- Fuel supply and barrel fabrication

- Do-it-yourself burner for working out: the principle of operation

- How to build an apparatus on your own according to the principle of a Babington burner: drawings

- Kinds

- Advantages and disadvantages

- What is a Babington burner

- Forge on mining (waste oil)

- drip burner

- 2 Advantages and disadvantages

- Additional Tips

- Dropper from a pipe

- 5 Necessary tools

- We start making our own

- Waste oil burner

- 5 Homemade Babington Burners

- The principle of operation of the Babington burner

Fuel supply and barrel fabrication

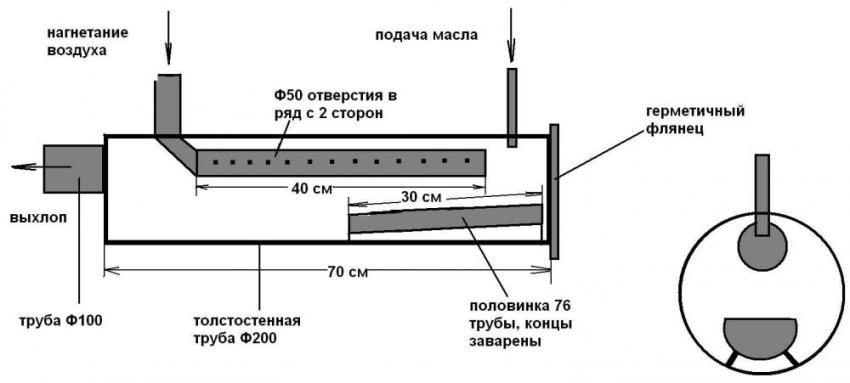

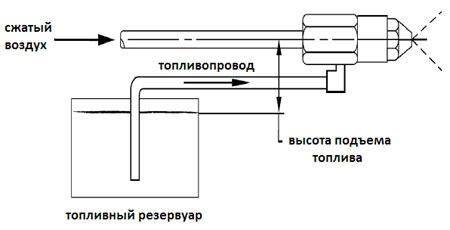

We have already figured out a little about how a Babington burner is made. The product scheme, despite its simplicity, has several pitfalls. For example, you need to use a suitable pump. In this case, gear is best. It is optimal for working with viscous liquids. But if there is no pump, then you can use the elementary scheme for organizing the supply of fuel by gravity. But such a solution only takes place if the amount of oil in the sump, and hence the pressure, is maintained at a high level.

The barrel is an ordinary metal pipe 6 inches in diameter and 3 feet long. Just one nozzle is enough.If there is a pipe with thick walls, then it is better to use it, since this option is better suited for the combustion process. Pipes of this type retain heat much longer. At the final station, don't forget to install the depulsator. The Babington burner will operate without flame pulsation.

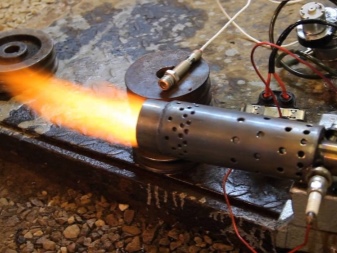

Do-it-yourself burner for working out: the principle of operation

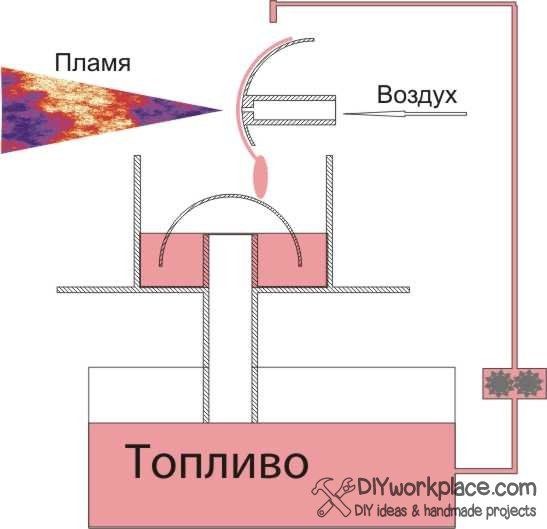

If you look at the photos, drawings and drawings, it becomes obvious that the recycled oil forms a thin film on the curved surface. Through the groove, under slight pressure, gas or air is fed into the container. After warming up, the oil is sprayed by this air stream, providing high-quality ignition.

It was this method of ignition that became the basis for inventions that became widespread in home-made devices and drip burners on used oil produced in the factory. Waste oil is, in fact, free fuel, used suspension. Therefore, it is considered more advantageous against the background of other heat sources:

It is possible to make a waste oil burner with your own hands

- solid fuel and briquettes for a homemade pellet burner;

- gasoline and diesel fuel;

- electricity;

- natural gas;

- kerosene;

- fuel oil.

The first devices powered by kerosene, diesel fuel and oil smoked heavily and emitted an unpleasant odor. Later, they offered a do-it-yourself gasoline burner and devices using other combustible raw materials, but an active search was made for budget fuel. The oil proved to be a suitable source of heat, but the soot and smell negated all advantages. Therefore, all the efforts of the inventors went to eliminate these shortcomings of the burner for waste oil boilers.This should have been facilitated by the full combustion, heating and filtration of contaminated fuel.

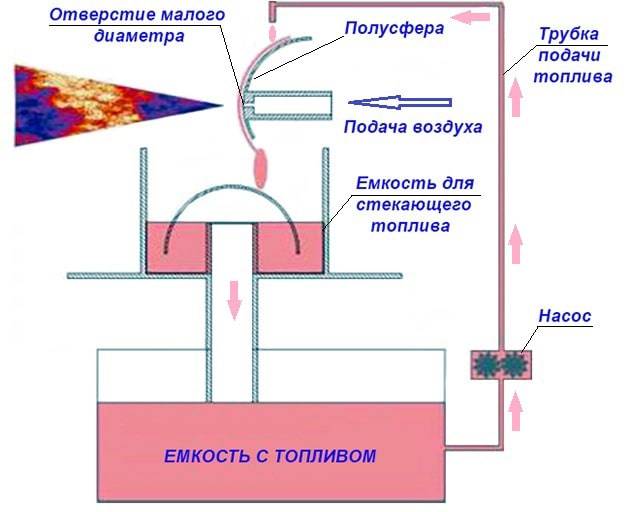

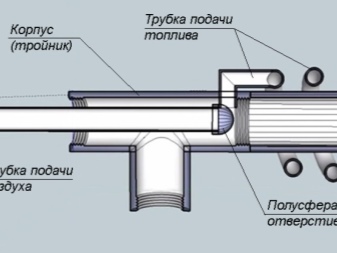

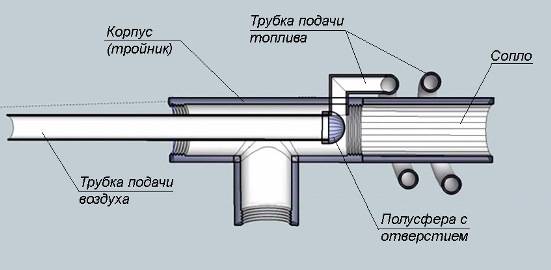

How to build an apparatus on your own according to the principle of a Babington burner: drawings

