- Hydropneumatic flushing and pressure testing of the heating system

- Why is hydrotesting necessary?

- Methods for cleaning radiators

- Method of chemical cleaning of heating systems

- Cleaning heating systems with hydraulic pneumatics

- What is flushing and pressing

- What is flushing and pressure testing of the heating system

- flushing

- Crimping

- Hydroflushing, how and why

- Training

- Method for cleaning the heating system

- Signs of air pockets

- Ventilation of heating circuits

- Features of aluminum radiators

- Test tools

- Is this compression necessary?

- Rules and procedure for carrying out different types of washing

- Hydropneumatic Flushing Technology

- Chemical Flushing: An Alternative to Overhaul

- Pneumohydropulse flushing is an effective hardware method

- Instructions for flushing the heating system

- Washing by hydropneumatic method

- Chemical flush

- Crimping stages

- Washing equipment

- Is it possible to flush a separate battery?

Hydropneumatic flushing and pressure testing of the heating system

Heating devices in a residential building are a complex structure connected to an autonomous or centralized network.Long-term and uninterrupted operation of engineering equipment depends on the rules of operation. If the conditions of use are not observed, the devices begin to clog, the quality of space heating decreases. To prevent breakdowns and for preventive purposes, mandatory hydropneumatic flushing and pressure testing of the heating system is required.

The Importance of Regular Maintenance

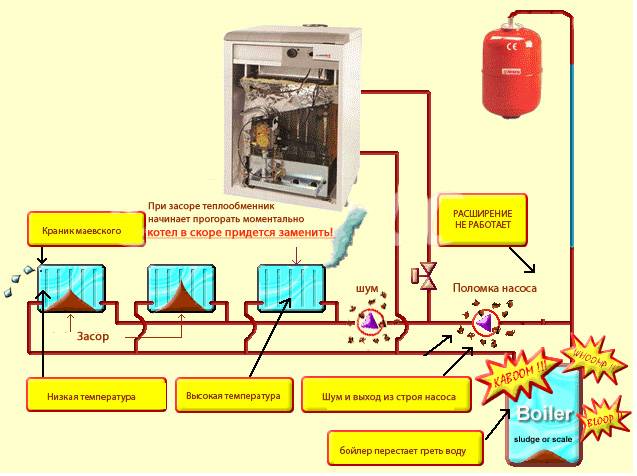

The accumulation of scale in pipelines not only reduces the efficiency of work, but can also lead to an emergency. The smallest amount of deposits, 1 mm thick, reduces the level of heat transfer in an apartment building by 20%. The precipitate is a specific insulator that holds energy. Layers can affect the internal surfaces of pipes and heating devices, causing corrosion processes and the formation of fistulas.

To improve the quality of equipment operation, it is important to carry out hydropneumatic and hydraulic flushing with a certain frequency, at least once a year.

To determine the status, diagnostics are carried out. In apartment buildings, when replacing sections of a centralized network, scale and rust enter the pipeline, which is deposited in the devices. If the analysis is carried out independently, the following indicators can be included among the obvious signs:

- Whistling, gurgling and other sounds coming from appliances.

- Long period of time for heating.

- Hot state of pipes with cold batteries.

- Increased energy consumption.

- Cleaning is also necessary when replacing the boiler.

When flushing internal heating systems by the hydropneumatic method, carried out by specialized organizations, a special procedure is noted.The equipment is examined with an assessment of the technical condition. Primary pressure testing in an apartment building should show a pressure with a minimum value of 2 atmospheres. This is necessary so that the detected defects are eliminated before work begins.

Tricky meter that saves electricity Pays for itself in 2 months!

Professionals draw up an act of work taking into account hidden procedures, for example, the dismantling of radiators of a heating system. By identifying the condition of the pipes and the amount of scale, the method of flushing is determined with the customer. Most often, hydraulic technology is used, less often - chemical cleaning. They draw up an estimate, sign a contract, which includes deadlines. After that, they start cleaning, then carry out a secondary pressure test. This is necessary to check the performance of equipment in a residential building.

Why is hydrotesting necessary?

Hydrotesting - checking the integrity and tightness of the heat main. Testing allows you to timely detect leaks and gaps at the points of threaded fittings, battery connections, which can lead to leakage, flooding. Hydraulic testing is a mandatory measure at the stage of preparing pipelines for commissioning.

The companies operating the building are aware of the period of testing. The process is carried out by specialized firms, whose employees have the necessary qualifications. Preparation of heat supply systems includes pressure testing of the main line and flushing of pipelines.

Methods for cleaning radiators

Method of chemical cleaning of heating systems

During chemical cleaning of parts of heating systems, their internal cavity is filled with special solutions.These include substances from acids or alkalis. They include inhibitors. They are able to prevent metal corrosion, help to preserve its inner part, prolong the service life heating systems. During work, old solutions of alkali and acid should be drained. Such solutions are quickly neutralized. They add the acidic components of the alkaline solution. This cleaning method is used when washing steel pipes. The composition of the reagents cleans the inside of the battery from rust, salt deposits.

