- How to hear and prevent a threat

- Technical means of protection

- Pipe replacement

- Replacing shutoff valves

- Mounting shock-absorbing elements

- The use of compensators

- Use of pumps with frequency converters

- Safety valves

- Video description

- Conclusion

- Water hammer protection

- Consequences of hydraulic shocks

- Causes of water hammer

- What is water hammer

- Causes of water hammer

- Consequences of water hammer

- What is a water hammer?

- Ways to prevent water hammer

- Smooth adjustment

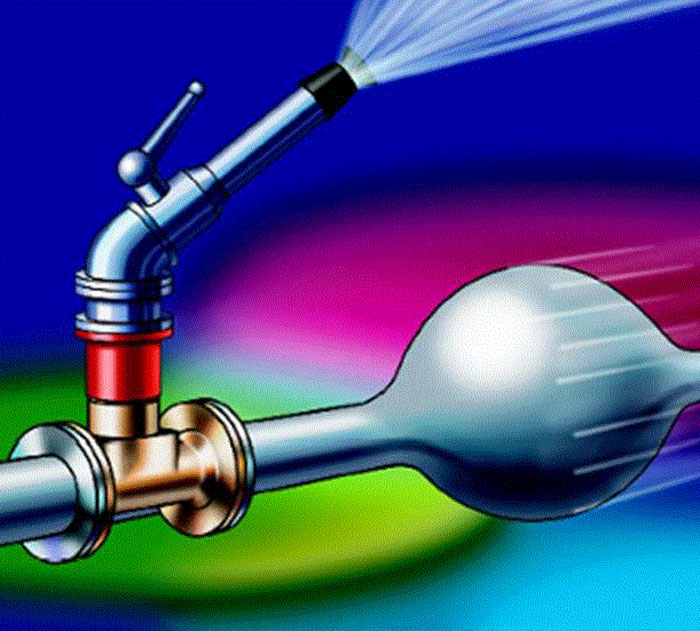

- Automatic protection

- Use of compensators

- Safety valve

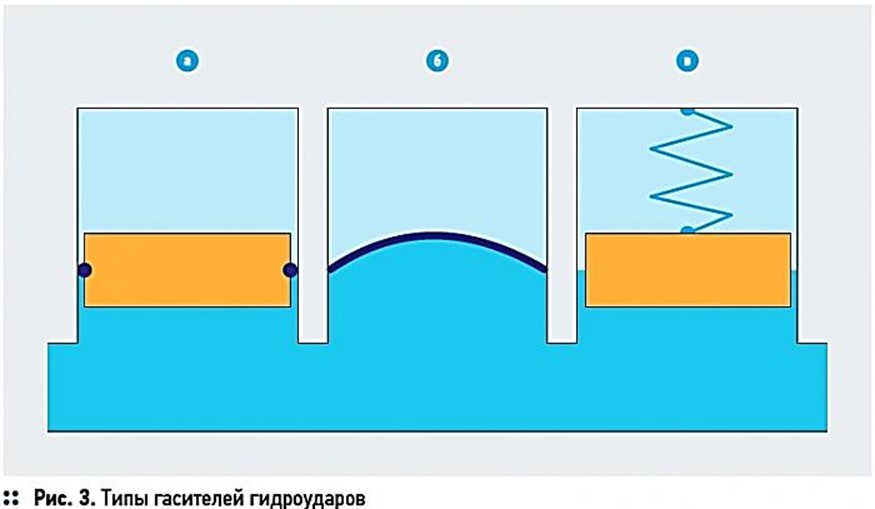

- shock absorbers

- Safety thermostat

- Bypass capability

- What is a water hammer in a pipeline, causes

- Consequences of hydrodynamic impact in the heating system of a private house

- Other ways to deal with water hammer

- Vulnerability of pipes during water hammer

How to hear and prevent a threat

In metal-plastic and polypropylene pipes there is a sound-proof layer. Excessive pressure inside the system - the struggle of water with an air lock, according to hearing, is more like a loud rumbling of a full cat or an irritated intestine. Metal and copper pipes amplify the sound, broadcasting it throughout the system.The farther from its source, the stronger and longer the grinding.

An open faucet can be considered the best way to relieve stress from the inner surface of the walls of the pipeline, if the cause of poor water permeability is an air lock formed during a sharp suspension of water supply. When exiting, the liquid will be saturated with air bubbles.

Attention! The more stopcocks in the system, the more reliable the protection. Shutting off the passage of liquid to the damaged area, and not along the entire length of the pipeline, reduces the risk zone for water hammer

Technical means of protection

The system should be protected as much as possible from rash human actions, improper operation and untimely and incomplete maintenance. To do this, there are a number of technical solutions to minimize the consequences of fluid pressure surges in water supply and heating networks and prevent their occurrence.

Pipe replacement

To do this, it is necessary to revise the entire pipeline, old steel pipes should be replaced with modern ones made of polymeric materials. They are more reliable, practically resistant to corrosion and last longer. In this case, the pipes must be selected taking into account the operating conditions (pressure and temperature in the network) with a small margin in terms of parameters. To reduce the flow rate, it is desirable to choose products with the largest diameter possible for pressure. Find the golden mean.

