- Furniture items

- Closed heating system: what is it, principle of operation, pros and cons

- Construction schemes, use in apartment buildings

- Calculation

- Security group for heating for a private house. Composition and principle of operation

- What parts does the heating system consist of?

- Principle of operation

- How to properly set a security group

- Common Instructions for Installing a Security Group

- Expansion tank for closed heating system

- Volume calculation

- Place for installation of expansion tank of membrane type

- 1 Causes of the accident

- Features of the heating circuit with a membrane expansion tank

- Assigning group members

- Structural elements

- Accurate pressure gauge

- Mayevsky crane

- Safety valve

- Choice

- pressure gauge

- Air vent

- Safety valve

- Group types

- Valtec VT460

- Watts KSG

- Uni fit

Furniture items

A few examples of furnishing a kitchen combined with a living room:

- 1. Sofa. It becomes an object that zones the space. The sofa is placed with its back to the place where food is prepared. In small rooms (less than 20 sq m) they put a corner, which is located against a wall installed perpendicular or parallel to the kitchen.

- 2. Headset. According to the designers, minimalist models without elaborate details look modern.The service, vases or glasses are placed on an open shelf. You can buy a fashion showcase for them. Furniture is placed near the wall. If the space is large (20 sq m, 25 sq m or 30 sq m), then in the central part you can install an island, which also has departments for kitchen appliances.

- 3. A set of furniture. Style should be combined with the design of both rooms. In small rooms, a compact table and chairs made of transparent material or painted in light colors look good. In the interior of the living room, you can put a table with a round top. In spacious rooms, the kit is installed near the wall or in the central part. An elongated rectangular dining table will look good here.

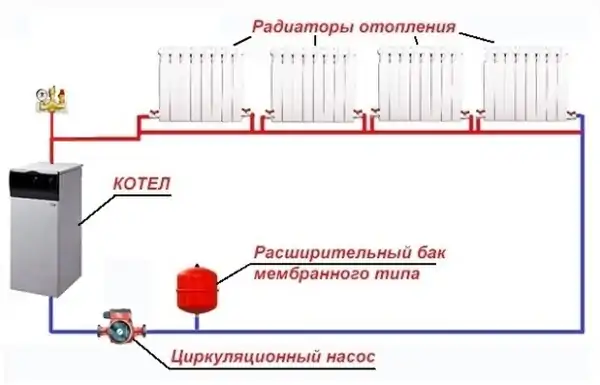

Closed heating system: what is it, principle of operation, pros and cons

In such schemes, expansion membrane tanks are used. The sealed container is divided into two parts by an elastic membrane.

When the temperature rises, the valve opens and the excess liquid moves into the tank.

When the temperature drops, the coolant enters the system, due to which a stable pressure is maintained in the latter.

A non-pressure tank can be completely filled with liquid, so the pressure maintenance installation must be more compact than a conventional tank. It allows you to adjust the specified parameters in the circuit and automatically feed the structure.

The closed loop consists of the following elements:

- from a sealed membrane tank;

- from batteries (radiators);

- from the heating boiler;

- from the circulation pump;

- from pipes;

- from connecting elements (valves, taps, filters).

A closed heating circuit has several advantages:

- the possibility of using any coolant;

- durability of the structure due to complete tightness;

- no extra noise

- the possibility of self-installation of the system;

- high speed of movement of the liquid, providing maximum heat transfer;

- no need for thermal insulation for the highway;

- reducing the financial cost of heating the house.

The disadvantages include dependence on electrical energy and the need to purchase a large membrane tank, the price of which is quite high. The problem of volatility is solved by installing uninterruptible power supplies or small generators that provide emergency power.

