- How to choose the right cable?

- Installing the heating cable inside and outside the tube

- Types of heating cable

- Self-regulating heating cable

- Resistive heating cable

- Installation instructions for self-regulating cable

- Gasket inside the pipe

- Laying outside the pipe

- Placement methods

- Heating pipeline installation

- Mistakes when installing heating cables

- Conclusion

- Why a heat cable is needed: do it yourself

- 7. Is subsequent insulation of the heated pipeline necessary?

- cable cost

- Thermal insulation for water supply pipes

- Rigid insulation

- Roll insulation

- Segment (casing) heaters

- Sprayed insulation (PPU)

- 6. Useful tips regarding installation work

- How to perform thermal insulation of polypropylene pipes

How to choose the right cable?

When choosing a suitable hot cable, it is necessary to determine not only its type, but also the right power.

In this case, it is necessary to take into account such parameters as:

- the purpose of the structure (for sewerage and water supply, calculations are performed differently);

- the material from which the sewerage is made;

- pipeline diameter;

- features of the area to be heated;

- characteristics of the heat-insulating material used.

Based on this information, heat losses are calculated for each meter of the structure, the type of cable, its power are selected, and then the appropriate length of the kit is determined. Calculations can be performed using a special formula, according to calculation tables or using an online calculator.

The calculation formula looks like this:

Qtr - heat loss of the pipe (W); - coefficient of thermal conductivity of the heater; Ltr is the length of the heated pipe (m); tin is the temperature of the contents of the pipe (C), tout is the minimum ambient temperature (C); D is the outer diameter of communications, taking into account the insulation (m); d - outer diameter of communications (m); 1.3 - safety factor

When heat losses are calculated, the length of the system should be calculated. To do this, the resulting value must be divided by the specific power of the cable of the heating device. The result should be increased, taking into account the heating of additional elements. The power of the cable for sewerage starts from 17 W / m and can exceed 30 W / m.

If we are talking about sewer pipelines made of polyethylene and PVC, then 17 W / m is the maximum power. If you use a more productive cable, then there is a high probability of overheating and damage to the pipe. Information about the characteristics of the product can be found in its technical data sheet.

Using the table, choosing the right option is a little easier. To do this, you first need to find out the diameter of the pipe and the thickness of the thermal insulation, as well as the expected difference between the temperature of the air and the contents of the pipeline. The latter indicator can be found using reference data depending on the region.

At the intersection of the corresponding row and column, you can find the value of heat loss per meter of pipe. Then the total length of the cable should be calculated.To do this, the size of the specific heat loss obtained from the table must be multiplied by the length of the pipeline and by a factor of 1.3.

The table allows you to find the size of the specific heat loss of a pipe of a specific diameter, taking into account the thickness of the heat-insulating material and the operating conditions of the pipeline (+)

The result obtained should be divided by the specific power of the cable. Then you need to take into account the influence of additional elements, if any. On specialized sites you can find convenient online calculators. In the appropriate fields, you need to enter the necessary data, for example, pipe diameter, insulation thickness, ambient and working fluid temperature, region, etc.

Such programs usually offer the user additional options, for example, they help to calculate the required diameter of the sewer, the dimensions of the thermal insulation layer, the type of insulation, etc.

Optionally, you can choose the type of laying, find out the appropriate step when installing the heating cable in a spiral, get a list and the number of components that will be needed for laying the system.

When choosing a self-regulating cable, it is important to correctly consider the diameter of the structure on which it will be installed. For example, for pipes with a diameter of 110 mm, it is recommended to take the Lavita GWS30-2 brand or a similar version from another manufacturer

For a 50 mm pipe, the Lavita GWS24-2 cable is suitable, for structures with a diameter of 32 mm - Lavita GWS16-2, etc.

Complex calculations will not be needed for sewers that are not used often, for example, in a summer cottage or in a house that is used only occasionally. In such a situation, they simply take a cable with a power of 17 W / m with a length corresponding to the dimensions of the pipe.A cable of this power can be used both outside and inside the pipe, while installing a gland is not necessary.

When choosing a suitable option for a heating cable, its performance should be correlated with the calculated data on the likely heat loss of the sewer pipe

For laying a heating cable inside a pipe, a cable with special protection against aggressive effects, for example, DVU-13, is selected. In some cases, for installation inside, the brand Lavita RGS 30-2CR is used. This is not entirely correct, but a valid solution.

This cable is designed for heating roofs or storm drains, so it is not protected against corrosive substances. It can only be considered as a temporary option, since with prolonged use in inappropriate conditions, the Lavita RGS 30-2CR cable will inevitably break.

