- Dimensions

- How to choose?

- Mounting procedure

- Sewer pipe preparation

- Corrugation installation

- Installing corrugations for the toilet, how to properly connect to the sewer

- With vertical toilet outlet

- For horizontal outlet type

- Installing a corrugation on a toilet bowl with an oblique outlet

- Advantages and disadvantages

- Installation of corrugations for the toilet, its types, length, dimensions

- What is a corrugation for a toilet

- Features corrugations for the toilet

- Installing a toilet corrugation

- How and when to replace a corrugated pipe

- How to connect the toilet to the water supply

- Helpful Tips

- Repair work

- Switching to plastic products from cast iron pipes

- Dismantling and cleaning of cast-iron socket pipes

- Installation on the socket of the rubber cuff

- Types and sizes

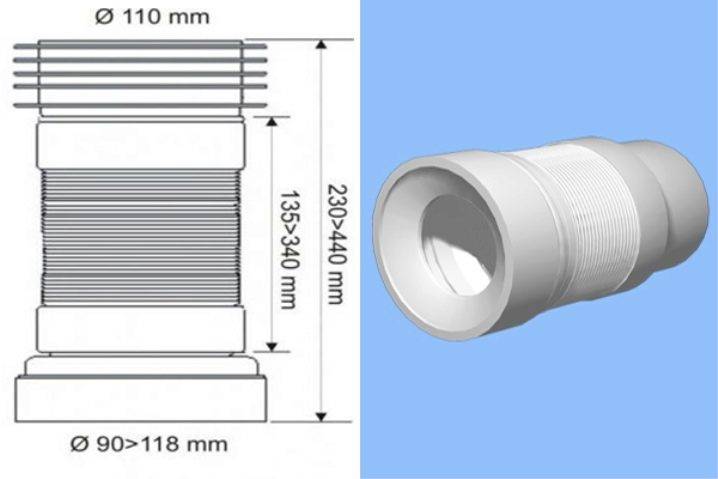

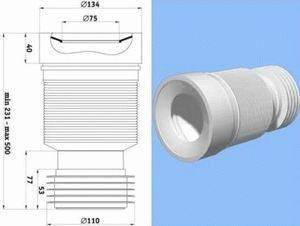

Dimensions

The corrugation for the toilet can differ not only in diameter, but also in length. If you buy such a pipe with a margin, then no more than 5 centimeters. If you exceed this figure, then for sure it will sag under the weight. As a result, the likelihood of clogging increases. The same goes for the short pipe.

If the stock is not enough for stretching, then the stiffness rings will diverge to the limit, and the material between them may simply burst.

In diameter, the product can be 72 mm, 50 mm, 90 mm.Experts do not advise using products whose parameters go beyond the specified values, since there is little benefit from them.

![Installing the corrugation on the toilet and the specifics of connecting plumbing with it]()

How to choose?

When choosing a corrugation for a toilet bowl, you must immediately decide for yourself what requirements the product must meet. If there is not enough space in an apartment or a private house for installing plumbing, then it is better to use a soft pipe, since it bends easily and does not lose its properties. The length should be chosen clearly, not taken with a large margin, since this will not bring any benefit. Such a product can be selected for the toilet, regardless of the built-in exhaust system. It is quick and easy to install, showing the necessary elasticity.

If you want to put the corrugation for a long time and not return to this issue for several decades, then the choice should be on a rigid product and preferably reinforced. Of course, such a pipe has less mobility, but thick walls demonstrate excellent wear resistance. A consumer who prefers to receive high quality without focusing on cost will choose a reinforced product. It is more durable, so there will be no complaints about its durability.

In the modern market, such pipes are manufactured by foreign companies; it is not easy to find a domestic product of high quality. Those who are faced with the problem of installing a toilet for the first time do not always know whether it is better to buy a long or a short pipe.

Experts advise to pay special attention to this point when buying

The length should be equal to the distance from the sewer to the installed plumbing with a small margin of a couple of centimeters.

If the installation process is complicated by the inconvenient location of the toilet, then it is better to purchase a model that has a curved socket. The bend angle can be 90 degrees or half of that. In apartments where there is little space in the bath and it is required to include additional plumbing equipment in the sewer, it is better to use pipes with a tap.

All corrugated products are standardized. So, the length will be 21.2 cm in a compressed state, and 32 cm in a stretched state. This is a short corrugation. The long pipe is 28.5 cm in a compressed state, and 50 cm in a stretched state. If, after the calculations made, it turns out that a short product needs to be strongly stretched in order to be installed in the sewer system, then it is worth buying the second option.

