- According to section 4 of SP 61.13330.2012

- The main tasks of thermal insulation, features of the choice of materials

- Change of norms planned in Russia

- Sanitary rules and regulations

- SNiP 23.02.2003: thermal protection of buildings

- A little about basic terms

- Actions in case of non-compliance with heating standards

- Why do we need SNiP norms

- Heating payment rules

- Document text

- Repair of plaster facades of buildings

- Documentation for the type of insulation material

- List of GOST for ventilated facades

- Features of heating an apartment building

- Types of heating in residential buildings

- What SNiPs regulate heating issues

- Heating systems

- The use of various heaters

- Styrofoam

- Expanded polypropylene

- Mineral wool of different classes

- Expanded polystyrene, polyurethane foam - extruded materials

- Foam concrete, aerated concrete

- Decorative thermal panels

- Sanitary requirements and standards

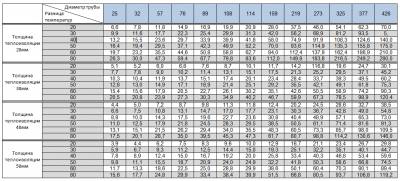

According to section 4 of SP 61.13330.2012

4.1 The heat-insulating structure must ensure the parameters of the coolant during operation, the standard level of heat loss by equipment and pipelines, and the temperature of their outer surfaces that is safe for humans.

4.2 The design of thermal insulation of pipelines and equipment must meet the requirements of:

- energy efficiency - to have an optimal ratio between the cost of a heat-insulating structure and the cost of heat losses through insulation during the estimated service life;

- operational reliability and durability - to withstand without reducing the heat-shielding properties and destruction of operational temperature, mechanical, chemical and other influences during the estimated service life;

- safety for the environment and service personnel during operation and disposal.

Materials used in heat-insulating structures should not emit harmful, flammable and explosive, unpleasantly smelling substances during operation, as well as pathogenic bacteria, viruses and fungi, in quantities exceeding the maximum allowable concentrations established in sanitary standards.

4.3 When choosing materials and products that are part of heat-insulating structures for surfaces with positive coolant temperatures (20 °C and above), the following factors should be taken into account:

- location of the isolated facility SP 131.13330;

- temperature of the insulated surface;

- ambient temperature;

- fire safety requirements;

- aggressiveness of the environment or substances contained in isolated objects;

- corrosive effect;

- surface material of the isolated object;

- permissible loads on the insulated surface;

- the presence of vibration and shock;

- the required durability of the heat-insulating structure;

- sanitary and hygienic requirements;

- temperature of application of heat-insulating material;

- thermal conductivity of thermal insulation material;

- temperature deformations of insulated surfaces;

- configuration and dimensions of the insulated surface;

- installation conditions (constraint, altitude, seasonality, etc.);

- conditions for dismantling and disposal.

- The heat-insulating structure of pipelines of heating networks of underground channelless laying must withstand without destruction:

- groundwater impact;

- loads from the mass of the overlying soil and passing traffic.

- When choosing heat-insulating materials and structures for surfaces with a coolant temperature of 19 °C and below and a negative temperature, one should additionally take into account the relative humidity of the ambient air, as well as the humidity and vapor permeability of the heat-insulating material.

4.4 The composition of the design of thermal insulation for surfaces with a positive temperature should include as mandatory elements:

- thermal insulation layer;

- cover layer;

- fastening elements.

4.5 The composition of the design of thermal insulation for surfaces with a negative temperature should include as mandatory elements:

- thermal insulation layer;

- vapor barrier layer;

- cover layer;

- fastening elements.

A vapor barrier layer should also be provided at a temperature of the insulated surface below 12 °C. The installation of a vapor barrier layer at temperatures above 12 ° C should be provided for equipment and pipelines with temperatures below ambient temperature, if the design temperature of the insulated surface is below the "dew point" temperature at the design pressure and humidity of the ambient air.

The need to install a vapor barrier layer in the thermal insulation structure for surfaces with variable temperature conditions (from “positive” to “negative” and vice versa) is determined by calculation to exclude moisture accumulation in the thermal insulation structure.

Anti-corrosion coatings of the insulated surface are not part of the heat-insulating structures.

