- Execution of work operations

- What to consider when choosing a corrugated pipe

- The price of a metal corrugation for a cable

- Corrugated cable laying: varieties of flexible products

- How the cable is laid in the corrugation and dismantled, is a probe needed

- Corrugation for cable, dimensions, prices

- Size selection

- Prices

- What is corrugation for?

- The nuances of the selection and installation of corrugated channels

- Specifications

- Installation of corrugated pipes

- Installation of wiring in the corrugation

- Features of open laying on the street

- Scope of corrugated pipes

- Which manufacturers are trustworthy?

- Types of corrugations and its features

- Advantages and disadvantages of laying wire in an automobile corrugation

- Which corrugation to choose?

- What is corrugation and where is it used

- Hidden gasket

- open laying

Execution of work operations

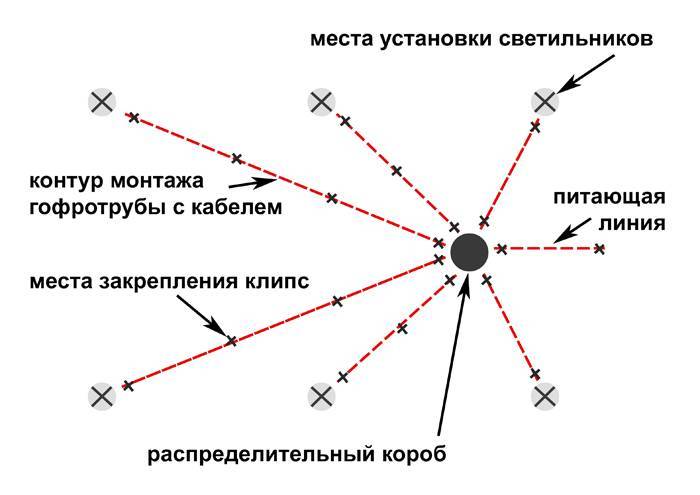

The following action plan will help to implement the project at a reasonable cost, without errors.

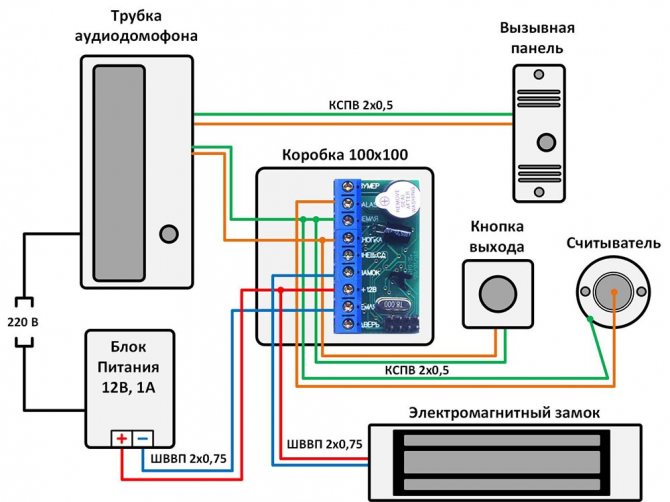

| Illustration | Actions |

| Determine the quantity and composition of component parts. It is planned to install a network cable for 220 V lamps in the false ceiling structure. Choose a light plastic corrugated pipe for electrical wiring, diameter 16 mm. Mounting clips are purchased in accordance with this size. Their number is calculated taking into account the distance between them during installation from 25 to 35 cm. |

| To save on consumables, straight lines of the route and the shortest distances are used. Under the decorative coating, the wiring will not be visible, so an excellent appearance is not needed. Marking is applied in advance. |

| Taking into account the obtained dimensions, the necessary sections of the corrugated pipe are created. The soft shell is cut off with a clerical knife. Only after that, the wire inserted inside is separated with wire cutters. This operation is performed carefully so that the probe does not end up inside the corrugation. It is difficult to remove it, as the sharp tip of the hard wire can get stuck in the sheath and damage it. |

| According to the markup, clips are installed. One product - for each end of the tube. Further - with the selected step. As a rule, plastic dowels and self-tapping screws are included in the standard delivery. To drill holes, you will need the appropriate tools. |

| It is more convenient to work with a cable in a common dense insulation. A hole is pierced in it, where the probe is inserted. The wire is bent in such a way that it does not create obstacles during movement inside the pipe. If several wires are used, they are assembled into a bundle, pulled together with insulating tape. |

| The cable is pulled in such a way that, at the end of the procedure, wires protrude from each end of the corrugation. Their length (8-10 cm) is made sufficient for connecting lamps, a junction box. To simplify subsequent installation operations, the braid is cleaned and the layers of insulation are removed (approximately 1 cm on each conductor). |

| Without applying excessive force, the tube is inserted sequentially into the clips. |

| To create a secure fastening, standard plastic ties are used. |

What to consider when choosing a corrugated pipe

When choosing corrugations for wires, you need to consider some recommendations

Pay attention to the color scheme of the material. The color is better to choose a uniform and without inclusions

Since heterogeneity indicates that the product is made from recycled plastic.

To facilitate the installation process, do not save too much and choose a tube without pulling

This is important for small diameter pipes.

