- Hydraulic seal for a well - technology for sealing gaps in concrete

- How to prepare a solution to fix a leak yourself?

- How to seal a leak with a prepared solution?

- Where else are hydraulic seals used?

- Do-it-yourself sealing of seams in a well

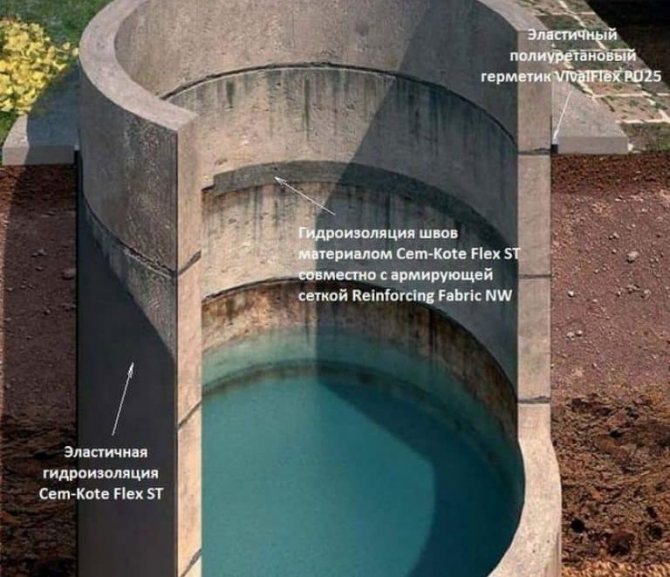

- Modern way of sealing

- Ways to increase the moisture resistance of concrete rings

- How to prepare a solution to fix a leak yourself

- Types of waterproofing wells

- Weak spots

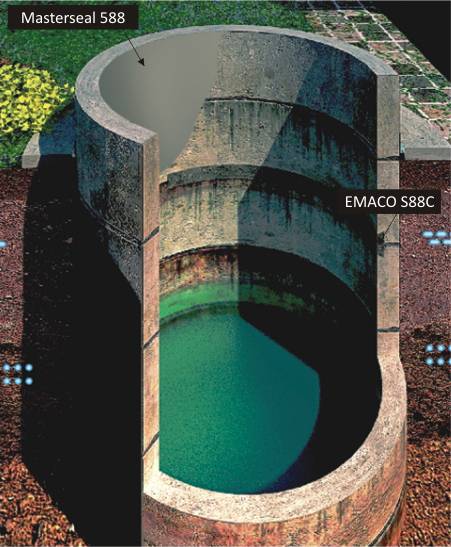

- How to seal the surface of a well

- Finished waterproofing seals

- Price:

- Ready-made hydraulic seal for wells: how to use it

- Sealing technology

- 2.1. Opening and preparation of the joint surface of a plastic pipe with concrete

