. — Compressors for refrigerators are produced at the Baranovichi Machine-Tool Plant, which is also part of CJSC Atlant. Since 2008, a new technological line for the production of compressors has been operating under license from Danfoss (Denmark). Also at the Minsk plant of refrigerators a new painting line was put into operation, equipped with equipment from the German company Eisenmann, which, among other advantages, made it possible to produce refrigerators in a wide range of colors.

In general, the first refrigerator (Minsk 1) was produced at the plant back in 1962, the first two-chamber unit - in 1998, and since 2004 Atlant refrigerators of the New Wave series with electronic control and indication have been produced. The quality management system for the development, production and service of products is confirmed by certificates of compliance with the requirements of international standards ISO 9001, and the environmental management system for development and production is confirmed by environmental certificates of conformity.

Basically, Atlantes are two-chamber refrigerators - combi (with a lower freezer), and a significant part of the range is two-compressor appliances. The presence of two compressors allows consumers to turn off the freezer and refrigerator compartments separately from each other.

The width of almost all "Atlants" is 60 cm, the depth is 63 or 64 cm, but there are also a couple of more compact models (with a top-mounted freezer). The "growth" of two-chamber refrigerators is very diverse: two-compressor combi range from 176 to 205 cm, single-compressor - from 142 to 205 cm. Refrigerators

with the upper freezer lower - from 147.5 to 176 cm.

Models with a lower location of freezers have the largest refrigerating chambers with a volume of 278 liters, the smallest - 205 liters (for two-compressor), 168 liters (for single-compressor); the largest freezers - 154 liters, the smallest - 76 liters.

For refrigerators with a top freezer chamber volume of the refrigerating chamber varies from 210 to 240 liters, and the volume of the freezer - from 50 to 80 liters.

Each model is available in several versions: you can choose not only the color, but also choose the energy efficiency class A or B. The color of the “two-chamber” can be white or silver, “marbled” models, the “metal-plastic” version are also available.

There is a built-in refrigerator XM 4007 with a bottom freezer in the range.

All “two-chamber” refrigerants use R 600 a.

The factory also produces single-chamber refrigerators of class A or B, but there are only five models: four with a freezer (two of them with R 134 a refrigerant), one without a freezer. In addition, you can pick up a vertical freezer, mainly models with 240 liters are offered.

Warranty for Atlant equipment is 3 years. The range includes an A + class refrigerator for energy efficiency. In addition, there are a lot of modifications and designs of Atlant refrigerators, which allows everyone to choose a refrigerator with the optimal set of characteristics and color schemes.

Brand "Crystal"

The most advanced absorption refrigerators were produced thirty kilometers from the city of Kyiv, at the Vasilkovsky plant specially created for this purpose. The enterprise was built in 1954 and was completely focused on the production of Kristall brand devices.

The plant provided the necessary capacities for the manufacture of almost all components for refrigerators. There were metal rolling shops, as well as the production of foam rubber, polystyrene and plastic products. There were also assembly sections at the plant.

The most advanced absorption refrigerators of the Soviet Union had their advantages and disadvantages. Consumers were satisfied with their silent operation, which was accompanied by an almost complete absence of vibration, as well as the possibility of using not only electricity, but also gas as an energy source. But such refrigerators also had disadvantages. Among them are increased power consumption, as well as constant work without shutdowns.

In the eighties of the last century, the plant began producing refrigerators of the Kristall-9 brand. The total volume of such a device was 213 liters, and the freezer, in which the temperature was maintained at -18 degrees, was 33 liters.

"Crystal-9" was a full-size unit. However, its remarkable characteristics were supported by a larger power consumption than that of compressor devices.

Video about legendary refrigerators

Despite their reliability and build quality, the “old men” of the ZiL also fail. But here, too, they have a slight advantage over modern technology: the devices are easy to disassemble by yourself, and consumables are inexpensive (however, after years of prescription, there may be problems with their purchase).For more information about the famous refrigerators, see our video selection.

The history of the Soviet brand of refrigerators "ZIL":

Replacing the thermostat at ZIL-64:

How to make a stylish rarity out of an old device - restoration of the ZiL case:

Despite their glorious history, the ZIL models are outdated long ago and cannot be compared with modern refrigerators either in terms of spaciousness, quiet operation, or ease of defrosting. But if you have such a rarity, do not rush to part with it - some workshops offer services for upgrading old appliances and will be able to turn your ZIL into a stylish highlight that will decorate the interior of a summer house or apartment in vintage style.

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _