- What to pay attention to when installing

- How is the installation carried out

- Advantages of the corrugation for connecting the hood

- Main disadvantages

- Comparison with rigid plastic duct

- Comparison of a rigid duct and a flexible corrugation for ventilation

- The choice of diameter and installation features of corrugated pipes for ventilation

- Under what conditions is corrugated hood used?

- Secrets of installing an exhaust duct

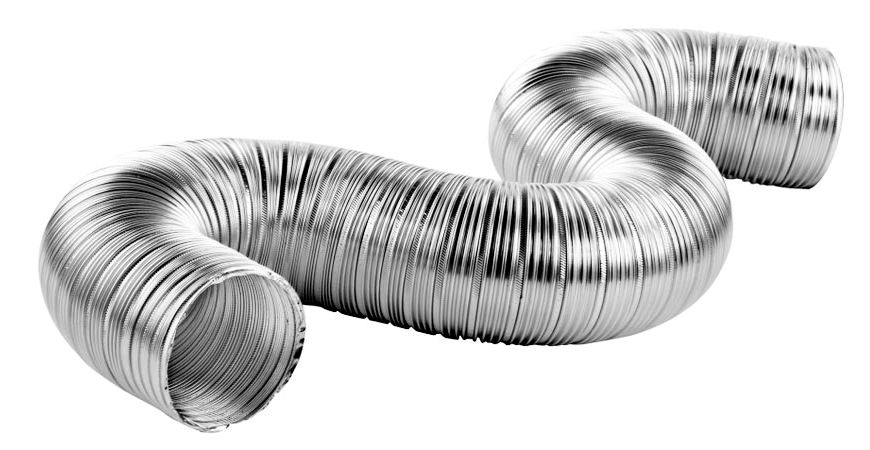

- Design features of the corrugation

- Installation

- How to choose the size

- How to fix the corrugation on the hood

- Why you need to install corrugations on the hood

- Corrugated pipe for exhaust: advantages and disadvantages of the device

- Video about the selection and installation of corrugations

- Good reasons to replace the pipe

- The main criteria for choosing a corrugated pipe for an air duct

- Pipe materials

- Manufacturing methods and their features

- Selection of shape and section

- Extra options

- Subtleties of installation and installation

- Types and differences of air ducts for hoods

- Features and benefits of metal (corrugated) air ducts

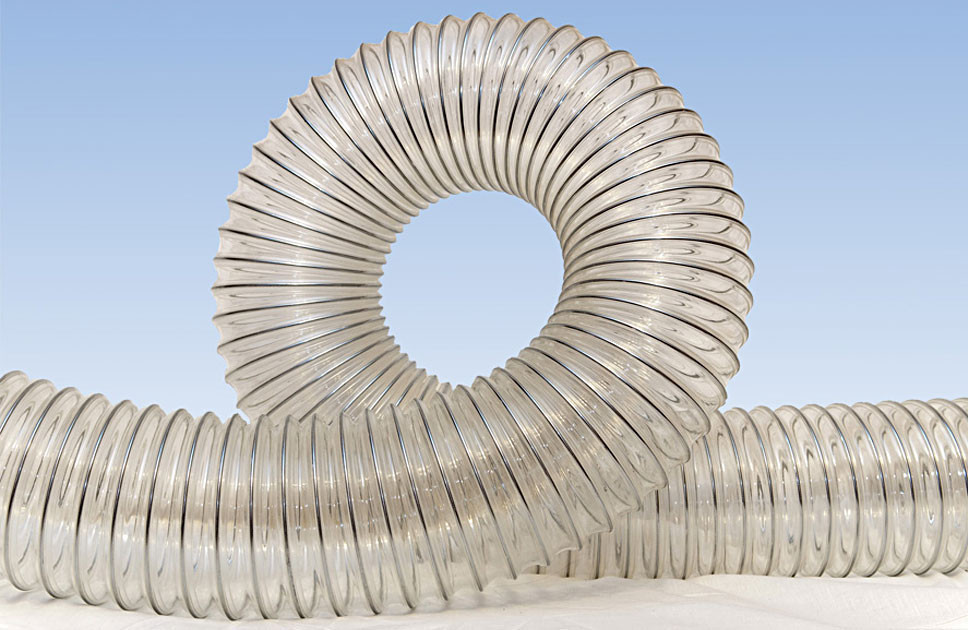

- Features and benefits of plastic air ducts

- Which option is better?

