- Hydraulic seal for a well - technology for sealing cracks in concrete

- How to prepare a solution to fix a leak yourself?

- How to seal a leak with a prepared solution?

- Where else are hydraulic seals used?

- Ready-made hydraulic seal for wells: how to use it

- Overview of famous brands

- Waterplug

- peneplag

- Puder Ex

- Types of wells requiring insulation

- Operation Precautions

- Hydraulic seal properties

- Why is the roof leaking?

- Internal protection

- What is a hydraulic seal and what is it for?

- Filling gaps and cold joints in reinforced concrete structures

- Seal holes up to 2 sq. cm

- Fixing a leak through a large hole

- Closing a slotted hole

- Seal a strong leak

- Sealing cold joints

- How the composition works

- Weak spots

- Operation Precautions

- Cement mortars for grouting joints

- How to close the seams in the well: types of hydraulic seals

- Conclusions and useful video on the topic

Hydraulic seal for a well - technology for sealing cracks in concrete

To protect clean well water from possible contamination by groundwater containing harmful impurities, various waterproofing materials are used.The seams between the rings, the places where engineering communications are inserted into the well shaft, as well as the defects that have appeared during operation in the body of reinforced concrete products, need special sealing. A hydraulic seal for a well allows you to quickly eliminate leaks - a quick-hardening material that can restore solidity to the structure within a few minutes

When buying this material, you should pay attention to the presence of a certificate confirming the safety of the components that make up the seal for drinking water

This video clearly demonstrates how to use the Waterplug/Peneplug hydraulic seal. Materials from other manufacturers, produced for the immediate elimination of pressure leaks, are used in a similar way.

However, they must be used in accordance with the attached instructions.

How to prepare a solution to fix a leak yourself?

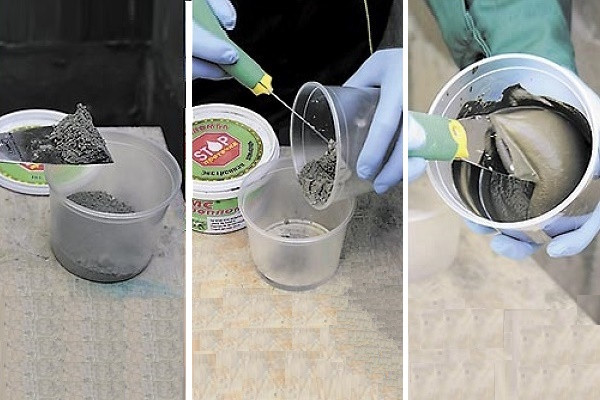

When preparing the solution yourself, you must follow the manufacturer's recommendations. The amount of dry mixture is taken depending on how active the leak is. Usually, 150 grams of water is taken per kilogram of hydraulic seals for a well. Otherwise, the proportion is calculated based on the volume of the components, while five parts of the mixture are taken for each part of water.

Important! If the flow pressure is significant, then the proportion of the ingredients in the solution is changed, increasing the amount of the dry mixture in the solution to seven parts (water refers to the mixture as one to seven). The temperature of the water taken to prepare the solution should be + 20 ° C

After a quick kneading, the time of which should not exceed 30 seconds, a solution is obtained that looks like dry earth.Immediately a large amount of the solution can not be kneaded, as it instantly seizes. Therefore, it is necessary to prepare the mixture in parts, after applying one of them to the area of the leak, proceed to the preparation of the next

The temperature of the water taken to prepare the solution should be + 20 ° C. After a quick kneading, the time of which should not exceed 30 seconds, a solution is obtained that looks like dry earth. Immediately a large amount of the solution can not be kneaded, as it instantly seizes. Therefore, it is necessary to prepare the mixture in parts, after applying one of them to the area of the leak, proceed to the preparation of the next one.

How to seal a leak with a prepared solution?

First, the surface is prepared for work, for which the internal cavity of the leak is freed from loose, exfoliated concrete using a jackhammer.