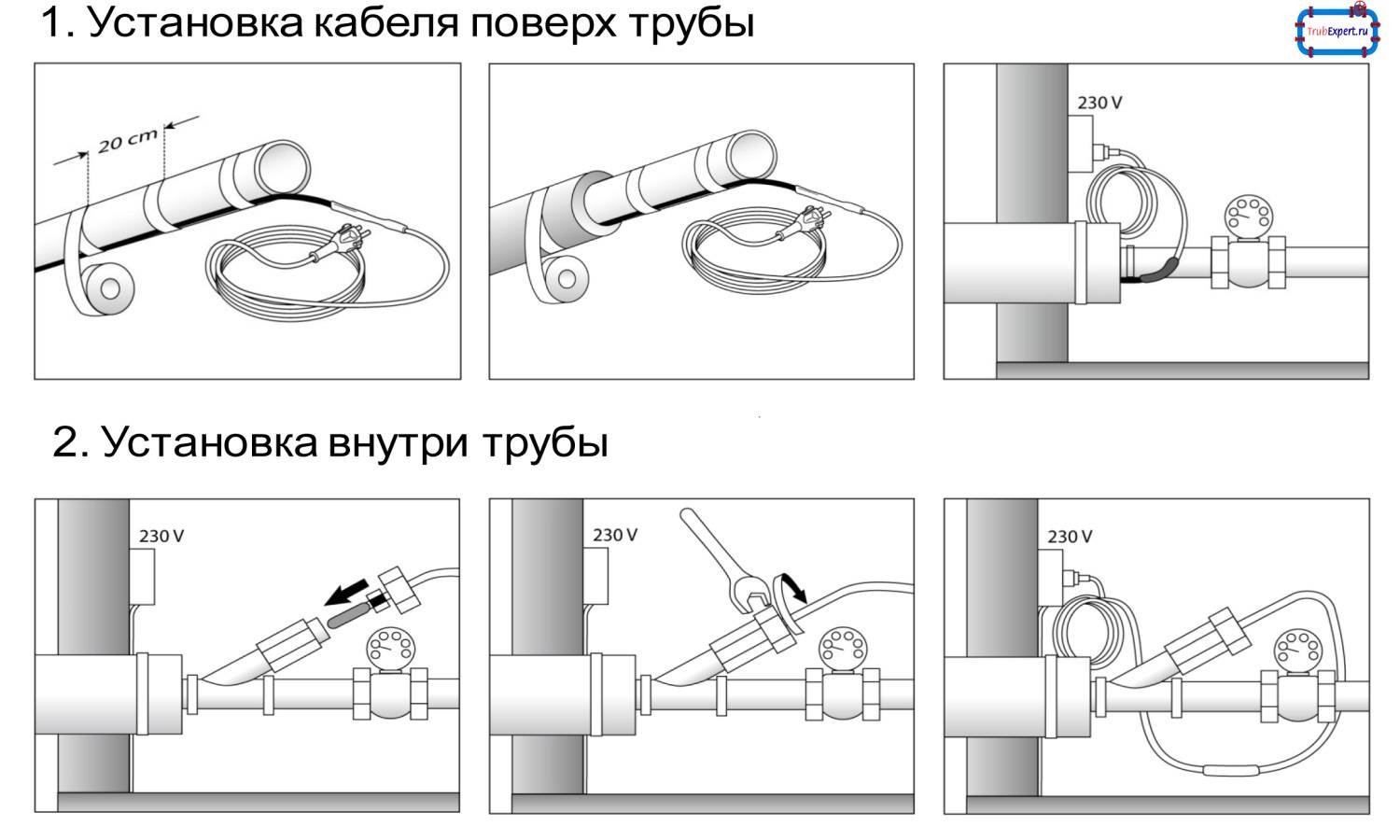

Installing the heating cable inside and outside the tube

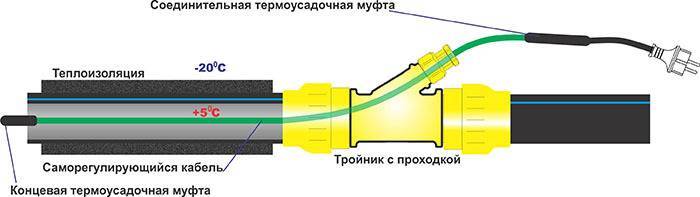

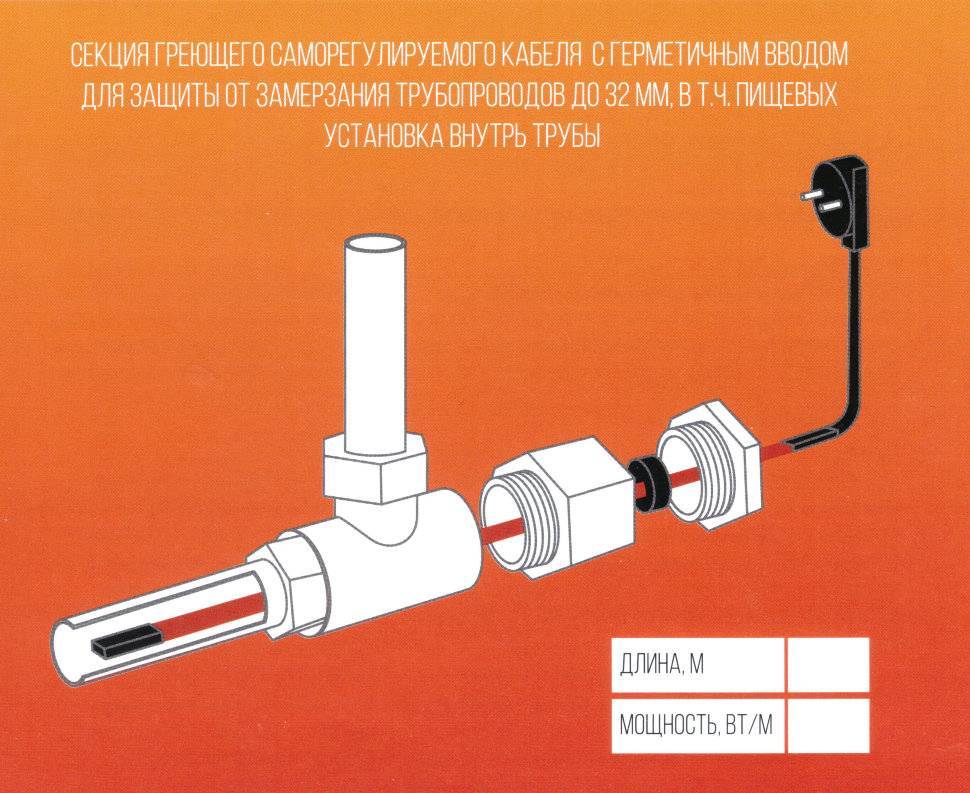

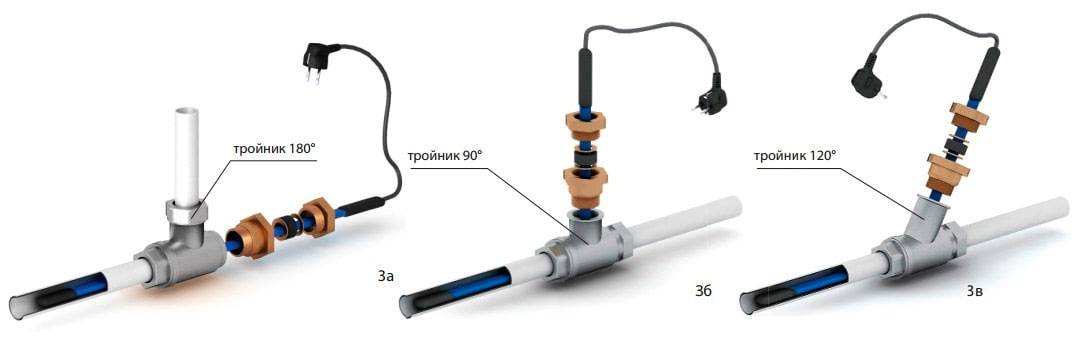

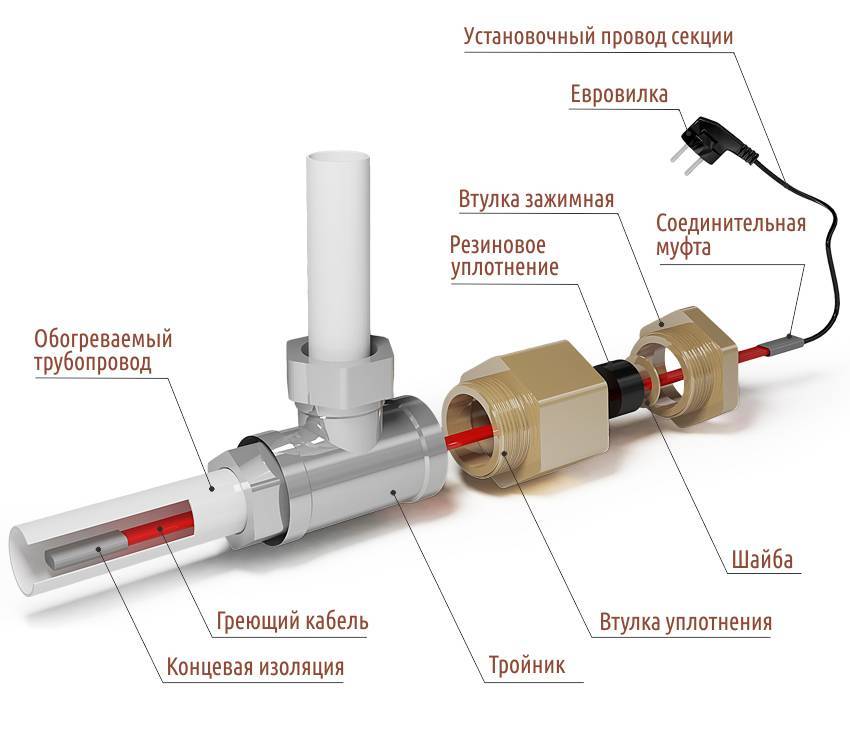

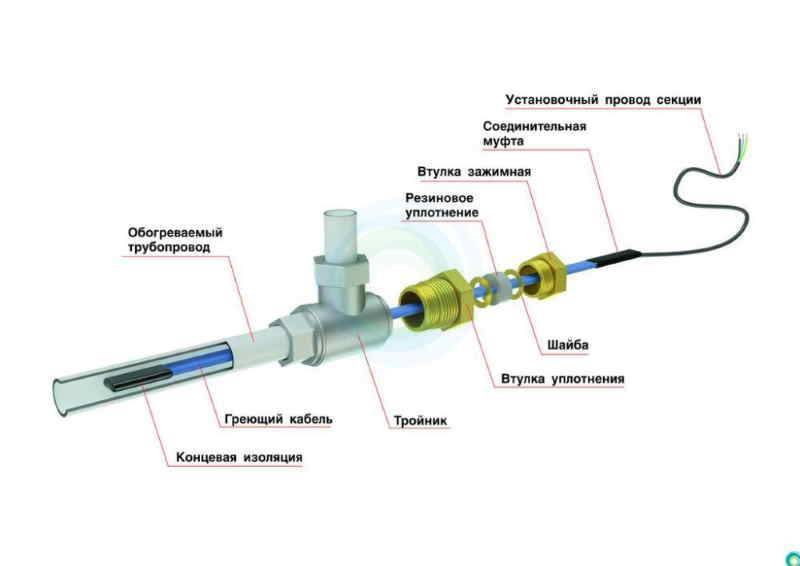

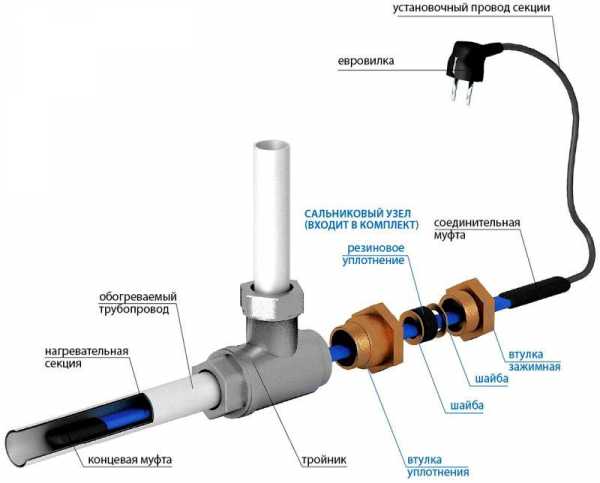

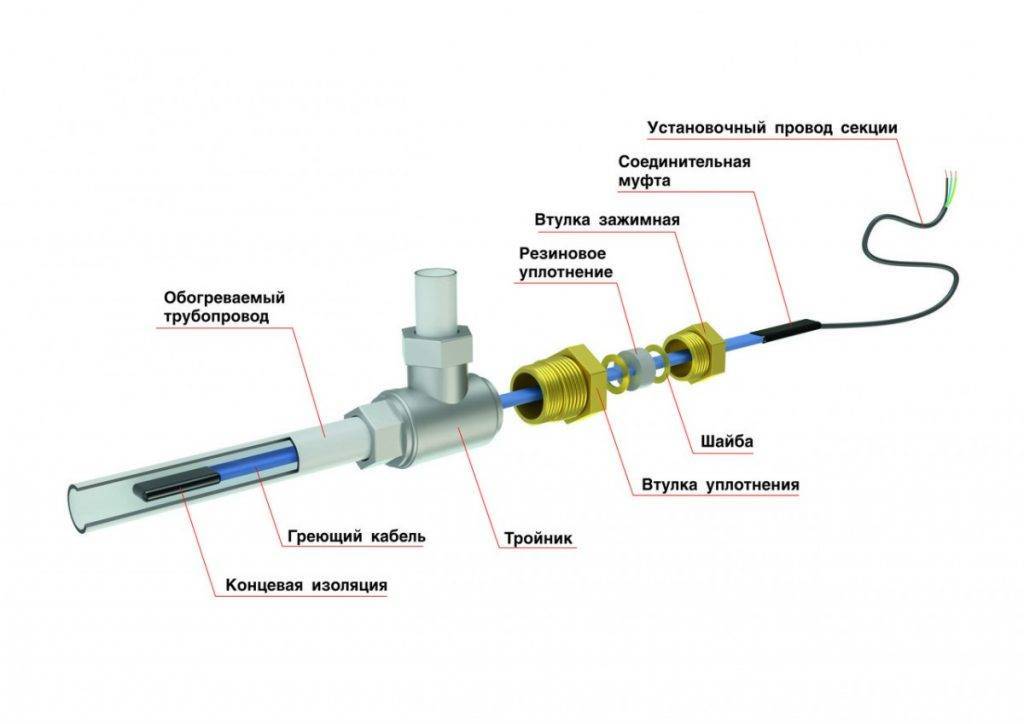

It is recommended to entrust the installation of a self-heating cable inside the pipe to specialists. The process involves inserting a tee through which the wire is inserted inward through the sleeve. In this case, care must be taken that the cable coating is not damaged when passing inside.

Installing the heating cable from the outside in a straight lineThe components of the cord are made of harmless materials, so you do not have to worry about water quality.

