- How to make a safety block for heating with your own hands

- Components of the security block

- How does it work

- For solid fuel

- For gas

- What is included in the heating system security group

- Automatic air vent

- pressure gauge

- Safety relief valve

- Security group for heating for a private house. Composition and principle of operation

- What parts does the heating system consist of?

- Principle of operation

- How to properly set a security group

- Common Instructions for Installing a Security Group

- Structural elements

- Accurate pressure gauge

- Mayevsky crane

- Safety valve

- Purpose and device of a safety group for heating boilers, installation procedure

- Functional purpose

- Price

- Where to set the security group?

How to make a safety block for heating with your own hands

If you separately purchase a safety valve, a pressure gauge and an air vent, connect them using tees, adapters, you can assemble a security group with your own hands.

In the case of purchasing all components separately and self-assembly of safety automation, the price will be significantly lower than if you buy a ready-made boiler safety unit:

- safety valve - 6 c.u. e.;

- manometer - 10 at. e.;

- automatic air vent - 5 c.u. e.;

- brass cross DN 15 as a collector - 2.2 c.u. e.

When choosing components, it is necessary to take into account the following recommendations:

- Don't buy the cheapest safety valves. Chinese models, as a rule, after the first operation, they begin to leak or do not relieve pressure at all.

- Chinese pressure gauges, most often, lie very much. If during the filling of the system the device underestimates the readings, then after heating an accident may occur, since the pressure in the network may jump to a critical value.

- The safety valve must be selected based on the operating pressure of the boiler, which is indicated in the technical data sheet.

- Purchase only a straight type air vent, as the angular one creates increased resistance to the outgoing air.

- The crosspiece must be made of high quality thick-walled brass. When choosing, you just need to weigh the more expensive and cheaper model in the palm of your hand, and the difference will be immediately noticeable.

The body of the security group can also be made independently from scraps of polypropylene pipes and fittings, this will cost much cheaper than the factory-made model, where there is a lot of brass.

It must also be remembered that a safety group made of polypropylene must be installed only in low-temperature heating systems (for example, underfloor heating, but in no case radiators). The reason is that when the coolant reaches 95 degrees, polypropylene begins to break down, and as a result, a rather unpleasant situation may arise.

Installation of a homemade security group is quite easy.The air bleeder is screwed into the upper outlet of the cross, and into the side ones - a safety valve and a pressure gauge as it will be convenient. The finished element must be cut into the line next to the boiler.

AT if there is a desire to make the solid fuel heating boiler as safe as possible, it is necessary to pay attention to the thermal discharge valves. Their principle of operation is as follows: in case of overheating of the coolant, it is discharged from the water jacket of the boiler and a mixture of cold tap water is started. Conclusion: the purchase and installation of a safety group for a closed heating system is not a mandatory requirement for all boilers

Most of the wall-mounted gas boilers are already equipped with this automation from the factory, which is indicated in their operating instructions

Conclusion: the purchase and installation of a safety group for a closed heating system is not a mandatory requirement for all boilers. Most of the wall-mounted gas boilers are already equipped with this automation from the factory, which is indicated in their operating instructions.

However, some manufacturers of solid fuel boilers also complete their products with parts for the safety group, but you will have to work on installing them yourself.

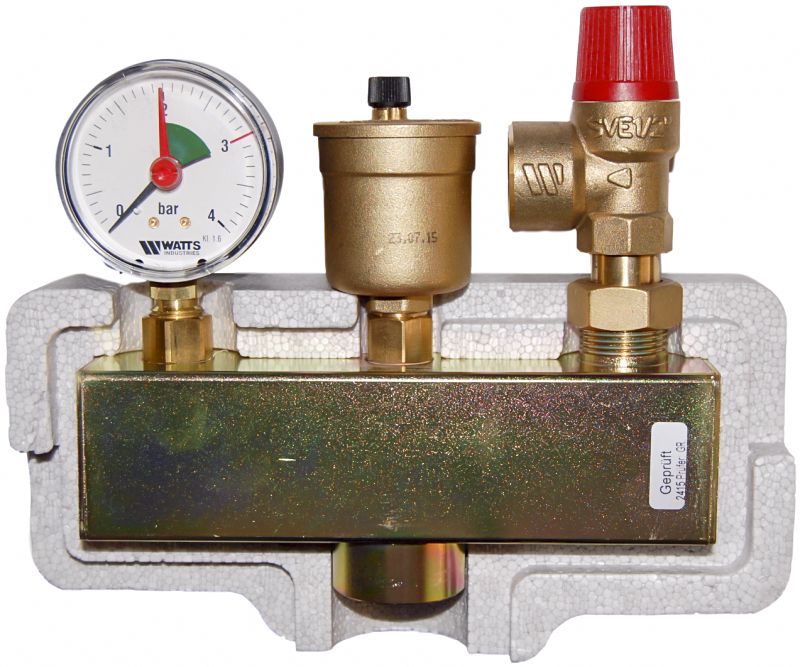

Components of the security block

To understand the essence of the protection mechanism, you need to consider the design of the security group. It is a system consisting of several elements. Each of the key links performs its specific task.

The security system for heating includes the following modules:

- Housing made of galvanized steel.

- Automatic air vent. It is also called the Mayevsky crane.Designed to remove excess air from the system. As a rule, brass is used for production.

- Safety valve. Needed to duplicate the air vent. If the automatic vent does not release air, the valve does the work for it. It also removes excess water. The safety valve is made of brass alloy.

