- Questions about choosing waterproofing for your bathroom

- Tile bathroom waterproofing technology

- Coating waterproofing for the bathroom

- Tile bathroom waterproofing

- Helpful Hints

- Popular technologies for waterproofing a bathroom under a tile

- Application of roll materials

- Coating waterproofing device

- Plaster waterproofing

- Impregnation compositions

- Combined waterproofing

- Types of waterproofing and materials used

- Coating

- Roll materials

- Types of materials

- Polymer films and membranes

- Roll materials based on bitumen

- Mastics

- Polymer plasters

- penetrating compounds

- For tiled floor

- For tiled walls

- Tile bathroom waterproofing rating

- Third place. Waterproofing Eskaro Aquastop Hydro

- Second place. Waterproofing Litokol Aquamaster

- First place. Waterproofing Knauf Flachendicht

- How to deal with moisture in the bathroom?

- Materials used

- What should be the floor waterproofing device

- Coating waterproofing for a floor under a tile

- Liquid waterproofing for a bathroom under a tile

- Bulk waterproofing of the floor in the bathroom

- Roll waterproofing under tiles

- Insulation with liquid rubber

Questions about choosing waterproofing for your bathroom

This is a rather complex question that cannot be answered unambiguously. The choice of insulation type depends on many factors. First of all, it is the material of the floors. If it is a tree, it is advisable to use glued insulation. Any type is suitable for concrete.

It is also important to understand how serious repairs are planned to be carried out. If there is an opportunity and desire to perform the highest quality waterproofing, it is better to choose pasting, laid under the screed, followed by treatment with coating compositions

High-quality waterproofing of the bathroom will protect finishing materials and building structures from premature destruction.

Such a tandem will provide guaranteed protection against any leaks for more than a dozen years. However, this is the most labor intensive option. If a relatively small repair is planned, only coating waterproofing can be laid.

It is worth considering the number of storeys of the building. If the bathroom is located on the first floor of a private house, floor and wall insulation will be sufficient. For high-rise buildings, you will also need work on the ceiling.

When choosing a material, it is also important to take into account the possibility of changing the height of the room. If this is highly undesirable or impossible, impregnating or liquid coated insulation should be used.

To work with the floor, any of the existing types of materials can be selected.

It is worth considering the configuration of the room. The rolled panel will be extremely difficult to lay in a complex-shaped bathroom. For walls and ceilings, only impregnating and coating compounds are used.

Tile bathroom waterproofing technology

For bathrooms, gluing or coating materials based on bitumen, latex (for example, Knauf Flahendicht waterproofing) or polymers are most often used. They may differ in composition, application technology and price, but the basic principles for determining the scope of work and choosing a specific type of protective substance are the same.

Apron tiles for the kitchen. Photo tiles of different types and styles. How to choose a tile for an apron in the kitchen, types of tiles for an apron. Apron design in the interior of the kitchen.

What is better to protect from all-penetrating water: only parts of the floor or its entire area? Do walls and other surfaces need to be treated? There are three ways to distribute the waterproofing layer:

- Only on the floor surface with the formation of bumpers on walls about 20 cm high.

- On the floor and sections of the walls surrounding the plumbing.

- On the floor and walls, having processed vertical surfaces along the entire height.

Scheme of arrangement of coating waterproofing: 1 - polymeric moisture-proof composition; 2 - tape for seams; 3 - tile adhesive

At the same time, sometimes the same type of material has to be applied to horizontal and vertical surfaces in different ways. This should be taken into account when choosing a waterproofing technology.

