- What should be a good pump

- Well parameters

- Criterias of choice

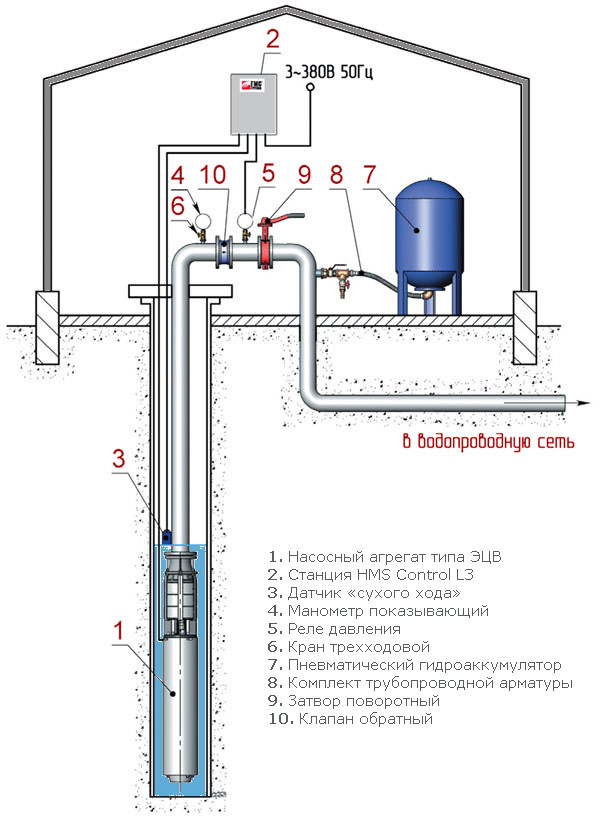

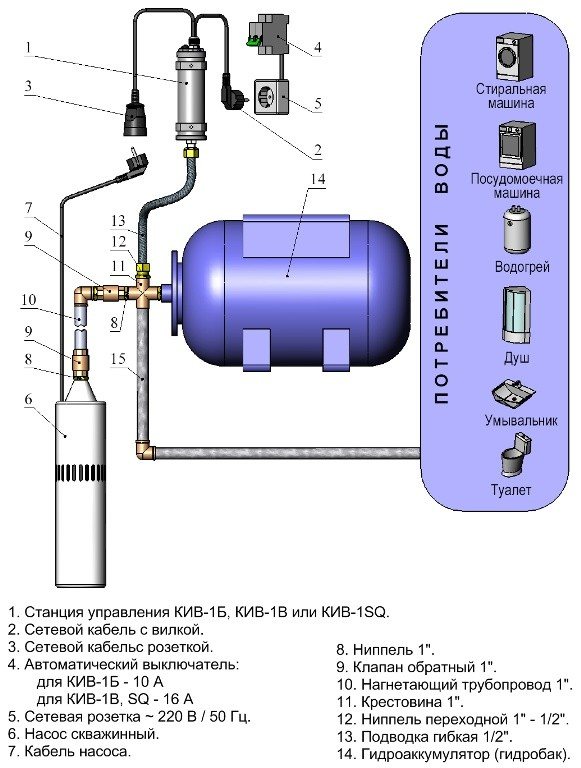

- Well pump piping

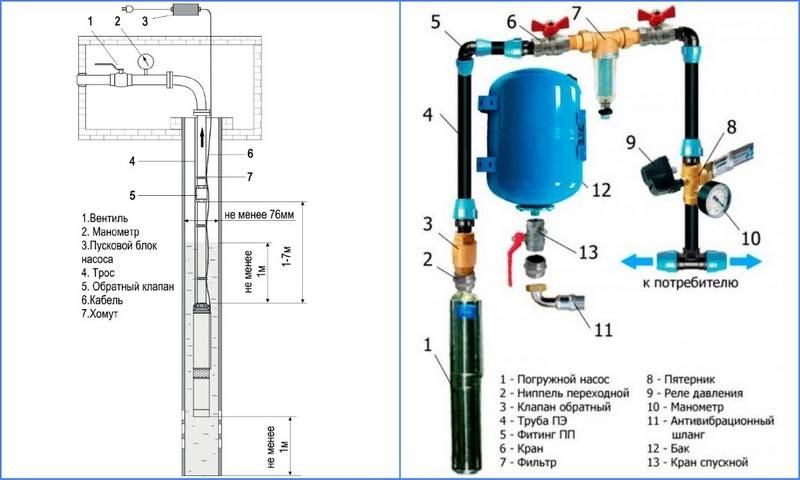

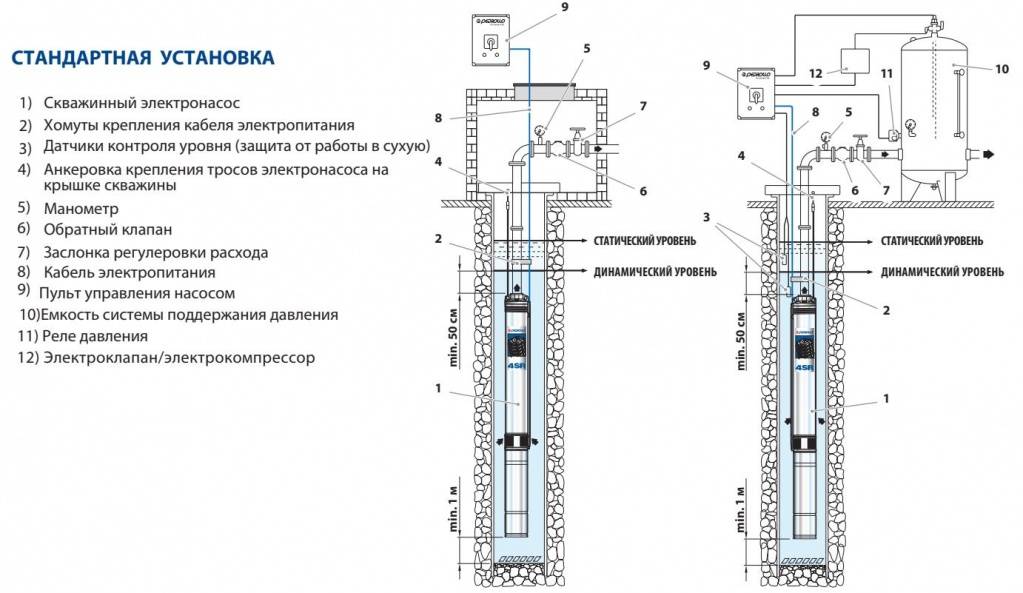

- The procedure for installing a deep pump.