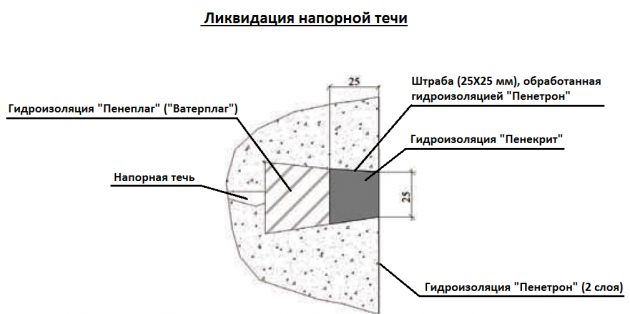

The place where the leak appears is embroidered to a width of up to 25 mm and a depth of 50 mm, it can be a little deeper. The shape of the hole should resemble a funnel.

Then, in a clean container, stir the required amount of the mixture to seal the leak. Hands form a lump from the solution, which is pressed into the embroidered hole with a sharp movement, and held for several minutes (2-3 minutes are enough).

Important! Hydraulic seal for wells made of reinforced concrete rings, stone, brick can be applied to both vertical and horizontal surfaces. Note that this does not require formwork

If the hole has an oblong shape and is not plugged at a time, then it is sealed from top to bottom.

Where else are hydraulic seals used?

With the help of quick-hardening solutions, it is possible to effectively deal with:

- with water leaks from reinforced concrete tanks;

- with water breakthroughs in basements, tunnels, mines, adits, galleries;

- with defects that have arisen in the bowl of pools and other artificial reservoirs;

- with capillary leaks appearing in the area where the floor and walls meet, between foundation blocks, etc.

Operation Precautions

The technology of using a hydraulic seal for a well is not particularly difficult, and therefore can be performed by a novice master without the involvement of specialists. When working with the solution, protect your hands with gloves. After use, the tool is immediately washed from the remnants of the mixture, otherwise, after the final hardening, it will be difficult to clean it only mechanically.

The cost of this waterproofing material is high, so not all companies involved in the construction and repair of drinking wells use it. When contacting specialized firms, clarify this issue immediately, as other materials may not be as effective in combating leaks.

Ready-made hydraulic seal for wells: how to use it

A solution for sealing a leak can be prepared from a dry mixture, strictly adhering to the instructions. As a rule, 150 ml of water 18-20 degrees is needed for 1 kg of dry mix. If necessary, you can knead small volumes of waterproofing composition, based on the proportion of 1 part of water - 5 parts of dry cement.

The solution is mixed for half a minute, after which it is immediately applied to the area with a leak.

What mixtures for waterproofing are better:

- Waterplug. Diluted with slightly warm water. It hardens within 120 seconds, it is applied at temperatures from +5 to +35 degrees.

- Peneplag. In addition to concrete, it can be used to fix leaks in brick and stone wells.Freezing time - 40 sec.

- Puder ex. One of the fastest fillings, hardens in 10 seconds. Not applicable at temperatures below 5 degrees.

During the preparation of the solution, as well as subsequent work with it, certain rules should be followed. Always wear a respirator and protective gloves when working. Do not use any liquids to mix the solution - only ordinary water, and the container must be metal.

Overview of famous brands

The modern construction market contains a lot of offers from various companies. Despite the fact that the technologies for using hydraulic seals are similar, the efficiency and quality are different. Therefore, it is recommended to opt for the products of the world's leading brands, which have proven themselves with specialists who are professionally engaged in shotcrete.

Waterplug

This is a dry mix that is packaged in a plastic container. Before use, it is necessary to prepare an aqueous solution in accordance with the attached instructions. The composition includes quartz sand, and special hydraulic cement is used as a binder.

The peculiarity of this mixture is that it is possible to seal holes through which water breaks out under pressure. Three minutes is enough for the solution to solidify. Efficiency concrete well waterproofing It is achieved due to the ability to expand when solidified, due to which the pores are filled, and a strong, tight connection is provided.

peneplag

This is a similar composition of the dry mix, but the aqueous solution has a greater setting speed.It takes from 40 seconds to a minute to eliminate a pressurized leak. Sealing is carried out due to the ability of the mixture to expand when solidified.

The advantages of this hydro seal include:

- Fast setting, effective sealing, durable.

- It can be used at temperatures from 5 degrees Celsius.

- Resistant to water and aggressive environments.

Puder Ex

Quick-setting material allows you to seal holes under pressure. The composition is resistant not only to water pressure, but also to capillary action of moisture. In the well, dry joints are sealed in 7 seconds. That is how much a hydraulic seal needs to make the concrete structure airtight again.