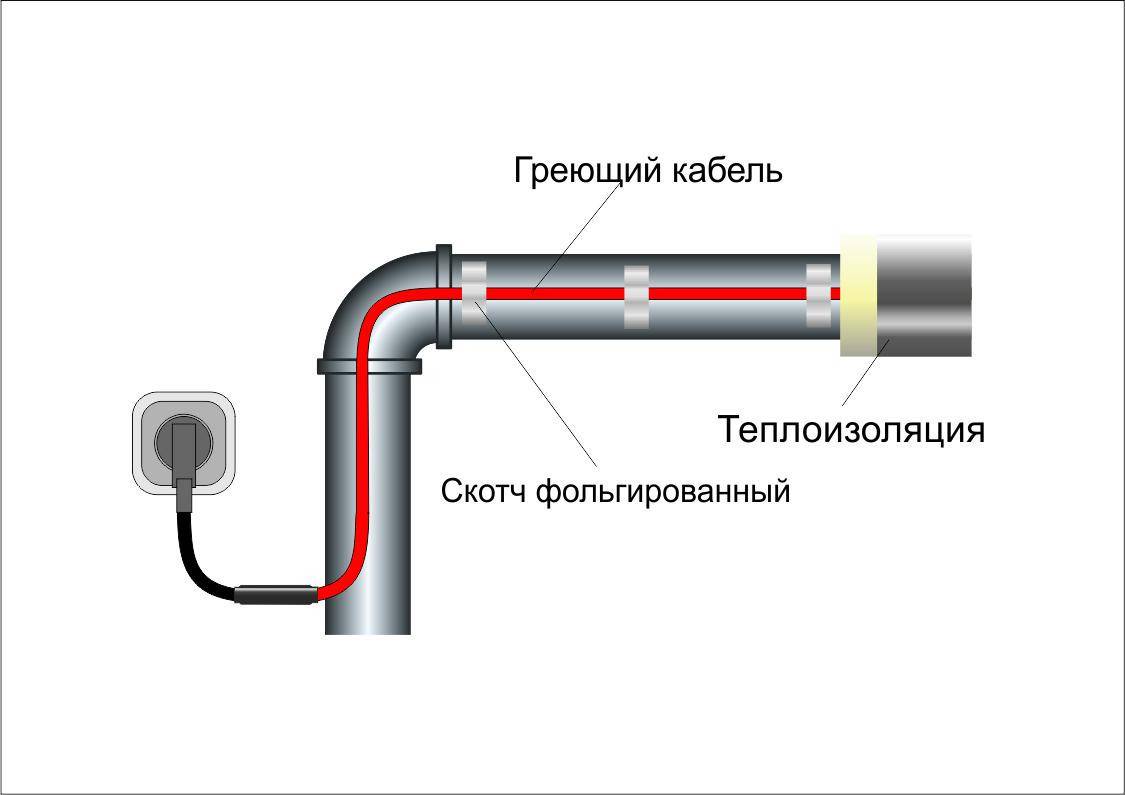

Installing a heating cable for sewerage outside is much easier. It is enough to attach the wire to the pipe using a mesh or adhesive tape. You can fix it in two ways: around and in a straight line. But it should be borne in mind that with a spiral installation, its efficiency will be higher, but the cost of heating will also increase.

The simplicity of outdoor installation allows you to correctly and quickly install the heating cable for sewer pipes.All work can be done by hand. When installing the cord inside the pipe, the maximum length according to the established rules should not exceed 60 m, if installed outside, then this figure is 100 m.

Possible connection schemes for one- and two-core heating resistive cables, as well as a self-regulating cable for a sewer pipe on the video:

Types of heating cable

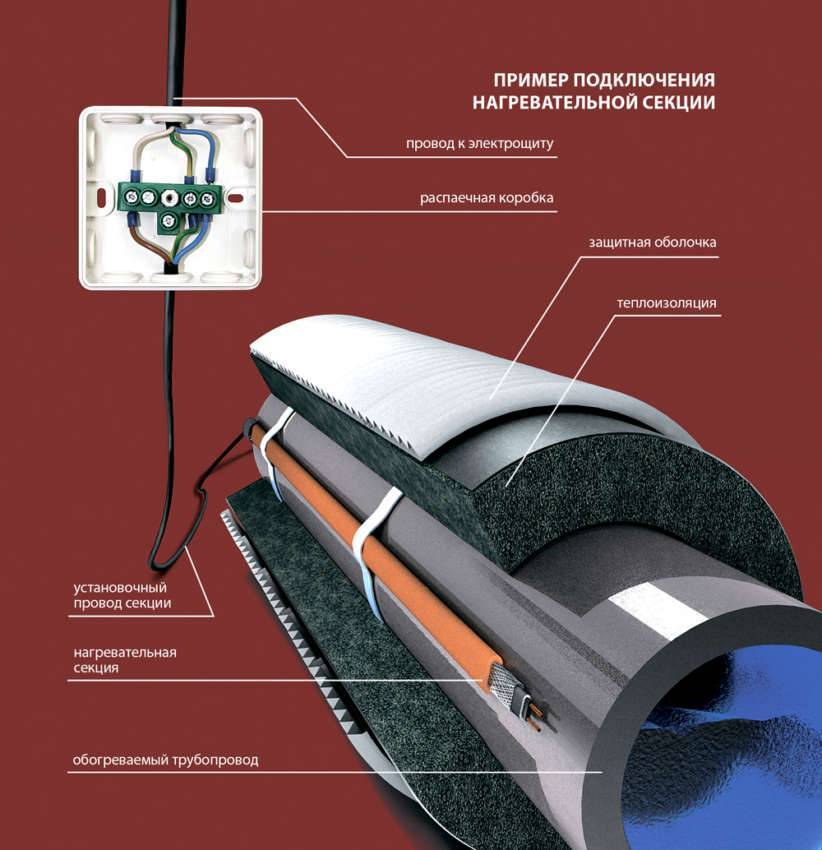

Picture 5. Mounting example

In total, there are two main types of these products:

Resistive heating.

The function of heating elements is performed by current conductors when it comes to these products. For pipes, these types of heaters are used less and less.

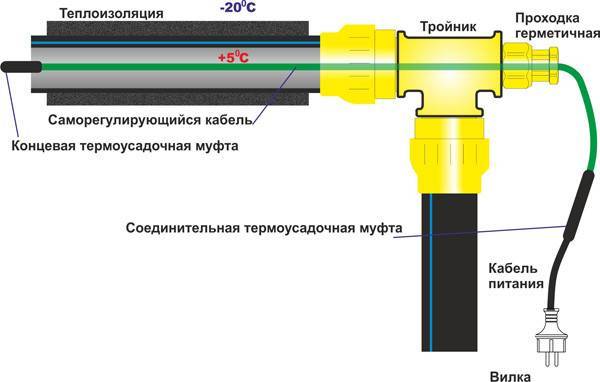

Self-regulating heating cables.