Mounting procedure

The first step is to prepare a sewer hole. In order for the corrugation to stand up qualitatively, it must be clean and smooth. If you are going to do installation work in a new building, then, of course, no preparation is needed, since all the pipes there are new.

But if we are talking about an old house, then, most likely, a cast-iron pipe was installed there from the toilet to the sewer. Moreover, usually the toilet outlet was built into the cast iron tightly, this was done with the help of cement mortar.

If you have just such a case, then you will have to change the entire toilet. You can read about this entire procedure in other articles on our portal, but here we will talk exclusively about working with the drain.

Sewer pipe preparation

So, we have a cast-iron knee in which the toilet is cemented. We take a hammer and just break the sanitary ware right at the pipe. Before doing this, be sure to put on safety glasses so that the fragments do not get into your eyes.

Now it is necessary to remove cement residues and various hardened deposits from the inner walls of the pipe. To do this, we again need a hammer: gently tap the cast iron on all sides with it. Do not overdo it, otherwise you can split the pipe, since old cast iron sometimes surprises with its sudden fragility.

When you get rid of all global deposits and other interference, treat the pipe from the inside with a cleaning agent such as toilet "Duckling". Let it work for about 10-15 minutes, and then thoroughly scrub the walls using a wire brush.

Finally, wipe the cleaned surface with a rag. The most important area that should be given more attention at all stages of cleaning is a piece of pipe at the very exit, about five centimeters. It is his condition that will directly affect the quality of docking with the corrugation. Therefore, this area must be properly prepared, absolutely clean and smooth.

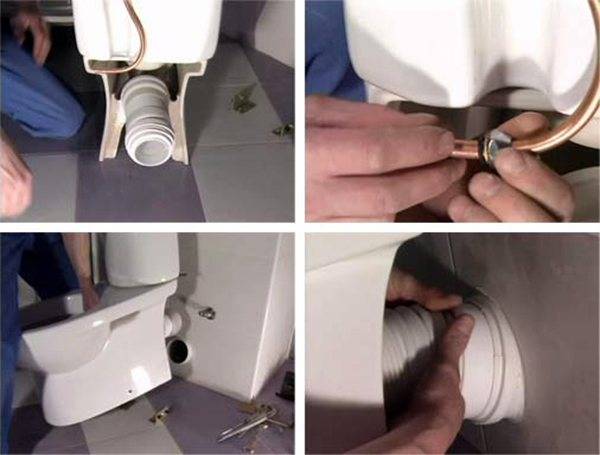

Corrugation installation

So, the drain is prepared for docking, you can proceed directly to the installation. Please note that the corrugation should be a third longer than the distance between the outlet and the sewer hole. Therefore, before buying, do not forget to take the necessary measurements.

For installation, we need the corrugated pipe itself, rubber cuffs, seals and silicone-based sealant. The procedure is extremely simple.

- We apply a thick layer of silicone sealant to the edge of the sewer hole.

- We install a rubber cuff-seal in this place.

- We are waiting for the silicone sealant to completely dry, it usually takes about two hours. A more accurate time is indicated on the package.Until the moment of drying, try not to touch the pipe at all, so as not to disturb the reliability of the connection with the sewer.

- Now find the rubber tip located on the opposite end of the pipe. It also needs to be coated with a silicone layer.

- Pull this rubber tip over the toilet pipe and wait again until the sealant has completely cured.

Finally, test the system: draw a full tank of water several times and drain it, while carefully inspecting the corrugation for leaks. If none are found, then congratulations - you did it!

Important note: if during the installation process it turned out that the corrugated pipe needs to be stretched, do it evenly along the entire length. If you stretch any one section, then in the end you will get the very sagging that was mentioned above.

I am sure that if you follow all the nuances described in the article, you will successfully solve the problem of connecting a toilet bowl to the sewer using corrugations. Just in case, watch the video as well, so that the knowledge is definitely fixed in your head. Good luck!

Installing corrugations for the toilet, how to properly connect to the sewer

You can connect or change the corrugation on the toilet bowl yourself. To do this, you need a tape measure, plumbing sealant. If the corrugation is being replaced, they additionally take a hammer, a chisel. This is necessary to dismantle the toilet. Before starting work, the flow of water to the drain tank is turned off. If there is no time for this, you can invite a plumber or similar specialist.

During dismantling, part of the water from the elbow may fall onto the floor. It is recommended to prepare a rag.

