- Kinds

- Requirements for outdoor piping

- Construction of external sewerage

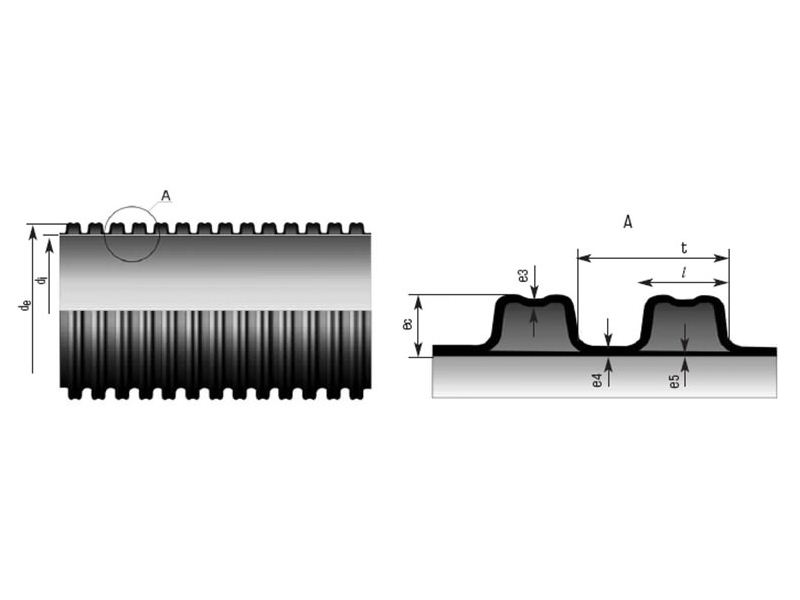

- Corrugated pipes

- Basic requirements for a sewer pipe

- Characteristics of external PVC sewerage

- Video description

- Diameter and stiffness

- Mounting methods

- External sewerage: work sequence

- Check valve device

- Video description

- Types and characteristics

- PVC sewerage

- Polypropylene (PP)

- corrugated polyethylene

- Asbestos-cement

- Concrete

- metal

- Cast iron sewer

- Ceramic products

- Stages of installation of corrugated pipes

- What are sewer pipes

- Laying a pipeline from corrugated pipes

- Trench preparation

- Pipe connection

- backfilling

- The price of corrugated pipes for outdoor sewage

Kinds

The range of corrugated pipes is represented in modern markets by different models of products that have differences in design:

- single-layer - very flexible and lightweight, used to connect gas appliances and protect cables for various purposes;

- two-layer - have a smooth inner wall and a corrugated outer layer, have increased strength characteristics (rib and ring stiffness), resistance to mechanical stress.

- corrugated hoses.They are used as flexible conduits to portable and mobile communications devices in cases where their connection with rigid pipes is technically difficult or completely impossible.

- reinforced - made of low-pressure polyethylene by co-extrusion with reinforcement with synthetic, mineral or steel fibers. They have a three-layer wall structure, where the basis is a smooth elastic HDPE pipe, the outer layer is a corrugated waterproof shell, and a reinforcing insert acts as a layer. This production technology makes it possible to obtain pipes of large diameters with high ring stiffness at the outlet without thickening the corrugations. The metal insert is completely protected by polyethylene and is not subject to corrosion.

Corrugated pipes also differ in the material used for their manufacture:

- polyethylene of low (HDPE) and high (PVD) pressure. This is the most common type of plastic with versatile physical and chemical properties. Produced in compliance with standards, this plastic is an environmentally friendly material. It is frost-resistant, poorly propagates combustion, does not conduct electric current, therefore flexible pipelines made of polyethylene corrugated pipes do not need to be grounded. Polyethylene absorbs shock loads and can be a reliable protection for cable lines from mechanical damage and vibration loads. The inertness of polyethylene in relation to chemicals makes it possible to protect electrical wiring from many types of solvents, acids, oils and other aggressive compounds;

- polyvinyl chloride. PVC is a safe material that does not emit toxic substances and does not cause allergic reactions.It is absolutely neither flammable nor susceptible to moisture, it is resistant to corrosion and temperature extremes, as well as low electrical conductivity. PVC corrugated pipes can withstand heavy loads, so they can be laid under a thick layer of concrete or in the ground;

- stainless steel. The unique properties of stainless steel, combined with ease of installation, make it possible to use such products for radiator heating systems, underfloor heating, cold and hot water supply pipelines;

- aluminum. Lightweight and durable ventilation ducts, kitchen hoods and chimneys are obtained from aluminum corrugated pipes. This material is non-combustible, corrosion-resistant, heat-resistant - withstands heating without loss of shape up to +270ºС.

Requirements for outdoor piping

External sewer networks have to function in difficult conditions. Pipes covered with earth are forced to carry the weight of the soil, on which people, and often cars, can move.

They are also affected by soil water, which can provoke a displacement of the docking points, which can lead to depressurization of the sewer network.

Systems have to constantly resist the static/dynamic effects of wastewater that is transported through pipes.

External sewer pipes used to install wastewater systems have to be underground in difficult conditions

That is why special requirements are imposed on the elements of external sewer networks.

Pipes must have such qualities as:

- strength and rigidity;

- the ability to endure temperature fluctuations without losing working qualities;

- frost resistance;

- wear resistance, long service life;

- resistance to aggressive chemical environments.

For the manufacture of external sewer systems, various materials (polymers, steel, cast iron) can be used, but all of them must comply with the above factors.

It should also be taken into account that the quality of the pipeline is influenced not only by the specific properties of the pipes, but also by the quality of installation and installation of the system.

Our site also has other useful materials on the rules for arranging sewerage.

We recommend that you check them out:

- Laying sewer pipes in the ground: technological rules and nuances

- Sewer slope calculation: formulas and standards

- How to lay sewer pipes in a private house: schemes and laying rules + installation steps

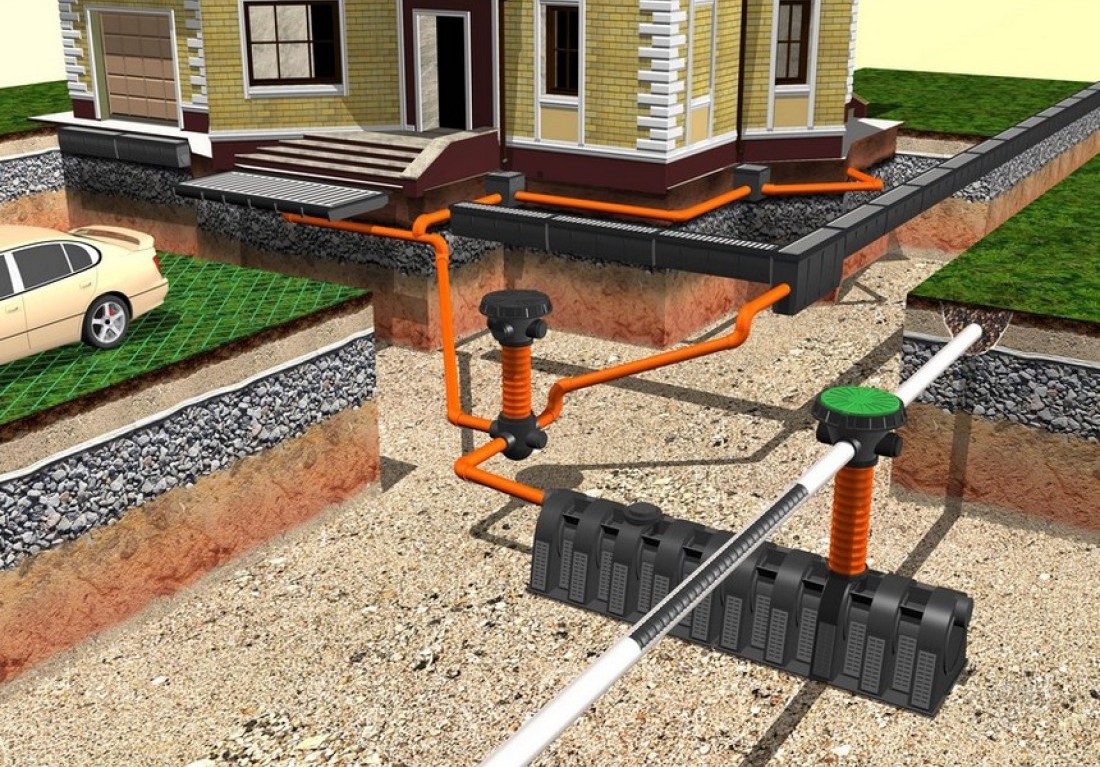

Construction of external sewerage

External sewerage is very essential for the disposal of sewage and other waste. A number of conditions are imposed on corrugated pipes for external sewage:

- Resistant to the composition of the waste.

- Strength, environmental friendliness, thermal stability.

- Ease of service.

When laying corrugated products for external sewage, soil composition and flow load are provided. At the sewer corrugated pipe 110 mm, the volume begins at least the specified number. If the sewer-flushing structure is placed in the landscaping zone, then a simple view is preferred; in an area with a small flow of moving vehicles - a heavy structure; under highways and railway tracks - a super-heavy version of the product.

When laying corrugated products for external sewage, soil composition and flow load are provided. At the sewer corrugated pipe 110 mm, the volume begins at least the specified number. If the sewer-flushing structure is placed in the landscaping zone, then a simple view is preferred; in an area with a small flow of moving vehicles - a heavy structure; under highways and railway tracks - a super-heavy version of the product.

When laying corrugated sewer-flushing structures in the same soil, one of the key advantages of the product is visible: the soil is closely adjacent to the corrugated profile cracks, and it acquires a stable position.

Corrugated pipes

When laying storm sewers, both smooth and corrugated products can be used. What is the difference? Corrugated models are characterized by increased density, due to the special ring stiffness. At the same time, corrugated products are usually divided into several types:

- Lightweight - used for laying external sewerage;

- Heavy - characterized by increased strength, can be buried in the ground;

- Extra heavy - used for laying under highways and even railways, able to withstand high levels of load and vibration.

Corrugated pipes can be made from both PVC and HDPE.

Basic requirements for a sewer pipe

Products for external sewerage are subject to increased requirements for strength: they are located in the soil and experience constant pressure from the soil layer.

Basic requirements for pipes for external sewerage:

- Durability, crush resistance.

- Durability.

- Chemical inertness - the pipe should not rust, overgrow with salts, react with aggressive environments, and be destroyed under the influence of bacteria.

- Plastic.

- Frost resistance - do not collapse when working at low temperatures and freezing with water inside.

- The smoothness of the inner walls - this prevents the accumulation of salts on the walls and the faster passage of the contents.

In addition, the pipe system should be easy to install, there should be a sufficient range of fittings for installation and creating a network of any configuration.

Characteristics of external PVC sewerage

Video description

PVC pipes for outdoor sewage are a new generation of products that, due to their properties, displace pipes made of other materials from domestic systems. They do their job well; designed for temperatures up to 60°C and pressures up to 10 MPa. In practice, two types of products are used, which should be distinguished:

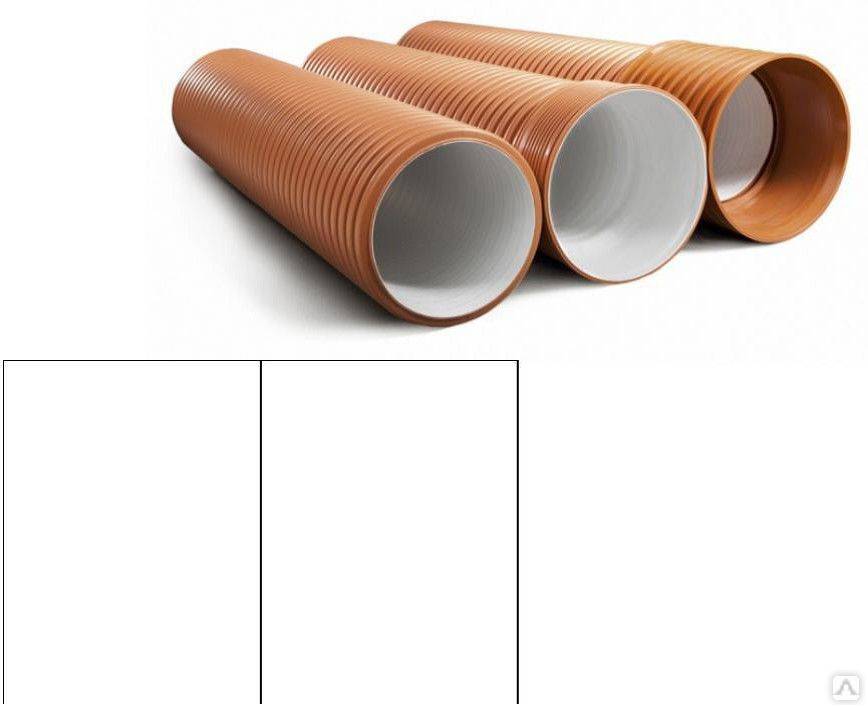

Diameter and stiffness

Important parameters that determine the properties of the drainage system. Manufacturers offer products for external sewerage of two types:

- Single-layer (smooth), 110-160 mm in diameter, mainly used in private construction.

- Three-layer (corrugated), from 110 to 630 mm.

According to the rigidity (strength), external sewage pipes are divided into:

Class SN8. They have the thickest walls and are placed at a depth of up to 8 m.

Class SN4. They are laid to a depth of 2-6 m.

Class SN2. They are laid to a depth of 0.8-2 m, mainly involved in the private sector.

When designing, the strength of products is taken into account

Mounting methods

Installation of PVC pipes is carried out in one of the following ways:

- Socket connection. Does not require special equipment. Products are selected by diameter. The smooth end of one pipe is inserted into the socket of the other. The connection is sealed with a rubber seal.

- Cold welding (gluing). Special adhesive is used, no equipment required.

- Flange connection (detachable). Pipes are mounted using fittings (connecting elements of various configurations that create turns and additional branches); if necessary, the unit can be disassembled.

- Clutch connection. It is used if it is necessary to connect products made of PVC and other materials, often during repairs.

Pipes with a socket are suitable for assembling a gravity system; the pressure system is mounted from products without a socket.

External sewerage: work sequence

Sewer trench preparation. Its depth depends on the depth of soil freezing, groundwater occurrence and other features of the site. According to SNiP P-G.3-62, laying is carried out 0.5 m below the freezing mark. For pipes with a diameter of 110 mm, a trench width of 0.6 m is laid.

Checking the slope angle is an important part of the installation

- Pipeline installation. Starts from the foundation of the house; pipes are connected in a suitable way and laid with a slope. If the sewer is laid shallow, the pipeline is insulated. At the exit from the building, the pipe must be insulated.

- The slope angle is checked, then the trench is covered.

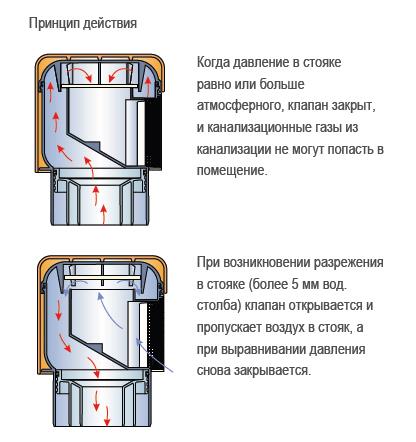

Check valve device

Improper installation and violation of the rules for operating the drainage system leads to an emergency situation - blockage. The contents of the pipes can move back with all the ensuing consequences on the 1st floor. Installing a sewer check valve helps to avoid dramatic developments.

The check valve allows the liquid to flow only outward; the return flow of sewage is reliably blocked. The valve with a diameter of 110 mm is mounted on a common pipe, with a diameter of 50 mm - on each PVC drain pipe.

Valves are made from cast iron, brass or steel. Due to the widespread use of PVC pipes, the demand for cheap and durable PVC valves has increased. By design, check valves are:

- PVC valve. Mounted on both horizontal and vertical pipes. Inside there is a reciprocating locking part - a plate fixed at a slight angle.It bends under the pressure of the outgoing fluid, and the reverse flow presses it, blocking the return movement.

- Ball valve. The locking mechanism is a metal ball. If back pressure occurs, it presses against the hole and blocks the flow.

Cross-sectional ball check valve

Video description

On the Russian market, you can find products from both foreign and local companies. The number of domestic pipe manufacturers is growing due to the constant growth in demand. Enterprises master the latest technologies and produce products of excellent quality (confirmed by a certificate) at an affordable price.

When designing external communications, pipes are given increased attention; the efficiency of the system directly depends on them. For the installation of external sewerage in suburban housing, PVC pipes with a diameter of 110 mm and a stiffness of SN4 are recognized as the most practical material

They are reliable under constant load (can withstand large volumes of wastewater); they can be positioned without fear of external loads (in front of the garage, under the garden path).

Types and characteristics

For laying sewer systems, manufacturers offer finished pipes, tees, corner products, adapters, crosses. The materials used in production determine several varieties of products. These can be polymer, metal or ceramic components.

PVC sewerage

PVC pipes have a smooth surface, sufficient strength for internal and deep sewerage, are not afraid of ultraviolet radiation, can last more than 50 years and are inexpensive. The classification of types of PVC sewer pipes is based on strength indicators:

- SN2 - lungs.

- SN4 - medium.

- SN8 - heavy.

Regarding the application, there are restrictions due to poor resistance to low and high temperatures exceeding +40 degrees Celsius. The material becomes brittle and elastic, which leads to cracks and deformations. During combustion, toxic substances are released.

Polypropylene (PP)

Compared to PVC pipes for sewerage, plastic polypropylene pipes are inferior in strength, therefore they are used only for laying inside the building without external mechanical load. The permissible drain temperature is +80 degrees Celsius. The smooth surface contributes to the free flow of the medium, which is important for the circulation of drinking water. Inside the dwelling, it is better to lay noise-absorbing products (for example, under the rehau or politek brand).

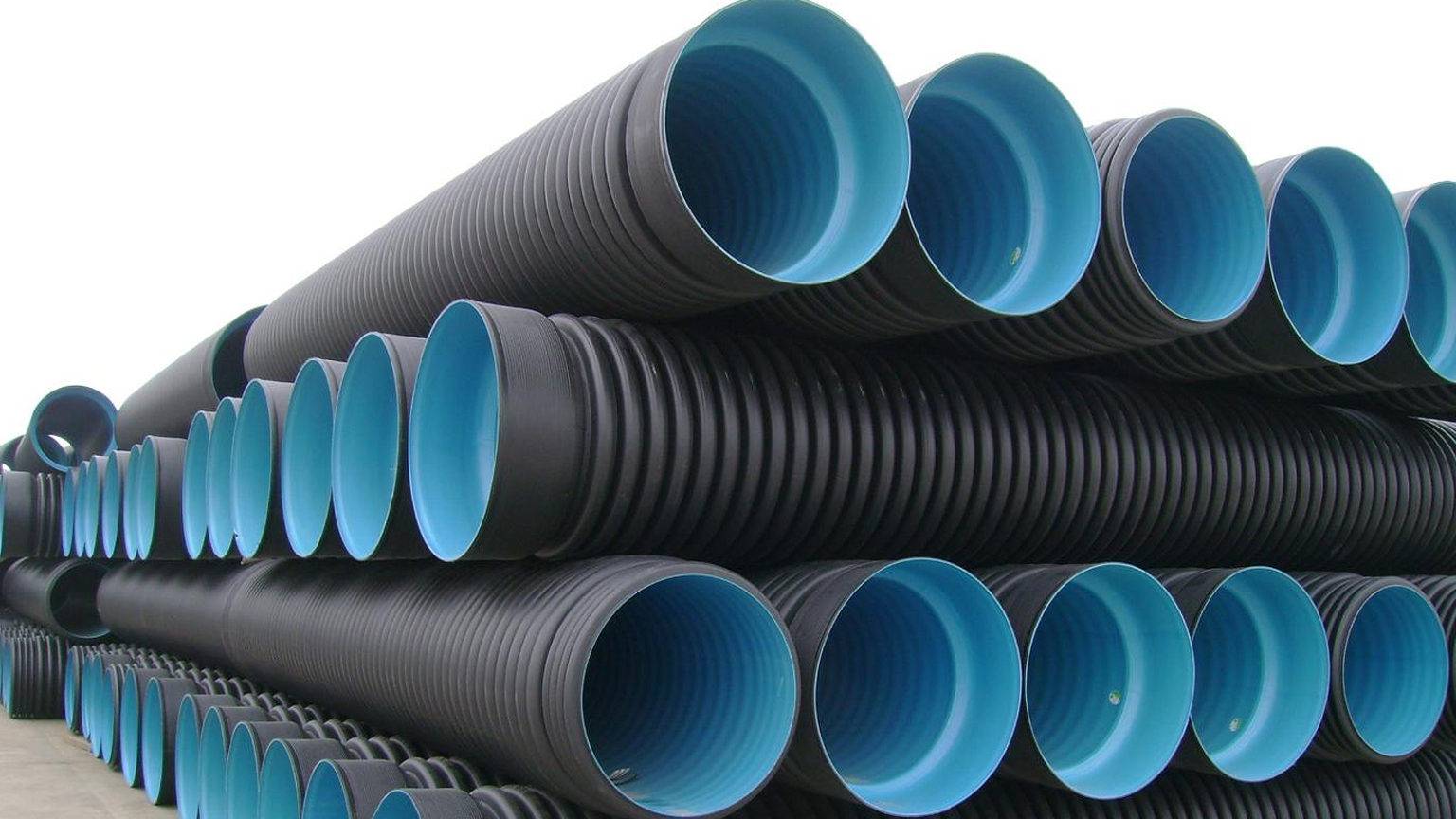

corrugated polyethylene

Structurally, HDPE pipes are represented by a solid corrugation and a built-in smooth-walled channel. This design provides increased rigidity of products, which is important for deep laying (up to 16 m.). According to the technical characteristics, the material is similar to the plastic counterpart. It is used more often for the construction of engineering communications for the transportation of hot waste.

Asbestos-cement

Asbestos in the composition of the cement mortar plays a reinforcing role. Products belong to the most budget option for a sewerage device. Contact with water has a positive effect on the strengthening of the walls. Pipes have a low coefficient of thermal expansion and do not corrode. The characteristics are relevant for pressure systems and outdoor laying.

Concrete

For the manufacture of pipes, as a rule, M350 concrete is used.It is characterized by water absorption up to 3%, 200 cycles of freezing and thawing and high compressive and tensile strength. The material does not rot, does not burn, does not corrode, is resistant to chemical environment and low temperatures. It is used in the industrial, hydrotechnical and urban planning sectors with a low degree of aggressiveness.

metal

Such products are represented by steel-rolled products with a galvanized anti-corrosion coating. The material has high strength, long service life, withstands temperature extremes in a wide range and is relatively inexpensive. However, it is rarely used in the private sector due to its heavy weight. More often, a sewer pipeline of this nature is laid at industrial enterprises of the chemical and oil refining type.

Cast iron sewer

Cast iron is an alloy of iron and carbon. The material is characterized by higher strength, pressure endurance and corrosion resistance compared to steel. It also has a service life of over 80 years.

For laying sewers, a negative fact is the rough inner surface, which makes it difficult to transport wastewater and contributes to the formation of plaque. In the private sector, cast iron is rarely used due to its significant weight, high cost and the need to additionally resort to sealing agents. More often, such pipes are used for the internal construction of risers and sewers in multi-storey buildings.

Ceramic products

The production of ceramic pipes is based on the processing of clay. The raw material has water resistance, resistance to aggressive environment in terms of temperature, chemicals, corrosion.Among the advantages, an unlimited service life is also noted. However, brittleness complicates installation work, the installation of fittings and limits the installation in places of increased mechanical stress. The use of ceramic pipes is relevant for sewerage in industrial areas, at strategic sites.

Stages of installation of corrugated pipes

When laying the internal pipeline, standard methods are used: rubber sealant, shaped elements. Installation of sewer pipes of the external system involves digging a trench. Main stages of work:

- site preparation;

- excavation;

- pipeline installation;

- backfilling.

The area is cleared of weeds. A pipeline laying plan is drawn up, then the site is marked out, for this, stakes and a rope are used. Trenches are being dug. Their width is determined taking into account the diameter of the communications: a small distance is left between the walls of the ditch and the pipe.

When digging a trench, a slope is provided. The value of this parameter is determined in accordance with SNiP. If the ditch passes near the house, you need to step back 20 cm from the wall. A sand cushion is arranged at the bottom of the trench. Then the communications are laid out, after which you can proceed to their connection. If you plan to use a corrugation, a sealant is installed on the sewer pipe (on the second turn). Sections of the pipeline are connected using shaped elements. At the last stage, sand (10 cm layer) and soil are backfilled.

What are sewer pipes

According to the method of water drainage, the following types are distinguished:

Plastic pipes for sewerage

Plastic pipes for sewerage

- internal pipes - divert water from the source of consumption (baths, toilets, sinks).As a rule, they are painted in gray colors.

- external - produce a tap from houses and cottages, into the general sewer.

According to the material from which pipes and fittings are made, they are divided into:

cast iron. Most sewers are made from this material. It is strong, durable (70-85 years), withstands heavy loads. The disadvantages include high cost and installation problems associated with heavy weight. In addition, the inner walls of cast-iron pipes are rough, which makes it difficult for water to move, and build-ups form over time.

Cast iron pipes Attention! Experts do not recommend installing cast iron pipes in places with weak or saline soil. plastic

Pipes are made from this material for both internal and external sewage. Its main advantages are light weight, which facilitates the process of transportation and installation, relatively low cost, as well as smooth inner walls, which reduces the percentage of congestion. There are three types of plastic pipes and fittings: PVC (mainly used for wastewater. They can withstand temperatures up to 70C, but are not very resistant to aggressive environments and UV rays); polyethylene (used for pressure internal and external pipelines. They expand under the influence of hot water, withstand temperatures from -40 to +40. Not used for hot water); polypropylene (withstand high temperatures, resistant to acids and alkalis. Most often used to drain water from washing machines and dishwashers)

plastic. Pipes are made from this material for both internal and external sewage.Its main advantages are light weight, which facilitates the process of transportation and installation, relatively low cost, as well as smooth inner walls, which reduces the percentage of congestion. There are three types of plastic pipes and fittings: PVC (mainly used for wastewater. They can withstand temperatures up to 70C, but are not very resistant to aggressive environments and UV rays); polyethylene (used for pressure internal and external pipelines. They expand under the influence of hot water, withstand temperatures from -40 to +40. Not used for hot water); polypropylene (withstand high temperatures, resistant to acids and alkalis. Most often used to drain water from washing machines and dishwashers).

Fittings for PVC pipes (external sewerage)

Fittings for PVC pipes (external sewerage)

- stainless steel pipes are not very popular due to their low resistance to corrosion.

- copper pipes are the most expensive, do not corrode and are neutral to the action of acidic and alkaline environments. But their main drawback is the ability to change the color and smell of water.

Laying a pipeline from corrugated pipes

When laying a sewer pipeline, several stages of work can be distinguished:

- trench preparation;

- pipe joining;

- backfilling.

Let's take a closer look at the stages of working with plastic.

Trench preparation

Earthworks when laying a sewerage pipeline from corrugated pipes are carried out in accordance with the requirements of SNiP 3.02.01 - 87. Here are the main rules for their conduct:

- The width of the prepared trenches must be such that the installer, being below, can carry out his work normally.That is, the distance between the side wall of the trench and the wall of the laid pipe should not be less than 20-25 cm.

- After the trench is dug, you need to carefully examine its bottom. There should be no large stones and frozen areas. Boulders must be removed in advance, and the excavation site must be covered with soil and compacted.

- If the soil on the site is very loose, then it may be necessary to carry out activities to strengthen the bottom. Strengthening is carried out by concreting.

- When preparing the trench, the angle of inclination specified in the pipeline design should be maintained. If this condition is not met, gravity sewerage will not work normally.

- For any type of soil, a “pillow” device for pipes is provided. Clean sand or fine gravel (granule size - up to 20 mm) is used as a backfill. The thickness of the bedding layer is 15 cm.

Pipe connection

How can a corrugated sewer pipe be connected? As a rule, in private construction, a "bell" connection is used. Basic installation rules:

- It is necessary to carry out work on assembling the pipeline in warm weather, the air temperature outside should be above 15 degrees.

- Before starting the assembly, it is recommended to inspect the pipes for their compliance with the dimensions specified in the project, as well as for the absence of any defects that can be detected visually.

- The pipes should be laid out along the side of the prepared trench, and the pipe sockets should be oriented in the direction opposite to the slope.

- Before starting the connection operation, it is necessary to clean the socket itself and the smooth end of the pipe, removing dust and other contaminants.

- For socket connections, rubber seals must be used. The sealing ring is placed in the groove on the second turn of the corrugation, while making sure that the sealant profile is directed in the opposite direction from the direction the pipe is inserted into the socket.

