- Reasons for waterproofing concrete rings

- How to properly waterproof a septic tank?

- External waterproofing of a septic tank

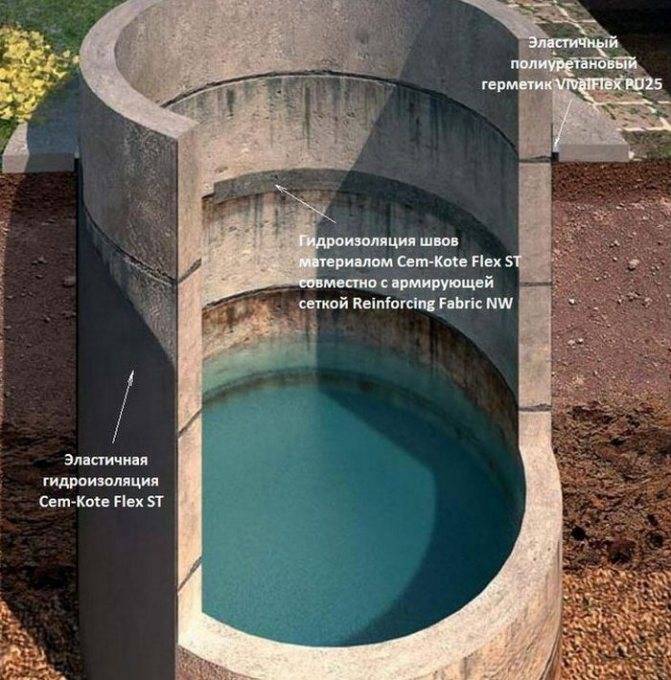

- Internal waterproofing of a septic tank

- Septic tanks

- Well waterproofing technology outside

- The need for work

- Internal waterproofing of the well

- Work performance technology

- Overview of materials

- Technologies and types of materials for sealing rings

- Choose a place

- Other means

- Sealing joints with plaster mixtures

- Hydroseals

- Technology of use

- Homemade hydroseal

- Waterproofing of joints of rings

- Installation

- The main methods of waterproofing a septic tank

- Waterproofing the inner surface of the rings

- Waterproofing methods: injection waterproofing

- Choosing a septic tank configuration

- plastic cylinders

- Features of waterproofing a septic tank and a technological well

Reasons for waterproofing concrete rings

The main reasons why such ring wells require mandatory waterproofing are as follows:

- Waters, especially aggressive environments of septic tanks, lead to leaching (destruction) of concrete;

- Corrosion of unprotected reinforcing cage;

- It is possible for the well to overflow with rising groundwater. In addition to overflowing the well, they also lead to the destruction of concrete structures;

- Seepage from inside the well of fecal fluid into the soil. This causes her infection.There is an unpleasant odor in the area around it.

For these reasons, sealing the structure is more beneficial than periodic overhaul.

How to properly waterproof a septic tank?

External waterproofing of a septic tank

The work should be done in stages:

- To obtain high-quality adhesion of concrete with an insulating material, the prepared surface of the septic tank must be treated with a primer. It can be prepared by dissolving one part of bitumen in three parts of low-octane gasoline. The primer should be applied with a large brush or brush.

- To improve the quality of the insulation, all seams of the structure can be glued with rubber tape or CeresitCL 152.

- After the primer solution has dried, the outer walls of the septic tank must be smeared with a cold-curing tar mixture. Bituminous mastic in its pure form is not recommended, as it cracks over time.

- A richly lubricated surface must be pasted over with rolled insulation from above. You will need at least three layers.

- All insulation joints must be treated with mastic, and then fill the septic tank with soil from the outside.

External waterproofing of the septic tank from groundwater should be carried out in a respirator, since bitumen and gasoline fumes are not healthy.

Internal waterproofing of a septic tank

After the surface preparation described above, the internal waterproofing should be carried out in the following order:

- Treat the septic tank from the inside with a primer, applying it with a wide brush. The composition is sold in the store and is an aqueous emulsion that must be diluted before use according to the attached instructions. Two coats of primer will suffice. Let the first layer dry before applying the second.The composition should be well absorbed into the pores of the walls of the septic tank. This will take 1-2 days.

- After priming, the container with bitumen-polymer mastic must be opened and the material gently mixed with a mixer. If the mastic is too thick, it can be diluted with white spirit.

- The prepared composition must be applied to the walls of the septic tank in a dense layer, avoiding drips. The coating must be even and uniform. The work must be done with a paint brush.

- When the mastic dries, the treated walls of the septic tank must be inspected. If areas of coating with a violation of solidity are identified, another layer of material should be applied. After 2-3 days, the coating will dry, and the septic tank can be used for its intended purpose.

Important! All measures for external and internal insulation of the septic tank should be carried out after sealing its mounting seams, hatches and branch pipes.