Cleaning heating systems with hydraulic pneumatics

This method of cleaning the heating system is recognized as the most versatile, inexpensive and most in demand. With this method of cleaning, you need to use a lot of water. In autonomous heating systems, all internal parts are washed only with cold water.

Flushing sequence using hydraulics:

- start the heating system in reset mode;

- a stream of air is directed to the coolant of the system, which will quickly clean the internal structures of the battery from scale, formations;

- if there are risers in the heating system, then they are flushed; if the heating system is cleaned by the tenant himself, then the risers should be washed individually. This is done in order to flush the radiator itself.

According to the drawn up contract, and this is necessary, in order to check the quality of the flushing, it is necessary to carry out coolant control intakes. Such work is carried out in a thermal unit, in other parts of the system. This is done for the equipment acceptance commission, which will sign the equipment acceptance certificate. She can always make sure that the water is pure and that there are no impurities.

The topic of this article is documenting the flushing of the heating system. We are interested in drawing up an estimate, concluding a contract and drawing up an act.

In addition, the criteria by which the work performed is evaluated are also curious.

What is flushing and pressing

Flushing and pressure testing of heating systems is carried out in cases where the layer of deposits in the pipes becomes too large for them to continue to function. As a preventive measure, such events are rarely carried out, since this pleasure is quite laborious and expensive. For hydropneumatic flushing, acid solutions are used, which remove plaque from the pipeline walls to the outside. Metal particles cling to the inner walls of the pipes, thereby reducing their diameter. It leads to:

- increase in pressure;

- increase in the speed of the coolant;

- decrease in efficiency;

- increase in costs.

What is pressure testing of a heating system - this is an ordinary test, according to the results of which one can say whether it is safe to use such equipment or not, and also whether it can withstand the necessary loads. After all, no one wants to become a victim of circuit depressurization and be a patient in the burn department. Pressure testing of the heating system is carried out in accordance with SNiPs. It is a mandatory procedure. After it, a document is issued confirming the technical serviceability of the circuit. Here are the main cases when pressure testing of the heating system is carried out:

- when assembling a new circuit and putting it into operation;

- after the repair work;

- preventive checks;

- after cleaning pipes with acid solutions.

Pressure testing of the heating system is carried out in accordance with SNiP No. 41-01-2003 and No. 3.05.01-85, as well as the rules for the technical operation of thermal power plants.

From these rules, it is known that such an action as pressure testing of a heating system is carried out either with air or liquid. The second method is called hydraulic, and the first is called manometric, it is also pneumatic, it is bubble. The rules for pressure testing the heating system state that water tests can only be carried out if the temperature in the room is above five degrees. Otherwise, there is a risk that the water in the pipes will freeze. Pressurization of the heating system with air removes this problem, it is carried out in the cold season. In practice, hydraulic pressure testing of the heating system is used more often, as everyone is trying to complete the necessary planned work before the heating season. In winter, only the elimination of accidents, if any, is performed.

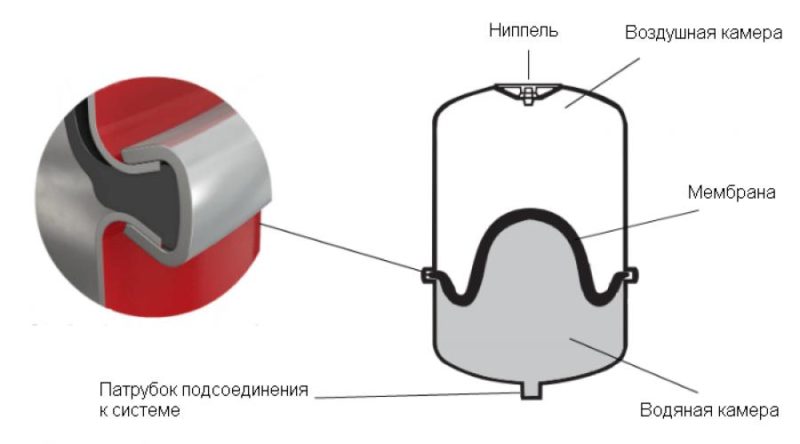

It is possible to start pressure testing of the heating system only when the boiler and expansion tank are cut off from the circuit, otherwise they will fail. How is the heating system pressure tested?

- all liquid is drained from the circuit;

- then cold water is poured into it;

- as it fills, excess air descends from the circuit;

- after water has accumulated, a pressure supercharger is supplied to the circuit;

- how the heating system is pressurized - the amount of atmospheres gradually increases. In this case, the maximum test pressure should not be higher than the tensile strength of the various elements of the circuit;

- high pressure is left for a while and all connections are inspected.It is necessary to look not only at the threaded connections, but also at the places where the parts of the circuit are soldered.