- 2.2. Priming and application of the main layer of Dehydrol luxury brand 7

- 2.4. Care

- 2.5. Subsequent work

- The need for waterproofing

- Ways to increase the moisture resistance of concrete rings

- Some details

- Overview of famous brands

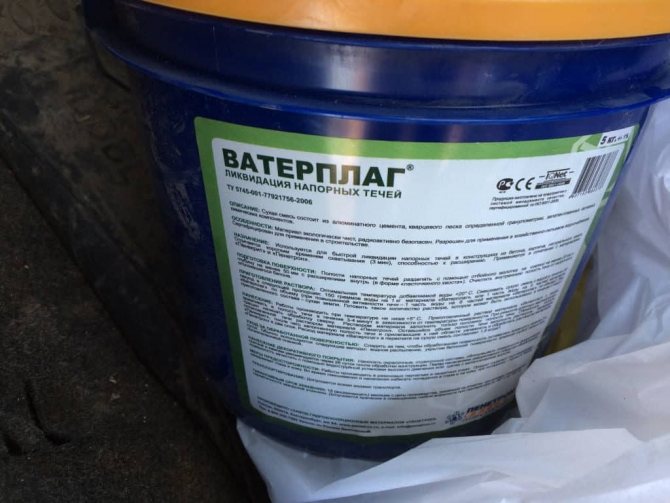

- Waterplug

- peneplag

- Puder Ex

Hydraulic seal for a well - technology for sealing cracks in concrete

To protect clean well water from possible contamination by groundwater containing harmful impurities, various waterproofing materials are used. The seams between the rings, the places where engineering communications are inserted into the well shaft, as well as the defects that have appeared during operation in the body of reinforced concrete products, need special sealing.A hydraulic seal for a well allows you to quickly eliminate leaks - a quick-hardening material that can restore solidity to the structure within a few minutes

When buying this material, you should pay attention to the presence of a certificate confirming the safety of the components that make up the seal for drinking water

This video clearly demonstrates how to use the Waterplug/Peneplug hydraulic seal. Materials from other manufacturers, produced for the immediate elimination of pressure leaks, are used in a similar way.

However, they must be used in accordance with the attached instructions.

How to prepare a solution to fix a leak yourself?

When preparing the solution yourself, you must follow the manufacturer's recommendations. The amount of dry mixture is taken depending on how active the leak is. Usually, 150 grams of water is taken per kilogram of hydraulic seals for a well. Otherwise, the proportion is calculated based on the volume of the components, while five parts of the mixture are taken for each part of water.

Important! If the flow pressure is significant, then the proportion of the ingredients in the solution is changed, increasing the amount of the dry mixture in the solution to seven parts (water refers to the mixture as one to seven). The temperature of the water taken to prepare the solution should be + 20 ° C

After a quick kneading, the time of which should not exceed 30 seconds, a solution is obtained that looks like dry earth. Immediately a large amount of the solution can not be kneaded, as it instantly seizes. Therefore, it is necessary to prepare the mixture in parts, after applying one of them to the area of the leak, proceed to the preparation of the next

The temperature of the water taken to prepare the solution should be + 20 ° C. After a quick kneading, the time of which should not exceed 30 seconds, a solution is obtained that looks like dry earth. Immediately a large amount of the solution can not be kneaded, as it instantly seizes. Therefore, it is necessary to prepare the mixture in parts, after applying one of them to the area of the leak, proceed to the preparation of the next one.

How to seal a leak with a prepared solution?

First, the surface is prepared for work, for which the internal cavity of the leak is freed from loose, exfoliated concrete using a jackhammer.

The place where the leak appears is embroidered to a width of up to 25 mm and a depth of 50 mm, it can be a little deeper. The shape of the hole should resemble a funnel.

Then, in a clean container, stir the required amount of the mixture to seal the leak. Hands form a lump from the solution, which is pressed into the embroidered hole with a sharp movement, and held for several minutes (2-3 minutes are enough).

Important! Hydraulic seal for wells made of reinforced concrete rings, stone, brick can be applied to both vertical and horizontal surfaces. Note that this does not require formwork

If the hole has an oblong shape and is not plugged at a time, then it is sealed from top to bottom.

Where else are hydraulic seals used?

With the help of quick-hardening solutions, it is possible to effectively deal with:

- with water leaks from reinforced concrete tanks;

- with water breakthroughs in basements, tunnels, mines, adits, galleries;

- with defects that have arisen in the bowl of pools and other artificial reservoirs;

- with capillary leaks appearing in the area where the floor and walls meet, between foundation blocks, etc.

Operation Precautions

The technology of using a hydraulic seal for a well is not particularly difficult, and therefore can be performed by a novice master without the involvement of specialists. When working with the solution, protect your hands with gloves. After use, the tool is immediately washed from the remnants of the mixture, otherwise, after the final hardening, it will be difficult to clean it only mechanically.

The cost of this waterproofing material is high, so not all companies involved in the construction and repair of drinking wells use it. When contacting specialized firms, clarify this issue immediately, as other materials may not be as effective in combating leaks.

Do-it-yourself sealing of seams in a well

Elimination of leaks in wells can be carried out without the involvement of craftsmen; any owner can repair the leak with his own hands. To eliminate the leak in the well, first of all, you need to take your time and follow the technology of work.