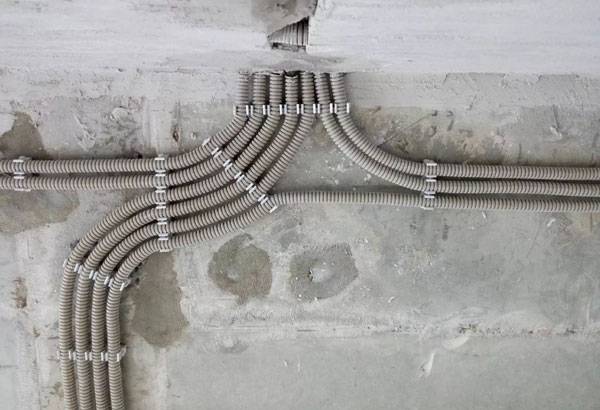

Multiple wiring installation

When purchasing fixtures, do not forget about special fasteners for installing pipes. In this case, you can use clamps, clips and dowels.

Various types of cables are used in the corrugation for electrical wiring, so it is important to choose the right dimensions, which depend on the cross section of the wires. For computer lines, a pipe with a cross section of 16 mm is suitable, and for connections to sockets, a pipe of 20 mm is used

For power structures, pipes with a diameter of 25-55 mm are suitable.

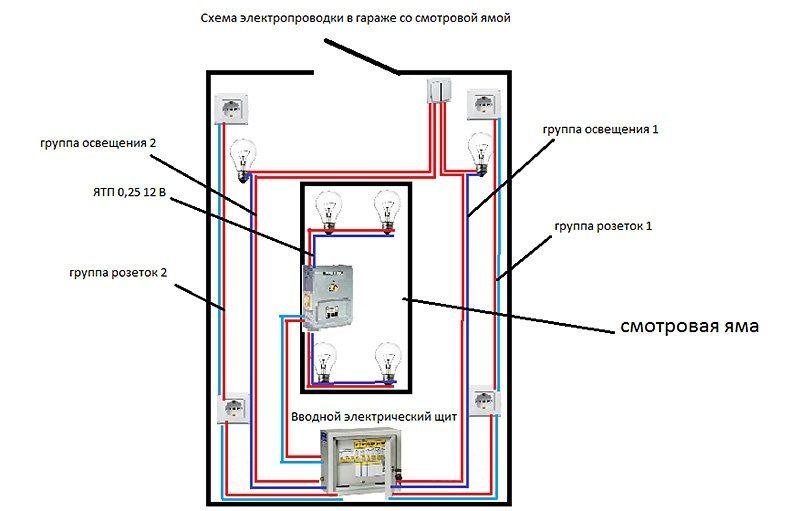

Wiring diagram option

In the table you can see how to choose a corrugation, taking into account the color scheme.

| Corrugation color | Applications |

|---|---|

| White | For computer wires. |

| Grey | For all electrical lines. |

| Black or brown | For various household units. |

| Green | For telephone lines |

| Red | For wires outside the building. |

| Blue | For underfloor heating structures and for water supply lines. |

| Yellow | Gas supply. |

According to fire safety, this material is divided into three categories:

- for installation on non-combustible surfaces made of concrete or brick, any pipes are used;

- in frame buildings, LDPE and PVC corrugations are used;

- for laying in combustible structures, pipes with fire resistance are used. On such surfaces it is forbidden to use plastic.

The price of a metal corrugation for a cable

The average price for a corrugation for a meter cable varies from 10 to 800 rubles. The cost of a metal pipe will be higher.

In the table you can see the price for specific corrugation models.