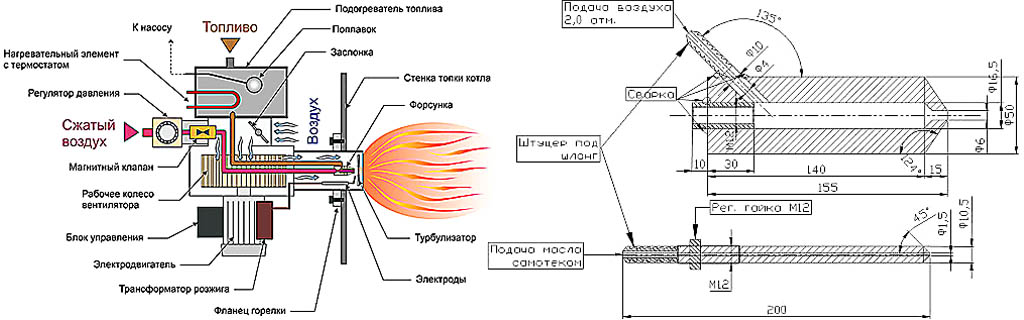

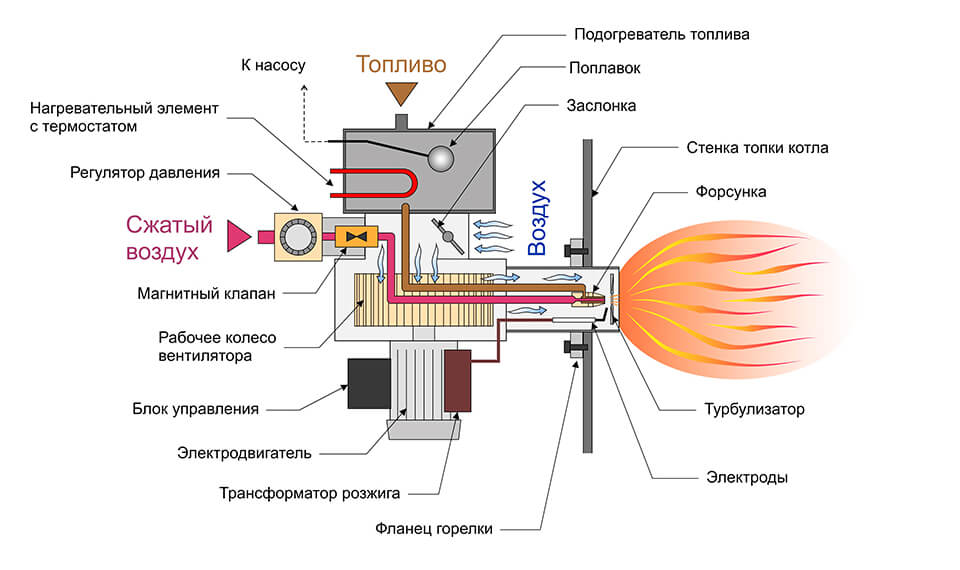

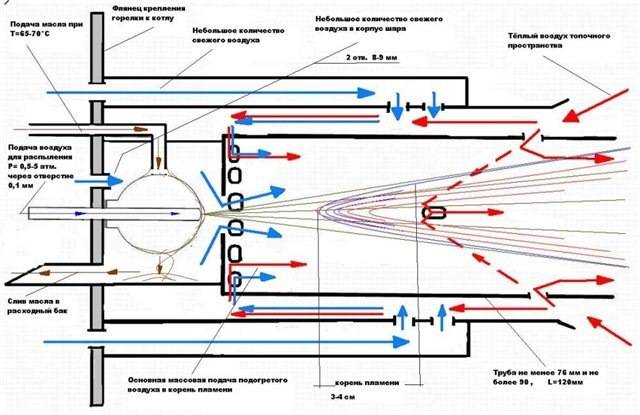

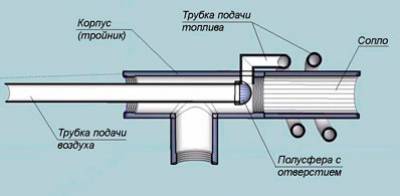

The principle of operation of a homemade burner, made on the basis of the idea of Robert Babington, is clear from the drawings, where the components of the unit are visible:

Babington waste oil burner drawing

- waste oil tank;

- pallet for mining;

- tube for supplying fuel;

- a small fuel pump for supplying portions of oil;

- hemisphere for spraying with a small hole;

- heating chamber with heating element (may be absent).

Waste oil, evaporating, flows down the hemisphere. These oily vapors mix with the air mass, resulting in a fuel mixture. The remaining oil, which did not have time to be disposed of, drains into the sump, and from there - through the tube back to the fuel tank.

This unit, based on the Babington patent, designed to burn liquid fuels, is quite simple. Therefore, it is available for reproduction from improvised parts in a home workshop. Success depends on the exact correspondence of the parts to their intended purpose and on the coordinated work of all nodes. Therefore, before you make a burner with your own hands, you should carefully calculate all the parameters.

The design of the burner is quite simple, so it can be made from improvised means

Kinds

The Babington burner, or automatic oil burner, is in high demand and can be made at home. The oil in this unit is supplied under low pressure, and therefore drains freely.The shape of the installation resembles a sphere or a bowl, the fuel forms a thin film, after which the fuel vapors, together with air, turn into a torch, which is ignited and gives off heat.

A drip-type device does not have a complex structure; fuel for it is very affordable. The supply comes from a remote tank, which ensures the stability and safety of the device. This evaporative burner is in demand not only in industrial environments

It is important to note that most of these devices are great for operating a solid fuel boiler and stove.

A liquid fuel burner can be called a mobile and efficient device. It is easy to operate, runs on cheap oil, but you need to choose high-quality fuel to run the device.

The pyrolysis burner works with solid fuel, which is placed on the grate. After the fuel is ignited, the door closes and the smoke exhauster is turned on. Thanks to such a damper inside the chamber, the temperature rises to 800 degrees Celsius, but due to the lack of air, fossil fuel begins to smolder and char, releasing gases. The latter enter the grate, mix with nitrogen and oxygen, then the mixture acquires the ability to burn. The radiated heat is sent to the organic fuel, thereby supporting the smoldering process.