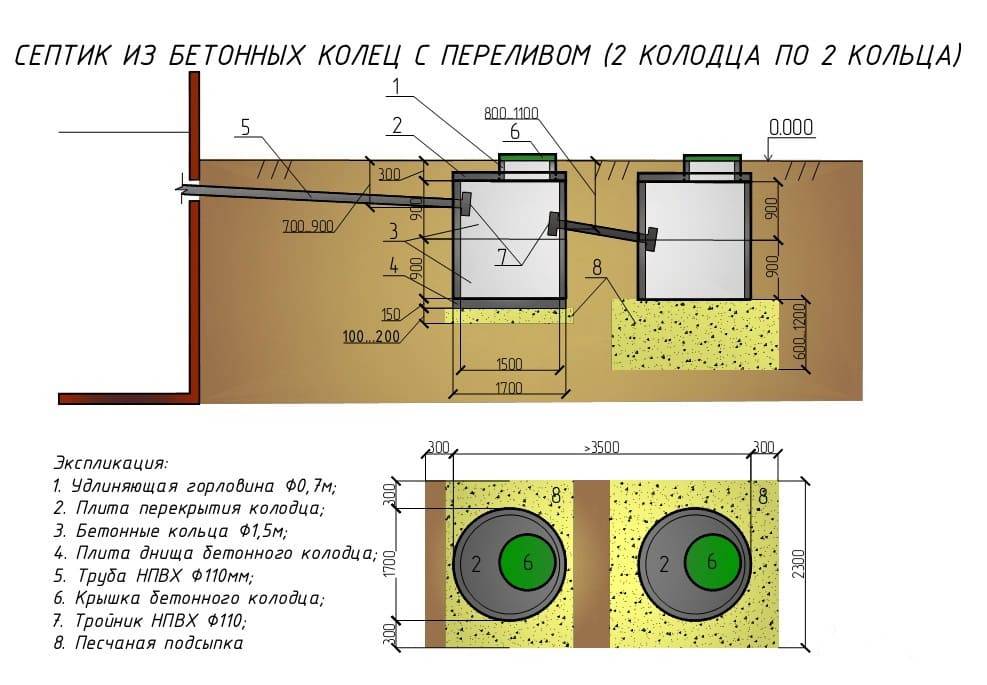

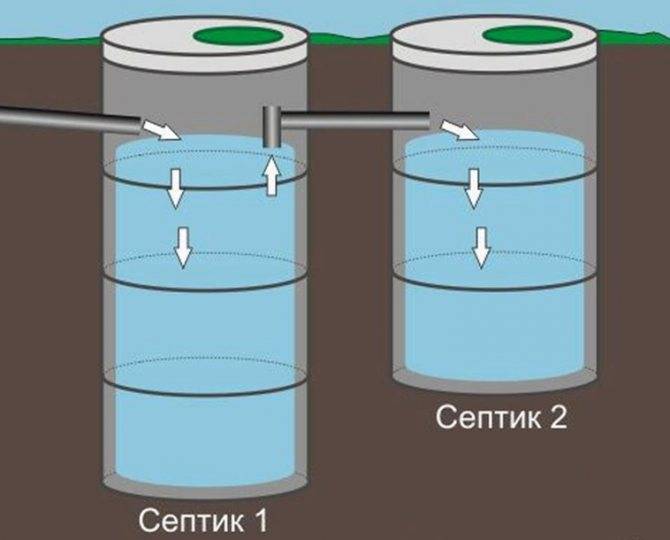

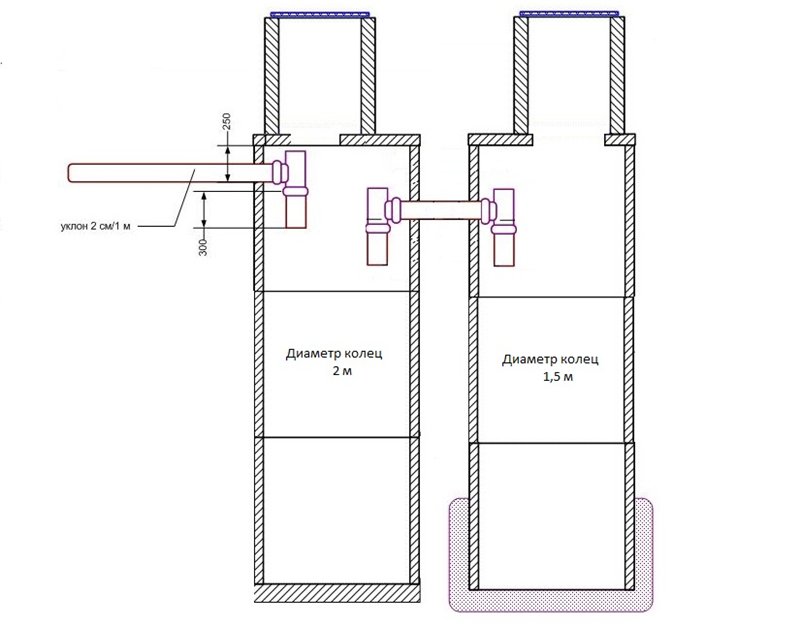

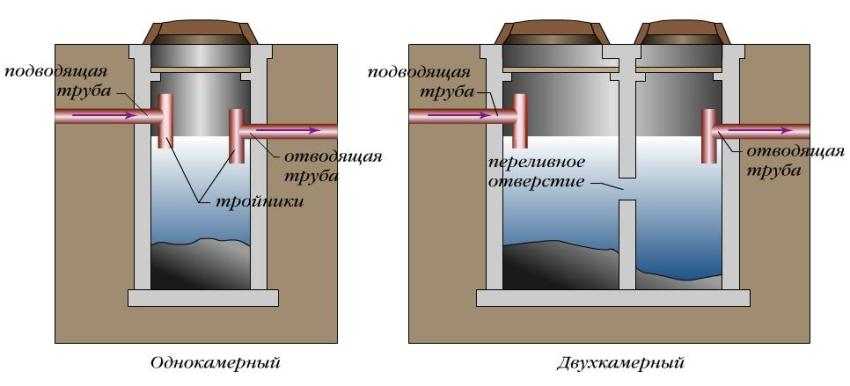

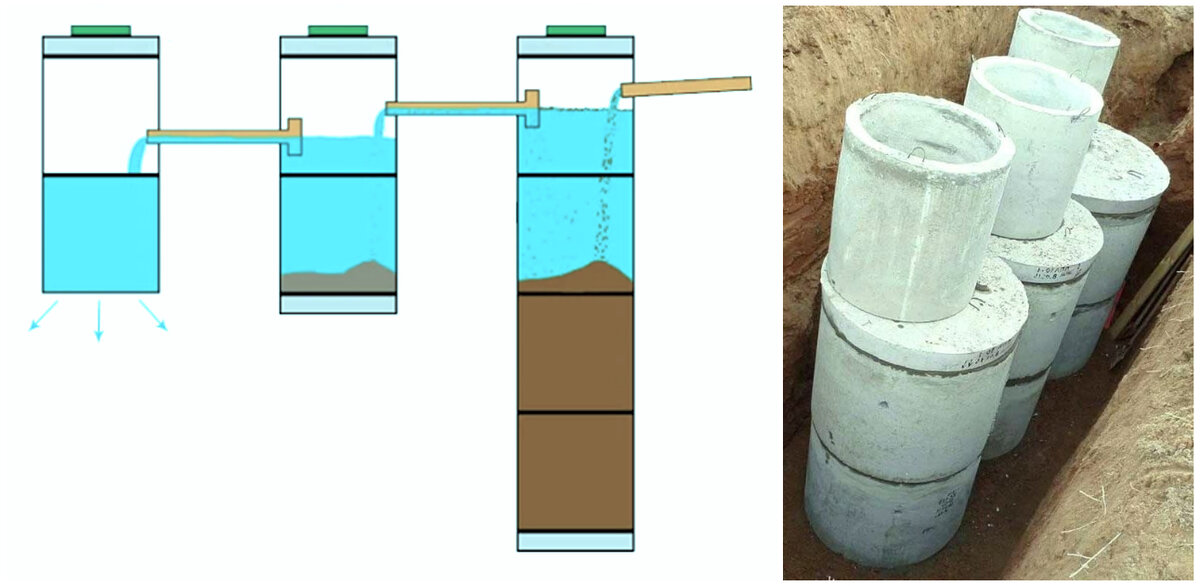

Septic tanks

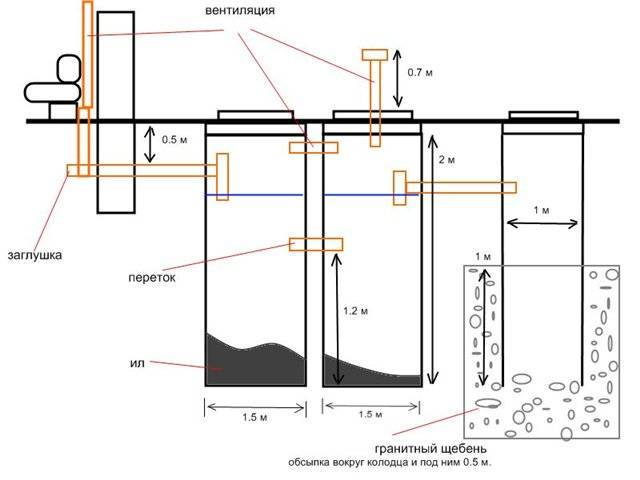

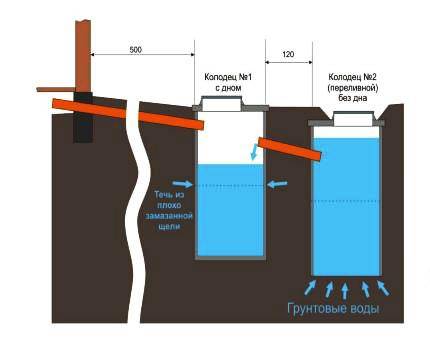

Most often, septic tanks (overflow wells) have such a concrete structure. They are 2-3 tanks, interconnected by bypass pipes. Septic tanks are designed to collect sewage from a private house. Insoluble impurities of such effluents settle at the bottom of the first reservoirs. Purified from impurities, water is poured through a pipe with an inclination by gravity into the next tank. In this case, the separation of the solid and liquid phases of wastewater occurs. The last, filtering, tank has no bottom.