| Image | Product | price, rub. |

|---|---|---|

| Corrugated pipe 32 mm T Plast 50 m | 660 |

| PVC pipe B 16mm with a broach 100 m | 450 |

| Pipe 20 mm (100 m) | 487 |

| Corrugated pipe. PVC with probe d 16 | 560 |

| HDPE pipe d 16 with probe | 1350 |

| Flexible pipe for PVC cable 50 mm, 15 m | 525 |

The diagram shows the installation of a corrugated pipe using special fasteners

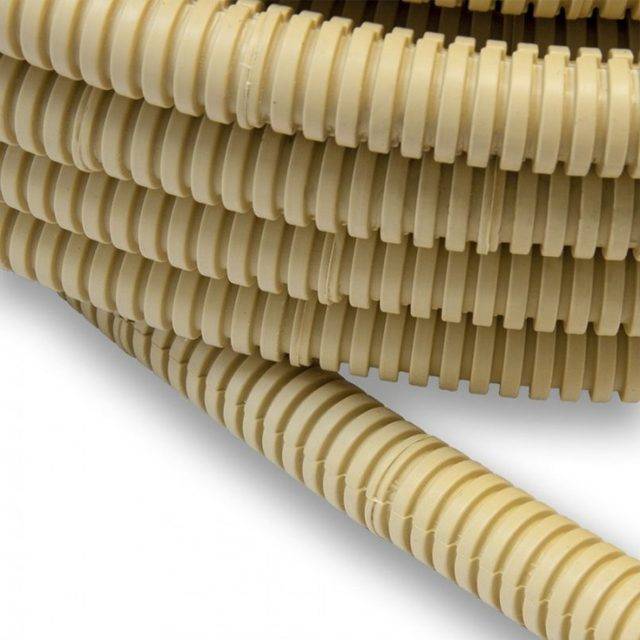

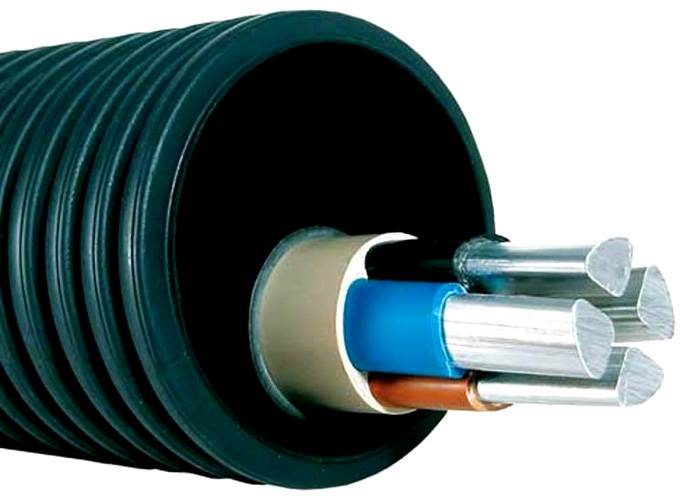

Corrugated cable laying: varieties of flexible products

At the moment, a protective polymer sleeve is produced for various construction needs, including sewer corrugation and protection for cables of different voltages. Depending on the properties of the polymer and the size of the corrugation for the cable, experts recommend using it for different types of wiring:

- for power cable;

- for low-voltage networks (telephones, television and computer UTP wire).

The protective corrugation, in accordance with the purpose, is produced not only in polymer, but also in metal. Flexible tubular products differ in material, color and design (for example, there is a double corrugation). A cable is pulled inside the product, often not even one - it all depends on the working conditions and the type of wiring:

hidden internal;

Corrugated pipes differ in the material of manufacture, dimensions and other technical characteristics.

- outdoor;

- underground.

There is another type of product classification - according to the degree of strength:

- light pipes;

- heavy;

- superheavy.

According to the degree of strength corrugation differs: light, heavy and extra heavy

Light corrugation is used for concealed installation inside the building (UV sensitive).Heavy and dense corrugated products are produced for laying underground (they are characterized by increased resistance to pressure).

For the convenience of determining the purpose, a conventional color designation is used, which is reflected in the table:

| No. p / p | Corrugation color | Scope of application |

| 1. | Grey | Standard electrical wire |

| 2. | White | Computer networks, internet |

| 3. | Green | Telephone or other low current cable |

| 4. | Red | External power cable |

| 5. | Blue | In the "warm floor" system and flexible water pipes |

| 6. | Yellow | Gas supply needs |

| 7. | Corrugation black and brown | Insulated wires of household appliances and other electrical appliances |

This is a general industrial and construction standard, but it is not always followed, especially if there is a small stock of the product in bays in the balance after a large amount of work.

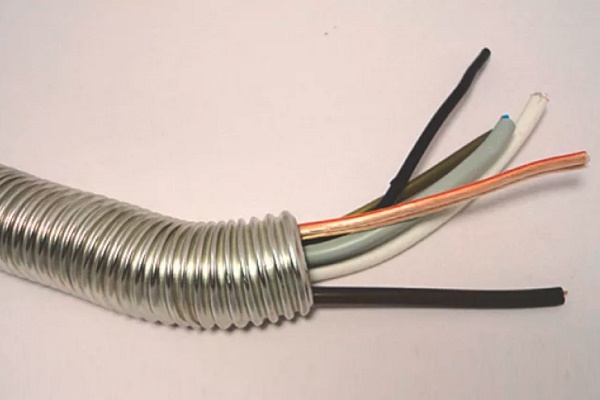

How the cable is laid in the corrugation and dismantled, is a probe needed

Before the advent of protective flexible pipes made of PVC for electrical systems, the cable was directly walled into a recess in the wall. Installation was complicated by the fact that the open ends were screwed to a tire or other support passed through a piece of metal pipe. In case of emergencies or malfunctions, the cable was removed from under the plaster (with the risk of damage).

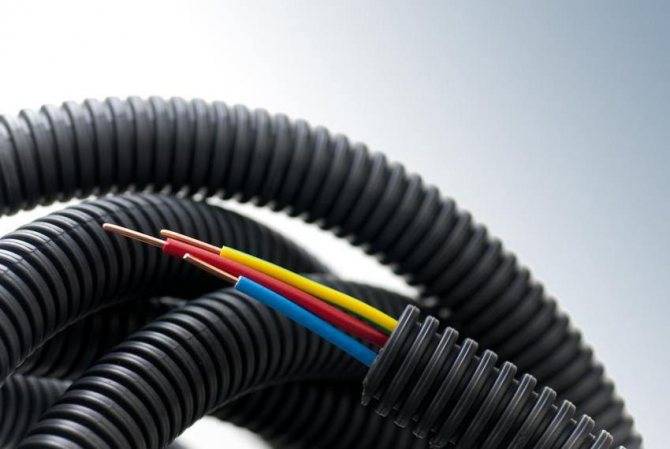

In most cases, manufacturers make a corrugated pipe with a broach for ease of laying electrical networks.

A close examination of the range of modern offerings in this field of application makes it obvious that a conventional hollow corrugation and a product with an internal probe are being sold. It is often called a "broach" - and this is its purpose.

The probe, if provided, is always visible inside the polymer tubes. This is a thick metal wire located inside along the entire length.The protective sheath for wiring is cut along with the probe as needed.