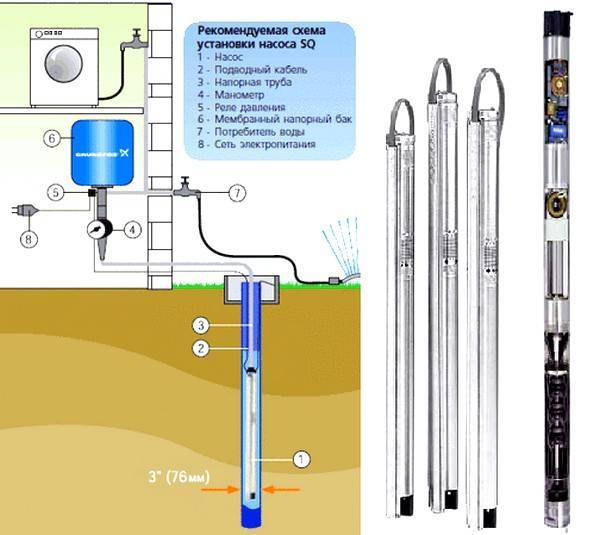

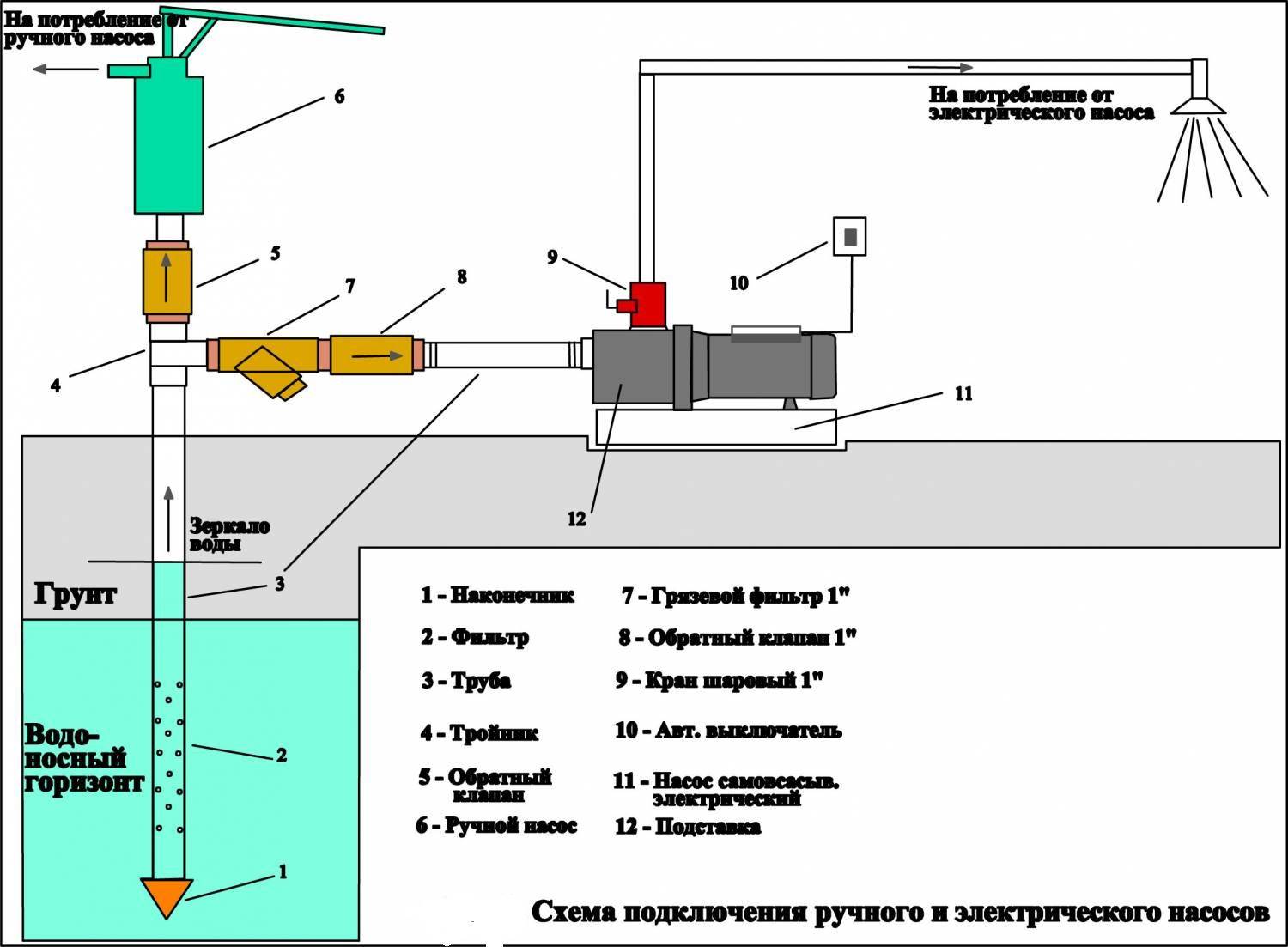

- Popular schemes for the implementation of water supply

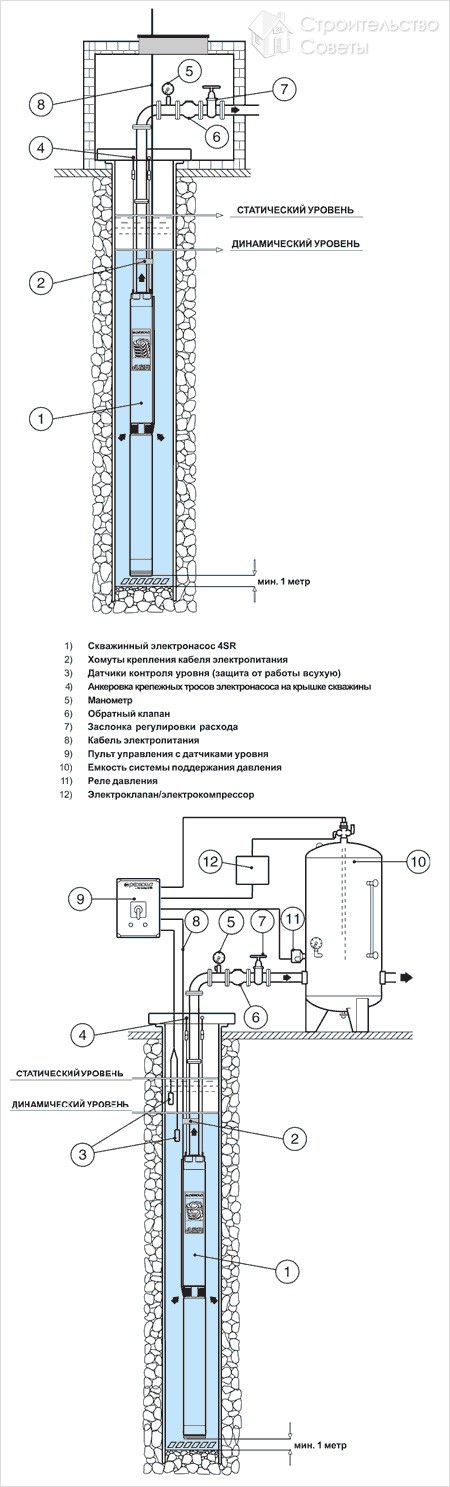

- Well or well with a depth of more than 8 meters

- Well or well up to 8 meters deep

- Container with gravity water supply

- Kinds

- 1st generation

- 2nd generation

- 3rd generation

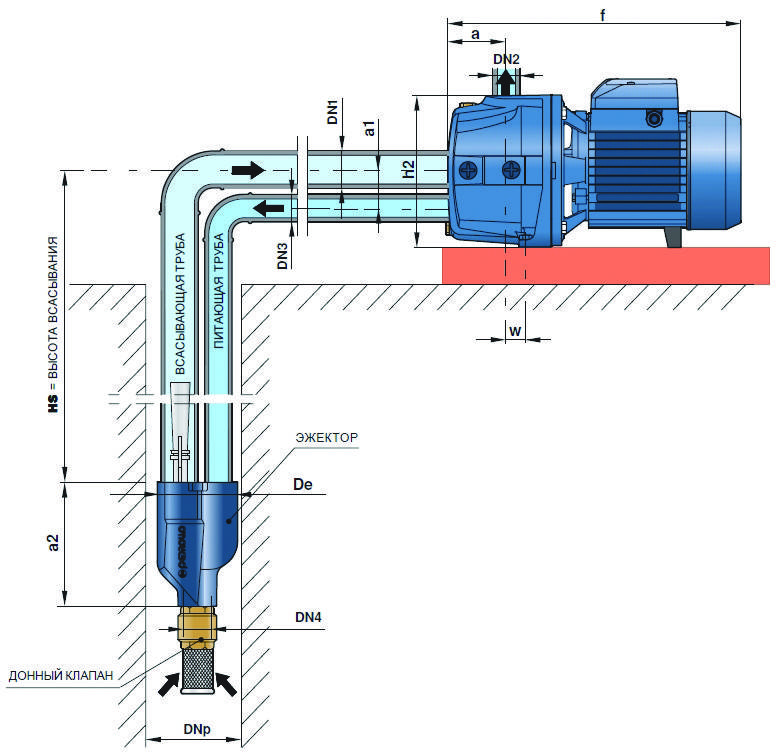

- Pros and cons of surface pumps

- How is the pumping station set up?

- Vortex

- Centrifugal

