- What does water hammer mean?

- Water hammer theory

- Threats of water hammer in the water supply

- Basic Prevention Measures

- Protection method "reconstruction"

- Protection method "centrifugal pumps"

- Avoiding water hammer - basic rules

- Pipes with increased protection against water hammer

- Pressure reducer, safety valve, hydraulic shock absorber - what to put where?

- Drops and their causes

- How to increase the pressure in the heating system?

- Why does the pressure in the heating system increase?

- How to eliminate gaps?

- Methods for a comprehensive system upgrade

- Method #1. The use of compensators and shock absorbers

- Method #2. Installing a Diaphragm Type Safety Valve

- Method #3. Equipping the thermostatic valve with a shunt

- Method #4. Using a thermostat with super protection

What does water hammer mean?

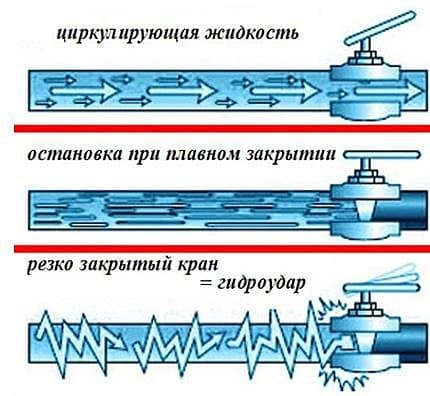

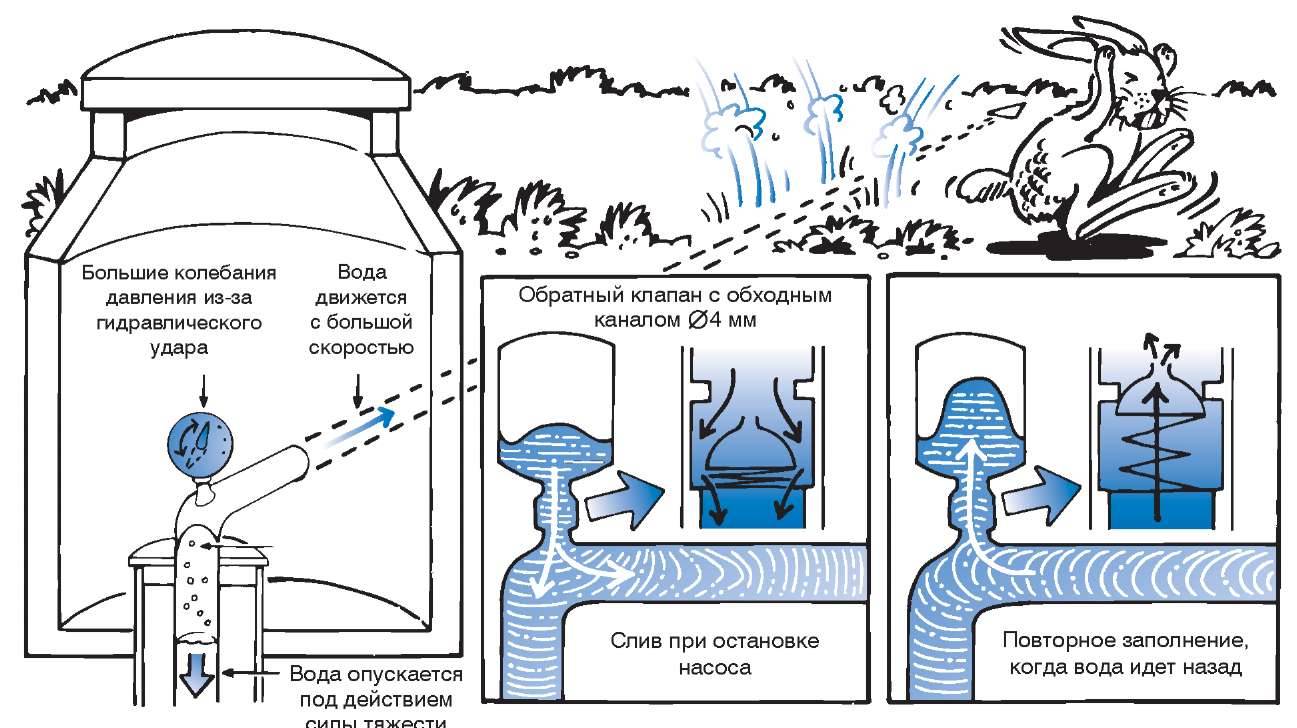

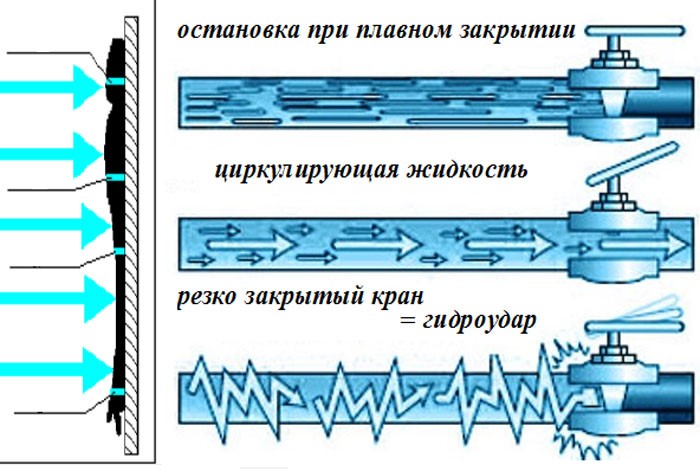

Water hammer (water hammer) is a physical phenomenon characterized by a sharp increase in hydraulic pressure in a separate section of a fluid system, caused by a significant change in flow rate.