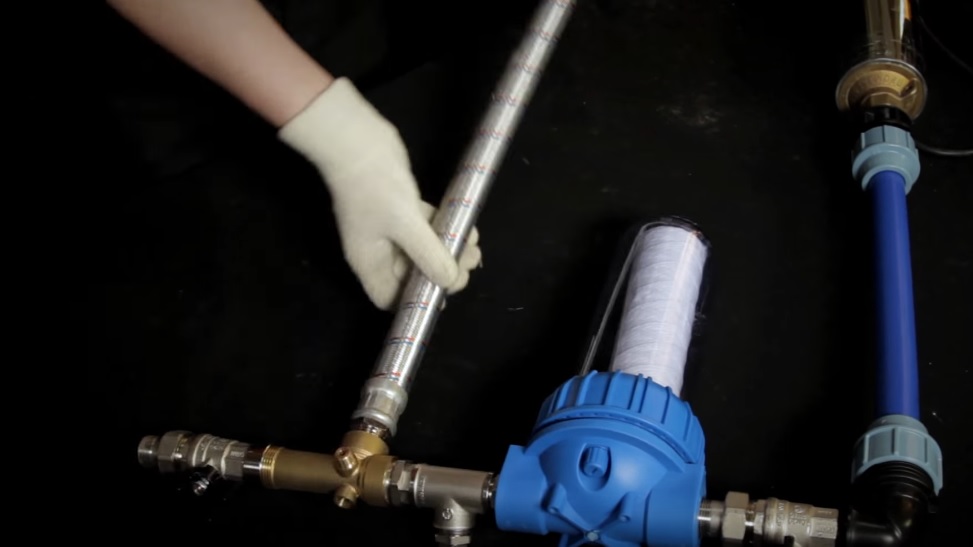

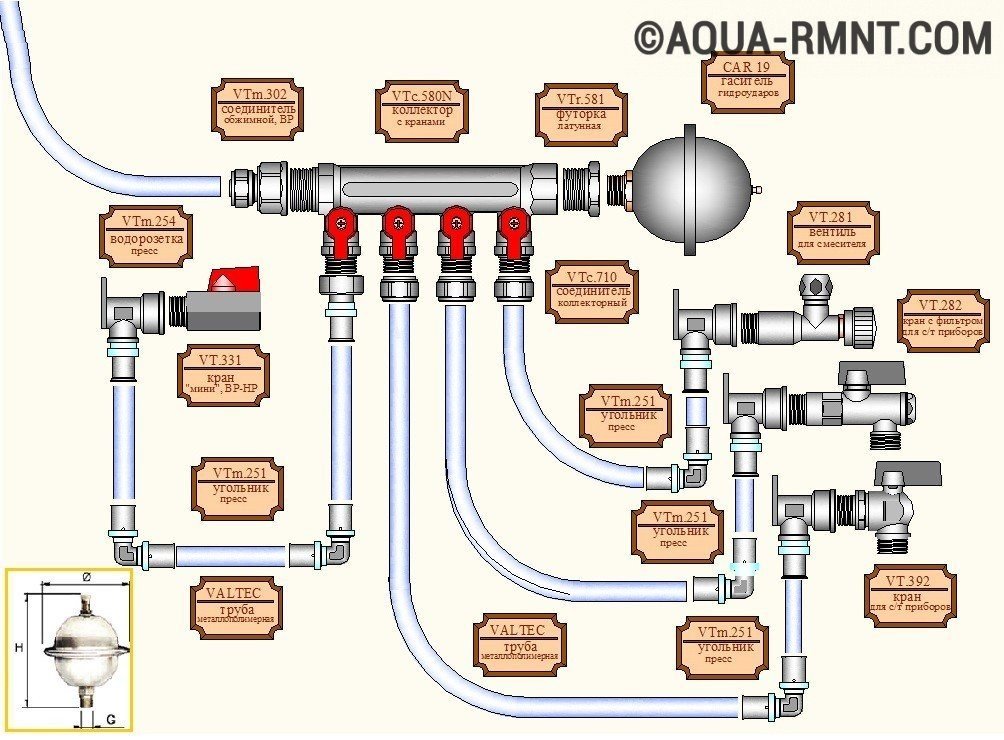

Modern reliable pipes and fittings made of polymeric materials

Replacing shutoff valves

Replacing ball valves with valve valves can be called a return to the past, but this will avoid sudden pressure drops, regardless of how the valves open and close.It is not necessary to change all the locking devices, you can limit yourself to only those that are critical to the system.

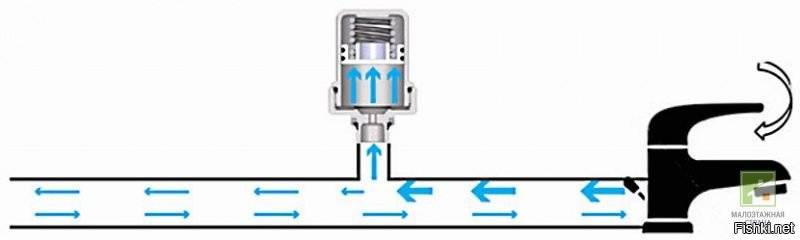

Mounting shock-absorbing elements

The use of reinforced plastic or rubber inserts that can expand or contract with pressure surges will reduce the deforming effects on the rest of the pipeline. The walls of shock absorbers, unlike rigid pipes, do not deform during compression or expansion and return to their original state, taking the main part of the impact of the liquid on themselves. For most systems, a section of 20 to 40 centimeters is sufficient.

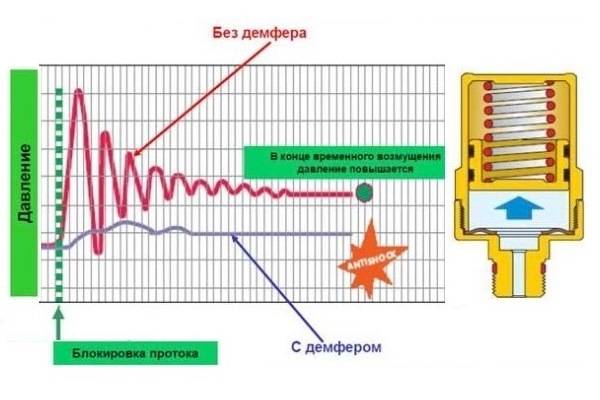

The use of compensators

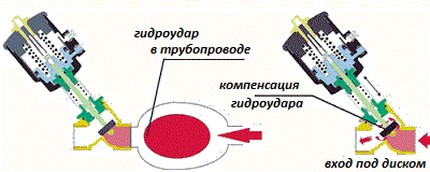

Compensators are cylindrical containers (an inverted glass) inside which there is a spring. One end of it rests against the upper fixed part of the inverted "glass", and the lower one - against a movable plastic disk. When the pressure in the system increases, the water presses on the disc, compressing the spring; when the pressure decreases, the elastic force of the spring compensates for the loss of pressure.