What to pay attention to when installing

The corrugation for the hood is considered ideal if it is completely hidden in a wall cabinet.Work is carried out without the use of special adapters and complex fastening elements, which makes it possible not to spend extra money on work. The elastic ribbed design easily bends around obstacles, which eliminates the need for additional connections and fittings. Before starting work, the corrugation is fully stretched and installed in this form, which reduces noise during fan operation. Otherwise, the resulting folds will certainly create vibration, and the operation of the hood will be accompanied by increased rattling.

The corrugation is attached to the branch pipe of the ventilation system using special metal or plastic clamps. To properly carry out installation work, you should follow simple rules:

- If the vent is at a great distance from the hood, the pipe should be laid under the ceiling. This will help avoid sharp corners and make the system more efficient and reliable. For these purposes, it is better to use suspended ceilings, which will ideally hide the corrugation from prying eyes;

- the diameter should be carefully selected, since a narrow duct will create a large load for the fan, which will certainly affect its operation. If the hood has a round hole, do not use a rectangular pipe. This will make the work inefficient, since you will have to install special adapters that will reduce the passage of air through the duct channel.

How is the installation carried out

- Before starting work, a grate with a built-in check valve is installed. It will help to ensure the flow of fresh air to ventilate the room when the fan is off.

- By installing an anemometer at the base of the pipe, you can determine the volume of ventilation system performance, which should be at least three volumes of the kitchen.

- Before installation, check the presence of reverse thrust; for this, attach a sheet of paper to the grate of the hood, it must adhere tightly to the hole. The presence of reverse draft can reduce the effectiveness of the forced ventilation system.

- When installing, you should try to ensure that the design has as few bends and turns as possible, since this reduces the effectiveness of the work many times over.

The choice of the air duct is made after the purchase of the ventilation system, since the quality of the system as a whole depends on the correctly selected diameter. The diameter of the outlet must exactly match the parameters of the pipe - this is the only way to achieve maximum efficiency.

Often, trading organizations, along with the hood, offer a corrugated pipe as a set. You can refuse the imposed service if you read the instructions in a timely manner and calculate the required amount of corrugation. Then you will buy the exact amount without overpaying for extra meters.

An ideal way to make a chimney, you can not be afraid of overheating the pipe. It is quickly and easily mounted in any type of ceiling. When installing gas heating or water heating equipment, it can ensure maximum outflow of combustion products, making it possible to guarantee the reliability of boilers and boilers. A system of such pipes has proven itself well when installing fireplaces, stoves or other heating systems.

The steel inner frame and heavy-duty film allow you not to worry about the durability and reliability of the structure.Remember that the more responsible approach to the choice of corrugations, the better and longer your ventilation system will work. You should not save on a drain pipe, since the ingress of carbon monoxide into an apartment can lead to sad consequences.

Advantages of the corrugation for connecting the hood

The advantages of a corrugated pipe for an exhaust hood in the kitchen are as follows:

- The corrugated pipe duct is easy to install. It does not require the use of corner elements, since the corrugation can be bent to the desired angle.

- If necessary, you can connect several pipes with clamps, which is done quickly and easily. The whole structure is easy to assemble and disassemble, which simplifies installation, maintenance and disassembly in the future.

- The pipe is stretched and compressed, and without additional tools. It can be given the optimal length and laid along the desired path.

- Allows you to avoid creating 90-degree corners, making smoother bends. This reduces noise and simplifies the operation of the device (the fewer right angles in the duct, the easier it will be for air to pass through it).

- It is convenient to use for arranging an air duct in a limited space and a kitchen with a non-standard layout.

- Aluminum corrugation is easily cut with ordinary scissors.

- Acceptable price. Corrugation is several times cheaper than a metal or plastic exhaust pipe.

- On the construction market there are corrugations with different sections, which allows you to choose the right diameter for a specific hood.

- The corrugation cannot catch fire or melt during operation of the device, since it is designed for temperatures up to 300 degrees.

Main disadvantages

The corrugation also has obvious disadvantages:

- Due to the non-smooth surface of the pipe, grease and other dirt accumulate faster on its walls (both inside and outside). Washing all the folds to complete cleanliness is much more difficult than cleaning a smooth plastic pipe.

- Due to the non-smooth surface, much more noise is generated than in smooth-walled ducts.

- The corrugation looks less aesthetically pleasing than a regular plastic pipe, and fits worse into the kitchen interior. You either have to come to terms with such a “decoration”, or figure out how to close the corrugation of the hood.

Comparison with rigid plastic duct

Of all the exhaust pipes, the most common and popular options are aluminum corrugated and smooth plastic pipe. To make the right choice, you need to understand the fundamental difference between them:

- A plastic exhaust duct will cost more than an aluminum corrugation.

- Plastic pipes cannot be stretched, compressed or bent. Therefore, you need to know in advance all the dimensions of the duct, the length from the hood to the vent, angles, etc. In addition, the installation of such an air duct itself is more difficult than the installation of corrugations.

- A plastic air duct is much more difficult to mount in a limited space without impairing the performance of the device.

- A plastic hood does not get as dirty as a corrugated hood and is much easier to clean.

- A smooth-walled plastic duct, unlike corrugations, creates much less noise (because the air does not “cling” to a smooth surface).

- Plastic can be matched to the color of the kitchen and the style of the renovation, as it is available in different colors. If necessary, it can be easily painted or pasted over with something.

Corrugated pipe in the kitchen does not look very nice

What is better to choose: corrugated or plastic? Decide what is more important for you: aesthetics and cleanliness (for plastic products), or low price and ease of installation (for corrugated pipes).

Comparison of a rigid duct and a flexible corrugation for ventilation

Plastic and aluminum corrugations are very popular among users. Polymer air ducts are more expensive than metal counterparts, but they look more beautiful in the kitchen. You should know that plastic does not change its shape, like aluminum corrugation, so before installation you need to know the exact dimensions of the future structure. Plastic air ducts are more difficult to install, however, they provide a low noise level of the hood. In addition, you can choose a corrugation of almost any color that will blend perfectly with the overall design concept of the kitchen and furniture wall.

Number of blocks: 26 | Total number of characters: 34751

Number of donors used: 7

Information for each donor:

The choice of diameter and installation features of corrugated pipes for ventilation

For the arrangement of ventilation and exhaust, it is necessary to use two-layer corrugated pipes with smooth inner walls. Plastic corrugation can be used for ventilation installation with air flow speed up to 30 m/s and pressure within 0.8-5 MPa.

According to the provisions of GOST No. 21.602 “Heating and ventilation”, the minimum hood section for different premises is:

- kitchen and dining room - ∅ 190 mm;

- bathroom (1st floor) - ∅ 190 mm;

- bathroom (2nd floor) - ∅ 160 mm;

- boiler room - ∅ 170 mm;

- dressing room - ∅ 140 mm.

The data are for natural exhaust, not equipped with a fan. PVC corrugated pipes for exhaust and ventilation on the market have a diameter of 80 to 400 mm, the measured length of products varies between 1-6 meters.

Corrugated pipes for ventilation with smooth inner walls

When installing ventilation, the following recommendations should be considered:

- The installed exhaust pipe should not have deflections that reduce the throughput of ventilation, it is mounted in the most stretched form.

- Do not bend the corrugation - the permissible bending radius is equal to twice the diameter of the ventilation pipe, reducing the radius leads to a decrease in pressure in the ventilation duct.

- The ventilation pipe is installed so that the air moves in the direction of the corrugation spiral, which is indicated on the stacks of the pipe.

- When placing the hood inside the walls, the plastic corrugation must be laid inside the protective metal sleeves.

Corrugated pipes for exhaust have a minimum weight, which allows them to be fixed on walls or ceilings using aluminum mounting clamps. To connect ventilation pipes to each other, shaped elements are used - couplings.

The pipe is installed in such a way that at least 3 turns of the corrugations go inside the coupling, in which sealing rings made of rubber or synthetic rubber (EPDM) are provided. The rings are placed between the ribs of the corrugated pipe, fixing it and ensuring the tightness of the ventilation duct.

Before installing the exhaust pipe inside the coupling, the surface of the corrugation must be coated with silicone sealant. It is necessary to press the pipe inside the coupling manually, impacts with a hammer are unacceptable, since they can violate the integrity of the plastic structure.

Under what conditions is corrugated hood used?

First, let's decide what kind of animal this is, corrugation? Externally, this component is a flexible pipe of round or rectangular section. According to its functional purpose, the corrugated duct for the hood is a conductor between the hood and the ventilation shaft.

The longer the length of the pipes, the slower the air in the kitchen will be cleaned.

So in what situations is it necessary to use such a part? There are several currently known options.

- Installation of a hood with a tap to the ventilation in the kitchen.

- Installation of a gas water heater (columns).

But you can do without installing corrugations, if you consider the option of a hood for the kitchen without a vent to the ventilation!

Similar pipes are also used in heavy industry, mainly for laying electrical cables or sewer networks.

We will talk about the rules and features of the installation separately, but for now, let's look at the technical parameters.

Secrets of installing an exhaust duct

Proper installation will ensure trouble-free and long-term operation of the exhaust system.

- Almetyevsk Pipe Plant (ATZ)

- Bor Pipe Plant (BTZ)

- Volgograd Pipe Plant (VEST-MD)

- Volgorechensk Pipe Plant (Gazpromtrubinvest)

- Izhora Pipe Plant (ITZ)

Add company

- We carry out calculations for the pipe deflection independently

- Features of insertion into gas pipes

- Dealing with condensate from chimneys

- Ways to fix leaking pipes under pressure

- How to make a fungus on a chimney pipe with your own hands

TrubSovet .ru We know everything about pipes

2015–2017 All rights reserved

When copying materials from the site, be sure to place a back link to

Design features of the corrugation

The corrugated pipe is based on a metal frame made of steel wire, which is twisted into a spiral. With the help of a spiral, a cylindrical shape of the product is formed. A material is applied around the wire spiral on both sides, creating the shape of a pipe. In the pressed state of the rings, the overlay material folds into an accordion. In the stretched position, the material straightens, and the corrugation itself lengthens. The ability of the product to decrease and increase in length is very useful if the pipe material needs to be transported or stored.

Spiral - the frame is not rigid, which means that the corrugation bends easily, which is undoubtedly one of its positive qualities. There are positions in building projects when communications are laid in hard-to-reach and inconvenient places. It is in such areas that it is recommended to lay a corrugated sleeve. In this regard, it is easier with the kitchen hood duct, because its length is small, and more often there are two or three bends from straightness in it. Therefore, for the kitchen, this is the best option for a hood.

Installation

How to install corrugation on the hood in the kitchen yourself and why? In order for the air to be updated regardless of whether the hood is turned on or not, it is worth attaching the corrugation through the grill to the vent. Because in the hole there is a compartment for the air duct and for the removal of air. When installing, it is also necessary to take into account the technical characteristics - the size and length of the pipe, otherwise all the work done will be inappropriate. Remember the quality and reliability of the material you choose. In addition, it is better when everything is done in the same style, for the interior.It should be understood that the cost does not guarantee the proper execution of the installation, so study the collation. It also says how to install an exhaust duct in the kitchen.

How to choose the size

It is necessary to measure the entire length with a tape measure. And take into account the route along which the duct will pass. For example, its possible path lies through the closet, along the walls or along the ceiling. After calculations, it is worth adding another 10 to 15 percent to the total length. This is an important point before connecting the corrugation to the hood.

In the opposite situation, with a shortage of material, you can attach the missing piece with adhesive tape, but this option will reduce the duct's patency. This should be done only in extreme cases. With the smallest number of angles, but with a larger degree, the hood is able to work much more smoothly.

How to fix the corrugation on the hood

In order to somehow connect the corrugation with the hood, you will need:

- corrugated pipe

- self-tapping screws

- hose clamps or soft wire

- ventilation grate or adapter

- silicone sealant

- adapters, there was no corrugation of a suitable size

How to attach the corrugation to the hood, after all the tools are ready:

- Before work, clean the ventilation in the apartment

- First, stretch the corrugation along its length, check the constituent elements. Avoid kinks, then the air draft will remain good.

- Lubricate the neck of the hood with sealant

- Put on the corrugation and secure with a clamp, if it is not there, then wrap it with wire.

- It is necessary to lay this way to the end of the ventilation hole

- Fix the ventilation grate with self-tapping screws

- Then put on the corrugation with sealant

- Fasten the work with a clamp

- Check the exhaust system by connecting the hood to the mains.This is done as follows: turn on the hood at maximum power, now take a sheet of paper and bring it from below to the grate. A sign of proper mounting is the retention of the sheet - which means that air is sucked in. Everything, the problem of how to put the corrugation on the hood is solved.

REFERENCE! Do not wipe the outer surface, this will save you from extraneous unwanted odors.

You need to know that a vent hole is required. You can not close the mine completely.

If you do not want the corrugation to be on public display, then there is the possibility of hiding it. How to insert the corrugation into the hood inside so that it is invisible? This is easy to do with the help of wall cabinet doors, a decorative box, or other elements. To disguise it, you need to choose a color to match the furniture. To give harmony, try to arrange everything based on the style of the kitchen. Another option is to install overlays. It can be formed along the contour of the cabinet, thereby ensuring the secrecy of ventilation. It will not be difficult to lay inside kitchen sets. However, this will lose a lot of the necessary space, as well as add holes that will need to be cut.

If you don’t want to figure out how the corrugation is attached to the hood, then you can simply order a professional installation. Especially if the kitchen was made together with a custom-made hood. Then, the installation of the corrugation for the hood may not go according to the standard scheme.

Why you need to install corrugations on the hood

The use of corrugated pipes is good because they have many advantages.For example, most can afford to install them, and installation, as it turned out, is quite simple. In addition, they have a wide range of types and sizes and low weight in a compressed state. Hardy at high temperatures, thereby do not undergo combustion. It is possible to install both indoors and outdoors, which indicates functionality. They are placed in different planes, used in different parts of the systems. It is only worth taking care of once, as the freshness in the room is guaranteed for a long time.

Corrugated pipe for exhaust: advantages and disadvantages of the device

Related Article:Plastic air ducts for ventilation. From our review, you will learn the types of devices, sizes, classification, popular manufacturers, average prices, how to calculate the air duct according to the area of \u200b\u200bthe room and other parameters, the secrets of installation.

Consider what advantages and disadvantages corrugated ducts for exhaust have. First of all, it should be noted the ease of installation and the ability to bend the structure at a certain angle. In addition, you can simultaneously connect several sections using clamps.

The air duct is freely stretchable and can return to its original state. The flexibility of the design provides some reduction in the noise level during operation of the hood. Due to these properties, corrugated channels are used in rooms with a non-standard layout and in conditions of limited space for arranging ventilation systems.