- If it is necessary to connect a corrugated pipe with pipeline elements made of other materials (cast iron, reinforced concrete, asbestos cement, etc.), it is necessary to use special fittings - couplings or flanges.

In some cases, butt welding of pipes is used instead of a "bell" connection. This work is carried out in accordance with the requirements of GOST 16310-80. When welding, the same devices are used that are used to connect simple polyethylene pipes.

The essence of the process is to heat the ends of the pipes before the plastic melts and connect them with a certain pressure. After cooling the plastic, a monolithic seam is formed.

Another method of connection is the use of a coupling with an o-ring. In this case, the seal is installed in the groove of the corrugation:

- With a pipe diameter of 250-1200 mm, the ring is inserted into the first corrugation groove.

- With a pipe diameter of 125-200 mm - in the second.

The connection with the help of couplings is tight and reliable.

backfilling

When backfilling, sand is used first. The layer of sand should be 8-10 cm higher than the pipe. At the same time, sand should be compacted along the edges of the pipe, but this is not required above the pipe itself.

On top of the sand, you can pour the soil that was taken out when digging a ditch.It is necessary to ensure that large boulders or large frozen clods of earth do not come across in the soil being filled up.

Polymeric corrugated pipes are almost an ideal material for the construction of outdoor pipelines. These can be sewer systems, drainage schemes or stormwater.

The price of corrugated pipes for outdoor sewage

On the price of corrugated pipes for sewerage influenced by such factors:

- The material from which they are made. PVC products are considered the cheapest, HDPE products are considered the most expensive.

- Wall thickness. Massive products take a lot of material, so their cost is higher. The stiffness class depends on the wall thickness. Therefore, we can say that the higher the rigidity, the more expensive the products.

- Place of manufacture. The farther the goods are transported from the place of manufacture, the greater the cost of transportation and the higher the final price of a corrugated pipe for outdoor sewage. Traditionally, the cost of domestic products is lower than prices for foreign analogues.

- Product quality. This factor most of all affects models that are connected by welding. To obtain a high-quality joint, it is necessary that there are no defects in the surfaces to be joined - there are no cracks, ovality, the dimensions correspond to the declared values, etc. Therefore, before buying a corrugated sewer pipe at bargain prices, check its condition.

The average price of a corrugated polypropylene pipe for external sewerage in Russia:

| Outer diameter, mm | Inner diameter, mm | Brutality class | price, rub. |

| 160 | 139 | SN8 | 3040 |

| 200 | 174 | SN8 | 4414 |

| 225 | 200 | SN8 | 6487 |

| 250 | 218 | SN8 | 7901 |

The average price of a corrugated pipe made of polypropylene for outdoor sewerage in Ukraine:

| Outer diameter, mm | Inner diameter, mm | Brutality class | Price, UAH. |

| 160 | 139 | SN8 | 1350 |

| 200 | 174 | SN8 | 2100 |

| 225 | 200 | SN8 | 3050 |

| 250 | 218 | SN8 | 3430 |

The average price of a corrugated HDPE pipe for external sewerage in Russia:

| Outer diameter, mm | Inner diameter, mm | Brutality class | price, rub. |

| 110 | 94 | SN8 | 150 |

| 133 | 110 | SN8 | 188 |

| 160 | 136 | SN8 | 268 |

| 189 | 160 | SN8 | 312 |

| 200 | 171 | SN8 | 358 |

| 230 | 200 | SN8 | 455 |

| 250 | 216 | SN8 | 567 |

The average price of a corrugated HDPE pipe for outdoor sewerage in Ukraine:

| Outer diameter, mm | Inner diameter, mm | Brutality class | Price, UAH. |

| 110 | 94 | SN8 | 65 |

| 133 | 110 | SN8 | 85 |

| 160 | 136 | SN8 | 120 |

| 189 | 160 | SN8 | 140 |

| 200 | 171 | SN8 | 155 |

| 230 | 200 | SN8 | 220 |

| 250 | 216 | SN8 | 250 |

Watch a video about corrugated pipes for outdoor sewage:

Thus, we can conclude about the practicality of external sewer routes from corrugated two-layer pipes. Products serve for a long time and reliably, and you can build such a structure yourself, saving money on assembly. But to create a reliable external sewage system from corrugated pipes, it is necessary to know the properties of each type of product so that the features of operation do not destroy it.

Related article: The best pipes for plumbing