4.6 Depending on the design solutions used, the design may additionally include:

- leveling layer;

- protective layer.

A protective layer should be provided when using a metal cover layer to prevent damage to the vapor barrier materials.

The main tasks of thermal insulation, features of the choice of materials

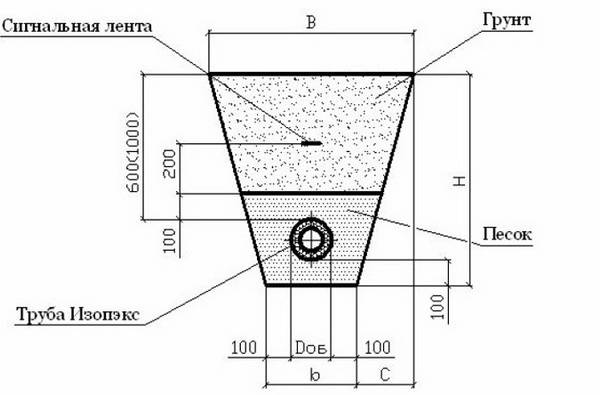

The main purpose of thermal insulation is to reduce heat loss in heating systems or pipelines with hot water supply. The main function of the insulation is to prevent condensation. Condensation can form both on the surface of the pipe and in the insulating layer. In addition, according to safety standards, the insulation of pipelines must provide a certain temperature on the surface of the insulation, and in case of stagnant water, protect it from freezing and icing in the winter.

According to the norms of SNiP, thermal insulation of pipelines is used both for centralized heating and reduces heat losses from in-house heating networks. What to consider when choosing thermal insulation:

- Pipe diameter. It depends on what type of insulator will be used. Pipes can be cylindrical, semi-cylinders or soft mats in rolls. Insulation of pipes of small diameter is mainly carried out using cylinders and half-cylinders.

- Heat carrier temperature.

- The conditions under which the pipes will be operated.

Change of norms planned in Russia

According to TASS, from 2020, the calculation of the heat consumption standard will depend on the number of storeys.The new system was planned to be introduced in 2016, however, at the request of members of the State Duma committee, the project was postponed to 2020. According to the new procedure, the Gcal norm is set depending on the following conditions:

- house material: brick, stone, concrete, wood;

- year of construction: before 1999, after 1999;

- number of storeys.

According to the clarifications of the press service of the Ministry of Construction of Russia, the application of the new calculation terms will be the right of the regional authorities, but not an obligation. As of 2019, the new procedure is not regulated by law, but is already being applied in the constituent entities of the Russian Federation, for example, in Krasnoyarsk (Decree of the Government of the Krasnoyarsk Territory No. 137-p).

Sanitary rules and regulations

These developed requirements (SanPiN heating) are applied in accordance with Russian legislation. They provide mandatory norms in terms of epidemiology and sanitation when determining living conditions in residential buildings.

Sanitary rules must be observed when building a house

Sanitary rules must be observed when building a house

They, together with the requirements of SNiP, are observed in the design of houses, the reconstruction of buildings, the construction of a new and the operation of the old multi-storey sector. Sanitary and epidemiological authorities supervise the implementation of the order.

In accordance with the provisions of legislative documents for the microclimate, air ventilation and heating systems, there are such requirements:

- Highways regulate the permissible indicators of the atmosphere in housing.

- They provide constant and uniform heating of the internal air during the entire heating period without interference, odors and the release of harmful components.

- Heating of their surface does not exceed +90°C, areas with temperatures above +75°C are subject to thermal insulation.

- Autonomous boiler houses are created subject to indoor air hygiene and noise standards.

Natural air outflow through windows and vents is provided in the premises or occurs through ventilation ducts. Flows to neighboring apartments are not allowed. It is allowed to include the removal of the atmosphere from the administrative premises into the common ventilation shaft if they do not contain harmful components.

More about autonomous heating:

SNiP 23.02.2003: thermal protection of buildings

The norms of SNiP affect not only the insulation of walls directly, but also regulate the relevant measures to improve the efficiency of energy saving.

The documentation specifies the requirements for heaters, the features of their installation, the procedure for calculating energy efficiency. The documents were developed taking into account not only Russian standards, but also European requirements for insulation. The norms apply to all residential and public buildings, with the exception of those that are heated periodically.