Available materials are used to create such structures, the duration of the burner cycle is just over a day

It is important to note that this type of installation is considered fireproof, and it also supports the use of pallets, firewood and coal.Boilers with such a burner have a low amount of combustion products, so they are considered environmentally friendly.

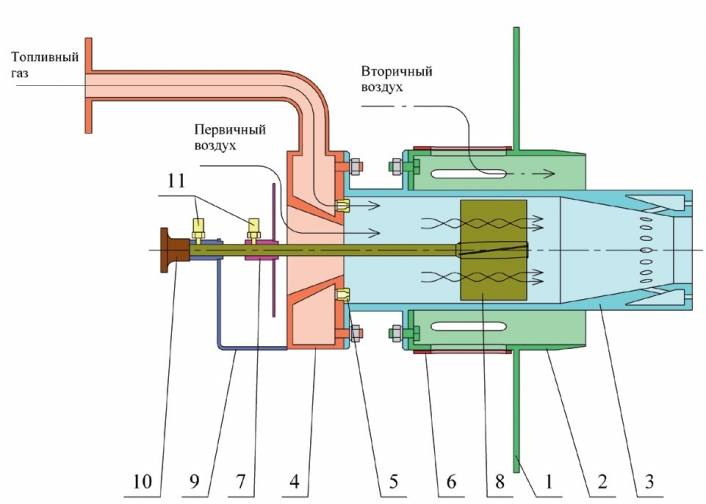

The next type of burner is the pressurized injection burner, which is used in conjunction with smelting furnaces for the forge.

Advantages and disadvantages

The main advantage, due to which the homemade burner at the Babington mine has gained wide popularity, is its omnivorous nature, as already mentioned above. In fact, any heated oil of a reasonable degree of contamination can be poured onto a spherical surface, a properly made burner will still work stably. She is not afraid of impurities of gasoline or antifreeze, unless their ratio with oil is one to one, then problems will inevitably arise. And then, this is not at all a reason to get rid of such a mixture, for the normal functioning of the burner on used oil, it will need to be well diluted with “correct” mining, and then put into action.

Another advantage is the simplicity of design, which is why craftsmen quickly mastered this product. Indeed, it is quite simple to make the "heart" of the device from a ball or hemisphere placed in the case. It is somewhat more difficult to organize fuel supply and air injection, and even set up the entire system so that the Babington burner, made by hand, works stably and safely. But there is a wide scope for the introduction of various technical solutions.

Of the serious shortcomings of the unit, only one catches the eye. This is the constant presence of dirt in the room where the oil burner operates.Unfortunately, it is impossible to completely eliminate the accidental spill or seepage of contaminated engine oil through leaks, even if all interfaces are tight and Babington burner automatics are installed. To some extent, it will be dirty in the room, you will have to put up with it.

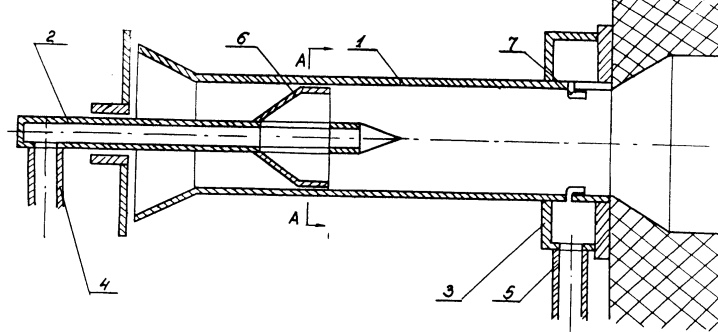

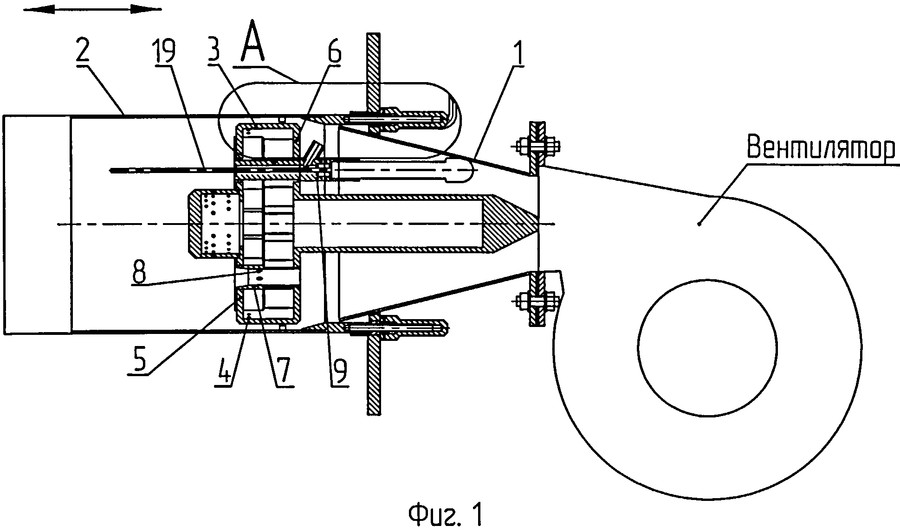

Due to its popularity and simplicity, the burner for the mining boiler is made by craftsmen in different variations, but we will undertake to describe the simplest design that will be available for repetition at home. First you need to select the necessary materials, here is a list of them:

- Steel tee with internal threads with a diameter of 50 mm - for the body.

- Squeeze with an external thread with a diameter of 50 mm - for the nozzle. Its length is accepted at will, but not less than 100 mm - for the nozzle.

- Elbow made of metal DN10 with external threads - for connecting the fuel line.

- Copper pipe DN10 of the required length, but not less than 1 m - on the fuel line.

- A metal ball or hemisphere that freely enters the tee is for the working part.

- Steel tube not less than DN10 - for connecting the air path.

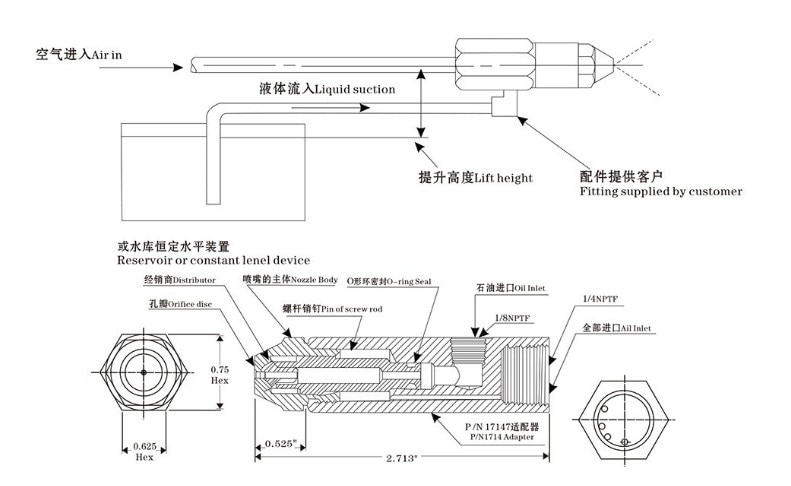

To make a burner for testing with your own hands, you need to perform one precise operation - make a hole in the center of the sphere. Hole diameter - from 0.1 to 0.4 mm, the ideal option is 0.25 mm. You can make it in 2 ways: drill with a tool of the appropriate diameter or set the finished jet to 0.25 mm.