Please note that the aluminum corrugated duct can be easily divided into sections of the desired length with scissors. Compared to plastic and metal counterparts, the price of the device is much lower

It should also be noted that the corrugation is resistant to high temperatures. The air duct made of aluminum can withstand up to +300 ° C, so its ignition is completely excluded.

Table 1. Disadvantages of aluminum ducts

| Device flaw | Description |

| Difficulty cleaning | Since the corrugation has a relief surface, on it (in comparison with smooth types of air ducts) soot and fat deposits accumulate faster. This makes it difficult to clean the device. |

| High noise level | Compared to exhaust ducts (smooth-walled) made of plastic or steel, the noise level of aluminum corrugations during operation is significantly higher. |

| Unattractive appearance | Corrugated air ducts, in comparison with plastic channels, have a less attractive appearance. For this reason, some difficulties arise in the design of the kitchen interior (you need to figure out how to close the corrugation). |

Video about the selection and installation of corrugations

Video clip on how to connect an air duct in the kitchen - features of using a corrugated pipe:

The metallized corrugation used as an air duct in a kitchen hood can be hidden behind a decorative casing. This video instruction will help you properly connect it to the hood:

A visual video about the additional details used when connecting a corrugated pipe to the hood:

Video review of a flexible corrugated aluminum pipe:

An interesting video clip on how aluminum foil air ducts are made:

Having dealt with selection and installation features corrugations, you can save money by doing everything yourself. These works do not require special skills and professional tools, which allows you to do without calling specialists.A high-quality corrugated pipe, properly connected to the hood, is able to provide kitchen ventilation for at least the next 10 years.

Good reasons to replace the pipe

Corrugation is an inexpensive and very worthy solution to the problem of arranging ventilation at home. If it is installed correctly, then there will be no problems with use. The main thing is to follow the recommendations specified by the manufacturer of the product.

There is no need to take care of the corrugated duct. One thing is unpleasant - it is very inconvenient to get dust out of the walls. Over time, after 8-10 years, a rather thick coating of particles of fat, burning, and dust forms inside the pipe. You won't be able to clean it. The only way out is to put a new corrugation.

If you compare the service life of 10 years with the cost of a new ventilation duct, then replacement does not look like a problem at all.

When replacing, you will first have to dismantle the old pipe, and then install a new one.

When replacing, you will first have to dismantle the old pipe, and then install a new one.

When dismantling, it is necessary to perform all the actions that during installation, only in the reverse order.

After removing the pipe, you need to carefully clean the joints, clean the ventilation grill or even replace it. Then perform all the steps for installing a new corrugation.

The main criteria for choosing a corrugated pipe for an air duct

When choosing corrugated pipes for connecting the hood to the ventilation system, the following parameters must be considered:

- pipe material;

- preparation method;

- the shape and dimensions of the section;

- additional options.

Pipe materials

Corrugated pipes for air ducts can be made from the following materials:

stainless or galvanized steel.The advantages of the materials under consideration are absolute incombustibility, long service life and resistance to mechanical stress. However, the high cost and complexity of installation lead to a decrease in demand for this type of product;

Corrugated duct pipe made of galvanized steel

aluminum. The aluminum corrugated pipe is characterized by low weight and medium rigidity, which facilitates the installation of the air duct, the duration of use and the possibility of using it in different temperature conditions. Among the shortcomings can be noted a high level of noise and the presence of vibration;

Corrugated aluminum pipe

plastic (polyethylene of low or high pressure, as well as polyvinyl chloride). Plastic corrugated pipe features the lowest cost, light weight and easy installation. But disadvantages such as flammability, susceptibility to mechanical stress and odor at high temperatures significantly reduce the possibility of its use.

Corrugated pipe made of plastic

For domestic purposes, aluminum and stainless steel air ducts are most often installed.