BC 1xBet has released an application, now you can officially download 1xBet for Android by clicking on the active link for free and without any registration.

The aggressive sewage environment inside septic tanks requires especially careful sealing of each reinforced concrete ring.

The displacement of the rings of the wells can cause the destruction of the insulation between them.The upper ring is subject to the greatest "walking" due to soil freezing. Therefore, during the installation of each, it is necessary to provide for its fastening with neighboring ones: brackets, rings with locks, etc.

Well waterproofing technology outside

During the construction of a well, external waterproofing measures are usually carried out. If we are talking about the need to protect the old structure, then a fairly large amount of earthwork will have to be carried out. For this, roll materials are usually used, for example, roofing material. However, penetrating protection can also be applied.

The surface must be prepared. The outer walls of the structure open as much as possible. To do this, dig the earth around the well 4 m deep. The base is free of contaminants. If you have to work with an old structure, then you can see some parts of the reinforcement that have been exposed during operation. They should be cleaned and treated with an anti-corrosion compound.

If the waterproofing of the well is being repaired, then the walls must be covered with soil, you can use Betonkontakt or a bitumen-rubber composition, which have proven themselves well, as well as a cement-sand mortar, to which PVA glue is added. The composition is left to dry, and then bituminous or tar mastic is applied to it. Ruberoid is glued onto its surface, the seams between the sheets should be smeared with mastic. When choosing penetrating insulation, the stage of priming the walls should be abandoned. They are moistened and smeared with Penetron, leaving for three days to dry. The surface should be moistened periodically.

The need for work

Concrete does not collapse from exposure to moisture.The main feature of this material is that it passes water well if it has not been waterproofed. Because of this, the properties of the structure will be exposed to moisture, in contact with wet concrete, this includes metal and wood. Rust will grow along the reinforcement, deforming it and making it less durable. This causes the destruction of the entire structure.

It is necessary to waterproof the well from concrete rings in order to exclude the ability of the material to absorb moisture. Reinforced concrete rings are subjected to such protection even at the production stage. Typically, suppliers use the following waterproofing methods:

- constructive;

- technological;

- use of waterproof cement.

The first technique involves the treatment of products with water-repellent substances after manufacture. At the production stage, technological waterproofing is used, this should include the technology of compacting concrete, which is still in the forms. The material is subjected to centrifugation, vibrocompression and vacuum removal of excess moisture.

Moisture protection can also be provided by adding various water repellents to concrete. These ingredients begin to work after the concrete hardens, swell and clog pores and microcracks. This provides the concrete with the ability to withstand moisture.

These measures contribute to the rise in the cost of reinforced concrete rings, but if you decide to save on rings, then it is important to seal the seams and joints between structural elements. This will provide long-term protection against rot, corrosion, mold and mildew.

Internal waterproofing of the well

Internal insulation is carried out after the construction of the well and the device of the bottom. If you need to seal the inside of an old well, then the water must be pumped out and the concrete walls dry well, since most insulation materials must be applied to dry surfaces.

You can perform work using the following waterproofing compounds:

- - special cement putty;

- - molten bitumen or bitumen-gasoline composition;

- - cement-polymer mixture;

- - bitumen-polymer composition;

- - polymeric waterproofing.

If during the preparation of the walls for insulation from the inside there are leaks of external water, use the so-called hydraulic plug - the AQUAFIX or Peneplug instant-hardening cement composition. This will allow you to perform all the necessary operations for waterproofing the well with high quality.

AQUAFIX is a fast-setting hydraulic solution for stopping water leaks instantly, with a flow rate of approx. 1.6 kg/l.

Figure #9. Hydroplug AQUAFIX

"Peneplug" is a dry building mixture, which consists of special cement, quartz sand of a certain granulometry and patented active chemical additives. "Peneplug" is used for instant elimination of pressure leaks in structures made of concrete, brick, natural stone and has a flow rate of about 1.9 kg / l.

Work performance technology

Preparatory work in general is similar to work with external waterproofing of a well: the well must be drained and kept dry throughout the entire period of repair work, clean and prepare the surface.

Figure #10. Coating waterproofing AQUAMAT-ELASTIC

All potholes must be repaired with a cement-polymer mixture and wait for the solution to dry completely, and then proceed to the final stage of work. At the end, it is necessary to cover the surface of the well with coating waterproofing in two layers. Follow the instructions in the instructions for the material. Our experts recommend using the special AQUAMAT-ELASTIC compound from ISOMAT.

Overview of materials

cement mixture

- there are ready-made dry mixes on sale, which you only need to dilute with water according to the instructions and apply in several passes so that a layer of about 0.7 cm is obtained. The composition should dry for several days, so the surface must be moistened several times a day, and the well itself must be closed lid. The service life of such insulation does not exceed 15 years. For example, such mixtures are manufactured by the manufacturer LITOKOL.

Bitumen-gasoline painting

- the composition is prepared by their components in equal quantities. It must be applied in three layers with a break of 12 hours. Observe safety regulations. This option, as well as bitumen-polymer mixtures, is valid for use only in sewer wells. The service life is short - 5-10 years. Fused rolled insulation can properly serve up to 30 years.