Using the broach is very simple: hooking the wire with the end of the probe, the cable is pulled through the entire length of the polymer tube. The probe is a guarantee of the convenience of filling the tube with an electric cable. The simplest engineering solution confirms the saying that all ingenious is simple. Only by pulling the electric cable inside the corrugation to a great length, one can appreciate the simplicity and wisdom of this solution.

The corrugation is very flexible, but at the same time it has stiffeners - protection of the cable from mechanical damage

On small sections of corrugated tubes (for example, when there is a need to insulate a wire connection), the probe is not used.

The convenience of using corrugations also lies in the fact that cable protection is carried out without special tools and does not require much effort. All you need is an internal probe and a cutting tool, after which the cable is laid in the prepared grooves (strobes).

When dismantling the old electrical wiring circuit, it is not necessary to remove the corrugated sleeve from the groove under the plaster. After removing the wires from the insulating cavity, the probe is no longer required. The corrugation hidden in the strobe can remain in it, which will eliminate the need to make repairs. It is enough to remove the desired piece of the electrical cable by pulling on its end. It is recommended to fill an empty corrugation around the edges with foam.

When dismantling old electrical wiring, it is not necessary to remove the corrugated pipe from under the plaster

Corrugation for cable, dimensions, prices

Corrugated pipes for electrical networks are available in sizes from 16 mm to 65 mm.When choosing a size, it should be borne in mind that these products have two diameters - outer and inner. If you are going to lay several conductors - wires or cables - the diameter must be selected so that there is a gap of at least half the radius. This requirement is based on the fact that with group laying (it is necessary, by the way, to take a special cable), it will heat up more and the presence of an air gap will contribute to better heat dissipation.

Price for corrugated electrical pipes depends on many factors

Size selection

The choice of corrugation diameter also depends on the area where it will be laid:

- to lighting fixtures - 16 mm;

-

to sockets and switches - at least 20 mm;

- from the main junction box to the next box, from the shield - at least 25 mm;

- the connection between two electrical panels is at least 32 mm, and it is better to have a spare second line;

- passage through the floor overlap - with a rigid corrugation of at least 40 mm in diameter;

- laying low-current cables (telephone, internet, antenna, etc.) - from 25 mm.

The diameter of the corrugation for laying the cable is selected depending on the number and cross section of the wires. Data for copper conductors are given in the table.

Table for selecting the diameter of the corrugations for cables and wires, depending on the cross section and number of wires

This information is for reference, but you can navigate it. You can take a larger, but not a smaller diameter.

Prices

Generally speaking, the cheapest is corrugation for PVC cable, in the middle range - PP and HDPE, the most expensive is metal corrugation. Moreover, the option with broach is slightly more expensive than without it.

When buying, you need to pay attention to the same wall thickness, color uniformity

Different materials, colors, wall thickness and different prices

Corrugation for cable is sold in coils of 50 and 100 meters, less often it can be found in meters, but then the price is slightly higher. In general, the price depends not only on the material, but also on the wall thickness. The cheapest is light PVC corrugation for cable, but sometimes it looks more like just a film. From what it can protect, it is difficult to say. If you are concerned about quality, it is better to purchase everything related to electrics not in construction supermarkets such as Leroy, etc. and in specialized ones. The quality there is usually better, and the prices, if higher, are justified. In order for you to have an idea about the possible spread of prices, in the table we will summarize several types of corrugations with a brief technical description.

| Name | Type of | External diameter | Inner diameter | broach | Price per meter | IP | Purpose |

|---|---|---|---|---|---|---|---|

| PVC corrugation | light | 16 mm | 11.4mm | Yes | 2.4 rub | ||

| Corrugated HDPE pipe black | DCS | 15.7mm | 11.3mm | Yes | from 7.5 rub/m | 55 | for concealed laying |

| Corrugated HDPE pipe black | DCS | 19.5mm | 14.5mm | Yes | from 8.9 rub/m | 55 | for concealed wiring |

| Pipe HDPE red double-walled | tough | 50 mm | 41.5 mm | Yes | 78.5 rub/m | 44 | for concealed laying |

| Heavy HDPE pipe | heavy | 31 mm | 23.4mm | Yes | from 9.7 rub/m | 55 | hidden gasket |

| Pipe PPL (polypropylene) corrugated | light | 19.7mm | 14.8mm | Yes | from 28 rub/m | 55 | open, concealed gasket |

| Corrugated pipe polyamide | black | 21.2 mm | 16.8mm | No | from 52 rub/m | 68 | open, concealed laying, UV resistant |

| Corrugated pipe polyamide | gray | 21.2 mm | 16.8mm | Yes | from 48 rub/m | 68 | open, hidden gasket |

What is corrugation for?

The main purpose of the corrugation is to protect the conductor from mechanical, thermal, physical and other damage.It saves other elements behind the corrugated pipe in case of fire or accident. At the moment of burning, it compresses the wire and blocks the air to it. As a result, fire extinguishes. It is used in a wooden building or passage between rooms.

In addition, thanks to it, an aesthetic interior is created. It also facilitates cable installation. There is no need to strobe the walls, since you can make open wiring by placing the cable in a special latch element. It is worth pointing out that the installation of the conductor can be done using a plastic clip, dowel-clamp or dowel-stud, plastic tie, metal cable or frame, as well as using a strobe with further finishing. The most important thing at the time of installation is to choose the right material for the corrugated pipe, based on what the operational operation will be. For long-term and reliable operation of electrical wiring, it is necessary to follow the recommendations.