- Manometer and thermometer. The thermometer shows the temperature level, and the pressure gauge for heating shows information regarding the pressure in the heating system. The optimum pressure is considered to be the one that suits the operating parameters of the heating boiler. As a rule, this figure is 1.5 atmospheres. It should be noted that today there are also thermomanometers for heating, which are a device that measures both temperature and pressure in gaseous and liquid media.

All protection and control elements, including pressure gauges and thermometers, are attached to the top of the metal case. Separate elements of the protective mechanism are not installed. Since in the absence of one of them, the entire complex will not be able to fully function. For example, there are pressure gauges and thermometers for heating systems, but no safety valve. In this case, the user will see that the pressure is increasing, but will not be able to fix the problem.

All protection and control elements, including pressure gauges and thermometers, are attached to the top of the metal case. Separate elements of the protective mechanism are not installed. Since in the absence of one of them, the entire complex will not be able to fully function. For example, there are pressure gauges and thermometers for heating systems, but no safety valve. In this case, the user will see that the pressure is increasing, but will not be able to fix the problem.

Or, for example, there is an air vent, but there is no safety valve. In this case, excess air will escape, and the superheated liquid will remain in the housing. Which can lead to failure of the entire heating system.To control the heat supply system, a heating and hot water controller is designed, which guarantees the maintenance of the optimum temperature in the apartment, depending on fluctuations in the level of outdoor temperature.

Or, for example, there is an air vent, but there is no safety valve. In this case, excess air will escape, and the superheated liquid will remain in the housing. Which can lead to failure of the entire heating system.To control the heat supply system, a heating and hot water controller is designed, which guarantees the maintenance of the optimum temperature in the apartment, depending on fluctuations in the level of outdoor temperature.

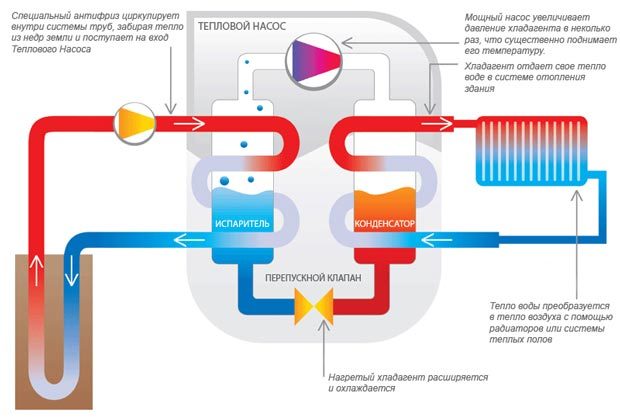

How does it work

The safety group is a set of elements responsible for the overall safety of the heating system. It includes by default:

- manometer;

- air vent;

- safety valve.

All three elements are fixed on the same basis - the console, which is a pipe segment with a set of necessary fittings, inlet and outlet. Optionally, taps can be added to connect an expansion tank, additional sensors or redundant systems, including automation.

The manometer indicates the current actual pressure in the heating system, by which it is possible to judge its general condition and take action in case of unacceptable deviations. Increased pressure always indicates the presence of a problem, moreover, a critical one that requires immediate action. Reduced pressure signals an insufficient volume of coolant, a violation of the tightness of the pipeline, boiler or radiators.

The air vent is included in the safety group as a safety element that allows not only to solve the problem of air pockets that can nullify the circulation of the coolant, but also to obtain reliable values and adequate operation of the pressure gauge and safety valve.

It should be noted that if the valve and pressure gauge from the safety group are needed only in one copy, then the air vent must be installed both in the group and at all points in the system where air can accumulate, including necessarily at the highest point of the wiring.

The safety valve performs automatic discharge of the coolant when the pressure rises above the allowable threshold. The valve is triggered if, for some reason, the expansion tank did not cope with the task assigned to it, or the pressure increased so much that the tank was not physically enough to eliminate the imbalance. The safety valve protects the system from rupture in case of boiling of the coolant in the boiler or a gradual increase in pressure due to uncontrolled accumulation of gases, for example due to the chemical reaction of aluminum, in radiators with water.

Each element has specific characteristics necessary for adequate operation. The pressure gauge must have a measuring range corresponding to the design pressure in the system. If, according to calculations in the boiler, the pressure should be 3 atmospheres, then the pressure gauge should be able to measure pressure up to 4-5 atmospheres. This is enough for diagnosis.

The safety valve must operate at the upper limit of the allowable pressure for the boiler. This value is indicated in the instructions and technical data sheet for boiler equipment. Accordingly, the valve is selected strictly for it.

The automatic air vent is the most unpretentious, it is enough to know that it is able to vent air, and, first of all, at the point of connection of the security group, in order to nullify any errors in the operation of the valve and pressure gauge.

The console for the group is made of steel or brass, in a single block. Often, for safety or aesthetic appearance, the console and installed devices are closed in a protective casing, a common plastic or metal case.

For solid fuel

In a solid fuel boiler, the risk of the coolant boiling is much higher than in any other. The main element of the safety group in this case is the safety valve.

You can choose the simplest pressure gauge, with the desired measurement range. In any case, it will not be possible to diagnose a malfunction by minimal pressure changes. It is more important to fix only significant fluctuations. The best option is to have additional pointers arrows that will mark the maximum and minimum value reached during the observation period.

For gas

In wall-mounted gas boilers, almost always a safety group is already included in the equipment, so there is no need to install an additional one.