Pressurizing the heating system with air is even easier. Just drain all the coolant, close all outlets in the circuit and bring air into it. But in this way, it is more difficult to determine the malfunction. For example, if there is liquid in the pipes, then at high pressure it will seep through a possible gap. It is easy to identify visually. But if there is no liquid in the tubes, accordingly, there is nothing to go out except air. In this case, a whistle may be heard.

And if it is inaudible, while the pressure gauge needle indicates a leak, then all connections are smeared with soapy water. To make it easier, you can check not the entire system, but by dividing it into segments. In this case, it is easier to carry out pressure testing of heating pipes and determine possible places of depressurization.

What is flushing and pressure testing of the heating system

Flushing pipes is necessary for the normal operation of the heating system

Works for the preparation and resumption of the uninterrupted functioning of heating guarantee the trouble-free flow of the coolant.

flushing

If in Batteries began to heat worse in the apartmentthan before, there are several reasons:

- poor boiler performance;

- pump breakdown;

- airing pipes.

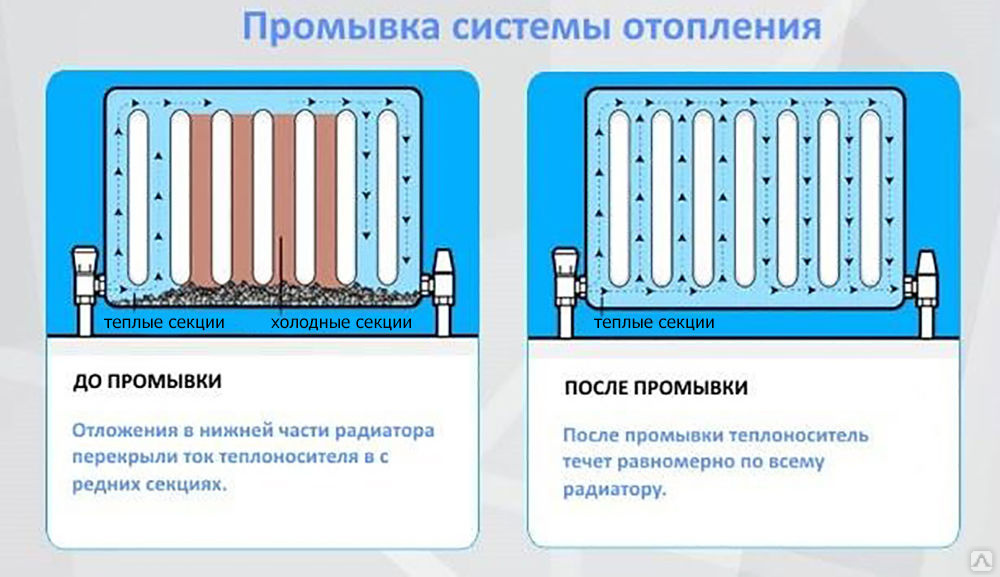

During many years of operation, garbage, scale particles, rust accumulate in pipes, heaters, collectors. Growing inside, they clog the passage hole for the coolant, the porous structure reduces the heat capacity of the metal parts of heating devices.

Consequences of blockages:

- burnout of the heat exchanger, requiring its replacement;

- temperature difference in batteries;

- noise in the pump with subsequent failure;

- boiler breakdown.

Flushing is performed to eliminate and prevent contamination.

Mineral deposits can completely block the movement of the coolant

The decrease in heating efficiency occurs for 2 main reasons:

- The appearance of mineral deposits. Non-galvanized pipes readily accept calcium and magnesium salts on the surface. There are no such problems with galvanized pipes.

- Growth of silt in pipe sections with low coolant velocity. Multi-section cast-iron radiators are subject to this phenomenon. The dependence is proportional to the increase in volume and number of sections.

- special hydropneumatic equipment;

- chemical reagents.

The basis of chemicals is acid.

Crimping

This procedure is designed to check the hydraulic system for weak points. The tests are carried out by means of an overpressure water circuit or by the pneumatic method.