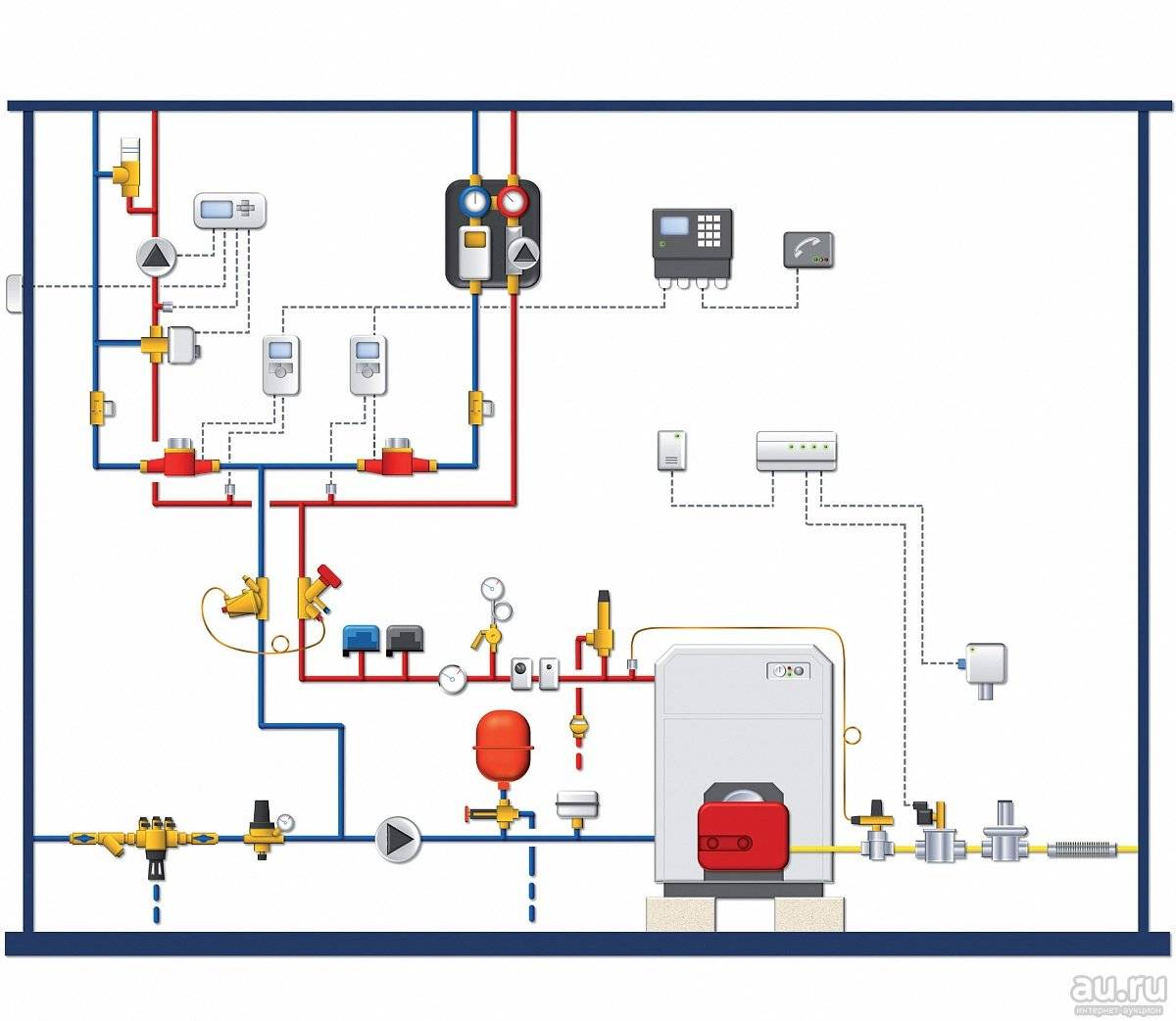

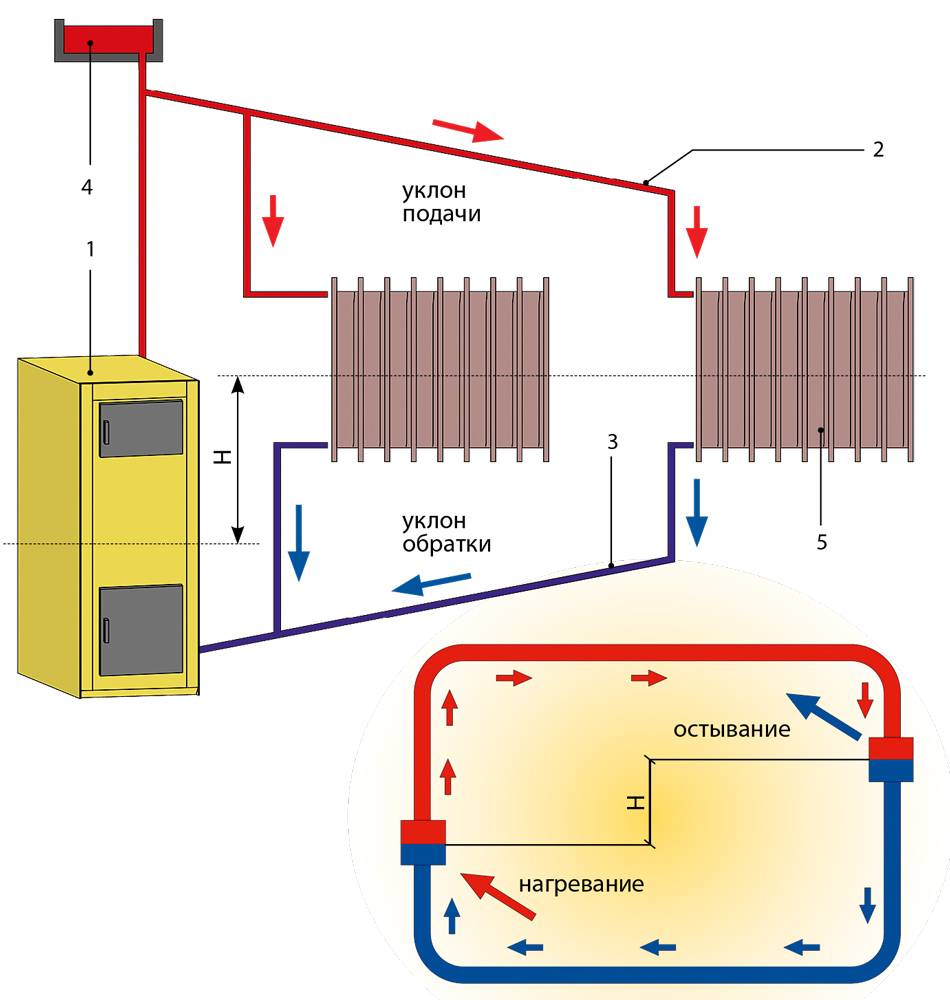

Construction schemes, use in apartment buildings

In private houses, a single-pipe or two-pipe heating circuit is used.

The single-pipe scheme is used in rooms with a small area, where no more than five radiators are required for heating.

Photo 1. Scheme of a closed heating system with a single-pipe circuit. Each of the radiators is connected in series.

All batteries are included in the circuit in series, so the last heater will always be colder than the first. The obvious advantage of such a scheme is the lower consumption of pipes.

If one battery fails, the others will continue to operate normally while using the bypass. The single-pipe system is horizontal and vertical. The horizontal one does not allow you to adjust the amount of coolant, therefore, when laying it, bypasses are installed. A vertical single-pipe circuit is in most cases used in high-rise buildings.

A two-pipe (two-circuit) scheme heats the premises more evenly.The liquid from the heat generator to the batteries circulates through two circuits. Radiators in this case are connected in parallel. The coolant has the same temperature in all batteries. This method is much more expensive, but it makes it possible to regulate the temperature in each room.

Calculation

In order to choose the right circulation pump and pipe diameters, a hydraulic calculation of the heating circuit is carried out. It allows you to identify hydraulic pressure losses in specific areas and minimize operating costs.

Attention! It is advisable to install the circulation pump in the return line. In this case, the service life of the device will increase, since an already cooled coolant will pass through it.

Calculations are carried out by a specialized specialist using thermal engineering calculation and after selection of batteries. As a result of the calculations, the pressure value necessary for the circulation of water by the circulation pump will be obtained. After this stage, the value is calculated to determine the volume and selection of the membrane tank.