However, it is important to check this point in advance. The group is mounted inside the case as high as possible

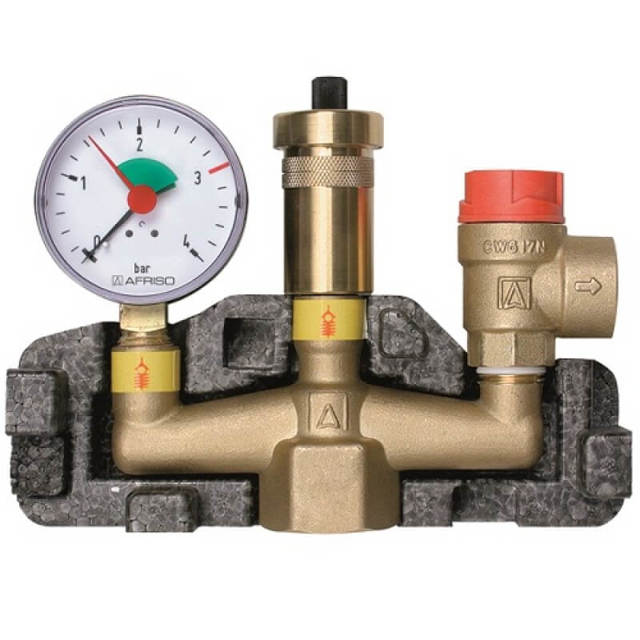

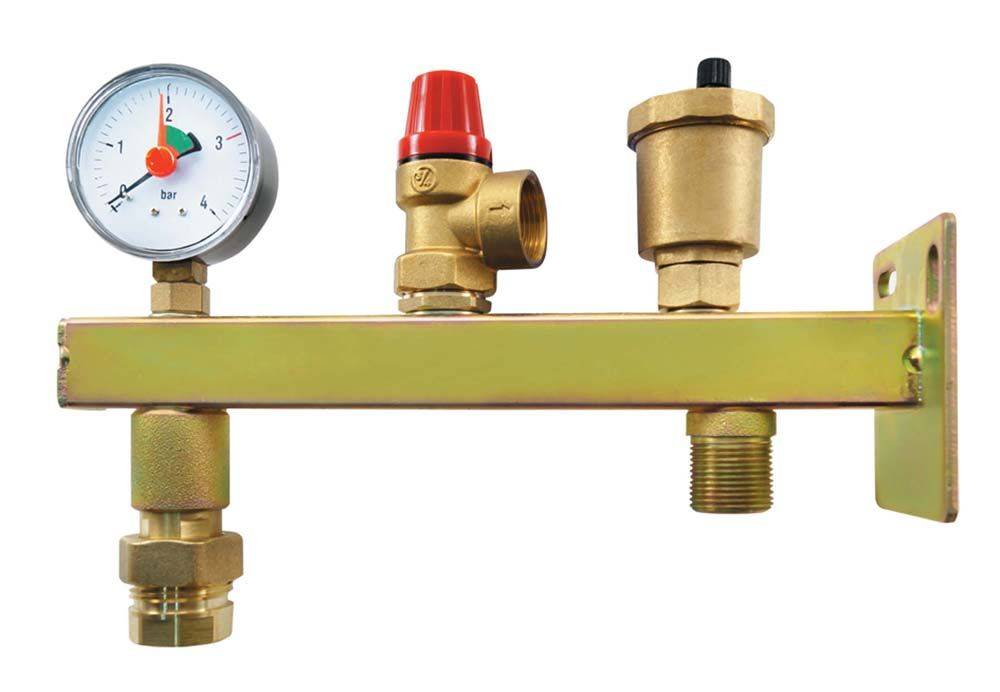

What is included in the heating system security group

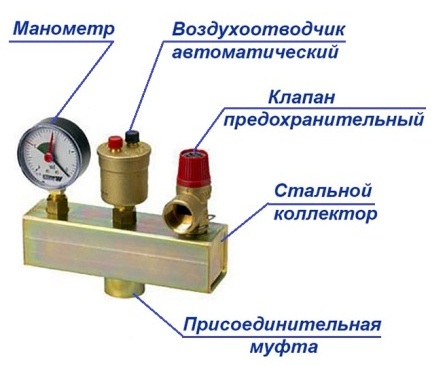

The composition of the classic security group. The safety group consists of three elements connected by a collector (a technical element that divides the flow into several parallel branches).

Automatic air vent

The automatic air valve is designed to discharge air masses from the heating system. Its earlier alternative is Mayevsky's manual taps on radiators.The air in the pipes and radiators of the heating system slows down the heating and circulation rate of the coolant, reduces the efficiency, and when heated above 90 ° C, it seriously increases the pressure, which can lead to damage and depressurization of the heating system.

Air can appear even with competent and careful operation of CO. The most common reasons:

- initial filling of the heating system with coolant with air admission;

- release of air bubbles when heating water used as a heat carrier above 90°C;

- improper use of the make-up tap;

- wear of elements and components of the heating system, which violates its tightness.

The automatic air vent requires no adjustment or human intervention. As soon as air is formed in the system, it enters the air vent channel. The float located in this cylindrical channel descends, lowering the locking rod: the valve opens and bleeds all the air from the channel.

pressure gauge

The purpose of the pressure gauge is to display the exact pressure inside the heating system to monitor performance. As a rule, bars are used as units of measurement. By setting a certain pressure level, looking at the pressure gauge, you can make sure that the system is working properly, all components are completely sealed, and other elements of the safety group are performing their functions.