Hydroflushing, how and why

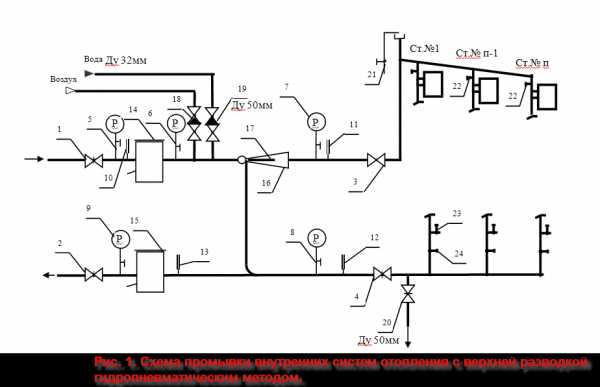

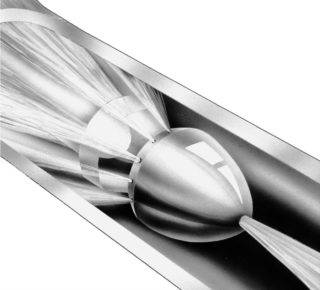

Hydropneumatic flushing of the heating system is based on the simultaneous supply of air under pressure in a certain amount and water to sections of pipelines. The water-air mixture that was formed at the same time cleans the heating communications thanks to the multiple pulses that the compressor performs for flushing.

Impulses in the water of the pipelines create small bubbles, and they gradually destroy deposits on the walls of the pipes of heating communications.

In order for the flushing process to be successful, it is necessary to perform the following calculations:

- Lengths of pipelines to be flushed;

- Air flow and pressure determined based on pipe diameters;

- The speed and flow of water.

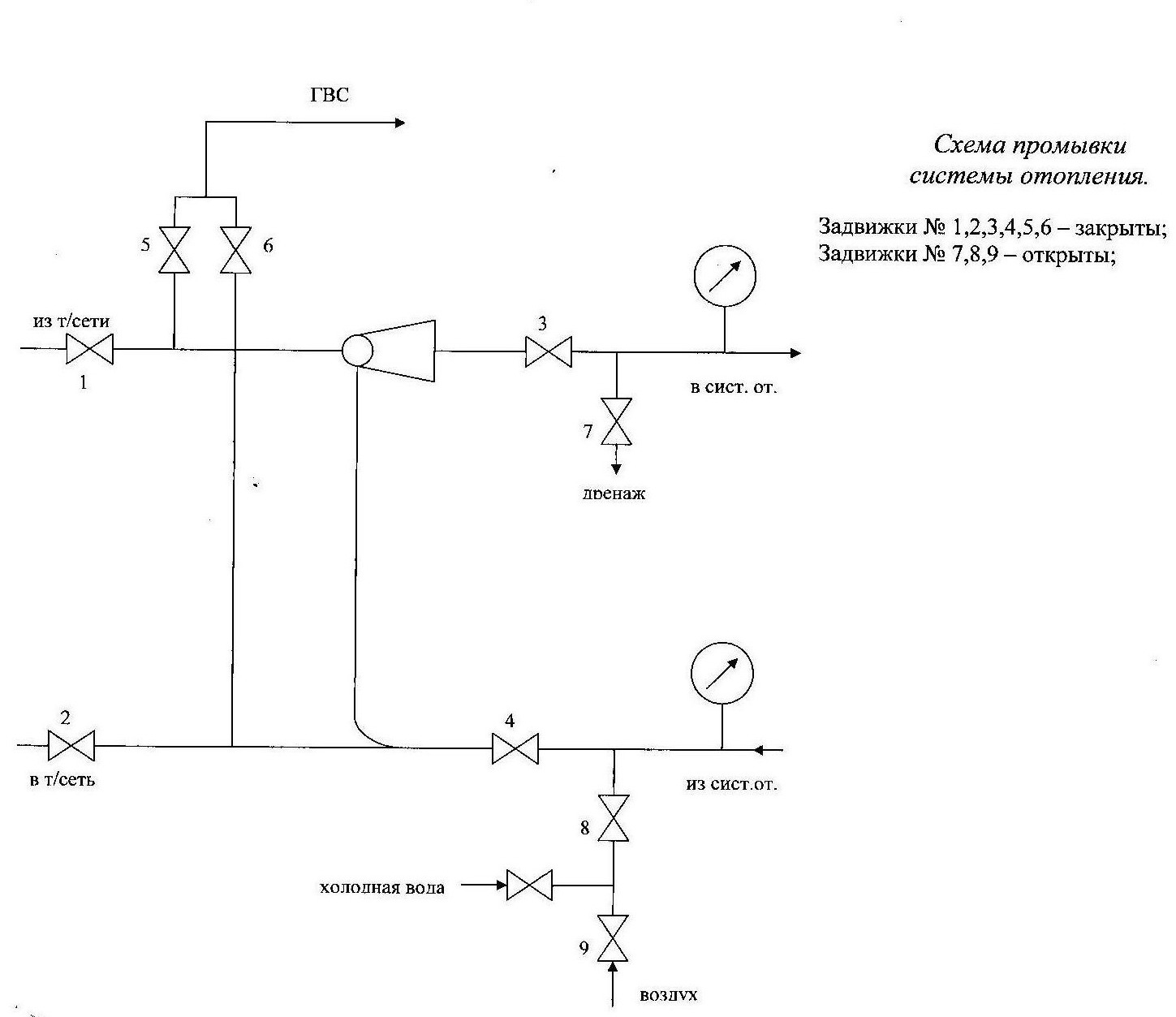

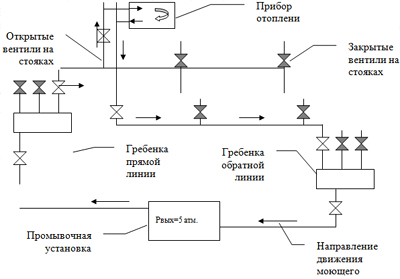

Typical scheme for work

Training

In order for the hydraulic flushing process to be successful, you need to individually approach each heating system and take into account its features.