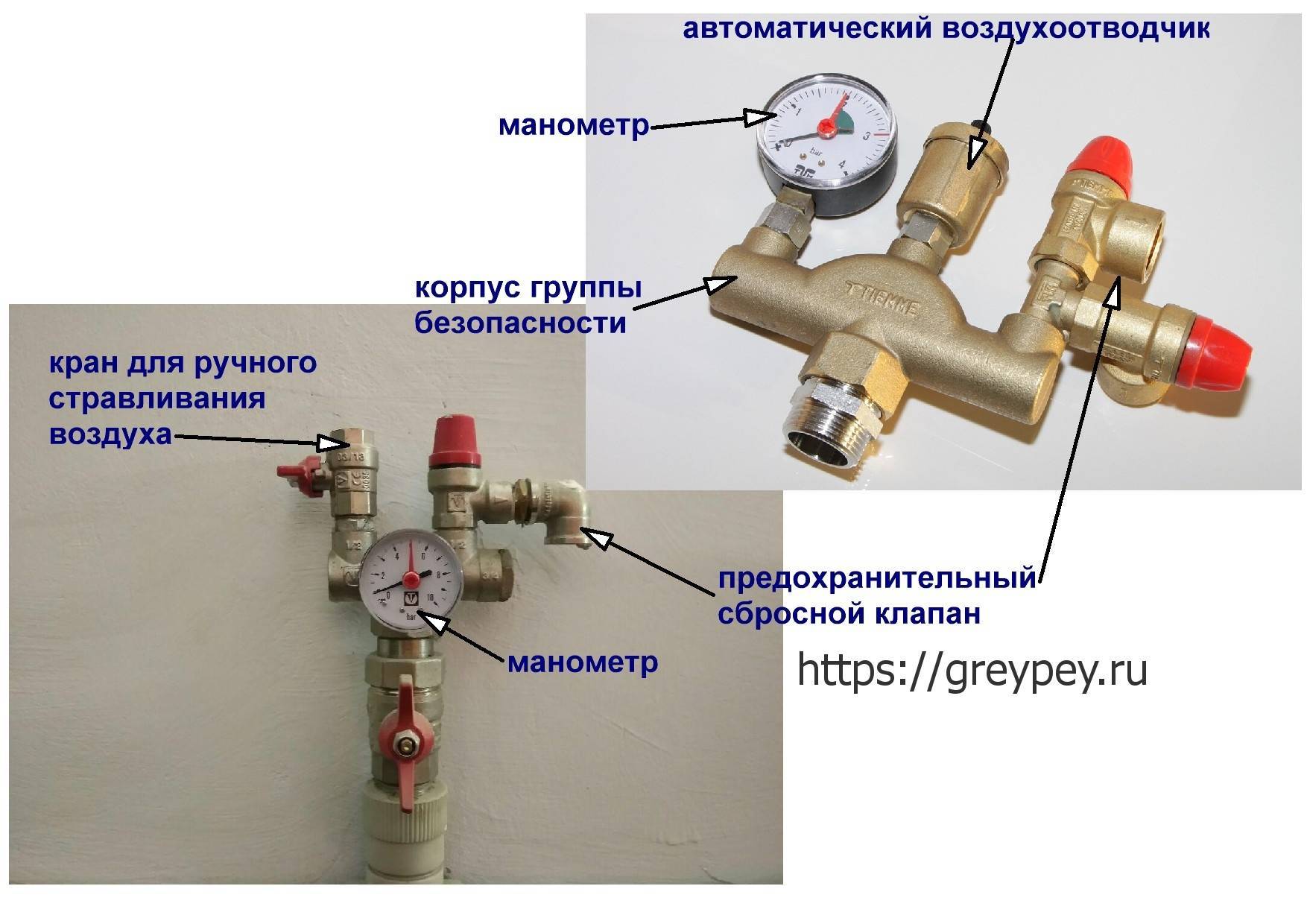

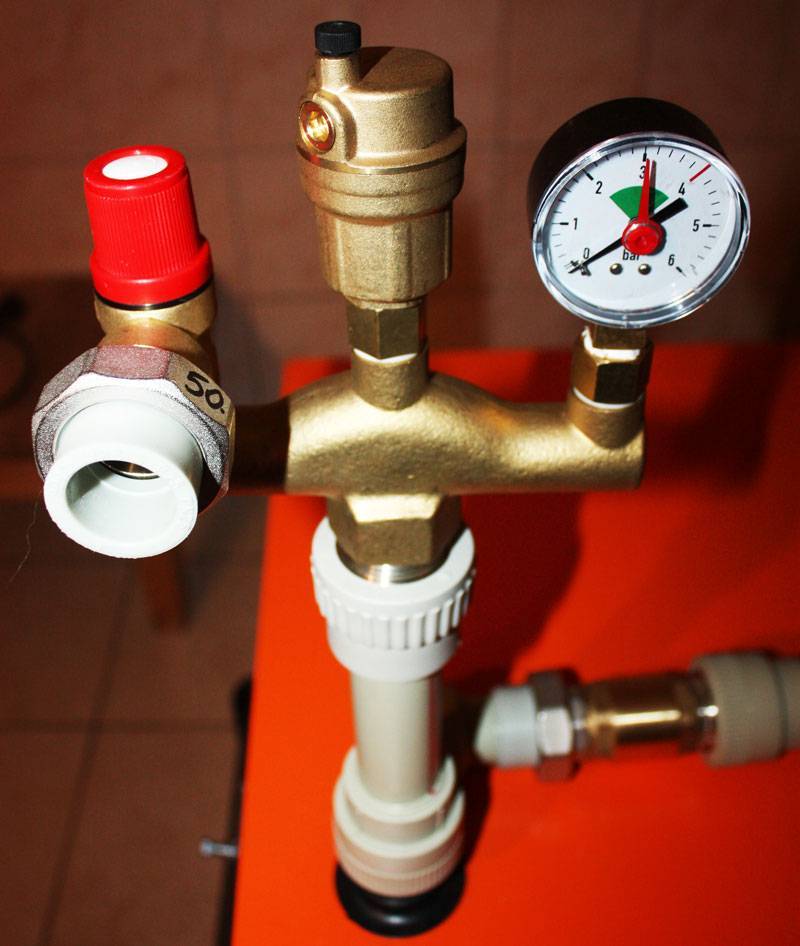

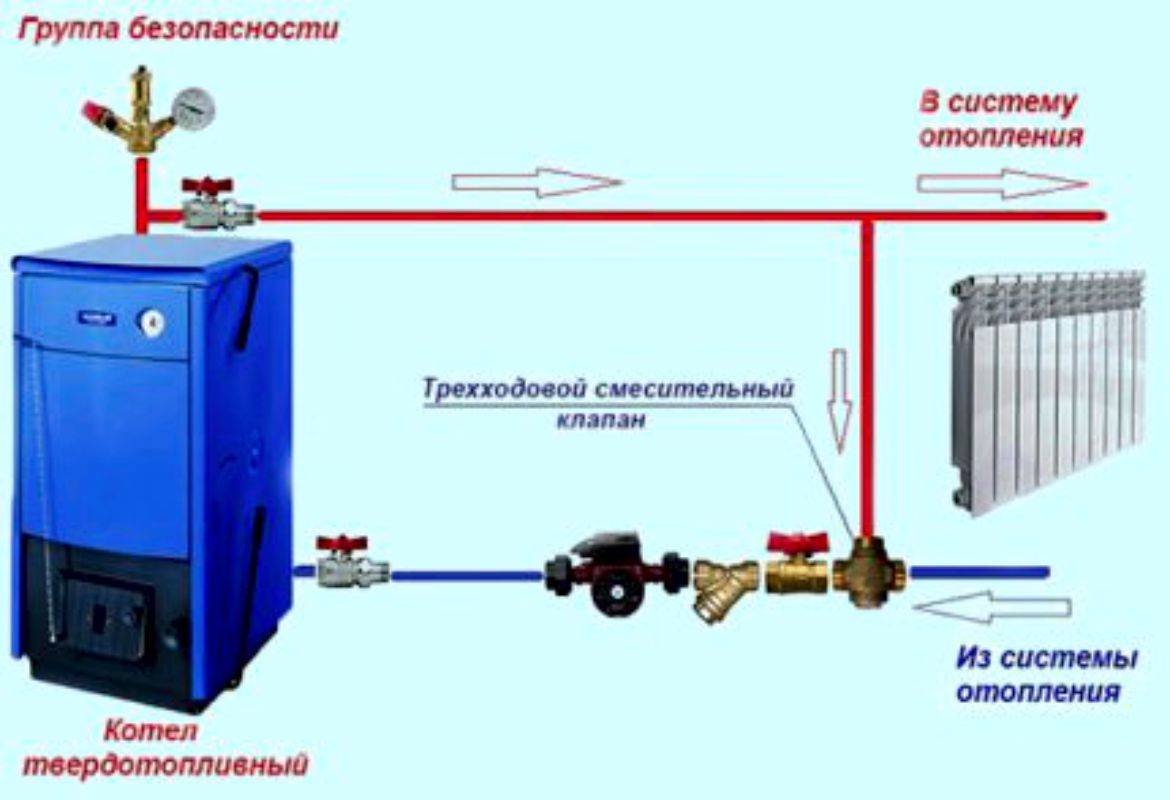

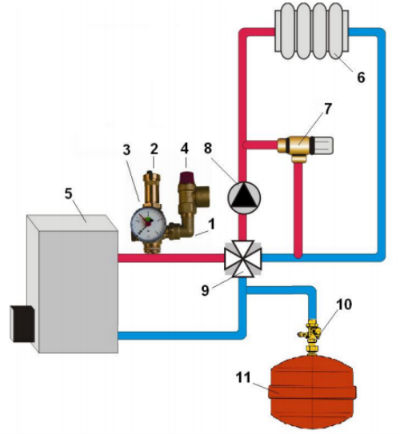

Security group for heating for a private house. Composition and principle of operation

Group heating security is a mechanism that consists of a whole set of devices. Thanks to their well-coordinated work, trouble-free operation of the system is ensured, as well as full control of the pressure in the coolant.

What parts does the heating system consist of?

When an emergency occurs in a private house or an expansion tank fails, the pressure in the heating system increases sharply. This can lead to an explosion in the pipe, as well as damage to the heat exchanger of the heating tank.Of course, each person cares about heating a private house. The safety group, in the event of a breakdown, will compensate for excess pressure, and also prevent airing of the system. It works in automatic mode and tries to quickly relieve excess pressure.

The safety group includes a metal case, which has a threaded connection. A pressure gauge, a safety valve, and an air vent are installed here.

- The pressure gauge is a measuring device that provides visual control over the resulting pressure, as well as the temperature regime in the heating system.

- Air vent. It works in automatic mode and dumps excess air in the system.

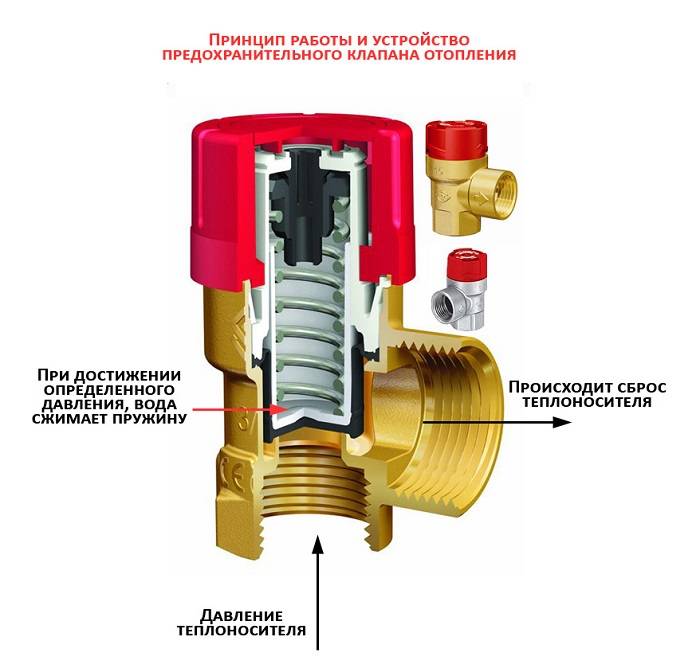

- Safety valve. It is designed to remove excess fluid that is in a closed system. Sometimes, when the coolant is heated, it can expand and create excess pressure.

Principle of operation

If certain situations arose, and the expansion tank could not compensate for the expansion of the coolant in time, then the safety valve mechanism will work in this case. The heating safety group will open the way to release excess coolant. Unwanted air can escape through the air vent.

To prevent a person from getting burned during the sudden opening of the check valve and the release of excess coolant, it is necessary to connect a drain pipe. It must be directed to the sewer system. Many people believe that there will be little liquid left in the system when the safety valve is activated.But this opinion is erroneous, because in most cases, in order to normalize the pressure, the system dumps no more than 120 grams of coolant.