It is not easy to make such a small hole exactly, thin drills easily break. Instructions on how to do this correctly are shown below:

Another way to make a calibrated hole in the spherical part of an autonomous burner is to insert a jet of the required diameter there. To do this, a hole is drilled, whose diameter is slightly smaller than the outer diameter of the jet, and processed with a reamer. The jet is pressed inward and polished, as described in the video:

When this operation is completed, we assemble the burner, based on the drawing:

On the side of the nozzle, it is necessary to make a hole wide enough to ignite the unit. A large fuel heating spiral is not needed, 2-3 turns are enough. The finished product can be mounted on a mounting plate and built into any boiler, including home-made ones. At the end of the work, you need to connect the air and fuel lines, and then organize the supply of oil and air. The simplest way to supply fuel is by gravity; for this, a waste tank is suspended from the wall above the burner and a tube is laid from it.

If you use a pump to pump oil, then later you can use control sensors and a control unit, then you will get an automatic burner that will be safer to operate. Detailed instructions for selecting materials and assembling the device are shown in the video:

If everything is done correctly and the diameter of the air hole is 0.25 mm, then the fuel consumption at the burner should not exceed 1 liter per hour. There should be no black soot during combustion, it is necessary to achieve even burning of the torch. Adjustment is carried out by moving the sphere back and forth or by changing the air pressure. Any compressor can handle its injection, even from a refrigerator, since the working pressure is never higher than 4 bar.

What is a Babington burner

A homemade oil burner can be used for a variety of purposes, for example, to work with a universal boiler or as part of a simple oil stove. The main task is to assemble a nozzle that will give a powerful flame. And here are the requirements:

- Small power consumption;

- Ease of manufacture;

- High efficiency;

- Impeccable homemade work even on contaminated fuel.

We have already said that in order to effectively burn used oil, you need to heat it up or spray it. The easiest way is to heat it using a heating element to a high temperature, but this is fraught with high energy costs. A liquid burner should become a source of cheap heat, but in the case of electric heating (evaporation), this is impossible - the tariffs for utilities in our country are very high.

Since we cannot ensure the heating of used oil with its subsequent evaporation, therefore, we need to try to spray it. This is exactly what the Babington burner, which has an extremely simple design, allows you to do. If we take a simplified drawing, we will see that the fuel flows down here along a spherical surface, in which a thin hole is made - the air leaving the compressor is supplied through it. The air jet, as it were, blows away particles of used oil from the surface of the sphere, as a result of which a fuel-air mixture is formed.

The above diagram gives, albeit a somewhat simplified, but still quite intelligible explanation of the principle of operation of the burner.

The resulting mixture is ignited, and the burner flame is used for one purpose or another. For example, nothing prevents you from installing a burner in a universal boiler that can work with any type of fuel.It is also possible to independently manufacture boilers, there is nothing complicated in this. An interesting fact is that there is virtually no evaporation here - the process takes place at almost a low temperature, due to the pressure of air from the thinnest hole.

For more efficient combustion in a liquid fuel burner, a waste oil heating system is activated due to a low-power heating element. Here is an approximate scheme for the manufacture of such a burner.

The Babington burner is a fairly simple device, but to make it you still need some skills that you can hardly get anywhere except by experience.

The Babington burner has many advantages. First of all, it does not need pre-treatment of used oil, and there are a lot of impurities in it - it is not without reason that it has such a black color. Secondly, it is extremely easy to manufacture. If you love and know how to work with tools, you will easily cope with its assembly and get at your disposal a simple and effective source of heat.

The evaporative burner in mining requires another heat source. This leads to the need to use a large amount of electricity or to complicate the design - you need to somehow heat the fuel so that it begins to decompose into flammable fractions. The scheme from Babington is much simpler - it is difficult to do without a compressor, but it can do without evaporation. It provides for the simplest spraying of fuel, after which it ignites without much difficulty.

Forge on mining (waste oil)

Repeatedly, both beginners and experienced blacksmiths came to the conclusion that over time, the fuel for maintaining a fire in a furnace or burner, whether it be gas, fuel oil, coal or coke, would invariably rise in price.

Therefore, the issue of reducing the cost of resources is becoming more and more urgent. In this article, we offer you a more detailed consideration of such a type of fuel for forging equipment as used oil.

In principle, such a resource is quite common and often does not cost as much as other types of fuel.

Craftsmen are not so easy to stop talking about complexity. And over time, the first installations began to appear, so to speak, experimental prototypes for covering household needs, running on used oil.

The inventors took as a basis the burner equipment, heaters, stoves and potbelly stoves that have long proven themselves. The refinement was carried out, as is customary with us, with improvised means - spare parts from tractors, cars and scrap metal, which has nowhere to use, but it's a pity to throw it away.

After a long journey of trial and error in blacksmithing, the craftsmen managed to adopt a novelty from those who switched to a more economical type of fuel. Having penetrated into what is the essence of the process of formation of a combustible mixture, gas furnaces were reworked.

In the process of work, one significant drawback appeared - it is difficult to ignite processing.

To solve the problem, they went in different ways: they supplemented the hearth with a compartment for preheating the oil with coal or firewood; installed oil filters; mixed mining with gasoline or diesel fuel.

As for forging on an industrial scale, no work is currently underway to switch to this type of fuel. This is due to factors such as:

- expensive modernization of industrial plants,

- possible interruptions in operation due to clogged oil supply nozzles,

- as well as a high percentage of sulfur in this type of fuel, which entails additional consumption and changes in the structure of the upper layers of the metal.

drip burner

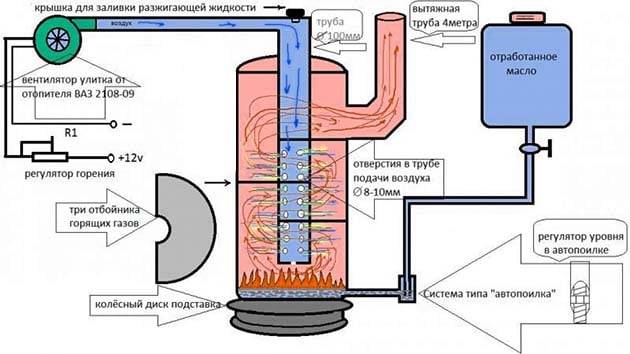

A good solution would be a do-it-yourself waste oil drip burner. The design consists of the following elements:

- containers of 5-10 liters with fuel located above the combustion site;

- a thin hose with a tap for supplying fuel to the burner;

- the burner consists of a metal pipe with a diameter of 5 mm and a length of 50 cm, a metal container with a recess for burning fuel and a thick-walled pipe with a diameter of 10 cm with many drilled holes for air supply.