With vertical toilet outlet

In toilets with a vertical outlet, the installation of a corrugated pipe is impractical. The reason is that in this system there is no problem of axial displacement between the outlet of the toilet bowl and the sewer pipe. For connection, you can use a standard plumbing cuff or a rigid pipe.

If you try to install the corrugation, the seal may be broken. The distance between the connection points in this system does not exceed 5 cm. The length of the shortest corrugated pipe is 150 mm. Its installation will be impossible. Additionally, the junction will be hidden. Therefore, it is recommended to stop at the option with a rigid pipe.

For horizontal outlet type

A reliable connection of the toilet bowl with a sewer pipe for plumbing fixtures with a horizontal outlet is carried out according to the standard scheme. First, the old corrugation is dismantled. Using a knife or chisel, the old sealant is removed. To reduce friction, you can finish the edges of the WD-40 cuff. After that, the mount can be easily removed.

The toilet must be rearranged to provide free access to the sewer pipe. Its inner surface is cleaned. To improve sealing, a piece of plastic pipe can be installed in the pipe socket. Its length is equal to the length of the bell. The reason is that the outer cuffs (several rows of o-rings) will be better pressed.

Step-by-step instructions for installing a corrugated pipe on a toilet with a horizontal outlet.

- Dismantling of the old corrugation.

- Removing the toilet base. It can be put aside for now.

- Preparation of the sewer pipe - checking the dimensions, cleaning the surface.

- Calculation of the optimal distance from the riser to the outlet.

- Insert the corrugation into the riser pipe. She must go all the way.Otherwise, leaks are possible.

- The toilet can be put in place, the cuff must be pulled all the way.

- Application of several layers of plumbing sealant to the joints. You can cover the composition in several layers.

- Examination. The maximum load is simulated - several buckets of water are drained into the toilet, the absence of leaks in the corrugation is checked.

After that, the final installation of the toilet bowl is performed, fixing its base to the floor. Within a few days, the sealing of the system is checked. It should not let moisture through, there is no unpleasant smell from the fan riser.

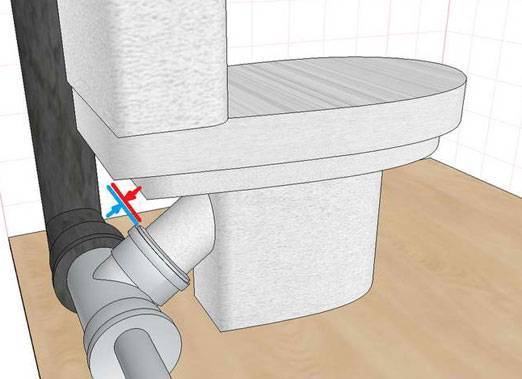

If the distance between the plumbing fixture and the riser is small in models with a horizontal outlet, the corrugation can bend strongly at the junction with the toilet. The way out is to put on the 45° elbow adapter.

Installing a corrugation on a toilet bowl with an oblique outlet

To securely connect the toilet with an oblique outlet to the sewer pipe, you can use the above diagram. However, in such models it will be more difficult to put on the corrugation. The reason is that the length of the toilet outlet in the upper and lower parts is different. It is difficult to ensure a secure connection.

The way out is to put on an additional collar over the cuff

It is important not to strongly transfer the plastic, otherwise the opposite situation may occur - a violation of tightness. Due to constant moisture, the clamp will rust relatively quickly.

Therefore, it is recommended to replace it every 6-8 months.

Slanted outlet toilets provide an optimal connection angle to the sewerage system. In such models, leaks and blockages are the least likely to occur, since the central axes of the corrugation, outlet and riser pipe almost coincide.

Advantages and disadvantages

The advantages of plastic corrugations are many, and they are quite significant:

- Ease of installation - a person without special knowledge can easily cope with the replacement of the pipe.

- Budget - perhaps the main advantage along with ease of installation.

- The only available option in case of moving or shifting the toilet.

- In the event of a mismatch between the outlet on the toilet and the sewer socket, only plastic can be installed.

- Suitable for a temporary toilet installed before the end of the repair.

Along with a large number of advantages, there are also disadvantages.

- The fragility of the structure due to the small thickness of the pipe walls. If you drop something with sharp edges into the toilet, such as a piece of ceramic tile or glass, the corrugated pipe may be damaged and will have to be replaced.

- If the corrugation is placed at the wrong angle or given the wrong bend, it can easily become clogged.

- If the corrugated pipe is too long, it may sag under the weight of the contents.

- The corrugation cannot be placed in the wall, only outside.