SNiP was developed by qualified specialists from various fields. It takes into account all the nuances of thermal insulation work, including the compliance of insulation with other regulatory documents, in particular SanPiN and GOST. The documents set out the basic requirements for:

- heat transfer properties of insulated structures;

- specific coefficient of heat energy consumption;

- the difference in heat resistance in the cold and warm seasons;

- breathability, as well as moisture resistance;

- improving energy efficiency, etc.

The system of regulatory documents indicates three indicators of thermal protection, two of which must be observed during insulation without fail.

A little about basic terms

SNiP operates with the following terminology:

- Thermal protection of buildings. The combination of external and internal heat-insulating structures, their interaction, as well as the ability to withstand external climatic changes.

- Specific consumption of heat energy. The required amount of energy to compensate for heat losses during the heating period per 1 m².

- Energy efficiency class. Interval energy consumption coefficient for the heating period.

- Microclimate. The conditions in the room in which the person lives, the compliance of temperature indicators, humidity of the insulated structure with GOST.

- Optimum microclimate. Characteristics of the indoor environment in which 80% of those present feel comfortable in the room.

- Additional heat dissipation. The indicator of heat coming from the people present, as well as additional equipment.

- The compactness of the building. The ratio of the area of enclosing structures to the volume that needs to be heated.

- Glazing index. The ratio of the size of window openings to the area of enclosing structures.

- heated volume. A room bounded by floors, walls, and roofs that requires heating.

- Cold period of heating. The time when the average daily air temperature is less than 8-10°C.

- Warm period. The time when the average daily temperature exceeds 8-10°C.

- duration of the heating period. A value that requires the calculation of the number of days in a year when it is necessary to heat the room.

- Average temperature indicator. It is calculated as the average temperature coefficient for the entire heating period.

p> These definitions have something in common and affect each other.Some indicators may differ for the insulation of residential and public buildings.

Actions in case of non-compliance with heating standards

What to do if the apartment is too cold or too hot? If there is a clear temperature deviation from the optimal temperature regime, the tenant can independently or jointly with neighbors invite employees of the management company to take measurements. The management company must respond to each appeal of the tenants, taking measurements on demand.

If the appeal to the management company did not produce the desired effect and did not lead to an improvement in the situation, the consumer should file complaints with the local authorities of the housing inspectorate and Rospotrebnadzor. The last step in the struggle for comfortable living conditions is to go to court with a lawsuit against the management company.

Why do we need SNiP norms

All these standards were developed and are used in order to avoid man-made disasters, in the form of gas explosions, wall cracks, building shrinkage, electrical wiring short circuit, collapse of walls and ceilings, and so on. As for the heating system itself, compliance with the norms and rules set forth in SNiP 41-01-2003 is very important to maintain the temperature and humidity of the air in the room, safe for human health.

Let's say you want to install radiators in your room. There are three ways to install radiators: side, diagonal, bottom connection. Having chosen the scheme, you can proceed with the installation, remembering all the recommendations of SNiP and the manufacturer:

- The installation of radiators according to the norms involves the installation of radiators 100 mm below the window sill, so as not to impede the access of warm air to the room.If the gap is less than ¾ of the depth of the radiator, this will make it difficult for the passage of warm flow.

- The distance of the heating radiator from the floor is 120 mm, it should not be less than 100 mm, so as not to impede the passage of the flow of warm air, and also not to impede the cleaning process. If you make it 150 mm, then the temperature difference in height will increase, this will be noticeable at the top of the room.

- The radiators must recede from the wall by at least 20 mm, otherwise the heat transfer will deteriorate, and a lot of dust will accumulate on top of the battery.

Installation of heating devices is also regulated by SNiP.

- Initially, you need to mark the places for the brackets, which should be at least 3.

- Strengthen the brackets with dowels or cement mixture.

- Install the Mayevsky crane, plugs, adapters, etc.

- Install the radiator.

- Connect the radiator to the pipes of the heating system.

- Install an automatic air vent.

- Remove the protective film from the radiators.

Heating payment rules

Clause 42.1 of Decree No. 354 offers two ways to pay for heat energy:

- During the period when the heating is on.