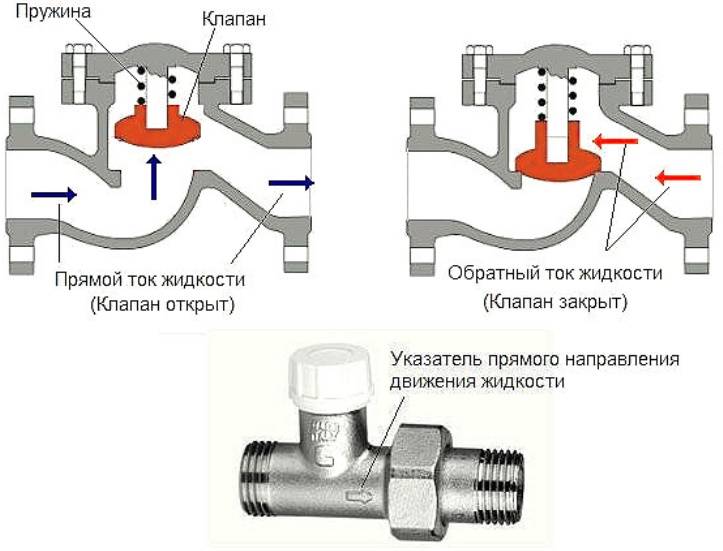

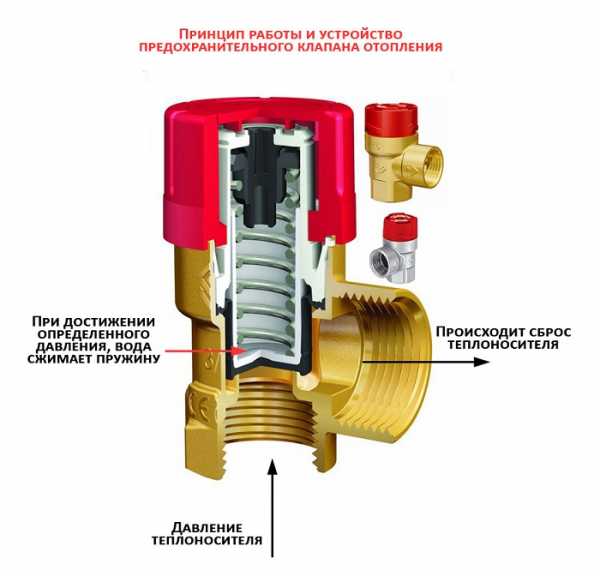

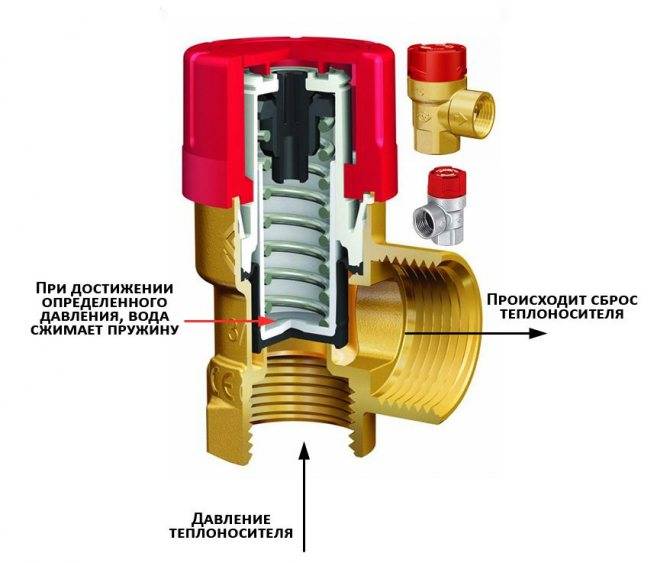

Safety relief valve

The principle of operation of a spring-loaded safety valve designed for an individual heating system. The safety valve provides automatic discharge of air, steam or coolant when a critical point is reached, thereby freeing up space in the system for further expansion of the coolant.An increase in pressure in the heating system can be caused not only by the formation of air (which the air vent handles), but also by the expansion of the coolant itself during strong heating, which can lead to damage and leakage.

If radiators and pipes usually withstand a pressure of 7-9 bar without problems, then the most vulnerable element of the heating system is the boiler heat exchanger, often designed for 3 or even 2 bar.

It is for the maximum allowable working pressure that the safety valve is selected: there are models designed for a specific pressure and models with an adjustable value, which is set during installation and configuration. The most common and best in terms of price-quality ratio is the spring mechanism, it is he who is used in almost all options for security groups.

The principle of operation of a spring-loaded safety valve is to balance the pressure inside the system and the clamping force of the valve spring:

- from the inside, the coolant exerts pressure on the valve shutter;

- on the other hand, the spool is pressed by a stem, on which a spring presses, thereby holding the valve in the closed position;

- as soon as the pressure in the system exceeds the critical value, it outweighs the clamping force of the spring and the valve opens slightly, bleeding off excess air, steam or coolant;

- as soon as the pressure drops below the critical point, the spring force is sufficient to move the valve to its original closed position.

Security group for heating for a private house. Composition and principle of operation

The heating safety group is a mechanism that consists of a whole set of devices.Thanks to their well-coordinated work, trouble-free operation of the system is ensured, as well as full control of the pressure in the coolant.

What parts does the heating system consist of?