The most convenient to use.

Self-regulating heating cable

They consist of one or more cores, which are isolated from each other with the help of special shells. The areas of application of the products are different.

The necessary operating power is maintained independently by the product. The same goes for the amount of heat generated. Most often, the parameters are determined by what weather conditions develop where the system is used.

The operation of the cable depends on the resistance. The current supply is reduced if the resistance is greater. As a result, power is also reduced. Areas where it is necessary to raise or lower the degree are automatically determined by the heating cable.

Resistive heating cable

Consists of one or two conductive wires. They are not subject to self-cutting; they differ from existing analogues in a fixed length.

Without the use of thermostats in this case, it becomes impossible to change the power. Such heating cables are often found inside sewer pipes.

If the product includes two parallel cores through which current passes, then this is a zonal subspecies. A wire attached to the cores at a fixed distance acts as a heating element. Such varieties are supplied with special marks, according to which it is easy to cut when installing the heating cable.

Installation instructions for self-regulating cable

2 methods are used:

- hidden installation - this option is used to heat communications underground;

- open installation - for heating pipes located on the surface of the earth.

The cable is laid in sections of the pipeline where there are no shut-off valves, since this reduces the risk of damage to the wire. Installation is carried out in the warm season. Before starting work, the flow of fluid through the pipeline is stopped.

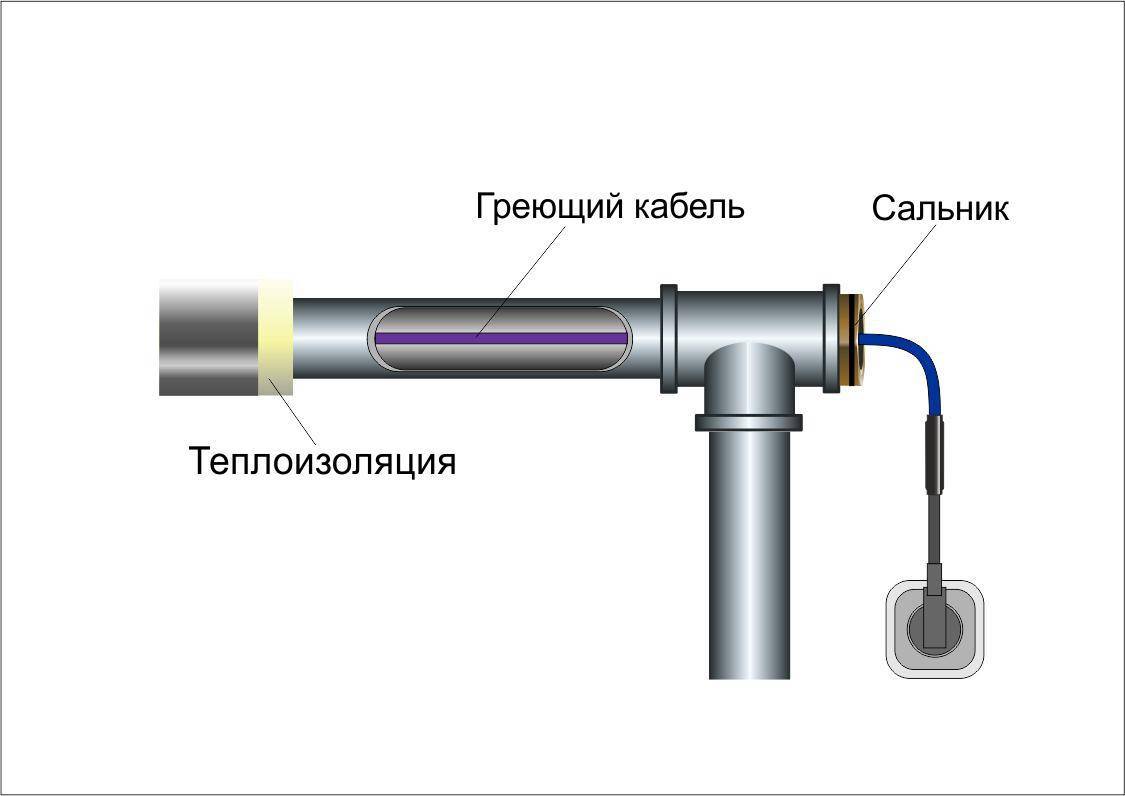

Gasket inside the pipe

Instructions for installing the cable using the first of the methods:

- The end of the cable is protected by a shrink film. This increases the reliability of the conductive wires.

- A gland is placed on the wire.

- The cable is pushed into the pipe.

- The plug is connected to the second end of the wire. In this case, the soldering method is used. This area is then protected with a coupling.

- The seal is fixed.

- A resistance measurement is in progress. Sometimes during the test phase, a short circuit is detected when voltage is applied, in which case the cable is removed and inspected for damage.

- The tightness of the pipeline is checked, for which a test water supply is performed.

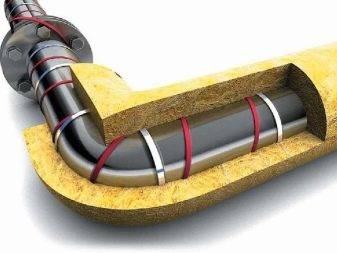

- The pipe is protected by thermal insulation against heat loss.

Laying outside the pipe

If the instructions that come with the heating system indicate the need to install one or another heater, you must follow it.

When it is planned to use an open mounting method, consider another connection scheme:

- Considering that the wire intended for such a task is characterized by elasticity, it is also used to prevent icing of valves.

- Various mounting methods are used: coil, straight. The second is less efficient, because it heats a small part of the communication surface, but the material consumption in this case is reduced. The coiled version is considered more effective, however, the costs will increase many times when using it, since the wire is wound around the outside in tight turns. It is permissible to combine these methods: first, the cable is laid along the communications, then it is wound in turns.

- The wire is fixed with tape along the entire length.

- To reduce heat loss, communications are covered with foil or roll insulation.

Placement methods

Installation of the heating system is possible inside the pipelines or outside. The process of laying in pipes is simple both during installation and maintenance. In the case of placing a heating wire on the surface of a tubular product buried in the soil, repair work will be complicated. In most cases, the wire is attached in one line through the pipe. It is considered undesirable to place it on top of the reinforcement, since in this case there is a high probability of mechanical deformation due to objects or stones falling from above.Also, freezing of water starts from below, so this arrangement of the heating element is considered more effective.

Options for placing the heating wire on the surface of the pipe:

- arrangement in one or more straight rows that are at a distance from each other;

- spiral laying around the pipe, taking into account a certain step.