The corrugation has an open and convenient fastener. Such wiring is easily mounted or rewired. It repeats the relief of the walls and this differs from the tubes. Allows you to determine the color of a specific type of wire and protect it from dust, moisture and direct heat. Mandatory for electrical safety regulations. It is necessary at the time of underground laying, creating a network for finishing and laying cables in the open air.

Electrical wiring protection as the main purpose

Electrical wiring protection as the main purpose

It is worth pointing out that when making a rush or short circuit, it is easy to remove the wires from the corrugation, even if the wiring goes under part of the panel, tile or ground. It can prevent the spread of fire in the room.

The nuances of the selection and installation of corrugated channels

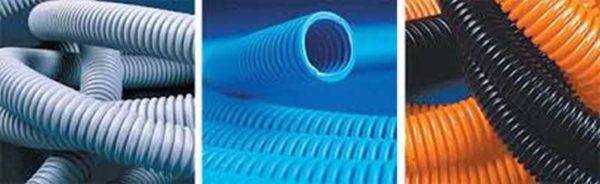

Plastic corrugations for cables are available in various colors. Gray ones are usually made of PVC, black ones are made of polyethylene, and blue ones are made of polypropylene. But there are no strict rules in terms of color.

Each manufacturer adds a dye to the polymer in the manufacture of corrugated pipes at their discretion. However, there is an international standard for coloring such products and wires in them, which provides for the choice of color in accordance with the purpose of the cable route.

It is recommended to use white wires and corrugations for computer networks, gray and black ones for general purpose, green wires for telephone lines, and red ones - exclusively for external street laying.

Following these recommendations greatly simplifies the life of electricians when they come to repair in an unfamiliar place. So the direction of each line is clear at a glance.

Visually, the following gallery of step-by-step photos will acquaint you with the procedure for laying a cable in a corrugated pipe:

After pulling the cable into the corrugated channel, we proceed to fastening the lines to building structures:

For a cable wiring device with a cross section of 3 × 2.5 mm², they usually buy a corrugated pipe with a diameter of 16 mm and mounting clips of the appropriate size.

It is strictly forbidden to lay several types of cables with different purposes in one corrugated hose, it is better to use a separate pipe for each wire

Installation of corrugations and electrical wiring in them is carried out in five stages:

- The corrugated sleeve and cable are cut into pieces of the desired length.

- With the help of a cable stocking, a built-in broach, or a wire simply inserted into the pipe, the wire is pulled into the corrugation.

- Sleeves with a cable inside are fixed in a gate, on a floor or a wall.

- Laid and fixed corrugations are connected to the inlet holes on the bodies of boxes, shields and socket boxes, or simply inserted into them, and the wires are brought out.

- Further - the usual wiring of devices connected to the mains.

To simplify the installation of electrical wiring, you should look for a corrugated hose with a special bundle (broaching) inside. This is an ordinary wire that was pre-stretched through a corrugated pipe at the factory.

Only when cutting the corrugations, one must be careful so that this broach does not go inside. The cable on it for pulling into the sleeve is attached using ordinary electrical tape.

Pulling the cable into the corrugated channel can be handled even alone, but it is much easier for two people to perform this procedure.