The burner design itself is located inside a potbelly stove or brick oven. Mining by gravity falls on a heated surface, where it ignites. It is necessary to provide a container for collecting residues of combustion products.

2 Advantages and disadvantages

The burner is created not only because of its efficiency. The design has several advantages:

- simple device without moving parts;

- easy to make at home;

- freely available drawings and diagrams;

- low cost of fuel;

- high efficiency;

- small sizes;

- safety in use.

The disadvantages include frequent contamination of the fuel tank, which is why the oil must be constantly filtered. The pump and air compressor are powered by the mains, which is expensive.In residential areas, the burner should not be used for a long time, as it emits an unpleasant odor. For combustion products, you need to make a tap.

Additional Tips

When using a homemade burner, there are usually increased requirements for compliance with fire safety rules.

Important to remember:

- Do not leave a running nozzle unattended.

- It is forbidden to install the equipment in a residential area.

- To heat the heating mains boiler, they usually make a special room without a flammable coating on the walls, ceiling and floor.

- To increase the efficiency of work, enrich heavily contaminated mining with clean oil.

- Reliable ventilation is built in the boiler room to remove gases and smoke after fuel combustion.

- Perform regular maintenance and equipment checks.

With proper use, a homemade burner will last for many years. The savings from the use of this type of heating is obvious, because the used oil has already been paid for, and if it were not for a home-made firebox, it would have to be disposed of.