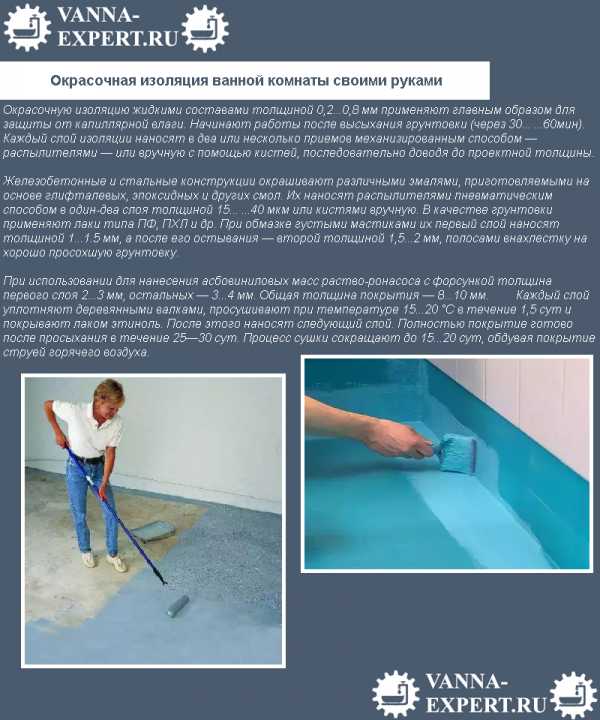

Coating waterproofing for the bathroom

This type of protective coating is performed by applying a plastic composition. Its thickness, depending on the number of applied layers, can be different: from 1 mm to several cm. The main advantage of coating waterproofing is that when it is used, a seamless, durable, but elastic coating is created. The advantage is also that it does not need a perfectly flat surface and can be applied to any base.The use of coating compositions as a waterproofing of the floor under the tiles in the bathroom is preferable in cases where it is necessary to fill the screed.

A plastic moisture-proof mixture is applied with a thickness of 1 mm to several centimeters.

Useful advice! In general, for a waterproofing layer 2 mm thick per 1 m 2 of surface, 3.2 kg of bituminous mastic will be needed. Therefore, its use is one of the most budget options.

The specific type of material depends on the place of its use:

- On horizontal surfaces - bitumen and bitumen-polymer mastics, pastes based on oxidized bitumen, modified with additives to increase elasticity and strength with a decrease in toxicity.

- Compounds that create a thin film on the surface - bitumen or mastic diluted to a liquid, water-repellent varnishes or paints for wood or metal elements. These substances are simply poured onto the floor and evenly smeared with a rubber spatula; on other surfaces they are applied with a brush or roller in two layers.

Processing corners in the bathroom with a moisture-resistant sealant

Tile bathroom waterproofing

Pasting waterproofing is made of a waterproof coating in the form of a film, sheets or rolls, fixed in several layers with the help of special adhesive mixtures. To get tight seams, the sheets are overlapped.

Important! Sometimes, to fix the sheets of gluing waterproofing, heating of their edges with a gas burner is used, but this method is not safe. The advantage of waterproofing with pasting is the low cost of the material. However, it will require a calculation of its quantity, accurate cutting, and the laying and leveling of the panels is a rather time-consuming process.

Pasting material after cutting should lie flat for a day

However, it will require a calculation of its quantity, accurate cutting, and the laying and leveling of the panels is a rather time-consuming process. Pasting material after cutting should lie flat for a day

The advantage of waterproofing with pasting is the low cost of the material. However, it will require a calculation of its quantity, accurate cutting, and the laying and leveling of the panels is a rather time-consuming process. Pasting material after cutting should rest in a straightened form for a day.

Tape waterproofing of bathroom walls using sheet material

The surfaces are leveled and, after the screeds and plasters have completely dried, they are covered with a primer, all seams are waterproofed and, if necessary, polymer glue is applied. Then start laying sheets - from anywhere on the floor. After the formation of the first layer of waterproofing, the sides that go onto the walls are arranged, about 20 cm high. Additional protection of areas adjacent to sanitary equipment is also possible. When pasting the walls, the sheets are superimposed from the bottom up.

Helpful Hints

In order to properly waterproof the bathroom with your own hands, you can use the following tips:

- it is necessary to choose the right waterproofing materials;

- identify areas that are most prone to moisture ingress;

- before starting work, it is necessary to prepare the surface well, clean it by about 2-3 millimeters;

- all pipes must be equipped with special seals;

pay great attention to the joints of walls and floors, as well as corners;

when waterproofing the floor, it is necessary to capture about 20 cm of the wall;

pasting waterproofing is at risk of ruptures, so it is better to strengthen it with a concrete screed;

when hovering a solution from any dry mixtures, it is better to first pour in water, and then gradually add the dry component, this will prevent the appearance of lumps. It is also better to use an electric mixer to achieve a uniform consistency;

- with self-production, it is not necessary to immediately make a large amount of the mixture, otherwise the stagnant residue will lose its qualities and properties;

- during waterproofing work, it is necessary to exclude the presence of drafts, as well as direct sunlight;

- as for wooden houses, even with good waterproofing in bathrooms, it is better to monitor the possible accumulation of water on surfaces and wipe it dry as soon as possible;

- in the process of waterproofing the floor, you have to work on your knees, so you can build a stand from a board and soft rags so as not to damage the waterproofing and for ease of work;

- it is better to treat pipes and sewers with a waterproofing solution at least twice and very carefully;

- when applying several layers of waterproofing, you need to lay them in different directions;

- for gluing sheets of waterproofing, you can use a gas burner.