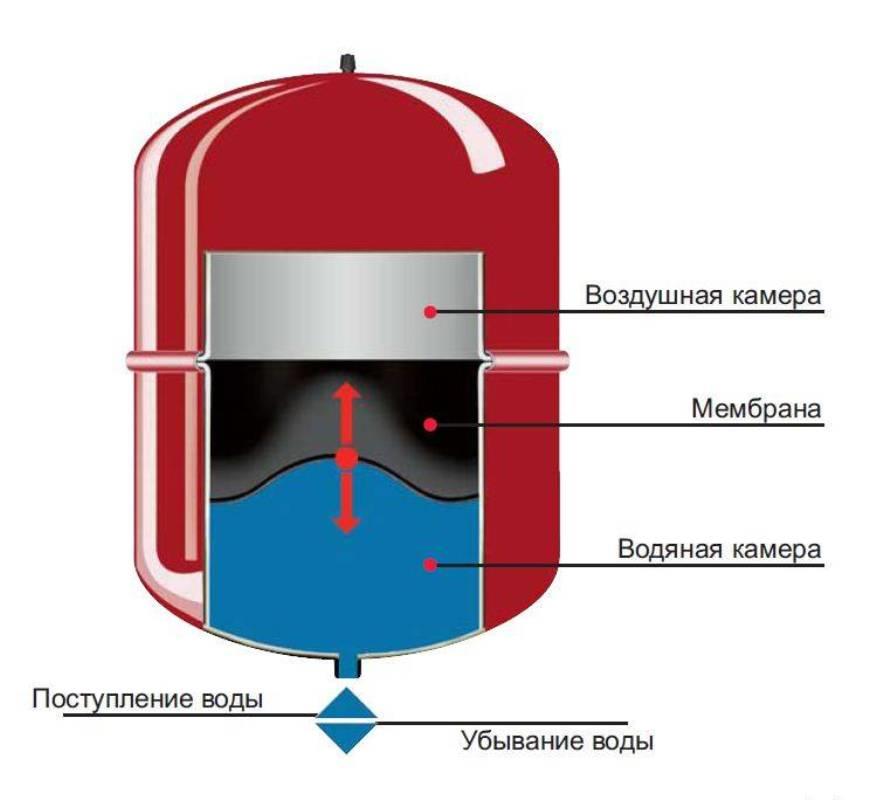

When an emergency occurs in a private house or an expansion tank fails, the pressure in the heating system increases sharply. This can lead to an explosion in the pipe, as well as damage to the heat exchanger of the heating tank. Of course, each person cares about heating a private house. The safety group, in the event of a breakdown, will compensate for excess pressure, and also prevent airing of the system. It works in automatic mode and tries to quickly relieve excess pressure.

The safety group includes a metal case, which has a threaded connection. A pressure gauge, a safety valve, and an air vent are installed here.

- The pressure gauge is a measuring device that provides visual control over the resulting pressure, as well as the temperature regime in the heating system.

- Air vent. It works in automatic mode and dumps excess air in the system.

- Safety valve. It is designed to remove excess fluid that is in a closed system. Sometimes, when the coolant is heated, it can expand and create excess pressure.

Principle of operation

If certain situations arose, and the expansion tank could not compensate for the expansion of the coolant in time, then the safety valve mechanism will work in this case. The heating safety group will open the way to release excess coolant.Unwanted air can escape through the air vent.

To prevent a person from getting burned during the sudden opening of the check valve and the release of excess coolant, it is necessary to connect a drain pipe. It must be directed to the sewer system. Many people believe that there will be little liquid left in the system when the safety valve is activated. But this opinion is erroneous, because in most cases, in order to normalize the pressure, the system dumps no more than 120 grams of coolant.

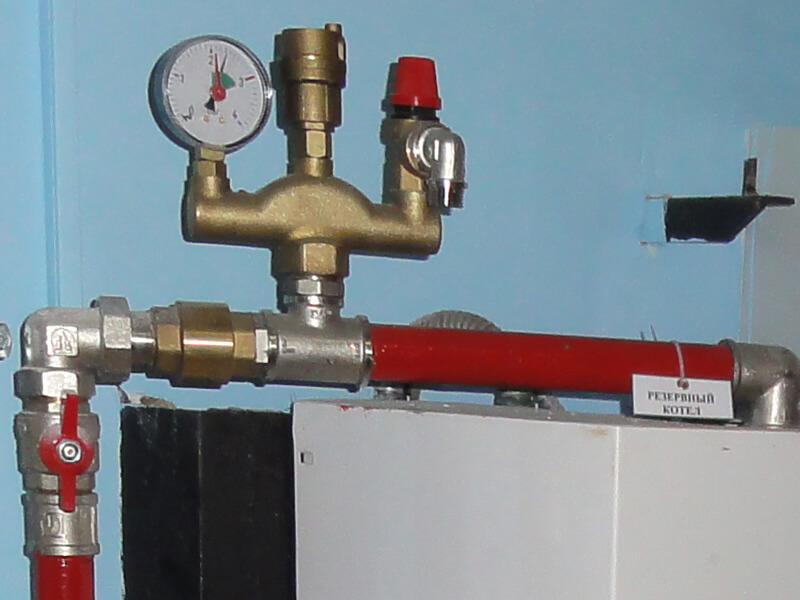

How to properly set a security group

Today, wall-mounted boilers for heating a private house are in great demand. In most cases, they already have a safety group for the heating system. In a floor boiler, especially if it is from a domestic manufacturer, there is no such unique device. That is why buyers will have to think about additional installation of a boiler system. In order for it to work correctly and properly, the installation process must be trusted only by qualified specialists. Only they will be able to set all parameters and settings. If errors or oversights are made during installation and connection, the heating safety group will not work correctly.