In heating systems, the main type of coolant is water. Water is incompressible by definition, as are the vast majority of liquids. When the flow moves, obstacles can form in its path. Moreover, for the occurrence of water hammer, an obstacle must arise unexpectedly.When a barrier occurs, the fluid loses velocity, the gradient of which tends to zero.

When the volume of liquid stops, the force of the device that circulates water continues to act on it. Under the influence of the injection force, the hydraulic pressure of the liquid rises in the area. Pressure acts on the walls of pipelines, vessels.

With a sharp removal of the barrier to movement, the fluid rushes into the zone of least resistance and pressure. At the same time, it acquires tremendous speed due to the pressure difference at the high pressure point and in the free zone. The liquid moves at high speed, and due to its incompressibility, it can damage the elements and structures of the heating system. The force of the strike is often much greater than the force of a backhand blow with a hammer. Therefore, strong water hammer can destroy metal products and devices. In this case, the communications are depressurized and there is a risk of burns with hot water.

Water hammer theory

The occurrence of the phenomenon is possible only due to the lack of compensation for pressure drops. A jump in one place causes the force to spread along the entire length of the pipeline. If there is a weak point in the system, the material can be deformed or destroyed completely, a hole is formed in the system.

The effect was first discovered at the end of the 19th century by the Russian scientist N.E. Zhukovsky. He also derived a formula by which one should calculate the period of time required to close the tap in order to avoid unpleasant consequences. The formula looks like this: Dp = p(u0-u1), where:

- Dp is the pressure increase in N/m2;

- p is the liquid density in kg/m3;

- u0, u1 are the average indicators of the water velocity in the pipeline before and after the valves are closed.

To know how to prove water hammer in a water supply system, you need to know the diameter and material of the pipe, as well as the degree of compressibility of water. All calculations are carried out after establishing the water density parameter. It differs in the amount of dissolved salts. The determination of the rate of propagation of hydraulic shock is carried out according to the formula c = 2L/T, where:

- c is the designation of the shock wave velocity;

- L is the length of the pipeline;

- T is time.

The simplicity of the formula allows you to quickly identify the speed of impact propagation, which, in fact, is a wave with oscillations of a given frequency. And now about how to find out fluctuations per unit of time.

For this, the formula M = 2L / a is useful, where:

- M is the duration of the oscillation cycle;

- L is the length of the pipeline;

- a is the wave speed in m/s.

Simplifying all calculations will allow knowing the indicators of the shock wave velocity upon impact for pipes made of the most popular materials:

- steel = 900-1300 m/s;

- cast iron = 1000-1200 m/s;

- plastic = 300-500 m/s.

Now you need to substitute the values in the formula and calculate the frequency of the water hammer oscillations in the section of the water pipe of a given length. The theory of water hammer will help to quickly prove the occurrence of the phenomenon and prevent possible risks when planning the construction of a house or replacing a plumbing or heating system.

Threats of water hammer in the water supply

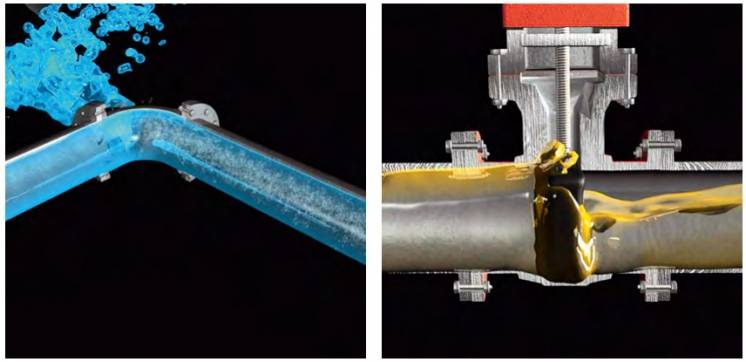

As we have already found out, the barrier created in the way of the movement of water forms a pressure that, from a theoretical point of view, has no limiting critical indicators. Simply put, a few tens of atmospheres can be converted into a more significant figure.Rigid elements of the system, threads, and the pipeline itself will eventually collapse (slowly or quickly) from the permanent effects of water inertia.