Progress:

- Prepare the surface. Remove loose concrete from the walls of the well with a jackhammer or perforator. Expand the resulting pothole on the sides and in depth by 20-40 mm. Clean off dust.

- Prepare a solution. It is recommended to knead the waterproofing mixture a couple of minutes before application. The finished composition should resemble dry earth. When mixing, strictly adhere to the rules for cooking.

- Close up the crack. Fill the prepared place with a solution, leaving the fourth part unfilled. Hardening, the composition expands and completely fills the gap.

- Stabilize the filling.Press the filling with a hand or a spatula, as if pressing it inward.

- According to the instructions, it may be necessary to periodically moisten the seal a couple of times during the day.

- Treat the seal with a special waterproofing compound - Hydrotex or Osmosil.

After completing all work, it is recommended to immediately wash all the tools, otherwise the solution will harden and it will be problematic to clean it.

It is better to use ready-made hydraulic seals, a home-made composition does not give a full guarantee of quality.

Modern way of sealing

Now tow and wedges made of wood are a relic of the past, and sealing technologies in this way have gone down in history. Thanks to progress, new methods have appeared for sealing well cracks in concrete and joints between reinforced concrete structures.

However, sealing holes and cracks in concrete hydraulic structures - the direct purpose of a hydraulic seal - can be afforded by every homeowner who has his own source on the site. Among the advantages are durability, not exposed to moisture, the possibility of using for wells with drinking water.

Ways to increase the moisture resistance of concrete rings

There are the following methods of waterproofing concrete wells:

- Constructive. Treatment of concrete rings with hydrophobic impregnations directly at the factory, after the products have hardened.

- Technological. The use of special techniques for compacting concrete poured into molds is envisaged. We are talking about centrifugation, vibrocompression and removal of moisture by the vacuum method.

- Improving the water resistance of cement.It is possible to increase the resistance of concrete rings to moisture through the introduction of special water repellents into the composition of the solution. The specificity of the action of these substances lies in their swelling and blockage of pores and microcracks as the concrete hardens.

The use of these methods increases the cost of reinforced concrete rings. A cheaper option is the sealing of the walls and butt sections between the individual elements of the well shaft.

Sometimes it’s easier and cheaper to just put hydraulic seals (cover up internal joints), but no one can guarantee how effective and durable it will be.

How to prepare a solution to fix a leak yourself

- The required amount of the mixture and water is measured in the indicated proportions. The standard ratio of the volume of the mixture and water is 5 to 1, but if measurements are made by weight, then 150 g of water falls on 1 kg of dry powder. When repairing leaks under high pressure, the proportion of powder increases to a ratio of 6 or 7 to 1.

- The water is heated to a temperature of 20°C.

- The components are thoroughly and quickly (no more than 30 seconds) mixed with gloved hands or with the help of improvised tools. The ready-to-use solution is similar in consistency to dry soil.

The hydraulic seal for the well should be quickly mixed in the required proportions and pressed into the place where the leak has formed

The air temperature during work should not fall below +5°C.

After adding water, the dry waterproofing mixture completely hardens within a few minutes, so it is worth preparing the solution in small portions, in the amount necessary to seal one damage.

The cost of the finished mixture is quite high, so the sealing of holes and non-pressure leaks that do not come into direct contact with water can be done using a solution prepared by handicrafts. To do this, without adding water, 2 parts of sand and 1 part of cement are mixed, after which the resulting composition is placed with a spatula in all places to be repaired. The repaired areas are covered with iron sheets for 2-3 days (you can fix the sheets with the help of spacer bars). After 2-3 days, the sheets are removed, and the surface of the improvised hydraulic seals is covered with a layer of cement or other waterproofing solution.

Waterproofing of wells during the construction process can be carried out using a solution prepared on the basis of cement and PVA glue. For preparation, cement (1 part), sand (2 parts), water (1/3 of the total volume), PVA glue are used. Such waterproofing for concrete is applied on a dry surface, in joints between reinforced concrete rings pretreated with a primer.