Summing up, we can say that waterproofing a bathroom in an apartment or house is a very important stage in the renovation process, and it is better not to ignore it. You can do the waterproofing with your own hands, since this process is not so complicated. It is possible to choose any materials that correspond to the surfaces of the room, the preferences of the owner, as well as the planned costs.

Before starting work, it is important to prepare the room well, as well as to study all the instructions and recommendations indicated by the manufacturer. With proper observance of them, as well as following useful tips, you can independently mount high-quality waterproofing of your bathroom, which will last for many years.

For information on how to make waterproofing in the bathroom, see the video below.

Popular technologies for waterproofing a bathroom under a tile

Materials differ in structure and installation method. If you plan to waterproof the bathroom tiled rooms - which is better, 4 options are considered for this:

- roll;

- coating;

- moisture resistant plaster;

- penetrating compounds.

Coatings are designed for use in various conditions. So, before buying, you should consider a number of factors:

- purpose of the premises;

- type of base material;

- the intensity of the loads exerted on the floor.

Let us consider in more detail what kind of waterproofing to choose for a bathroom under a tile.

Application of roll materials

This group includes polyethylene film, roofing felt, glassine, fiberglass. In terms of properties, the latter option is superior to analogues, however, when laying, the edges may be damaged. Its main disadvantage is the high price.

Roofing material is rarely used indoors, because new, more technologically advanced materials have appeared. Installation methods:

- Fixing with fasteners. This is a less common method, due to the violation of the integrity of the coating. These areas are isolated before proceeding with the installation.

- Surface stickers. Use polymer paste, bituminous mastics, special glue.

- Fusion. Using this technology, roofing material is laid.A heat gun is used to heat the coating.

Coating waterproofing device

In this case, different types of mastics are used: based on cement, bitumen and polymer additives. Materials are applied to the prepared surface. In this case, the strength of the coating depends on the quality of the base.

It is not necessary to protect a crumbling floor with a coating mixture; insulation will not hold on such a surface.

The advantage of such compositions is a high degree of protection of load-bearing structures and partitions.

When applied, an impermeable layer is formed. The material fills leaks, cracks, pores. Mastic is easy to work with as it can be used to protect surfaces of any configuration. The coating applied by coating technology serves for a long time, does not deform as a result of shrinkage.

Plaster waterproofing

To protect surfaces, it is permissible to use only materials that include polymer additives. Such components help to improve the properties of insulation, prevent its cracking, increase strength.

Plaster materials are suitable for protecting load-bearing structures in the bathroom. However, they should be used together with accessories of the same brand (for example, sealing tape), which will help increase the reliability of the structure.

It is important to thoroughly clean the surface before applying a layer of mortar.

Impregnation compositions

At the heart of such mixtures are bituminous, polymeric additives, liquid glass. The principle of operation of impregnating compositions is based on deep penetration into the structure of the construction material.

Such a measure helps to strengthen the foundation.

The composition fills the pores, thereby preventing the penetration of moisture into the structure.Due to this, the service life of the structure is increased. As a result, the base material is more resistant to moisture.

It is possible to improve the water-repellent properties of the structure if the treatment is correctly performed.

Combined waterproofing

If, due to difficult operating conditions, it is necessary to protect the supporting structures, different technologies are used simultaneously. They combine impregnating, coating, roll materials.

Impregnation materials are distinguished by reliability. For this reason, it is used if it is necessary to cover areas subject to high loads. Roll analogs are quickly deformed.

Such materials do not withstand the effect of tensile deformation loads. Coatings are also inferior in strength.

Types of waterproofing and materials used

There are two classic types of waterproofing coating and pasting. The first type is represented by liquid means (pastes, mastics, solutions). The second is rolled film materials. Both have their pros and cons. In the case of bathroom waterproofing, liquid mastics are better - they are more convenient. First, the technology of work is simpler. Secondly, material consumption is less. Thirdly, the quality of the coating is higher.