Note! More than others, it is long circuits that suffer from water hammer - for example, a water “warm floor”, through the pipes of which a heated liquid circulates. And to protect the system from impacts, the circuit under the floor covering is equipped with a special thermostatic valve. Tellingly, this device is able to save systems only if properly installed, in other cases it can even create an additional threat.

Tellingly, this device is able to save systems only if properly installed, in other cases it can even create an additional threat.

As soon as the thermostatic valve, which is on the liquid supply to the circuit, is closed, the water will continue to move under the action of inertia for some more time. As a result, a vacuum is formed in this area, although the difference in performance is very small - no more than one atmosphere. And in view of the fact that the circuit is calculated for all four atmospheres, there should be no problems. The valve at the outlet also blocks the movement of fluid. But when faced with such a barrier, the liquid will be backed up by the next portion and will begin to stretch, destroy the walls of the pipeline, having a pressure of more than ten atmospheres. But we digress a little, let's get back to the water supply.

How to make water heating with your own hands

We advise you to read our guide to self-installation and installation of water heating in the house. See all details here

The consequences of constant water hammer in the system can be the most unpredictable.The most common of these is breakthrough. And still nothing if such a breakthrough is formed on an accessible section of the highway, that is, in a place where there will be no difficulties with its elimination. But sometimes pipes are laid in the walls, and this, of course, adds a headache.

Be that as it may, even if only minor damage appeared in the water supply system due to water hammer, the cause of such an unpleasant incident must be found. After all, sooner or later it will lead to more serious consequences.

Basic Prevention Measures

In addition to strict adherence to all established operating rules, it is possible to prevent the occurrence of an accident if a number of preventive actions are carried out in a timely and regular manner. The whole reason is that in the main heating or water supply system, absolutely all processes are closely interconnected. A water hammer unexpected by the user is just the final destructive stage, which may well lead to various negative consequences. All this happens against the background of a relatively poor technical condition of pipes used for years.

The pressure drops and the resulting vibrations only contribute to the formation of various cracks in the thickness of the metal. Over time, more serious defects occur, which, after the onset of water hammer, instantly appear in areas of too high internal stress. These can be various places of bends, mechanical connections and even welds.

Preventive manipulations include the following steps:

- Timely check of the pressure behind the elastic membrane of the operating expansion vessel.If during this procedure the master finds unsatisfactory results, then it is forbidden to operate the system without a qualitative adjustment.

- Checking the health of the involved security groups. This applies to the air vent, safety valve, as well as the classic pressure gauge.

- Control of the position of the valves involved shut-off and control metal fittings.

- Periodically check the status of all filters. These elements are responsible for the retention of fine sand, classic scale, rust fragments. If necessary, the master needs to clean and then rinse the filters.

- Testing the system in use for leaks. You also need to check the degree of wear of all elements.

Many experts recommend replacing the classic rigid pipe with a plastic product. It is more flexible in application and is able to expand rapidly under pressure. But you need to be careful, since depressurization of the joints is not excluded.

A professional approach to prevention, which is aimed at the general maintenance of the optimal state of the heating and water heating system, necessarily includes elementary types of work. It is not recommended to ignore this step. This is due to the fact that the repair of heating in a private house entails a large expenditure of finances and free time. All the described protection measures will be effective if you approach the work comprehensively. Only in such a situation it is possible to neutralize various undesirable consequences and extend the period of coordinated operation of the system.

Installing a high quality backwash filter

Protection method "reconstruction"

thermostatic valves

In order to avoid water hammer, it is necessary to adhere to certain rules for the reconstruction of systems:

Replace the rigid pipe in front of the thermostat with a piece of pipe made of flexible plastic or reinforced heat-resistant rubber.

These materials tend to stretch, so they will independently reduce the energy of water hammer in the event of high pressure.

The shock absorber will require an elastic pipe about 20-30 cm long. If the pipeline is very long, then the shock absorber pipe must be taken another 10 cm longer.

Shunt with clearance up to 0.4 mm in thermostatic valve.

A narrow tube with a cross section from 0.2 mm to 0.4 mm is inserted into the thermostat from the side of the liquid movement. You can make a hole of a given diameter yourself. If the system is working normally, then the shunt does not affect its functioning in any way.

In the event that the pressure rises, it is able to smoothly reduce the volume in excess of the critical rate. Of course, this method can only be activated when you are well versed in the design of the thermostat. Otherwise, it is not recommended to take this case.

These devices have special springs that are located between the valve and the thermal head. The spring is released when the pressure rises. Thus, it does not allow the valve to close completely.

When the force of the water hammer decreases, the valve closes smoothly on its own

To correctly install thermostats with a safety device, you must pay attention to where the arrow on their body is pointing. It is necessary to mount strictly following the direction of the arrow.

Connection diagram for thermostatic valves

It is worth paying attention to the fact that not all models of thermostats have water hammer protection. You can find out if the device is equipped with this function by reading the technical documentation that comes with the product.

Protection method "centrifugal pumps"

Centrifugal pump

In order to smoothly start and stop the engineering system, it is necessary to use centrifugal pumps with automatic adjustment.