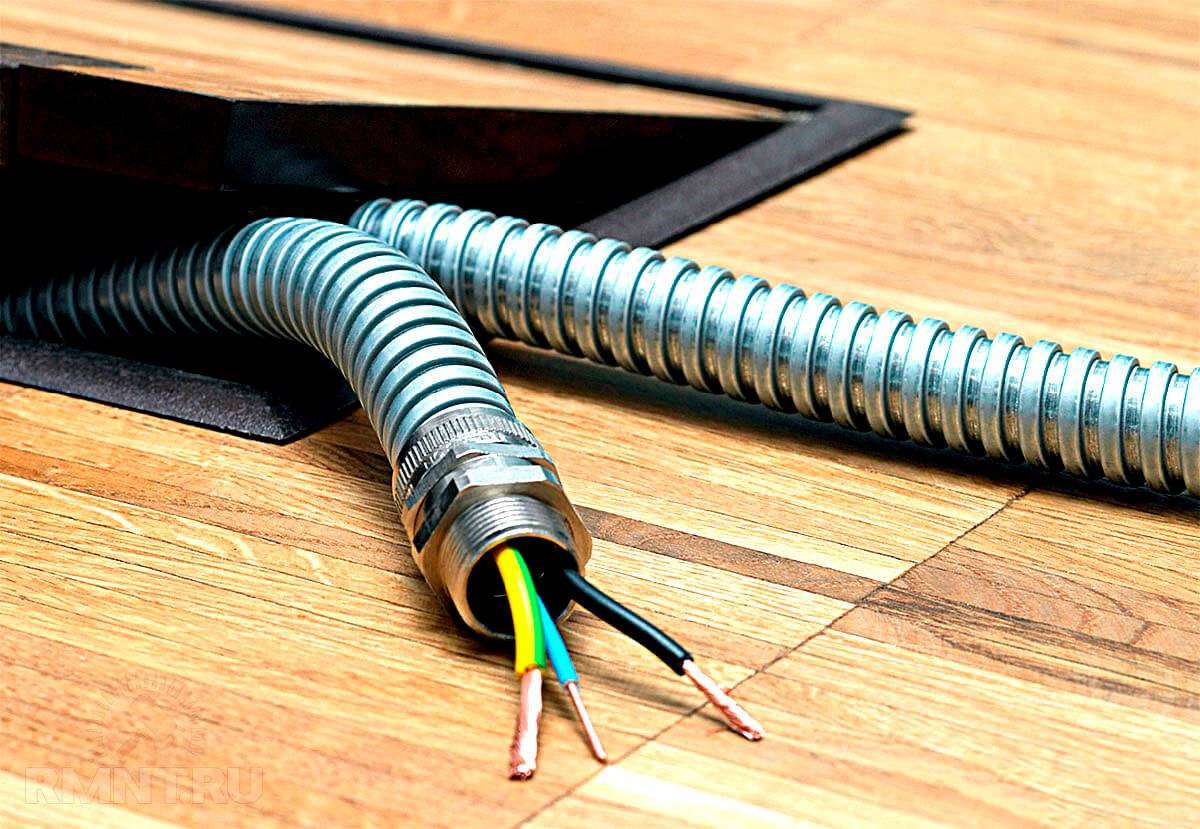

Metal corrugation must be grounded. And do it on both sides of the sleeve. The inner diameter of the corrugated pipe is selected by doubling the total cross section of all cables laid in it. This is necessary both to simplify installation and to prevent overheating of the wires inside.

The corrugation must fit flush into the body of the socket, switch or shield. Any "peeping" of the cable or gaps between the end of the pipe and the housing of the installation or switchgear are unacceptable.

In this case, you can forget about protecting the wiring with a corrugated sleeve. Such incorrect installation will only take time and money, there will be zero sense from it.

Specifications

The corrugation is plastic and metal. It is also presented in various modifications and has its own unique technical characteristics with chemical compositions.

Plastic models come in three varieties: polypropylene, polyvinyl chloride and polyethylene. The first are made using a blue self-extinguishing waterproof material that does not support combustion. Used to lay wires in outdoor and wet areas.

The second is gray. They have the function of self-extinguishing and resistance to moisture. Still others are made from low pressure polyethylene. This type of corrugation is painted in orange or black. It has the function of protection against burning and is moisture resistant. Often used in cables located in internal and external walls, screed.

Metal corrugation is created using stainless or galvanized steel. It differs in resistance to burning, resistance to mechanical and chemical influence. It is used in the wiring of a wooden and frame house. Suitable for street wiring.

To ensure that fire safety requirements are met, metal corrugations must be used. In addition to the fact that the material is non-flammable, it is also resistant to physical stress and the effects of rodents. The corrugation has a thickness of 2 millimeters. This provides short circuit protection.

As for the size, the corrugation has a length of 16 to 65 millimeters. A product with a diameter of 16 millimeters is suitable for laying a power line from a switchboard to a lighting fixture. Pipes with a diameter of 20 millimeters will be ideal for pulling electrical wiring to the outlet and switch. A corrugation with a diameter of 25 millimeters is needed to stretch the wires from the shield to another element of the electrical circuit.

Note! To connect several electrical panels, you will need to take a product with a diameter of 32 millimeters, and to conduct wiring between floors, you will need to take a product with a size of 40 millimeters. Specifications of the plastic model

Specifications of the plastic model

Specifications of the plastic model

Installation of corrugated pipes

For outdoor (open) installation, special plastic clips are used to fasten the corrugations for cables and wires, which are selected according to the outer diameter of the pipe. Clips are fixed after 20-30 cm on self-tapping screws or dowels - depending on the type of wall. A corrugation for the kbale is inserted into the installed clips, pressed until it clicks. When mounted in a strobe, it is fixed with plastic ties or dowel-ties. You can also use homemade fasteners - tin strips with nails or screws in the middle.

When developing a route, the following recommendations should be taken into account. They proceed from the fact that the route should be without sharp turns - in order, if necessary, to tighten a new piece of cable. That's why:

- The maximum possible length of the section is 20-25 meters. Provided that the track has no more than 4 turns.

Lay the electric corrugation in parallel, trying to make as few turns as possible - Turns should not be adjacent. The distance between them is at least 4-5 meters. If there is a need to make turns nearby, it is better to put a junction box or an inspection hatch near them.

- The angle of rotation is at least 90°, the radius is larger, the better.

- If the routes for electrical wiring and low-voltage cables and wires go side by side, the minimum distance for laying two corrugation sleeves is 200 mm. They can only intersect at right angles.

These rules relate to the development of a route for ground (suspension) and underground cable laying, including. If the route is long, and you want to be able to pull the cable “in case of emergency” without replacing the corrugations, develop the route taking these rules into account.

Installation of wiring in the corrugation

When installing wiring in a house or apartment, pieces of corrugation are fixed between junction boxes, from them to switches / sockets, to lighting fixtures. Here the sections are usually small, straight, with a maximum of one or two turns. So there are no problems with tightening the cable.