How to properly set a security group

Today, wall-mounted boilers for heating a private house are in great demand. In most cases, they already have a safety group for the heating system. In a floor boiler, especially if it is from a domestic manufacturer, there is no such unique device. That is why buyers will have to think about additional installation of a boiler system. In order for it to work correctly and properly, the installation process must be trusted only by qualified specialists. Only they will be able to set all parameters and settings. If errors or oversights are made during installation and connection, the heating safety group will not work correctly.

In most cases, installation is carried out to the boiler on the supply line. The most optimal distance is about 1.5 meters, because it is in this position that the pressure gauge will be able to control the pressure in the system.

Common Instructions for Installing a Security Group

Each manufacturer that produces such equipment prescribes all the installation rules in the instructions. But there are generally accepted regulatory documents, where all the installation rules are clearly described.

Safety valves that are located in the heating system must be installed on the supply pipeline. They are mounted right next to the boiler

A certain level of power is taken into account in order to cut and duplicate these devices.

In a system where there is hot water, valves must be installed at the outlet.In most cases, this is the highest point on the boiler.

No devices should be placed between the valves and the main pipes. The heating safety group in the system plays an important role during the operation of the boiler

To ensure complete safety, care must be taken to properly install this system.

The heating safety group in the system plays an important role during the operation of the boiler. To ensure complete safety, care must be taken to properly install this system.