Cement-polymer mixtures

- this is the most affordable of modern effective waterproofing materials. The best for today is the ISOMAT system. It includes the already named AQUAFIX hydroplug, a modified MEGACRET-40 repair compound for sealing cracks and grouting joints, and a finishing two-component elastic mixture of cement and polymeric materials, which must be applied by coating with a layer of up to 0.3 cm. This composition is completely inert, environmentally friendly safe, does not affect water quality in any way.

Figure #11. Repair compound MEGACRET-40 for sealing cracks and grouting joints

The same high-quality result can be obtained using inexpensive non-shrinking coating "Penecrete" or "Penetron Admix". It is applied in 3 layers with a spatula. The service life of cement-polymer waterproofing is about 40-50 years.

A more expensive option is the two-component composition CeresitCR 166, which has increased elasticity. It should be applied in two layers, on the first before hardening it is necessary to lay a reinforcing fiberglass mesh. The service life of this waterproofing exceeds 60 years.

Polymer waterproofing mixtures

- this is the most expensive, but also the most effective method, since the polymer membranes that are installed on special mastics are very elastic. If your well is unstable, deformations and new cracks may appear, then you should not save money, but purchase polymer waterproofing. The most attractive price / quality ratio for domestic products of the TechnoNIKOL trademark. In this case, for at least 40 years, you will not be bothered by leaks in the well.

Technologies and types of materials for sealing rings

It is better to create a hermetic connection of circles at the stage of building a septic tank. A gasket is installed between them, which cushions and waterproofs the structure. Plastic materials maintain the tightness of the structure even when the rings are displaced.

There are plenty of materials for sealing the septic tank: the photo shows one of the possible options

There are high quality modern materials:

- sealing tape, such as Rubber Elast;

- armcloth type Fibertec - requires UV irradiation before use;

- rubber gaskets with bentonite clay granules.

The last item deserves special attention. The granules included in the composition, upon contact with water, increase in volume up to 400%, completely cover all gaps. This gasket is also laid between the first circle and the foundation.

If sealing was not carried out during construction, there are methods to do this later:

| Sealing methods | Durability | Application method |

| Cement-polymer composition | 40 years or more | Manually in 3 layers with a spatula |

| Polymer membrane on mastic | 50 years | Treated with a special mastic, after 24 hours the membrane is glued |

| CeresitCR 166 | 60 years | On a clean surface with a brush, then a reinforcing mesh and a second layer |

| Plastic inserts | Lower into the well, fill the empty space with dry sand and cement |

Choose a place

The location for installing a septic tank is very important for maintaining sanitary standards on the site. When choosing a place, you must build on the following requirements:

- Distance from the house should be 5-10 meters.

- From the septic tank to any source of drinking water must be at least 50 meters.

- Check the groundwater level - it should not be higher than the depth of the septic tank.

- It is necessary to organize an access road for sewage equipment.

- It is not recommended to mount too far from home - the cost of laying sewers will increase significantly.

When laying a sewer pipeline, install an inspection well after 15-20 meters of a straight path, as well as when turning the sewer.

Other means

If you need to urgently eliminate the leak between the concrete rings, use linen tow, hemp or jute, which are impregnated with fibrorubber. The material is sold in stores that specialize in waterproofing pools.Sealing inserts allow you to seal gaps up to one centimeter. This is a temporary measure, then sealing is carried out with more reliable materials.

Sealing gaskets temporarily solve the problem of sealing joints between concrete rings

It is not always possible to buy seals, especially in small towns. But almost every hardware store has liquid glass. First, cement is mixed with sand in equal proportions, then the same part of liquid glass is added. Use the solution immediately, because after a minute it will become solid.

Sealing joints with plaster mixtures

The most commonly used special formulations. Narrow slots are shtrobat, the prepared solution is pressed with a spatula. The plaster is applied until the mixture fills the gap, after which it is leveled. It is undesirable to use a conventional solution of sand and cement - this is a material similar to rings, which will crack and leak without additional protection.

Polymer cement mortars reliably seal the seams between the concrete rings of the septic tank

Hydroseals

This is a modern material with additives that provide plasticity and the fastest possible hardening. It is represented on the construction market by various manufacturers:

| Name | Compound | Peculiarities | Application conditions | Price for 25 kg | Consumption |

| penecrete | Cement, quartz sand, chemical additives | Eliminates, prevents water seepage, increased adhesion | Temperature not lower than +5°, use the solution within 0.5 hours, apply on a damp surface | 225 r. | 1.4 kg/r.m |

| water plug | Special cement with quartz sand | Freezes in 3 minutes | Temperature above 5°, keep the treated surface moist for 24 hours | 150 r. | 1.9 kg/dm2 |

| Peneplug | Aluminum cement and quartz sand | Sets in 40 seconds, eliminates leaks | Temperature +5° and above, maintain humidity for 3 days | 290 r. | 1.9 kg/dm2 |

| Megacret-40 | Cement with polymers, fiber reinforced | Achieved strength in 24 hours, for particularly demanding work | Thoroughly cleaned surface, moisten for 2 days | 2300 | 17.5 kg/m2 with a layer thickness of 2 cm |

Hydraulic seals set quickly, they can not only seal the seams, but also eliminate leakage

When using, it is important to adhere to all recommendations of the manufacturer.