- According to many users, the design has an unattractive and bulky appearance.

Installation of corrugations for the toilet, its types, length, dimensions

In the old days, the entire sewer system was cast iron: the collector, the risers, the pipes, and the elbows for connecting to the toilet. The advantage of such a system was reliability, and the disadvantage was the roughness of cast iron, which contributed to the overgrowth of pipes with dirt, and sometimes their complete clogging.

Over time, the “style” of toilet bowls and the way they were attached to the floor changed. Thanks to the repairs, the level of the walls and floor in the bathroom changed. These factors led to the fact that when installing a new toilet, it became problematic to select pipes and elbows of the right size and configuration for joining the plumbing fixture and the sewer riser.In this case, a new adapter can come to the rescue, made of durable thermoplastic materials, which, when stretched, changes size and, due to this, bends - corrugation. Installing a toilet corrugation greatly simplified its installation and connection to the central sewerage system.

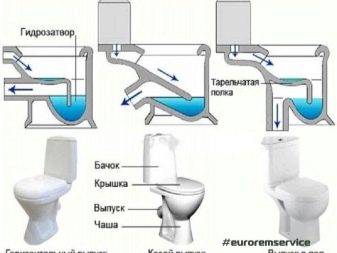

What is a corrugation for a toilet

Referring to the drain fittings, in contrast to the pipe - flexible, and from the drain cuff - long, it is a plastic "sleeve with a cuff" through which water flows. The length of the corrugation for the toilet bowl can vary from 231 to 500 mm, and the standard diameters are 134 (inside - 75) mm - on the cuff worn on the toilet bowl socket and 110 mm - at the end inserted into the outlet of the sewer riser.

Features corrugations for the toilet

The corrugation inside has a pipe with a diameter of 75 mm, which has a perfect smooth surface, which does not allow it to accumulate debris and overgrow with dirt.

The disadvantage of the material from which the corrugated adapters are made is its fragility, it can crack from an impact or load exceeding its tensile strength. To strengthen the product, it is reinforced with metal plates. Not all models are reinforced, this detail needs to be checked with the seller.

In general, it must be said that the quality of corrugations is very dependent on its manufacturer and cost. You should not risk repairs, comfort, time and money and put cheap low-quality corrugation on your plumbing. If you want to not have to change it for 5-10 years, it is better to stop at the model of Italian, French, Czech or English manufacturers.

Installing a toilet corrugation

one.First, the end of the corrugation, which has internal membranes that are designed to ensure the tightness of the connection, must be put on the toilet pipe, which must be clean. To enhance the tightness, you can first coat the toilet outlet with sanitary sealant and then put on the wide end of the corrugation. It is necessary to ensure that it is put on evenly and symmetrically over the entire diameter of the pipe. After that, the silicone should be allowed to dry.

2. We mount the toilet in the right place.

3. The opposite edge of the corrugation, which has external sealing rings, must be inserted all the way into the sewer pipe leading to the riser. The pipe must first be cleaned of rust and debris. For greater reliability, you can also lubricate with silicone this end of the corrugation - inserted into the pipe.

4. After the silicone has dried, to check the quality of the work done, pour a bucket of water into the toilet. If there are no leaks, the corrugation performs its function well.

As you can see, installing a corrugation on a toilet is a fairly simple task, and it is not necessary to involve a professional plumber to complete it.

How and when to replace a corrugated pipe

Not everyone likes the corrugated pipe in the toilet. It is quite thick and noticeable, it cannot be decorated, closed from prying eyes. When compared with cast iron or metal, plastic is inferior to them in strength. The alternative in this case would be:

- chrome tube;

- PVC tube.

In the first case, the product will also be visible. But its appearance will become the “chip” of the room.

In the second case, choose plumbing that has an oblique outlet. It must be higher than the sewer socket, otherwise the liquid will not leave the toilet. The oblique pipe immediately enters the riser or with the help of a short, barely noticeable PVC tube. For sealing, rubber seals, "liquid nails", sealants are used. You can do without them - melt the pipe, pull it over the toilet outlet, let it harden. The same can be done with the second part of the tube, the one that goes into the drain.