- Year-round, throughout the year.

At the same time, the choice of the payment method or the change from one method to another is the prerogative of the state authority in the constituent entity of the Russian Federation. Neither local self-government bodies, nor the collective meeting of tenants, nor the management company can, by their own decision, change the payment calculation system.

The decision to change the method can be made only once a year, until the first of October. If a decision has been made to introduce year-round payment, it will come into force on July 1 of the next year.If it has been decided to charge the fee at the start of the heating season, the decision will come into effect on the same date as the start of the heating season next year.

Document text

Construction

norms and rules SNiP 3.04.01-87

"Insulating

and finishing coatings

(approved

Decree of the Gosstroy of the USSR of December 4

1987 N 280)

Instead

sections of SNiP III-20-74*; SNiP III-21-73*; SNiP

III-B.14-72; GOST 22753-77; GOST 22844-77; GOST 23305-78

Term

entry into force - July 1, 1988

emulsion-bitumen

compositions

mixtures,

bitumen perlite and bitumen expanded clay

tough

and semi-rigid fiber products

and device

coverslips

shells of thermal insulation made of rigid

materials

elements

designs

technological

equipment from corrosion

(anti-corrosion

work)

interiors

buildings

1.

General provisions

1.1.

Current building codes

apply to production and

acceptance of work on the installation of insulation,

finishing, protective coatings and floors

buildings and structures, except

works subject to special conditions

operation of buildings and structures.

1.2.

Insulating, finishing, protective

floor coverings and structures

be carried out in accordance with the project

(finishing coatings in the absence of

project requirements - according to the standard).

Replacement of those provided by the project

materials, products and compositions are allowed

only in agreement with the design

organization and customer.

1.3.

Works on the production of thermal insulation

work can only start after

execution of an act (permit) signed

customer, representatives of the assembly

organization and organization that performs

thermal insulation work.

1.4.

The device of each insulation element

(roof), floor, protective and finishing

coatings should be done after

performance checks

corresponding underlying element

with the preparation of an inspection certificate

hidden works.

1.5.

With appropriate justification

agreement with the customer and design

organization is allowed to appoint

ways of doing work and

organizational and technological solutions,

and establish the methods, scope and

types of quality control registration

works other than those

these rules.

2.

Insulating coatings and roofs

emulsion-bitumen

compositions

mixtures,

bitumen perlite and bitumen expanded clay

tough

and semi-rigid fiber products

and device

coverslips

shells of thermal insulation made of rigid

materials

elements

designs

General

requirements

2.1.

Insulation and roofing works

allowed to perform from 60 to minus

30°C ambient (production

works using hot mastics -

at ambient temperature

not lower than minus 20°C, with the use of compounds

water-based without antifreeze

additives not lower than 5°С).

2.2.

In bases under roofing and insulation in

according to the project

do the following work:

close up

seams between prefabricated slabs;

arrange

temperature shrinkage seams;

mount

embedded elements;

plaster

vertical surfaces

stone structures to the height of the junction

rolled or emulsion-mastic

roofing carpet and insulation.

2.3.

Insulating compositions and materials must

be applied uniformly and uniformly

layers or one layer without gaps and

influxes. Each layer is necessary

arrange on a hardened surface

previous with leveling applied

compositions, with the exception of paints.

In preparation and preparation

insulating compositions must be observed

Table 1 requirements.

Table

1

Download the file to continue reading...

Repair of plaster facades of buildings

Repair Work

Repair of plaster facades of buildings

Composition of operations and controls

| Stages of work | Controlled Operations | Control (methol, volume) | Documentation |

| Preparatory work | Check: — filling of window and door openings; - the presence of a document on the quality of the incoming solution and its quality; - cleaning the surface of the walls from exfoliated plaster, salts that have come out; – installation of removable stamps and beacons; - wall humidity and air temperature (in winter). | Technical inspection Visual Same Same Measuring | General work log, passport |

| Plaster work | To control: - the quality of the plaster; - the average thickness of the spray, soil, plaque; - deviations of slopes, pilasters, pillars, etc. from vertical; - the quality of the plaster surface. | Laboratory control visual, measuring Measuring Visual | General work log |

| Acceptance of work performed | Check: - the adhesion strength of the plaster layers with the base; - compliance of the quality of the plastered surface with the requirements of the project and SNiP. | Technical inspection Measuring | Act of acceptance of work performed |

| Control and measuring tool: construction plumb line, metal ruler, rail-rule, pattern. | |||

| Operational control is carried out by: master (foreman), laboratory assistant (engineer).Acceptance control is carried out by: employees of the quality service, foreman (foreman), representatives of the technical supervision of the customer. |