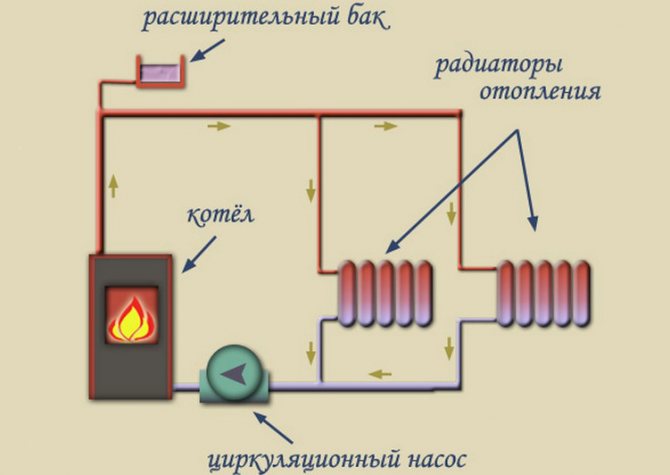

Expansion tank for closed heating system

The expansion tank for is designed to compensate for changes in the volume of the coolant depending on temperature. In closed heating systems, this is a sealed container, divided by an elastic membrane into two parts. In the upper part there is air or an inert gas (in expensive models). While the coolant temperature is low, the tank remains empty, the membrane is straightened (picture on the right in the figure).

The principle of operation of the membrane expansion tank

When heated, the coolant increases in volume, its excess rises into the tank, pushing the membrane and compressing the gas pumped into the upper part (in the picture on the left). On the pressure gauge, this is displayed as an increase in pressure and can serve as a signal to reduce the intensity of combustion. Some models have a safety valve that releases excess air/gas when a pressure threshold is reached.

As the coolant cools, the pressure in the upper part of the tank squeezes the coolant out of the tank into the system, the pressure gauge returns to normal. That's the whole principle of operation of the expansion tank of the membrane type.By the way, there are two types of membranes - dish-shaped and pear-shaped. The shape of the membrane does not affect the principle of operation.

Types of membranes for expansion tanks in closed systems

Volume calculation

According to generally accepted standards, the volume of the expansion tank should be 10% of the total volume of the coolant. This means that you have to calculate how much water will fit in the pipes and radiators of your system (it is in the technical data of the radiators, but the volume of pipes can be calculated). 1/10 of this figure will be the volume of the required expansion tank. But this figure is valid only if the coolant is water. If an antifreeze liquid is used, the tank size is increased by 50% of the calculated volume.

Here is an example of calculating the volume of a membrane tank for a closed heating system:

- the volume of the heating system is 28 liters;

- expansion tank size for a system filled with water 2.8 liters;

- the size of the membrane tank for a system with antifreeze liquid is 2.8 + 0.5 * 2.8 = 4.2 liters.

When buying, choose the nearest larger volume. Do not take less - it is better to have a small supply.

What to look for when buying

The stores have red and blue tanks. Red tanks are suitable for heating. Blue ones are structurally the same, only they are designed for cold water and do not tolerate high temperatures.

What else to pay attention to? There are two types of tanks - with a replaceable membrane (they are also called flanged) and with an irreplaceable one. The second option is cheaper, and significantly, but if the membrane is damaged, you will have to buy the whole thing

In flanged models, only the membrane is bought.

Place for installation of expansion tank of membrane type

Usually they put an expansion tank on the return pipe in front of the circulation pump (when viewed in the direction of the coolant). A tee is installed in the pipeline, a small piece of pipe is connected to one of its parts, and an expander is connected to it, through fittings. It is better to place it at some distance from the pump so that pressure drops are not created. An important point is that the piping section of the membrane tank must be straight.

Scheme of installation of an expansion tank for membrane type heating

After the tee put a ball valve. It is necessary to be able to remove the tank without draining the heat carrier. It is more convenient to connect the container itself with the help of an American (flare nut). This again facilitates assembly/dismantling.

Empty device weighs not so much, but filled with water has a solid mass. Therefore, it is necessary to provide a method of fixing on the wall or additional supports.

1 Causes of the accident

To avoid malfunctions in the heating system, a safety block is used. It helps to achieve the required volume of liquid in the boiler and the heating line. With an excessive pressure value, excess hot water is discharged from the circuit. Emergencies, such as overheating of a water apparatus, lead to an overestimated temperature regime of the coolant. The liquid increases in volume, for which the closed-type heating system is not designed - there is no additional reserve.

The consequences of increased pressure above the norm may be situations in which breakdowns of the elements of the heater or breaks in the line occur.The heating protection group will help control the pressure and prevent dangerous moments.

Features of the heating circuit with a membrane expansion tank

A circulation pump in a closed circuit allows you to organize the structure according to any scheme, regardless of the hydraulic resistance indicator. Forced circulation makes it possible to use various options for organizing heating:

- sequential arrangement of radiators;

- collector circuit;

- warm floor.

Diaphragm expansion tank and circulation pump can be located together with the heat generator in the same room

This reduces the total length of the pipelines, therefore, when organizing a heating circuit, it is not necessary to install pipes of large diameters and pay attention to the angles of inclination

Photo 2. Scheme of the structure of a membrane tank for a closed heating system. The arrows indicate parts of the structure.