Manufacturing methods and their features

Corrugated pipes can be made in two ways:

framed (the metal frame of the pipe, usually made of wire, is covered with aluminum or plastic foil). Pipes made by this method are elastic and are able to return to the shape specified by the manufacturer after repeated stretching;

Corrugated pipe made on a frame base

spirally wound (a metal tape is wound onto a template). Such pipes are able to stretch strongly, but after stretching they do not return to their original position on their own.

Corrugated pipe made in a spiral-wound way

In domestic premises, both spiral-wound and frame pipes can be installed.

Selection of shape and section

According to the shape of the section, the duct can be:

rectangular. This form is mainly used for the construction of industrial ventilation systems;

Corrugated pipe with a rectangular section

round, which is optimal for domestic ventilation.

Manufacturers produce pipes of different diameters and standard sizes. The selection of a suitable corrugated pipe diameter is based on the diameter of the outlet pipe of the exhaust device.

Extra options

In order to purchase a corrugation that is optimally suited for the given conditions, it is also necessary to pay attention to such parameters as:

- duct length. In accordance with the rules for the manufacture of the ventilation system of the utility room, it is not allowed to bend the duct at an angle of more than 90 °;

- the presence of a heat-insulating layer, which allows the installation of an air duct on the street, and in a cold climate.

Corrugated pipe for outdoor ducting in cold climates

Subtleties of installation and installation

Connecting the corrugation to the hood and ventilation system will be within the power of the home master. To do this job, you have to take:

- flexible pipe;

- clamps;

- aluminum tape;

- grille with check valve;

- silicone sealant;

- adapters from round to square.

The last point is useful when the hood has a square or rectangular pipe, and the corrugation is round.

There are adapters available for smaller and larger diameters.They should be used only when necessary, so as not to reduce the performance of the exhaust equipment.

It is good to buy all the necessary parts together with a corrugated pipe. This will allow you not to make a mistake with the number of necessary spare parts.

All components for the future installation of the air duct should be selected, having previously taken measurements at the site of the upcoming installation (+)

If you need to connect 2 or more flexible pipes together, you can use aluminum tape. It connects the material of metal air ducts well, provided that it is carefully glued to the surface.

Aluminum tape can not only connect 2 corrugations together, but also seal an accidentally broken hole

The corrugated pipe is to be stretched to its full length. In this state, one end must be attached to the outlet of the hood. For fastening, a metal pipe and sealant will be used.

Sealant should only be applied to a dry and clean surface. Otherwise, it will not be able to securely close the joints

Then, every 1.0 meters vertically or 1.5 meters horizontally, additional clamps must be installed. These fixtures will ensure that the duct is properly secured. If there is only 0.5-0.8 meters to the ventilation hole, then no additional clamps will have to be installed.

With a large length of the ventilation duct, sharp corners should not be made - each of them will reduce the performance of the hood by 10%.

If there is more than 3 meters to the entrance to the ventilation, then you need to choose a more powerful model of the hood or stretch the corrugated pipe in a straight line under the ceiling to shorten the path. After all, the longer the channel, the more powerful the equipment should be.

Having put additional clamps, it remains to connect the corrugation with the ventilation hole by inserting its second end into the corresponding hole in the wall grille.

Wall grills for ventilation are available with or without a built-in non-return valve

The joints of the grate with the pipe should also be properly treated using a sealant. Now we have to check the quality of the installation. To do this, turn on the hood and attach a sheet of paper - if it is attracted, then everything is mounted perfectly. So you can start decorating.

As a decor, a decorative casing of the hood itself can be used. Sometimes this is clearly not enough. Then the owners turn on their imagination, choosing the most optimal option, for example, to hide the pipe in wall cabinets.

Sometimes the ventilation duct is hidden in a plastic box. If you also mount a backlight in it, then no one will guess about the metal corrugation inside.

Depending on the style of the kitchen interior, the corrugated pipe can be hidden under the false ceiling. If the furniture in the room is in high-tech style, then the metal corrugation will organically fit into the overall picture. It happens that the air duct fits perfectly into the interior of the kitchen, being a logical continuation and not standing out from the overall composition.