With the help of automation, there is a smooth increase in the speed of the electric motors of pumping equipment. In addition, the pressure in the pipes after start-up also rises systematically. The same mechanism of action is typical for the reverse order.

The pumps are programmed in such a way that they are able to independently observe pressure changes occurring in engineering networks. Pressure parameters are adjusted automatically.

The nature of the occurrence of water hammer is not so difficult to understand. The action occurs in two cases:

- When the rules for using communications are not followed;

- When networks are designed illiterately.

If you do not pay attention to clicks and unpleasant noise, then very unpleasant consequences await the household.

It would be much more reasonable to deal with the causes of noise effects and eliminate them than to subsequently repair the pipeline system that could not withstand the powerful pressure.

Avoiding water hammer - basic rules

People who are faced with water hammer and know firsthand about their detrimental effects are interested in: is it possible to avoid all this? There are several options at once, let's get acquainted with each of them.

- First of all, act carefully and gently.Do not close the ball valve abruptly, otherwise a blow will occur. To avoid its appearance, close the fittings smoothly, while not in a hurry. Take the time to spend a few extra seconds - this is not so much compared to the upcoming plumbing repair.

- To reduce this effect, you can slightly improve the system. As already noted, for this, hydraulic accumulators are installed (they are also called dampers), which accumulate water in the event of an increase in pressure in the circuit.

If shocks occur due to the stoppage of the pump, you can put a special valve for protection. Such devices operate exclusively upon impact and reduce the increasing pressure in the line. This valve is extremely reliable. It is installed next to the pump.

Automation is another possible solution to the problem. Thanks to special control units, activation and shutdown of the system will be extremely smooth. The pump will increase or decrease the pressure as needed, which reduces the risk of water hammer to almost zero.

Finally, if water hammer occurs due to improper planning of the entire system, then the only way out is to completely redo it.

Note! If the problems are not eliminated immediately after the appearance of shocks, then in any case, sooner or later, the system will still have to be redone. After all, if the situation repeats itself all the time, then all elements - including pipes - will soon fail.

After that, repairs will cost much more.

Pipes with increased protection against water hammer

An important point: among a number of the above methods of protection and prevention of water hammer, the technical characteristics of the pipeline system itself, such as the modulus of elasticity and wall thickness, are also of considerable relevance.

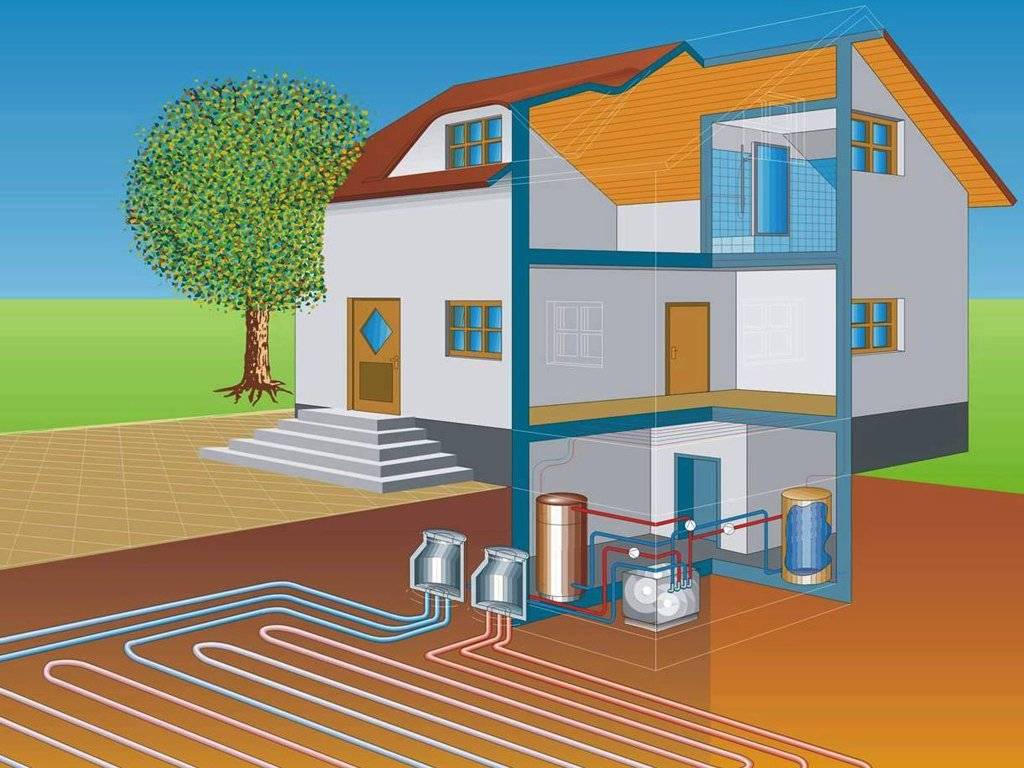

The low modulus of elasticity of aquatherm GmbH pipes, as well as the increased wall thickness (compared to metal pipes) ensures a higher resistance to the impulse pressure that occurs in a critical water hammer situation.

aquatherm green pipe

Polypropylene pipes made in Germany, wide range of applications.