Pasting materials in the form of rolls are mounted in two ways: by welding the material or by gluing. For melting, a building hair dryer or a gas burner is used. The second option is already equipped with an adhesive surface, it is enough to remove the protective film. The advantage of this type of waterproofing is low cost, and minus the complexity of installation.

If the ceiling height is critical, and it is impossible to raise the floor level even by fractions of a centimeter, impregnation can be used as a waterproofing layer as a waterproofing.These are special liquid compounds that are applied to a wet concrete or cement floor, soak into it and form a film that can protect the floor from high humidity and even water flow. Such materials for the floor and walls are more expensive, but in this case the end justifies the means.

Coating

Modern liquid products for insulating floors and walls under tiles have excellent properties. They are resistant to aggressive factors in rooms with high humidity and temperature changes.

The most popular types of liquid waterproofing:

- cement-polymer mixtures have become classics of the genre. Universal agent for coating waterproofing. In fact, it is a cement mortar enriched with special additives. Such a mixture sets quickly (from 5 minutes), has good adhesion, is sold dry or ready-made;

- bitumen-polymer mastics - have proven themselves from the very best side. Thanks to special plasticizers, latex filler, bitumen-based organic solvents, this composition is characterized by increased strength and adhesion to a concrete base;

- bitumen waterproofing is a fairly popular and economical type of mastic. There are two varieties of these mixtures, which differ in the way they are used: cold and hot. The main disadvantage of cold is that it is capricious about interaction with concrete. Hot is used when heated to a temperature of plus 160 degrees, this is a difficult-to-implement method at home;

- acrylic mastic is the most modern type of water-based waterproofing. It is an odorless eco-friendly material with excellent durability, so it is better than other materials.

Bituminous mastic Coating waterproofing

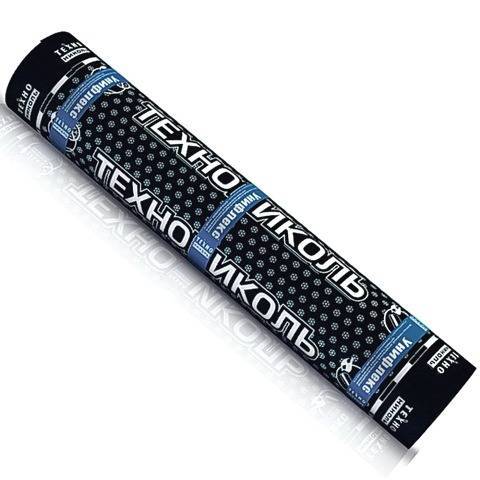

Roll materials

It happens that roll materials made on the basis of fiberglass or polyester are used for waterproofing under tiles. The lower part of this material is coated with an adhesive compound, and the upper part is coated with a special component that provides adhesion with tile adhesive.

This type of waterproofing is ideal for wooden floors, because rolled materials perfectly tolerate the movement of wood and do not lose solidity. In addition, the roll method is suitable for large areas. Stacking of roll materials is carried out with an overlap of more than 10 cm on top of each other with a call to the walls

When gluing seams with a roller, it is very important that all air bubbles are removed, otherwise all the work will be done in vain.

Types of materials

Waterproofing materials are available in various versions:

- polymeric membranes and films;

- rolled bituminous materials;

- mastics;

- polymer plasters;

- penetrating compounds.

Each of them has characteristic advantages and disadvantages.

the option of using waterproofing in the bathroom under the tiles in the renovation of the room

Polymer films and membranes

The film thickness is 0.2 mm. They are made from polyethylene or polypropylene.

The membranes are thicker: from 0.8 to 2 mm. They are made of PVC or EPDM and EPDM synthetic rubbers.

Films and membranes are glued with mastics, some are provided with an adhesive layer covered with a celluloid film.

The advantage of these materials is the significant size of the panels: the width of the roll can reach 15 m, the length is 60 m. This allows you to make a seamless waterproofing coating even in the most spacious bathroom.

Roll materials based on bitumen

The addition of polymers provides the following benefits:

The addition of polymers provides the following benefits:

- service life increases;

- there is the possibility of laying by welding.

Instead of low-strength cardboard, a non-rotting base is used: polyester, fiberglass or fiberglass.

This technology produces a variety of materials:

- bicrost;

- rubemast;

- stekloizol;

- fiberglass, etc.

The common everyday name for everyone is euroroofing material. Narrow rolls - 1 m wide.