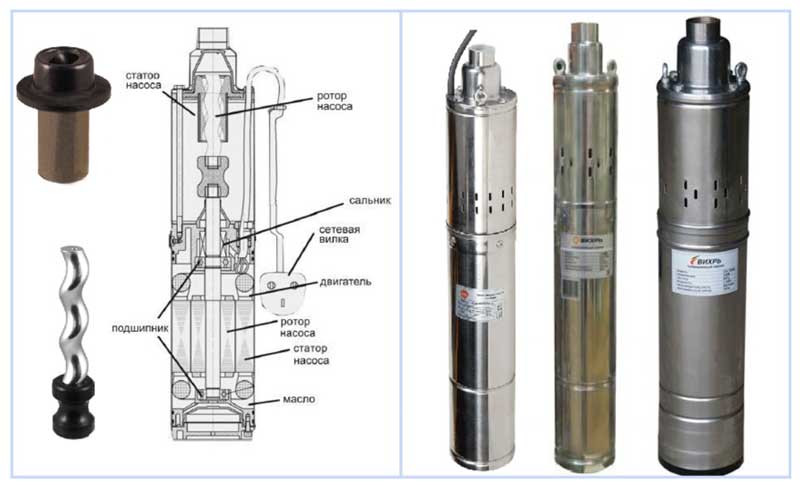

- The device of a centrifugal submersible pump for water intake

- The principle of operation and the device of centrifugal electric pumps

- Connecting the deep pump to the water supply system

What should be a good pump

The flow rate of a local source is an important indicator when choosing a device. For high performance, a large power unit is required. Depth is the determining factor. A model designed for 40 m will supply water from 50 m, but will quickly fail.