Technical requirements

SNiP 3.04.01-87 tab. 9

Permissible deviations:

- surface irregularities of the new plaster when applying a 2-meter lath:

- with simple plaster - no more than 3 irregularities with a depth or height of up to 5 mm

- surfaces from the vertical with simple plaster - 3 mm, but not more than 15 mm per floor;

- husks, mustaches, window and door slopes, pilasters, pillars - 10 mm for the entire element.

Instructions for the production of work SNiP 3.04.01-87 paragraphs. 3.4, 3.7-3.10

Surface preparation of building facades consists of the following operations:

— surface cleaning from old lime, silicate and other paint coatings;

- chipping of fragile plaster;

- processing of insufficiently rough surfaces;

– coatings metal mesh with cells size 10 x 10 mm or braided wire with cells no larger than 40 x 40 mm (required architectural details).

When plastering the surface of the facades, the application of each subsequent layer of plaster coating is allowed only after setting.

When repairing facades, the thickness of the decorative layer for mortar:

- with fine-grained filler

(with a weak plaster relief) - 4-6 mm;

- with medium-grained - 6-8 mm;

- with coarse-grained - 8-10 mm.

The decorative layer is applied in two stages. With highly relief plasters with a covering layer of 15-18 mm, the solution is applied in three stages.

Documentation for the type of insulation material

GOST 16136-2003 “Perlite-bitumen thermal insulation boards. Specifications»

GOST 15588-2014 “Polystyrene heat-insulating plates. Specifications»

GOST R 56590-2016 “Polyisocyanurate foam based heat and sound insulating boards. Specifications»

GOST EN 12091-2011 “Heat-insulating products used in construction. Method for determining frost resistance "

GOST EN 822-2011 “Heat-insulating products used in construction. Methods for determining the length and width "

GOST EN 823-2011 “Heat-insulating products used in construction. Method for determining the thickness "

GOST 32312-2011 “Heat-insulating products used for engineering equipment of buildings and industrial installations. Method for determining the maximum operating temperature "

GOST 31912-2011 “Heat-insulating products used for engineering equipment of buildings and industrial installations. Determination of the calculated thermal conductivity "

GOST 31911-2011 “Heat-insulating products used for engineering equipment of buildings and industrial installations. Determination of declared thermal conductivity»

GOST 33949-2016 “Heat-insulating foam glass products for buildings and structures. Specifications»

GOST 32314-2012 “Heat-insulating mineral wool products for industrial production used in construction. General technical conditions»

GOST 32313-2011 “Heat-insulating mineral wool products for industrial production used for engineering equipment of buildings and industrial installations. General technical conditions»

GOST 23307-78 “Heat-insulating mats made of mineral wool vertically layered. Specifications»

GOST 22950-95 “Mineral wool boards of increased rigidity on a synthetic binder. Specifications»

GOST 21880-2011 “Stitched heat-insulating mineral wool mats. Specifications»

GOST 4640-2011 Mineral wool. Specifications»

GOST 22950-95 "Mineral wool boards of increased rigidity on a synthetic binder"

GOST 9573-2012 “Heat-insulating slabs of mineral wool on a synthetic binder. Specifications»

GOST 10140-2003 “Heat-insulating plates made of mineral wool on a bituminous binder. Specifications»

GOST 10499-95 “Heat-insulating products made of glass staple fiber. Specifications»

GOST 21880-94 "Mineral wool pierced heat-insulating mats"