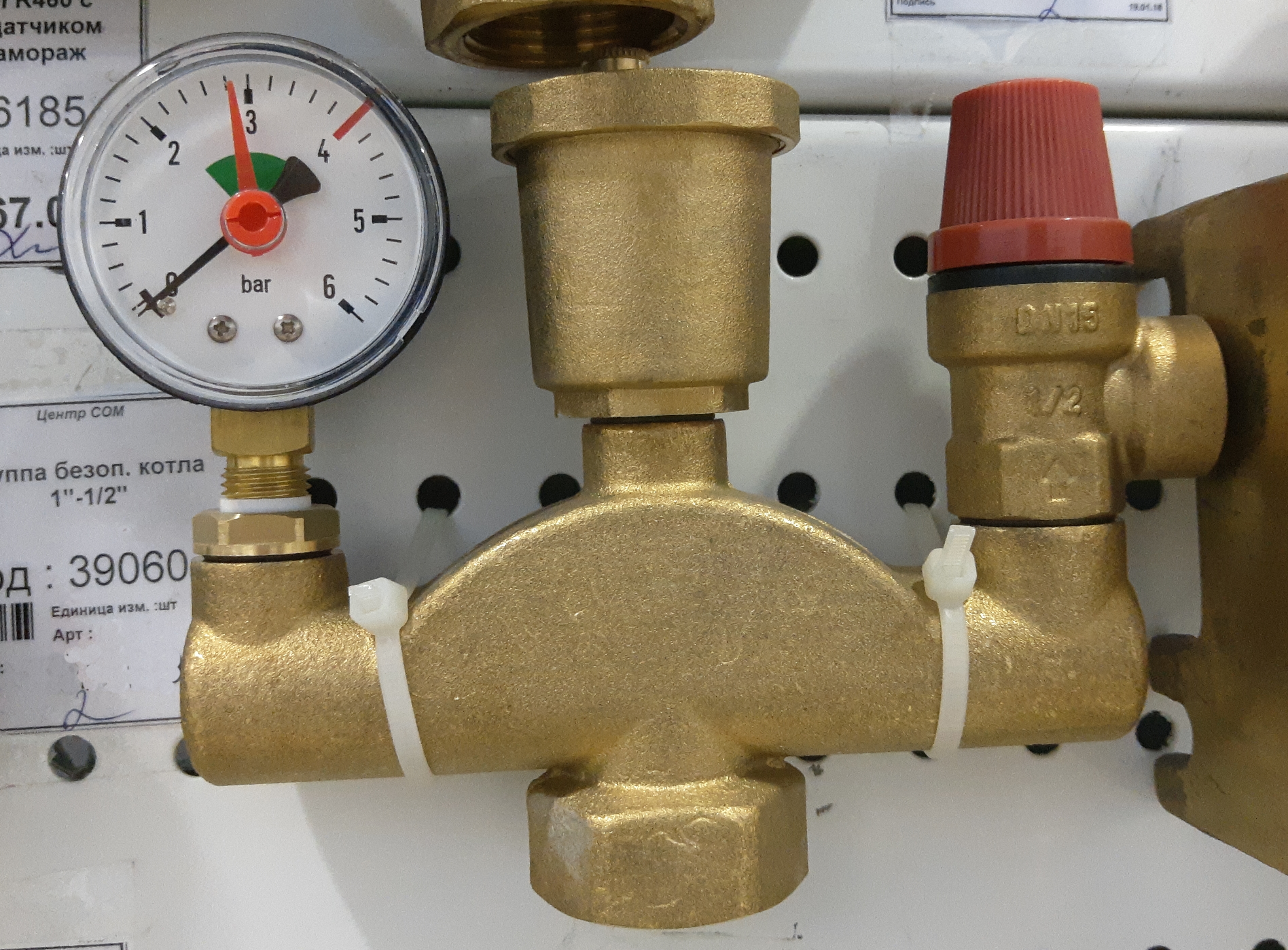

Assigning group members

Security group members

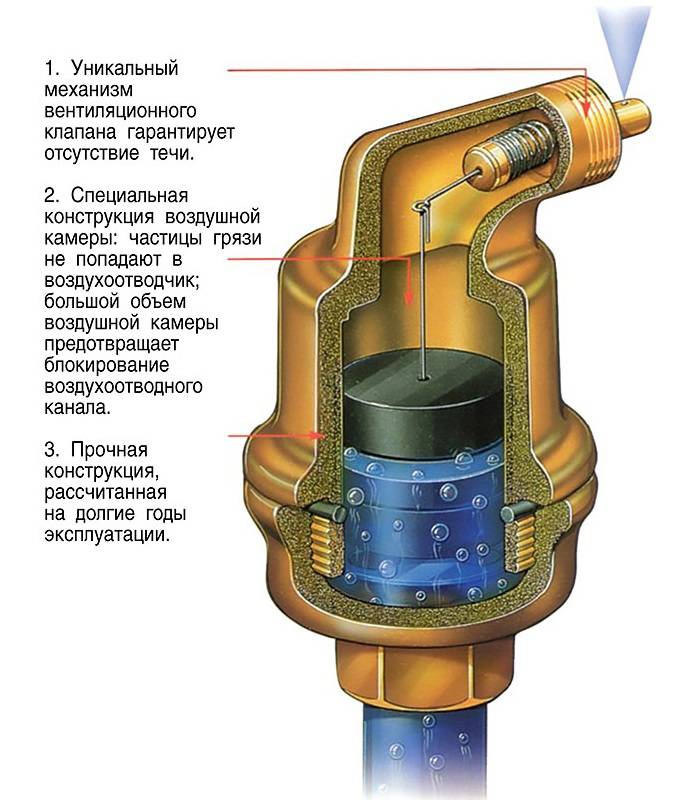

Security group members

When considering the individual elements of the security node, special attention is paid to their purpose:

- the pressure gauge is designed to control the water pressure in the boiler tank, as well as in the entire system as a whole; its other purpose is to monitor the coolant pressure when filling pipelines in closed-type units;

- a device for bleeding excess air allows you to get rid of the so-called "traffic jams" when setting up the heating network; also with its help, portions of steam are released, which are formed in the boiler tank during overheating;

- the safety valve is designed to relieve the pressure of water, steam or their mixture when they exceed a predetermined threshold level.

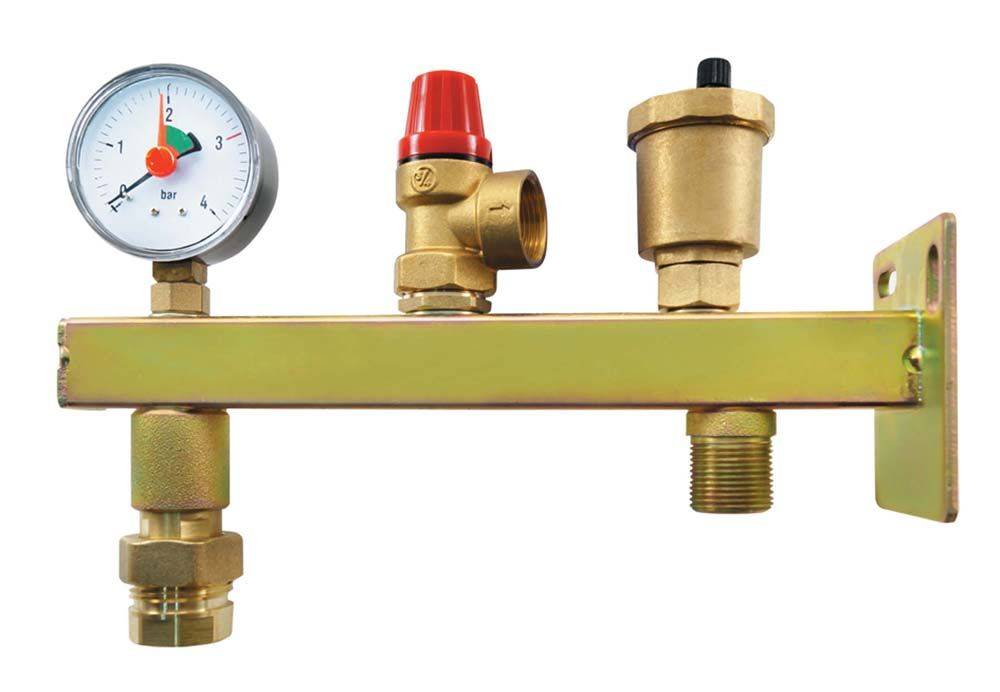

Structural elements

The scheme of the heating safety group provides for the use of all structural elements. Otherwise, the unit will not function properly, which can lead to various breakdowns and accidents.

Accurate pressure gauge

This device is designed to measure pressure (in atmospheres or bar) and provide instant results. To do this, a scale is graduated on the pressure gauge and there are two arrows. One of them shows the pressure in the heating system, and the second - the limit value, which is set during the setting.

- For pipelines of heating systems installed in apartment buildings - 1.5 bar.