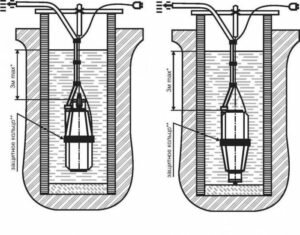

The level of drilling quality should also be taken into account. If the work was carried out by a professional team, the shaft can withstand heavy loads and is resistant to external influences. For do-it-yourself pits, it is better to buy centrifugal models designed specifically for wells for installing a submersible pump.

When choosing equipment for pumping water, special attention is paid to the dimensions of the device. They must be selected in accordance with the internal section of the casing

The pump must pass freely into the pipe. If the unit is in contact with the walls, it is better to look for an option with smaller dimensions.

Finding a pump model that fits a 4" casing is easier than a 3" one. This factor must be taken into account when drawing up a plan for installing a submersible pump in a well.

Deep pump mechanisms have different power supply schemes. Single and three-phase devices are allowed to be used in a water mine.

Well parameters

When deciding which pump is best for a well, you need to focus on the characteristics of the water intake point. We are talking about its static and dynamic level, debit, distance to the bottom, pipe diameter. If the well was drilled by a team of specialists, then they provide the site owner with a special document with relevant technical information. This also applies to the above parameters. If a lot of time has passed since the drilling of the well, all the parameters indicated in the technical data sheet require additional clarification.

It happens that the owners of the house build a water intake point on their own, or invite "shabashniks" for this. In this case, when choosing the best pump for a well, it is not possible to rely on documentation. There is only one way out - to take the appropriate measurements yourself, using simple tools. The static level is the distance between the surface of the water in the well and the surface of the earth. You can determine the distance using a simple rope with a load at the end (it is desirable that it has a cylindrical or conical shape).There is also an option with a plastic tube, tape measure or ruler.

Measurement procedure:

- It is recommended to refrain from using the well about an hour before it starts. This will allow you to get the maximum water level.

- Lower the rope with the load inside the wellbore until a characteristic sound indicates the contact of the load with water. As a rule, this sound is well audible.

- Having put a mark on the rope, pull it to the surface and measure the distance between its end and the mark. This will be the indicator of the static level.

The next parameter that you need to know to select a submersible pump for a well is the dynamic level. We are talking about the distance between the surface of the earth and the water in the well at the time of minimum filling. More thorough preparation is required for this measurement. Water is pumped out with a powerful pump (it can be rented or borrowed). In the process of emptying the shaft, the pump must be lowered lower and lower until the water stops decreasing. This level is considered the minimum. To determine the distance between water and the surface of the earth, the same procedure is followed as for determining the static level.

By comparing both indicators, it is possible to make a preliminary conclusion about the level of well productivity. This will greatly help in solving the problem of how to choose a pump for a well. A small difference between the two levels indicates a high rate of water column recovery. To service such a well, a high-capacity pump is required. In some cases, studies of an artesian well indicate the equality of the dynamic and static levels.This is an indicator of the high productivity of the hydraulic structure. As a rule, the most powerful one is recommended to select a pump for a well. Most often they also make a well for a well, which is very convenient and practical.

A high capacity index of the water intake point indicates that the pumping rate is approximately the same as the rate of replenishment of the volume of liquid from internal resources. The difference in levels in such cases is usually no more than 1 m. Information about the dynamic level will help in the process of determining which pump to choose for the well. The pump must be installed in such a way that the degree of its immersion is 2 m more than the dynamic level indicator. This will allow the device to be constantly in the water.

Criterias of choice

A pump for a well, for example, Malysh, is the main element of the water supply system of a country house. The correct operation of the entire system depends on the correct choice of this unit. When selecting pumping equipment, several criteria must be taken into account at once:

- The main indicators influencing the choice of device are the level of liquid in the hydraulic structure and the depth of the well. The passport for pumping equipment must indicate the depth of water intake for which the pump is designed. If you do not know how deep your hydraulic structure is, it is better to measure it yourself using a special device or an ordinary rope. Also, with the help of a rope (its wet part), you can find out the height of the water column in the well. Next, we will consider the features of choosing a unit for wells with a depth of 30 meters.

- Water needs. The choice of pumping equipment without knowing this value is simply impossible.Depending on the type of pump, this figure can be in the range of 20-200 l / min. The calculation is made taking into account that one person uses 200 liters of water per day. Therefore, a family of four will need a pump whose power is in the range of 30-50 l / min. You can choose the simplest unit, for example, the Whirlwind or the Kid, but you should provide for a small power reserve. If, in addition to water supply at home, the device will provide irrigation of the garden, then an even greater power pump is needed. As a rule, about 2 thousand liters of water may be needed to water the garden per day, so the power of pumping equipment should be 50 l / min more.

- Well productivity. It is impossible to accurately calculate the volume of water produced for a certain period. For an approximate assessment of this parameter, the time during which all water is pumped out of the hydraulic structure is recorded, as well as the time during which a completely empty well is filled with water again. After that, the second indicator should be divided by the first. The result obtained will be the debit of the water intake. For the selection of pumping equipment, this approximate value will be quite enough.

- Well water pressure. This indicator is especially important for water intakes with a depth of 30 meters or more. To determine the pressure, you must know how many meters deep your well has. To this value add 30 and increase by 10 percent. As a result, you will get the height of the water column. According to this indicator, the pump is selected. For example, if your hydraulic structure is 30 meters deep, then the height of the water column will be 60 m + 30 + 10% = 66 m.In this case, it is better to choose a model of pumping equipment, for example, Malysh or Whirlwind, with a head of 70 meters.

- The diameter of the shaft of a hydraulic structure. This indicator is needed to determine the power of pumping equipment. If your well was drilled by professionals, then this value can be found in the water well passport. If you did the water intake yourself, then the diameter can also be measured independently. This value must be in inches, so to convert from centimeters, know that there are 2.54 cm in one inch. Most pumps, including the Malysh unit, are designed for 4-inch wells. If the diameter of the trunk of your structure is non-standard, the desired model can be ordered from the catalog. That is why, before making a water well, it is worth choosing a suitable 4-inch casing diameter in advance.