Ideally, before the process, it is necessary to perform preparatory activities:

- Inspect all heating communications;

- Determine sections of pipelines (risers, groups of risers) that will be washed separately, and break them down into stages;

- If there is a need, then it is necessary to install shut-off valves in order to block sections of pipelines and remove washed deposits from the heating system;

- Make calculations of air and water consumption to obtain the required result after washing;

- Determine the need for hydraulic testing (pressure testing) of pipelines.

Connected equipment to the elevator

After all the preparatory measures have been taken, the heating systems are hydraulically flushed until the water-air mixture brightens. After flushing, repressurization is performed.

The quality of the flushing is assessed by reducing the hydraulic heating system resistance, which is determined after and before hydraulic tests.

Method for cleaning the heating system

A branch pipe with a diameter of twenty to forty millimeters is inserted into the feed. The branch pipe is equipped locking elements and check valves. Next, you can start supplying water and compressed air to the system.

If you had to deal with a small system, then it is allowed to supply water and air through existing pipes.If there is an excess volume of water, then it can be dumped through the drain taps or for this purpose, a specially installed pipe for descent. In the event that an elevator is present, then the cone and glass are removed before washing.

Dismantled heating elevator

Compressed air is supplied to the heating pipelines thanks to the compressor, which you can see in the photo and video in our gallery. The compressor produces air with a pressure of about 0.6 MPa. To prevent the flushing liquid from entering the compressor receiver, it is necessary install a check valve on the pipeline. Pressure gauges are installed on the supply and return pipes, with a scale of up to one megapascal.

The washing itself can be carried out in two ways:

flowing. The heat supply pipelines are first filled with water, with the air collector valve open. After filling the pipes, the valve is closed and the compressed air supply is started. Both air and water mixtures are simultaneously fed into pipelines.

Flushing is stopped when clean water begins to flow through the pipe. After that, the water is drained into the drain. This method is used to clean heating and hot water systems;

filling method. With this method, there is some sequence in the actions. To begin with, the pipelines are filled with water, and the valve is closed. Compressed air is supplied to the second branch pipe for fifteen to twenty-five minutes, depending on the diameters of the pipes and pollution.

After the air supply is stopped, the valve is closed and the water is drained through the drain pipe. Upon completion, the system is flushed several times with clean water.

Signs of air pockets

The first sign of air in the system is poor heating of the batteries.The battery warms up unevenly, not enough, and if some sounds appear in it, then the answer is unambiguous - the air in the heating batteries prevents the circuit from working properly. If the radiators have a bottom connection, and its upper part is cold, then air has accumulated in such a radiator and bleeding from the heating radiator will restore normal operation.

Ventilation of heating circuits

What needs to be done and how to remove air from the heating battery is written a lot on the net. For open heating systems with an expansion tank, this problem is not relevant. In such systems, air exits independently through a tank located at the highest point of the circuit. There may be problems with some radiators, especially if the slope is not chosen correctly. Such air bubbles are removed using Mayevsky taps or automatic air vents.

For closed systems with forced circulation, the problem of how to get rid of air in the heating system is also quite solvable. The air from the batteries is removed manually by opening the Mayevsky tap. If a hiss is heard when it is opened, then the actions are correct, there is air in the system. It is necessary to release air before the appearance at the outlet of the Mayevsky crane water.

Such accumulations of air can completely stop the circulation of water in the system. If the installation of problem areas of the circuit, for some reason, cannot be changed, then in such problem areas an air release valve of the heating system is installed to bleed it.

Features of aluminum radiators

An unpleasant phenomenon is sometimes observed in aluminum radiators. Radiator material reacts with water.As a result, gases are constantly formed and they must be constantly removed from the radiator, and how to remove air from the radiator is described above. To avoid the problem described above, it is enough to buy and install aluminum radiators with an internal anti-corrosion coating. The correct solution would be to replace the aluminum radiator with a bimetallic one.

Test tools

To test the system for resistance to high pressure, a special device is used, which is called a pressure tester. It is a pump capable of creating pressure inside the system up to 60 or 100 atmospheres, depending on the type of mechanism. There are 2 types of pumps: manual and automatic. They differ only in that the second option stops pumping itself if the pressure has reached the desired level.