Technology of use

The application is simple, but it is necessary to adhere to important conditions:

- a very narrow gap is expanded and cleaned of pieces of concrete;

- the mixture is prepared in small portions;

- work is carried out as quickly as possible.

The advantage of a hydroseal over a cement-sand mixture is also that it is not necessary to dry the surface, which is difficult to do when repairing a septic tank that has already been used.

If the task is to seal the joint along the entire length, there is a desire to immediately prepare the right amount of mortar. This is by no means done. A person manages to use quite a bit of the mixture, the rest quickly hardens.

Homemade hydroseal

When it comes to a small area or sealing a crack, the use of a hydraulic seal is the most effective option. Sewing large areas is time consuming. Experts believe that you can make a hydroseal with your own hands.

Use fine-grained sand and ordinary cement in a ratio of 1:2. The mixture is stirred and dry rubbed with a spatula into the cracks, cracks. They are pre-expanded and cleaned.Then they are covered with sheet iron, fixed with a support. After 3 days, liquid glass is applied to the cork. The method is suitable for sealing dry joints.

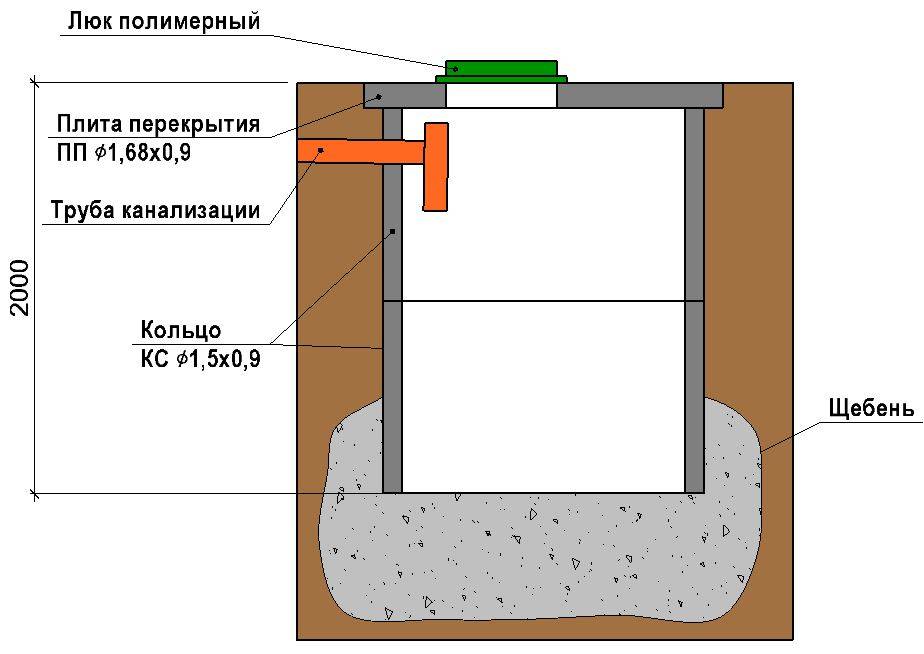

Waterproofing of joints of rings

For the construction of wells, rings with locks are usually used. The lock is called the groove on the ring at the top and bottom. When the rings are lowered into the well, they stand on top of each other, which is called “groove to groove”, a kind of “lock” is obtained, thanks to which it is easier to align the shaft vertically, and it is more difficult for the rings to move to the side. The advantage of rings with a lock is that a strong and tight connection of the rings is ensured and there is no need to additionally seal the joints between the rings. However, it will not be superfluous to cover the joint with cement mortar.

Figure #12. Waterproofing joints of concrete rings

It is necessary to start work with bottom insulation, after installing the ridge plate and the first ring. A special plate with a comb is installed at the bottom of the well, which is needed for the correct centering of the first ring.

Waterproofing joints of concrete rings the well is produced inside and outside. Between the rings (as well as between the first ring and the bottom) it is necessary to install a gasket cord (“Gidroizol M” or bentonite-rubber “Barrier”).

Inside, the joints can be waterproofed using the same AQUAMAT-ELASTIC coating waterproofing from ISOMAT, and on the outside, using a bituminous or rubber-based coating waterproofing, as well as rolled waterproofing, for example, the most common roofing material is suitable.