- The price of pumping equipment is an equally important indicator when choosing a unit. Also, when calculating costs, it is worth considering that you will need a steel cable to hang the pump in the well and an automatic connection. It is not necessary to choose the most expensive unit. There are relatively inexpensive domestic models, for example, the Malysh pump, which do an excellent job with the tasks.

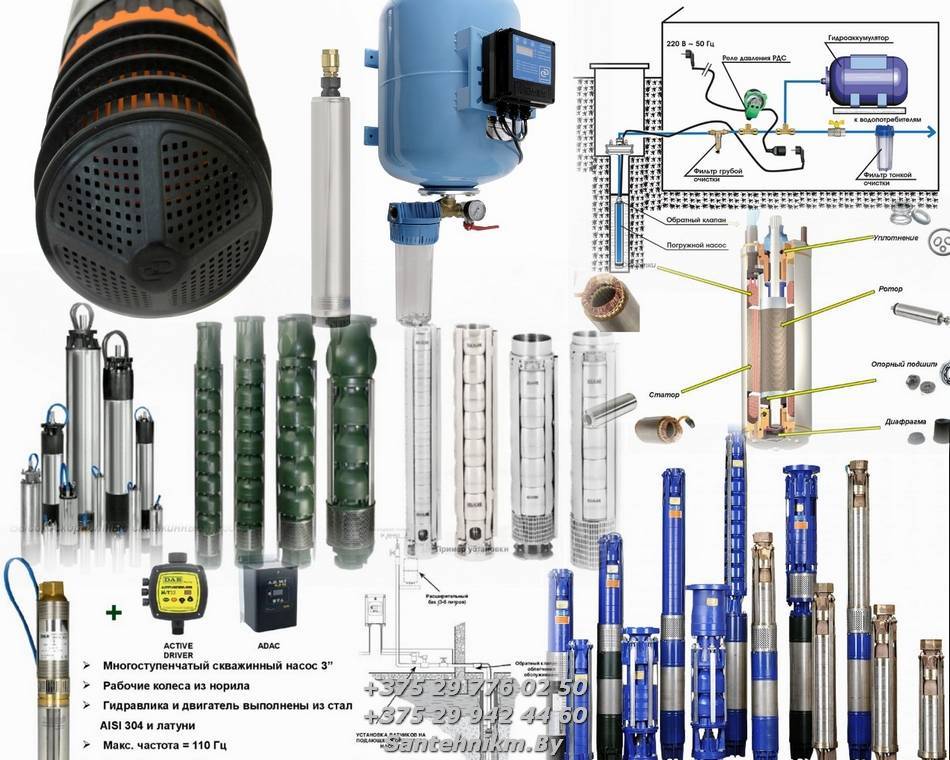

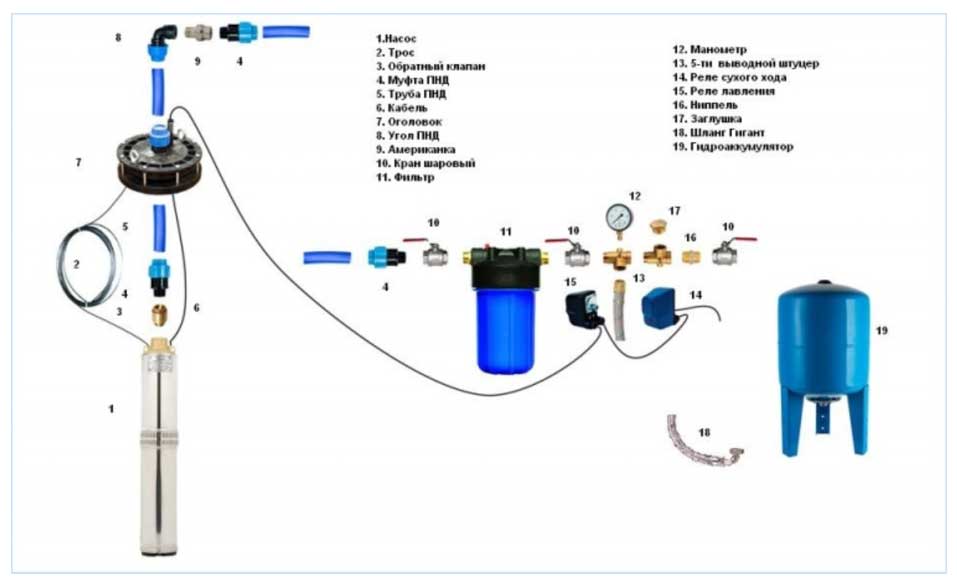

Well pump piping

For proper piping of a borehole pump, we need:

- Pump

- Check valve GG + nipple (or check valve GSH)

- Coupling HDPE with external thread

- HDPE pipe

- Tight head OGS 113/125 or OGS 127/165 (depending on casing diameter)

- Corner HDPE crimping (for pipe rotation)

- Polyamide cord 6mm or 8mm (for hanging the pump)

- Automation

There are three types of automation:

1. Block (assembled in parts and consists of a 5-pin fitting, a 3-pin fitting; Pressure switch PM / 5G, PA 12 MI; Pressure gauge; Dry running sensor; Water flow switch WATTS)

2. Complete (pressure switch PM/5-3W, Turbopress)

3. Assembled with water hammer compensator (Automation unit PS-01A, PS-01C)

Hydraulic accumulator or ATV water tank (recommended to use automatics PS-01A with the tank)

It should be noted that the full volume is indicated for the accumulator.

Remember, the main purpose is to compensate for water hammer.

Too much volume can lead to the effect of stagnant water.

So a 24-liter accumulator will store only 11.3 liters.