The cable strands are fixed with a specialized aluminum tape. Heat transfer is enhanced if the pipe is wrapped with foil before installing the heating product. When turning, the electrical wire must be installed as close as possible to the outer radius. Sections with metal components of the support are reinforced by heating when additional loops are introduced into the entanglement. The temperature sensor circuit should not be placed near the heating point. It must be placed not on the surface of the reinforcement, but in the lateral area. The point of attachment of the sensor is glued with aluminum tape, it is fixed on top with it.

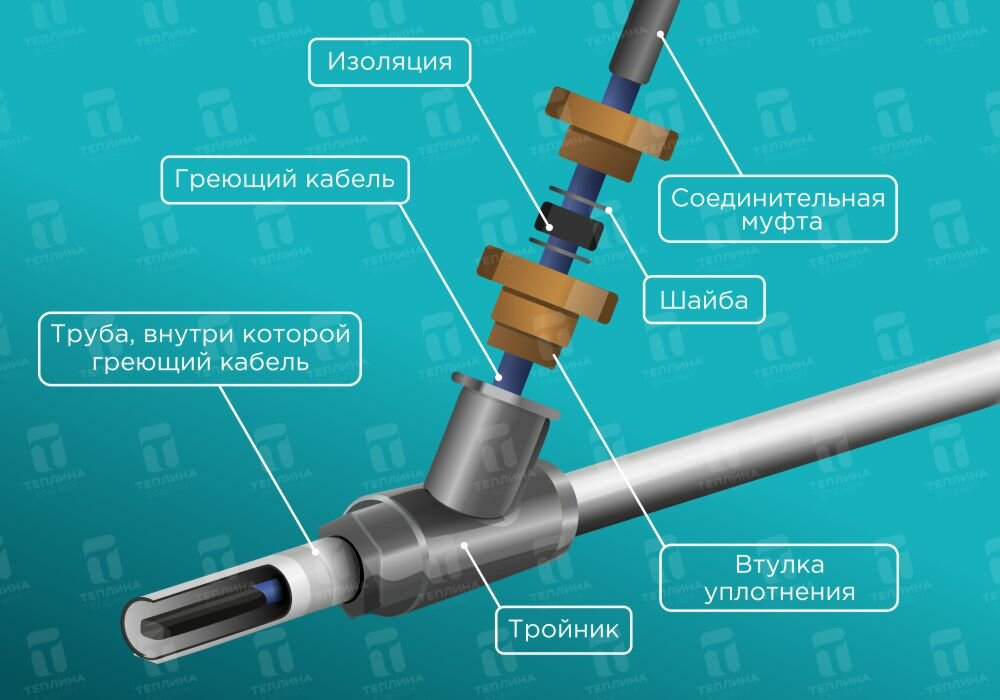

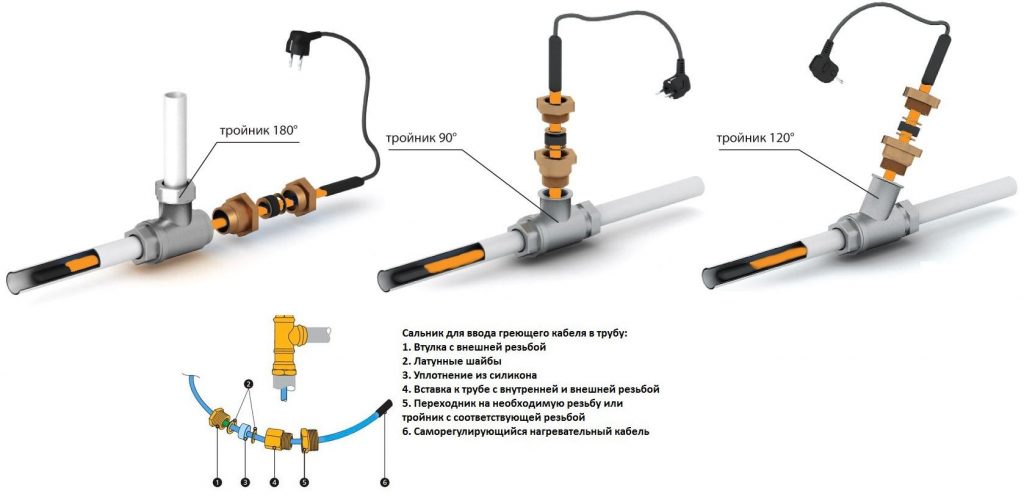

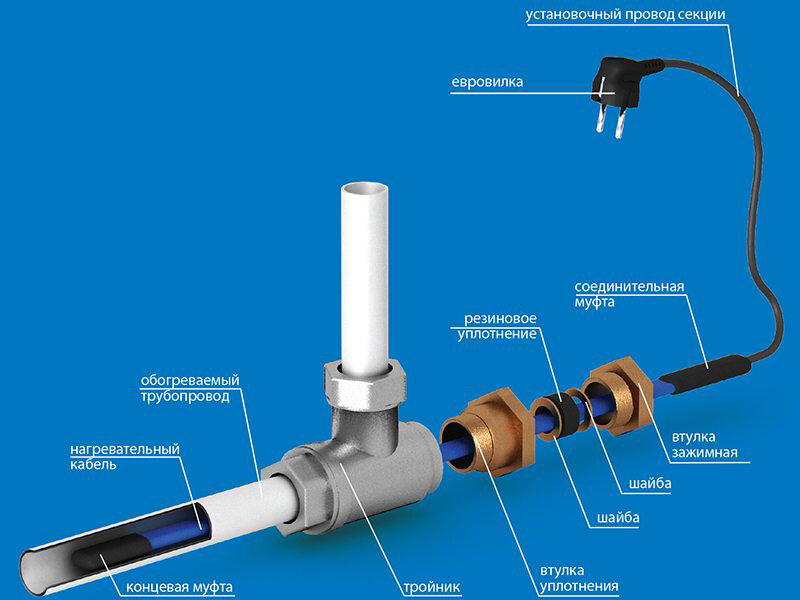

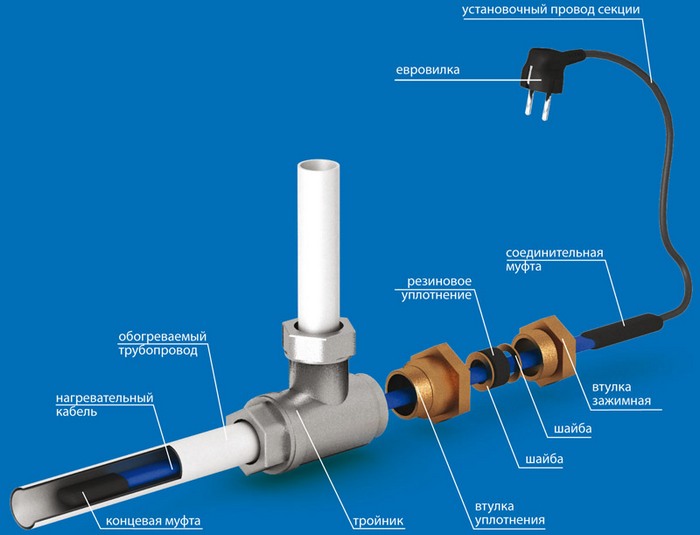

Laying inside the cable will require the purchase of exactly the model that is designed for such tasks with a round cross section and powerful insulation. The set contains elements for laying it inside the pipe: washers, bushings, seals.