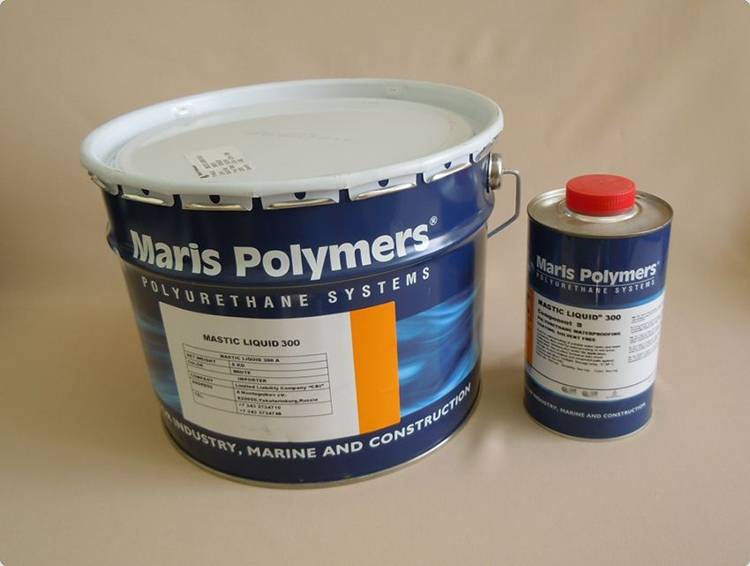

Mastics

They are divided into 4 varieties:

- Polymers based on MS polymers: butyl rubber, etc. The most durable and environmentally friendly: do not contain bitumen and solvent. Disadvantage: high cost.

- Bituminous and bitumen-polymer (with the addition of latex, crumb rubber, polyurethane and other polymers). They are cheaper, but less durable and contain solvents (releasing harmful substances).

- Acrylic based polymers. Cheap and short lived.

- Epoxy.

Mastic

The latter are intended for outdoor use, therefore they are not suitable for the bathroom.

Polymer plasters

They are made on the basis of non-shrinking or expanding cement with the addition of latex, other polymers or epoxy resin, bituminous emulsions and pastes. Ferric chloride, sodium aluminate, calcium nitrate act as sealing components.

penetrating compounds

They are absorbed by the porous surface and act inside the pores. Penetrating waterproofing is divided into two types:

- penetrating compounds: clog pores;

- water repellents: leave the pores open, but wet their walls, eliminating the capillary effect.

Concrete coated with a water repellent remains vapor-permeable; such insulation does not protect against direct exposure to water. It is used for the treatment of walls outside.

For tiled floor

In case of pipeline breaks or accidental splashing, water collects on the floor, therefore the most reliable waterproofing materials are laid here and, moreover, in several layers. These are films and bitumen-polymer roll materials.

For tiled walls

On vertical surfaces, first of all, the adhesion of the waterproofing material is taken into account.

The adhesiveness of films and membranes is low, therefore they are not suitable for tiling. Coating (most often), plastering and penetrating compounds are used - they are characterized by high adhesion.

In the direction of waterproofing materials for tiles are assigned to walls and floors.

Tile bathroom waterproofing rating

Waterproofing the bathroom under the tiles, which is better? Recently, roll waterproofing of the floor in the bathroom is used less and less. This is due to such disadvantages as the complexity of installation, a long period of bitumen smell weathering and a significant height of the waterproofing layer - up to 5 cm. Ready-to-use coating, sprayed, impregnating and liquid waterproofing options are more popular today. Therefore, the rating will consist only of such materials.

Third place. Waterproofing Eskaro Aquastop Hydro

This product is an excellent choice for waterproofing floors in bathrooms. Eskaro Aquastop Hydro is made on the basis of acrylic latex in the form of mastic and is ready for use. Also contains reinforcing fiber. The resulting film has excellent flexural elasticity and high tensile strength. Has good adhesion.

Waterproofing Eskaro Aquastop Hydro

Designed to create a seamless waterproofing, for use under tiles in rooms with high humidity.Not intended for waterproofing in basements, as well as for outdoor work. It is also not recommended to use it for waterproofing pools.

Second place. Waterproofing Litokol Aquamaster

Ready-to-use material based on an aqueous dispersion of synthetic resins without solvents. It has a low level of volatile substances. Does not require additional corner protection. Many are interested in how long the waterproofing dries in the bathroom under the tiles? Litokol Aquamaster dries very quickly. After 24 hours, you can glue the tiles.