The system is excellent for hot and cold water supply and heating systems, both in private and industrial scales. It is also used for transporting chemical media.

aquatherm blue pipe

Polypropylene pipes made in Germany, wide range of applications.

Piping system made of innovative fusiolen material, specially designed for refrigeration, surface heating, aggressive media and compressed air transport, as well as for geothermal energy systems.

Pressure reducer, safety valve, hydraulic shock absorber - what to put where?

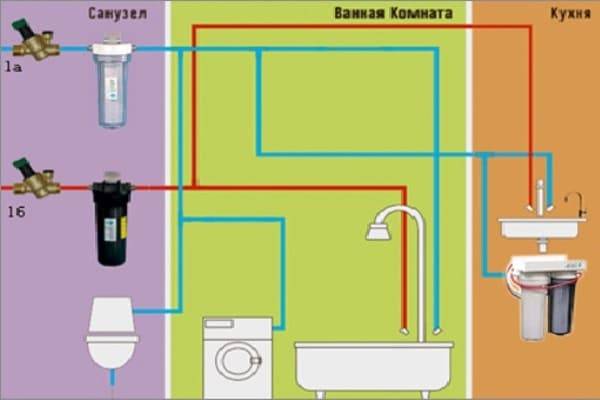

1. Pressure reducer Be sure to install, but as for its performance and damage, you should take care more about what flows in the pipes (see below for a water hammer absorber). For the gearbox, the purity of the working environment (water in the pipe) is more important. If you want the gearbox to serve you for a long time, then it is recommended to put a mechanical cleaning filter with a 100 micron mesh (for example, .) in front of you. I put the same self-cleaning filter with a Tiemme pressure gauge at home.

2. Water hammer dampener

Don't even bother.

If you have a flexible piping in your apartment, at least somewhere, then these hoses will work as water hammer dampers. For example, you have a one-handed faucet in your kitchen, and you close the water with a sharp jerk / blow of the lever, then a water hammer occurs. Then the flexible connection to the mixer (braided rubber hose) twitches from a sharp increase in water pressure. For other fittings, there are no special problems. Since at first the water hammer receives the eyeliner / hose, and everything in it goes out. After all, you are more likely to break the hose than the reducer or other fittings installed on the pipe. This problem is treated in an elementary way: by strict suggestion to lovers, abruptly close the mixer. In general, explain to family members that the taps must be closed smoothly, then there will be no water hammer. If the suggestion does not work, then you will have to be confused about installing a hard connection to the mixers (copper tubes or a corrugated stainless steel pipe). I prefer copper tubes (looks nicer and more reliable).

In general, if you want to install a hydraulic shock absorber, then install it. But don't bother adjusting. Leave the factory - 3.5 bar. Just adjust the reducers to 3.5 bar and that's it. For intra-apartment wiring, a pressure of 3.5 bar is enough for you.

3. Safety valve. This is exactly what you don't need in your apartment. See their characteristics and purpose (e.g. valve)): “Designed for installation on boilers, water heaters, pressure vessels, pipelines…”

The valve is not for the apartment. (For a house - yes, but not for an apartment) When the valve is triggered, an emergency discharge of water occurs (in the event of an increase in pressure in the system).Therefore, a connection to the sewer is required, naturally with a break in the jet, i.e. through a special siphon (or you need to put a bucket). In this case, two points must be taken into account: 1) A constant increase in pressure in the system will lead to a systematic operation of the valve. That is, water will drain through the valve constantly. And the bucket will no longer save, since the flow of water will pour without interruption. So splurge on the water. 2) If you install a reducer, then the pressure in the apartment after the reducer will be stable. The safety valve would then be redundant. And the only thing that can occur in the system is water hammer, but this is another problem and another solution (see above. Item 2)