Local compensator (mechanical) of water hammer for water supply

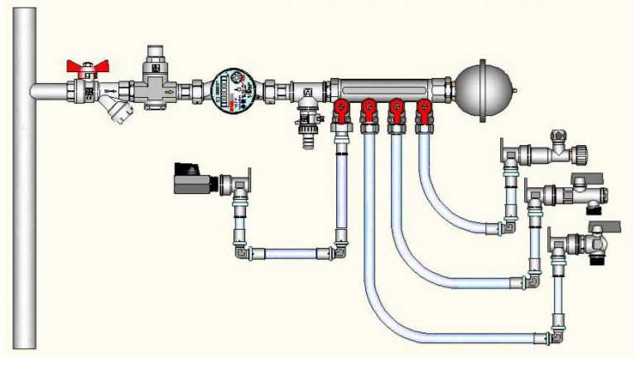

Compensating protection against water hammer in the water supply system is also carried out using hydraulic accumulators. This device is a tank of a certain volume divided into two parts (with water and air) by a rubber membrane. In case of excess pressure, it will be released into the tank by stretching the rubber membrane and reducing the volume of air inside the tank.

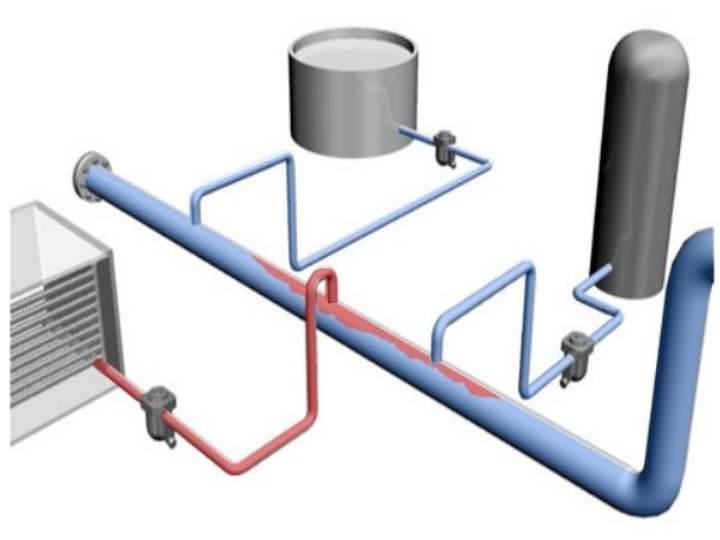

Use of pumps with frequency converters

Such pumping equipment, due to automation, allows for a smooth start and stop of the working bodies.This makes it possible to avoid a rapid increase in pressure, which is the cause of water hammer. The frequency converter regulates and sets the number of rotations of the pump wheel per unit time, by changing the frequency of the alternating current received from the electrical network. Adjustment is performed automatically depending on the value of the parameters transmitted by the sensors.

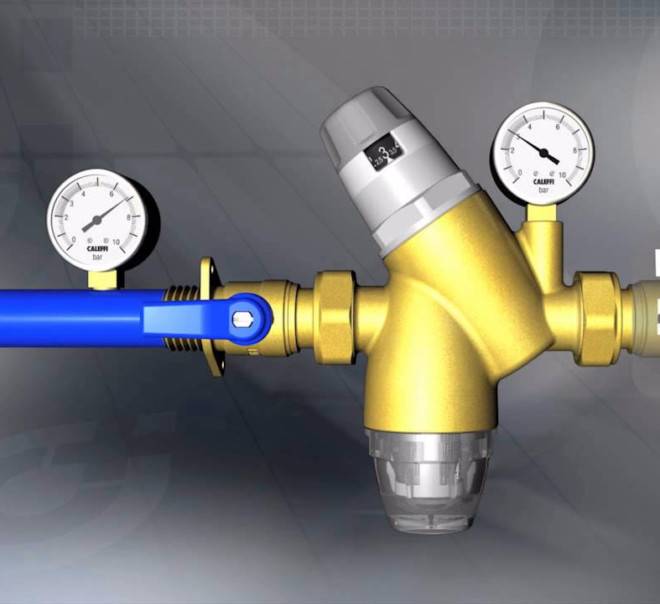

Safety valves

The principle of operation of these devices is quite simple. When the pressure values at the points of installation of the valves are higher than the critical parameters, the valves open and the liquid is discharged.

Main safety valve for pressure relief at critical values

They can be autonomous devices, which are opened by triggering mechanisms or electronic sensors, or be part of a system consisting of many sensors and valves controlled by a computer.

Video description

An example of protective equipment for damping water hammer in a water supply system, see the video:

Conclusion

Pressure surges or hydraulic shocks are a dangerous phenomenon inherent in the operation of plumbing or heating systems. Their number and negative impact can be minimized with the help of preventive measures and technical solutions. In order to comprehensively solve this problem, as much as possible to prevent the risks of danger to people and material damage, it is better to turn to professionals.

Source

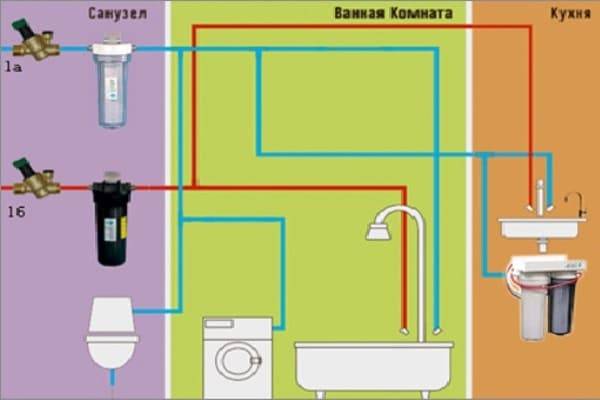

Water hammer protection

To protect the pipeline from water hammer, you need:

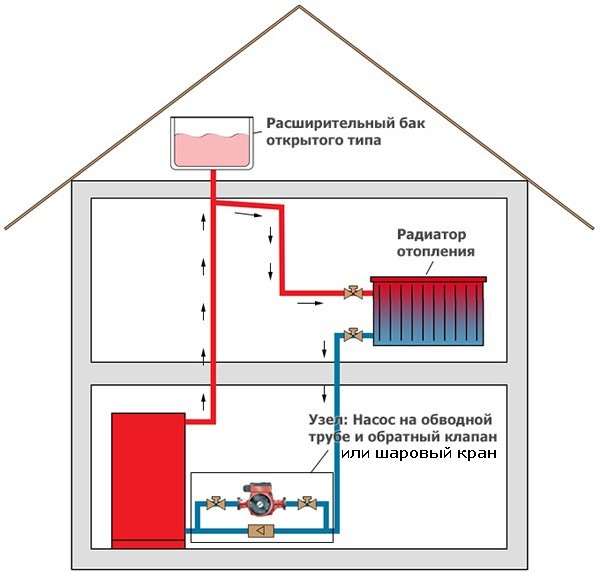

Smoothly open / close locking elements

When the valve is closed smoothly, the pressure in the pipeline will gradually equalize.In this case, the shock wave will have an insignificant force, and, consequently, the power of the hydraulic shock will be minimal. But not in all cases it is possible to ensure smooth closing of the tap.

Not all models have a valve design, many modern valves have a ball system - one careless sharp turn is enough and the valve will come to the “closed” position

Use large diameter pipes

In pipelines of large diameter, the working medium moves at a lower speed than in systems with a smaller diameter. And the lower the speed of movement of the fluid flow, the weaker the force of the water hammer. However, this method is much more costly. Costs increase due to the higher cost of pipes and thermal insulation.

Install shock absorber

This device is located in the direction of movement of the working fluid. As a shock absorber, a piece of pipe made of elastic plastic or rubber is used, which replaces a part of a rigid pipe in front of the thermostat. When a hydraulic shock occurs, the elastic segment is stretched and the impact force is partially damped.

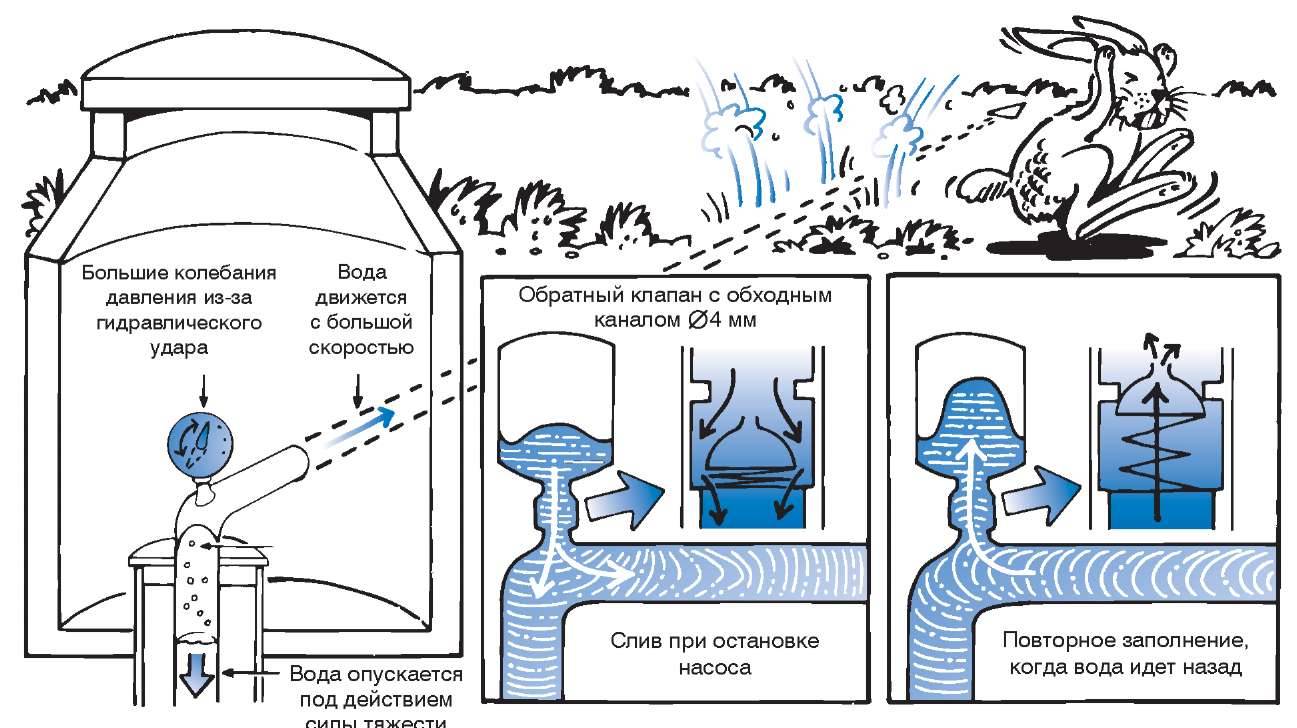

Use compensatory equipment

A hydraulic accumulator is used to dump excess fluid until the pressure in the pipeline normalizes. This equipment is made in the form of a sealed tank, equipped with a membrane and an air valve. The membrane is made of elastic material, the tank is made of steel.

Use pump automation

One of the reasons for the appearance of hydraulic shocks in the pipeline is pumping equipment. The movement of the working medium depends on how fast the pump shafts rotate.Therefore, a smooth decrease/increase in the rotation speed makes it possible to reduce the impact force and reduce the risk of water hammer.

In production, special regulators, frequency converters and other similar devices are used to control pumping equipment. This equipment is also suitable for domestic use.

Water hammer in communications appear when pumping equipment stops, for example, when the power supply fails. In production and public utilities, reserve sources have been used for a long time and have proven their effectiveness more than once. Prevention of emergencies and reduction of repair costs lead to significant cost savings. Turning on home pumping equipment through a water hammer protection device (stabilizers and backup power supplies) will help secure internal communication systems.