Previous Post

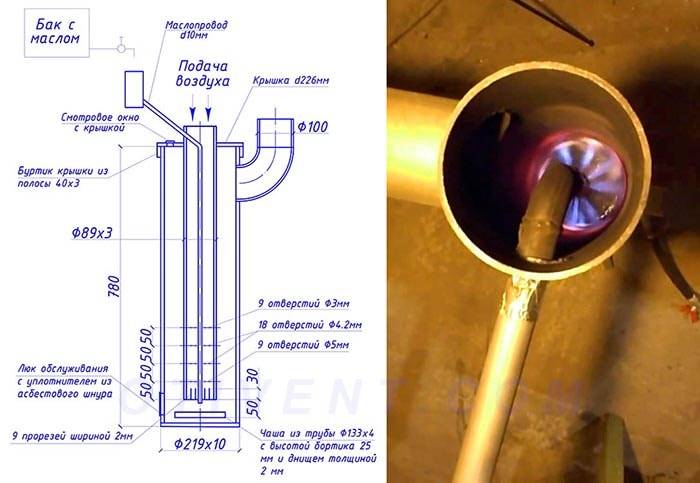

Dropper from a pipe

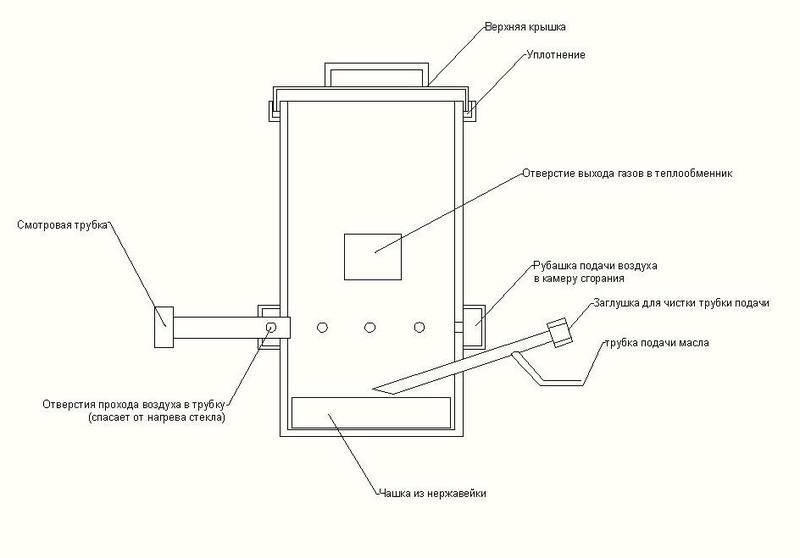

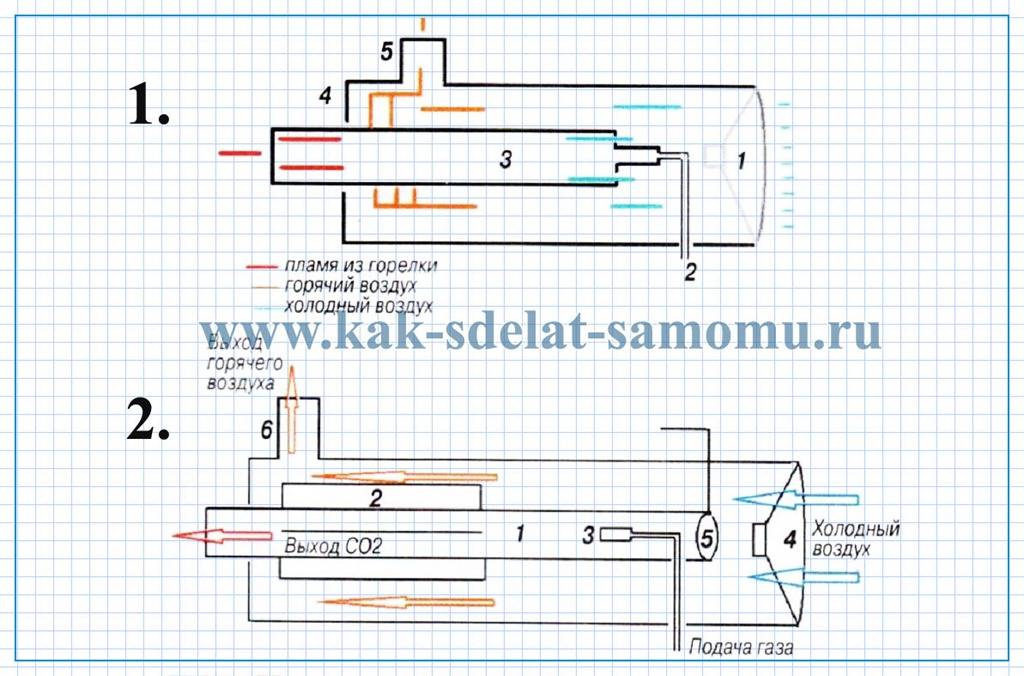

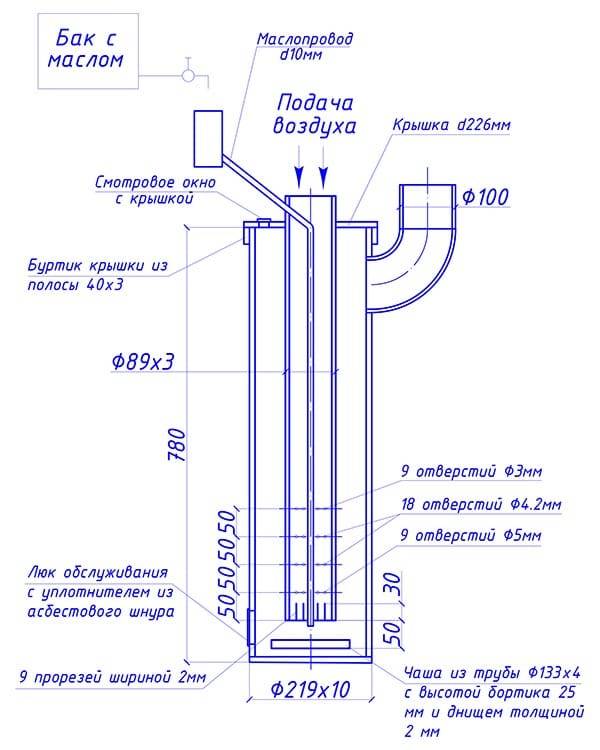

The device of a dropper stove from a pipe with a lower fuel supply

The device of a dropper stove from a pipe with a lower fuel supply

A drip stove that runs on waste oil consumes oil more economically than a potbelly stove. This is due to the fact that the fuel enters the furnace gradually. The principle of operation of the dropper stove is quite simple. Due to the evaporation in the ignition bowl, warm air circulates through the pipe and heats the room. It is necessary to make a dropper stove step by step, observing the correct dimensions:

- For the body of the dropper from the pipe, a pipe with a diameter of 21 centimeters is required. The wall thickness of the pipe must be at least one centimeter. Height - 78 centimeters. The bottom is made of steel sheet.The thickness of the steel should be from 5 millimeters. It is necessary to cut the bottom, taking into account the thickness of the pipe, and weld it to the structure. At the bottom you need to place a bowl for ignition. The legs of the stove can be made from any material. For example, wide bolts are suitable.

- A hole must be made in the pipe. The distance from it to the bottom of the structure should be at least 7 centimeters. Through this hole it will be possible to observe the operation of the stove, as well as additionally kindle the bowl. The hole must be closed with a door. To do this, a small door must be made from a sheet of steel or the remains of a pipe. In order for it to close tightly, an asbestos cord should be attached around the perimeter.

- A pipe is welded on the reverse side of the hole. Its diameter is 10 centimeters. The thickness of the pipe must be at least 4 millimeters. This pipe will serve to remove smoke.

- The cover of the structure is also made of sheet metal. To do this, cut a circle with a diameter of 22.8 centimeters. Walls 4 centimeters wide are welded along the edge. Two holes should be made. One on top of the lid with a diameter of 9 centimeters. The other should be placed on the side and be no more than 2 centimeters. You will need to make a door for the second hole, and you will also need to use an asbestos cord for tightness. A small hole will act as a viewing window.

- The next step is to create a pipe for air supply. This requires a steel pipe 76 centimeters long and 9 centimeters in diameter. In the pipe, it will be necessary to make several holes with a diameter of half a centimeter, stepping back from the edge of the pipe 0.5 cm. You should get 9 holes placed around the circumference.After another half a centimeter - 8 holes with a diameter of 4 millimeters. Through the same gap, 9 holes of 3 mm should be made. With the help of a grinder, 9 thin cuts of 3 centimeters are cut. At the other end of the pipe, a hole with a diameter of 1 centimeter is made through which the fuel supply tube will be inserted.

- The fuel supply tube should be small, with a diameter of only 1 centimeter. The length and bend should be made in such a way that the fuel from the tank can gradually enter the furnace.

- Pipes for air and fuel supply must be welded to the furnace cover.

- The chimney should be made taking into account the possibilities of the room. The height of the chimney pipe must be at least 4 meters. The chimney must be straight, without curved sections.

Dropper from a pipe - assembly diagram

Dropper from a pipe - assembly diagram

The drip stove consumes only 1-1.5 liters of used oil per hour. This is enough to heat a room up to 150 m3.

5 Necessary tools

Installations with an evaporator bowl, which have a drip method of fuel supply and forced air injection, are distinguished by high efficiency rates, while their manufacture is not particularly difficult. A water circuit can be placed in the combustion chamber, which allows the use of such heat generators for heating rooms up to 100 square meters.

Necessary tools and materials:

- Sheet metal with a thickness of at least 5 millimeters or blanks from gas cylinders.

- Metal corner measuring 20 by 40 millimeters.

- Welding machine.

- Bulgarian with a cutting wheel for metal.

The use of a blank from a gas cylinder as a basis makes it possible to significantly simplify the manufacture of a heat unit.The container must be properly prepared, for which the spherical parts are cut off from above and below and the edges are cleaned with a grinder to remove all existing burrs.

Recommendations for the manufacture of the heater:

- The flame bowl and the combustion chamber are made of stainless steel 3 mm thick.

- The oil supply pipe is made of stainless steel 1.5-2 mm thick.

- Flame tubes should be made of durable steel of 3-4 mm.

- The top cover is sealed with a steel strip and an asbestos cord.

- The inspection hatch can be made from a sheet blank 3 mm thick.

- The heat exchanger is made of stainless heat-resistant steel with a thickness of 4 mm or more.

You can make a supercharger snail with your own hands or use a cabin heater from a Zhiguli. In the latter case, the manufacture of the unit is somewhat simplified, and you can pick up the necessary components in car disassembly or in auto parts stores.

Step-by-step algorithm for manufacturing a boiler for testing.

- 1. A heat exchanger is welded from flame pipes with a diameter of 32 mm.

- 2. The inlet pipes for the water heating system are welded to the heat exchanger.

- 3. Prepare the blank of the cylinder, for which they cut off the upper and lower parts.

- 4. A fitting with a diameter of about 100 millimeters is welded to the neck, which will later be used as a cover for the heat generator.

- 5. Inside the boiler, a metal partition made of sheet steel is welded in, which separates the cylinder into two separate chambers.