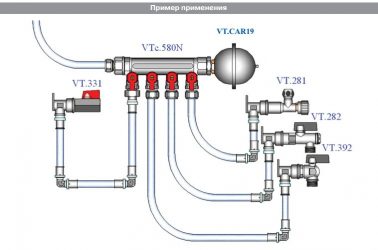

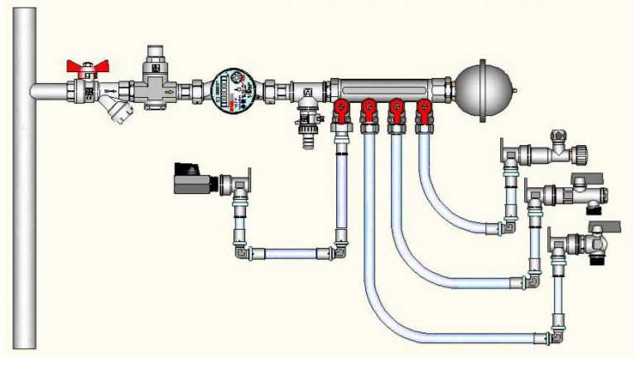

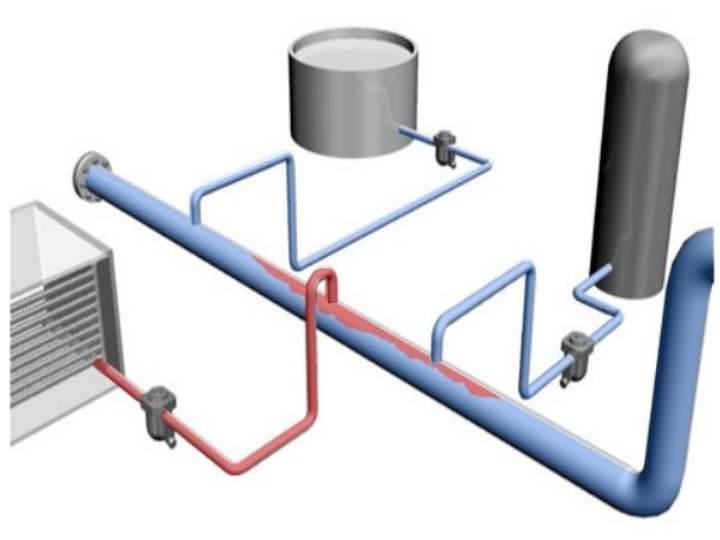

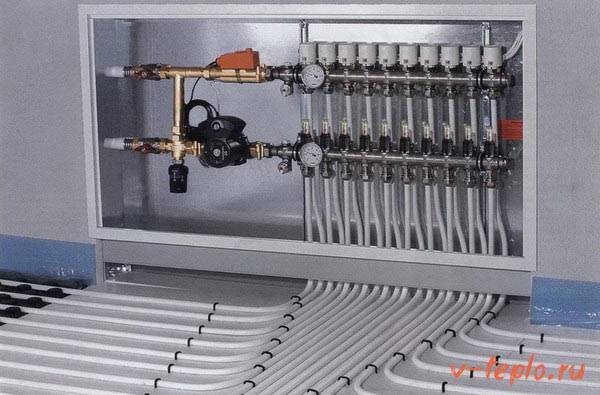

Installation scheme After the water meter, install a self-cleaning filter, then a gearbox. After that comes the collector, and at the end of the collector there is a hydraulic shock absorber.

Drops and their causes

Pressure surges indicate that the system is not working properly. Pressure loss calculation in the heating system is determined by the summation of losses at individual intervals, of which the entire cycle consists. Timely identification of the cause and its elimination can prevent more serious problems that lead to costly repairs.

If the pressure in the heating system drops, this may be due to such reasons:

- the appearance of a leak;

- failure of the expansion tank settings;

- failure of pumps;

- the appearance of microcracks in the boiler heat exchanger;

- power outage.

How to increase the pressure in the heating system?

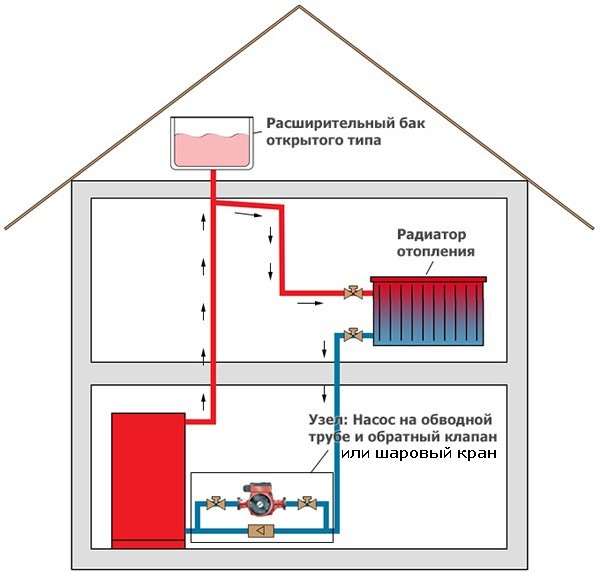

Expansion tank regulates pressure drops

In the event of a leak, check all connections. If the cause is not visually identified, it is necessary to examine each area separately.To do this, the valves of the cranes alternately overlap. The pressure gauges will show the change in pressure after cutting off one or another section. Having found a problematic connection, it must be tightened, previously additionally compacted. If necessary, the assembly or part of the pipe is replaced.

The expansion tank regulates the differences due to heating and cooling of the liquid. A sign of a tank malfunction or insufficient volume is an increase in pressure and a further decline.

To the result obtained, a gap of 1.25% should be added. The heated liquid, expanding, will force the air out of the tank through the valve in the air compartment. After the water cools, it will decrease in volume and the pressure in the system will be less than necessary. If the expansion tank is smaller than required, it must be replaced.