-

If the hydraulic accumulator is removed from the automation, then an HDPE coupling with an external thread 1″ and a HDPE coupling with an internal thread 1″ will be additionally required

-

PND coupling with external thread 1″ for pipe outlet after automation

-

Additional elements of plumbing at your discretion (faucets, tees, nipples, etc.)

-

Caisson (at your discretion)

A caisson is a well in which the upper part of the well and a sealed head are located. It is used as a rule to avoid getting debris on the surface of the well section. Also for decorative purposes when the well is located somewhere on the site. It consists of a polymer-sand ring, a cone, a bottom and a hatch.

- Pipe insulation when laying in the ground (foamed polyethylene or expanded polystyrene)

- Heating cable

Mounted on open sections of the pipeline in the well (to the water) and the pipe laid to the house (in the insulation). Also, the cable comes in two versions: outdoor cable

(mounted on the surface of the pipe) and internal cable (stretches inside the pipe).

As a rule, non-food heat shrink is used for the outer cable, but for the inner cable, in addition to food heat shrink, you will also need a special AKS1 gland to insert the cable into the pipe and a tee with an internal thread for a 3/4 or 1/2 gland. As a rule, a 1″x3/4x1″ or 1″x1/2x1″ tee is usually suitable.

You can also always consult with our managers by calling, order a call (via the form on the site) or contact online.

.

The procedure for installing a deep pump.

Prepare the power cable:

• solder the stripped ends of the cable with lead;

• insert the prepared cable ends into copper sleeves, which are soldered to the output ends on the motor;

• also solder the connections (use rosin as a flux);

• clean the places of soldering, then carefully insulate this place with PVC tape;

• check the insulation.

Use a megger to test the insulation. The cable connection point must be lowered into water (temperature up to 30 degrees) for 1.5-2 hours. Place a vessel with water isolated from the motor housing on the gasket. Connect one terminal of the megger to a container of water, and connect the other in turn to the cores of the supply cable.

The insulation resistance must be above 500 MΩ (this number is usually indicated in the instructions).

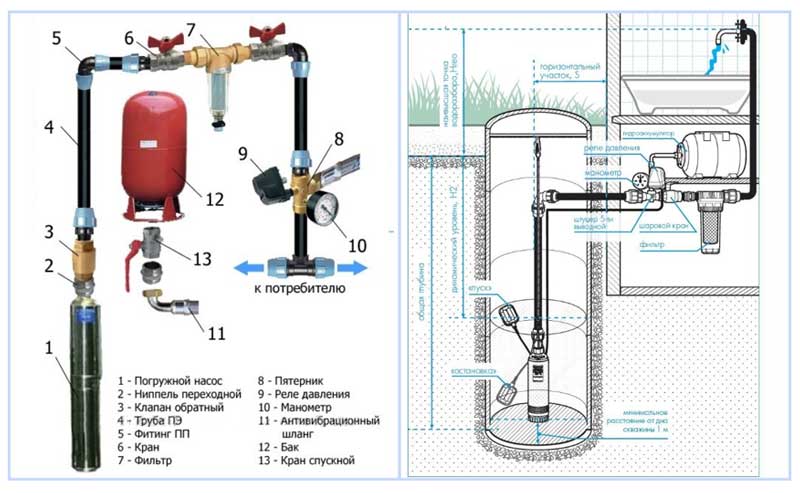

Popular schemes for the implementation of water supply

Well or well with a depth of more than 8 meters

When lifting water from a depth of more than 8 meters, the best solution would be to use a submersible pump. When choosing, the maximum height of the water column, power, and the presence of filters are taken into account. The body must not come into contact with the walls of the well.

Advantages:

- reliable supply with high pressure;

- exclusion of freezing of the pump;

- simple drain from the system into the well;

- lack of noise of the working pump;

- use of better quality water from the second or third aquifer.

The disadvantages include:

- high cost of well construction and the pump itself;

- impossibility of service of the pump.

Well or well up to 8 meters deep

To lift water, you can use a pumping station, and a vibration pump from a well.

The advantages of this scheme:

- lower cost in comparison with a submersible pump and an artesian well;

- the possibility of servicing the pump;

- from the well you can take water with a bucket, in the absence of electricity.

This scheme has many more disadvantages:

- unreliable feed from a depth of more than 5 meters;

- noisy operation of the pumping station;

- for work in winter, the pumping station must be located in a warm room, therefore, the room must be located near the source (no further than 10 meters);

- rise of insufficiently pure water from the first aquifer;

- draining is difficult, you need to think over the scheme in advance;

- a small amount of hydroaccumulator at the station.

Water pressure in the water supply system in an apartment and a private house: what is the standard measured in

Home water supply is common. We get used to it so much that we only remember it when a malfunction occurs. For example, the pressure decreases, and household appliances stop working ....

Container with gravity water supply

Outdated water supply system. Its use can be justified by using a low-power pump with a water source with a small debit (flow rate). The pump during long-term uninterrupted operation, fills the tank, which can be spent just as long.The only advantage is the reserve supply of water if the pump managed to fill it before the power outage.

There are a lot of shortcomings, so we will reflect the most significant:

- load on the attic floor;

- very weak pressure, it is necessary to install household equipment taking into account this factor;

- you will need an additional pump if the pressure does not suit;

- if the automation fails, overflow from the tank is possible, it becomes necessary to drain;

- the tank and outlet must be insulated for operation in winter.

A modern alternative to a pressure tank will be a 250-500 liter storage tank, even taking into account the return of water 1/3 of its volume. Such a tank can be installed in any insulated place. Only at the entrance to the house, after the fine filter, a check valve is installed to prevent the water from draining from the tank for irrigation needs. In this case, the pump is selected, not according to the consumption of liters per minute by consumers during peak hours. And according to the debit of the water source, if it is much less than required. But at the same time, the pump must create sufficient pressure so that the pressure in the storage tank at the end of the set is at least 1.0 bar, preferably more. Taking into account the subsequent flow, the pressure will drop to 0.5-0.3 bar, and this is the minimum value for a domestic water supply.