Despite the high performance and benefits, the price of this dry mix is low. The German quality and reasonable cost made it popular among the builders of hydraulic structures and workers of specialized teams performing their repair and maintenance. The maximum withstand water pressure is up to 7 atmospheres, which means that this hydraulic seal will be able to eliminate any leak.

Types of wells requiring insulation

Structures made of reinforced concrete rings have various purposes. Seam processing is carried out in such cases:

The well is a source of drinking water.

Upper aquifers are polluted with biological and chemical wastes. The need for treatment is associated with the possibility of penetration of contaminated surface water into the mine. To protect clean water sources, the most reliable external waterproofing is required.

The well is used to collect sewage.

Seam processing is carried out in order to prevent the infiltration of contaminated fecal effluents into the ground.These works are mandatory, especially if there is a source of drinking water on the site.

Septic tanks are treated inside and out, paying great attention to the tightness of the bottom

The shaft is used for equipment maintenance.

Typically, such wells are built to accommodate pumping units, automation systems and other devices for organizing automatic water supply. For the normal operation of electrical equipment, it is necessary to maintain a certain humidity inside the mine, therefore, before the start of operation of such structures, external and internal processing of walls and joints of rings is performed.

Operation Precautions

When performing waterproofing work using seals on your own, you need to follow simple safety rules. The cement included in the solution causes irritation of the skin and mucous membranes, therefore it is recommended to use smooth rubber gloves and goggles for work. If the solution comes into contact with the skin, the affected areas are washed with plenty of water.

Having entrusted the waterproofing of the well to the specialists of one of the many companies providing such services, it is worth asking in advance what materials are used by this organization to carry out the work. Unscrupulous contractors may try to save on expensive material by doing the old-fashioned way, causing problems in the coming months or years.

Hydraulic seals are used to seal water leaks through structural cracks or seams. The funds are used to stop leaks in underground structures, ground tanks, to repair cracks, cavities and joints.They have excellent adhesion to concrete, brick and metal substrates.

Hydraulic seal properties

Hydraulic seals can be in the form of dry powder quick-setting mixtures of high-strength cement and special additives. From such a mixture, prepare the amount of solution necessary for quick work, form a cork and plug the hole. In the process of hardening, literally from 40 seconds to 2 minutes, the cork expands and closes the hole. When solidified, such a cork penetrates into all cracks and forms a monolith, creates water resistance even with water backwater.

Technology

Sealant for concrete - action and varieties

If you have a concrete floor in your basement or garage, it may be worth covering it with waterproof sealant to prevent water and mold damage.

Waterproofing mixtures

When working with structures that will subsequently come into contact with water, it is necessary to take into account the effects of water on the building material.

Waterproofing materials for the protection of frame houses

Roofing material and glassine, made from cardboard impregnated with bitumen, have long been used in waterproofing work. These materials allow you to isolate the wooden structures of the frame house from the backfill.

Waterproofing the walls in the apartment: live dry

Finishing with wallpaper, plastic panels or some other materials does not protect the walls from moisture. This is especially true for apartments on the first, and sometimes the last floors.

Market of waterproofing materials in Russia

According to various expert estimates, the number of active players in the waterproofing market is more than 40 companies

Incredible result - reliable waterproofing in construction

The article in an accessible form tells the types of modern films designed for waterproofing, which become a reliable protection for walls, basements and foundations of buildings.

If you want to use drinking water, and not technical fluid, then you need a hydraulic seal for the well, which will cut off the shaft from groundwater and sewage.

The hydraulic seal is inserted into the seam between the rings, integrated into the casing junction and protects the tie-in of utilities. And in this article we will consider the nuances of the use of protective hydraulic seals.

Hydroseal is sold as a dry mixture, which must be diluted in a certain volume of water. The exact recipe for preparing the solution is indicated by the manufacturer of the dry mix. And it should be just a seal for the well, which does not include harmful substances. Dry mixes for sealing reinforced concrete structures, sewerage and drainage systems and other reinforced concrete products are not suitable in this case.

The resulting solution close up both small and large cracks, previously embroidered (expanded) with a jackhammer or perforator. The recommended width and depth of the "joint" are 2.5 and 5 centimeters, respectively. And yet - all the "loose" concrete will have to be scraped off the walls of the ring.