The bypass is an additional section of the pipeline, which is used as a bypass channel and serves to regulate the throughput of the heating network. Such devices can be mounted both in new systems and in existing ones.

This is a simple but effective invention that works on the principle of an expansion tank for heating communications. With a sharp pressure drop, the liquid moves into the membrane damper. After the pressure in the pipeline drops to the working value, the liquid will be pushed back into the system. The return of water is ensured by the excess pressure of the air located on the opposite side of the membrane.

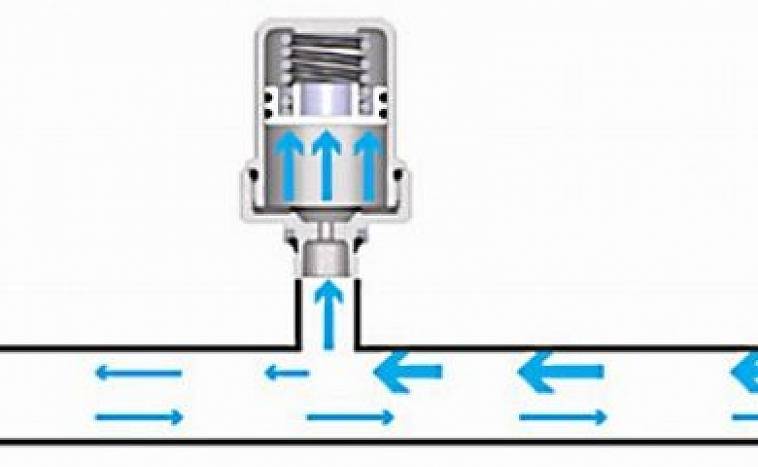

The water hammer protection valve is located in the piping system next to the sediment. It responds to pressure surges by accepting a reverse wave and preventing water hammer. The valve is equipped with a special regulator, which smoothly opens it when the pressure drops. Thus, when the return flow of the working medium reaches the pump unit, the valve is already in the open state. As a result of this, water is discharged, and consequently, the pressure is reduced to an acceptable value. After normalizing the pressure, the regulator closes the valve to prevent the system from emptying.

Consequences of hydraulic shocks

Any incidents with a water supply system are associated not only with material damage to itself, but also with the costs of eliminating the consequences of water exposure to nearby objects. Especially, this is aggravated for pipelines with hot water and under high pressure. In these situations, there is even a danger to the health and life of people and pets. They may be scalded or injured. In particular, this negative phenomenon may be followed by the following:

- destruction of pipe wiring;

- flooding of residential, administrative and utility premises;

- failure of pumping equipment and valves;

- damage to furniture, household appliances, computers and the like;

- interruption of water supply;

- destruction of structures of buildings and structures (especially in winter, due to the force of expansion during freezing of moisture);

- interruption of electrical supply;

- fires due to electrical short circuits.

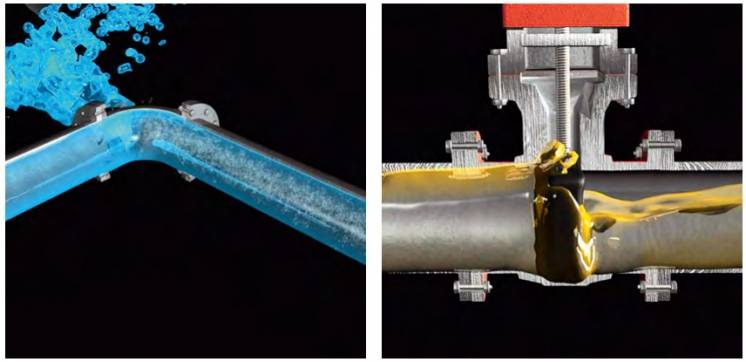

Danger of consequences of damage to heating and water supply due to water hammer

Accidents on the main networks can cause traffic congestion, in winter, ice caused by gusts usually completely blocks the movement of cars for a while.

Causes of water hammer

The physical nature of this phenomenon lies in the complete loss or a significant decrease in the throughput of water pipes, as a result of which the fluid pressure in the system increases.

In houses where engineering communications were illiterately designed and equipped, one can often hear characteristic tapping and clicking in the pipeline.

They are an external manifestation of water hammer and occur when the fluid circulation suddenly stops in a closed system, and then its movement also suddenly resumes.

Air plugs, adapters from a larger diameter to a smaller one, or installed shutoff valves often act as natural pipeline obstacles.

If an obstacle arises in the path of a water flow moving at a certain speed, its speed of movement slows down, and the volume continues to increase. Finding no way out, it forms a reverse wave, which, colliding with the main water mass, increases the pressure in the system. Sometimes it can reach a threshold of 20 atm.

Due to the tightness of the highway, the accumulated volume has nowhere to go, but powerful energy still seeks to find a way out into the external environment. The impact force resulting from such a collision creates the danger of rupture of the pipe, which does not have an adequate margin of safety.

For this reason, for the arrangement of the system, it is necessary to use seamless water and gas pipes adapted for water networks that comply with GOST 3262-75, or pressure metal-plastic analogues manufactured in accordance with GOST 18599.

From the permanent impact of water energy, both the pipeline itself and the rigid elements of the system will gradually or quickly begin to collapse

The main factors provoking the occurrence of water hammer in pipes are:

- interruptions in operation or failure of the circulation pump;

- the presence of air in the closed circuit of the system;

- power outages;

- in case of sudden closing of the shutoff valves.

A short-term increase in pressure in a closed circuit due to fluid injection above the prescribed norm may occur if, when the pump is turned on, the impeller starts its movement at high speeds.

Lately at arrangement of an autonomous heating system instead of old valves and gate valves, ball valves are increasingly being used, the device of which does not provide for a smooth ride.

Their ability to have a fast-acting effect has a downside, being one of the most common causes of water hammer.

If no air is bled from the system when the system is started up, when the ball valve is opened, air collides with a practically incompressible fluid.