An increase in pressure can be caused by a damaged membrane or an incorrect setting of the pressure regulator of the heating system. If the diaphragm is damaged, the nipple must be replaced. It's fast and easy. To set up the tank, it must be disconnected from the system. Then pump the required amount of atmospheres into the air chamber with a pump and install it back.

You can determine the malfunction of the pump by turning it off. If nothing happens after shutdown, then the pump is not working. The reason may be a malfunction of its mechanisms or lack of power. You need to make sure that it is connected to the network.

If there are problems with the heat exchanger, then it must be replaced. During operation, microcracks may appear in the metal structure. It can't be fixed, only replaced.

Why does the pressure in the heating system increase?

The reasons for this phenomenon may be improper circulation of the fluid or its complete stop due to:

- the formation of an air lock;

- clogging of the pipeline or filters;

- operation of the heating pressure regulator;

- incessant feeding;

- blocking valves.

How to eliminate gaps?

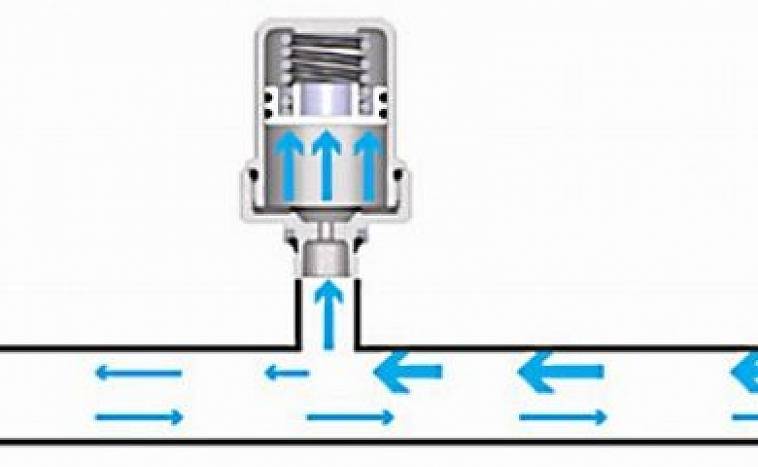

An airlock in the system does not allow fluid to pass through. Air can only be bled. To do this, during installation, it is necessary to provide for the installation of a pressure regulator for the heating system - a spring air vent. It works in automatic mode. Radiators of the new sample are equipped with similar elements. They are located at the top of the battery and work in manual mode.

Why does the pressure in the heating system increase when dirt and scale accumulate in the filters and on the pipe walls? Because the fluid flow is obstructed. The water filter can be cleaned by removing the filter element. Getting rid of scale and clogging in pipes is more difficult. In some cases, washing with special means helps. Sometimes the only way to fix the problem is to replace the pipe section.

The heating pressure regulator, in the event of an increase in temperature, closes the valves through which liquid enters the system. If this is unreasonable from a technical point of view, then the problem can be corrected by adjustment. If this procedure is not possible, replace the assembly. In the event of failure of the electronic control system of the make-up, it should be adjusted or replaced.

The notorious human factor has not yet been canceled. Therefore, in practice, shut-off valves overlap, which leads to increased pressure in the heating system.To normalize this indicator, you just need to open the valves.

Methods for a comprehensive system upgrade

A comprehensive modernization of the system involves the installation of equipment aimed at neutralizing the effects of overpressure.

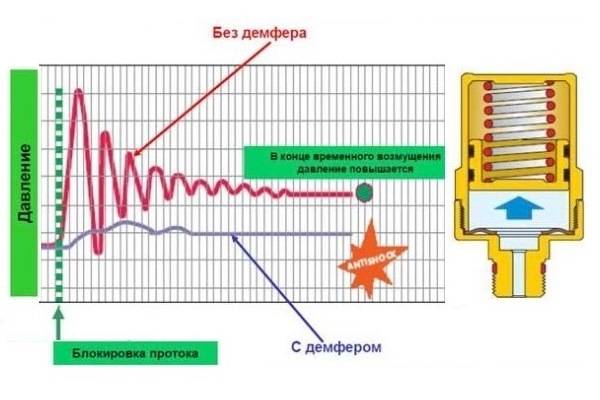

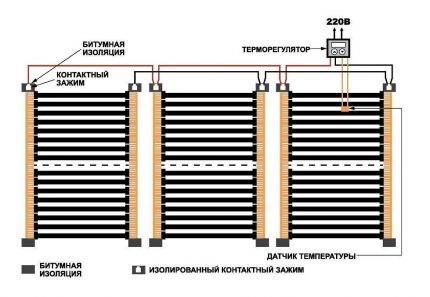

Method #1. The use of compensators and shock absorbers

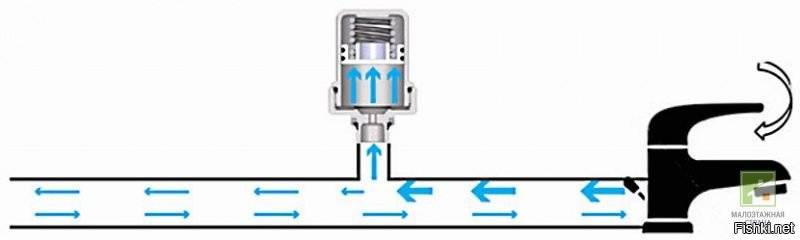

Extinguishers and hydraulic accumulators simultaneously perform three functions: they collect liquid, while eliminating its excess volume from the system, and also help prevent an undesirable phenomenon.