After that, the surface is smoothed with a spatula, which can be used to transfer excess mixture to surfaces freed from loose concrete. At the same time, I process wide and deep cracks with a spatula from top to bottom, and small-sized defects - as you like.

Why is the roof leaking?

Factors that affect the leakage of roofing materials: - natural wear of the roofing material, drain and fasteners; - wetting of the heat-insulating layer; — damage to the coating; - problems in the water drainage system; - low-quality materials were used during installation; — technology disruption during styling; - negative influence of microorganisms (moss, fungus). Also, the roof may begin to leak due to a violation of the hermetic properties of the material in the butt sections with the vertical parts of the building (parapets, pipelines, antennas, etc.).

The amount of repair work will depend on the current condition of the roof.

It is important to understand that it can be extremely difficult to determine the problem area, especially when it comes to pitched roofs.

Only an experienced specialist will be able to perform a competent inspection, assess the condition of the roof and offer the best methods for arranging defects.

Internal protection

If the purpose of the well is a septic tank or an inspection shaft, then inside it can be waterproofed with the same materials as the outside. In the case of a drinking well, the use of chemistry is unacceptable, then special tools will come to the rescue.

During waterproofing work at the construction stage, the processing of seams can be started immediately, in the case of the restoration of the well, its cavity must be cleaned of drains and pollution, the water must be pumped out. The walls must be cleaned and degreased, the seams are embroidered up to 3 cm deep for ease of filling. If a leak occurs during the cleaning stage, close the hole with MEGACRET-40 repair mortar and wait for it to dry completely.

The waterproofing itself is made with any safe solutions intended for drinking wells, for example, liquid glass, the joints are filled with AQUAMAT-ELASTIC, Peneplag or their analogues.

It is not necessary to process the entire inner side of the well, it is enough to work out the joints of the rings and the place where the bottom meets the shaft.

What is a hydraulic seal and what is it for?

Hydroseals are special mixtures that have a minimum setting time, quickly gain strength and have a high degree of adhesion with any type of material. Thanks to these properties, the composition allows you to quickly localize a pressure or non-pressure leak and create the necessary conditions for the overhaul of the damaged area.

Based on the physical and technical characteristics of the material listed above, it is possible to clearly identify the possible areas of use of a hydraulic seal:

- Well device. Only high-quality waterproofing can prevent groundwater from seeping into the well. With the help of waterproofing mixtures, it is possible to reliably seal the joints between the rings, as well as eliminate chips and other defects of the rings.

- Elimination of leaks in reinforced concrete structures. In case of violation of the waterproofing of pools, artificial reservoirs and other containers, with the help of the composition, it is possible to temporarily eliminate the leak, thereby ensuring the possibility of overhauling the waterproofing.

- Carrying out emergency repairs. The hydraulic seal is widely used to eliminate pressure leaks that occur in mines, tunnels, and basements when groundwater breaks through.

- Elimination of minor leaks. Such leaks occur when the waterproofing of the foundation is damaged, at the joints of load-bearing walls and ceilings, etc.

- Emergency repair of pipelines. In this case, a hydraulic seal is used as a temporary measure that allows you to stop the leak and perform the necessary repairs in a quality manner.

Filling gaps and cold joints in reinforced concrete structures

Seal holes up to 2 sq. cm

In the absence of water pressure, leakage can be eliminated if the gap is tightly and quickly filled with dry powder. If a jet of water with pressure, then it will wash the powder before it has time to harden. Therefore, a more complicated procedure is required here:

- knead a hard lump on water, form it in the form of a “sausage” the size of the diameter and depth of the hole;

- hold it in your hand for 30 seconds (until it heats up) and press it like a cork deep into the hole;

- hold the seal with your hand until it is completely hardened.

Hydro seal is ready for use

Hydro seal is ready for use

Fixing a leak through a large hole

If the size of the gap is up to 10–15 sq. see, then the installation of a hydroseal is done using fabric. A “gag” is prepared with a cloth, into which the powder is poured and rolled up, then the finished “gag” is rolled in it and the leak is plugged.

Preparing the concrete surface for sealing a leak

Preparing the concrete surface for sealing a leak

The size of such a seal should be slightly larger than the hole. If it is too large, then it will not be possible to push it into the hole, and if it is smaller, it will not be possible to clog it tightly. It is pushed to such a depth that within the hole it is possible to apply a layer of “dough” of a hydraulic seal with a thickness of at least 15 mm.