- In suburban one-story buildings - from 2 to 3 bar.

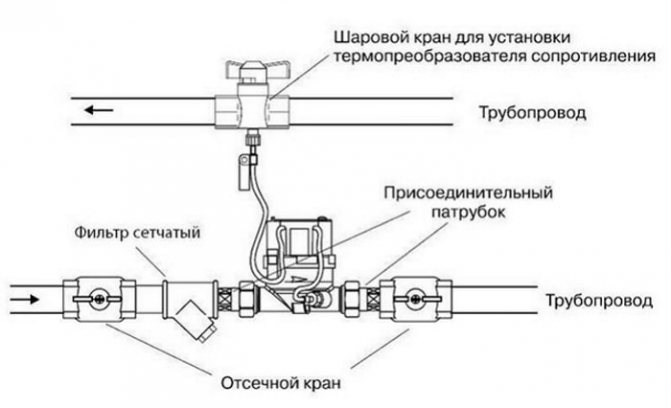

Mayevsky crane

An automatic air vent must be installed in the heating security system of a private house and a city apartment. It is best to do this at the highest possible height. This feature is due to the fact that air is lighter than the coolant. It moves up and accumulates there, preventing the equipment from working properly.

Read also: how to properly release air from a heating battery.

Air may appear due to the following factors:

- Rubber seals of poor quality or premature wear.

- The first start-up of the installation and filling the pipes with coolant.

- Corrosion formation inside the lines of the device.

- Incorrect installation or non-observance of tightness conditions.

- Drinking water.

Such a faucet protects your heating system from the ingress of various dirt.

Mayevsky's crane is designed in such a way that the smallest particles of dirt cannot get into the air chamber. The air vent is assembled from the following parts:

- case with cover;

- jet;

- float;

- spool;

- holder;

- body and valve sealing rings;

- cork;

- spring.

Safety valve

During operation of the heating system, an increase in the volume of the coolant is compensated by an expansion tank, which is mounted on top of the heating devices and pipes. The user independently sets the desired outlet temperature, which leads to a change in the liquid level in the expansion tank.

In most cases, the performance of this node remains effective for a long time. As wear increases, the likelihood of any breakdown increases. It is absolutely impossible to determine the problem visually, since its root is hidden inside the pipeline. Such a malfunction will lead to a rapid increase in pressure and the destruction of the nodes of the heating system. To combat this phenomenon, a safety valve is used. It is installed together with other parts of the safety group and protects the device from damage. In addition, the owner of the dwelling will see the discharge of fluid, which will confirm the presence of a problem.

Before starting operation, it is necessary to check the safety valve for operability. You can do this in the following way:

- The handle, which is located at the top, turns in the indicated direction and opens the water.

- Then the same actions are done in the opposite direction.

- If the liquid still flows out, then it is necessary to open and close the safety valve several times in a row.

- If the manipulations performed did not give the desired result, then the valve is broken and must be replaced with a new one.

Choice

It is important to choose a safety group that exactly matches the characteristics of the assembled heating system. Each element of the group, pressure gauge, safety valve and air vent has its own technical and operational characteristics, which must exactly meet the requirements of the heating project

Manufacturers offer ready-made solutions and security group assemblies based on the most common home heating options, for various boilers and wiring methods.

Before proceeding with the selection, you should carefully read the technical manual for your boiler. If this is a wall-mounted gas or electric boiler, then it already has a security group, moreover, it is fully consistent with its parameters, therefore it does not need to be duplicated. In the case of floor-standing boilers, solid fuel, stoves and fireplaces with a water circuit, there is no built-in equipment and piping in most cases. Read more about how to choose a heating boiler here.

All elements of a security group are pinned to a single console. This is actually a pipe with prepared triples for connecting equipment and two outlets for inclusion in the heating circuit.

When choosing, you should specify:

- Diameter for connection pipes (1’, ¾’, ½’).

- Connection option (corner, bottom, side, etc.), from which side pipes should be brought to the safety group, and how exactly to orient it.

In any case, the air vent is mounted at the top of the group. So it should remain connected. Below it is a pressure gauge and a safety valve.This is done so that air accumulating in the air chamber does not affect the reading of the pressure gauge and the operation of the explosion valve.

Safety console material: nickel, stainless steel, bronze, cast iron.

Cast iron is used only for high-pressure and productive heating systems with a large cross-section of pipes on the wiring. Basically, these are collective industrial boiler houses. For a private home, it is better to choose from nickel or stainless steel. In this case, the console and equipment can simply be covered with an outer casing made of black cast iron for additional protection.

pressure gauge

Two main characteristics:

- permissible measurement range (upper and lower limit);

- accuracy of measurement and indication of indications (scale and error).

The measuring range must cover with a margin of 0.5-1 bar the nominal value of the pressure in the system and the permissible deviations during operation.

Suppose, for heating, a nominal pressure of 3 atm is assumed. The permissible deviation to the smaller side will be equal to 1.5 atmospheres. A decrease below 1.5 atm will be considered a signal for an emergency. The upper limit will be 4.5-5 atm, after which the safety valve should inevitably work. Accordingly, the pressure gauge range should be from 1 to 5-6 atm. It is desirable that the scale be as accurate as possible and indicate areas of attention. At the same time, the scale is conditionally divided into 3-4 zones, marked with color markers, so that even with a cursory glance, you can respond to any deviations.

Air vent

It is characterized by the working pressure in the system and the response parameters. Almost all automatic valves are adjustable to set the optimum pressure and actuation conditions.If you set the adjustment knob to the minimum position, then at the slightest accumulation of air, the valve will operate. At the maximum setting, the valve operates less frequently, but accumulates more air. It is difficult to say which setting would be more appropriate. It is easier to leave the factory settings unchanged if the heating system is installed independently.

Safety valve

The main parameter of the valve is the response pressure. The upper limit of the pressure in the circuit, upon reaching which the valve opens and dumps part of the coolant. It is for this characteristic that you should choose a security group in the first place. The response pressure can only be adjusted within small limits.

It is useful to clarify in advance the method of installing the safety group and determine how and in which direction the valve discharges water. The discharge fitting must be oriented away from the main equipment and the heating boiler. It is necessary to pick up a hose for draining into the sewer.