Image gallery

Photo from

When installing an exhaust hood in an apartment building, the corrugation is led out into the common house ventilation duct. Most often just connected to the ventilation grill

In private houses, it is more reasonable to bring an exhaust duct from a corrugated pipe through the ceiling and a non-residential attic to the street. This scheme is better from a thermotechnical point of view

Within the kitchen, a corrugated pipe is placed at its own discretion.However, the priority is the complete masking of the air duct behind a hard box

It is not necessary to completely cover the corrugated channel with a box, it can only be partially masked

Conclusion of the corrugations in the general house ventilation

Conclusion of a corrugated pipe in a private house

Masking a corrugated pipe with a box

Corrugation partially closed by a box

Types and differences of air ducts for hoods

The air duct for the hood can be conditionally divided according to the following characteristics:

- According to the material from which the channel is made: plastic or metal.

- Shape: round or rectangular.

- Rigidity: flexible or rigid.

Features and benefits of metal (corrugated) air ducts

Corrugated metal (or rather, aluminum) pipe is the most popular option for creating an air duct. You can read more about the selection and installation of corrugations for the hood separately. Let's take a brief look at this option below.

Corrugated air duct in the interior of the kitchen

- Diameter 100 mm: about 90 rubles per meter.

- Diameter 120 mm: about 120-130 rubles per meter.

- Diameter 150 mm: about 135 rubles per meter.

The advantages of such an air duct include:

- flexibility (the corrugation can be easily bent, giving the duct the desired shape);

- the ability to stretch and fold (which means the ability to adjust the length of the channel);

- ease of connection (for corrugations, you do not need to separately buy and mount adapters and connecting elements).

Of the minuses:

- a relatively high noise level (however, the noise of the motor of a working hood will still block the noise from the air passing through the channel);

- faster pollution (than PVC products);

- ugly appearance (corrugation spoils any interior, so the metal duct is almost always closed, which means that you need to spend extra time and money on creating a “cover”).

Features and benefits of plastic air ducts

Plastic pipe is a rigid product, not bending. The cross-sectional shape can be either round, rectangular or square.

Rectangular plastic duct for exhaust

The main advantages of plastic (compared to metal):

- noiselessness (smooth, flat surface does not contribute to the appearance of noise);

- ease of care (smooth surface becomes dirty much more slowly and is easier to clean);

- aesthetic appearance: in the interior, a plastic pipe looks much neater than a corrugation.

The most successful solution is to use a rectangular duct. It is easy to run such a pipe along the wall, saving space. On the other hand, such a channel requires an adapter, which will connect the rectangular pipe to the round holes of the hood and shaft. You will also need connecting elements - to fasten a system of several segments.

Of the minuses:

- more complex installation;

- the cost is higher than that of the corrugations (both the pipes themselves are more expensive, and in addition it will be necessary to buy adapters and elbows);

- inability to bend, stretch or compress the pipe.

More complex installation is the most serious minus of plastic. The corrugated metal sleeve is flexible and easily bends, stretches and folds. Even if you made a mistake in the calculation, it can be adjusted to the desired conditions without any problems. But this will not work with a plastic duct: it must be measured and planned as accurately as possible.

Plastic duct parts

- Plastic adapter from a rectangular channel 60x120 mm to a round hole with a diameter of 120 mm: about 150 rubles.

- Flat air duct, section 110x55 mm: about 260 rubles per 1 meter.

- Round air duct, diameter 100 mm: about 250-270 rubles per 1 meter.

Which option is better?

The question of which air duct to choose (corrugated or plastic) is not critical. If it is correctly calculated and laid, the hood will work normally.

There are several minor differences:

- Appearance in the interior. Here plastic clearly wins. However, air ducts are often decorated, so the corrugation will still not be striking.

- Ease of installation. In this regard, it is clearly easier to take the corrugation.

- Air duct price. Corrugation will cost a little less.