Installation sequence inside the tubular product:

- each component to enter the system is put on a wire, then it is connected to a cold cable;

- the entry point is equipped with a tee having a special sealing sleeve;

- the wire is inserted into the pipe to the desired length, however, it must be remembered that it is not necessary to pass it through a valve, faucet and places with sharp protrusions that can deform its integrity;

- fixation of all fasteners, stuffing box component to protect against depressurization.

Heating pipeline installation

The main requirement for such a connection to the source is the location of the outlet below the freezing depth of the soil. This factor depends on the climatic conditions of the area.

Video

For the Moscow region, it is about 1.8 meters, in the Chelyabinsk region - 1.9. Let's imagine a situation when the supply section should be 10-15 meters long with a trench depth of more than 2 meters (up to 30 cm will be a drainage layer device). At the same time, its width should ensure convenient operation of the excavator. It's time to order an excavator here!

When using heating cable routes, it is enough to dig a ditch up to 50 cm deep and about 30 wide. A drainage device is also necessary. Laying a plastic pipe with a heating cable must be done freely, not stretched.

With this placement of the pipe, its deformations are inevitable due to soil movements, but in the case of using plastic products, they are not dangerous due to the plasticity of the material.

The cable for heating plastic pipes can be placed on it in various ways:

winding on a pipe

This fastening provides the largest contact surface between the object and the heating element. Fastening is carried out with metallized adhesive tape in the transverse and longitudinal directions;

laying the heater along the pipeline wall parallel to its axis

With this arrangement of the heat emitter, one or two threads are used from different sides of the pipe. Mounting is done in the same way;

placement of the heater inside the pipeline. It is better to entrust this operation to experienced specialists, since it is fraught with damage to the wire, which leads to its rapid failure.

To prevent heat loss to the environment, heated pipes are in all cases equipped with an additional heat-insulating layer of detachable insulators, winding of porous sheet insulators or ordinary rolled insulation. To protect it, various materials are used from roofing felt to metal foil.

Cable installation in plastic pipes with an internal location is not used for heating spillway sewers. Such drains often contain chemically active substances that can cause significant damage to the highway in a short time.

It is not uncommon for heating cables to be used to thaw drainpipes to prevent them from collapsing. In this case, more powerful heat emitters are used at the rate of 30 - 50 W per meter.

The cable for defrosting plastic pipes of drainage systems should also have the same power.

Mistakes when installing heating cables

Consider typical errors in the construction of heating systems:

- the installation of heaters at a laying depth of wiring below the level of soil freezing, this can be considered as non-productive costs. In this case, it is sufficient to install local heating in places of increased risk, where the system is not deep enough. Such a place, as a rule, is the point of entry into the house;

- some consumers believe that the heating system is able to replace the insulation of the pipeline, which is not true. In the absence of external insulation, they receive an inefficient heating system that does not save from freezing;

- the belief that the heating line should work continuously is erroneous, often this is not necessary, and the consumption of electricity at a consumption rate of 18 W per meter can be a significant amount. Additional costs for automatic switching on / off of heating using temperature sensors in this case will pay off in the shortest possible time.

Video

The cable for defrosting plastic products is installed, as a rule, for a preventive purpose in order to avoid the formation of ice plugs in places of increased risk, in particular, at the outlet of the drain system from the house.

Not the fact that it will be used constantly, but in any climate extreme operating conditions may occur. In this case, the additional possibility of heating / defrosting pipes will not be superfluous.

Conclusion

The costs incurred for the heating cable for plastic pipelines and its installation will significantly reduce the cost of construction work and reliably protect the consumer from climatic vicissitudes.

Why a heat cable is needed: do it yourself

A thermal cord or heating hose can be purchased at any hardware store, but they are very expensive. If you have some knowledge and technical skills, then you can make a heating cable yourself. To do this, you will need a simple telephone cable. According to its technical characteristics, a home-made wire is similar to a purchased heating conductor. It is just as thin, rigid and durable, so it can be safely used to supply heat to the pipeline. Connecting a homemade wire is done manually, it is not at all difficult to do this.

Heating pipes with a heating wire can not only prevent icing, but also extend the life of the pipeline. The use of such heating elements guarantees the owners of private houses and summer cottages comfortable use of the plumbing system throughout the year.

The heating cable has one very important feature: it can be installed on any pipeline that is located underground or outside. You can even equip a chimney with such a heating cable so that it does not freeze in winter. Why is a heating conductor so necessary?

Positive aspects of using this type of cable:

- Saving;

- Ease of use;

- Safety;

- Versatility.

Such a thermal element is simply necessary for the full functioning of the water supply system all year round, especially in the harsh winter period.

7. Is subsequent insulation of the heated pipeline necessary?

Another topical issue when organizing a pipe heating system is whether subsequent thermal insulation of the heated pipeline is needed? If you do not want to heat the air and operate the cable at maximum power, then insulation is definitely necessary. The thickness of the insulation layer is selected depending on where the pipes are located and what are the minimum temperatures typical for your region. On average, for the insulation of pipes that are located in the ground, a heater with a thickness of 20-30 mm is used. If the pipeline is above ground - at least 50 mm

It is very important to choose the “right” insulation that will not lose its properties even after several years.

- It is not recommended to use mineral wool as an insulating material.They are not intended for use in conditions of high humidity, and when wet, they instantly lose their properties. In addition, if wet cotton wool freezes, then when the temperature rises, it crumbles and turns into dust;

- Also, materials that can compress under the influence of gravity are not always suitable. This applies to foam rubber or foamed polyethylene, which lose their properties when compressed. It is permissible to use such materials if the pipeline passes in a specially equipped sewer, where nothing simply can put pressure on it;

- If pipes are laid in the ground, rigid pipe-in-pipe insulation must be used. When another rigid pipe of a larger diameter is put on top of the heated pipes and the heating cable. For additional effect or in case of operation in harsh conditions, you can wrap the pipes with the same polyethylene foam, and then put on the outer pipe;

- It is permissible to use expanded polystyrene, which is fragments of pipes of different lengths and diameters. It has high thermal insulation properties, is not afraid of moisture and is able to withstand some loads, depending on the density. Such a heater is often called a "shell".

cable cost

Today, in the construction market, there are several manufacturers who have proven their products on the good side.