Video number 4. Well construction rules

Installation

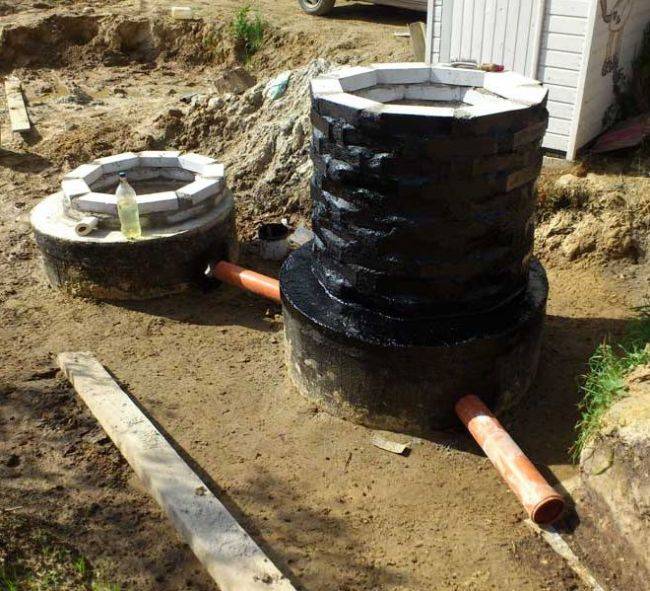

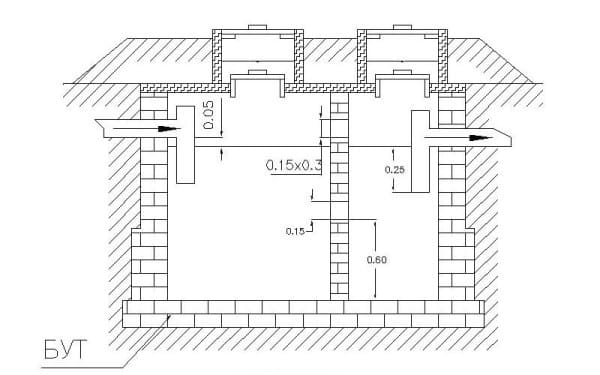

Installation of a septic tank made of concrete rings is quite difficult to do on your own, reviews say that you can’t do without lifting equipment or several assistants.At the same time, it will not be difficult to make these very rings - you just need to make a solution and pour it into a special form. Many experts recommend reinforcing containers. For successful design, you can use ready-made drawings.

Principal drawing

Scheme and instructions for installing a septic tank from concrete rings:

- A hole is being dug. The dimensions of the trench should be several centimeters larger than the dimensions of the drive; after installing the well, soil will be compacted into the gaps or a clay (concrete) box will be poured;

pits

- The bottom is compacted with sand and gravel - the height of the layer is from 20 to 40 cm;

Installation of a septic tank

- A homemade septic tank is not much inferior in efficiency to a professional one. Therefore, we will consider the installation using the example of a do-it-yourself design. The first ring goes down first. After it is tamped and leveled, the bottom is set;

- After the second ring is mounted and all subsequent ones. For the winter, it is recommended to fill the gaps around the well with clay - this will increase the thermal insulation of the structure;

- After the whole system is left for tamping for several days, periodically it will be necessary to sprinkle it with earth and align the rings;

- When the device is compacted, it remains only to fix the cover on it.

The dimensions of the pit for installing a septic tank exceed the diameter by an average of 5 centimeters (this depends on the thickness of the concrete rings). After that, bacteriological filters are installed. Pumps and outlets to the sewerage.

Related video:

You can buy ready-made kits for mounting wells at any manufacturer of concrete and sanitary products.

The main methods of waterproofing a septic tank

- Bitumen-based mastics. Pure bitumen, when applied hot, has only one plus - cheapness. Otherwise, the bituminous coating leaves much to be desired: it quickly cracks, and after several cycles of seasonal freezing and thawing, it peels off safely. Bitumen with polymer additives works much more reliably. Such mastic can be applied cold, which greatly simplifies the isolation process. Polymer additives increase the chemical resistance and service life of the coating. For their manufacture, rubber and polyurethane are used.

- Polymer-cement coating. It is more expensive than bituminous mastic. The composition can be applied with a wide brush. For high-quality insulation, two layers of coating are required. It is not necessary to wait for the previous layer to dry before applying the second one. Therefore, the work will go quickly. The service life of such a coating is 40-50 years. Especially good is a non-shrink coating such as Penetron Admix or Penekrit.

- Polymer insulating compound. It is the most expensive, but very effective. It has high elasticity and is used to protect unstable wells, which are characterized by frequent deformations, accompanied by the appearance of new cracks. The optimal ratio of cost and quality has a mixture of the TechnoNIKOL brand. The coating made using this material can last more than 40 years.

- Penetrating waterproofing. It is not among the cheap compositions and requires strict adherence to the application technology. Penetrating into the pores of the walls of the septic tank, the mixture forms crystals under the influence of the liquid. The structure becomes waterproof. If a new crack appears in it, a self-healing effect occurs: the liquid that has entered the problem area again activates the crystallization of the mixture.Penetron or Lakhta are referred to expensive penetrating compositions, Elakor-PU Grunt-2K / 50 to cheaper ones.

- Injectable mixtures. They are too expensive to insulate septic tanks and are therefore used if other materials do not work. This happens extremely rarely. The repair mixture is pumped into pre-prepared holes in the walls of the structure through special injectors. The material for injection can be polyurethane and epoxy resins, liquid glass, acrylate, etc.