- 6. The partition should be sealed with asbestos cord.

- 7. Make an afterburner in the form of a metal bowl and fix it at the bottom of the boiler.

- eight.A perforated pipe is welded into the partition separating the boiler into two chambers.

- 9. A pipe is welded to the afterburner, which is responsible for the air supply. A snail is installed that injects oxygen into the combustion chamber.

- 10. All that remains to be done is to make a chimney pipe, the length of which is at least a meter.

The boiler for working out with your own hands is ready. It is necessary to carry out a test run of the heat generator, if necessary, adjust the intensity of the air and fuel supply to the evaporator. Subsequently, home-made boilers will not require any maintenance, and such equipment, provided that high-quality sheet steel and thick-walled cylinders are used, will last for many years.

A home-made waste oil boiler is a versatile thermal equipment that will allow you to heat utility rooms, garages, workshops and private houses with high quality. The presence of an additional water circuit allows you to increase the efficiency of the heater, and thanks to its simple design, it will not be difficult to manufacture the device yourself. Do-it-yourself boiler drawings for working out can significantly simplify the manufacture of equipment. You can make the device with a double circuit, which allows you to solve problems with hot water and heat in the room.

We start making our own

- welding machine;

- Bulgarian;

- lathe.

In appearance, the burner looks like a small empty gas cylinder, with oppositely directed steel pipe sections welded on the upper and lower sides.The size of the inside of the burner is only 1 inch (2.54 cm), and its walls are quite large.

A piece of pipe at the bottom is required to supply oil and air to the part where combustion occurs. The short pipe at the top is used as a burner bell, from which flames will erupt.

Technician's tip: A normal household high power vacuum cleaner can be used to set the air flow into the oven.

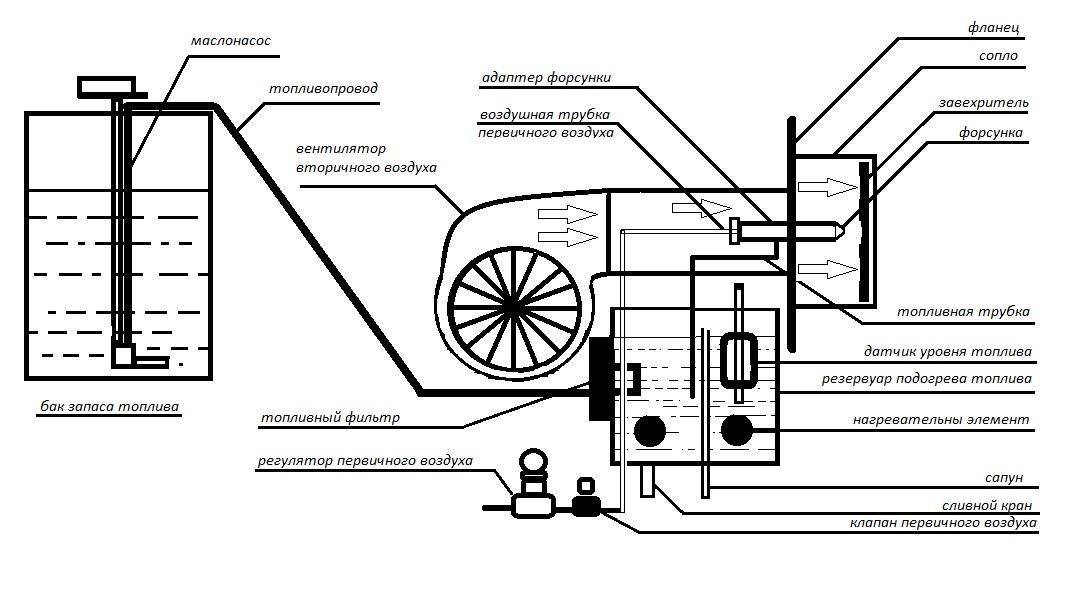

Waste oil burner

Today, waste oil burners are a type of equipment that is needed in almost all heating systems for technical or industrial premises.

Waste oil burners are installed in boilers and furnaces, water heaters, heat generators.

Disposal of used engine oil (waste) is a rather serious problem all over the world.

At the same time, the energy potential of mining is high; burning it, you can get a lot of heat, incomparably cheaper than from any other energy source.

The question of how to make a burner for working out with one's own hands is of interest not only to those professionally associated with the automotive industry - the working out reserve will help save a significant amount on heating utility rooms in private households.

For heating residential premises, mining is completely unsuitable because of the original additives it contains in engine oil and impurities that have got into it during operation.

However, mining is a very specific fuel, and any other liquid fuel burner will not work on it.

Waste oil burners are designed for burning waste oils in hot water boilers, process plants and hot air generators.

It is combined and successfully uses used oils, diesel fuel and oils of vegetable origin as fuel, which is very convenient in terms of operation and reduces the cost of maintaining several types of burners.

Thanks to a wide range of capacities (from 24 kW to 595 kW) they fully satisfy any needs of consumers.

In terms of performance, the burners operate on waste oil and are regulated within various limits.

The fuel for the burners can be diesel, vegetable oils and various types of recycled oils, with a viscosity of up to 90 units, are also possible.

Among other things, the burners are very convenient to use, as they do not require adjustment when switching from one type of fuel to another.

5 Homemade Babington Burners

Buying factory-made Babington burners is problematic. Most manufacturers of heating equipment do not produce such boilers, and for modifications available on the market, the cost will be comparable to the best gas and solid fuel models. Therefore, most homeowners make their own oil burner or order it to be done by an experienced craftsman.

You can find various drawings of the Babington burner with your own hands, which will allow you to get acquainted with the principle of operation of such a heater and make it yourself.