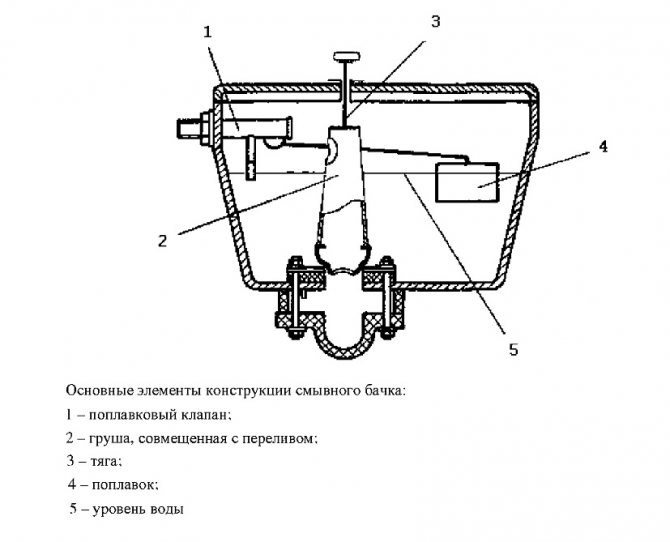

How to connect the toilet to the water supply

Equally important is the connection of the toilet tank to the water pipe. From it, water is drawn into the tank for draining. In all apartments (old and new type), so-called water sockets are brought out to supply tap water to the tank.

How to connect the toilet bowl to the water supply:

-

The water is shut off and a special tap is installed on the outlet. This will allow you to carry out the necessary repairs and inspection of the tank without disconnecting the apartment from the water supply. The crane crashes with the help of an adapter (if the pipe is plastic and the fitting is metal) and FUM tape;

-

A tank inlet is connected to the outlet of the tap. It can be flexible and rigid (for modern attachments). Its thread is also sealed with plumbing tape, the liner is tightened with a nut from above;

- The second end of the liner is connected to the tank pipe. A rubber gasket is installed at the connection point of this hose to prevent leakage of the storage tank.

After that, the installation process can be considered complete. You can use the toilet immediately after the installation work is completed.

Helpful Tips

When purchasing, experts recommend taking into account the length of the corrugation

This is especially important for those bathrooms or toilet rooms in which the toilet moves away from the wall quite far. The corrugated pipe can be pulled out, but this action has certain limitations.

And the more you stretch it, the thinner its walls will become, which has an extremely negative effect on its strength.

Before mounting on the toilet, it is undesirable to pull out the fittings. Only when docking with a sewer can it be stretched. If you do not follow this advice, the structure may sag, and this is fraught with the formation of a blockage in the system.

You can shorten the corrugation after measuring the desired length, but even then you should not cut it exactly to this distance. You need to leave a small margin of length.

When installing a corrugated pipe, it is important that the channel is bent, without preventing the water from draining freely. Do not pinch the pipe, otherwise damage is possible, and in the future it will begin to leak

After that, it is determined which area needs to be removed. It is cut off, then this end is installed back into the pipe, but the seam joint is additionally treated with silicone sealant. It is necessary to allow the material to dry completely, which can take up to 2 days. Then drain the water in the tank to check the quality of the joint. This option is used only if the corrugation is installed for a short period.

Repair work

When repairing this system, consider the following:

- The volume of the tubular product must be greater than or the same as the riser.

- The end of the pipe should be placed in such a way as to create a weathering of an unpleasant odor.

- They stretch such networks in heated rooms and end up cold. They are not placed in attics, otherwise a bad smell will penetrate into the rooms from there.

- The design of housing is tied to fan systems, as they are especially visible on the attic and roof.

- Such a network is repaired by connecting to one drain riser, while the remaining risers are equipped with valves.

The material presented shows what a fan pipe is (see for sewerage), and makes it clear that, despite the simplicity of installation actions, all work must be carried out strictly according to existing rules. And, if any difficulties arise, you can always turn to specialists for help and get qualified advice or help from them.

Watch the video

Switching to plastic products from cast iron pipes

Cast iron sewer pipes that go to the riser from the toilet have a cross section of 123 mm, and from the sink in the kitchen and bathroom - 73 mm. Plastic products of orange or gray color differ from the elements of the cast-iron sewer system with a diameter of 50 and 110 mm, respectively.

When replacing an old piping or connecting a new toilet, it becomes necessary to connect plastic pipes to a cast-iron riser, which has a larger diameter. To solve this problem, a special rubber cuff is bought, it is installed in the cleaned socket of the sewer system.

Dismantling and cleaning of cast-iron socket pipes

To perform dismantling work that is associated with the removal of the old cement composition at the junction of the socket and pipe, you need to stock up on a mount, a flat screwdriver, and a hammer.