- Cylindrical plastic inserts. When using them, the well takes the form of a "glass in a glass." The gap between the well wall and the insert is filled with concrete. The finished structure can last more than 30 years and is a model of reliability, as it guarantees complete tightness of the septic tank even if its rings are displaced as a result of heaving of the soil.

- clay castle. With it, you can protect the septic tank from melt and rainwater. The top of the gap that remains after the installation of the septic tank between its rings and the outer soil is filled with clay. But before that, the soil around the well should settle and become dense. Clay is laid in portions, carefully ramming each layer. Leaving voids in the clay castle is excluded, since otherwise the desired effect cannot be achieved.

- mechanized plaster. To implement this method, a cement gun is needed. With its help, the walls of a concrete septic tank are covered with two thick layers of waterproof cement. The first layer is dried in the heat, moistening it every 10 hours with water, and the second layer is applied on top after the previous one has solidified. Labor intensity and the need to use special equipment are the disadvantages of this method of isolation.

From the above analysis, three most suitable methods for self-waterproofing septic tanks can be distinguished. In our opinion, this is the use of bitumen-polymer mastics, penetrating compounds and polymer-cement coating.

Waterproofing the inner surface of the rings

By sealing the seams, the tightness of the structure is achieved, but there is a threat that, under the influence of sewage, the concrete will collapse after some time. Joints are also a weak point, especially if they are sealed with cement and sand.

The work is carried out in several stages:

- clean the surface;

- primed;

- apply mask.

Dirt on the surface impairs adhesion, so the concrete is cleaned before the start of the main work. Close up all cracks, defects, not disregarding small ones. For repair use sealants or putty.

Next, they proceed to priming the surface with bitumen dissolved in diesel fuel, using a brush or roller. The coating is two-layer, the second is done after the first has completely dried. After a day, when the soil is absorbed into the concrete, work continues.

The protective layer is a mastic, of which there are enough varieties on sale. The container with it is opened immediately before use. Prepare for use by stirring with an electric drill with a mixer attachment. If necessary, add a solvent, the brand of which is indicated in the instructions. Cover the surface with a brush.

When the mastic dries, cracks are noticeable. The task that stands when applying the second layer is to cover them up, but the surface is completely covered. If necessary, apply another layer so that the protection becomes flawless. Allow time between operations to allow the mastic to dry.

Waterproofing methods: injection waterproofing

The dimensions of the concrete rings are not the only thing that is important to choose for the correct operation of the system. It also needs to be waterproof

Injectable materials - this is the case when you should seek help from specialists. Waterproofing of this kind is an expensive pleasure, but it does not have to be done again, because the material is ready to last exactly as long as the entire structure will be used.

Polymer compounds are pumped into the material, clog cracks and pores. The advantages of this method of moisture protection are:

- the possibility of using for insulation of new structures;

- the possibility of repairing the waterproofing of the well;

- no need for surface preparation;

- the ability to eliminate gushing and pressure leaks.

However, such a waterproofing of the well from groundwater also has some disadvantages, among them the high cost and the need to use high-pressure pumping equipment should be highlighted.

Choosing a septic tank configuration

With their own hands they build one of three options for a concrete septic tank:

- A single-chamber sump is suitable for summer cottages with a seasonal residence of a small number of people. Inexpensive for initial investment, later it will require periodic costs for calling a pumping machine.

- A two-chamber septic tank is a more advanced option that gives minimal cleaning. The first container is used for settling heavy fractions, and through the second chamber, settled water goes into the ground through the drainage layer of gravel.

- A complete treatment system is a three-chamber septic tank, consisting of two settling tanks and a drainage well.Wastewater treatment reaches 80–90%, and in general, such an installation lasts much longer without the need for maintenance.

plastic cylinders

Sometimes the wear of the rings is so significant that neither the sealing of the joints nor the protective layer on the surface helps. Until the structure is completely destroyed, plastic inserts are installed inside.

“This does not exclude that the seams should be sealed and the walls waterproofed first, otherwise the inserts will help for a short time.”

V.P. Money, CTO

Plastic inserts radically solve the problem of sealing, but are rarely used due to the high cost.

The material used for the cylinders is high-strength polymers with a wall thickness of 5–8 mm. They are similar to a large diameter corrugated pipe due to the finning of the outer walls. These rings increase rigidity, allow you to increase the design to any size. The latter feature does not play a role in sealing the septic tank. The liners, on the contrary, have to be cut, since their height is 4.5 m.

The industry produces polymer liners in sizes that correspond to the diameter of the rings. The option is ideal for use, but has not received distribution - buyers are stopped by a high price.

Features of waterproofing a septic tank and a technological well

The device of a multi-chamber sewage septic tank assumes the presence of several successive wells. So the last of them does not need to be waterproofed, because the essence of filtration is that the water goes into the ground as much as possible. Since it is an excellent biofilter, a small amount of wastewater will not bring harm.But, anyway, you must first consult with the environmental service - they may have their own restrictions.

But from what the septic tank must be very carefully protected, it is from the ingress of rain and melt water. Therefore, it is necessary to carefully seal all the joints between the elements.

Video #3. Waterproofing the well from the inside