In terms of safety, screw valves are more preferable, because due to the phased unwinding of the axle boxes, they provide a smooth opening / closing of the valves.

A similar situation also occurs when air is not bled from the circuit before starting the system.At the moment the tap is opened, the water collides with an air plug, which, in a closed system, acts as a kind of pneumatic shock absorber.

What is water hammer

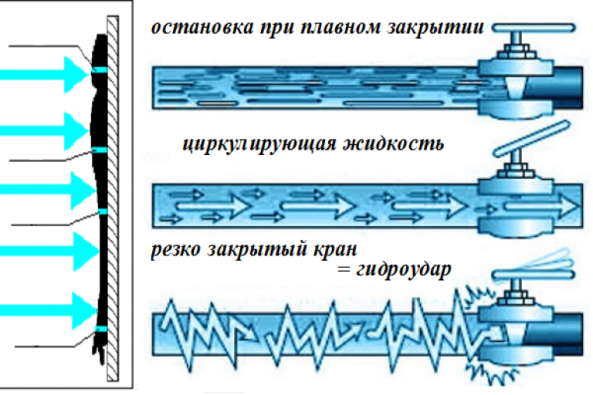

Water hammer (water hammer) is a short-term, but sharp and strong increase (decrease) in pressure in the pipeline (in the water supply system) during sudden braking (acceleration) of the fluid flow moving through it.

Water hammer in the water supply system

In simple words, water hammer is a sharp jump in pressure in pipes.

Water hammer happens:

- Positive - when the pressure in the pipeline rises very sharply. This can happen when a tap (valve, valve) is quickly closed or a pump is turned on.

- Negative - when, on the contrary, there is a decrease in pressure in the water supply system, due to the fact that the tap was opened or the circulation pump was turned off.

The greatest danger to the water supply is a positive water hammer. Let's say you turn on the faucet and wash the dishes. Finished washing, you do not need water, turned off the tap.

In this case, the following happens in the water supply. The water flow for some time, by inertia, flows at the same speed. Then it collides with an obstacle (the crane was closed, after all). And "hitting" on this barrier, a reverse wave is formed. And since the entire water supply system is sealed. This reverse wave collides with the water flow going to the meeting. The result is water hammer.

The very first signs of a water hammer are thuds and clicks heard when the tap is opened or closed. The appearance of smudges at the junction of water pipes or leaking taps.

Causes of water hammer

The main reason for the occurrence of water hammer in the water supply system:

- Sharp overlapping of shut-off valves (faucets, valves, gate valves.

- Breakdown or shutdown of the circulation pump, pumping station.

- Air locks in the plumbing system.

- Differences in the cross-section of water pipes.

Basically, water hammer occurs when a shut-off valve closes abruptly. Water passes through pipes at constant pressure, but when there is a sharp shutdown of the water flow. The water pressure on the pipe walls increases several times.

And as a result, pipes may burst or seals of threaded joints and locking elements will become unusable.

Crack in the pipe - after a water hammer

Of course, a sharply closed tap is not the only cause of water hammer. A similar situation occurs when air remains in the system. The moment the faucet opens, the water collides with the plug of air.

And this air plug in a confined space acts as a shock absorber. As a result, it pushes water out with great force and an impact occurs.

Also, the appearance of water hammer can provoke pipes of different diameters. Pressure drops, if the pipes are not reduced to a common denominator, are guaranteed

Consequences of water hammer

Pressure above the permissible norm is critical for pipes and their connections. Shutoff valves can also fail.

From the first water hammer, damage to the water supply usually does not occur. After all, products for water supply are made with a margin, in case of pressure increase. But subsequent water hammers will hit the same weak spot. And at some point, the pipe or valves will fail.

If a water pipe break occurs in an apartment building, then flooding will occur, the property of your apartment and neighbors from below will be damaged.

The consequences of water hammer - flooded the apartment

In the event of damage to the central water supply, shutdowns of several houses or an area may occur. That is already a state of emergency. Since residents of apartment buildings will be left not only without drinking water, but also without sewage.

Well, if as a result of a water hammer a hot water pipe is damaged. This could result in serious burns.

What is a water hammer?

Water hammer is a short-term but significant pressure surge in a fluid-filled system. This phenomenon occurs at the moment of collision of a fluid flow with an obstacle that has arisen in its path. Typical examples of the occurrence of such barriers include a sharp overlap of valves, a sudden stop of the pump, an air lock, etc.

Faced with an obstacle, the flow of water by inertia continues to flow at the same speed with which it moved before the appearance of the obstacle. The first layers in contact with the obstacle are compacted at the same speed due to the arrival of the following layers.

Due to the constant injection of new layers of flow, the pressure is rapidly increasing, and the liquid is “looking” for a way to dump its part in order to discharge it.

A similar situation almost always occurs when the flow is interrupted by a ball valve or gate valve. At first glance, the phenomenon may seem harmless. That is why many owners do not give it much attention.

But in fact, if the prerequisites for an emerging defect in pipes and fittings are found, it should be eliminated as soon as possible.Indeed, due to water hammer, splits and cracks appear in the heating system, as well as damage to equipment.

This serious problem may be preceded by clicks and knocks, as well as extraneous noise in the water supply pipes, accompanied by a characteristic "growl".

Clicking mainly occurs in those places where pipes of a larger size are connected to nozzles of a smaller section. The water passing along their inner walls encounters an obstacle, albeit inferior, but still.

The regular occurrence of water hammer adversely affects the operation of the system, significantly reducing its service life.

In the event of an emergency, the following may suffer from the effect of water hammer:

- equipment (tightness of pipelines is broken and heating devices are destroyed);

- property (water flowing from a damaged network will flood the housing and lead to damage to furniture);

- households (if a violation occurred in the heating system, there is a danger of serious thermal burns).

According to statistics, the "lion's share" of pipeline accidents, which is about 60%, occurs due to water hammer. More often, the negative consequences of this effect can be observed in worn-out pipes covered with corrosion.