Tapping gently on the handle of the screwdriver with a hammer, slowly release the connection of the elements of the sewer system from the cement mortar. When the solution layer is completely removed, a wooden stick is installed in the pipe. By lowering and raising it, they loosen the fixed location of the cast-iron pipe, and with little effort they take it out of the socket

By lowering and raising it, they loosen the fixed location of the cast-iron pipe, and with little effort they take it out of the socket

Deposits, plaque, rust are removed with a metal brush, which is mounted on an electric drill. To clean the cast-iron walls, a chisel or a flat screwdriver is also used. The smoother and cleaner the walls of the socket are, the more reliable and better the pipes made of various materials will be connected.

Installation on the socket of the rubber cuff

Reliable fastening of the cuff in the sewer socket is ensured with the help of a sealant, which is applied to its walls. Sealant must be applied in a thick layer on the outer surface of the cuff, then it is installed in the socket hole.

Carefully tapping the cuff on the edge with a hammer, you need to achieve tight adhesion of the walls of the two elements of the sewer system. A little technical vaseline is applied inside the cuff, which makes it easier to push the plastic tee into the outlet socket. Then you need to connect a pipe or corrugation to the tee, thereby connecting the toilet to the sewer system

Then you need to connect a branch pipe or corrugation to the tee, thereby connecting the toilet bowl to the sewer system.

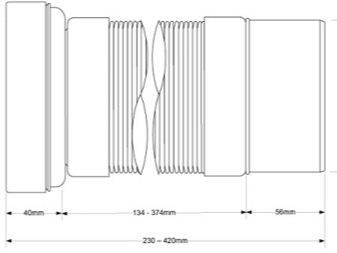

Types and sizes

Toilet corrugations may have such parameters.

- Elasticity. Depending on it, they are soft and hard. The latter have higher strength and wear resistance. Soft corrugation can be installed on the toilet bowl of any configuration and with any type of outlet (vertical, oblique or horizontal). The more flexible the pipe, the easier it is to install.

- Reinforcement. With it, plastic pipes are strengthened. For this, steel wire is used.Reinforced reinforcement lasts longer, but also costs much more.

- Corrugated pipes also differ in length. On average, the range varies from 0.2 to 0.5 m. When purchasing fittings, you need to take into account the distance from the toilet to the place where the corrugation cuts into the pipe. It is better to always buy a slightly longer channel, about 5 cm more than required. This makes it easier to avoid leaks.

The corrugation diameter can be 50, 100, 200 mm. Before buying, you need to measure the diameter of the toilet hole, and, based on the figure obtained, purchase a pipe with the appropriate cross section. You can buy it at any building and finishing materials store.

A cuff is a plumbing part that is responsible for ensuring a tight connection between the toilet bowl and the sewer outlet. For every floor-standing toilet, it is necessary. Therefore, when purchasing plumbing, you should also buy a cuff in the kit.

The models presented in stores are different in many ways: the material from which they are made, diameter, shape. The standard cuff diameter is 110 mm, but there may be other options. It is necessary to find out what type of outlet the toilet is equipped with, and what diameter it has, because it is on it that the cuff will be attached with the second end.

If we classify cuffs, we can distinguish the following varieties:

- straight smooth;

- corner smooth;

- conical;

- eccentric;

- corrugated.

There are also combined models: they are straight and smooth at one end, and corrugated at the other.

The fan corrugation is suitable for connecting toilet bowls with a horizontal or oblique outlet. It is installed in a 90 mm pipe (without cuff) or in a pipe with a cut of 110 m.

The cuff eccentric consists of two cylindrical surfaces connected together, but shifted relative to each other along the longitudinal axes. The standard diameter of the outlet seamless pipe is 72 mm.

According to the material from which they are made, the cuffs are divided into rubber and plastic. If the toilet model is modern, and the pipes are made of plastic, then polymer types are used. And for a joint with a cast-iron pipe, traditional dense rubber is suitable.

Be sure to take into account the shape of the outlet on the toilet. She may be:

- vertical;

- horizontal;

- oblique.

The required part is the clutch. Models for plastic pipes are produced in limited quantities - only five types:

- Pipe / pipe - products with smooth walls are fixed relative to each other by threads. Used for rigid plastic pipes, put on in turn at both ends.

- Box/pipe – the tube contains a cable on one side and a compression clamp on the other.

- Fitting with detachable connection.

- The transparent pipe is suitable for soft corrugated pipe joints, strengthened by winding.

If you do not want to be disturbed by unpleasant odors, you can equip the toilet with a check valve. It can be installed not only in the toilet, but also in other plumbing elements that have access to the sewer.