Waterproofing Litokol Aquamaster

Designed for both indoor and outdoor use. Can be applied to almost any kind of surface. In addition, tiles on waterproofing can be laid with mosaics and natural stone. Litokol Hidroflex is even used for waterproofing pools.

First place. Waterproofing Knauf Flachendicht

The product is made on the basis of synthetic latex and inert fillers. Easily applied to the surface, it has excellent adhesion to many building surfaces. Differs in good elasticity in the big range of temperatures. Capable of sealing cracks up to 2 mm. Aging resistance. If you need to waterproof the shower tray under the tiles, then Knauf Flachendicht is an excellent choice.

Waterproofing Knauf Flachendicht

It is intended for application under a ceramic tile both for internal, and for external works. It can be used in basements, when processing foundations, for waterproofing balconies, roofs and terraces. It is applied before laying of a tile in pools. It is even used to finish the bottom of the car from corrosion.After reviewing the characteristics of this product, many immediately decide what kind of waterproofing to choose for a bathroom under a tile.

How to deal with moisture in the bathroom?

High-quality exhaust ventilation should be considered the main way to combat moisture. It should remove the air supersaturated with water vapor, excluding the process of condensate deposition on the surface of the bathroom. The tile has a cold surface, which becomes an active site for steam condensation. This not only harms the materials and structures of the house, but also makes water procedures dangerous for people - it becomes slippery in the room, it is easy for a person to fall and get injured. A good solution would be not only an efficient hood, but also a warm floor, which excludes condensation from settling on a heated surface.

In addition, it is necessary to constantly monitor the condition of water pipes, connections of plumbing fixtures. It is necessary to immediately eliminate leaks, change the outlet set of sinks and siphons of all other devices in time. Spilled water must be immediately removed from the floor, without waiting until it is absorbed into the small holes or capillaries that are always present on any floor covering.

Materials used

The labor-intensive process of leveling, consisting of several stages, will take a lot of time, so experts recommend using gypsum boards for repairing partitions. The use of drywall sheets is justified with differences exceeding 6 cm. Considering the humidity of the room, moisture-resistant plasterboards should be purchased.

Drywall can be glued to the base or mounted on the crate. It is better to make it from a metal profile.You can also build a frame from wooden bars, but they will need to be protected from moisture by soaking with an antiseptic and painting in 2 layers. For the construction of the crate, it is necessary to purchase plastic dowels, self-tapping screws, U-shaped suspensions and connectors.

The alignment of the walls in the bathroom by plastering is carried out with a cement-sand mortar or a gypsum-based mixture. The use of cement mortar is more justified based on the increased level of humidity in the room. You can plaster an uneven base with a compound like Ceresit glue, but using such a building material will cost more.

The rules for preparing walls provide for their plastering on lighthouses. Without them, it will be impossible to create a flat surface. It is more expedient to use metal and plastic beacons as guides. To fix them on the partition, gypsum marks or clamps are used, which are installed on the partitions with the help of dowels and self-tapping screws.

To prepare the wall for laying tiles, you need to arrange a reliable waterproofing of the base. Before installing drywall, it is recommended to cover the surface with a special film that has water-repellent properties. When plastering, a primer composition can be used as a waterproofing agent.

What should be the floor waterproofing device

Waterproofing the floor in the room protects it from rotting and gradual destruction. Different materials are used depending on the type of premises. But the principle of action for everyone is based on creating a dense water-repellent and waterproof layer.So how to waterproof the floor in the bathroom?

Coating waterproofing for a floor under a tile

Both coating and painting waterproofing is applied with a spatula, roller or brush. Mastic for waterproofing the floor in the bathroom can be of different consistency, but in any case, you should not try to make the layer as thick as possible in one go, the recommended thickness is only 1-3 mm. It is better to repeat the application procedure several times. Each new layer should preferably be applied perpendicular to the previous one.

Coating waterproofing for the floor under the tiles can be applied both with a roller and with a brush

After applying the last layer, without waiting for drying, it is sprinkled with quartz sand. When the waterproofing is completely dry, remove excess sand. The sand will provide a better bond between the waterproofing and the tile adhesive.