In most cases, installation is carried out to the boiler on the supply line. The most optimal distance is about 1.5 meters, because it is in this position that the pressure gauge will be able to control the pressure in the system.

Common Instructions for Installing a Security Group

Each manufacturer that produces such equipment prescribes all the installation rules in the instructions.But there are generally accepted regulatory documents, where all the installation rules are clearly described.

Safety valves that are located in the heating system must be installed on the supply pipeline. They are mounted right next to the boiler

A certain level of power is taken into account in order to cut and duplicate these devices.

In a system where there is hot water, valves must be installed at the outlet. In most cases, this is the highest point on the boiler.

No devices should be placed between the valves and the main pipes. The heating safety group in the system plays an important role during the operation of the boiler

To ensure complete safety, care must be taken to properly install this system.

The heating safety group in the system plays an important role during the operation of the boiler. To ensure complete safety, care must be taken to properly install this system.

Structural elements

The scheme of the heating safety group provides for the use of all structural elements. Otherwise, the unit will not function properly, which can lead to various breakdowns and accidents.

Accurate pressure gauge

This device is designed to measure pressure (in atmospheres or bar) and provide instant results. To do this, a scale is graduated on the pressure gauge and there are two arrows. One of them shows the pressure in the heating system, and the second - the limit value, which is set during the setting.

- For pipelines of heating systems installed in apartment buildings - 1.5 bar.

- In suburban one-story buildings - from 2 to 3 bar.

Mayevsky crane

An automatic air vent must be installed in the heating security system of a private house and a city apartment. It is best to do this at the highest possible height. This feature is due to the fact that air is lighter than the coolant. It moves up and accumulates there, preventing the equipment from working properly.

Read also: how to properly release air from a heating battery.

Air may appear due to the following factors:

- Rubber seals of poor quality or premature wear.

- The first start-up of the installation and filling the pipes with coolant.

- Corrosion formation inside the lines of the device.

- Incorrect installation or non-observance of tightness conditions.

- Drinking water.

Such a faucet protects your heating system from the ingress of various dirt.

Such a faucet protects your heating system from the ingress of various dirt.

Mayevsky's crane is designed in such a way that the smallest particles of dirt cannot get into the air chamber. The air vent is assembled from the following parts:

- case with cover;

- jet;

- float;

- spool;

- holder;

- body and valve sealing rings;

- cork;

- spring.

Safety valve

During operation of the heating system, an increase in the volume of the coolant is compensated by an expansion tank, which is mounted on top of the heating devices and pipes. The user independently sets the desired outlet temperature, which leads to a change in the liquid level in the expansion tank.

In most cases, the performance of this node remains effective for a long time. As wear increases, the likelihood of any breakdown increases. It is absolutely impossible to determine the problem visually, since its root is hidden inside the pipeline.Such a malfunction will lead to a rapid increase in pressure and the destruction of the nodes of the heating system. To combat this phenomenon, a safety valve is used. It is installed together with other parts of the safety group and protects the device from damage. In addition, the owner of the dwelling will see the discharge of fluid, which will confirm the presence of a problem.

Before starting operation, it is necessary to check the safety valve for operability. You can do this in the following way:

- The handle, which is located at the top, turns in the indicated direction and opens the water.

- Then the same actions are done in the opposite direction.

- If the liquid still flows out, then it is necessary to open and close the safety valve several times in a row.

- If the manipulations performed did not give the desired result, then the valve is broken and must be replaced with a new one.