If you need to tighten several conductors into the corrugation for the cable, they are folded, fastened along the entire length with adhesive tape or electrical tape in increments of 30-50 cm (depending on stiffness). Rigid insulation is stripped from one edge by 10-15 cm, the wires are twisted into a common bundle, a loop is formed from it (secure the loop with tape or tape). If the tourniquet is too thick, you can form the loops separately, just stretch the twine through everything. A cable is tied to this loop, and then they begin to pull it from the opposite side, pulling the sheath over the cables. At the same time, it is necessary to pull without jerking, smoothly - so as not to damage the cable or cable.

How to pull the cable into the corrugation

When installing, be careful not to slip the broach. To be sure, you can secure the cable with a piece of tape. There are two installation approaches:

- First fix the corrugation, then tighten the cable or wires into the finished piece.

- First stretch the cable, then mount it.

The first method is good when installing internal wiring, where the distances are small - from the box to the box, from the box to the socket, etc. The second method is more suitable for installation of long sections.

Features of open laying on the street

When laying wiring on the street, it is usually suspended on a cable. For outdoor use, metal stainless steel is suitable, or better - metal-polymer corrugation for cable, as well as plastic polyamide (black or blue). All these materials are UV resistant and remain flexible at sub-zero temperatures.

Although this is a cheap way, it is not the best, as the ties burst

During installation, the cable stretched into the corrugation is suspended on a cable. The cheapest mount is ordinary plastic ties. There are also special hangers.

Scope of corrugated pipes

Corrugated pipe can be used for laying concealed and open wiring in both ordinary residential and industrial, technical, administrative premises. Corrugation can be attached to walls, ceiling or floor. It is used for laying not only power cable lines, but also for mounting cables of communication networks.

An advantageous advantage of corrugation over installation in a cable duct, which is mounted only on a flat and smooth wall, is the possibility of installation on any surface. The flexibility of the tube allows it to turn at almost any angle or even lie down in twists.

It is important to remember that polyvinyl chloride, from which most light corrugations are made, is sensitive to sudden changes in temperature, high humidity and ultraviolet radiation from the sun, so such products should be used for pulling cables only in enclosed spaces. For the installation of external wiring, there is a separate heavy type of corrugation, which has increased strength, high moisture resistance

For convenience, the color of the corrugated pipe is selected in accordance with the purpose.There is a common European standard according to which:

- White pipes are used for mounting computer networks

- Gray pipes are used when laying electrical wiring

- Brown or black are used when connecting household appliances

- Greens protect telephone wiring

- Red are used when laying external wiring

- Yellow are used in gas supply systems

- Blue for water pipes

Which manufacturers are trustworthy?

Do not buy frankly "non-name" corrugation, as practice has shown that the declared characteristics often do not correspond to reality. Of the manufacturers that are trustworthy, we note the following:

- DKC;

- IEK;

- EKF;

- KOPOS;

- ERA;

- Ecoplast;

- RUVINIL;

- NASHORN — so far only PVC corrugated in the range.

Their components are of course more expensive than their Chinese counterparts, but the quality is many times better. Moreover, there are no problems to buy in Russia.

Some more interesting things from the world of electricians:

- Why is there 220 V between phase and zero, and 380 V between phases?

- Why is the voltage in the USA 110 V, and in Russia 220 V?

Types of corrugations and its features

At the moment, a rich variety of corrugations is presented on the market, differing both in the material of manufacture and in the field of application. The metal corrugation is considered the most reliable.

So:

- For additional protection of cable products from other types of impact, cheaper PVC products are used. In addition to protection against mechanical influences, it copes well with the function of additional electrical protection.

After all, the insulation resistance of PVC corrugations reaches 200 MΩ, which, with a PUE standard of 0.5 MΩ for 380V electrical networks, is an excellent indicator. - The last version of the corrugation, on the scope of which we will dwell in more detail today, is the corrugation for auto wiring. Its main difference from PVC corrugations is its size.

If for ordinary PVC corrugations the minimum size of the hose diameter is 16 mm, then for automobile corrugations, sizes starting from 5 mm are presented. Not surprisingly, such space savings quickly found their way not only in the automotive industry, but also in construction.

Car corrugation dimensions

Car corrugation dimensions

Advantages and disadvantages of laying wire in an automobile corrugation

Automotive corrugation generally has the same properties as conventional PVC corrugated pipe. It bends perfectly, withstands temperatures from -25°C to +90°C and has a large selection of colors. But it also has a number of additional advantages, primarily related to its diameter. The advantages include:

- Protection against mechanical influences

- Protection against electric shock due to low electrical conductivity of the material

- Protection against the harmful effects of the environment and materials (oils, acids, etc.)

- Protection against ignition when using non-combustible corrugations.

- Protection of wires of different voltage classes, laid in one place, from contact in case of damage.

- Attractive appearance

- Possibility of installing a split corrugation on already laid wires or cables.

Laying wiring in a car corrugation

Laying wiring in a car corrugation

But there are not so many shortcomings of corrugation for automotive wiring, and all of them are characteristic of any type of corrugation:

- Higher wire wiring cost when using corrugated pipe.

- More time and a certain complexity of laying the wire.

- Increased heating of the wire due to incorrect calculation of the load of the cable line.

Which corrugation to choose?

To figure out which corrugated pipe to buy: HDPE or PVC, consider typical applications for different types of corrugations.

PVC is suitable for:

- Laying outdoor wiring in a wooden house.

- For connecting the electrical wiring of luminaires in a false ceiling and behind plastic and plasterboard panels.

- Wiring in the bath, in the bathroom and other places with high humidity.