A compensating device, the role of which is played by a hydraulic accumulator, is installed in the direction of water movement at those intervals of the heating circuit where there is a high probability of pressure fluctuations in the system.

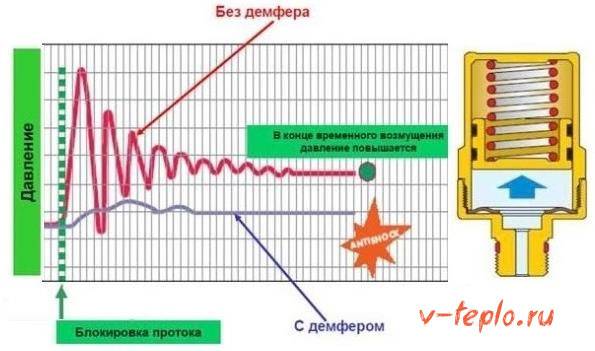

A hydraulic accumulator or damper is a steel flask with a volume of up to 30 liters, which includes two sections separated by a rubber or rubber membrane.

When overpressure occurs in the system, the water column of the first section begins to press on the isolating diaphragm, due to which it bends in the direction of the air chamber

When the pressure rises, the hydraulic shocks are “thrown off” into the reservoir. Due to the bending of the rubber membrane towards the air chamber at the moment of raising the water column, the effect of an artificial increase in the volume of the circuit is achieved.

Pipes made of heat-resistant reinforced rubber or elastic plastic are used as shock-absorbing devices.

The elastic material of the shock-absorbing devices spontaneously absorbs the energy of water hammer at the point where the pressure has reached a critical value

To achieve the desired effect, it is enough to use a product with a length of 20-30 cm.If the pipeline is longer, the shock absorber section is increased by another 10 cm.

Method #2. Installing a Diaphragm Type Safety Valve

A diaphragm-type safety valve is placed on the outlet of the pipeline near the pump in order to release a given amount of water at an excess of pressure.

The safety valve, equipped with a rigid seal that performs the function of a quick release of pressure, is a reliable fuse for an autonomous system

Depending on the manufacturer and model type, the safety valve is actuated by an electrical command from the controller or by a quick action pilot.

The device is activated when the pressure exceeds a safe level, protecting the pumping station in case of a sudden stop of the equipment. At the moment of a dangerous surge in pressure, it opens completely, and when it drops to a normal level, the regulator slowly closes.

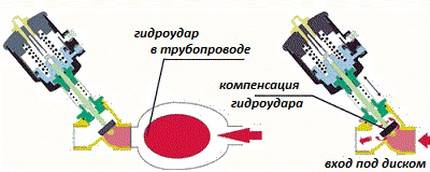

Method #3. Equipping the thermostatic valve with a shunt

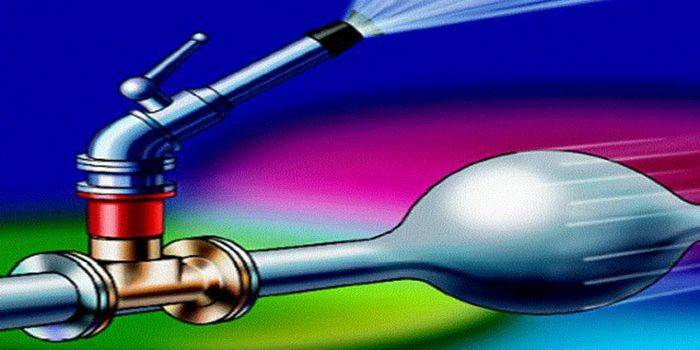

The shunt is a narrow tube with a clearance of 0.2-0.4 mm, which is installed in the direction of the coolant circulation. The main task of the element is to gradually reduce the pressure when overloads occur.

A narrow tube, the cross section range of which does not exceed 0.2-0.4 mm, is placed on the side from where the liquid enters the thermostat

The shunting method is used in the arrangement of autonomous systems, the pipeline of which is made only of new pipes. This is due to the fact that the presence of rust and sediment in old pipes can reduce the effectiveness of shunting to "no". For this reason, when using a shunt at the heating circuit inlet, it is recommended to install effective water filters.

Method #4.Using a thermostat with super protection

This is a kind of fuse that monitors the pressure in the system and does not allow it to work after the indicator reaches a critical level. The device is equipped with a spring mechanism placed between the thermal head and the valve. The spring mechanism is activated by excess pressure, preventing the valve from fully closing.

Such thermostats are installed strictly in the direction indicated on the body.