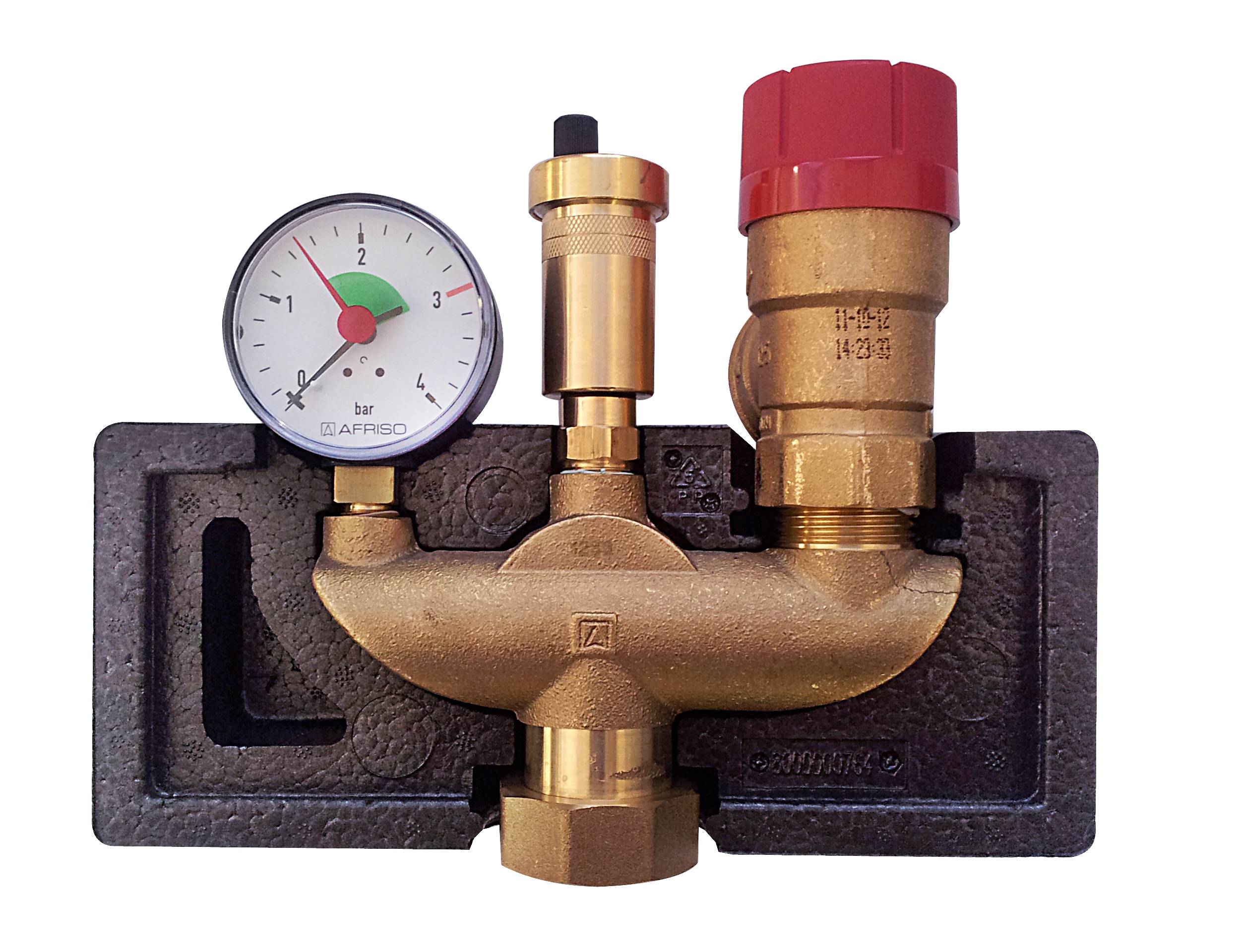

Purpose and device of a safety group for heating boilers, installation procedure

The operation of the heating system is a balanced process, the control of which should be carried out automatically. In addition to maintaining the optimum temperature of the water in the pipes, safety measures should be provided in case of emergency situations. First of all, this is a sharp jump in pressure in the line. To do this, a safety group is installed in the heating circuit.

Functional purpose

- Temperature - from 65°С to 95°С.

- Pressure - up to 3 atm.

In many respects, these parameters depend on the material of manufacture of pipes and their physical characteristics.

In open heating systems, compensation occurs due to the expansion tank. But if the system is of a closed type, then security measures cannot be dispensed with.

Most gas boilers and some solid fuel models are equipped with a pressure and temperature control system. But there is always the possibility of it failing. It is for such unforeseen situations that the installation of a security group is necessary.

Structurally, it consists of the following elements:

pressure gauge

Indicates the current pressure value in the system. In addition, for visual control, the device provides additional scales for the maximum and minimum pressure indicators.

Air vent

With a sharp increase in water temperature, steam is released in the system. For quick stabilization, it is necessary to quickly remove excess air, which is what the air vent does. Additional functions are the protection of heating elements from rapid corrosion, lowering the noise level during system operation.

Safety valve

The heating of the coolant is also accompanied by its expansion. The excess is removed using a safety valve that is activated when a certain pressure is reached. Usually it is set to a maximum value of 2.5-3 atm.

This is the basic configuration of the security group. In addition to the above elements, it may include a mixing unit, additional temperature sensors.

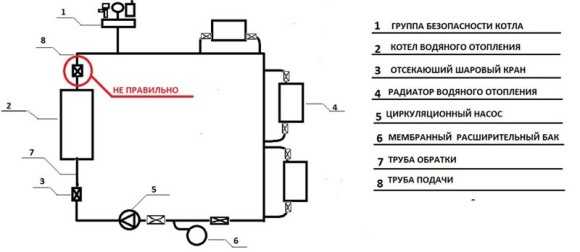

The correct functioning of the security group largely depends on a professional installation. During the design of heating, they always provide for the installation of shut-off valves, which cut off the flow of coolant during repair work, or the replacement of individual elements.At the same time, they often make a mistake by mounting a ball valve in front of the security system.

This is a gross violation of the installation rules, since if the system is blocked, the security system will not be able to perform its functions. It is best to consider this situation with a specific example.

Suppose a pipe breakage occurred - a leak caused water to flow. It is not possible to quickly extinguish a solid fuel boiler. It will still generate heat for some time. If the shut-off valves are installed according to the above scheme, then its overlap cuts off the safety group from the boiler operation system. At this time, the coolant heats up, the pressure rises, but the mechanism for its stabilization remains outside the operating boiler piping. And for obvious reasons, either a breakdown of heating equipment or a rupture of the pipeline occurs.

To avoid this situation, the installation should be carried out according to the following scheme:

Guided by this installation principle, you can safely carry out any repair and maintenance work without worrying about the safety of highways and the heater. After installation, the device is activated by opening the cap on the automatic air vent. Under no circumstances should it be removed completely. Also, at least once a month, a visual inspection of the valve is carried out. If it has not worked for a long time, then a layer of dirt appears between the seat and the plate of the device. This can lead to leaks later on. To flush it without dismantling, it is enough to turn the structure according to the arrow indicated on it.

Price

The cost of security groups is largely determined by the manufacturer, device parameters, and additional features. The main criterion is the power of the heater. Based on this, a choice of one or another model is made.