High-quality autonomous water supply is quite possible. It depends on the literacy of the specialists who install the plumbing in the house, and the financial capabilities of the customer. The choice of water source is important. And it’s good if the owner of the house understands these issues before he starts arranging the water supply system.

Video lesson on an open water supply system:

Views:

254

Kinds

All automation used to control the operation of the pump is divided into 3 types in chronological order according to the sequence of its creation.

1st generation

This is the first and simplest automated control system for pumping equipment. It is used for simple tasks when it is necessary to provide a constant source of water in the house. It consists of three main parts.

- Dry run sensor.It is necessary to turn off the pump in the absence of water, which serves as a cooler, without it the pump will overheat and the winding will burn out. But an additional float switch can also be installed. Its function is similar to a sensor and is repelled by the water level: when it drops, the pump turns off. These simple mechanisms reliably protect expensive equipment from damage.

- Hydraulic accumulator.It is a necessary element for system automation. Performs the function of a water accumulator, inside of which the membrane is located.

- Relay. The device that controls the pressure level must be equipped with a pressure gauge that allows you to set the operating parameters of the relay contacts.

Dry running sensor

Hydraulic accumulator

Pressure switch

Automation of the first generation for deep well pumps is simple due to the absence of complex electrical circuits, and therefore its installation on any pumping equipment is not a problem.

The functionality of the system is as simple as the mechanism of operation, which is based on a decrease in pressure in the accumulator when water is used up. As a result, the pump turns on and fills the tank with new fluid. When full, the pump turns off. This process continues cyclically. Adjustment of the minimum and maximum pressure by means of the relay is possible. The pressure gauge allows you to set the lower and upper limits for the operation of automation.

2nd generation

The second generation differs from the first in the use of an electronic control unit to which the sensors are connected. They are distributed throughout the pumping system and monitor the operation of the pump itself and the condition of the pipeline. All information is sent to the electronic unit, which processes it and makes appropriate decisions.

When using 2nd generation automation, a hydraulic accumulator may not be used, since the pipeline and the sensor installed in it perform a similar function. When the pressure in the pipe drops, the signal from the sensor goes to the control unit, which, in turn, turns on the pump and restores the water pressure to the previous level, and when completed, turns it off.

To install 2nd generation automation, basic skills in handling electronics are required. According to the principle of operation, the systems of the 1st and 2nd generation are similar - pressure control, but the cost of the 2nd generation system is much more expensive, as a result of which it is in less demand.

3rd generation

Such a system is highly reliable and efficient, but also more expensive than its predecessors. The precise operation of the system is ensured by advanced electronics and saves on electricity. To connect this system, a specialist is needed who will not only install, but also configure the correct operation of the unit. Automation provides a full range of equipment protection against breakdown, from dry running and pipeline rupture to protection against power surges in the network.The principle of operation, as in the 2nd generation, is not associated with the use of a hydraulic accumulator.

The main difference is the ability to more accurately regulate the operation of mechanical components.For example, when turned on, the pump normally pumps water at maximum power, which is not necessary with its low consumption, and electricity is consumed to the maximum.

Pros and cons of surface pumps

Surface pumps have many advantages:

- Compact overall dimensions;

- Light weight;

- Price availability;

- Ease of installation, operation and maintenance. Installation of a surface pump does not require special knowledge, skills and experience;

- Ability to work with a water layer of less than 80 cm. Under such conditions, submersible pumps can no longer work;

- Cooling by air, and not by water, as in submersible;

- Large water pressure;

- High efficiency;

- No need to supply electricity to the water intake;

- High reliability and durability;

- Stable operation even in the presence of air pockets in the system.

Also, surface pumps (as a class of equipment) have a number of disadvantages:

- Sensitivity to the presence of sand, impurities and other water contaminants;

- The maximum depth from which water can be raised is about nine meters;

- When using an ejector, the reliability and performance of the system is significantly reduced;

- Noise. For the operation of a surface pump, it is better to allocate a separate room;

- The need to fill the suction line with water.

How is the pumping station set up?

The level of comfort in a country house is largely determined by the presence of a professionally debugged water supply system, the main component of which is a pumping station.

The structure of the devices involved in the organization of water supply must be known in any case. It will come in handy if you lay the plumbing yourself or entrust the installation work to professionals.

Knowing the principle of operation of individual elements of the system, in the event of an accident or failure of one of the devices, you can independently, and most importantly, quickly repair the pumping station or replace it.

So, the most important components of the water supply scheme using a pumping station are the following:

- device for water intake with a filter;

- non-return valve that prevents the movement of water in the opposite direction;

- suction line - a pipe leading to the pump;

- pressure switch for adjusting the water supply;

- pressure gauge showing the exact parameters;

- hydraulic accumulator - automatic storage;

- electric motor.

Instead of a hydraulic accumulator, a more modern and practical device, a storage tank is sometimes used, which has several disadvantages (weak pressure, inconvenient installation, etc.).

The diagram shows one of the ways to install a non-pressure storage tank and a hydrophore that can regulate the pressure and water level in the system

However, now that many modern inexpensive models with a hydraulic accumulator have appeared in stores, there is no point in self-assembly of a system with a storage tank.

If you still decide to purchase a container for collecting water, try to consider the following nuances:

- The reserve tank is installed in the highest possible area (for example, in the attic) in order to create the necessary pressure.

- The volume of the tank should be such that there is a reserve for 2-3 days in case of failure of the pumping equipment (but not more than 250 liters, otherwise sediment may accumulate).

- The base for mounting the tank must be reinforced with beams, slabs, additional ceilings.

The reserve storage tank, as well as membrane equipment (hydraulic accumulator), should be equipped with a filter. In addition, it is mandatory to install a safety pipe to drain excess water. The hose connected to the branch pipe is led out into the drainage system or lowered into containers designed to store irrigation water.