The pump consists of a tank into which water is poured and a plunger pump with a handle that moves it. On the body of the mechanism there are taps to block the supply of pressure and pressure gauges to regulate the pressure. Also on the tank there is a tap that allows you to drain the water that remains in the tank.

The principle of operation of such a pump is similar to a conventional piston analogue, which tires are inflated with. The main difference lies in the cylindrical piston made of steel. It is tightly fitted inside the case and a minimum gap is made, which makes it possible to build up pressure up to 60 atmospheres.

Manual blower

For hand pumps, the biggest disadvantage is that such pressure testing of pipes will take a very long time due to pumping the system with water.This process can take several hours, as large systems that have radiators will need to be filled manually.

Automatic devices work on a similar principle, but when the pressure limit is reached, they turn off themselves. They also require electricity to operate, so manual ones are more suitable for places where there is no power supply yet. Automatic pumps can deliver pressures up to 100 bar and industrial devices up to 1000 bar.

Electric version of the compressor

Is this compression necessary?

Let's start with the basic concepts. What is a home heating system? Unless you have electrical panels, then, most likely, this is a pipe line with a coolant circulating through them. In order for it to move inside the system, by default the coolant must be in a liquid state. A liquid, as you know, always seeks to find a way out of a closed space. If the circulation is disturbed for some reason, the entire system stops working.

heating is the result of constant monitoring of the integrity of the entire system

heating is the result of constant monitoring of the integrity of the entire system And if the tightness of the main line is broken, then, in addition to the lack of heat, you may also face the need for emergency repairs of the apartment at home and even with your neighbors

And if the tightness of the main line is broken, then, in addition to the lack of heat, you may also face the need for emergency repairs of the apartment at home and even with your neighbors

There is only one simple way to check for possible violations in the operation of the line - to increase the pressure in the system so that defects in the connections are found, which should be paid attention to before starting the heating. Thus, pressure testing is an actual pressure test of the heating main before the operating season

To check the system for leakage, the pressure should be increased by 20-80%.The percentage of pressure increase depends on the equipment installed in the line. After detection of all malfunctions during pressure testing, the necessary repairs are made, the tightness of the system is restored.

All this takes time, so do not postpone the procedure until the last days before the start of the heating season.

All this takes time, so do not postpone the procedure until the last days before the start of the heating season.

Rules and procedure for carrying out different types of washing

Hydropneumatic Flushing Technology

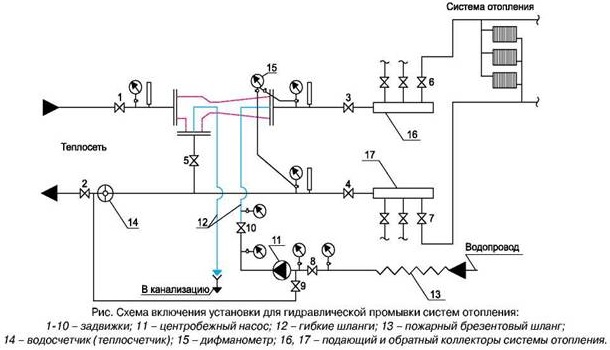

The technology of flushing the heating system by the hydropneumatic method consists in forcing compressed air into a pipeline filled with water. The resulting water-air mixture moves at high speed, thereby “loosening” and separating existing deposits from the surface of the pipes and taking them out of the contour.

Hydropneumatic flushing of heating using disinfectants

Hydropneumatic flushing is carried out in two ways. The first option involves a flow scheme. First, the system is filled with water - the air collector valve is open, after filling the valve is closed. Then, with the help of a compressor, compressed air is pumped in and the drain pipe is opened. As a result, the resulting water-air mixture passes through all heating devices, and then merges. The flushing process continues until clean water flows from the nozzle.

The second washing option is carried out according to a different algorithm. When filling the system with water, the air collector cock is closed. Then, compressed air is injected into the pipeline through the backup pipe for 10-15 minutes, after which the dirty liquid is drained through the drain pipe.

Chemical Flushing: An Alternative to Overhaul

Chemical cleaning of heating systems is based on the use of alkaline and acid solutions. The washing procedure consists in introducing a chemical solvent and a corrosion inhibitor instead of a heat agent, which protects the metal from oxidation. The reagent, circulating in the system, dissolves scale and deposits on the pipeline walls. Before draining the liquid, a neutralizer is added to reduce the toxicity of the drug.

Comparing the results before and after hydrochemical treatment

The composition of the solution and the exposure time of the agent are calculated individually, taking into account the contamination of radiators and pipes, and the material from which they are made. The advantage of this method is the possibility of carrying out the procedure during the heating season without turning off the heating. As a rule, one cycle is enough for high-quality cleaning.