This is an American company Raychem, which produces very high quality products using the most advanced technologies. It is also worth noting the products of the South Korean company Lavita, the price of which is lower, but the products are also impeccable in quality.Among domestic manufacturers, it is worth mentioning the Russian manufacturer CST, whose products compete with foreign companies.

Consider the pricing policy of the main manufacturers of heating cables. Basically, the price depends on several indicators. Firstly, this, of course, is the name of the manufacturer - the brand, and secondly, the price depends on the power per linear meter, and also on whether it is intended for outdoor or indoor installation in a pipe.

Also, the maximum temperature to which the cable can heat up is important for the price:

- The most affordable prices, perhaps, are from the South Korean manufacturer Lavita, represented on the Russian market. Prices for cables from this company start at 150 rubles per meter at a power of 10 W / m.

- The prices of products of the Russian manufacturer SST range from 270 rubles / m to 1500 rubles / m at a power of 10 to 95 W / m.

- Prices for the products of the most eminent manufacturer Raychem are in the range from 380 to 4500 rubles / m at a power of 10 to 65 W / m and a maximum heating temperature of 85 to 230 degrees Celsius. This company produces cable for both outdoor and indoor installation.

It is worth saying that the first self-regulating cable was produced by the American company Raychem back in 1973. And now the product range of this company is very wide. In addition to pipes, its cables are used for heating roofs, steps, paths, greenhouses, containers - wherever it is necessary to circulate liquids at any outside air temperature.

Thermal insulation for water supply pipes

It is not difficult to get confused in a wide range of thermal insulation materials. To choose the best option, you need, at a minimum, to know the main types and types, key characteristics and features.

Thermal insulation of water pipes is carried out by various heaters, which are grouped below (in the form of classification) according to the principle of unity of insulation technology.

Rigid insulation

This category includes polystyrene, expanded polystyrene (2560-3200 rubles / cubic meter) and Penoplex (3500-5000 rubles / cubic meter), thermal insulation properties and price depend on density.

Laying water pipes in a foam box

Roll insulation

This segment includes: polyethylene (as an additional material), foil foam (50-56 rubles / sq.m.), cotton wool (mineral (70-75 rubles / sq.m.) and glass wool (110-125 rubles / sq.m.) ), furniture foam rubber (250-850 rubles / sq.m., depending on the thickness).

Insulation of water supply pipes with roll insulation is also fraught with difficulties, which lie in the hygroscopicity of the material. Those. the insulation loses its properties under the influence of moisture, which means it has a narrower scope, or needs additional protection. Plus, it is necessary to think over the method of attaching the insulation to the pipe.

Basalt heat-insulating mats and foam rubber for insulation of water pipes

Segment (casing) heaters

The casing-insulation for pipes is the most progressive variant of thermal insulation of the pipeline. The water pipe insulation shell provides maximum tightness and, as a result, creates a reliable heat-insulating layer.

There are varieties of segment heaters:

Styrofoam shells for insulating water pipes are rigid (a heat-insulating casing for pipes is a shell made of expanded polystyrene (PPU) or foamed polystyrene. The price is from 190 rubles / m.p., depending on the thickness and diameter of the cylinder);

Sprayed insulation (PPU)

The peculiarity of insulation by spraying polyurethane foam is that thermal insulation is applied to the surface of the pipe, providing 100% tightness (the cost of components for polyurethane foam filling is from 3.5 euros per kg).

The number of components is determined by the thickness of the fill, the work is paid extra). On average, the cost of insulation by spraying polyurethane foam is 15-20 dollars / m.p.

Sprayed insulation also includes heat-insulating paint for pipes. You can apply it yourself, because. thermal paint is sold in cans in the form of an aerosol.

20 mm paint layer. replaces 50 mm basalt wool insulation. In addition, it is the only material that is not susceptible to damage from rodents.

Insulation of water pipes by spraying polyurethane foam (PUF) Water pipe insulated with polyurethane foam (PUF)

When choosing a heat-insulating material for insulating water pipes, you need to take into account the following factors:

pipeline installation site

Insulation of pipes laid on the ground and located underground is carried out in different ways, even when using the same materials (it is also important to take into account pipes laid to or below the freezing level);

pipeline operation frequency. For example, in a country house that is not intended for permanent residence, it is enough just to avoid a pipe rupture

To do this, a receiver is installed or the water pipe is insulated with a cable.But in a private house it is necessary to ensure the supply of water all year round. Here, the choice of insulation should be approached more carefully;

indicator of thermal conductivity of pipes (plastic, metal);

resistance to moisture, burning, biological activity, ultraviolet, etc. determines the need to protect the insulation from these factors;

ease of installation;

price;

life time.

6. Useful tips regarding installation work

There are some recommendations that will help you avoid mistakes when installing or choosing the heating element itself:

For mounting on a pipe with unstable temperature readings, it is better to choose a self-regulating cable

It is especially important to take this into account if part of the pipe is in the building, part is laid on the street, and then enters the building again. Heating will require different amounts of heat in different areas

A resistive cable will not only not be able to provide this condition, but will consume the same amount of electricity, thereby making its use uneconomical;

The choice of heat-insulating material for heated pipes should be given special attention.

Properly selected insulation will significantly reduce the consumption of heat and electricity and extend the life of the cable;

If you have definitely decided that you will lay the cable on top of the pipe, performing the winding, be sure to check the allowable bending limits

Otherwise, if the cable is bent beyond the permissible limits, its performance may be impaired;

In the case of using a heating cable on domestic pipes, it is imperative to connect it through a current leakage relay.This is necessary to protect against electric shock in case of damage to the outer insulation of the conductor;

It is not difficult to choose the length of the cable when laying over or inside the pipe - it is equal to the length of the pipe with a small margin. However, when winding the cable around the pipe, the calculation of the length must be made as 1.6 - 1.7 of the length of the pipe;

Even if you choose a self-regulating cable type, to further minimize energy costs, install a temperature sensor. Set the following parameters on it - turn on at a temperature of +3°C, turn off at +13°C. This mode will also extend the service life of the heaters, because they have a certain resource of working hours;

When installing the sensor, it is very important to do it correctly. The main difficulty lies in isolating it from the influence of the heater, but at the same time maintaining contact with the pipe. Only in this case it will read the correct readings.

How to perform thermal insulation of polypropylene pipes

Insulation for pipes can be of various shapes and designs: wound, glued, in the form of a shell - oval, etc. There is a wide range of insulation materials, linings and auxiliary insulation compounds available for use in hot water systems.

The list is constantly changing as new synthetic materials or application methods are developed. For example, the latest innovation in heat engineering is the use of antifreeze as a coolant for closed systems.

It does not make sense to consider any specific manufacturer of heaters, you need to pay attention to the types of materials used