Standard diagram of a pumping station with the designation of the main elements: check valve, pressure switch, pressure gauge, pressure pipeline; red arrow points to accumulator

The principle of operation of the pumping station is cyclical. As soon as the supply of water in the system decreases, the pump turns on and begins to pump water, filling the system.

When the pressure reaches the required level, the pressure switch is activated and turns off the pump. The relay settings must be set before starting the equipment operation - they depend on the volume of the tank and the characteristics of the pump.

Vortex

In vortex submersible pumps, the intake and expulsion of water occurs with the help of a single impeller with blades, which is located in the upper part of a vertically suspended casing near the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side face of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to work in an environment with sand particles.

Vortex-type devices have good pressure characteristics (liquid lifting height reaches 100 m) and average pumping volumes (about 5 cubic meters / hour).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Whirlwind, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump - design and appearance

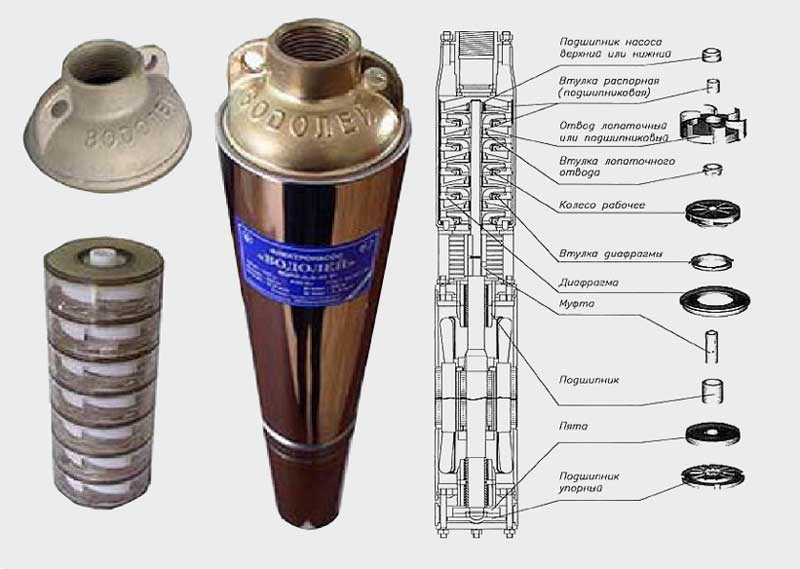

Centrifugal

Centrifugal devices have achieved such distribution due to the following properties:

- Their coefficient of performance (COP) is the highest of all analogues, in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel, and is pushed out through the side pipe. This allows you to make multi-stage centrifugal devices in which the ejected fluid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters / h.

- Centrifugal type units are less affected by fine sand particles on the working mechanism, they are widely used in sand wells, choosing a model to work with a suitable particle size indicated in the passport.

- A significant advantage of centrifugal types is the high level of automation, the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) supply their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save electricity during the operation of the electric pump (up to 50%), but also to significantly increase its service life.

If we list all manufacturers of centrifugal pumps that represent their products on the domestic market, the list will be quite voluminous, so we will limit ourselves to the world's leading manufacturers listed above. Of the domestic brands, Aquarius, Dzhileks Vodomet, Whirlwind, Belamos, Caliber, Unipump received the greatest fame.

Rice. 8 Centrifugal submersible pumps - design and materials of manufacture using the example of Grundfos SBA

The device of a centrifugal submersible pump for water intake

If the garden can be watered from shallow reservoirs using surface electric pumps, the simplest low-power vibration pumps, submersible drains, then the situation is different with the constant water supply of a country house from a deep well.

High-performance devices are required, capable of extracting water from great depths with high pressure, while their efficiency should be quite high.

The principle of operation and the device of centrifugal electric pumps

The main element of a centrifugal pump is an engine hermetically placed in the body of the apparatus, and an impeller in the form of a disk with a one-sided impeller, mounted on its shaft.

During operation, the liquid is drawn in through the inlet of the housing, located in the central part of the impeller, and its radially curved blades push it to the periphery.

The water is collected in a snail-shaped annular collector and is forced out through the outlet pipe under pressure by the next flow of water entering the housing.

To increase the pressure in the system, several wheels with separate chambers and outlet pipes, called stages, are often used, from each of them to the next the liquid is transferred with increasing pressure. Centrifugal pumps are highly efficient and can handle turbid water.

Connecting the deep pump to the water supply system

When constructing an individual water supply system, even at the stage of drilling operations, one should know the diameter and material of the pipeline, the depth of the water line, and the operating pressure in the system for which the equipment is designed. When installing and turning on the water supply, the following recommendations are guided:

When using the plumbing system in winter, you will have to take measures to protect it from the cold. Typically, pipes are laid underground and they must come out of the head of the well, so a caisson pit will be needed to install and maintain equipment. To make it more convenient and reduce the depth, the water line is insulated and heated with an electric cable.

Rice. 6 Assembling a pumping station with your own hands - the main stages

- When determining the immersion depth of the electric pump, set the dynamic level with the equipment turned on and hang the unit 2 meters below the set mark, the minimum distance to the bottom for deep models is 1 meter.

- When using sand wells, it is mandatory to install sand or coarse filters in the water line before the equipment.

- Electric pumps change their pumping efficiency when the supply voltage changes, so for stable operation it is better to purchase a voltage stabilizer and connect equipment to it.

- For ease of operation and maintenance, a do-it-yourself pumping station is often assembled. A pressure gauge and a pressure switch are mounted on the accumulator using a standard five-inlet fitting, but since there is no branch pipe for attaching a dry-running relay, it will have to be installed on an additional tee.

- Often electric pumps have a short power cable, not long enough to connect to the mains. It is extended by soldering, similar to the further insulation of the connection point with a heat shrink sleeve.

- The presence of coarse and fine filters in the plumbing system is mandatory. They must be placed before the automation of the control system, otherwise the ingress of sand and dirt will lead to their incorrect operation and breakdowns.

Rice. 7 Placement of automatic equipment in the caisson pit