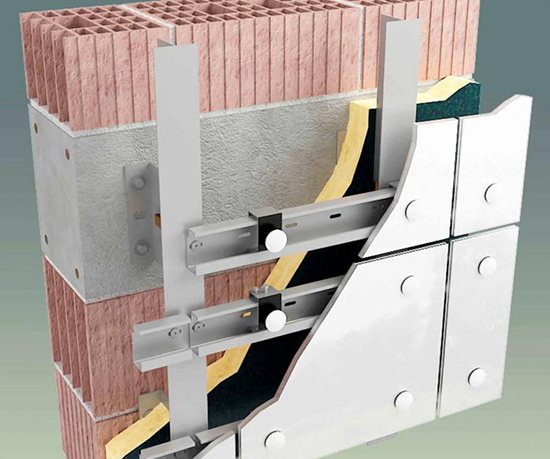

List of GOST for ventilated facades

Suspended ventilated facade cladding systems must be designed and installed in accordance with a set of rules based on the following regulatory documents:

- GOST 12.4.026 of 2020 (Work safety standards);

- GOST 7076-99 (Building materials and building products. Methods for establishing thermal conductivity indicators within the stationary thermal regime);

- GOST 7948-80 (technical specifications for building metal plumb lines);

- GOST 15588-2014 (Specifications for building thermal insulation boards made of expanded polystyrene);

- GOST 26629-85 (Constructions and buildings, methods for checking the effectiveness of thermal insulation of structures used for fencing);

- GOST 27321-87 (Specifications for scaffolding used for installation and construction work);

- GOST 31251 of 2008 (External part of external walls, methods for testing them for fire resistance);

- GOST 32314 of 2012 (Specifications for thermal insulation from mineral wool used in construction);

- GOST 54358 of 2011 (Specifications for decorative plaster mixtures used for exterior decoration of buildings);

- GOST 55225-2012 (Specifications for a reinforcing fiberglass mesh resistant to alkali);

- GOST 55412 of 2013 (Methods for checking thermal insulation systems for facades made of composite materials with a plaster layer);

- GOST 55836 of 2014 (Specifications for polymer-based adhesives used in the performance of work on the insulation of the external walls of buildings);

- GOST R 56707 of 2020 (General specifications for facade thermal insulation systems with an outer layer of plaster);

- GOST 57270 of 2020 (methods for testing the combustibility of building materials).

Features of heating an apartment building

The heat supply system in an apartment building has a number of nuances in operation:

- The inability of the user to influence the degree of heating of the coolant. All a tenant can do is shut off or reduce the flow to a particular radiator.

- Difficulties with the organization of metering of supplied heat. It requires installing IPU devices for 2-5 risers, which costs a significant amount for the family budget.

- The start and end dates of the heating season are set without taking into account the opinion of the consumer or natural conditions.

The tenant often has to make a lot of efforts to create an optimal microclimate. It is required to ensure good thermal insulation in the apartment, as well as to get the management company to carry out similar work to eliminate heat losses in the entrance and stairwells.

Types of heating in residential buildings

There are many technical schemes designed to ensure the optimal temperature in the room. They differ in performance, efficiency, cost and complexity of design, ease of use.

In the most general form, all heating systems for residential buildings can be divided into three groups:

- Individual systems provide thermal conditions in one household.Most often, this option is implemented in private homes. For multi-apartment buildings in Russia, such a scheme is exotic, although it is used in some new buildings. Its main advantages are the ability to independently regulate the temperature in the room, finely adjusting to every change in the weather. The disadvantage is the high cost.

- Centralized systems receive heat with a coolant from the main, and then distribute it to apartments. In most apartment buildings, such a scheme is implemented. Its advantages are cost-effectiveness and relatively low payment for thermal energy. However, it does not allow you to adjust the heat supply for a specific situation, which is why it can be cold in the apartment before the start of the heating season, and when a sudden thaw occurs, it can be too hot.

- Autonomous heating. In this case, heat is distributed throughout all the premises of an apartment building, but the source of energy is not the supply line from the CHP, but an autonomous boiler house. In most cases, such systems are implemented for industrial buildings or social facilities (schools, hospitals, etc.). In terms of its advantages and disadvantages, this option occupies an intermediate position between the first two options.

But whatever method is implemented, it must ensure that the temperature regime of the building complies with sanitary standards and regulatory documents in the field of heat supply.