Cleaning with chemical solutions extends the life of the heating system by 10-15 years and significantly increases the efficiency of radiators. The effect of flushing is equated to a major overhaul, while the cost of it is 10 times lower than for repair work.

The disadvantages of chemical washing include the high toxicity of drugs. This method cannot be used on systems with broken seals and thin pipes, the walls of which may not withstand the effects of concentrated reagents. For aluminum batteries, this aggressive method is prohibited!

Pneumohydropulse flushing is an effective hardware method

Pneumohydropulse cleaning is carried out without dismantling the system using a special pneumatic device. The impact of the device leads to the formation of a pulsed kinetic wave and cavitation bubbles in the coolant, which, when collapsing, create shock waves.All this increases the pressure in the pipes and radiators and leads to the cleaning of their walls from all types of deposits and the washing out of contaminants from the system.

Device for hydropneumopulse cleaning

Work with the help of a pneumohydropulse apparatus can be carried out at any time of the heating season. The technique does not require dismantling and turning off the heating and allows you to work with pipes with a diameter of up to 150 mm. This method is safe for all metals, as it does not involve exposure to caustic substances.

Flushing heating systems is a complex technological process with a lot of subtleties and nuances, so it should be carried out by professionals with sufficient experience and the necessary equipment.

Instructions for flushing the heating system

Scheme of pneumopulse cleaning

There are 2 main methods for flushing the heating system, namely:

- using special hydropneumatic equipment;

- using chemicals.

Washing by hydropneumatic method

Hydropneumatic flushing of heating systems - instructions

Hydropneumatic flushing of heating systems - instructions

This method is actively used by domestic ZhEKs and is quite effective. You just need to do everything in accordance with technology.

The principle is extremely simple: first, water is discharged from the system, then it is fed back. To "adjust" the water flow, a special pneumatic pump is used. As a result, under the influence of a rather powerful pressure, scale and other deposits peel off, and when the water is drained, they are removed from the system.

To independently carry out such a procedure, you will need a pneumatic pump capable of pumping pressure over 6 kg / cm 2.

The sequence of actions is as follows.

Turn off all taps before starting work.

End caps are unscrewed with a wrench

First step. Close the return valve.

Heating system line diagram

Second step. We connect the pneumatic pump to the valve installed after the valve.

Third step. Let's drop the return.

Fourth step. Let the pneumatic pump build up pressure above 6 kg / cm 2. and then open the valve to which it is connected.

Fifth step. We cover all the risers one by one. We do this so that at one moment no more than 10 risers are blocked. Following this rule will make the flushing procedure as efficient as possible.

Sixth step. We transfer the system to reset in the opposite direction. To do this, we do the following:

- close the discharge and close the valve connected to the pump and turn off the device;

- close the open valve, and then open a similar one on the "return";

- reset the heating system. To do this, we connect the pneumatic pump to the valve in the opposite direction, after which we open the valve and turn on the pump. The fluid will move in the other direction.

You can determine the required duration of flushing "by eye". Is a clear clear fluid coming out of the system? You can finish! Return the valves and valves to their original position and turn off the pump.

Prepare a suitable container to collect dirty water. If desired, you can connect a hose to the battery and ensure that the dirty coolant is discharged into the sewer.

Chemical flush

Scheme of chemical flushing of pipes

The use of this method can be resorted to only in two cases, namely:

- if necessary, cleaning the heating system with natural circulation, built using steel pipes. It is advisable to use chemicals in situations where, for any reason, there is no desire to flush the entire system. Most often, blockages are deposited in heat exchangers. The system can silt along the entire perimeter. In the second case, there will be little sense from chemical washing;

- if it is necessary to restore the old heating system. Over decades of operation, pipes can become clogged and overgrown so much that the power of the pneumatic pump will not be enough for effective cleaning. Of course, it would be possible to take a more powerful pump, but no one will give guarantees that the pipes will not burst under such pressure.

Important! If the pipes are very old, with traces of corrosion and deformation damage, there may not be any positive result from flushing. Chemical reagents will simply dissolve the rust, causing the pipes to start leaking.

The only effective solution in such a situation will be the replacement of obsolete highways.

Washing agent

The principle of flushing is simple: instead of a coolant, a special solution containing acid and alkali is poured into the system. Then the mixture is circulated for 2-3 hours (if it is not a line with natural circulation that is being cleaned, for this it will be necessary to connect a pneumatic pump), after which it is drained and the pipes are filled with a standard coolant.

Reagents for flushing and protection of heating systems

Important! According to the requirements of SNiP, such reagents are prohibited from being poured into the sewer.The best option is to neutralize the used mixture with a special composition.

You can buy it in the same place where you can buy the wash solution.

Never use such chemical mixtures to clean aluminum pipes. If the products remain intact after such washing, they will serve much less.