- Before preparing the solution, you should carefully prepare the place for installing the hydroseal. To do this, the surface is cleaned of contaminants, and exfoliated or damaged areas are removed.

- In the damaged area, a hole is drilled or knocked out in the form of a tapering funnel at least 25 mm in diameter and 50 mm deep.

- The surface on which the solution is applied is wetted.

- A small amount of solution is prepared, a lump of the required size is formed and, with a quick, strong movement, it is fixed in the prepared hole for several minutes.

- The remaining material is removed, the surface is leveled with a spatula.

After 30 seconds, the solution hardens, so all actions are performed very quickly. Holes of large diameter can be sealed in several stages.

Regardless of what material the well is made of, a hydraulic seal can be installed on a surface located in any plane (horizontal, inclined or vertical). Large vertical damage can be repaired in several stages, with the mortar applied from top to bottom.

Types of waterproofing wells

The installation of an underground structure is accompanied by waterproofing works of the following types:

- pasting sealing along the bottom of the structure;

- filling gaps and joints with sealants;

- installation of a polymer liner inside the mine shaft;

- the use of bituminous mastic, roll insulation to protect the outer walls;

- plastering - possible from any side of the structure;

- the use of modern sealants to seal leaks from the inside of the well.

The choice of waterproofing method is carried out at the stage of designing an underground working, when planning repairs during operation. The decision is made depending on many factors and circumstances, but the best result is a combination of several methods.

Weak spots

During operation, the waterproofing protection wears out due to various factors:

- Impact of groundwater and aggressive environments;

- Seasonal temperature fluctuations;

- Penetration of moisture under insulation through cracks in concrete;

- Errors in installation or use of low-quality materials.

In order to prevent significant leaks, it is important to periodically diagnose the well from the inside and, if defects are found, eliminate them in a timely manner.Seams between the rings can be depressurized, but more often problems arise with sealing the well wall at the pipe entry point

The fact is that the pipe enters the shaft at an angle, in addition, it is made of a different material (metal, plastic), so it is not always possible to achieve an ideal seal

Seams between the rings are susceptible to depressurization, but more often problems arise with sealing the well wall at the pipe entry point. The fact is that the pipe enters the shaft at an angle, in addition, it is made of a different material (metal, plastic), so it is not always possible to achieve an ideal seal.

How to seal the surface of a well

Ways of water penetration through holes in the walls of the well are eliminated with the help of special mixtures of waterproof properties. The working surface before applying the protective composition must be cleaned of dust, debris and random objects. Individual cracks, flaws, etc. needs to be expanded to remove loose particles.

Holes and other through damage to the concrete rings with which the well is lined must be covered on both sides. First, the surface must be cleaned. The protective composition is applied first of all from the outside, and then from the inside of the well.

First you need to disassemble the blind area. Then you need to remove the top layers of soil in order to gain access to the defect from both sides. When the damage is repaired, the excavated earth is evenly laid around the concrete rings. Then you need to level and compact it. At the end, a blind area is installed.

A significant investment of time and labor will be required when the concrete rings are shifted relative to each other. This happens when the joints are broken.To restore the integrity of the well in this case, it is necessary to remove the soil to the level of the defect. Then the displaced rings must be removed.

A strong water jet or mechanical means can be used to clean the mating edges of old coatings, dirt, algae, etc.. This will increase the level of adhesion after applying the waterproofing agent.

Then you need to correct all the noticed defects, expanding and / or deepening, if necessary, existing cracks, holes, etc. The prepared elements must be installed in place and the entire structure carefully aligned.