What SNiPs regulate heating issues

SantekhNIIproektSNiP 41−01−2003

The provisions of the building codes of this document have legal and technical regulation on heat supply, heating, air conditioning and ventilation systems in the premises of buildings and structures.

The content of this document begins:

- with introduction;

- Areas of use;

- normative references;

- general links;

Requirements are also considered:

- to indoor and outdoor air;

- heat supply and heating;

- to ventilation, air conditioning and air heating;

- smoke protection in case of fire;

- refrigeration supply;

- release of air into the atmosphere;

- energy efficiency of buildings;

- power supply and automation;

- space-planning requirements and design solutions;

- water supply and sewerage of heating, ventilation and air conditioning systems.

In the appendices, all the necessary calculations, coefficients, permissible deviations from the norms for all systems and equipment for them are considered.

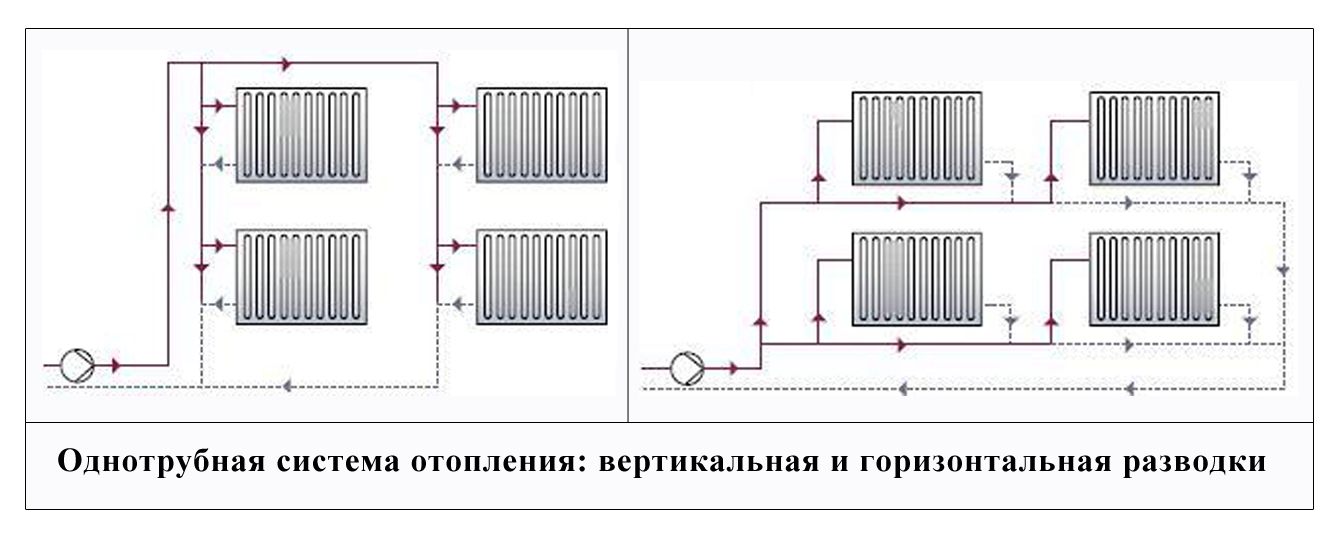

Heating systems

6.3.1. In heated rooms, the normalized air temperature must be maintained. 6.3.2. In buildings where there is no heating system, it is allowed to use local heating at workplaces and equipment repairs.

6.3.3. Flights of stairs may not be heated in cases provided for by the regulation of SNiP.

6.3.4

Heating is designed taking into account uniform heating and taking into account the heat consumption for heating air, materials, equipment and other things. A unit is taken as a heat flux of 10 W per 1 sq.

m.

In paragraph 6.4, all the requirements for heating pipelines are considered, where they can be laid, where they cannot be laid, they regulate the laying methods, and the service life is included in the project.They indicate the permissible error rates for the slopes of the laid pipes for water, steam and condensate under various conditions for the direction of steam movement and water speed.

Paragraph 6.5 discusses everything related to heating appliances and fittings, which radiators can be installed, connection diagrams, locations, distance from walls.

Paragraph 6.6 considers all issues related to stove heating: in which buildings it is allowed, what are the requirements for stoves, the temperature of their surfaces, the sections and height of chimneys.