Closing a slotted hole

Here, waterproofing is carried out in stages.Given the size of the gap, several "sausages" of hard lumps will be required. The first plug is installed at the top of the slot. After it hardens, the next one is installed below and so on until complete sealing. The use of "gags" made of fabric and mixture is allowed.

Slotted hole in concrete

Slotted hole in concrete

Seal a strong leak

This repair is the hardest. If there are wide gaps with high water pressure, then cut hoses with the same diameter are inserted. After that, the gaps between the holes of the hoses are first closed, where the water pressure is reduced. Then hydraulic seals are installed in the holes of the hoses. This whole structure should sink a little (by 20–30 mm) into the wall so that a layer of the mixture can be added from above for better waterproofing.

Seal a large leak in concrete

Seal a large leak in concrete

Sealing cold joints

Deformation cold joints are cuts in reinforced concrete structures. Cold seams, fistulas can appear in an emergency or during construction work. The use of hydraulic seals makes it possible to pour concrete slabs in 8–12 or more hours, which is very economical and convenient.

The procedure for installing a hydraulic seal

The procedure for installing a hydraulic seal

Their waterproofing is carried out in various ways, among which a hydroseal is often used, as one of the most effective options. Good waterproofing is necessary at the joints of reinforced concrete slabs, the most reliable materials are used here.

Before installing a hydroseal, the seam is pre-treated. On both sides of it, dovetail grooves are cut in the concrete - with beveled edges. Then the composition of the desired consistency is kneaded on water and tightly placed in the groove, aligned with the common surface.

How the composition works

According to the principle of its action, the hydroseal is a fast-hardening cement-based composition with the addition of a wide range of modifiers and plasticizers. The method of curing the mixture is hydration, and the process is forced by a high concentration of active compounds. In other words, the tighter the contact of the mixture with the liquid, the faster the curing process proceeds.

The hardness of the seal increases abruptly, after 40–300 seconds from the moment the dry mixture is mixed with water

In this aspect of use, it is very important to read the instructions: the compositions have a different dependence of the curing time on the degree of initial wetting. The curing speed must always be selected individually, depending on the size of the gap and the complexity of its shape.

The flow of chemical reactions in the composition of the seal is possible only under certain conditions, especially the temperature regime of use is important. Some types of seals are designed for use at low, but not negative temperatures - from +2 to +5 °C. However, it is worth remembering that under such conditions the curing speed inevitably decreases and this should be taken into account when planning the work technology, for example, to develop methods for holding the seal until it is completely cured.

A characteristic feature of hydraulic seals is considered to be zero shrinkage, and for the highest quality compositions, a moderate and normalized increase in volume. Also important is the fact that the plug material does not form a breeding ground for algae and microorganisms, which cannot be said about natural materials.In addition, we note that the application of this method of waterproofing does not require additional equipment and professional qualifications, it is enough to understand the principle of operation and correctly apply it depending on the conditions of use.

Weak spots

During operation, the waterproofing protection wears out due to various factors:

- Impact of groundwater and aggressive environments;

- Seasonal temperature fluctuations;

- Penetration of moisture under insulation through cracks in concrete;

- Errors in installation or use of low-quality materials.

In order to prevent significant leaks, it is important to periodically diagnose the well from the inside and, if defects are found, eliminate them in a timely manner. Seams between the rings can be depressurized, but more often problems arise with sealing the well wall at the pipe entry point

The fact is that the pipe enters the shaft at an angle, in addition, it is made of a different material (metal, plastic), so it is not always possible to achieve an ideal seal

Seams between the rings are susceptible to depressurization, but more often problems arise with sealing the well wall at the pipe entry point. The fact is that the pipe enters the shaft at an angle, in addition, it is made of a different material (metal, plastic), so it is not always possible to achieve an ideal seal.

Operation Precautions

The technology of using a hydraulic seal for a well is not particularly difficult, and therefore can be performed by a novice master without the involvement of specialists. When working with the solution, protect your hands with gloves.After use, the tool is immediately washed from the remnants of the mixture, otherwise, after the final hardening, it will be difficult to clean it only mechanically.