Mandatory flushing of the system of a private house is recommended to be carried out at least once every 7 to 10 years

Crimping stages

Work is carried out with the following frequency:

- when starting a new system;

- annually after the heating season;

- after flushing or repair of the heating main with the replacement of pipes.

For apartment buildings, the preparation is as follows:

- Inspection of shut-off valves in elevators, central pipes, risers. On cast-iron valves, seals are changed, paronite gaskets are renewed between the connection flanges, and unusable bolted connections are changed.

- The method of visual observation examines pipes, fittings for the presence of cracks, chips, corrosion, defects. Make repairs if necessary.

- Check the thermal insulation of risers, main pipes in basements.

Pressure testing after pressure cleaning is necessary to detect possible leaks

Crimping procedures and testing are carried out taking into account the parameters of heaters, thermal equipment indoors. Standards allow the use of operating pressures up to 6 bar for cast iron radiators. When they are in the walls, the maximum is 10 bar.

Hydraulic tests are carried out as follows: the system is checked as a whole, then a pressure higher than the working one is applied to the thermal unit.

According to Rules 115, clause 9.2.13., Tests are carried out with a pressure not lower than:

- 1 MPa - elevators, heaters for heating and hot water systems;

- 0.6 MPa - cast iron and steel heating radiators;

- 1 MPa - convector, panel heaters;

- working pressure plus 0.5-1 MPa for hot water supply;

- pressure recorded in the manufacturer's instructions for heaters.

The test pressure in steam systems is selected by the manufacturer from the maximum to the operating minimum:

- minimum - not less than 0.2 MPa, but not less than 1.25 working;

- the maximum is set by calculating the strength according to the standards;

Crimping takes place at temperatures from + 5 degrees. If negative - in emergency cases.

If there is no visible leak, but the pressure drops, the pressure gauge shows problems in hidden places

Pressing steps:

- Filling the system with cold water. During operation, the temperature of the liquid is not more than 45 degrees. The pressure rises gradually. The control is carried out using a manometer.

- When the set pressure is reached, the system remains at rest for about 30 minutes.

- During downtime, an inspection is carried out for leaks in pipes, batteries. Make sure there are no leaks. Method of control - placing toilet paper in dangerous places or wrapping pipes with it. With leaks, stains of water, silt are visible.

- The control takes place according to the readings of the manometer. The leak happens in a place inaccessible to observation. A drop in pressure will alert you to this.

Upon completion of pressure testing, a certificate of fitness for use is issued.

Washing equipment

- CILLIT–BOY Station. This is a modern electronically controlled device. The cost of purchasing it can soon pay off, since such a unit can be used not only for flushing heating, but also for cleaning drinking water from bacteria, as well as servicing the “warm floor” system.When used for heating, compressed air and water are evenly supplied. Its washing power is enough not only to clean pipes and radiators, but also to remove scale from the inside of the heating boiler, which prolongs its life and increases the heating level.

- Rocal. This compact compressor is mainly used for washing copper and steel pipes. It can clean systems with a capacity of up to 300 liters. It maintains a constant pressure of 1 bar, and its performance, despite its small dimensions, reaches 40 liters per minute.

- Ropulse. A powerful device that is used not only to flush the heating system, but also to purify the water going through the pipes to the house. It is permissible to use it for cleaning the “warm floor” and cleaning solar collectors from silt deposits. When purifying drinking water with such a device, not only rust and debris, but also bacteria are eliminated from it.

- Romantic 20. It is suitable for removing scale in heating pipes. It provides for automatic regulation of the pulse interval. The head height reaches 10 meters, the pressure is 1.5 bar, and the performance is the same as in the Rokal installation. It can be used for systems whose volume does not exceed 300 liters.

- the color screen displays an image at an angle of view of 36 degrees;

- on the lens of the device there is a focus ring;

- the shooting frequency reaches 9 Hz.

Is it possible to flush a separate battery?

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation as well.

Heating battery cleaning scheme

Important! It is necessary to flush a separate heating radiator strictly before the start of the heating season. Buy a flush faucet from a plumbing store

In addition, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Install the fitting on the hose

Purchase a flush faucet from a plumbing store. In addition, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Fit the fitting to the hose.

Direct flushing is carried out in the following sequence.

First step. We connect a flush valve to the heating radiator.

Second step. We connect the fitting with a hose to the flushing tap.

Third step. We direct the other end of the rubber hose into the toilet.

Fourth step. Open the flush valve and leave for 20-30 minutes. In the process of waiting, we hold the hose so that it does not jump out of the toilet.

Important! Although individual batteries are recommended to be flushed strictly before the start of the heating season, in some situations the need for flushing occurs when the heating is in full swing. If this is your case, stick the hose deeper, right into the riser

Otherwise, the hot coolant can destroy the toilet.