The use of various heaters

The SNiP documentation describes in detail how and how to properly insulate structures for various purposes. Insulation of the facade, according to the norms, can be carried out using various heat-insulating materials, while each of them must meet certain parameters.

Styrofoam

Styrofoam

In order for the insulation using foam to comply with the norms of SNiP, you should be very careful about the choice of material, since not all plates meet the requirements. The documents spell out foam boards, which have:

- density not less than 100 kg/m³;

- specific heat capacity from 1.26 kJ/(kg°С);

- thermal conductivity is not more than 0.052.

They also limit the possibility of using polystyrene for insulation, its combustibility, which should be taken into account if the building has increased fire safety requirements.

Expanded polypropylene

Expanded polypropylene

For such a facade insulation as foamed polypropylene, the SNiP does not specify exact requirements, since this is a fairly new heat-insulating material. As practice shows, this material is most often used to provide waterproofing.

Low thermal conductivity allows it to be used for insulation. But the application will require specialized equipment, which significantly complicates the process of applying polypropylene foam to the surface.

Mineral wool of different classes

mineral wool

Using mineral wool, it is easiest to achieve compliance with SNiP standards. Soft slabs are not used for facades, while the regulatory documentation allows for insulation with semi-rigid and rigid slabs.

The second option is recommended for use when working with a plastered surface. Semi-rigid mineral wool is the best choice for masonry and cellular concrete walls.

Expanded polystyrene, polyurethane foam - extruded materials

Styrofoam

Insulation with any materials from this category is allowed only for basements and attics. This is due to the special quality characteristics of heaters.

In addition, the work involves a number of difficulties, in particular the application of foam materials, and requires compliance with safety regulations and the use of personal protective equipment.

Foam concrete, aerated concrete

aerated concrete

According to building codes, the rules established by SNiP, the use of such heaters is relevant for thermal insulation of industrial facilities.

In residential and public construction, such materials are usually used only when filling wells in lightweight masonry walls.

Decorative thermal panels

Thermal panels

There are no clear instructions on the requirements for decorative heat-saving panels, but the basis of such plates is a finishing layer and a layer of insulation. It is on the qualitative characteristics of the internal material that it depends whether the thermal insulation will meet the norms of SNiP.

Specific standards are prescribed in the documentation for each type of heat insulator, so it is necessary to take into account what underlies the thermal panels - polystyrene foam, expanded polystyrene or mineral wool insulation.

In order to choose the right thermal insulation materials, you will need to take into account a lot of nuances, including not only the technical characteristics of the heat insulator, but also the design features of the structure, the climatic features of the region, etc. You will also need to strictly follow the installation technology in order to obtain thermal insulation that meets the requirements prescribed in SNiP. If there is any doubt that the calculations and selection of the material, as well as its installation, will be carried out correctly, then it is better to entrust such a procedure to specialists, which will guarantee that the insulation meets the standards established by the state.

Sanitary requirements and standards

Sanitary requirements are observed by the civilian population, government agencies, officials and legal entities. The principles for laying the heating system, labor protection standards, veterinary regulations, acts of law do not contradict the sanitary canons set forth in the collection. Violation or non-observance of legal regulations leads to administrative or criminal punishment of responsible persons.

When building houses, sanitary requirements and standards must be observed

From the point of view of law and technical features, the standards regulate heating, water supply, air purification, ventilation, and air conditioning systems in buildings. Compliance with the rules is required to prevent disasters, explosions, destruction of buildings, accidents on electrical lines.When designing and operating the heating system, compliance with the provisions allows maintaining the humidity and temperature in the room, which is safe for human health.

Installation of heating appliances, piping is done taking into account the recommended sanitary standards

The rules take into account technology, economy and legal aspects in the use of urban systems, take into account new engineering developments, architectural requirements, building principles. The goals are to protect the rights of residents using construction products and to comply with the norms of comfortable consumption of the final product.

SNiP heat supply for residential buildings cover the construction of thermal and ventilation systems. Neglect of the rules of the sanitary device is fraught with:

- the occurrence of cracks in buildings;

- foundation shrinkage;

- lack of heat in the home;

- poor water supply and violation of the standards of personal hygiene of citizens.