- It is the most common and most often used when installing in an apartment or in a house.

- For outdoor use, but provided that direct sunlight is minimized.

HDPE or LDPE, including two-layer ones, are suitable for laying cables in the ground (in a trench) and on the street.

The metal hose is used for laying wires and cables in places with an increased likelihood of mechanical damage. Can be used in explosive areas. There are options with flanges at the ends and a sealing layer - for use in damp places. Therefore, it is impossible to clearly say which is better, each corrugation has its own application.

An important point is the correct choice of the corrugation diameter for the cable. To lay a cable in this way, it must fit into a corrugated pipe, in addition, sometimes it is required to lay several wires in one pipe. For one wire you need:

- Determine the inner diameter of the corrugation.

- Determine the outside diameter of the cable.

The table below shows the outer diameters of popular cable products.

| Type of | External diameter, mm |

| VVG 3x1.5 | 8 |

| VVG 3x2.5 | 9.4 |

| VVG 3x4 | 10.8 |

| VVG 3x6 | 11.9 |

| PVA 3x1.5 | 8.2 |

| PVS3x2.5 | 9.8 |

| PVA 2x2.5 | 9.1 |

| VBbShv 3x4 | 15.5 |

| VBBSHV 3x6 | 16.5 |

For example, for laying electrical wiring from one VVG 3x4, you need a corrugation with an outer diameter of mm, and for VBBSHV 3x6 - 25-32 mm.

Whereas for laying several wires, you need to use the following algorithm:

- By the outer diameter, we calculate the total cross-sectional area of \u200b\u200bthe cable and the cross-sectional area of \u200b\u200bthe corrugation hole.

- The wiring should not fill the corrugated pipe by more than 35%, for more details see PUE 2.1.61.

For example, let's solve the problem:

It is necessary to lay electrical wiring to connect several powerful spotlights, there is a PVA wire 2x2.5, how many of them will fit in a PVC corrugation with a diameter of 50 mm?

Based on the tables above, we determine the outer diameter of the wire and the inner corrugations:

PVC 2x2.5 - 9.1

Corrugations - 39.6

S wires \u003d (n * d ^ 2) / 4 \u003d (3.14 * 9.1 ^ 2) / 4 \u003d 65 sq. mm

Scorrugations \u003d (3.14 * 39.6 ^ 2) / 4 \u003d 1231 sq. mm.

In this case, only 35% of the area can be filled:

1231*0.35=430 sq.mm

Then the number of wires in one corrugation is equal to:

430/65=6.61

It follows from this that up to 6 PVA 2x2.5 wires can be inserted into a 50 mm corrugation.

Now you know how to choose a corrugated cable, as well as what sizes and types of products exist today. Finally, we recommend watching useful videos on the topic:

What is corrugation and where is it used

Electrical corrugation is a corrugated pipe for laying an electrical cable in order to protect it or protect structures. Laying an electrical cable in corrugated tubes is used in various situations with open or hidden electrical wiring.

Hidden gasket

Hidden laying is the installation of electrical wiring inside the structures of walls, floors and ceilings, behind finishing materials. It is conditionally divided into the following types of installation:

Laying inside non-combustible structures is carried out in wall and ceiling strobes, in floor screed or simultaneously with the installation of load-bearing structures (for example, when concreting). In this case, corrugation is used for ease of installation, protection against cable crushing and the possibility of replacing electrical wiring without disturbing the finishing material, chasing or dismantling wall, ceiling or floor structures. When laying a corrugated cable inside structures made of non-combustible materials, the PUE allows the use of any type of corrugated tubes.

Laying behind finishing materials or in false spaces has the same goals as laying in non-combustible structures (protection against mechanical damage, the possibility of replacing wiring if necessary), but with the same installation requirements as when laying on combustible materials. The fact is that finishing materials often contribute to combustion, therefore, for such an installation, the requirements are quite strict.

It is important to use flame retardant or metal corrugations for this installation.

Underground laying is carried out in the course of landscaping works for wiring electrical power lines to lighting fixtures and various equipment (pumps for watering installations, gate and door opening systems), when laying low-voltage networks for security systems or telephone lines, and in other situations. The main requirement for such laying of corrugations with an electric cable is water tightness and high resistance to mechanical deformation (rigidity).

open laying

Open laying is carried out along load-bearing and enclosing structures, finishing materials and when installed outdoors to the facades of buildings or through the air.

Laying on combustible materials of structures involves the installation of electrical wiring in the corrugation to ceilings and walls with a combustible finish or made of wood, plastic and other materials that promote combustion. For reasons of fire safety, non-flammable (metal) corrugated tubes are used. With such an installation, according to the PUE, it is forbidden to use plastic corrugation made of self-extinguishing and non-flammable materials.

Laying on non-combustible structures and materials is carried out with any corrugated plastic tubes that do not spread combustion. It is possible to use metal corrugations to improve the aesthetics of installation or when used in special conditions (aggressive environments, the likelihood of mechanical damage).

Laying outside buildings and structures is used for the installation of lighting or the laying of power and low-voltage networks for various purposes along the facades of buildings and fences, as well as through the air between buildings. The corrugation used in this case should also not spread combustion and should be resistant to precipitation, ultraviolet radiation and be durable.

Cable laying in fire or explosive areas is carried out exclusively using metal corrugated pipes in combination with a flame-retardant electric cable.