The consequences of regular hydrodynamic shocks can be unpredictable, and the most common among them is a breakthrough

It delivers the most trouble to extended pipelines, for example, when arranging a “warm floor”, along the contours of which a liquid heated to a certain temperature circulates.

The degree of damage largely depends on the location of the obstruction: if it is at the beginning of a long pipeline, the magnitude of the increased pressure will be insignificant, but if at the end, it will be much higher.

Most often, the effect manifests itself when pipes of different diameters were used when laying the heating system. If "different-sized" pipes with the help of adapters are not brought to a common "denominator", an increase in pressure in the heating system is inevitable. In this situation, to protect the system, the circuit is equipped with a special valve - a thermostat.

Ways to prevent water hammer

It is practically impossible to get rid of the periodic appearance of excess pressure in the pipeline, therefore the main measures are aimed at reducing its intensity and creating effective protection for pipes and other elements of the system.

3 id="plavnaya-regulirovka">Smooth adjustment

The easiest and cheapest way to prevent hydrodynamic shock is to use a stepless control. This recommendation is spelled out in the regulatory documentation for the operation of facilities served by centralized water and heat supply.

This principle can be used not only in apartment buildings, but also in the private sector, where autonomous heating systems are usually used. Due to the smooth use of shut-off valves, a sudden increase in pressure does not occur: this process, as it were, stretches over time. As a result, while maintaining the total impact force, a decrease in its power is achieved.

It is most convenient to implement a similar method with taps with a gradual blocking of the flow.

Automatic protection

It is not always possible to achieve gradual correction of internal pressure manually.More convenient and reliable in operation are automatic water hammer dampers, which are installed on pumps in forced systems.

Automation makes it possible to smoothly increase the engine speed when turned on, and when turned off - just as smoothly reduce it. Thus, the internal pressure reaches its maximum not immediately, but after some time. At the same time, along with monitoring the pressure indicators, the electronics independently regulates the pressure.

Use of compensators

The task of the hydraulic compensator (it is also called a damper and a hydraulic accumulator) is to accumulate liquid and absorb its excess from the circuit, which helps to reduce the level of internal pressure. As a result, this allows you to extinguish the resulting water hammer.

The design of the compensator consists of a sealed steel tank, an elastic rubber membrane and an air valve built into it. The place of its installation is the sections of the heating circuit with the highest probability of pressure surges.

Safety valve

The place of installation of the protective valve with a diaphragm is a section of the pipe in the immediate vicinity of the pump, immediately after the return fuse (this allows you to bleed the required volume of liquid in case of excess pressure). In various models of devices, their activation can be carried out either by an electrical controller or by a pilot quick-acting device.

The valve is activated when the pressure exceeds the safe limit, which provides reliable protection of the circulation pump in case of its abrupt stop. When the dangerous internal voltage reaches its maximum, the fixture opens 100%.After the normalization of the situation, the regulator gradually closes. In this way, water hammer is avoided and a stable fluid circulation rate in the system is ensured.

shock absorbers

Another effective method of protecting water pipes is the use of shock-absorbing water hammer compensators.

Most often we are talking about plastic or heat-resistant rubber pipes. Their location must coincide with the direction of movement of the coolant (the thermostat is located immediately behind such a pipe). Due to the elasticity, the product is able to independently remove the energy of water hammer. On average, the length of the shock-absorbing section is taken in the range of 20-30 cm. For very long circuits, the length of the reinforced rubber pipe can be increased to 40 cm.

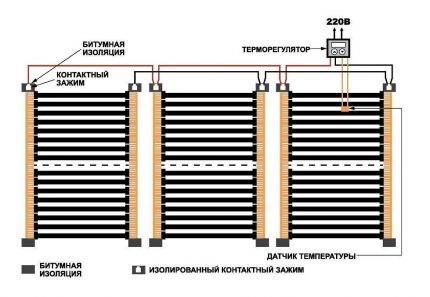

Safety thermostat

In some situations, a thermostat equipped with special protection against power surges helps to avoid water hammer.

Inside the device there is a spring filling that separates the valve and the thermal head. During a pressure surge, the triggered mechanism prevents the valve from closing completely. As the power of the water hammer decreases, the outlet hole gradually closes.

When installing a safety thermostat, it is important not to confuse the arrow on the body and the direction of movement of the liquid medium in the pipe

Bypass capability

You can also make a protective thermostat yourself by equipping the thermostatic valve with a special shunt. We are talking about a thin tube with a diameter of 0.2-0.4 mm or a hole of a similar section. If the system is not overloaded, the thermostat will operate normally.In the event of the appearance of internal stress, it will be smoothly removed.