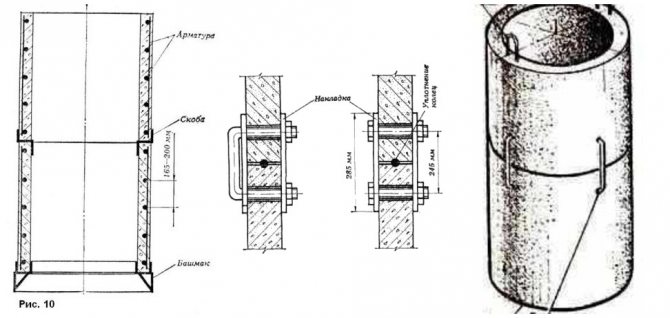

Docking seams and all existing damage must be carefully sealed from the outside and inside. This is done using a special grout mixture. For final protection against moisture, the treated surface must be covered with a waterproofing compound. It is applied from the outside after the grout has dried. Metal staples that fasten the rings will help prevent their displacement during operation. An important point during their installation is the level of soil freezing during the period of the lowest temperatures in the region.

Above this level, 4 staples must be installed for each seam. Below the soil freezing line, 2 staples are enough to fasten each seam. When all the protective compounds are dry, it is necessary to lay the extracted earth around the well. A blind area is installed along the perimeter of the well.

Finished waterproofing seals

Dry waterproofing materials enter the distribution network in paper bags or plastic buckets. Methods for applying hydraulic seals depend on the chemical composition and manufacturer of the product.

The best indicators of the effectiveness of waterproofing seals.

Of the waterproof materials on the domestic market, the best performance indicators for the products of the following companies:

- Dry mixes Peneplag and Waterplug (supplier "Penetron"). They are distinguished by short setting time (1.5-5 minutes), instant stop of leakage and good expansion ability. They are used in critical cases when other waterproofing materials are ineffective, and are washed off with water at the application stage.

- Mapei Lamposilex is a fast-setting and hardening hydroseal. Designed to eliminate leaks, fistulas in wells and other drinking tanks.

- Bostik Bosco Cem Plug is a fast curing compound that has proven itself in underwater applications and continuous moisture filtration. Possesses high frost resistance and durability.

- Ceresit CX 1 - products from a popular manufacturer of waterproofing materials. Hydroseal CX 1 is used to stop water leaks in building envelopes, to seal large diameter holes in underground structures.

Price:

from 3000 per sq.m. Waterproofing a drinking well is a guarantee that it will not become shallow, and the water in it will be drinkable throughout the entire period of operation. Properly carried out waterproofing of the well from concrete rings from the outside will prevent contact of its walls with groundwater and their destruction due to this negative impact. Not only that: the destroyed walls of the well cause the penetration of clay, ground salts, oil products that have fallen onto the soil, sewage, as well as the remains of decomposed organic matter into the water. It will be impossible to drink such water even after boiling.If we are talking about sewer wells, then their waterproofing, on the contrary, will prevent the penetration of sewage into groundwater.

Ready-made hydraulic seal for wells: how to use it

A solution for sealing a leak can be prepared from a dry mixture, strictly adhering to the instructions. As a rule, 150 ml of water 18-20 degrees is needed for 1 kg of dry mix. If necessary, you can knead small volumes of waterproofing composition, based on the proportion of 1 part of water - 5 parts of dry cement.

The solution is mixed for half a minute, after which it is immediately applied to the area with a leak.

What mixtures for waterproofing are better:

- Waterplug. Diluted with slightly warm water. It hardens within 120 seconds, it is applied at temperatures from +5 to +35 degrees.

- Peneplag. In addition to concrete, it can be used to fix leaks in brick and stone wells. Freezing time - 40 sec.

- Puder ex. One of the fastest fillings, hardens in 10 seconds. Not applicable at temperatures below 5 degrees.

During the preparation of the solution, as well as subsequent work with it, certain rules should be followed. Always wear a respirator and protective gloves when working. Do not use any liquids to mix the solution - only ordinary water, and the container must be metal.

Sealing technology

When working on sealing joints, it is extremely important to follow the technology specified in the instructions for use of the material. This is no less important than the correct selection of material for sealing the joint.

2.1. Opening and preparation of the joint surface of a plastic pipe with concrete

The joints of the plastic pipe with concrete must be cleared to a depth equal to twice the gap (i.e.open the joint with enthusiasm of 30 mm to a depth of 60 mm, obtaining a free groove 30 mm wide and 60 mm deep around the pipe). The depth of the opening of the joint in any case must be at least at least 40 mm.