Well waterproofing has always been a tricky business. Many, trying to carry out the necessary work, faced serious problems. For clarity, we will give a few examples - problems that arise in cases where the waterproofing in the well is done with violations or even worse, it is completely absent. This is a flow into the well, during the appearance of melt water, this is a violation of the filtration in those places where the seams of the well are located, and much more.

To avoid such troubles, the seams between the rings of the well must be sealed with a mixture of PVA glue and cement. Mix PVA glue and cement, thus obtaining a thick mixture. Next, gently coat the seams with a spatula (you can several times to align the seam). All! Water and dirt will never enter the well again.

Note: according to a similar scheme, you can first make a liquid primer from PVA and cement and smear the first layer with it to increase the impregnation of concrete in reinforced concrete rings. And after drying, coat with a mixture of PVA and cement.

After hardening and complete drying, you can still smear these places with liquid glass. Only it is impossible to mix liquid glass with cement. There will be instant freezing.

The second way to solve the problem is a clay castle or simply "waterproofing" around the well. To do this, the well is dug outside (the first 3 rings are enough, i.e. 3-4m) and sealed either with clay, but always without sand and earth, or with a cement solution.

And finally, the third option is special solutions for sealing wells, which today are presented in a large assortment on the building products market. For example, Penetron Hydrolast. They are a thin-layer (1.5-2 mm) waterproofing coating based on cement and special polymers of the latest generation. Possess vapor permeability (breathe) and elasticity, sufficient for application on the low-deformable bases. Coatings have a high degree of adhesion to any surface, weather resistance, environmentally friendly, prevent the penetration of water through the body of concrete even in the presence of high hydrostatic pressure.

It is quite easy to work with materials. Hydrolast is easily applied to a pre-moistened surface and forms a common crystal lattice with mineral bases, which eliminates the possibility of its delamination. Moreover, the coating allows you to carry out any finishing work in the future: applying plaster, painting, laying ceramic tiles, etc.

The process of applying Penetron resembles "staining": the prepared solution is applied to the surface of the concrete with a conventional synthetic bristle brush. More detailed information about each of them can be found on the company's websites ...

Cement mortars for grouting joints

It is possible to seal the connecting seams between the reinforced concrete rings of the well using a dry mixture of sand and cement, diluted with water to the required consistency. The main thing to remember is that liquid glass must be added to the resulting composition. This will increase the strength of the grout and its service life.

It is important! The composition of sand and cement, to which liquid glass is added, hardens very quickly. Therefore, the mixture is prepared in small portions in order to have time to apply it in no more than 10 minutes.

The required consistency of the finished composition is determined by the size of the processed cracks and gaps. The larger the surface area to be treated, the thicker the mixture will be required.

The work surface and everything you need to prepare in advance. This will help to quickly apply the composition and gently level it, filling the seams and leveling surface defects.

How to close the seams in the well: types of hydraulic seals

Hydroseal - a special composition that is used to eliminate leaks in wells. It is prone to rapid hardening and is not washed out by the pressure of water. If the crevice in the well is not repaired in a timely manner, groundwater can enter the well water and change its taste and quality.

An ordinary solution of cement and sand was washed out with water, so over time a hydraulic seal developed specifically for such purposes appeared.

Types of hydraulic seals:

- Pressure - harden within a couple of tens of seconds, a special layer of waterproofing is applied over the seal.

- Non-pressure - it takes 5-8 minutes to completely solidify. It is used during scheduled preventive maintenance.

Hydrocement is also used to repair pipelines and small gusts in basements.

Requirements for waterproofing seals:

- Fast freezing;

- Reliability;

- Ease of use;

It is also important that the seal does not corrode and is not deformed by temperature changes. Hydroseal should not change the taste of water and should not affect its composition

Conclusions and useful video on the topic

The video will introduce the procedure and technological stages of embedding seams in a concrete well:

Detailed video instruction on fixing a pressure leak using the Peneplag hydraulic seal:

Competent production of hand-made seals and the use of industrial compounds guarantees an excellent result, eliminates leaks and cracks in a reinforced concrete well shaft.

We are interested in your personal experience in fixing leaks in a concrete well shaft. Please write in the block under the article submitted for review. Ask questions here, share useful information and photos of the process of sealing cracks and weak spots in the wellbore.