Liquid waterproofing for a bathroom under a tile

This type of waterproofing is also called liquid rubber. Applied by spraying. It is an innovative and very effective material for waterproofing surfaces. Liquid waterproofing of the bathroom floor is one of the two-component. In the first case, it is already ready for use, in the second case, it must be mixed with a hardener.

Liquid waterproofing for the bathroom under the tiles is applied by spraying

Spraying is carried out using special spray guns. After hardening, a monolithic rubber surface is obtained without any seams, overlaps or joints. In addition, the surface has excellent adhesion to most finishing materials, including tile adhesive.

Bulk waterproofing of the floor in the bathroom

If you are still interested in the question of which waterproofing is better for a bathroom, then this type of insulation is optimal for use in places where engineering communications pass through floor slabs. It is distinguished by the absence of joints, which provides an absolutely tight coating. It is also used in places where not only tensile loads are possible, but also any kind of dynamic loads. Such strength is provided due to the high elasticity of the coating.

Bulk waterproofing of the floor in the bathroom withstands both tensile and dynamic loads

The advantages also include excellent vapor permeability and ease of application, which allows you to process even very large rooms. Good adhesion allows you to get a strong connection with any kind of surface. Also bulk waterproofing differs in high resistance to chemical influences.

Roll waterproofing under tiles

Or as it is also called pasting waterproofing. It happens not only in roll form but also in sheet form. The gluing type also includes a film for waterproofing the floor. Modern gluing materials for waterproofing have their own adhesive layer. Therefore, you do not have to think about what mastic to use.

Rolled waterproofing under the tile belongs to the gluing type

Before you start pasting the surface, you need to spread it on the floor and let the rolled waterproofing level out. Then apply bitumen-based mastic to the floor. On which to lay the prepared strips. The overlap between the sheets should be within 10-15 cm. Then, using a burner or a building hair dryer, the surface is heated to a temperature of 50 degrees.This makes the waterproofing very flexible, and it adheres perfectly to the floor. Joints can be glued additionally. After complete cooling and hardening, the surface is covered with a primer. The floor is ready for tiling.

Related article:

Insulation with liquid rubber

Another name for this material is bituminous mastic. This is a high-quality modern type of floor and wall surface protection from the harmful effects of moisture.

Liquid rubber for waterproofing

Liquid rubber for waterproofing

Such liquid insulation is made of bitumen and polymers. It is safe and easy to apply. In this case, the work can be carried out manually, using a brush and roller, or you can purchase special equipment for this, which automates the process.

There are such advantages of liquid rubber insulation:

- elasticity and softness of the applied layer;

- good adhesive properties;

- seamless type of insulation;

- easy application.

In addition to the above advantages of bitumen mastic, it is worth mentioning such a property as “undemanding” to the main coating. Even if the floor is not perfectly sanded, the presence of small flaws and roughness will not affect the quality of the insulation.

The technology for conducting liquid waterproofing of the floor in the bathroom includes the following steps:

- Surface preparation. It is necessary to carefully process the walls and floor before applying the mastic. It is necessary to make a screed, leveling the base. At the same time, do not forget about the requirements for the level of the floor in the bathroom. As you know, it is necessary to equip the threshold in order to avoid flooding of all rooms.

- At the next stage, the surfaces to be treated are cleaned and primed. Remove all debris and dust with a brush. After that, treat the floors with a special bitumen-polymer primer.This will ensure better adhesion of the waterproofing material to the base. The primed walls and floor are left for several hours to dry.

- Then you can proceed to the waterproofing itself. The floor and walls at the base are covered with bituminous mastic, measuring a distance of 20 cm from below. Work can be done with a construction brush or spatula.

Waterproofing with liquid rubber is widely used in modern construction. It is used for repairs in new buildings and for restoration work in old apartments.

Liquid rubber waterproofing process

Liquid rubber waterproofing process

The technology of applying such material is simple, does not require special skills. The work is quite capable of doing on their own. To cover one square meter of the room, 3 liters of bituminous mastic will be required.

This is a reliable type of insulation that well protects the tiled finish in the bathroom from mold and moisture seepage into the neighboring apartment.

Since bathroom renovations are usually more demanding, thorough waterproofing is a must. It requires some investment of funds, time and labor, however, in the future it will all pay off. You won't have to renovate your bathroom again in a year. There will be no problems with the operation of the bathroom.

If you doubt your abilities, you can invite an experienced craftsman to lay the waterproofing, who will do the job efficiently and according to technology.