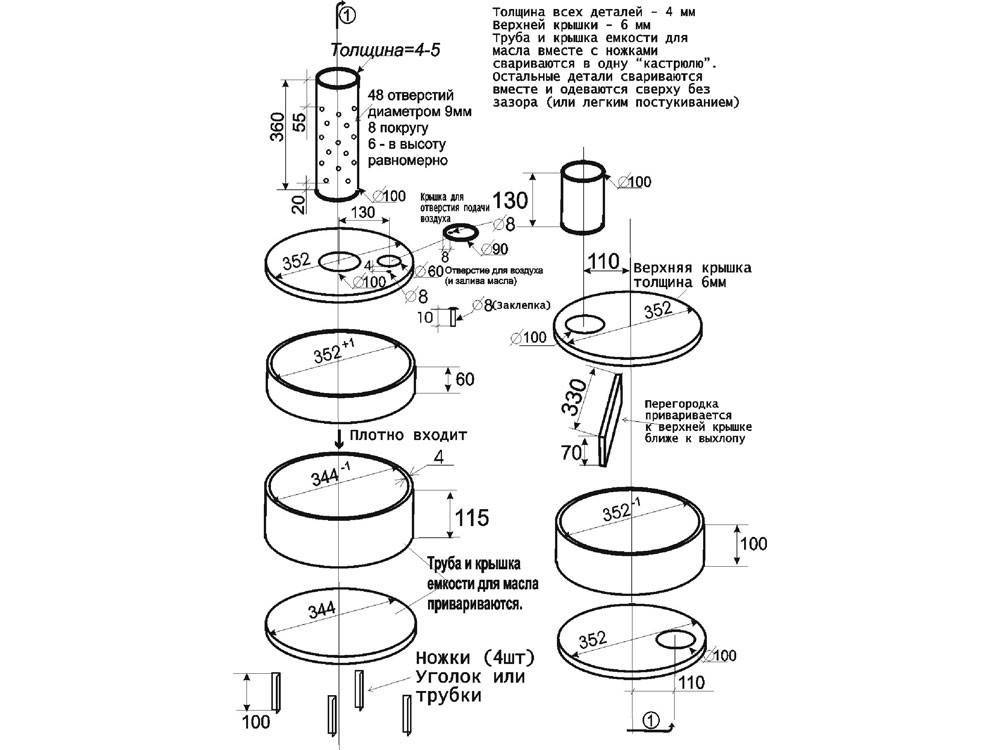

To perform the simplest model of a waste oil burner, you will need the following:

- A hollow ball or hemisphere from which the work surface will be made.

- The nozzle is made of a metal tube with a length of not more than 200 millimeters.

- Copper tube for the fuel path with a diameter of 10 millimeters.

- A metal or plastic tube that is responsible for the air supply.

- Threaded fittings for connecting fuel and air supply pipes.

In a makeshift hemisphere nozzle, you will need to drill a small diameter calibration hole. It is on the quality of the nozzle that the efficiency of the burner will subsequently depend. You will need to use the thinnest drill, which makes a hole no more than 0.4 mm thick.

Making holes larger in diameter will lead to a significant increase in fuel consumption, while the efficiency of the boiler will deteriorate. If there are thick nozzles on the nozzle, it becomes much more difficult to ignite the burner, and subsequently it is difficult to maintain uniform combustion, the boiler will often go out, requiring increased attention and constant maintenance.

Having made a hole in the nozzle, an air supply tube is brought to the ball, on which a tee is installed. A fitting is cut into it from above by soldering, to which a copper line supplying fuel is connected.

Next, a heat-heating element is mounted to heat the mining. Inside the hemisphere, an electric heating element with a thermostat is installed. Near the heater, several turns of the tube are made, which are responsible for supplying fuel. This will heat the liquid by 5-10 degrees, improving its combustion and increasing the efficiency of the boiler.

Electric ignition of the burner is carried out on the basis of one or two automotive spark plugs. They are screwed in at the beginning of the nozzle, connected to electricity. You will also need to install a starting electric relay, which will allow you to get a stable spark, which is necessary to ignite the burner.

Having made a Babington boiler with your own hands, you can use fuel oil, waste oil, biodiesel and other heavy oil products as fuel. The automatic device will have a combustion intensity regulator, while it is possible to independently manufacture heaters with a power of up to 30 kW. Now you can find numerous drawings of Babington burners, which are distinguished by their versatility and functionality of use. It is only necessary to be guided by such documentation, making heaters in full accordance with the drawing and diagram.

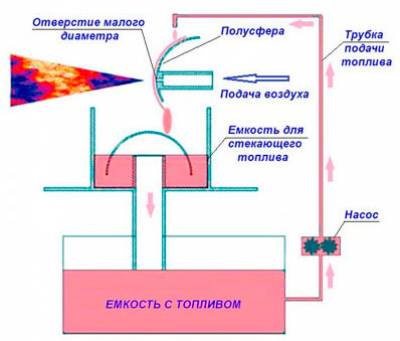

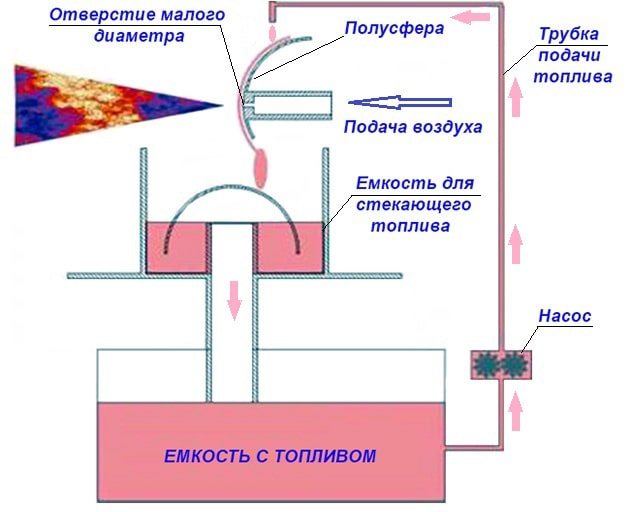

The principle of operation of the Babington burner

A few words about the history of the invention. The considered method of burning heavy fractions of liquid fuel appeared relatively recently - in the middle of the last century. More specifically, inventor R.S. Babington patented his diesel burner in 1969. However, the patent expired long ago and now her device is available to everyone interested.

Babington's invention is fundamentally different from traditional oil burners, where a mixture of air and fuel is injected by a pressurized nozzle:

- Mining or diesel is supplied from the tank by a low-capacity pump.

- Fuel drips onto the working surface - spherical or inclined. On it, the fuel flows down, forming a thin film.

- In the center of this surface, a hole of small diameter (no more than 0.3 mm) was made, through which the compressor pumps compressed air.

- The waste oil Babington burner works on the following principle: a stream of compressed air exiting through a small pressurized hole tears off part of the oil film from the surface.

- As a result, we obtain a jet of air-fuel mixture, which, after ignition, forms a stable flame. It is sent to the furnace or boiler furnace, heating the walls of the chamber or the water jacket. The figure below shows the operation of the burner:

Since part of the fuel flows past the hole, a drain is organized back into the tank. It is clearly seen that the unburned residues of used oil drain from the hemisphere into a special container, and from there back to the main tank. From it, the fuel is supplied for combustion already under low pressure, and it is preheated for liquefaction. As you can see, no filter elements are provided by the design.

Preheating used oil or diesel fuel before burning with a Babington burner is very important and here is why:

- The heated mining liquefies and forms a thinner film on the working surface, which is well sprayed by the air flow. This contributes to more efficient combustion.

- The finer the droplets of liquid fuel suspended in the jet, the easier it is to ignite the boiler or Babington furnace in manual / automatic mode.