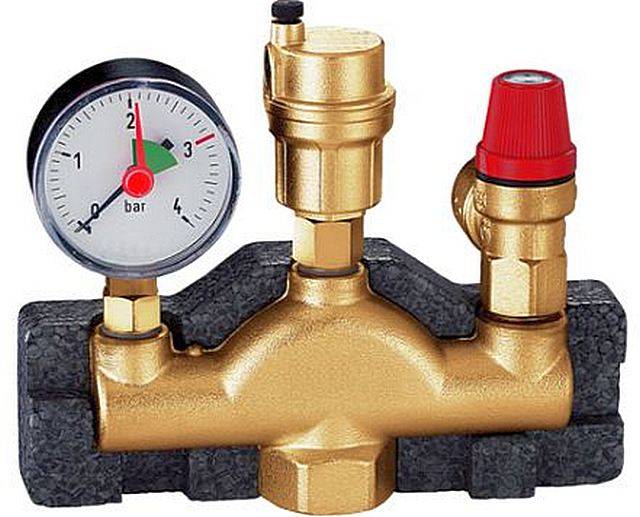

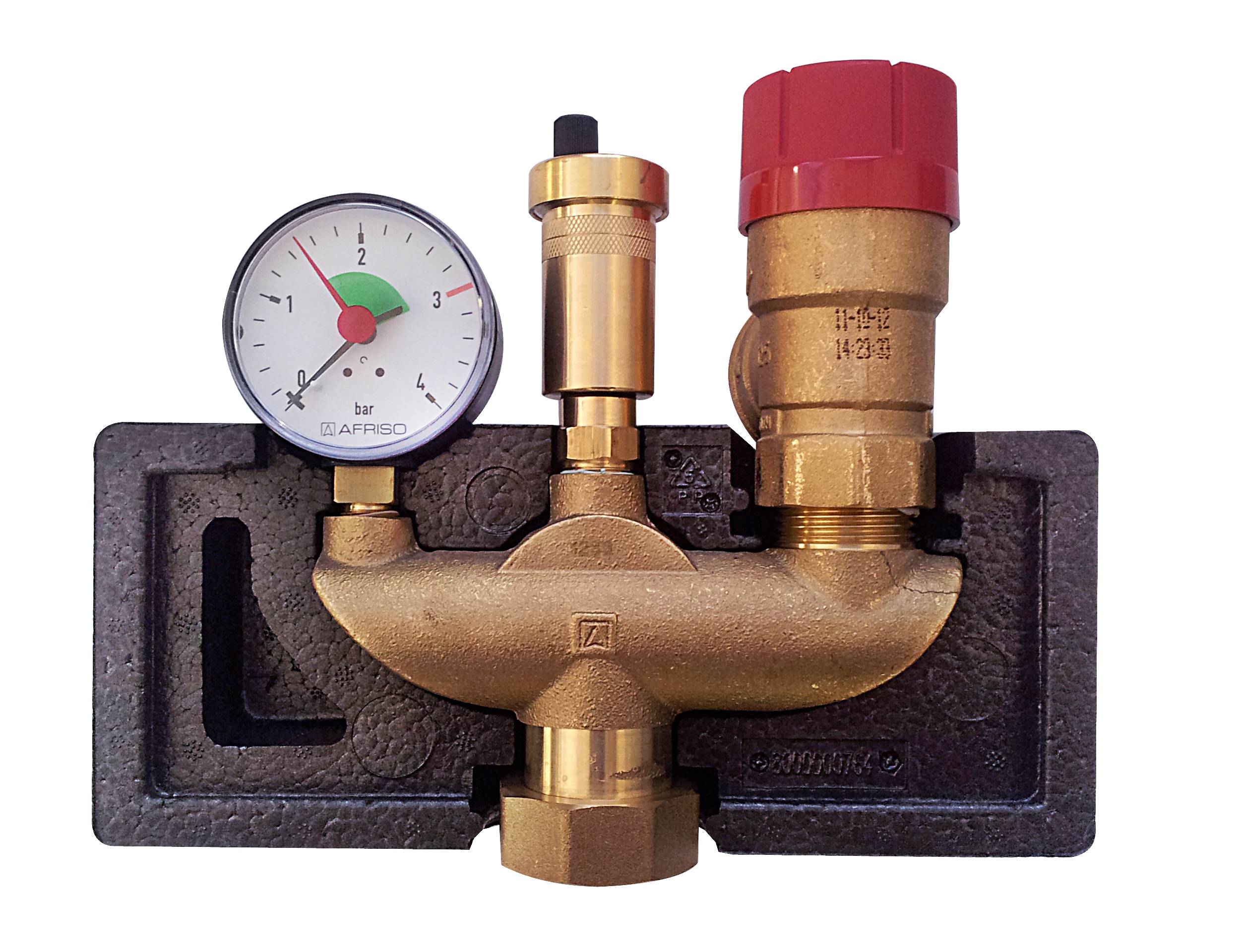

Group types

Consider the main characteristics of security groups using the following samples as an example.

Valtec VT460

This safety group is equipped with autonomous boilers, heating boilers, as well as hot water supply. They are widely used in thermal installations with power up to 45 kW, operating pressure up to 10 bar and coolant temperature up to 120 degrees Celsius. Water, steam, non-freezing liquid with a maximum glycol content of up to 50 percent are allowed as a heat carrier. The group includes a nickel-plated brass manifold, air vent, pressure gauge and safety valve. This unit is installed at the outlet of the heat generator.

This safety group is equipped with autonomous boilers, heating boilers, as well as hot water supply. They are widely used in thermal installations with power up to 45 kW, operating pressure up to 10 bar and coolant temperature up to 120 degrees Celsius. Water, steam, non-freezing liquid with a maximum glycol content of up to 50 percent are allowed as a heat carrier. The group includes a nickel-plated brass manifold, air vent, pressure gauge and safety valve. This unit is installed at the outlet of the heat generator.

Watts KSG

Safety groups of such models are installed on boilers of various capacities - up to 50, 100 and 200 kW. The composition of the equipment is the same as in the previous model - fuse, pressure gauge, air duct and manifold. Moreover, the collector is made of steel with galvanized coating. The safety valve operates at a pressure of 3 bar, the maximum operation of the coolant is not more than 100 degrees.

Safety groups of such models are installed on boilers of various capacities - up to 50, 100 and 200 kW. The composition of the equipment is the same as in the previous model - fuse, pressure gauge, air duct and manifold. Moreover, the collector is made of steel with galvanized coating. The safety valve operates at a pressure of 3 bar, the maximum operation of the coolant is not more than 100 degrees.

Uni fit

The safety group of Italian origin is used in closed heating systems and boilers with a rated power of up to 50 kW. The layout of the device is unchanged, and consists of an air outlet, a fuse, a bracket and a pressure gauge. Designed to work with a coolant temperature of up to 80 degrees, the fuse threshold is 3 bar. The device must be installed on the supply pipeline near the boiler. Operates with water or antifreeze in the system. This device is made of high strength steel.

The safety group of Italian origin is used in closed heating systems and boilers with a rated power of up to 50 kW. The layout of the device is unchanged, and consists of an air outlet, a fuse, a bracket and a pressure gauge. Designed to work with a coolant temperature of up to 80 degrees, the fuse threshold is 3 bar. The device must be installed on the supply pipeline near the boiler. Operates with water or antifreeze in the system. This device is made of high strength steel.