If there is access to the junction of the pipe with concrete from both sides of the concrete wall, then work is carried out from both sides of the wall.

Thoroughly clean the surfaces of concrete and plastic inside the joint from coatings (especially bituminous and polymeric) and contaminants. Remove loose concrete with broken structure. If necessary, repair concrete Dehydrol lux brand 5.

The upper glossy layer should be removed (for example, by roughening) regardless of its nature (whether it be cement "milk" or pebbles on a concrete surface, or gloss on plastic pipes in a waterproofed joint).

Before applying the working solution, remove dust and moisten the surface that will be in contact with Dehydrol.

2.2. Priming and application of the main layer of Dehydrol luxury brand 7

Before any application of the Dehydrol solution, you need to make sure that the surface to be treated is moistened. If necessary, re-moisten the concrete surface. It is forbidden to apply Dehydrol on a dry (including dried after moistening) substrate!

Prepare a Dehydrol Lux brand 7 solution, as indicated in the instructions for use, and prime the surface of concrete and plastic with it from the bottom and to half the depth of the prepared groove around the pipe. Then hermetically fill the groove from the bottom to half the depth with Dehydrol Lux brand 7 solution:

A solution of Dehydrol luxury grade 7 in the groove should be compacted in any way possible, and the surface should be smoothed to a gloss. The consumption of Dehydrol luxury grade 7 is 1.5 kg per 1 dm3 of the groove being filled.

In particularly critical cases, the surface of the groove is additionally impregnated with Kontacid grade 5 before each application of a layer of Dehydrol. In some cases - at high water pressure or when there is a danger of large water inflow - Dehydrol lux grade 7 is applied in layers (in two or three layers) with impregnation before each application of Dehydrol with grade 5 Contacid. grade 5 is approximately 2 liters per 1 m2.

Prepare a solution of Dehydrol luxury brand 5, as indicated in the instructions for use, and prime the surface of concrete and plastic with it in the groove remaining after sealing Dehydrol luxury brand 7 at the junction of the pipe with concrete. Then hermetically fill the groove flush with the adjacent surface with Dehydrol Lux brand 5:

The consumption of Dehydrol luxury grade 5 is 1.7 kg per 1 dm3 of the groove being filled.

Also, seal all joints of concrete with plastic pipes in all accessible areas.

2.4. Care

The surface treated with Dehydrol must:

- shelter from rain (during the first day after application);

- keep moist (at least 3 days), covering with a film or periodically moistening with a spray bottle;

- in hot or windy weather, protect the surface from rapid drying by frequent moistening or covering, for example, with polyethylene, stretch film, tarpaulin, etc.

When leaving, it is necessary to moisten not only the applied material, but also the concrete surface adjacent to it along the perimeter at a distance of at least 50-150 mm from the applied material

2.5. Subsequent work

For application to the sealed joint of cement-sand mortar, incl.plastering can be started 7 days after the completion of processing (at an ambient temperature of 20 ° C).

14 days after sealing (at an ambient temperature of 20°C), the joint can be operated without restrictions, incl. painted etc.

If the finishing of the applied layer of material is not planned, then the tank with the sealed joints of plastic pipes can be filled with water 7 days after the completion of the treatment (at an ambient temperature of 20°C).

The need for waterproofing

The underground structure is under the influence of many negative factors. Mistakes made during the arrangement of waterproofing concrete wells appear immediately or after 4-5 years of its operation.

If signs of joint depressurization are found, it is not recommended to postpone repair work for the following reasons:

- Freezing of watered soil occurs annually with the advent of winter. The resulting ice breaks the concrete, expanding the cracks more and more until the rings are completely destroyed.

- The quality of drinking water. When perch water contaminated with sand, clay, chemical and organic substances enters the mine, the analysis indicators deteriorate sharply. The liquid becomes cloudy, the water source dies.

- Overflow of the sewer well. Groundwater penetrates into liquid sewage through leaky joints, the container quickly loses its receiving volume. If daily pumping is not carried out, the soil will be contaminated with runoff.