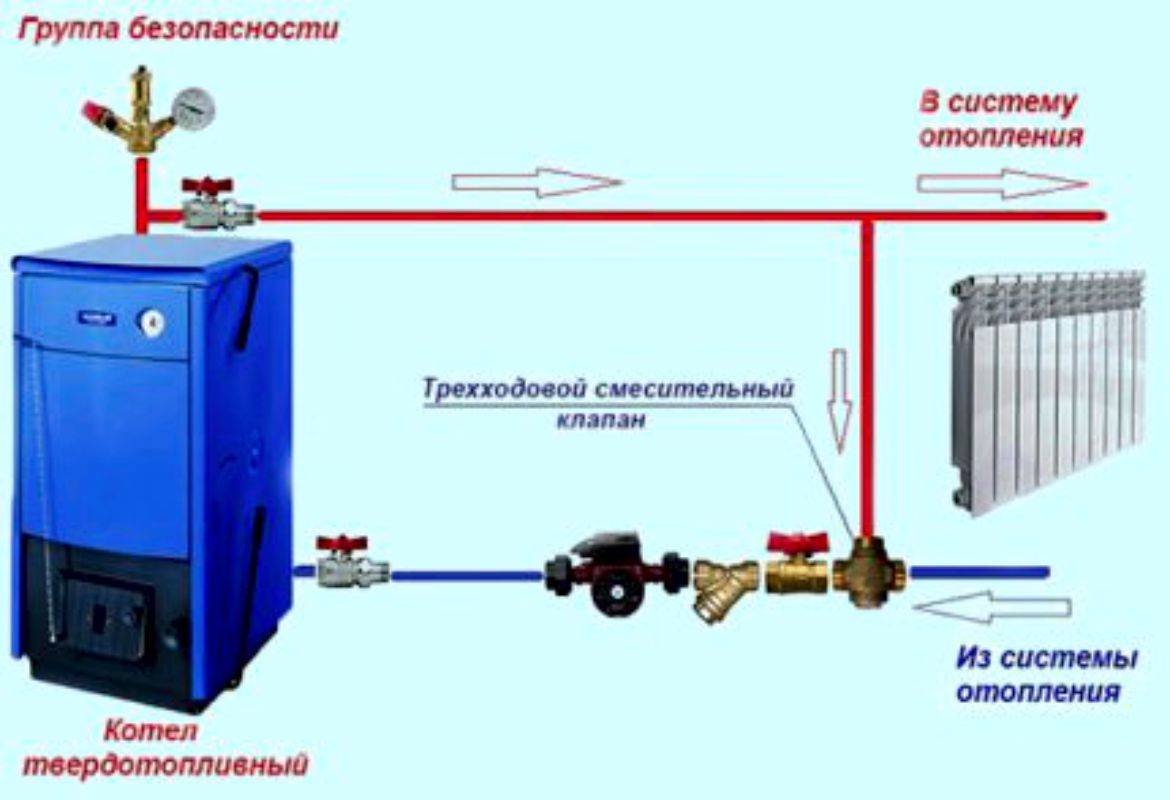

Where to set the security group?

By and large, the installation of a safety group for a heating system is not necessary for all systems, but if desired by the owner of the home, it can be mounted as a safety option on any system.

For example, for heat generators that run on diesel fuel or natural gas, or those whose operation depends on electricity, additional protection is not required in this case. These boilers initially have a high level of safety and in which case they can independently stop working and stop heating if the pressure and temperature increase.

Note: most often, on closed heating systems equipped with an electric or gas boiler, a safety group is mounted in order to make monitoring and service more convenient.

But boilers that run on solid fuel are more inert and cannot stop instantly. Even automated pellet boilers need some time to burn the fuel in the combustion zone. The controller or thermostat, in the event of a rise in temperature in the jacket, can instantly shut off the air, but the combustion will still continue for some time. Firewood will stop burning, but will continue to smolder, because of which the water temperature will rise by another couple of degrees.

Only the boiler safety group can prevent boiling and explosion in a solid fuel boiler, which is why it is one of the mandatory components for this type of heat generators.

Installing a security group is not a particularly difficult task. Anyone can cope with such a task with a standard locksmith tool kit at hand. Installation is of two types:

- installation on the "native" fitting that comes out of the boiler;

- tie-in into the supply pipeline at the exit from the heat generator.

The safety group must be mounted in a vertical position at any point in the heating system located above the boiler, but preferably where the temperature is as low as possible.

In the event that the boiler model is wall-mounted, then the manufacturers have already taken care of everything; in such models, the safety unit is installed inside or on the back wall. And for the floor model, the safety group will need to be purchased separately and independently embedded into the system on the supply pipe at a distance of 1-1.5 m from the boiler.

The pressure gauge must be positioned in such a way that, without straining, you can see its readings during a normal visit to the boiler room. The coolant that flows out through the safety valve should also be easily replaced, as this must be known.

Important! No valves are placed between the boiler and the safety group!

The diameter of the drain hose must match the diameter of the outlet of the safety valve and it must be laid in such a way that there are no obstructions when discharging steam or liquid, and in addition, so as not to endanger people.

In order to seal threaded connections, it is recommended to use FUM tape, flax with special pastes, polyamide thread with silicone or some other sealing materials that help to ensure sufficient tightness of the connections during the maximum operating temperature and coolant pressure. After the installation of the safety group has been carried out, it must be tested for tightness.