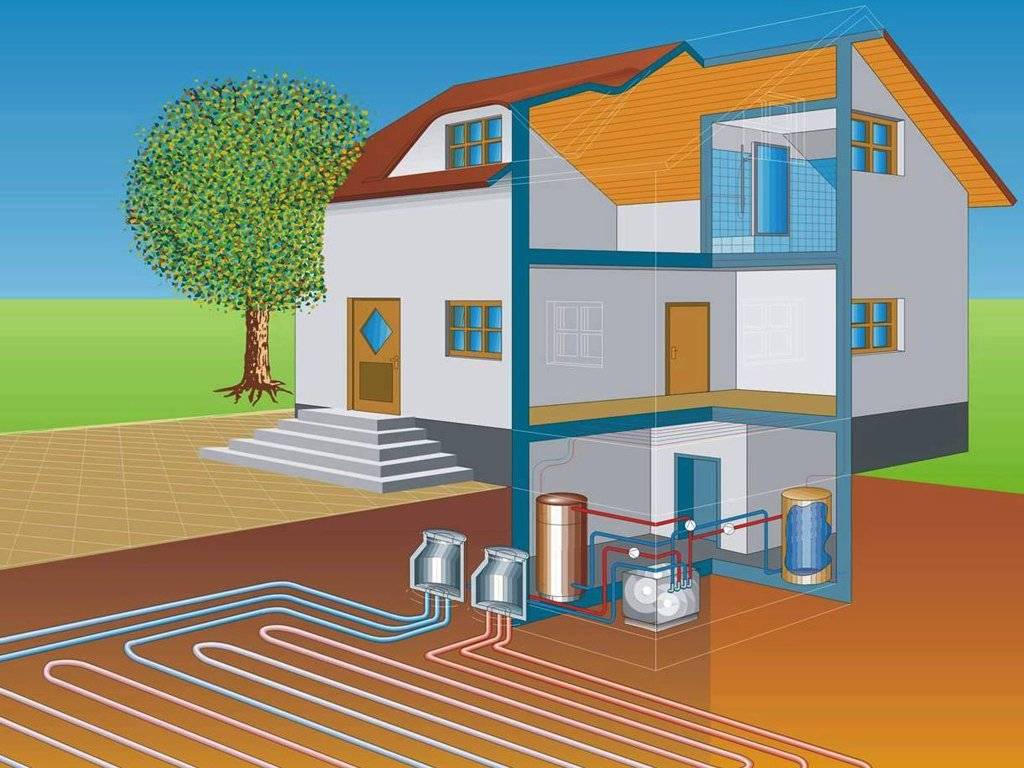

What is a water hammer in a pipeline, causes

If we talk about our houses and apartments, water hammer occurs in heating and water supply systems. In heating systems of private houses - when starting or stopping the circulation pump. Yes, by itself it does not create pressure. But a sharp acceleration or stop of the coolant is the load that acts on the walls of the pipes and nearby devices. In closed heating systems, there is an expansion tank. It compensates for water hammer if the pump is nearby. In this case, additional devices may not be needed. You can check the need to install a compensator using a pressure gauge. If the arrow does not move, or moves only slightly, everything is fine.

The most common cause of water hammer is a sudden shutdown of a tap.

In centralized heating systems, water hammer occurs when the damper closes abruptly, when taps are quickly opened to fill the system after repair / maintenance. According to the rules, this should be done slowly and gradually, but in practice it happens otherwise ...

In water supply, water hammer occurs even when a tap or other shut-off valve is abruptly closed. More pronounced "effects" are obtained in air-to-air systems. When moving, water hits air pockets, which creates additional shock loads. We may hear clicks or crackles. And if the water supply is separated by plastic pipes, during operation you can notice how these pipes shake. This is how they react to water hammer. You have probably noticed how the hose in the metal braid twitches. The reason is the same - pressure surges.Sooner or later, they will either cause the pipe to burst at its weakest point, or the connection to leak (which is more likely and more common).

Water hammer can cause serious damage

Why hasn't this been seen before? Because now most of the valves have a ball valve and the flow is blocked / opened very abruptly. Previously, the taps were of the valve type and the damper was lowered slowly and gradually.

How to deal with water hammer in heating and water supply? You can, of course, teach the inhabitants of an apartment or house not to turn the taps sharply. But you can’t teach a washing machine or dishwasher to respect pipes. And the circulation pump will not slow down in the process of starting and stopping. Therefore, water hammer compensators are added to the heating or water supply system. They are also called absorbers, shock absorbers.

Consequences of hydrodynamic impact in the heating system of a private house

Instantaneously increasing pressure acts on the heating elements.

Rigid structures are not capable of rapid stretching and experience enormous tensile loads.

The constantly increasing pressure of the liquid destroys all types of joints, affects the seams of heating devices.

Critical will be damage to long pipelines, underfloor heating (read about collector groups with a pump here), risers.

An indirect consequence will be the need for repairs.

This applies to hidden communications:

- behind wall panels

- in the underground space

- in a cement screed.

Such situations can be avoided by reducing the force or by neutralizing the effect of the liquid impact.

Other ways to deal with water hammer

One of the possible options for neutralizing the water hammer has already been voiced - close the taps smoothly.But this is not a panacea, and it is inconvenient in our fast-paced time. And there is also household appliances, you can’t teach them. Although, some manufacturers take this moment into account, and the latest models are made with a valve that smoothly shuts off the water. That's why compensators and neutralizers are becoming so popular.

Water hammer compensator - a small device (comparison with a brass ball valve)

You can deal with water hammer in other ways:

- When distributing or reconstructing a water supply or heating system, insert a piece of an elastic pipe in front of the source of water hammer. It is reinforced heat resistant rubber or PPS plastic. The length of the elastic insert is 20-40 cm. The longer the pipe, the longer the insert.

- Purchase of household appliances and shut-off and control valves with a smooth valve stroke. If we talk about heating, there are often problems with a warm water floor. Not all servomotors run smoothly when the flow is closed. The way out is to install thermostats / thermostats with a smooth piston stroke.

- Use pumps with soft start and stop.

This is how water hammer protection devices look in heating and water supply systems

Water hammer is a really dangerous thing for a closed system. He breaks radiators, breaks pipes. To avoid problems, it is better to think over control measures in advance. If everything is already working, but there are problems, it is wiser and easiest to install compensators. Yes, they are not cheap, but repairs will cost more.

Vulnerability of pipes during water hammer

A faucet not opened in time or a pressure pump not turned off in an emergency is a prerequisite for the fact that water will find and expand the hole. Each type of pipe has its weak points.

- Seamless metal is more likely to be damaged at bends, the steeper the angle, the greater the risk.

- Seams on rolled metal products are not designed for pressure exceeding what is indicated on the marking.

- In metal-plastic water pipes, risk zones are located at the joints with fittings - tees, stopcocks and corner joints.

- Polypropylene ones are more stable due to the larger diameter and soldered corners, but the risk zones are the same as in the metal-plastic water supply system.

Pipes with an internal diameter of less than 10 mm are most susceptible to damage during water hammer.

The weak point of welded stainless steel systems is the edges of the elements to be joined, which were affected by the plasma. The deterioration of the technical data of the metal is a more powerful argument in refusing to use stainless steel in the installation of an autonomous water supply system than the high cost of the material. Iridescent stains, attributed by professionals to tint colors, do not always indicate overheating of the steel. Emerging oxides are of great danger. In places where they are released, even stainless steel corrodes.