- Washing out of the insulating compound. A small trickle of liquid, if no measures are taken to eliminate it, quickly develops into a powerful stream that can expand a small hole and render the well unusable.

Land subsidence as a result of groundwater activity leads to the destruction of the joints of the circular lining. The time when it is necessary to carry out repairs is determined by the appearance of cracks from which water oozes. To avoid the loss of the well, you need to quickly take measures to seal the seams and gullies.

Ways to increase the moisture resistance of concrete rings

There are the following methods of waterproofing concrete wells:

- Constructive. Treatment of concrete rings with hydrophobic impregnations directly at the factory, after the products have hardened.

- Technological. The use of special techniques for compacting concrete poured into molds is envisaged. We are talking about centrifugation, vibrocompression and removal of moisture by the vacuum method.

- Improving the water resistance of cement. It is possible to increase the resistance of concrete rings to moisture through the introduction of special water repellents into the composition of the solution. The specificity of the action of these substances lies in their swelling and blockage of pores and microcracks as the concrete hardens.

The use of these methods increases the cost of reinforced concrete rings. A cheaper option is the sealing of the walls and butt sections between the individual elements of the well shaft.

Sometimes it’s easier and cheaper to just put hydraulic seals (cover up internal joints), but no one can guarantee how effective and durable it will be.

Some details

Primary sealing of joints in a well made of concrete rings is carried out during its arrangement. In the future, from time to time, repeated sealing of the seams is required. The main reasons for doing it are:

- initially incorrectly sealed joint;

- gradual destruction of the seams during operation.

Urgently sealing damaged seams is required if:

- the water becomes cloudy;

- an unpleasant odor appears;

- the liquid level in the well between the rings rises much higher;

- concrete rings used in well finishing are distorted, shifted, etc.

First you need to carefully study the technology of the process and understand how to repair damaged seams correctly and at no extra cost.

Answering the question of how to cover up the seams in the well, professional craftsmen recommend options such as:

- plastering;

- sheathing with moisture-proof roll-type material;

- sealing joints with special inserts;

- applying a special putty.

To complete the work, you need to invite one or two assistants. You will definitely need such protective equipment as:

- special wader boots;

- helmet;

- rubber gloves.

Overview of famous brands

The modern construction market contains a lot of offers from various companies. Despite the fact that the technologies for using hydraulic seals are similar, the efficiency and quality are different. Therefore, it is recommended to opt for the products of the world's leading brands, which have proven themselves with specialists who are professionally engaged in shotcrete.

Waterplug

This is a dry mix that is packaged in a plastic container. Before use, it is necessary to prepare an aqueous solution in accordance with the attached instructions. The composition includes quartz sand, and special hydraulic cement is used as a binder.

The peculiarity of this mixture is that it is possible to seal holes through which water breaks out under pressure. Three minutes is enough for the solution to solidify.The effectiveness of waterproofing concrete wells is achieved due to the ability to expand when solidified, due to which the pores are filled, and a strong, tight connection is provided.

peneplag

This is a similar composition of the dry mix, but the aqueous solution has a greater setting speed. It takes from 40 seconds to a minute to eliminate a pressurized leak. Sealing is carried out due to the ability of the mixture to expand when solidified.

The advantages of this hydro seal include:

- Fast setting, effective sealing, durable.

- It can be used at temperatures from 5 degrees Celsius.

- Resistant to water and aggressive environments.

Puder Ex

Quick-setting material allows you to seal holes under pressure. The composition is resistant not only to water pressure, but also to capillary action of moisture. In the well, dry joints are sealed in 7 seconds. That is how much a hydraulic seal needs to make the concrete structure airtight again.

Despite the high performance and benefits, the price of this dry mix is low. The German quality and reasonable cost made it popular among the builders of hydraulic structures and workers of specialized teams performing their repair and maintenance. The maximum withstand water pressure is up to 7 atmospheres, which means that this hydraulic seal will be able to eliminate any leak.